Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

276results about How to "High fiber strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

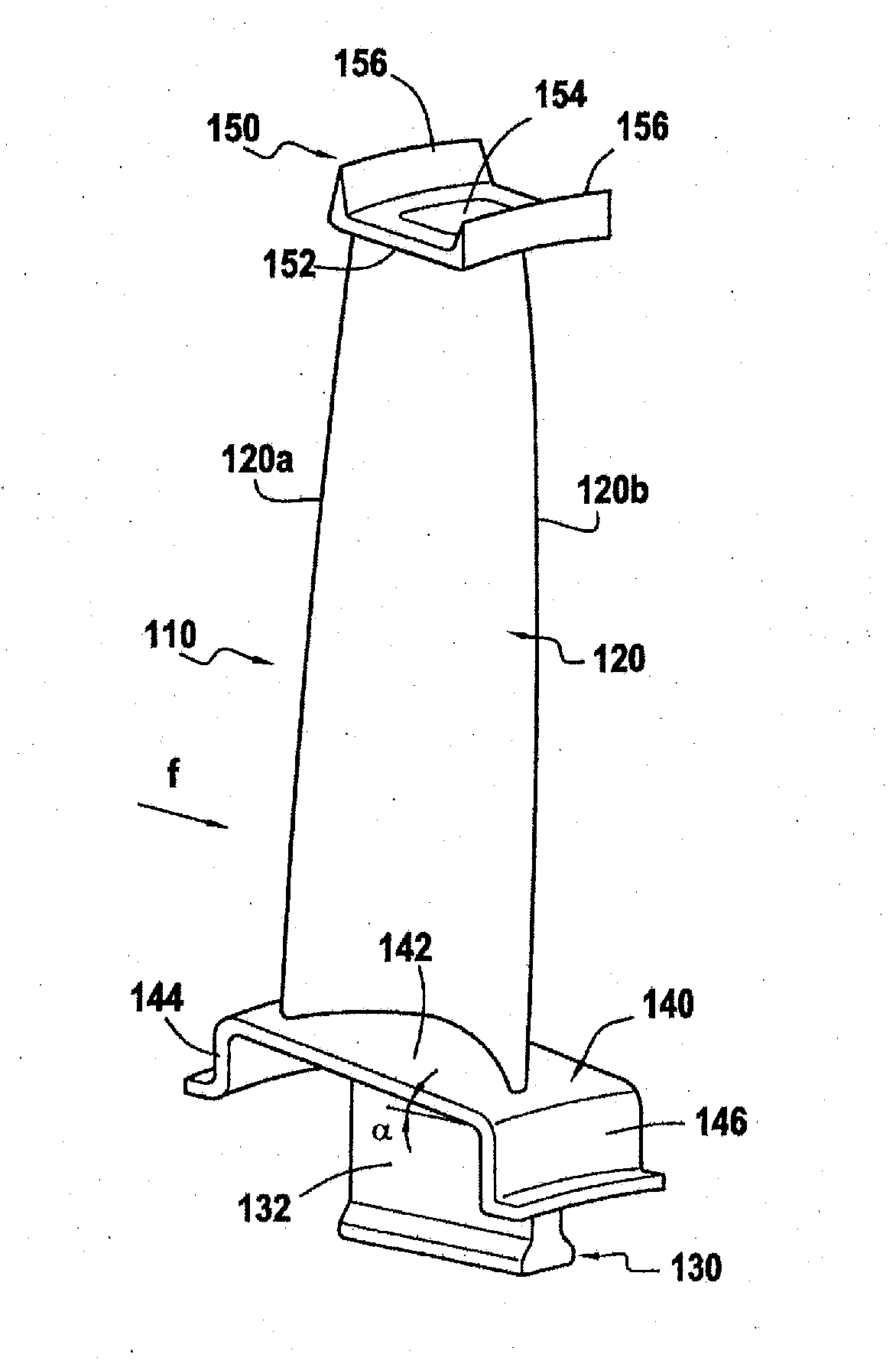

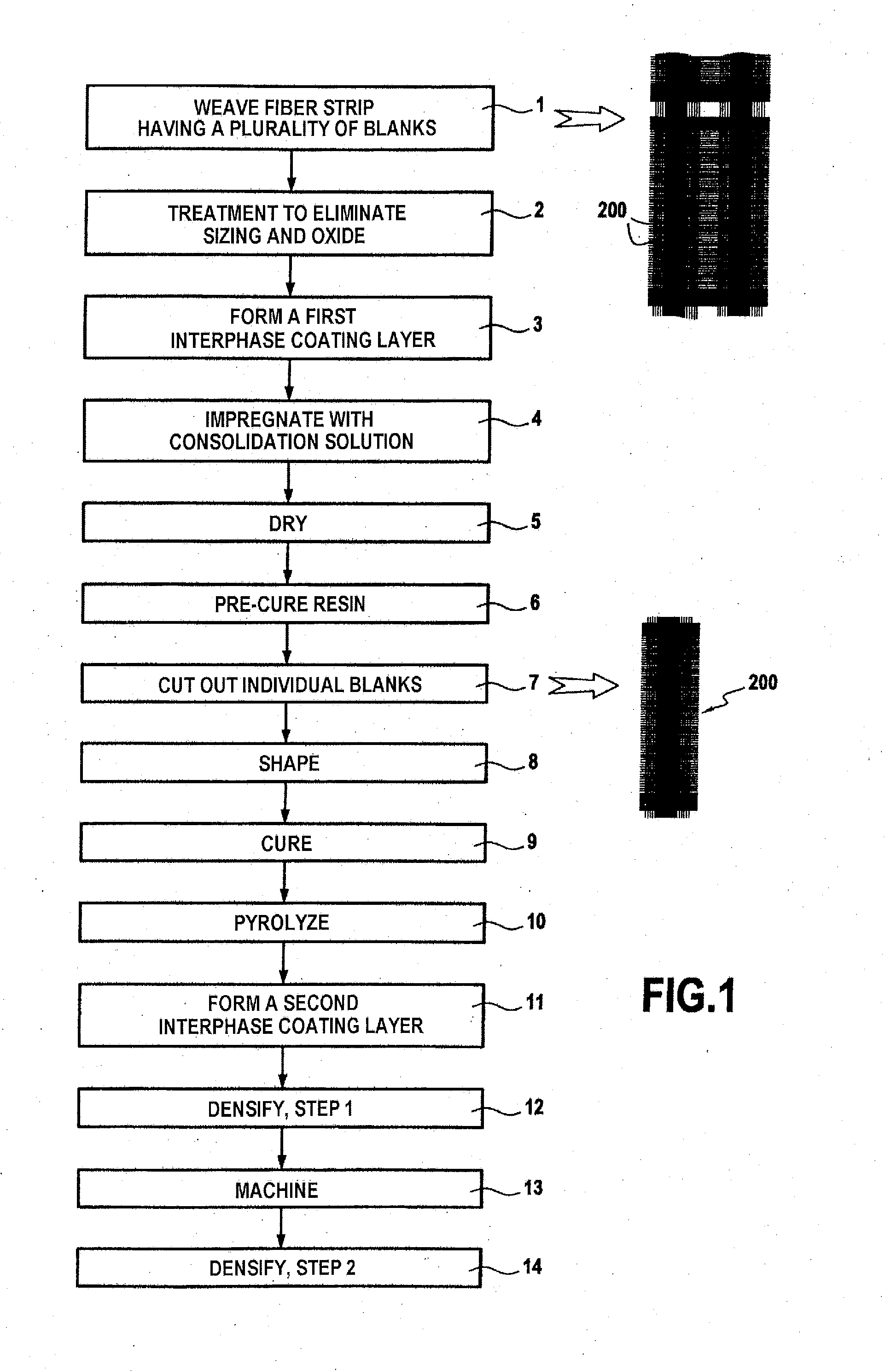

