Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

776results about How to "Optimizing Process Parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

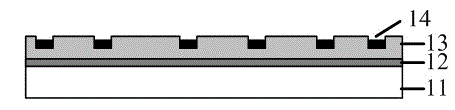

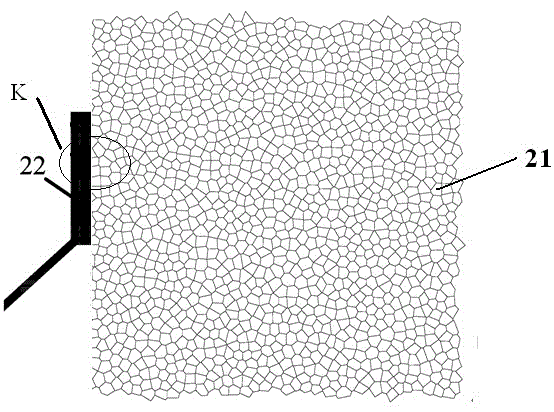

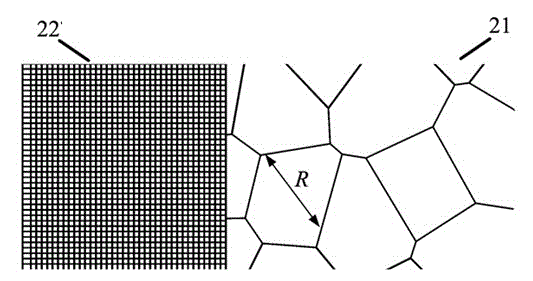

Metal grid conducting layer and touch panel equipped with the conducting layer

InactiveCN102722279AImprove adhesionImprove bond firmnessElectrical connection printed elementsInput/output processes for data processingFilling materialsConductive materials

The invention relates to a metal grid conducting layer and a touch panel equipped with the conducting layer. Surface of the conducting layer comprises a transparent electrode area and an electrode lead area, wherein the transparent electrode area is equipped with random metal grids in irregular shapes, and the electrode lead area is equipped with metal grids in regular shapes. Grid lines of the transparent electrode area are evenly distributed in each angular direction. Said grids are filled into grooves. In the transparent electrode area of the invention, grids are adopted so that conductive filling materials are more evenly filled in the grooves and are better connected with external conductive materials. In addition, the transparent electrode composed of irregular grids would no longer generate moire fringes.

Owner:NANCHANG O FILM TECH CO LTD

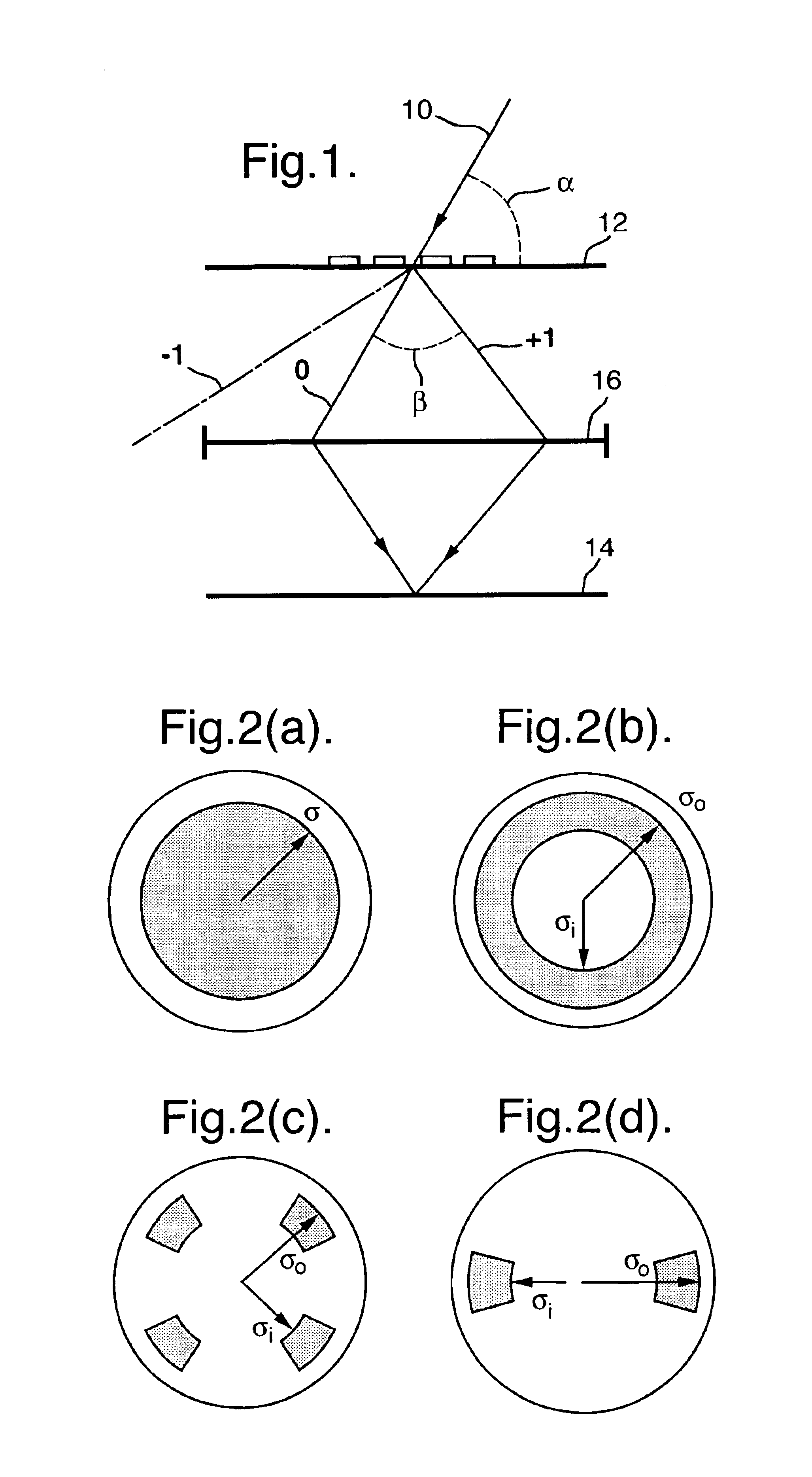

Lithographic method and apparatus

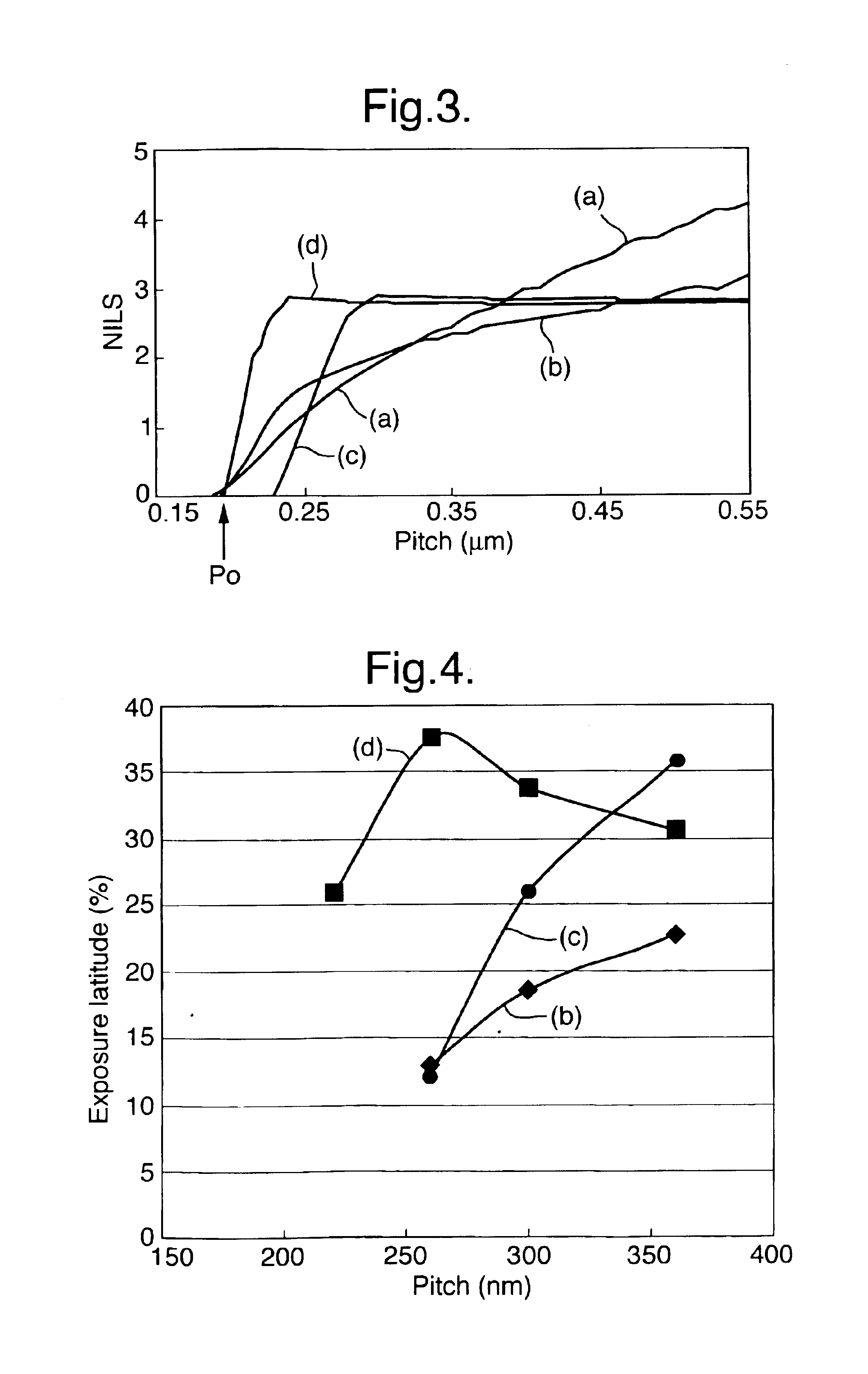

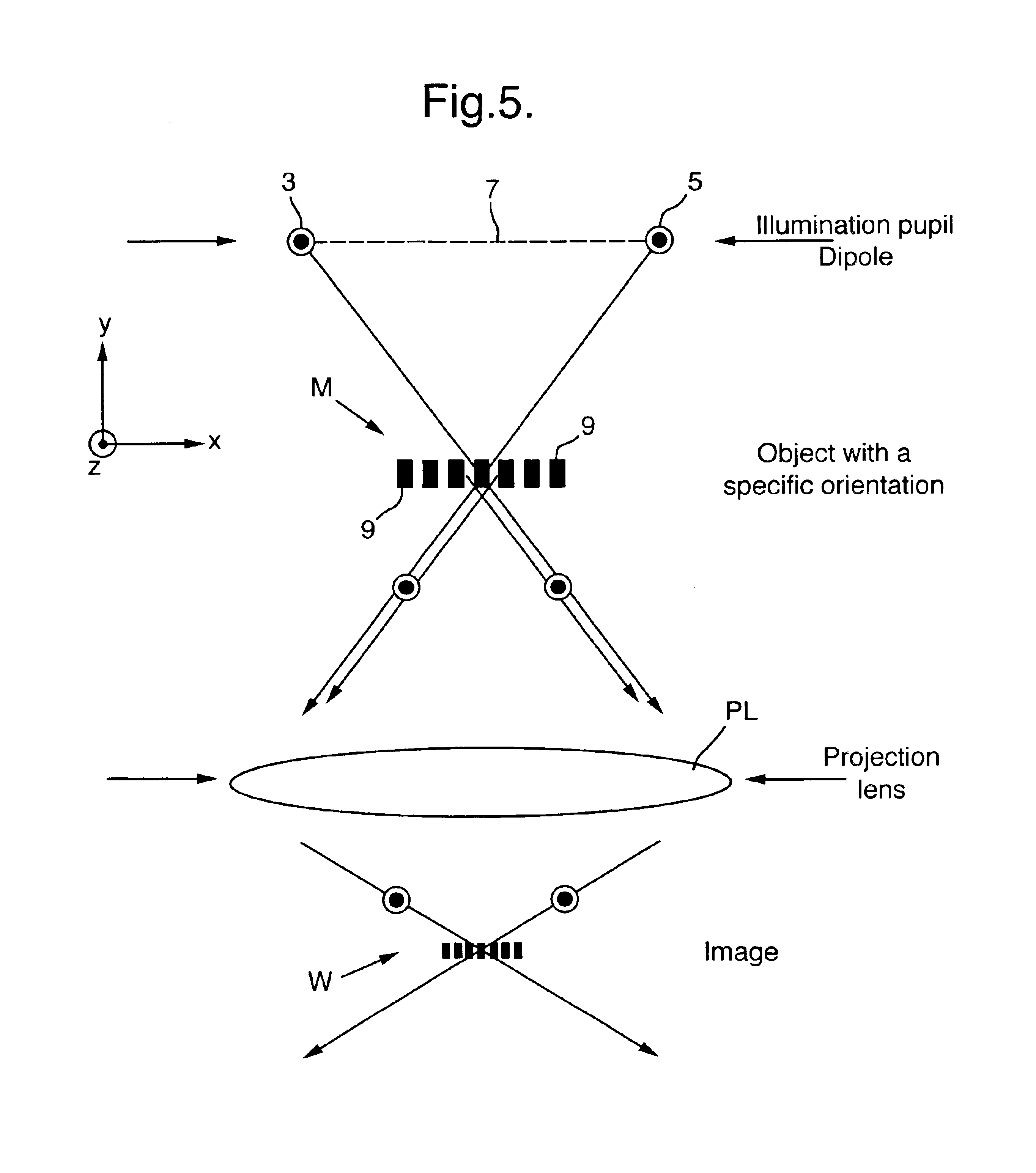

InactiveUS6855486B1Small feature sizeOptimizing Process ParametersPhoto-taking processesSemiconductor/solid-state device manufacturingSingle exposureMethod of images

A method of imaging a pattern in a microlithographic exposure apparatus includes performing two exposures, each with a different mask, the superposition of the images defined by the two masks produces the complete circuit pattern. A dipolar illumination mode is used for each exposure, the dipoles of the two exposures being mutually perpendicular. The dipolar illumination mode of the first exposure is used to image mask features parallel to a first direction, and the dipolar illumination mode of the second exposure is used to image mask features perpendicular to the first direction.

