Spun filament type low-melting-point polyester chip and preparation method thereof

A low-melting-point polyester and filament technology, which is applied in the field of spinning filament-type low-melting-point polyester, can solve problems such as poor wearing comfort, lower melting point, and affect filament strength, and achieve hot-melt adhesive flow performance Excellent, reduced polycondensation cycle, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

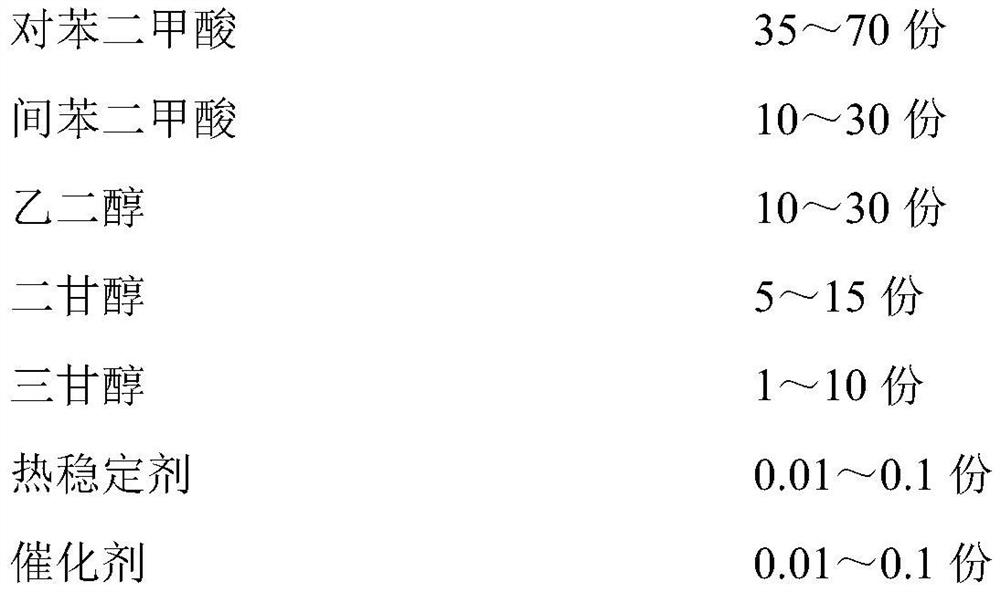

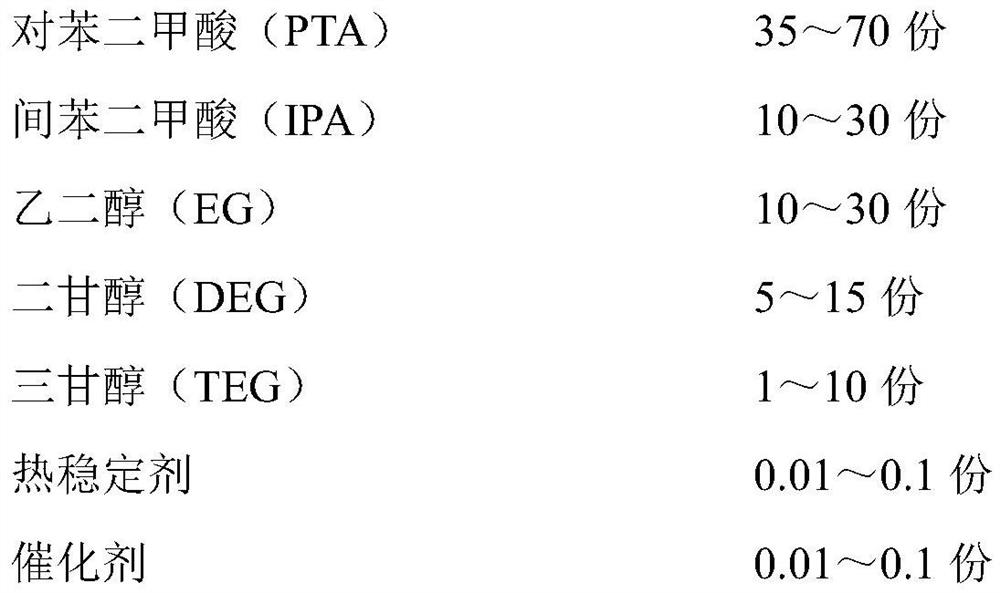

Method used

Image

Examples

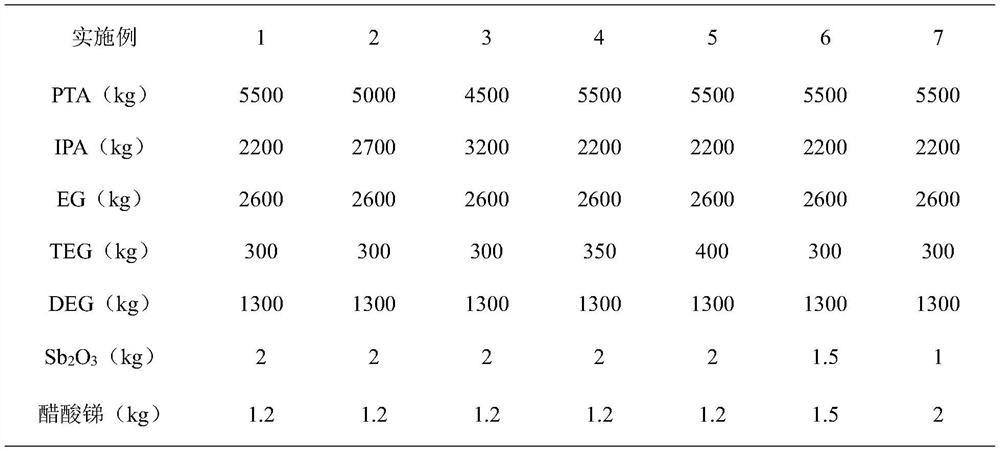

Embodiment 1

[0029] The preparation method of spinning filament type low-melting point polyester chip in the present embodiment is as follows:

[0030] Step 1, one esterification

[0031] Step 11. Add 255kg of IPA and 300kg of TEG (alkyd molar ratio: 1.3) to the slurry preparation kettle. After stirring evenly, add the esterification kettle through a metering pump to carry out the esterification reaction. The esterification temperature is controlled at 255-260 ℃, the esterification pressure is controlled at normal pressure, and the esterification reaction of TEG is completed when the esterification water is received to 44kg (the esterification rate is 80%).

[0032] Step 12. Add 1625kg of IPA and 1300kg of DEG (alkyd molar ratio: 1.25) to the slurry configuration kettle. After stirring evenly, add an esterification kettle through a metering pump to carry out the esterification reaction. The esterification temperature is controlled at 250-255 °C, the esterification pressure is controlled a...

Embodiment 2

[0040] The preparation process of this embodiment is the same as that of Example 1, the difference is that: in Example 1, the total amount of PTA is 5500kg, and the total amount of IPA is 2200kg; in this embodiment, the total amount of PTA is 5000kg, and the total amount of IPA is 2700kg; Process, all carries out according to the alkyd acid molar ratio of embodiment 1.

Embodiment 3

[0042] The preparation process of this embodiment is the same as that of Example 1, the difference being that: in Example 1, the total amount of PTA is 5500kg, and the total amount of IPA is 2200kg; in this embodiment, the total amount of PTA is 4500kg, and the total amount of IPA is 3200kg; Process, all carries out according to the alkyd acid molar ratio of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com