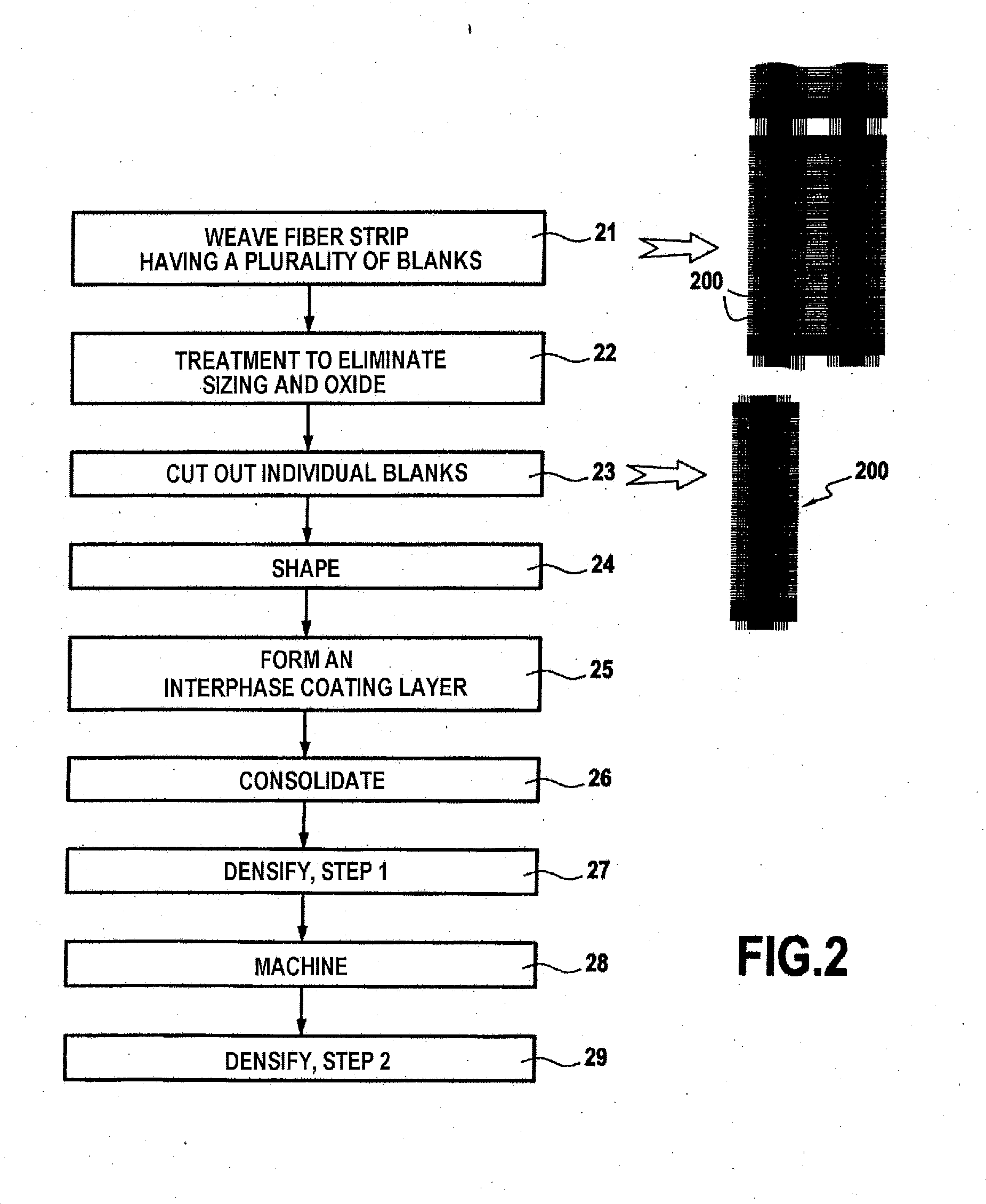