Owner:ASML NETHERLANDS BV

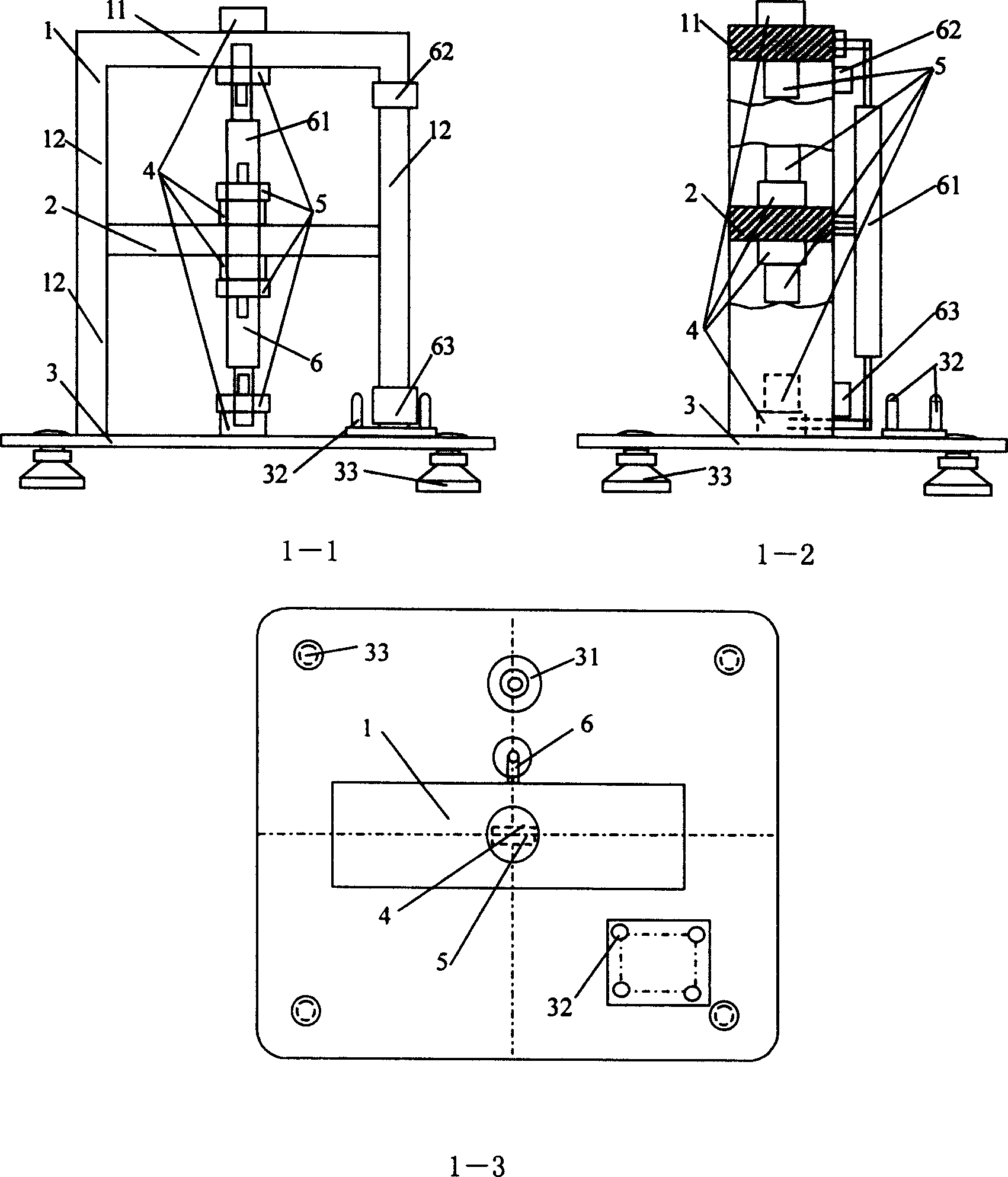

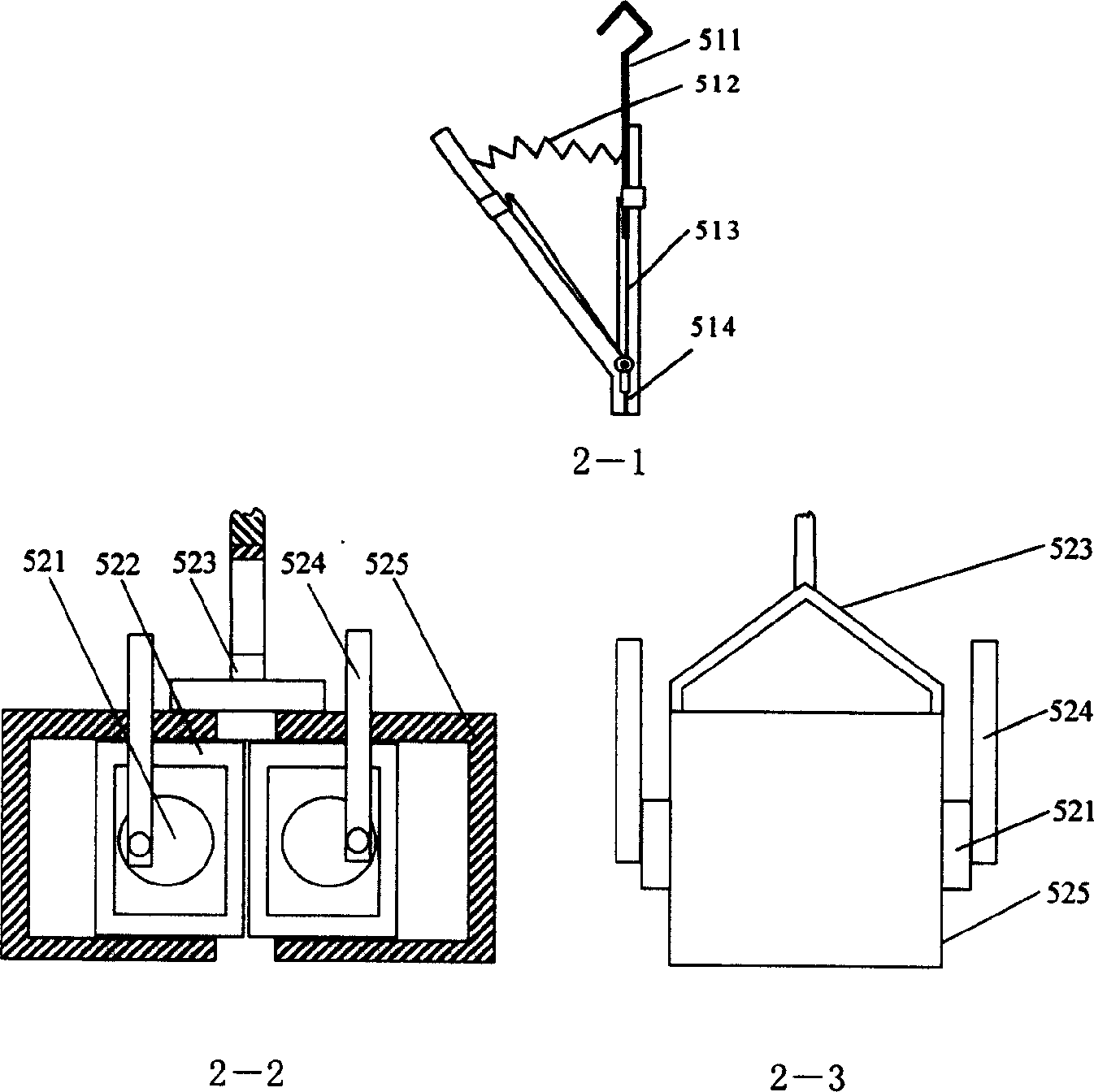

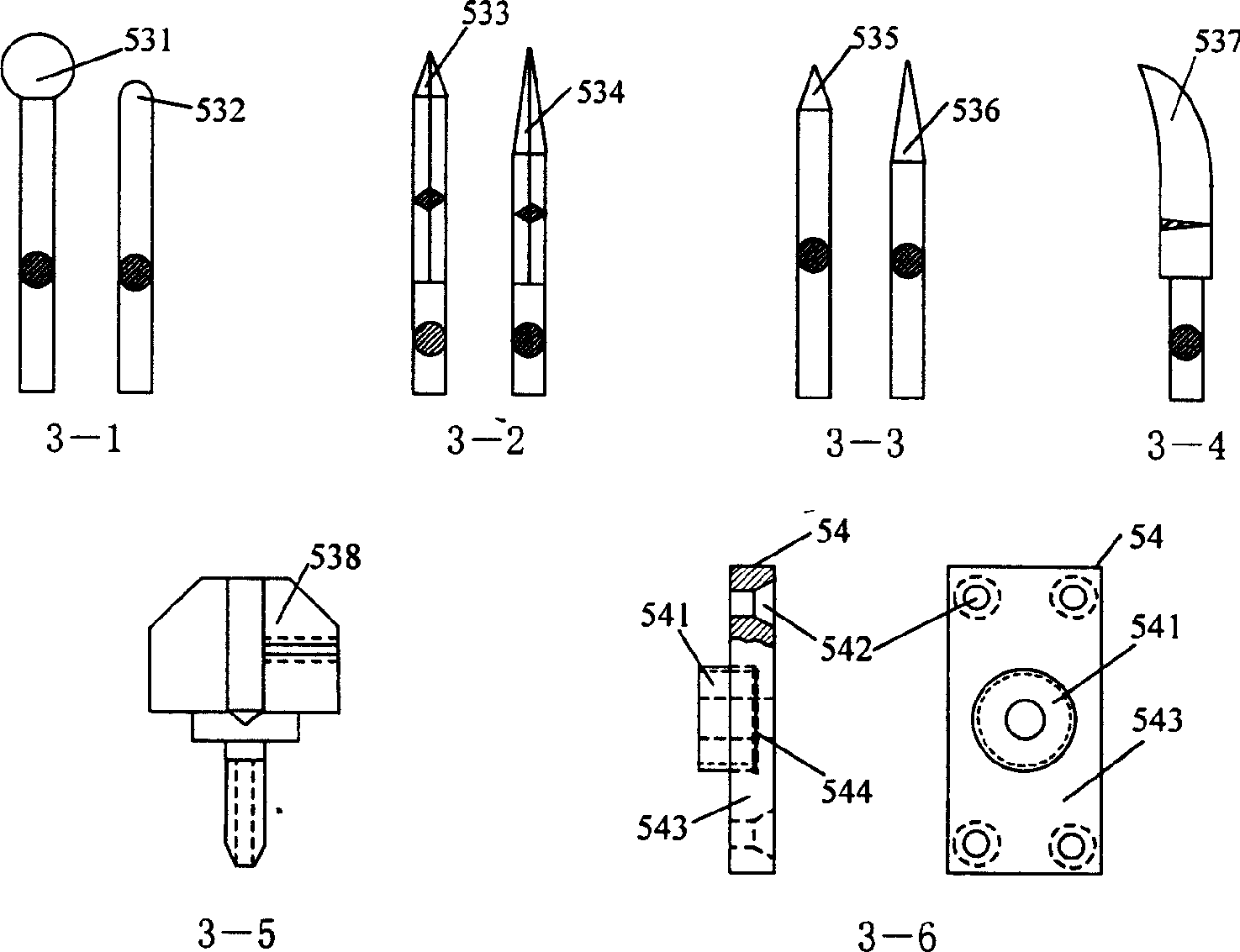

Combined measuring method and device for stretching, compressing, bursting and prick-cut

InactiveCN1587964AEasy to holdQuick gripMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesYarnFiber

The invention relates to a combining ability and displacement measuring method and device of textile materials containing fiber, yarn, cloth, film and composite material, by which combining ability-displacement curve and stress-strain carve and measurement of associative characteristic value are obtained. The measuring device is consisted of multi-functional clamper suitable for textile materials, frame top beam, middle beam and under beam where sensor and multi-functional clamper can be installed, driving element controlled by middle beam, force and displacement signal collection card And computer with modules of program control and data processing. The invention includes the following properties that force sensor can be fitted on anywhere of the under beam, which can measure force value of moving terminal, and its structure is simple, operation is convenient and multi-functional clamper can be replaced fast and conveniently.

Owner:DONGHUA UNIV

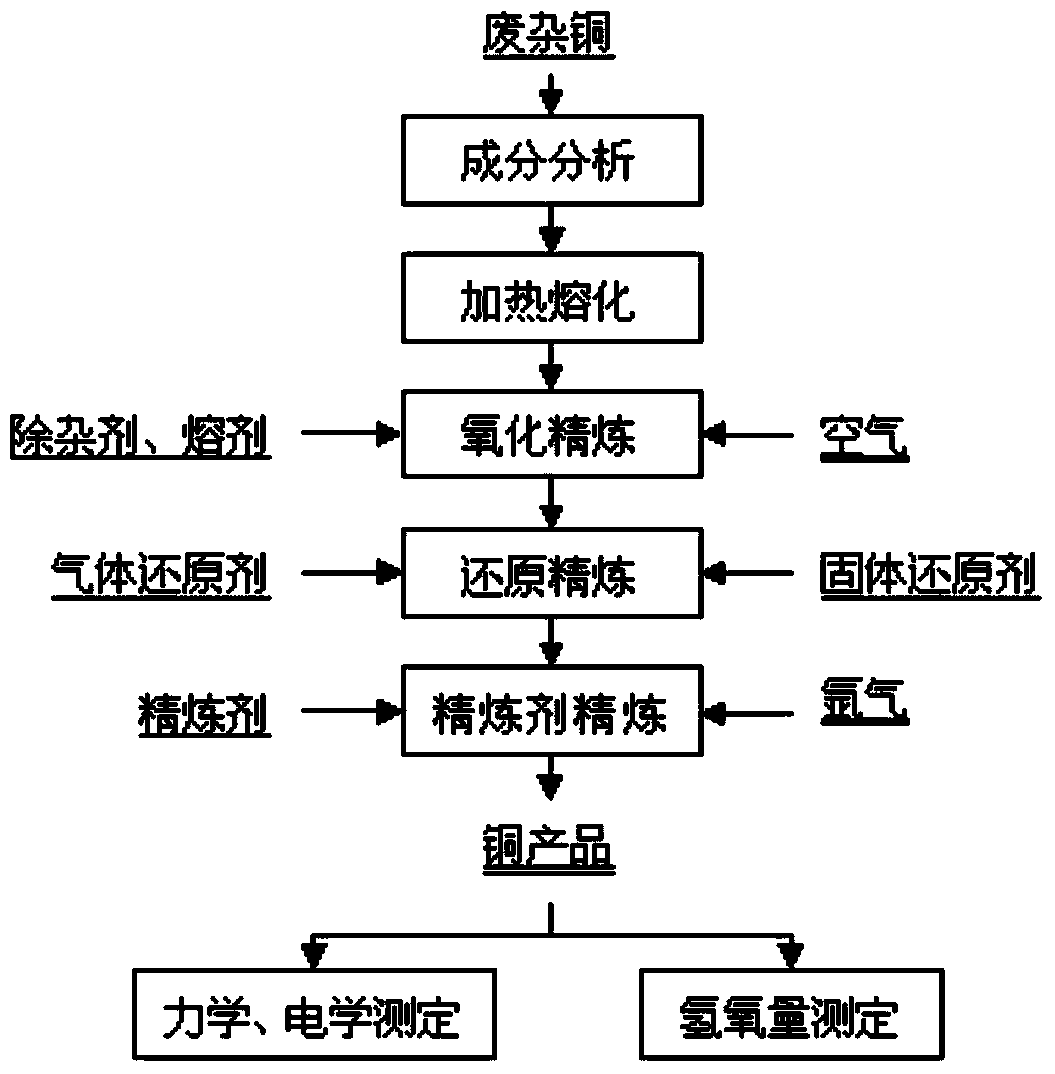

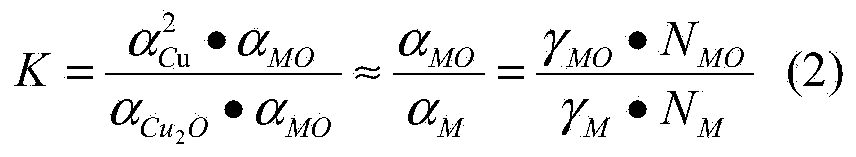

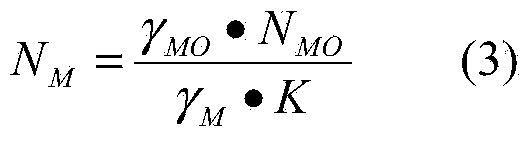

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

ActiveCN103725897AOptimizing Process ParametersReduce manufacturing costProcess efficiency improvementElectrolysisCopper wire

The invention relates to a method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: by taking scrap copper as a raw material; analyzing the component characteristics of each batch of raw material, and then preparing into a mixture, wherein the mass percent of a copper element in the mixture is greater than or equal to 93%; adding metaphosphate or phosphorus pentoxide and flux to the mixture; refining by oxidation; stewing and drossing after oxidation is finished, and then orderly carrying out reduction refining and refining agent refining under an agitation state, so as to obtain the high-purity oxygen-free copper of which the copper content is greater than or equal to 99.95% and the oxygen content is smaller than 0.003%, wherein the electrical resistivity of the obtained copper wire after drawing is below 0.017241omega / (mm), and the relative electrical conductivity is over 100% of International annealed copper standard (IACS). The method is strong in flexibility, significant in refining effect, and applicable to different components of scrap copper materials; the scrap copper can be used for directly making a rod after being refined. Compared with the traditional pyrogenic process smelting-electrolytic refining-copper cathode purification process, the method disclosed by the invention has the beneficial effects that the flow is shortened, the cost is reduced, the energy is saved, and continuous operation is achieved.

Owner:CENT SOUTH UNIV

High carbon high silicon martensite stainless steel billet and preparation method thereof

InactiveCN101967610AGuaranteed performanceSmall temperature fluctuationsProcess efficiency improvementElectric furnaceStress concentrationElectric arc furnace

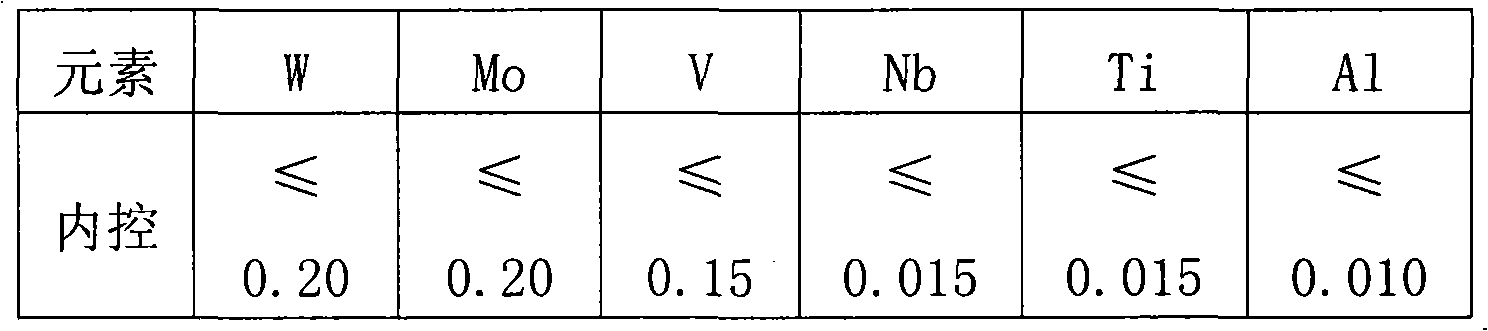

The invention provides a high carbon high silicon martensite stainless steel billet. The steel billet is characterized by comprising the following components by weight percent: 0.41-0.47% of C, 2.80-3.20% of Si, 0.50-0.80% of Mn, 8.50-9.20% of Cr, 0.30% or less of Ni, 0.028% or less of P, 0.005% or less of S, 0.20% or less of W, 0.20% or less of Mo, 0.15% or less of V, 0.015% or less of Nb, 0.015% or less of Ti, 0.010% or less of Al and the balance Fe and inevitable impurities. The invention also provides a preparation method of the high carbon high silicon martensite stainless steel billet. The method comprises the following steps: performing primary smelting with an electric arc furnace (EAF), performing argon-oxygen decarburization (AOD) smelting, refining with a low frequency (LF) furnace, performing continuous casting, annealing and rolling. The method of the invention has simple operation, can stably control the quality of the continuous casting billet, completely suppresse cracks, overcome the defect of concentration of stress and increase the casting yield and quality stability of the martensite stainless steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Silicon-slag microcrystalline glass and preparation method thereof

