Metal grid conducting layer and touch panel equipped with the conducting layer

A technology of metal grid and conductive layer, which is applied in the direction of electrical digital data processing, printed circuit components, electrical connection printed components, etc., can solve the problems of silver filling process difficulties, improve filling uniformity, and improve bonding firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Conductive layer in electrode lead area made in a regular grid shape

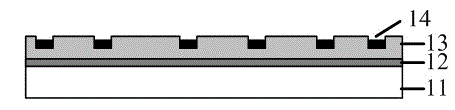

[0034] This embodiment is based on the cross-sectional schematic view of the embedded metal grid conductive layer as shown in figure 1 shown. The conductive layer is the substrate PET 11 from bottom to top, with a thickness of 188 μm; an adhesion-promoting layer 12; an acrylic UV adhesive 13 with a groove structure, the groove depth is 3 μm, and the width is 2.2 μm; the groove is filled with metallic silver 14. The thickness is smaller than the groove depth, about 2 μm.

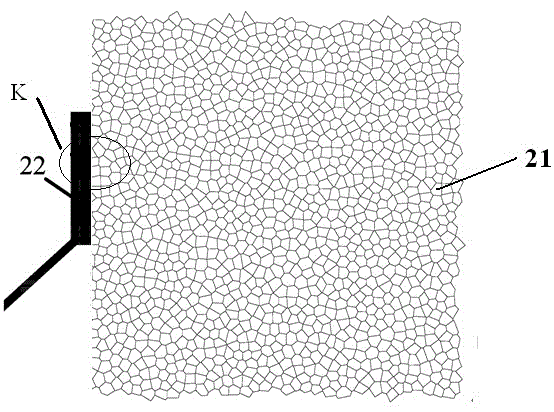

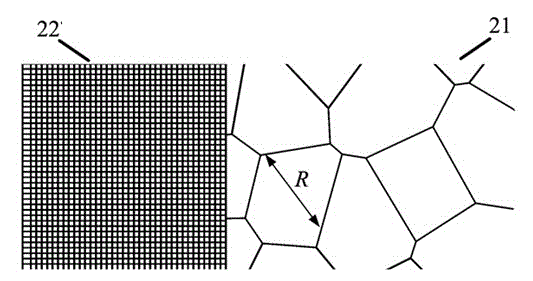

[0035] This embodiment is based on the schematic plan view of the embedded metal grid conductive layer as figure 2 shown. The conductive layer includes a transparent electrode area 21 and an electrode lead area 22 . The transparent electrode region 21 is composed of irregular polygonal random grids, the line width is 2.2 μm, the average diameter R of the grids is preferably 120 μm, and the relative transmittance is 96%. Since ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com