Wastepaper pulping and papermaking method

A technology for pulping and papermaking and production methods, which is applied in the direction of papermaking, paper machines, and waste paper processing, etc. It can solve the problems of poor recycling of pulp residue and tailings, insufficient optimization of process parameters, and insufficient product yield. Achieve the effect of beautiful appearance, lower production cost and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

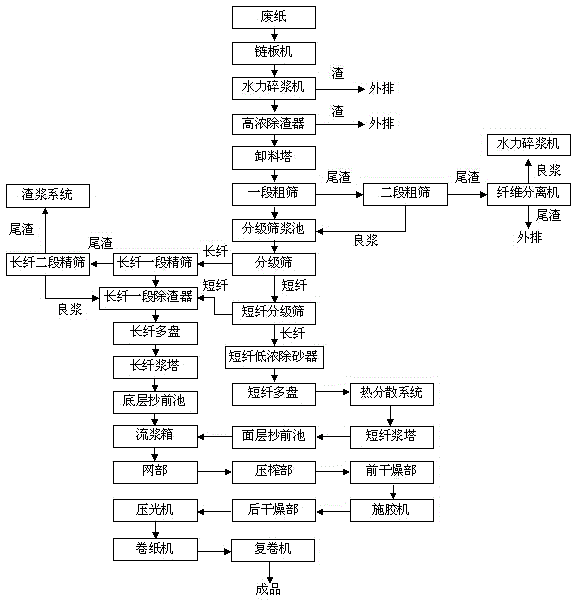

[0032] like figure 1 As shown, the production method of waste paper pulping and papermaking: the raw waste paper is transported to the hydropulper through the chain plate machine for disintegration, and the coarse pulp, slag, and plastic are discharged; the fine pulp after the disintegration of the hydropulper is pumped It is conveyed through the high-concentration desander and sent to the unloading tower, wherein the mud and sand screened by the high-concentration desander are discharged; the good pulp in the unloading tower is pumped through a section of coarse screen, and the good pulp is sent to the grading screen pool The pulp in the grading sieve pulp pool is transported to the grading sieve by the grading sieve feeding pump, and is classified into first-grade long fiber and first-grade short fiber after grading and sieving; the first-grade long fiber is transported to the first-stage fine sieve for long fiber, and passed through the first-stage fine sieve for long fiber....

Embodiment 2

[0034] On the basis of Example 1, the tailings of the first section of coarse screening are passed through the second section of coarse screening, and the fine pulp screened by the second section of coarse screening is transported back to the classification screen pulp pool; the tailings screened by the second section of coarse screening can also be transported To the fiber separator, the good pulp separated by the fiber separator is sent back to the hydraulic pulper, and the tailings separated by the fiber separator are discharged outside.

Embodiment 3

[0036] On the basis of Example 1, the tailings of the first-stage fine sieve of the long fiber can be transported to the second-stage fine sieve of the long-fiber, and the fine pulp processed by the second-stage fine sieve of the long-fiber can be transported to the first-stage slag remover of the long-fiber. The tailings treated by the second-stage fine screening of long fibers are transported to the slurry line for treatment and reuse.

[0037] The raw material of the invention can be waste paper or bamboo fiber processed from bamboo leftovers. The invention recycles and reuses waste resources, saves production costs, and achieves better environmental protection effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com