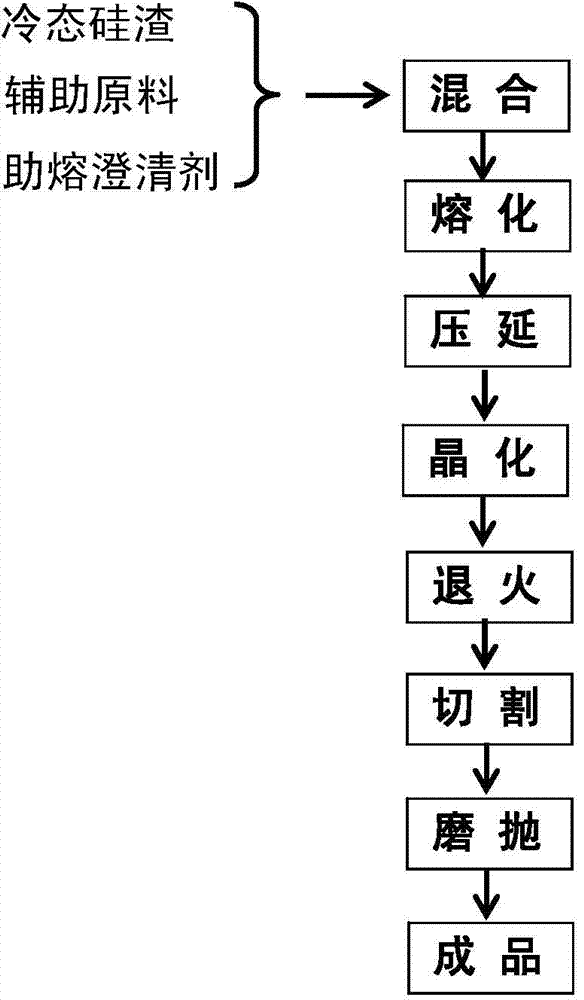

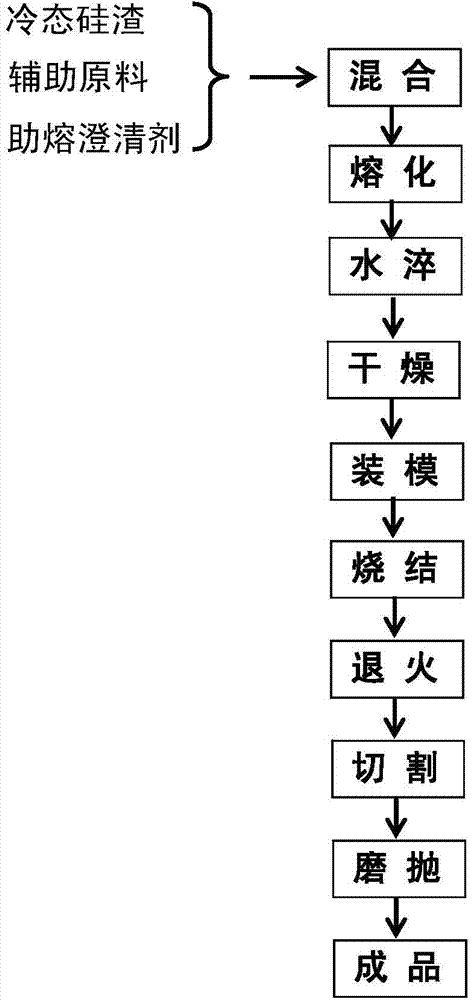

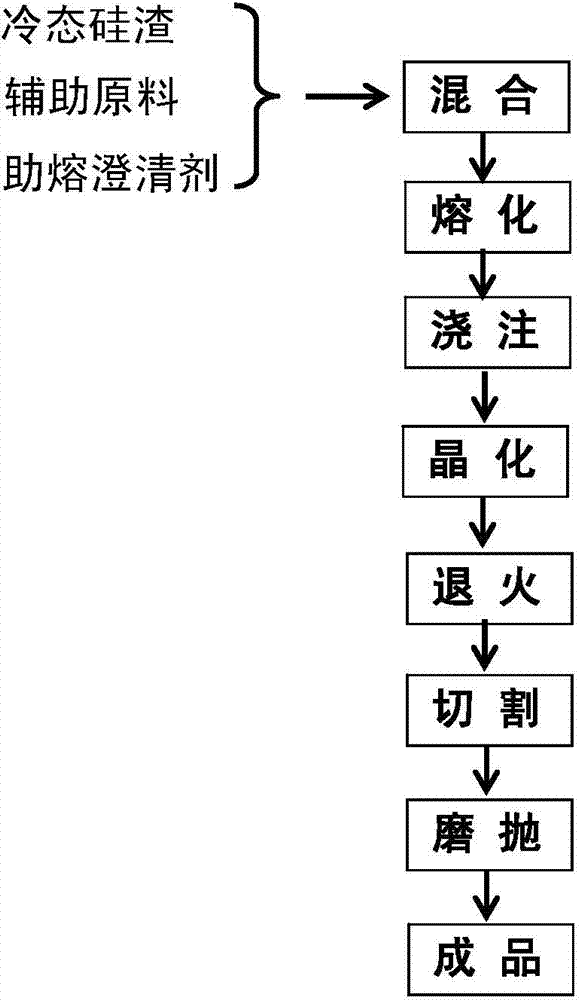

The invention relates to silicon-slag microcrystalline glass and a preparation method thereof. Silicon smelting waste slag is taken as a major raw material, and silicon dioxide or silica sand (SiO2), fluorite (CaF2), limestone or calcite (CaCO3), industrial sodium carbonate (Na2CO3), zinc oxide (ZnO) and potassium carbonate (K2CO3) are taken as auxiliary raw materials, wherein the dosage of the silicon smelting waste slag in the raw materials of the microcrystalline glass is 26.0-75.0wt%. The preparation method specifically comprises the following steps of: evenly mixing cold-state silicon slag with other auxiliary raw materials in a blender mixer to obtain a basic mixed batch, melting the basic mixed batch into qualified glass liquid in a melting furnace, and then performing calendering, casting or water quenching on the glass liquid to form a basic glass plate or granules; finally, subjecting the basic glass plate to crystallization heat treatment to obtain the microcrystalline glass. The density of the microcrystalline glass is 2.5-2.8 g / cm<3>, the rupture strength of the microcrystalline glass is 30.0-103.5 MPa, the compressive strength of the microcrystalline glass is 70.0-903.0 MPa, the Moh's hardness of the microcrystalline glass is 5-8 and the abrasive resistance of the microcrystalline glass is 0.063-0.15 g / cm<2>; the silicon-slag microcrystalline glass can be widely applied to the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

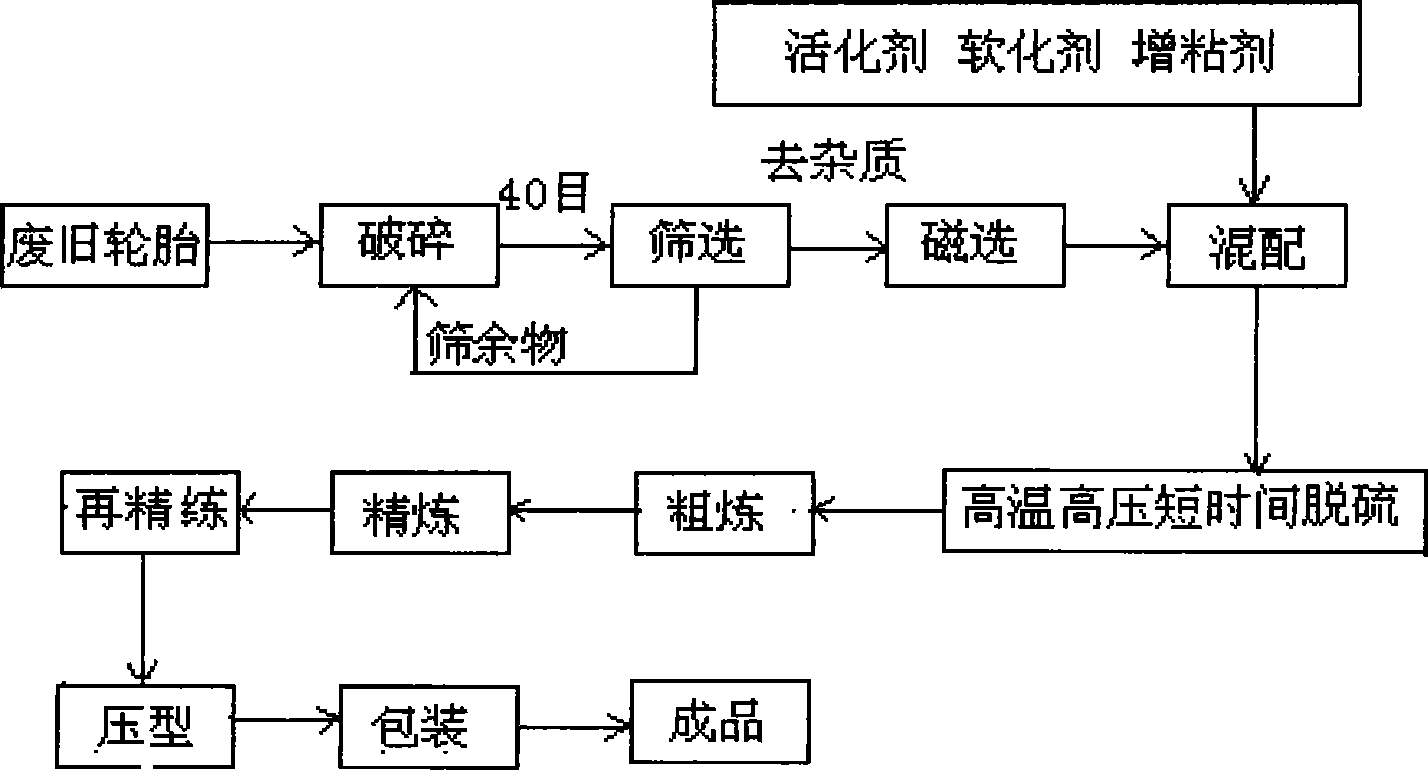

High-quality regenerated rubber and its production

InactiveCN101074302AStrong wear resistanceExtended service lifePlastic recyclingHigh pressureTemperature and pressure

A high-quality regenerated rubber and its production are disclosed. It improves composition and proportion, it adopts high-temperature and pressure desulfurizing method in short time and refining process is added. The tensile strength and breaking extensibility can be increased by 30-60%; it can substitute natural rubber or synthetic rubber and be used as various tyre and raw material of rubber products. It's simple, efficient and smokeless, has excellent abrasive performance, long life, less noise and no refused water discharge.

Owner:QINGWEI RUBBER SUQIAN

Garbage percolate treatment technique

ActiveCN101234836AOptimizing Process ParametersImprove water qualityWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesSludgeLitter

The invention discloses a technology for treating landfill leachate, which comprises the steps of pretreatment, upflow type sludge bed reaction, nitrification and denitrification reaction, mud-water separation and membrane treating. The technology for treating landfill leachate treats the landfill leachate by comprehensively using physics and biochemistry method, which largely reduces the cost for treating the leachate, simultaneously promotes effluent water quality at large amplitude, and can be widely used for treating landfill leachate in a waste treatment plant.

Owner:CHONGQING GROUP SANFENG TECH

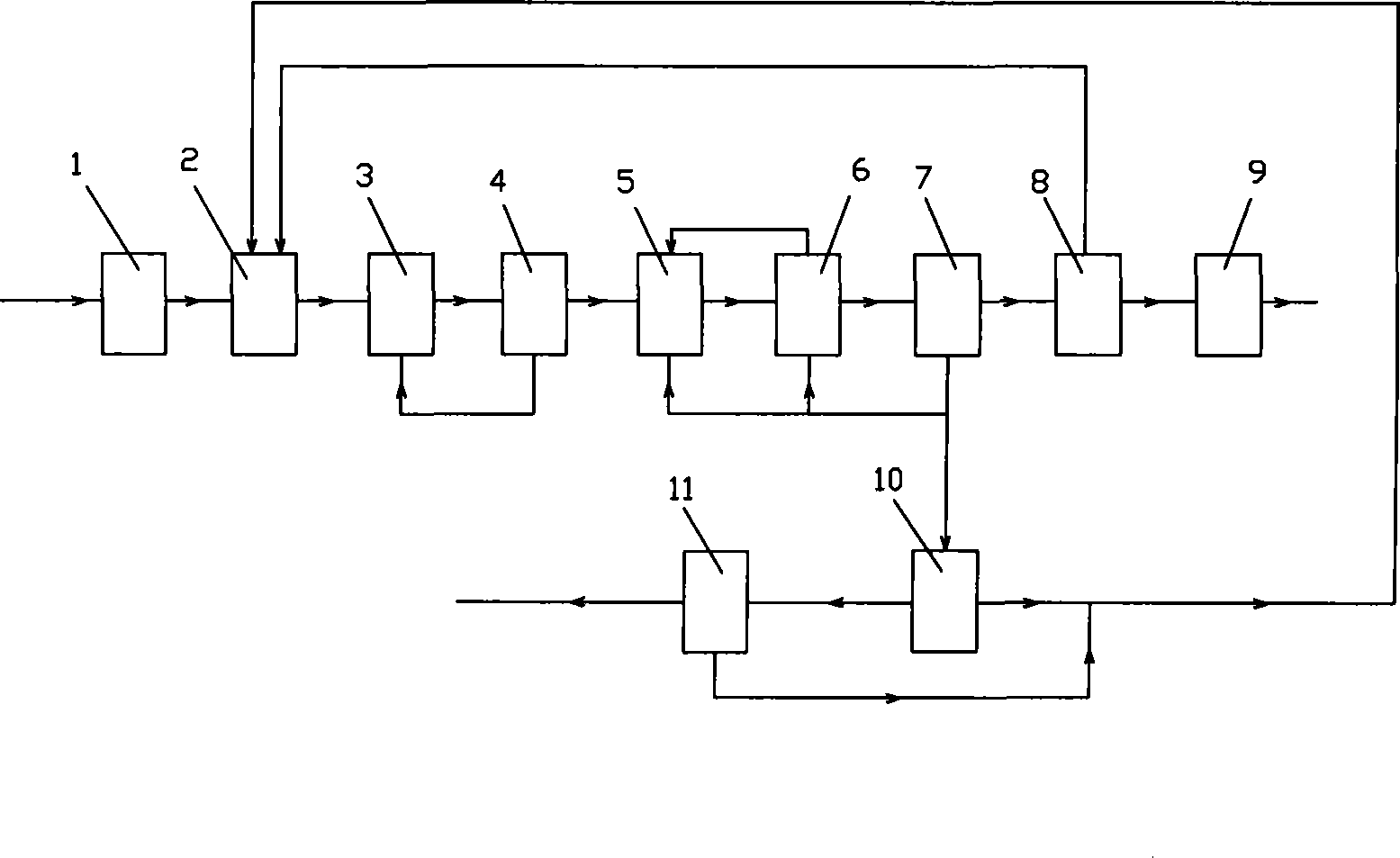

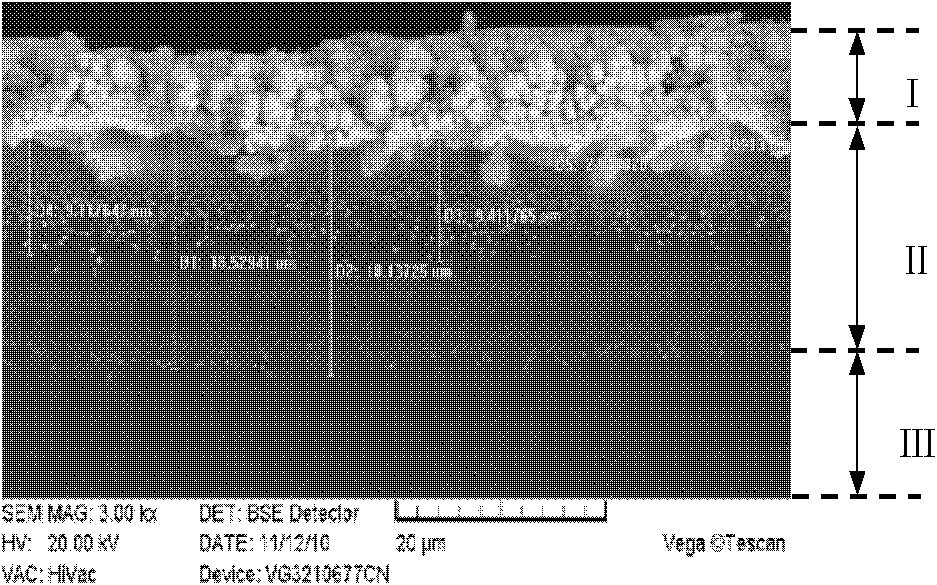

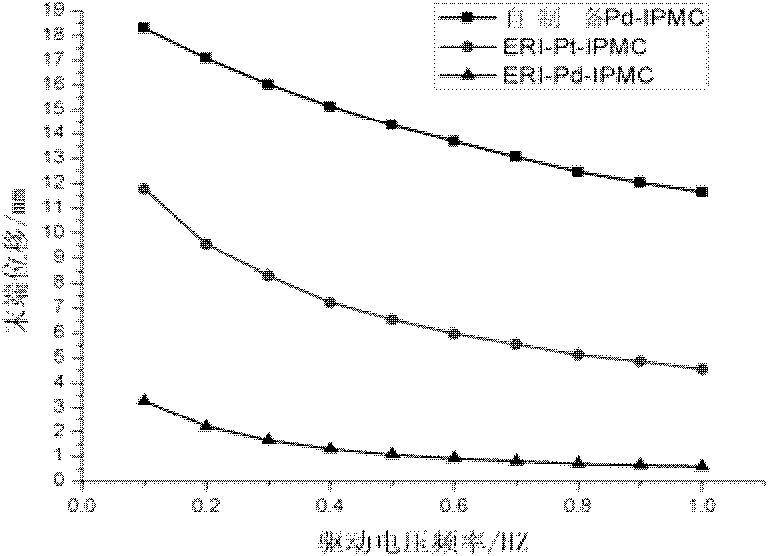

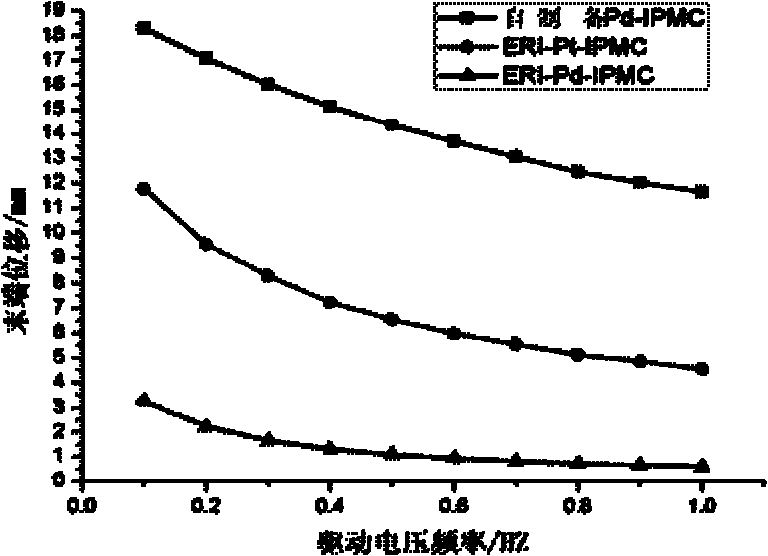

Preparation process of palladium electrode ion polymer and metal composite

InactiveCN102168260AIncrease profitImprove electrical actuation performanceLiquid/solution decomposition chemical coatingIonic polymer–metal compositesChemical plating

The invention discloses a preparation process of a palladium electrode ion polymer and metal composite, which is used for preparing a palladium metal electrode IPMC (Ion Polymer Metal Composite) by using immersion reduction plating and chemical plating methods in which an ion exchange membrane is used as a matrix material and [Pd (NH3)4] C12 is used as a main salt. The preparation process comprises the following four main steps of: (1) pretreatment of the matrix membrane: carrying out roughening, surface cleaning, foreign ion removal and full swelling on the matrix membrane; (2) immersion reduction plating including two processes, i.e., ion exchange and ion reduction: subjecting a pretreated Nafion membrane to repeated palladium ion immersion and exchange, and reducing the pretreated Nafion membrane with NaBH4 by adopting ultrasonic waves to form palladium metals on the surface and the internal surface of the ion exchange membrane; (3) chemical plating: wherein the thickening electrodes on the outer surface of a core material to compact internal surface electrodes by using an improved chemical plating method; and (4) postprocessing of the composite. The preparation process has a higher popularization value due to relatively improved efficiency, relatively lower cost and excellent actuation response.

