Easily biodegradable water-soluble polyester and preparation method thereof

A water-soluble polyester, biochemical degradation technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve problems such as high-efficiency sizing of polyester filaments, lower glass transition temperature, and low adhesion, etc., to achieve Suppression of parallelism, excellent copolymerization uniformity, and efficient sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

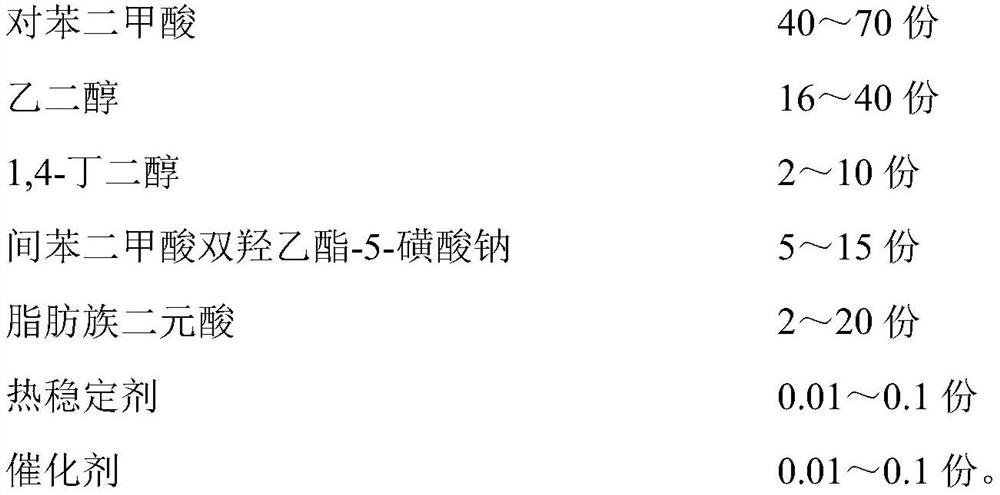

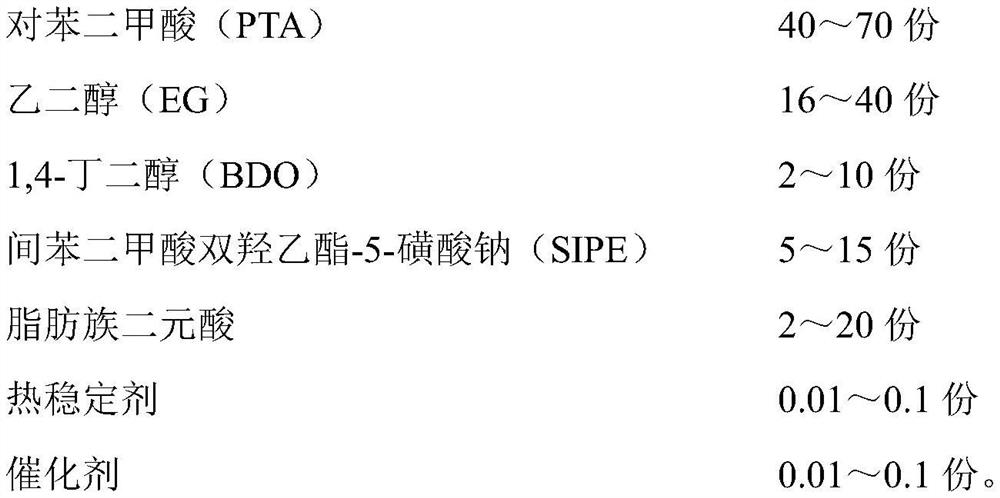

Method used

Image

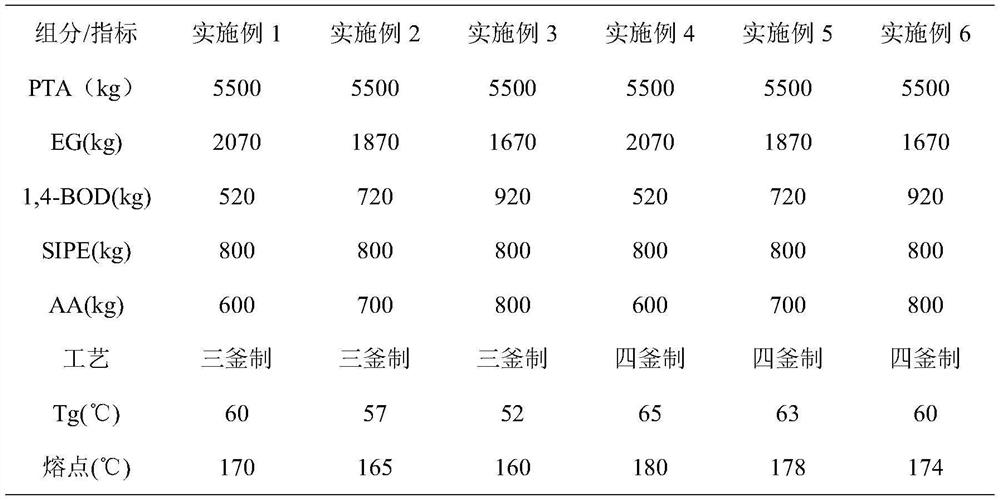

Examples

Embodiment 1

[0029] The preparation method of easily biodegradable water-soluble polyester in the present embodiment is as follows:

[0030] Step 1, one esterification

[0031] 5500kg of PTA, 2070kg of EG, 520kg of 1,4-BDO, 1.5kg of TMP and 2kg of Sb 2 o 3 Add it into the beating kettle, stir it evenly, and send it into the first esterification kettle through a metering pump to carry out the esterification reaction. The internal temperature of the first esterification kettle is 255°C, and the esterification pressure is normal pressure. The conversion rate is 80%, and a BHET esterification liquid is formed, and the material is introduced into the second esterification kettle by pressurizing nitrogen.

[0032] Step 2, Diesterification

[0033] After introducing the BHET esterification solution prepared in the first esterification kettle into the second esterification kettle, add 300L of normal temperature EG to the second esterification kettle to lower the temperature, lower the temperatu...

Embodiment 2

[0037]The preparation process of this example is the same as that of Example 1, the difference is that: the addition amount of EG in step 1 is 1870kg, the addition amount of 1,4-BDO is 720kg; the addition amount of dimethyl adipate prepolymer in step 2 is 2941kg (adipic acid solid content is 700kg).

Embodiment 3

[0039] The preparation process of this example is the same as that of Example 1, the difference is that the addition amount of EG in step 1 is 1670kg, and the addition amount of 1,4-BDO is 920kg; the addition amount of dimethyl adipate prepolymer in step 2 is 3361kg (adipic acid solid content is 800kg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com