Owner:XI AN JIAOTONG UNIV

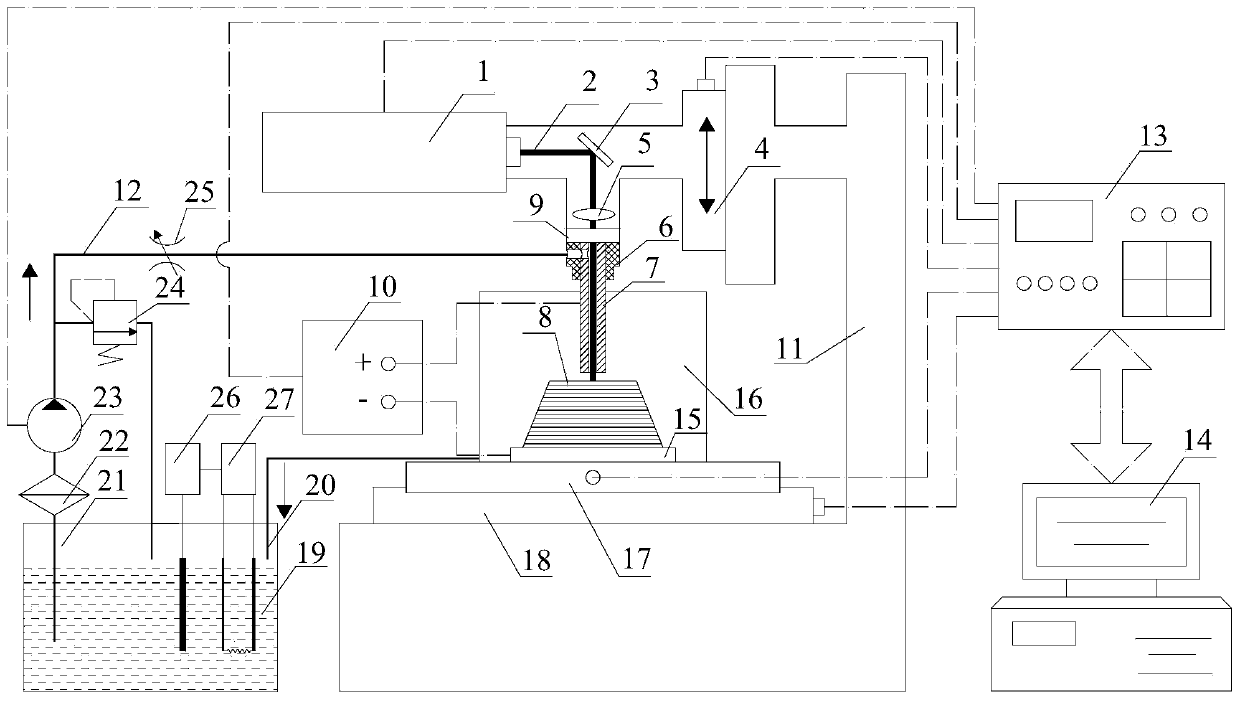

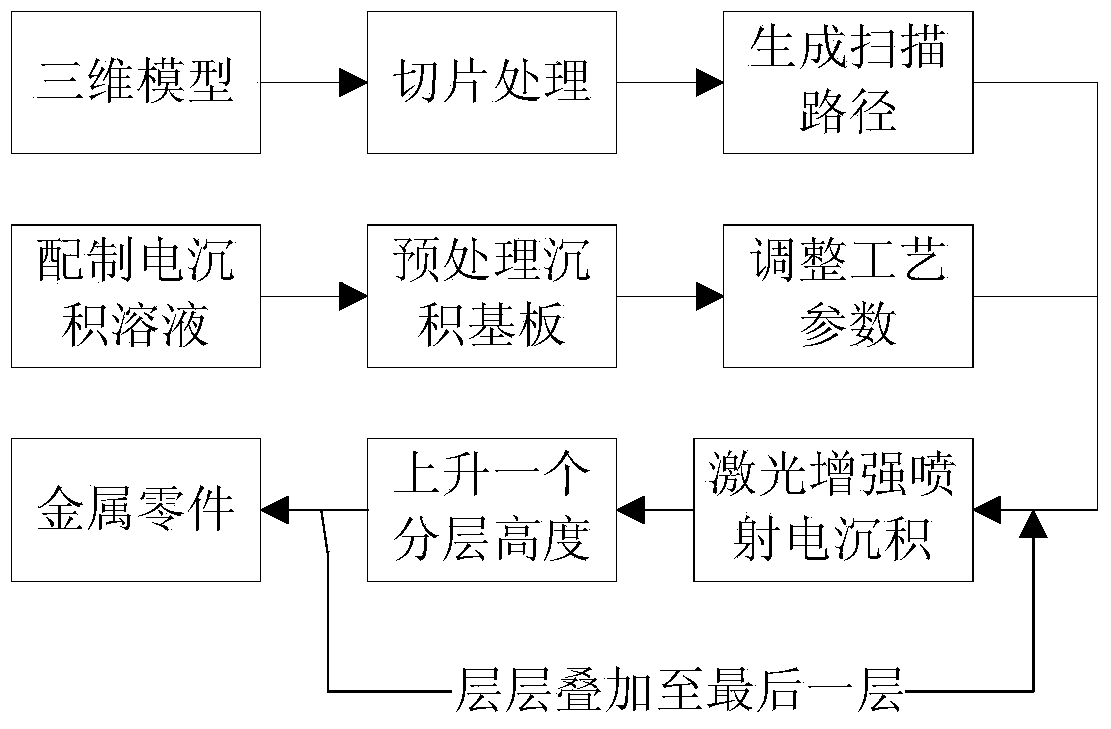

Laser-reinforced jet-electrodeposition rapid-prototyping processing apparatus and method

The invention discloses a laser-reinforced jet-electrodeposition rapid-prototyping processing apparatus and method. An anode is connected with a laser generation mechanism, an eye shield is located between the laser generation mechanism and the anode, a cathode is a deposition substrate which is arranged in a deposition groove, and a power supply is connected with the cathode and the anode; a Z-axis mobile platform is connected with the anode and the laser generation mechanism, and an X-axis mobile platform and a Y-axis mobile platform are successively arranged below the deposition groove; the liquid inlet end of a constant temperature liquid storage mechanism is connected with the anode, the liquid returning end of the constant temperature liquid storage mechanism is connected with the deposition groove, and a controller is connected with the laser generation mechanism, the power supply, the X-axis mobile platform, the Y-axis mobile platform, the Z-axis mobile platform and the constant temperature liquid storage mechanism. According to the invention, a high-energy density laser beam and a high-speed electrodeposition solution are synchronously jetted to the surface of the cathode through a tubular passive anode centre bore, combination of laser reinforced electrodeposition technology and electrodeposition solution injection is realized, and a high deposition speed is obtained.

Owner:TONGLING UNIV

High-strength cast magnesium alloy and preparation method thereof

ActiveCN102534330AReduce burning lossReduce the difficulty of protectionRare-earth elementCooking & baking

The invention discloses high-strength cast magnesium alloy and a preparation method thereof. The high-strength cast magnesium alloy comprises the following ingredients by mass percentage: 8 to 14 weight percent of Gd, 1 to 5 weight percent of Y, 0.6 to 2 weight percent of Al, less than 0.02 weight percent of impurity elements of Si, Fe, Cu and Ni and the balance of Mg. The preparation method of magnesium alloy comprises two process work procedures: smelting and subsequent heat treatment, wherein the smelting process work procedure is carried out under the protection condition of SF6 and CO2 mixed gas and comprises the steps of material baking, magnesium melting, Gd and Y addition, Al addition and casting, and the heat treatment process work procedure comprises solid solution treatment andaging treatment. Through the method of adding rare earth elements such as Al, Gd and Y into the alloy to generate Al-RE intermetallic compounds through in-situ reaction, the goal of refining crystalline grains is reached, the crystalline grain stability of the obtained high-strength cast magnesium alloy is excellent, the recession resistance performance of the refining effect is high, and higher tensile strength and elongation are realized.

Owner:SHANGHAI JIAO TONG UNIV

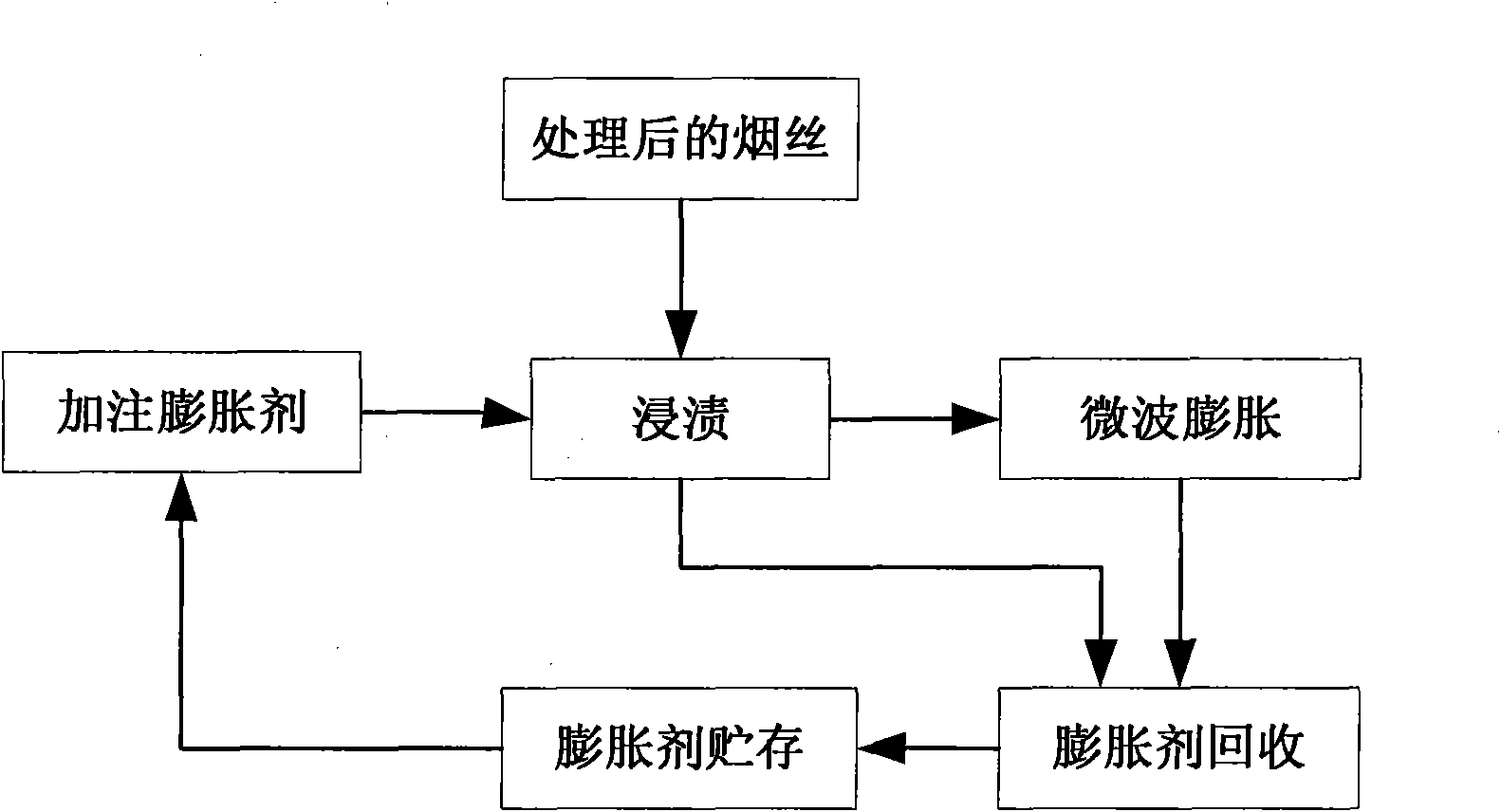

Method for continuous microwave expansion of cut tobacco

ActiveCN101617855AStable internal and external temperature changesNo damageTobacco preparationAlkaneMicrowave

A method for continuous microwave expansion of cut tobacco comprises the following steps: impregnating the cut tobacco in an expanding agent; recycling the expanding agent in an impregnating device after impregnation; carrying out microwave expansion on the impregnated cut tobacco by a microwave dryer to obtain the expanded cut tobacco. The expanded cut tobacco comprises one or more than two components of ethanol with 4-12 carbon atoms, ketone with 4-12 carbon atoms, halogenether with 2-12 carbon atoms, alkane with 3-12 carbon atoms or alkane with 3-12 carbon atoms substituted by 2 halogen atoms. The filling value of the expanded cut tobacco reaches above 7.5, the cutting ratio is above 90%, the moisture content after expansion is 12-13%, the expansion of the cut tobacco is even without water damaged cut tobacco; the whole set of devices has low energy consumption and high automation, and continuous closed mass production can be carried out.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

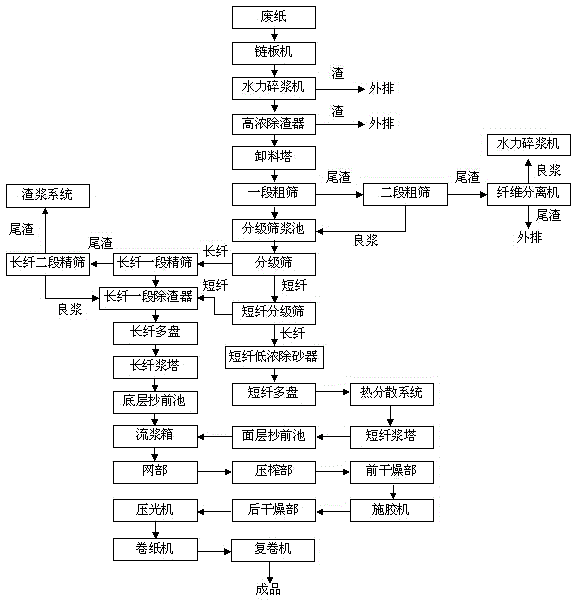

Wastepaper pulping and papermaking method

ActiveCN105780570AFine paperNice appearancePaper recyclingWaste paper working-upHigh concentrationSurface layer

The invention discloses a wastepaper pulping and papermaking method, and relates to the technical field of testliner board. The method specifically adopts the devices such as a hydraulic pulper, a high-concentration desander, an unloading tower, a grading sieve slurry tank, a grading sieve, a filament first-stage slag remover, a filament multi-disk, a filament pulp tower, a bottom layer pre-papermaking tank, a staple grading sieve, a filament first-stage slag remover, a staple low-concentration desander, a staple multi-disc, a heat dispersion system, a staple pulp tower, a surface-layer pre-papermaking tank deduster, a bottom-layer headbox, a surface-layer headbox, a press section, a drying section, a sizing machine, a calender, a reeling machine, a re-reeling machine, and the like. The method has a high finished product conversion rate. With the method, 20000 tons of wastepaper can be saved per year, such that production cost can be reduced. Process parameters are optimized, such that unit product energy consumption is reduced, and energy is saved. Therefore, the production cost is further reduced.

Owner:福建利树股份有限公司

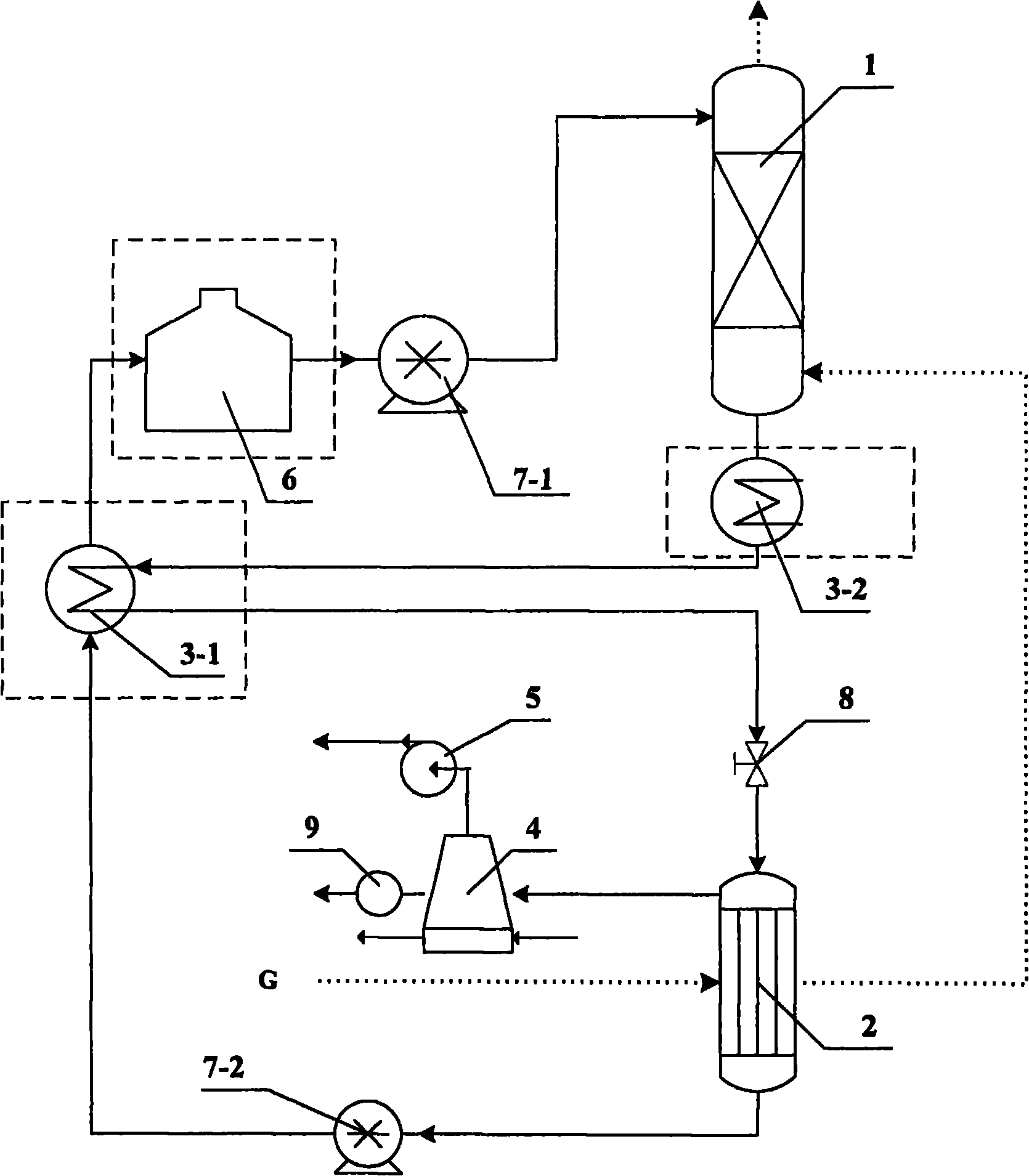

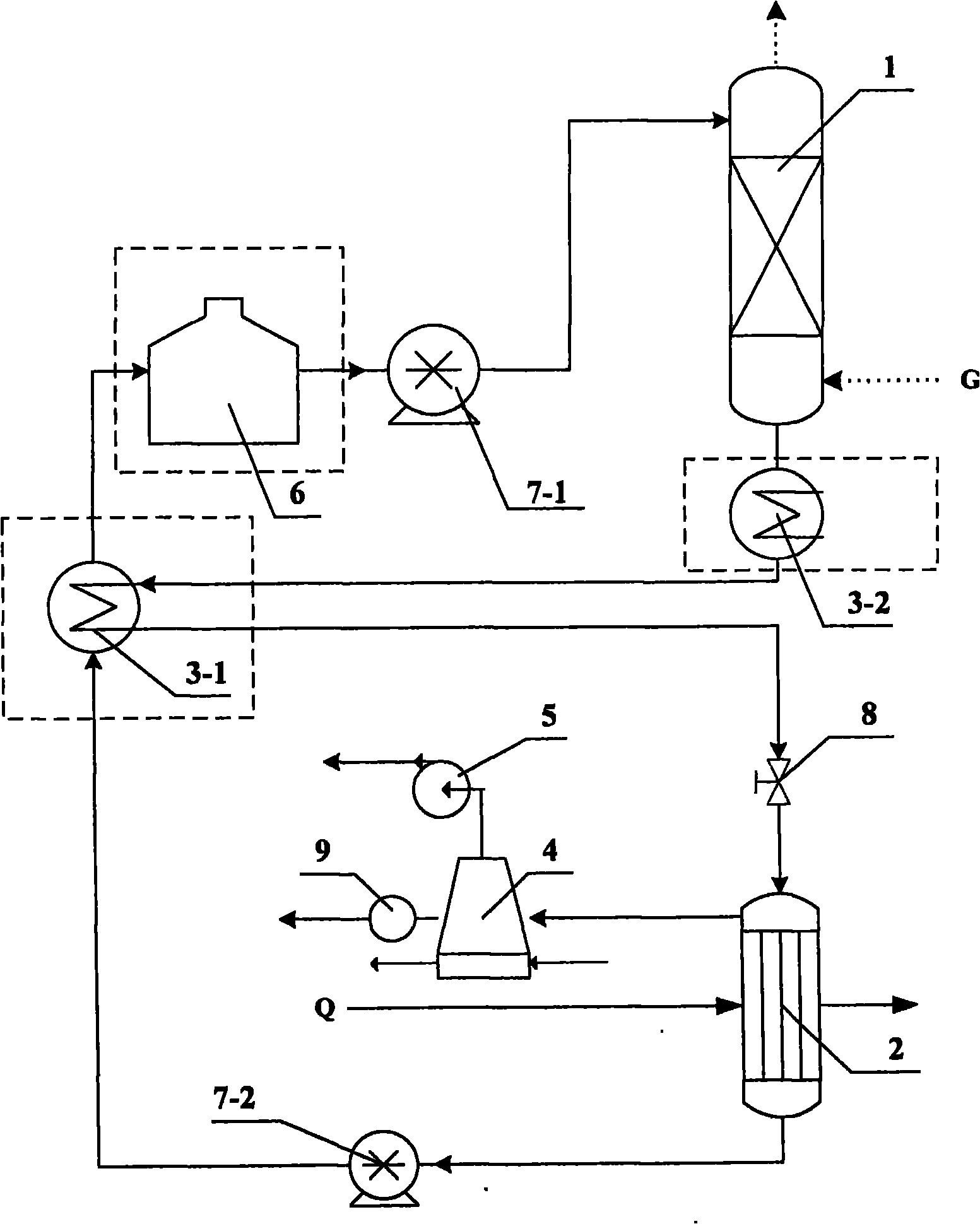

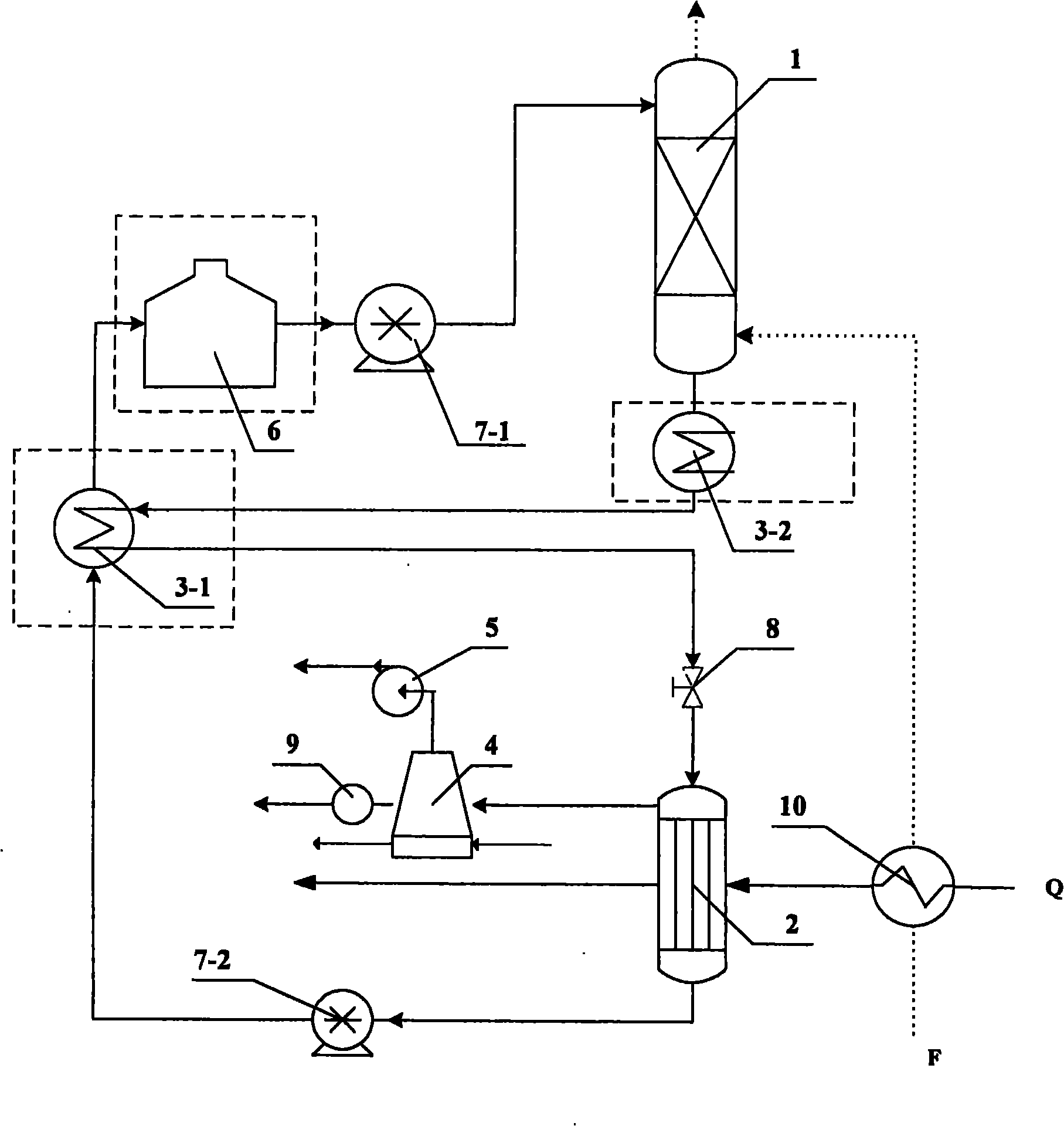

Method for simultaneously recovering water and latent heat in high-humidity flue gas and heat pump device

InactiveCN101922821AOptimizing Process ParametersLow costClimate change adaptationEnergy efficient heating/coolingHigh humidityFlue gas

The invention discloses a method for simultaneously recovering water and latent heat in high-humidity flue gas and a heat pump device, relating to the technique of energy-saving equipment. A heat exchanger is arranged in an absorber of the heat pump device, the top of the absorber is provided with a flue gas discharging pipe, the bottom of the absorber is provided with a dilute solution outlet, the side surface of the bottom is provided with a gas inlet pipe, the side surface of the top is provided with a concentrated solution inlet, and a concentrated solution pipeline is communicated with a spray head at the inner upper part of a cavity; the top of a regenerator is provided with a dilute solution inlet, the bottom of the regenerator is provided with a concentrated solution pipeline outlet, a gas-liquid heat exchanger is arranged in the regenerator, and an inlet and an outlet of the gas-liquid heat exchanger are communicated with a flue gas pipe; the flue gas pipe is communicated with the gas inlet pipe at the bottom of the absorber after passing through the regenerator; the bottom of the absorber is communicated with the regenerator through a dilute solution pipeline, in which a regulating valve is arranged; and the regenerator runs under negative pressure, and the bottom of the regenerator is communicated with the absorber through the concentrated solution pipeline, in which a solution pump is arranged. The method and the device directly recover the water and the latent heat in the flue gas and have the advantages of equipment simplification, better energy saving, environmental protection and economic benefit.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

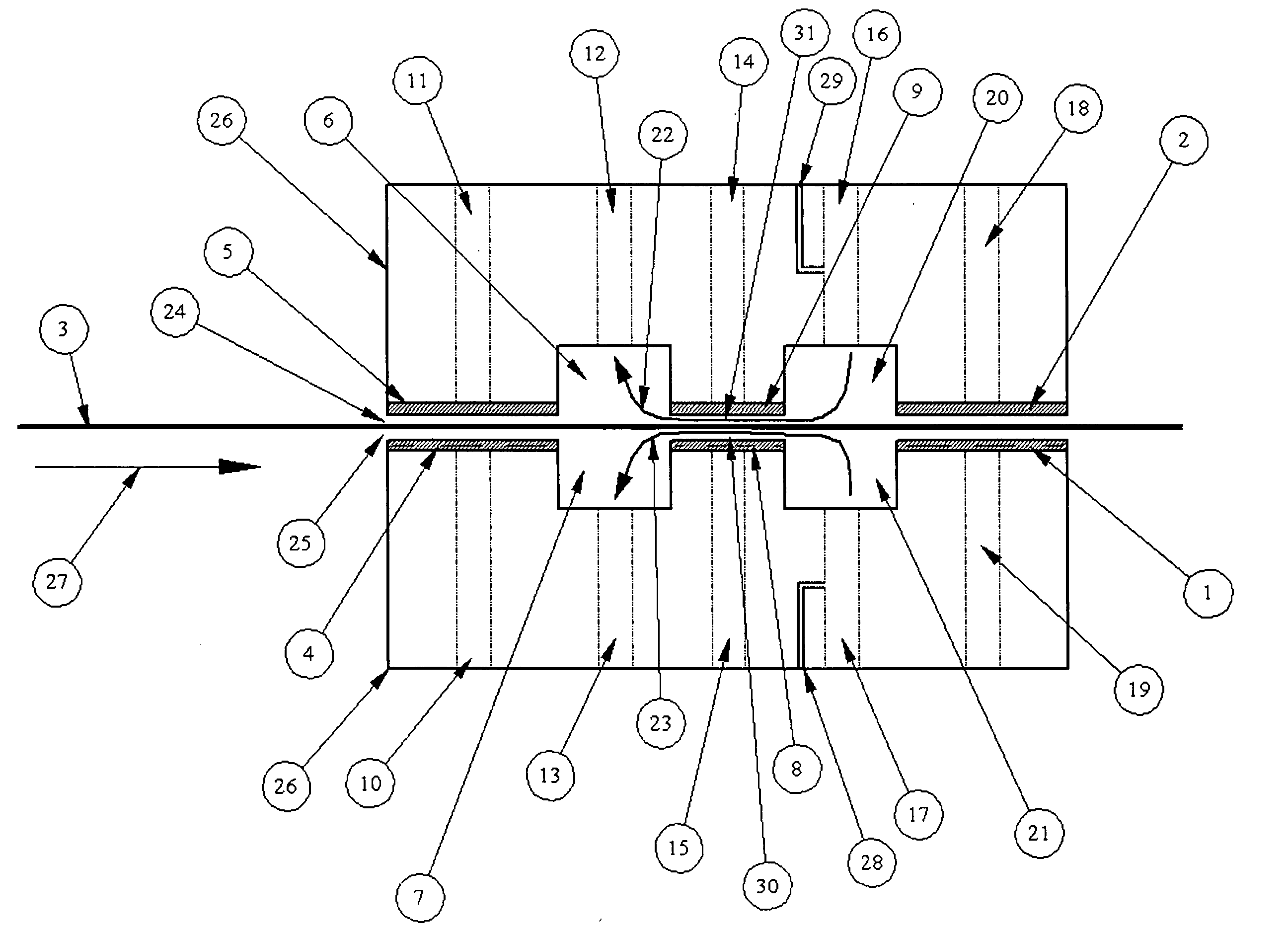

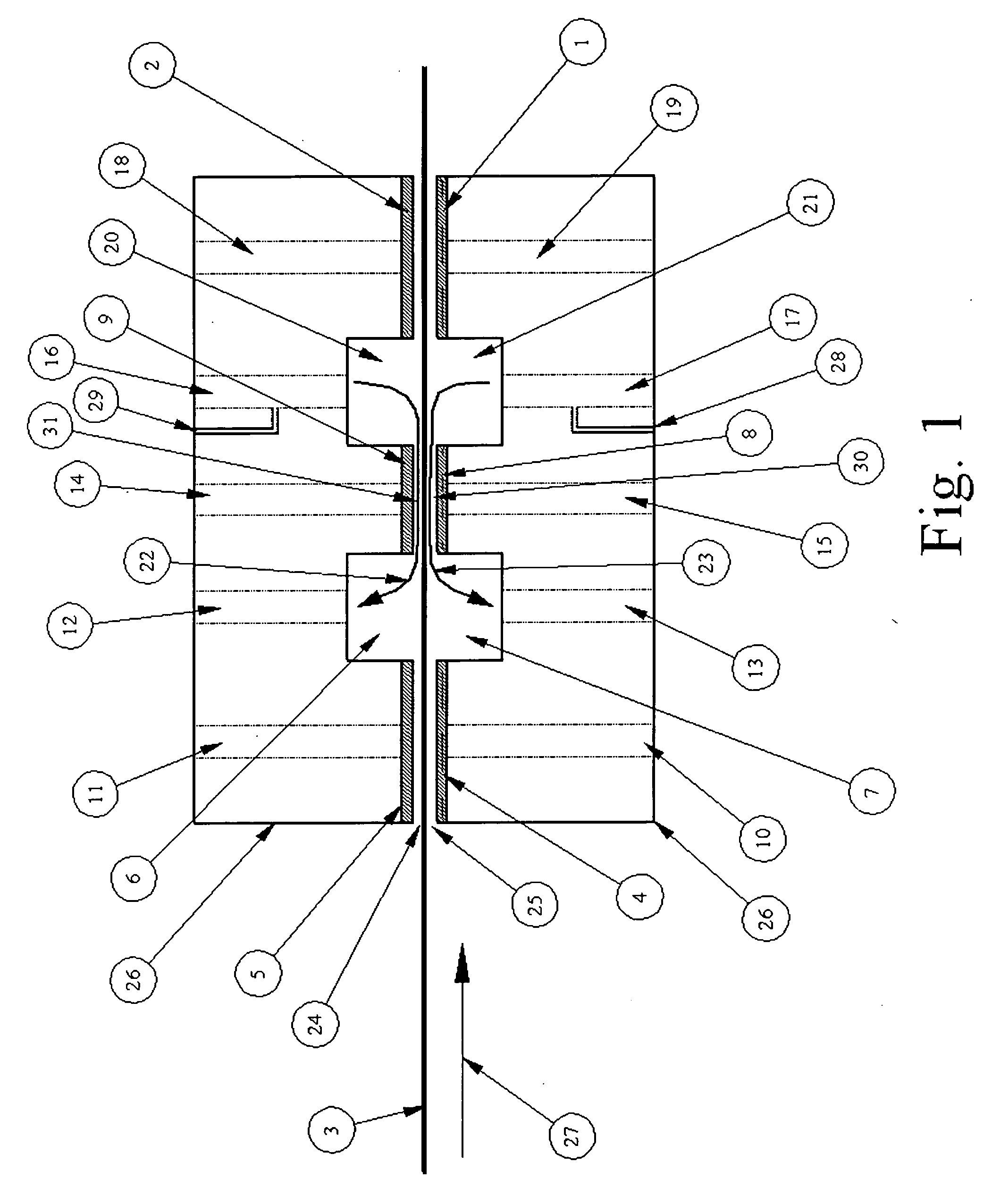

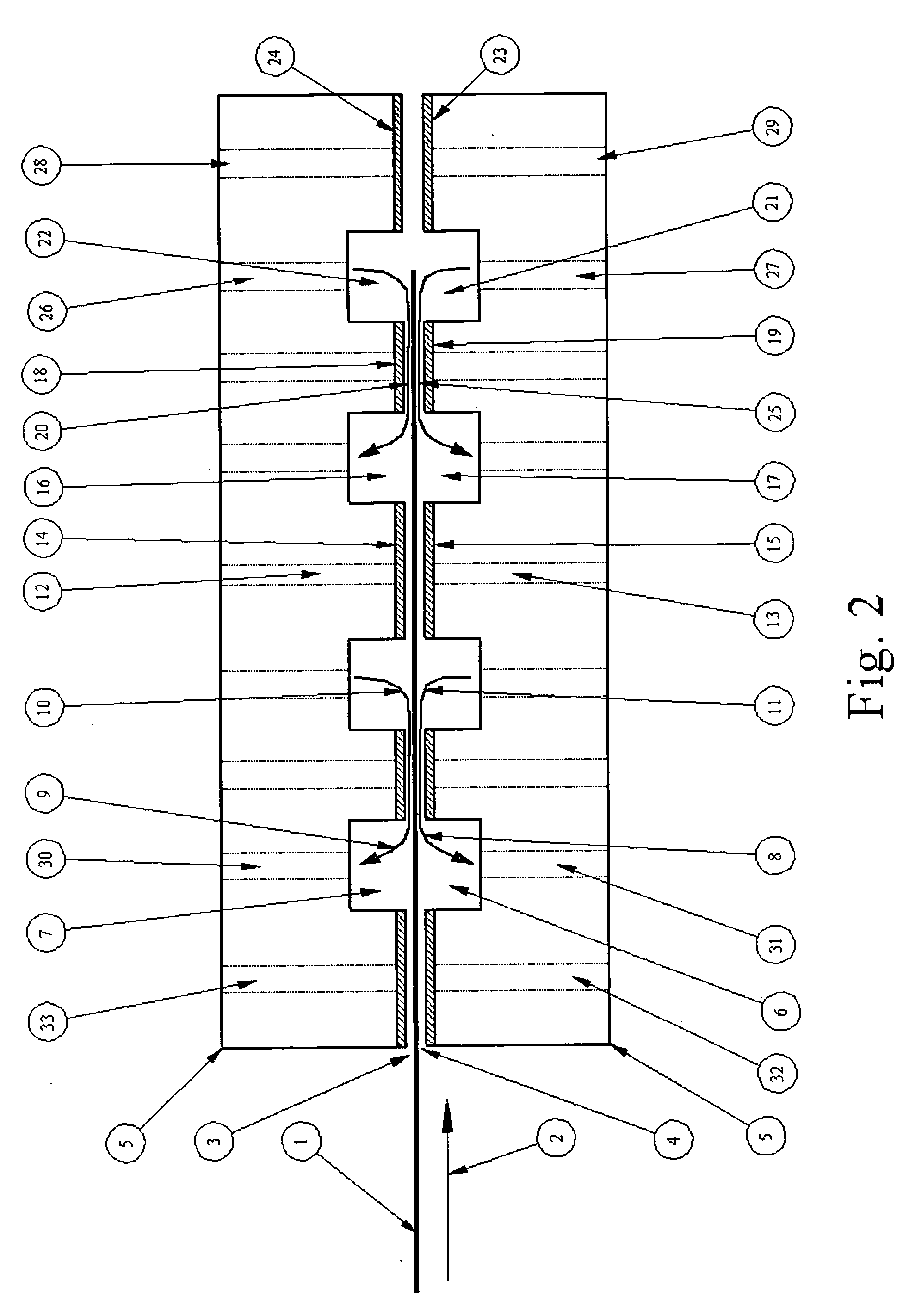

Method and apparatus for in-line processing and immediately sequential or simultaneous processing of flat and flexible substrates through viscous shear in thin cross section gaps for the manufacture of micro-electronic circuits or displays

InactiveUS20070034228A1Thin thicknessTransportation safetyVacuum evaporation coatingGlass transportation apparatusViscous shearPorous medium

A method and apparatus for cleaning, drying, coating, baking etching and deposition of surfaces on glass substrate as it transitions thru and between small gaps between hydro-static porous media bearings. Due to the non-contact nature of the device extremely high pressures can be induced upon the work piece through various fluids without damage to the substrate, allowing the system to utilize the viscous nature of fluids to accomplish the desired cleaning, drying, coating, etching or baking. The process also allows for simultaneous and immediately sequential ordering of processes.

Owner:NEW WAY MACHINE COMPONENTS

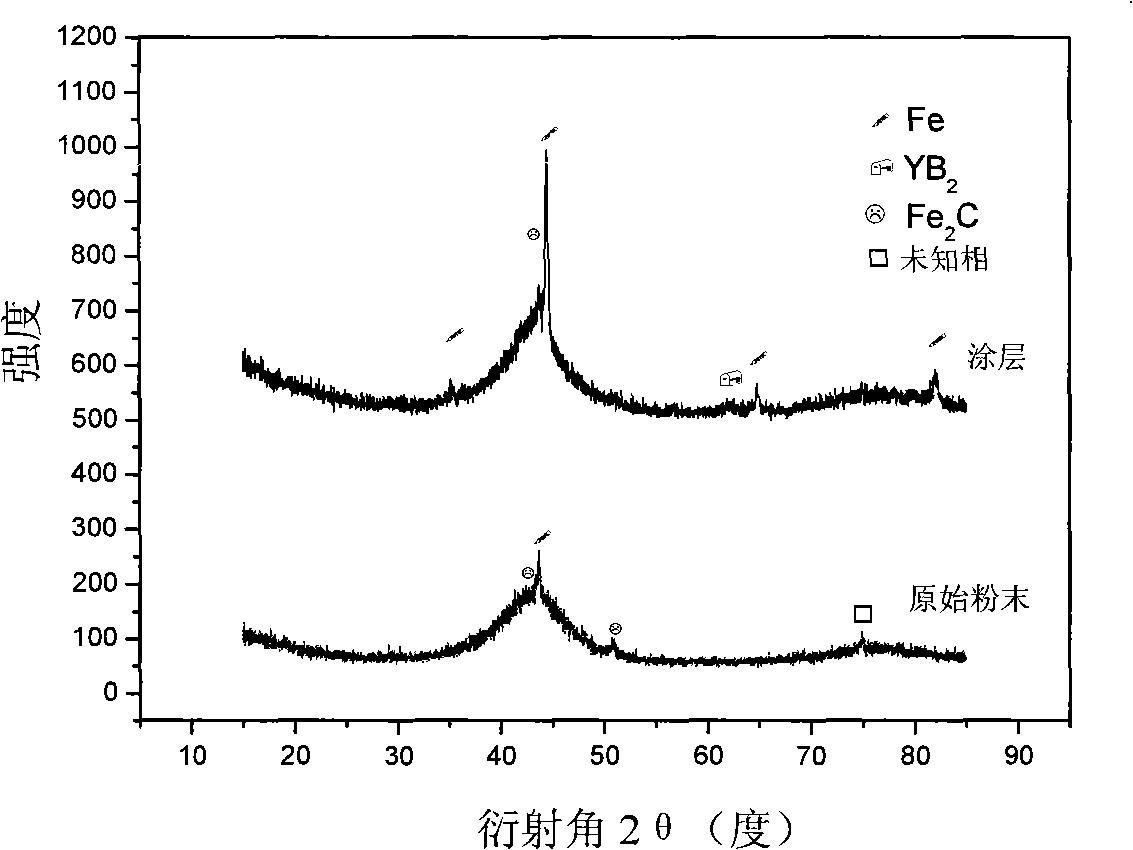

Preparation of non-magnetic high corrosion resistant amorphous steel coating

InactiveCN101323951AImprove mechanical propertiesGood physical propertiesMolten spray coatingHeat inorganic powder coatingSurface engineeringVoid ratio

The invention relates to a ferrous alloy with strong performance of glass formation and a technique method for preparing the coating of the amorphous alloy, in particular to a preparation method of non-magnetic amorphous steel coating with the performance of high anticorrosion and wearing resistance. The method of the invention solves the problem that large brittleness is existed in Fe-based large bulk of amorphous alloy and is a restriction as the structural material to go to engineering application, while the invention causes the application of bulk amorphous alloy to surface engineering field (especially amorphous alloy coating) to be possible. By adopting the Fe-based bulk amorphous alloy to prepare Fe-based amorphous alloy coating, firstly, mater alloy is produced by a method of vacuum induction melting according to needed components; then gas atomization technology is adopted to prepare amorphous alloy powder; supersonic thermal spray technology is adopted to prepare Fe-based amorphous alloy coating. The non-magnetic amorphous steel coating with high anticorrosion performance and wearing resistance produced by the invention is uniform, has low void ratio (less than 0.1 percent), is non-magnetic and has the performance of high anticorrosion and wearing resistance as well as vast application prospect to shell material of ships.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for directly casting and rolling aluminum plate base for PS plate with electrolytic aluminium liquid

ActiveCN101318288AQuality assuranceQuality improvementTemperature control deviceMetal rolling arrangementsSocial benefitsFiltration

The invention relates to a method for cast-rolling to produce aluminum substrates used in PS plates directly by electrolytic aluminum liquid; the main steps are as follows: electrolyzing the aluminum liquid under the high temperature, smelter hearth, adjusting element compositions, refining, conducting the furnace, adjusting the temperature to 740 DEG C to 750 DEG C, adding Al-Ti-B refiners to carry out the grain refinement, degassing, filtering, cast-rolling coils of strip, cool rolling, stretch bending and straightening, and producing finished products; various steps of the invention are synthesized to optimize technique parameters; the prepared aluminum substrates used in the PS plates is high in tensile strength and elongation, and the quality of the prepared aluminum substrates are better than that of similar products, thus omitting the remelting process when aluminum ingots are used, saving resources, reducing the production cost and increasing the economic and social benefits.

Owner:登电集团铝加工有限公司

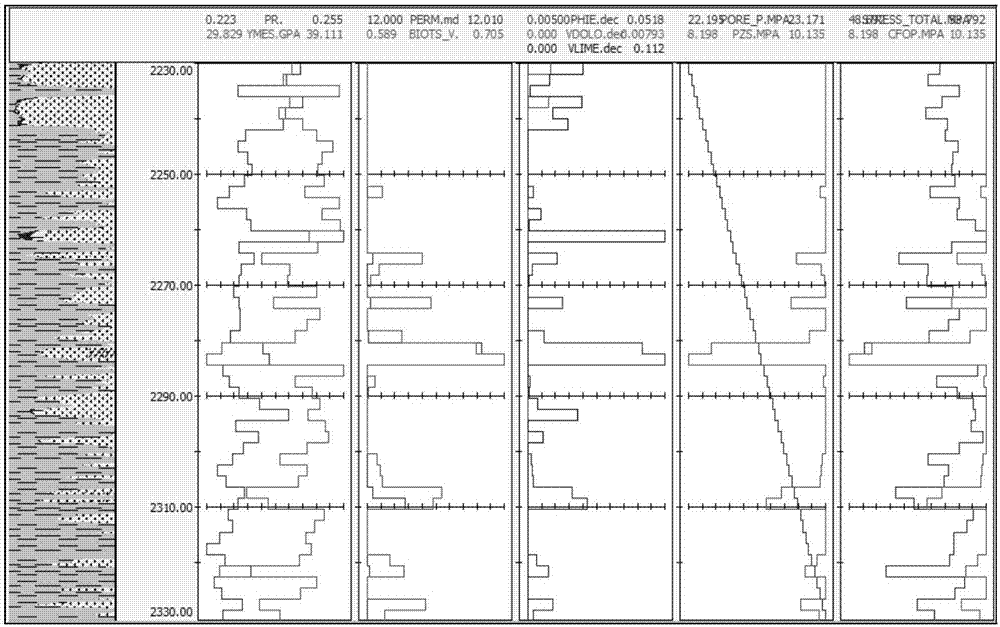

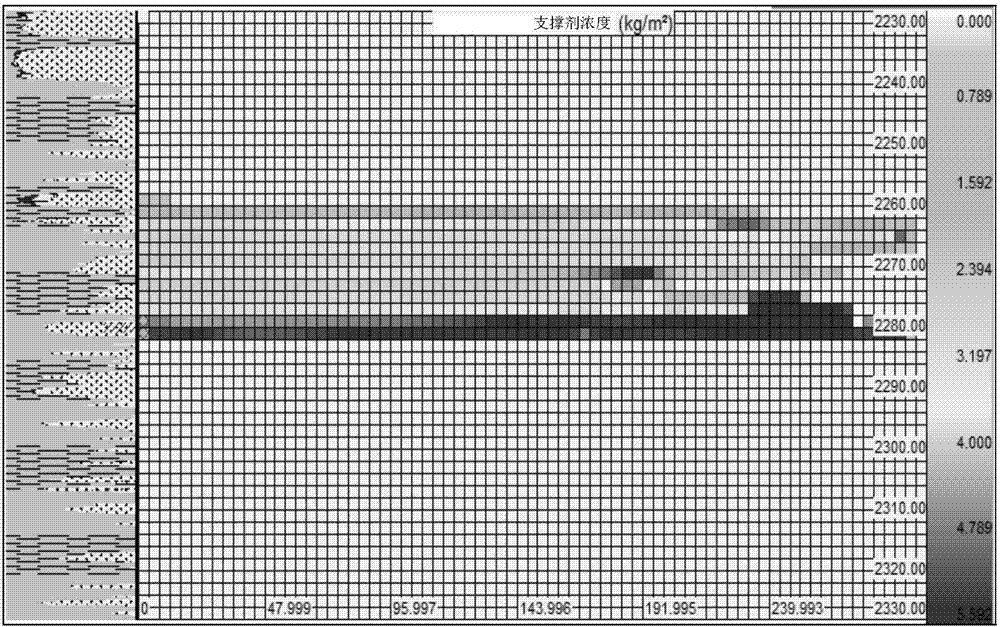

Layered refracturing method

ActiveCN107965305AAvoid unfavorable situations such as filtration damageImprove completenessFluid removalSection planeFracturing fluid

The invention provides a layered refracturing method. The method includes the following steps that the reservoir characteristic parameter and the initial crack characteristic parameter are obtained; and a layered refracturing mode, the fracturing fluid and layered refracturing construction parameter are selected; if necessary, initial cracks are repaired; refracturing is conducted to obtain new cracks; balancing and replacement are conducted. According to the method, a suitable layered refracturing mode is selected, the initial cracks and a propping agent are made full use of, the process parameters of refracturing are optimized so as to achieve optimum matching with a reservoir and form the new cracks, on this basis, the fracturing extent of each layer is improved, the height and extending of the new cracks are controlled, the crack propping profile is rationally optimized and controlled, the complexity degree of the new cracks is improved, and the volume is effectively transformed.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength heat-resisting magnesium alloy suitable for sand casting and preparation method thereof

The invention discloses high-strength heat-resisting magnesium alloy suitable for sand casting and a preparation method thereof. The high-strength heat-resisting magnesium alloy suitable for sand casting comprises, by mass, 7-11% of Gd, 1-4% of Y, 0.5-2.5% of Ag, 0.2-0.6% of Zr, 0.1-0.3% of B, lower than 0.02% of impurity elements and the balance Mg, wherein the impurity elements include Si, Fe, Cu and Ni. The preparation method comprises the steps of smelting and heat treatment. The Gd and the Y are used as main alloy elements of the high-strength heat-resisting magnesium alloy, the Ag is added into the alloy to improve the solid solution strengthening effect of rare earth alloy and refine a precipitated phase, a K2ZrF6 salt mixture and B2O3 are added to inhibit grain growth of the alloy in sand casting and follow-up solid solution process, reduce segregation of the elements Zr and B, improve the yield of the elements Zr and B and reduce the production cost of the magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV +1

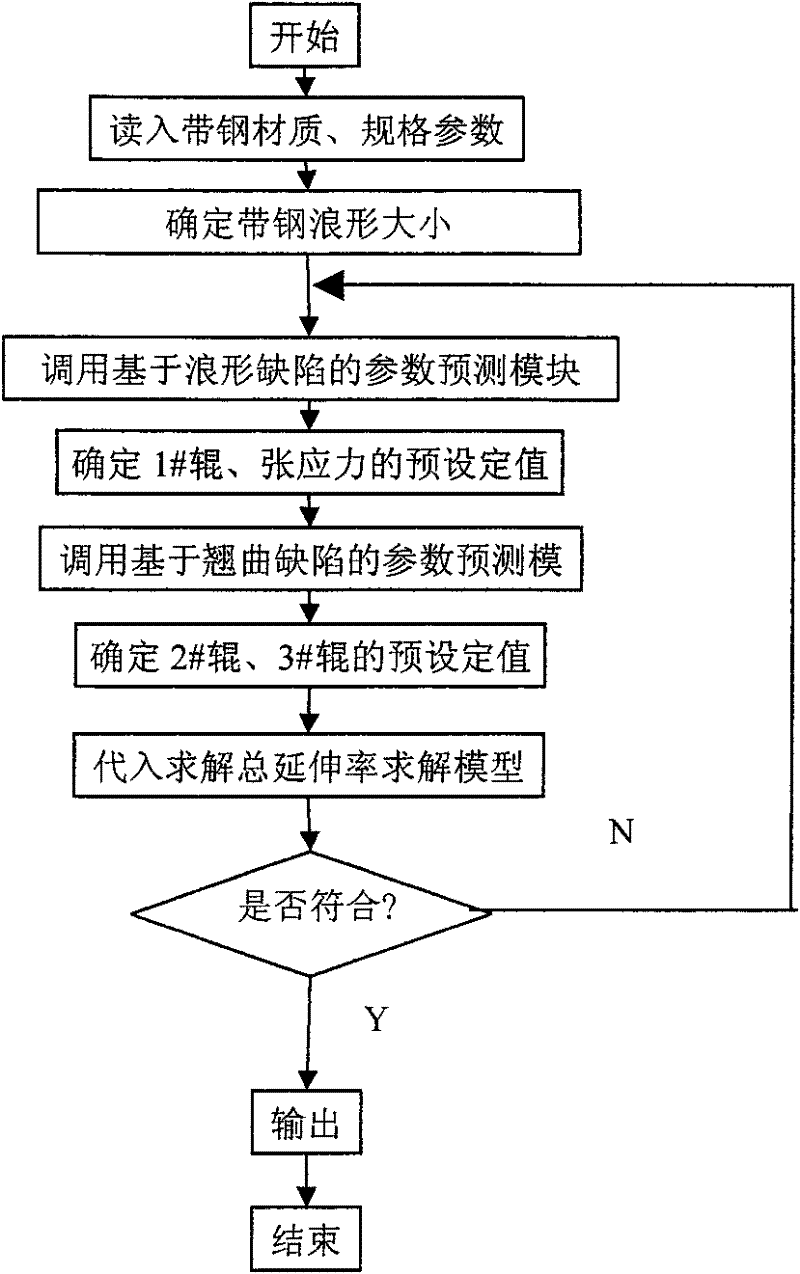

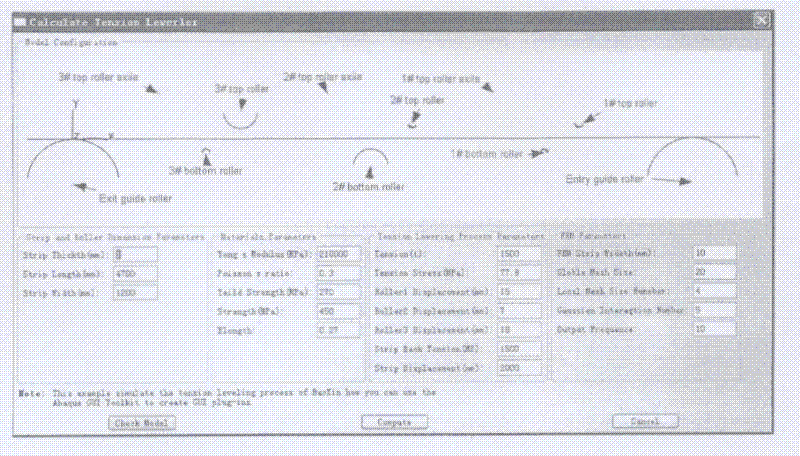

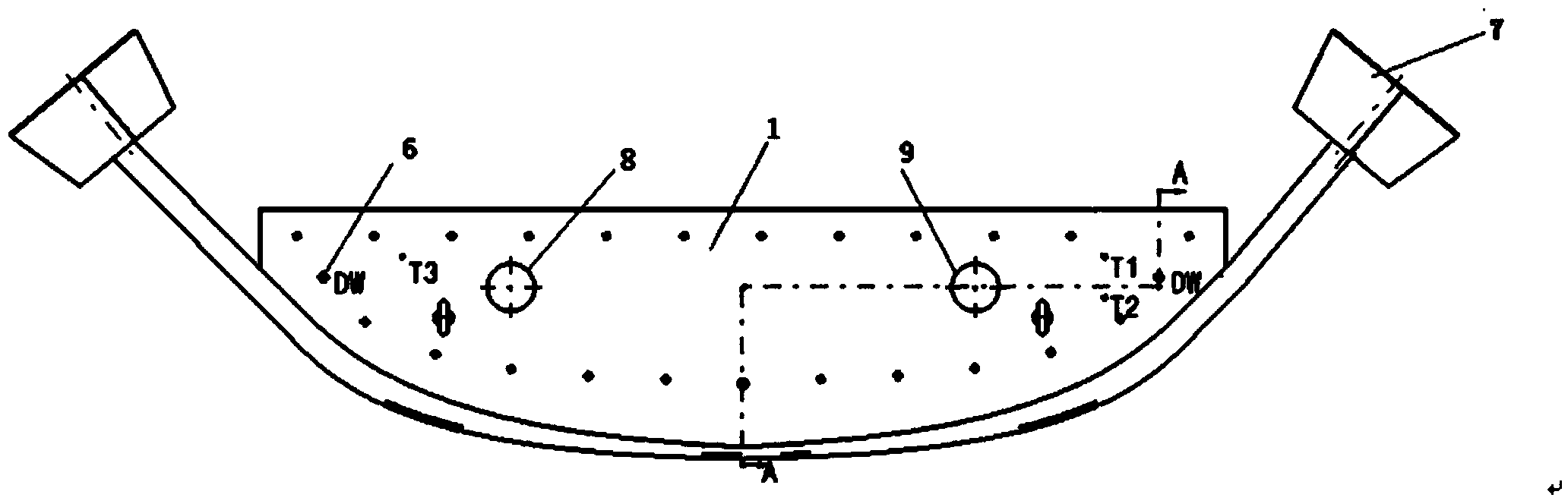

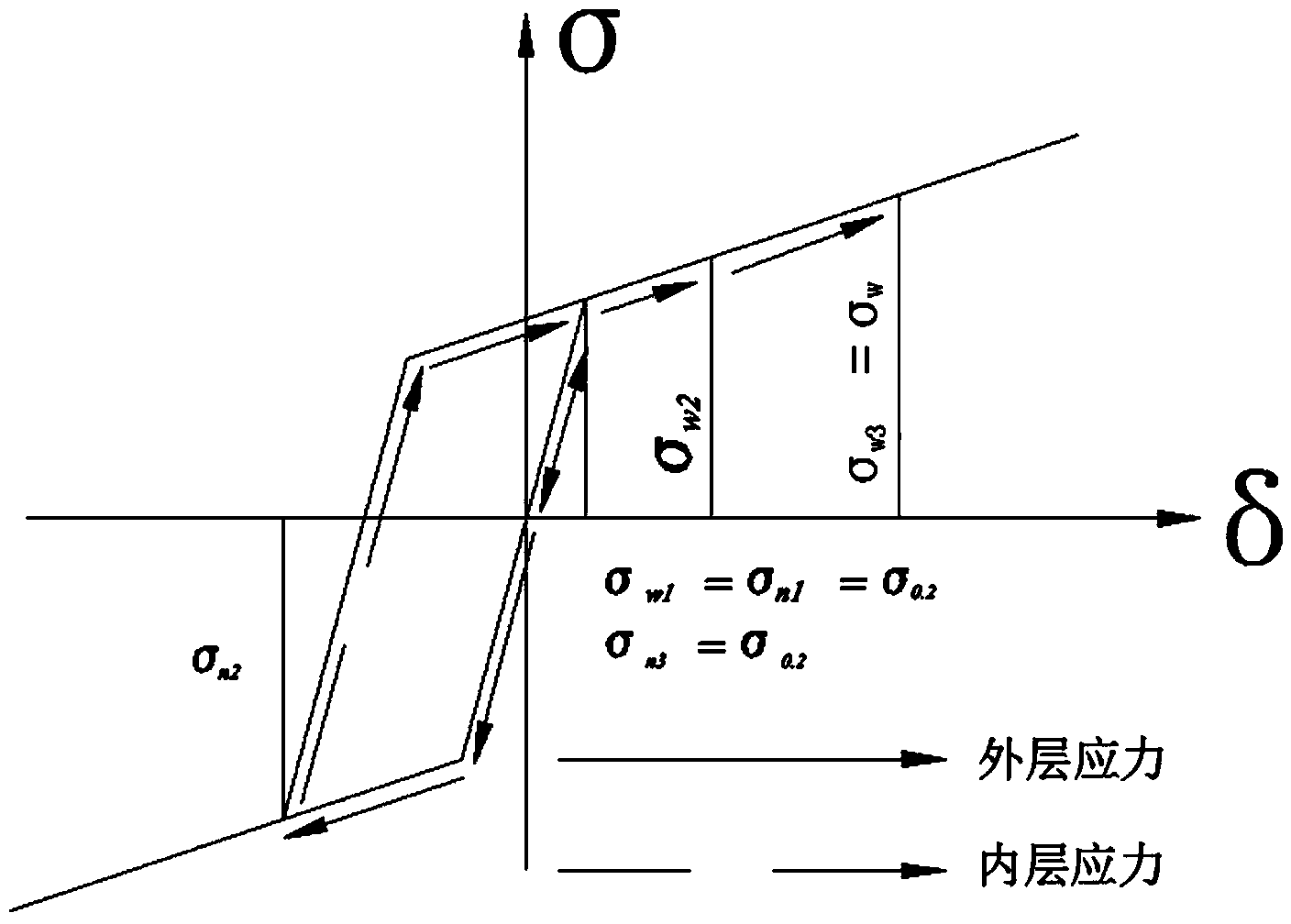

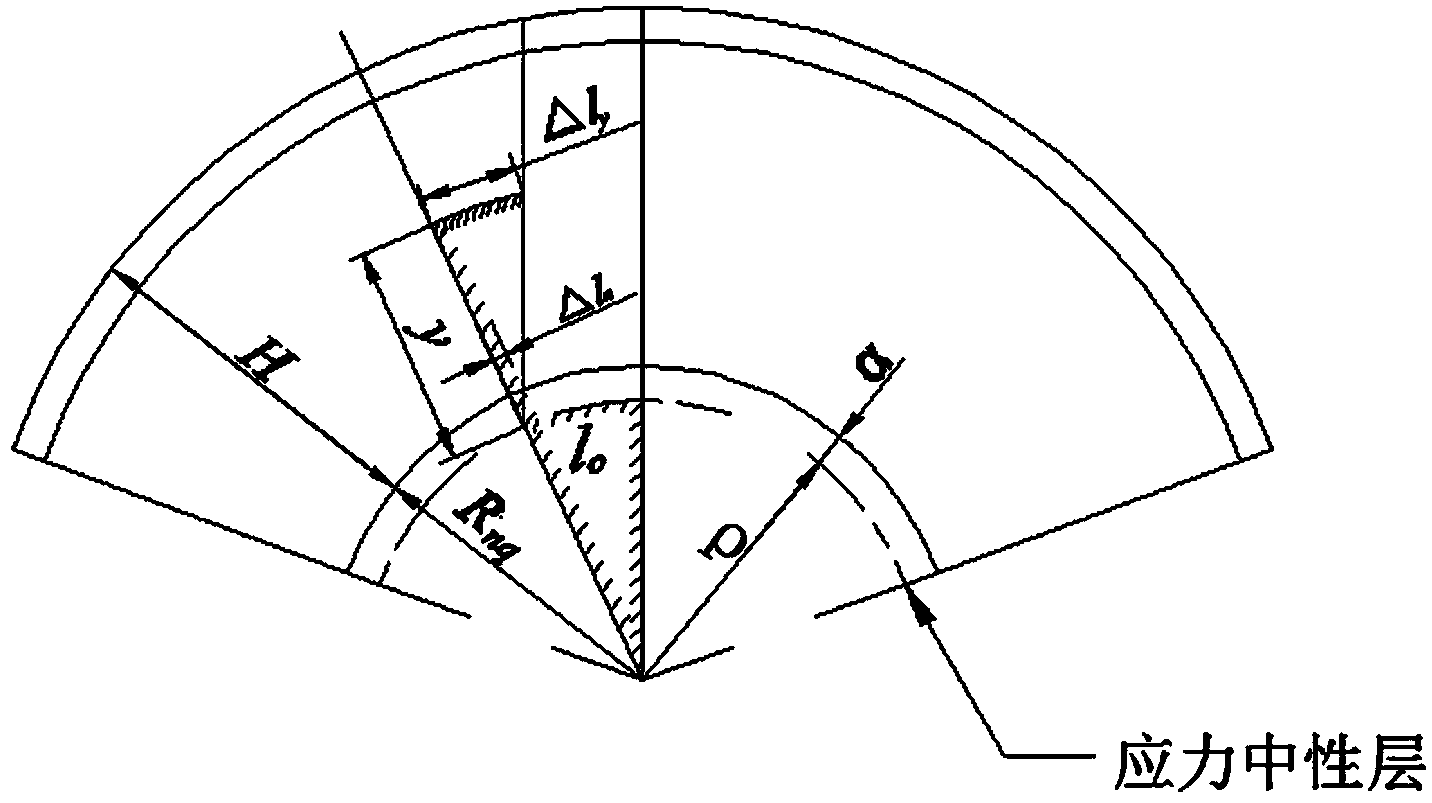

Method for setting process parameters of stainless steel strip steel withdrawal and straightening machine unit

The invention relates to a method for setting process parameters of a stainless steel strip steel withdrawal and straightening machine unit. The method is characterized in that a set of systemic method for setting the process parameters of a stainless steel withdrawal and straightening machine is established by utilizing finite element software to establish a simulation model and applying the stepwise regression principle to set the process parameters such as insertion depths and tension values of a 1# roller, a 2# roller and a 3# roller of a withdrawal and straightening machine, and optimization is achieved by combining application effects of actual production. By means of the method, defects of a wave plate shape and a warping plate shape easily occurring in the production of thinner stainless steel strip steel are eliminated well, theoretical guidance and technical support are provided for withdrawal and straightening of stainless steel, and quality of strip steel is greatly improved. Besides, a process parameter query and addition system interface has strong visuality so that the production is scientific and systematic, and the problem that the process parameters of work shifts are different due to personal experience factors of operators is solved. An adding system guarantees that technical personnel can add process parameters capable of enabling strip steel to obtain good plate shapes after a series of statistics according to actual conditions, so that a database can be kept updated frequently, and process parameter setting can be improved and optimized continuously. Therefore, the method for setting the process parameters of the stainless steel strip steel withdrawal and straightening machine unit has a wide application prospect.

Owner:NINGBO BAOXIN STAINLESS STEEL

Three-dimensional multi-curvature part bending method

InactiveCN104281725ALower requirementReduce the cost of updatesSpecial data processing applications3D modellingNumerical controlComputer Aided Design

The invention discloses a three-dimensional multi-curvature part bending method. According to the method, the structural form of a section bending die and a suitable section bending machine are determined by analyzing the shape, size, bending angle and forming force of a part to be bent; a digital model of the part to be bent is subjected to curvature analysis through a computer; bending springback theoretical analysis is adopted, and a die profile springback compensation design is performed by a numerical simulation method through computer aided design. The bending of a section requires matched bending chuck, bending die and machine tool. The die is processed by a numerical control technology. A measuring machine is used for detecting and correcting the die to be processed, and an error between theory and actuality is reduced, so that the part manufacturing accuracy is improved. Dies for three-dimensional complicated parts can be formed on a two-dimensional bending machine, the bending pass is reduced, and repair or scraping of the bending dies is reduced, so that the part manufacturing cost is effectively reduced; moreover, the production efficiency is high.

Owner:XIAN JIAYE AVIATION TECH

Preparation method of permanent magnetic ferrite

The invention relates to a preparation method of permanent magnetic ferrite. The preparation method comprises the following steps of: burdening; mixing; pelletizing and pre-sintering; crushing; forming; sintering; and cooling to obtain the permanent magnetic ferrite. Through selecting raw materials, optimizing a technological parameter, such as controlling a pulverizing process, controlling a forming parameter, controlling a sintering schedule, controlling a cooling process, and the like in a preparation process, particularly, controlling ball-milling and secondary ball-milling process parameters, the residual magnetism Br of sintered ferrite is not less than 500mT, the coercive force Hcb of the sintered ferrite is not less than 310kA / m, the intrinsic coercive force Hcj of the sintered ferrite is not less than 410kA / m, and the maximum magnetic energy product (BH)max of the sintered ferrite is not less than 35kJ / m<3>.

Owner:南通飞来福磁铁有限公司

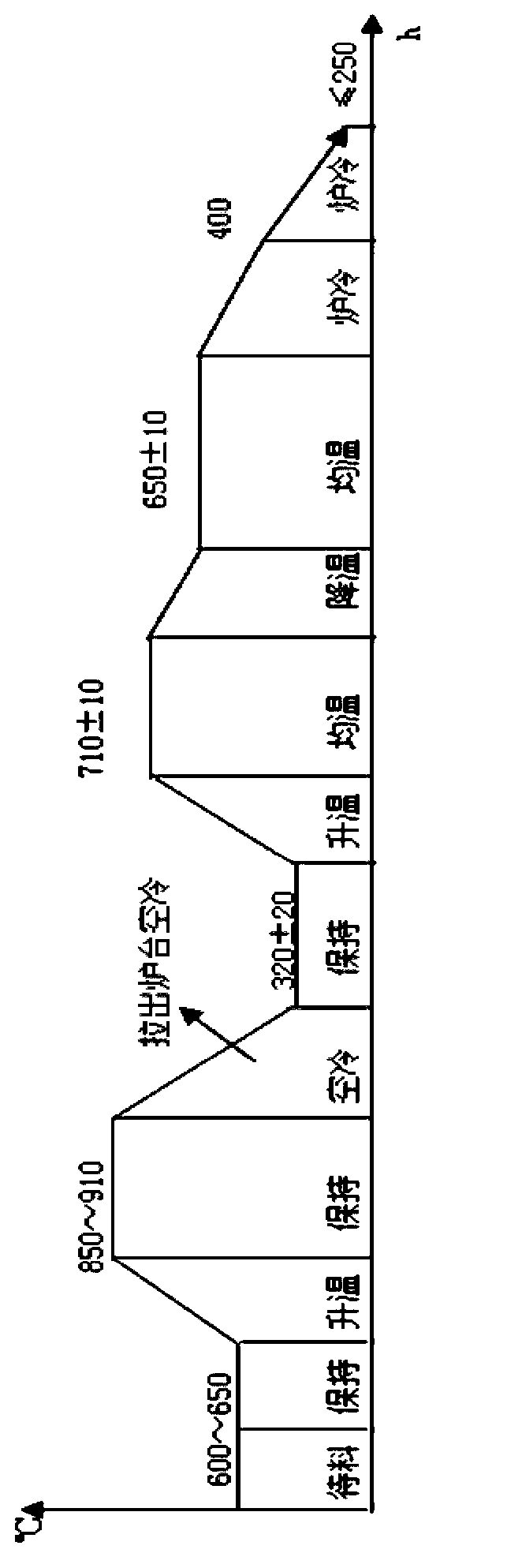

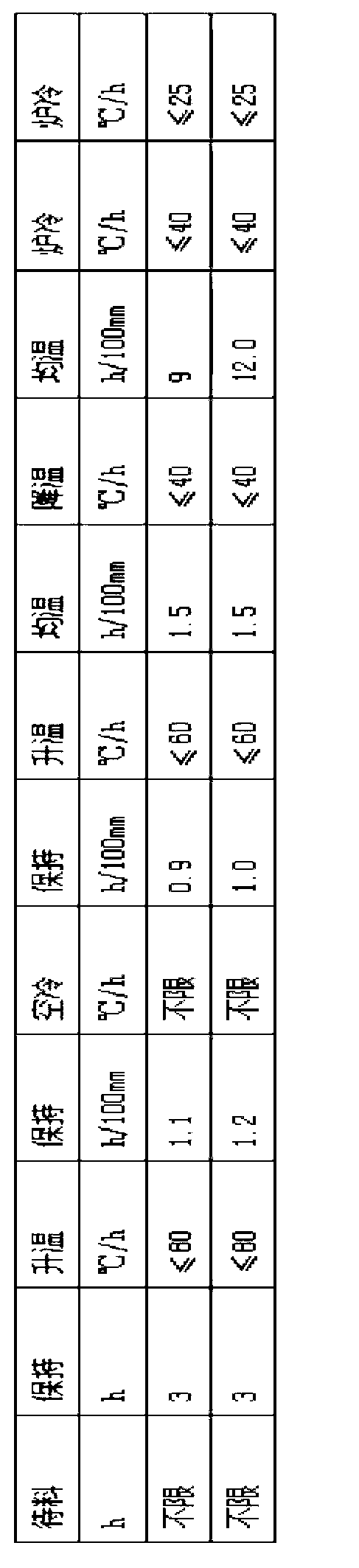

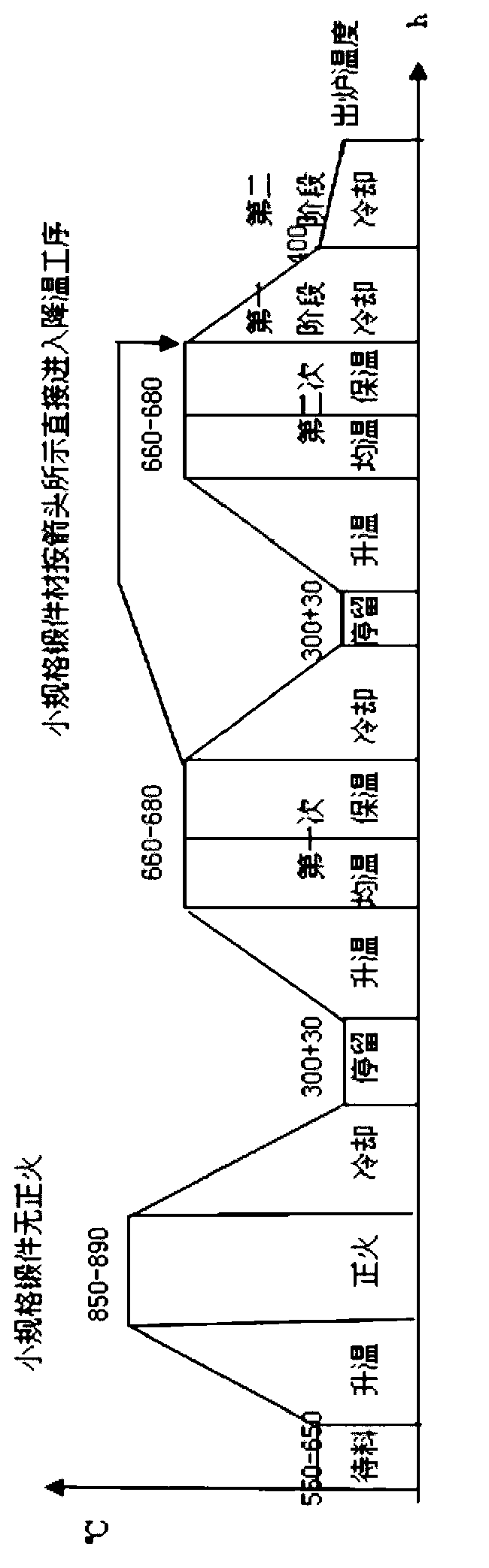

After-forging hydrogen diffusion and annealing method of forging material

The invention discloses an after-forging hydrogen diffusion and annealing method of a forging material, which is completed in an annealing furnace. For a large forging material, the after-forging hydrogen diffusion and annealing method comprises the following steps of: 1, normalizing a forged forging material at a temperature of 850-890 DEG C and remaining for 4-10h; 2, air-cooling the forging material normalized in the step 1 to 300-330 DEG C, remaining for 3-8h; 3, raising the temperature of the forging material air-cooled in the step 2 to 660-680 DEG C, homogenizing the temperature for 1-2h / 100mm, insulating the heat; 4, air-cooling the forging material insulated in the step 3 to 400 DEG C and furnace-cooling to 300-330 DEG C and remaining for 6-8h, then raising the temperature of the forging material to 660-680 DEG C, homogenizing the temperature for 1-2h / 100mm and then insulating the heat; and 5, cooling the forging material insulated by temperature homogenization in the step 4 to below 200 DEG C and discharging, wherein the total time of the heat insulation in the steps 3 and 4 is 7-16h / 100mm. The after-forging hydrogen diffusion and annealing method is simple in process and strong in adaptability for the large-specification forging material, and avoids the white dot defect of the forging material.

Owner:DAYE SPECIAL STEEL CO LTD

Method for overlaying wear-resistant layer of blade shroud of turbine working blade

InactiveCN102107314APromote maturityExtend working lifeArc welding apparatusPower flowWear resistant

The invention discloses a method for overlaying a wear-resistant layer of a blade shroud of a turbine working blade. In the method, manual tungsten electrode argon arc welding is used, and the specific process parameters meet the requirements that: welding wires are selected from a T800 cobalt-based wear-resistant alloy welding wire which is researched according to a B50TF193 standard of AmericanGeneral Electric Company and an S-6 cobalt-based wear-resistant alloy welding wire which is researched according to an American metal society standard AMS5788; the diameters are phi 1.6mm and phi 1.2mm respectively; a mark and the diameter of a tungsten electrode are WCe20 and phi 2.0mm; the diameter of a nozzle is phi 12mm; welding current is between 20 and 25A; and the flow rate of protective gas is between 10L / min and 12L / min. By the method, the condition of incomplete penetration or over-melting of a Z-shaped gear switching part R is avoided, the problem of overheating of welding is also solved, and the occurrence probability of welding cracks is greatly reduced or avoided. The method completely meets the requirements of the wear-resistant layer in a high-temperature working state after welding.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

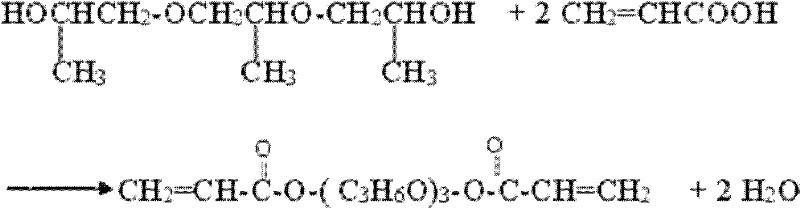

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolDipropylene glycol diacrylate

The invention which belongs to the light-cured material field relates to a clean production method of DPGDA or TPGDA. The method concretely comprises the following steps: 1, carrying out esterification reflux dehydration on dipropylene glycol / tripropylene glycol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; 2, adding sodium hydroxide and a small amount of water to neutralize; 3, adding a magnesium polysilicate adsorbent to adsorb a salt generated through neutralization; 4, carrying out reduced pressure dehydration and desolventization; 5, press-filtering to filter out magnesium polysilicate and the salt absorbed thereby; 6, adding alkaline calcium bentonit and calcium oxide to decolor, remove trace water and remove trace acids; 7, press-filtering; and 8, carrying out product index detection. The clean production method of the DPGDA or the TPGDA of the invention, which has the advantages of high yield, economic benefit possessing and environmental benefit possessing, fundamentally solves an organic wastewater pollution problem in the production process of the DPGDA or the TPGDA.

Owner:JIANGSU LITIAN TECH

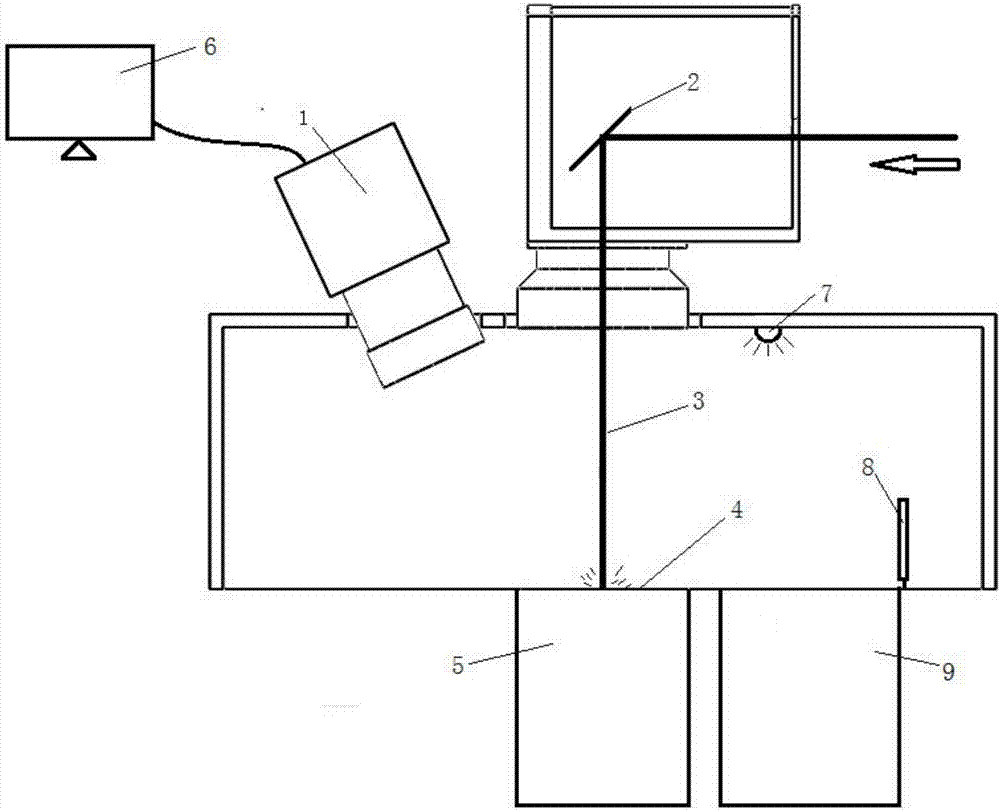

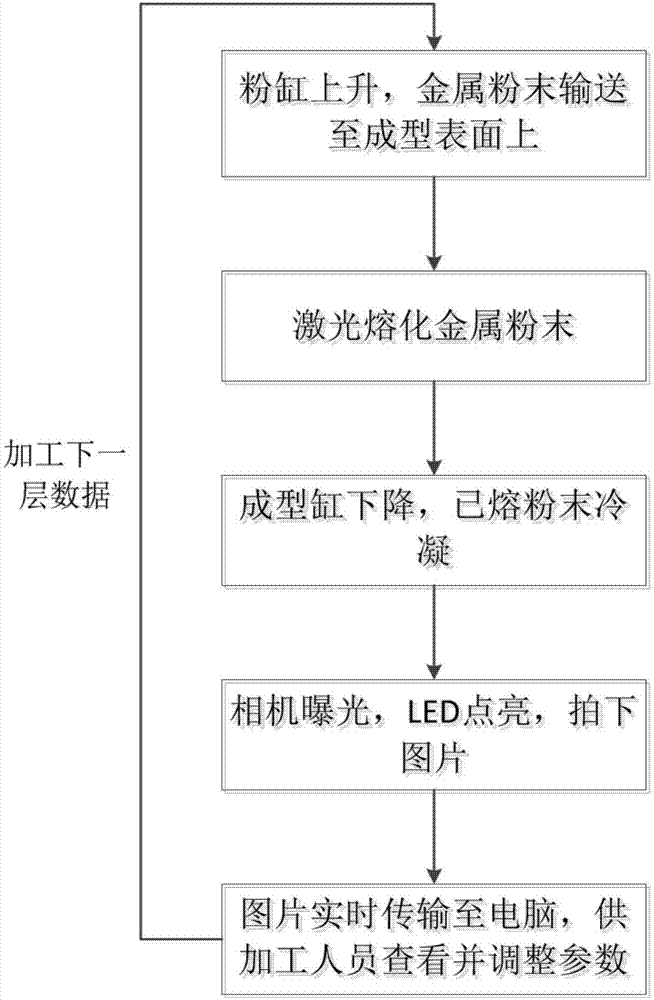

Camera-based real-time shooting 3D printing process monitoring method and device

InactiveCN106925784AIntegrity guaranteedHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyMachining processReal time transmission

The invention discloses a camera-based real-time shooting 3D printing process monitoring method and device. A camera is mounted on the upper portion of a sealing forming chamber and shoots the morphology in the molten layer 3D printing process. A light source is mounted on the inner side of the top of the sealing forming chamber. The light source is lightened in a pulse manner while exposure of the camera is achieved, the light source is extinguished after exposure of the camera is finished, and the morphology data of the layer are transmitted into a computer and stored in real time through the camera. By means of manual error analysis or intelligent error analysis, for defect parts existing in the printing process, the positions, time and reasons of defect generating can be accurately located, and effective bases are provided for optimizing and adjusting relevant parameters. The device is simple in structure and convenient to operate, integrity of data of each layer is guaranteed, process parameters are optimized, correction is achieved in time in the processing process, and part precision is greatly improved; or, after processing, by means of morphology analysis, problems existing in the processing process are found.

Owner:SOUTH CHINA UNIV OF TECH

Method for laser sealing glass and kovar alloy

InactiveCN103212812AOptimizing Process ParametersControl pulse widthLaser beam welding apparatusRoom temperatureLight beam

The invention discloses a method for laser sealing glass and kovar alloy. The method includes that (a) clean treatment is carried out on the glass, and derosination treatment and deoiling treatment are carried out on the kovar alloy; (b), the glass is placed on the kovar alloy and is contacted with the kovar alloy tightly; (c) straight-line radiation is carried out with a laser device, the focus of a laser beam is positioned in the junction of the glass and the kovar alloy to obtain a sealing body; and (d) the sealing body is moved to a heating furnace of 100-300 DEG C, stress relief annealing is carried out, and after cooled to room temperature along with the furnace, the sealing body of the glass and the kovar alloy can be obtained. According to the method, due to the fact that technological parameters are optimized, a heat action area and temperature distribution in the area are accurately controlled, and the pulse width, frequency, scanning speed and the temperature of the stress relief annealing are controlled, so that the low-stress and large-size sealing body of the glass and the kovar alloy is obtained, the sealing body can be applied to the construction industry, and the service life of a product is improved substantially.

Owner:SUZHOU UNIV +1

Method for producing bamboo pomace

ActiveCN1974921AIncreased surface area per unit weightPenetrate fastWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsPomaceViscose fiber

The present invention provides a preparation method of bamboo pulp, belonging to the field of chemical fiber technology. Said method includes the following steps: obliquely cutting bamboo strip material into the form of horseshoe, the chip cross-section spacing distance is 20-40 mm, then prehydrolyzing the prepared bamboo strip, adding alkali and cooking, removing sand, making one-stage or two-stage bleaching treatment, making the bleached pulp material undergo the processes of acid treatment, concentration and pulping so as to obtain the invented bamboo pulp. Said bamboo pulp can be used for producing viscose fibre.

Owner:吉林化纤股份有限公司

High-strength and high-elasticity-modulus casting Mg-RE alloy and preparation method thereof

The invention discloses a high-strength and high-elasticity-modulus casting Mg-RE alloy and a preparation method thereof. The casting Mg-RE alloy comprises 8-14wt% of Gd, 2-6wt% of Y, 1-5wt% of Zn, 0.5-2.5wt% of Si, 0.4-1wt% of Zr, the impurity elements of Fe, Cu and Ni and the balance of Mg, wherein the total content of the impurity elements of Fe, Cu and Ni is smaller than 0.02wt%. The preparation method includes the steps of smelting and heat treatment. According to the preparation method, Si is added and reacts with Mg and RE in an MG alloy to generate a high-elasticity-modulus Si-containing phase, meanwhile, Zn is added and reacts with Mg and RE in the Mg alloy to generate a stable eutectic phase, in this way, the crystallization range of an alloy melt is reduced, melt fluidity is improved, and accordingly through the following corresponding heat treatment process, the alloy has high room-temperature strength and elasticity modulus.

Owner:SHANGHAI JIAO TONG UNIV

A method of separating and purifying quercetagetin from tagetes erecta

ActiveCN105693676AWide variety of sourcesHigh degree of automationOrganic chemistryFiltrationEvaporation

A method of separating and purifying quercetagetin from tagetes erecta is provided. The method includes a step of drying tagetes erecta dry flowers, grinding into powder, dipping with ethanol or performing reflux extraction, subjecting a filtrate after filtration to rotary evaporation until a product is dry and dissolving the product to a methanol-water mixed solvent; a step of performing one-dimensional liquid chromatogram, wherein DAISO C18 is adopted as a chromatographic column, a mobile phase adopting water as an A phase and methanol as a B phase is adopted, isocratic elution is performed for 20 min with the concentration of the B phase in the mobile phase being 50-55%, eluate from the 6 min to the 12 min is collected according to an ultraviolet absorption spectrum, adopted as a target component, and subjected to rotary evaporation until a product is dry, and the product of the rotary evaporation is dissolved into the methanol-water mixed solution again; and a step of performing two-dimensional liquid chromatogram, wherein Acchrom X-Amide is adopted as a chromatographic column, a mobile phase adopting water as an A phase and acetonitrile as a B phase is adopted, isocratic elution is performed for 40 min with the concentration of the B phase in the mobile phase being 92-98%, and eluate from the 27 min to the 33 min is collected according to an ultraviolet absorption spectrum, adopted as the target component, and subjected to rotary evaporation until a product is dry to obtain quercetagetin the purity of which is 99% or above.

Owner:TIANJIN YAOYU BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com