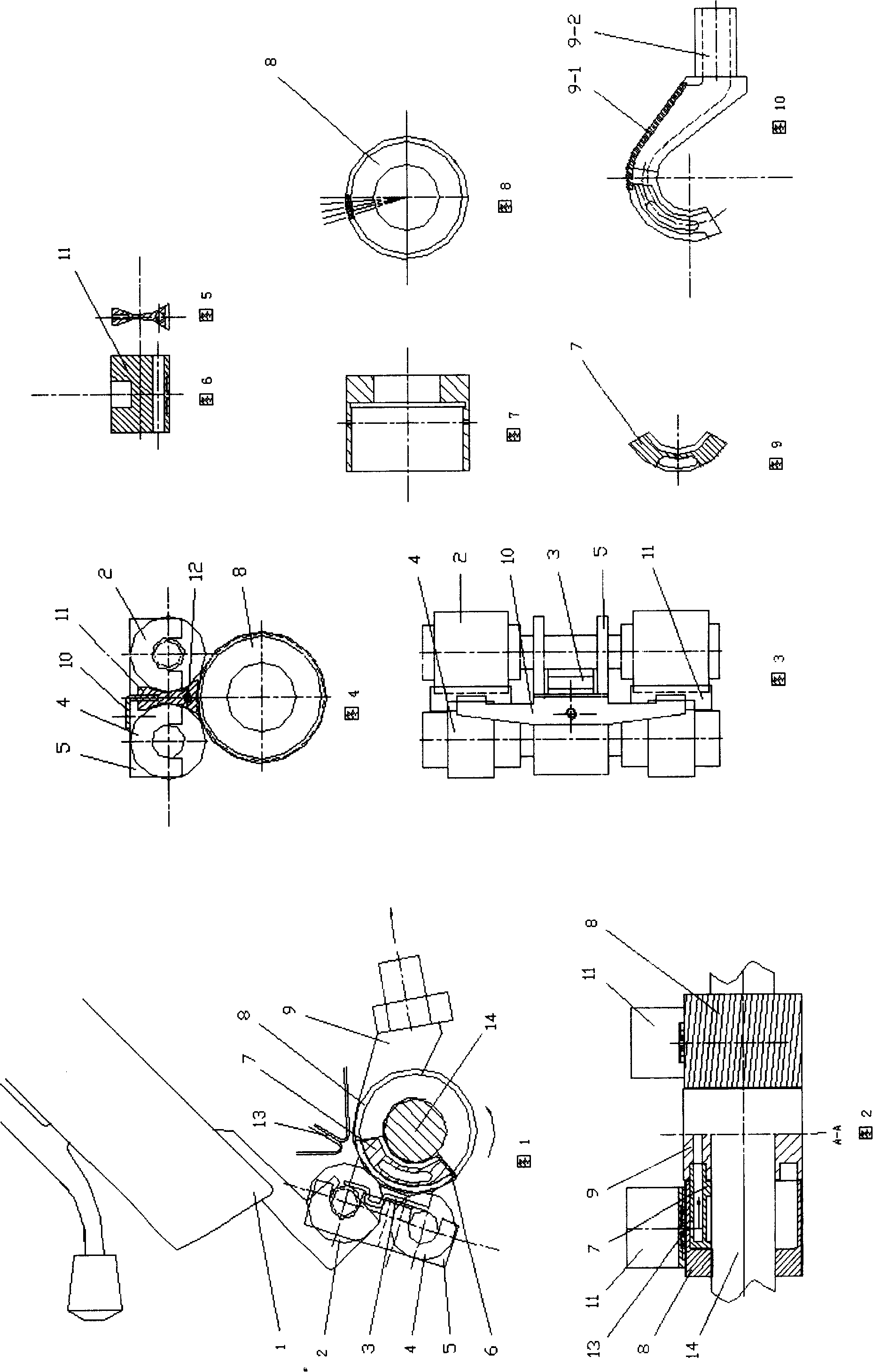

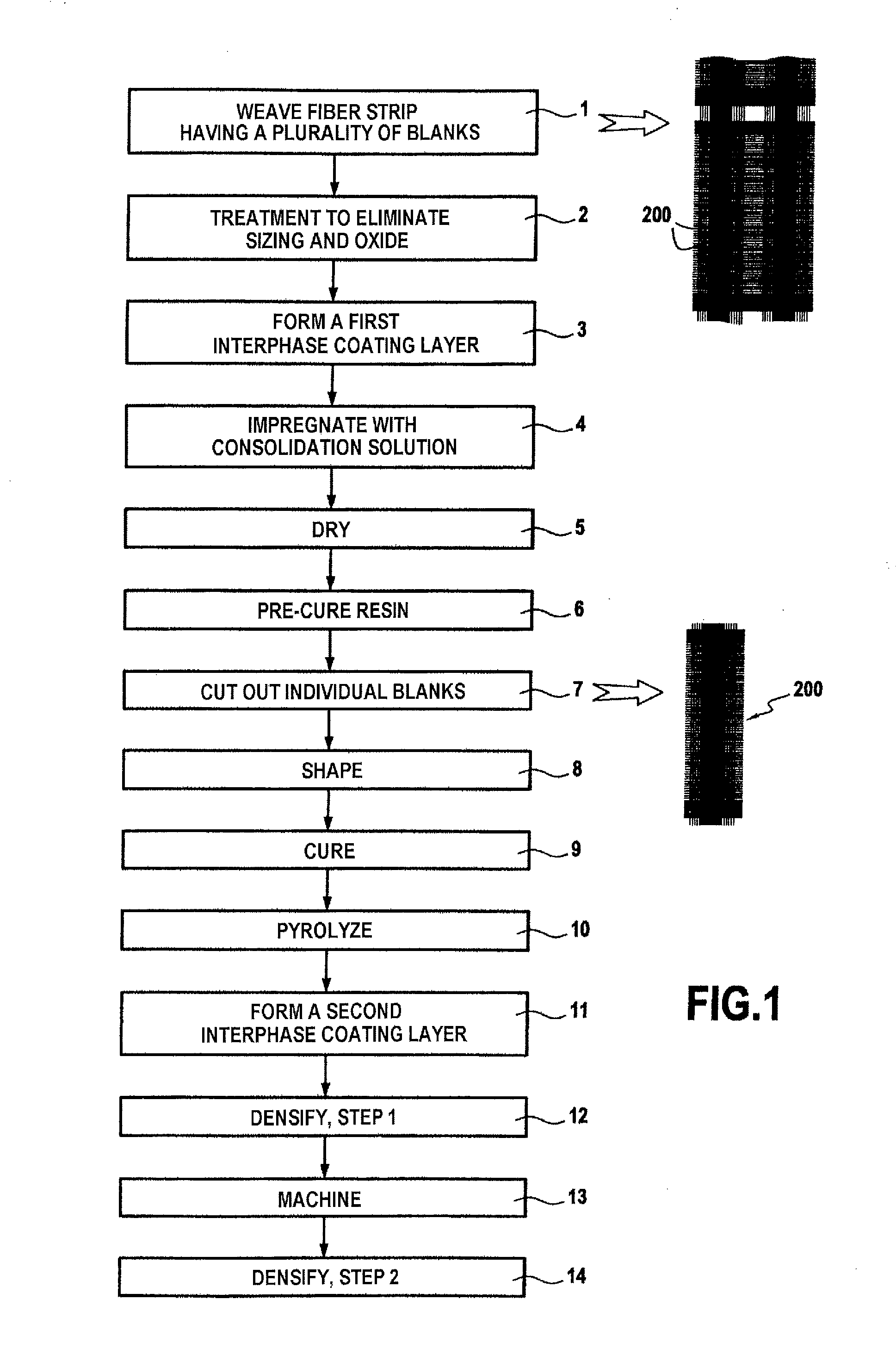

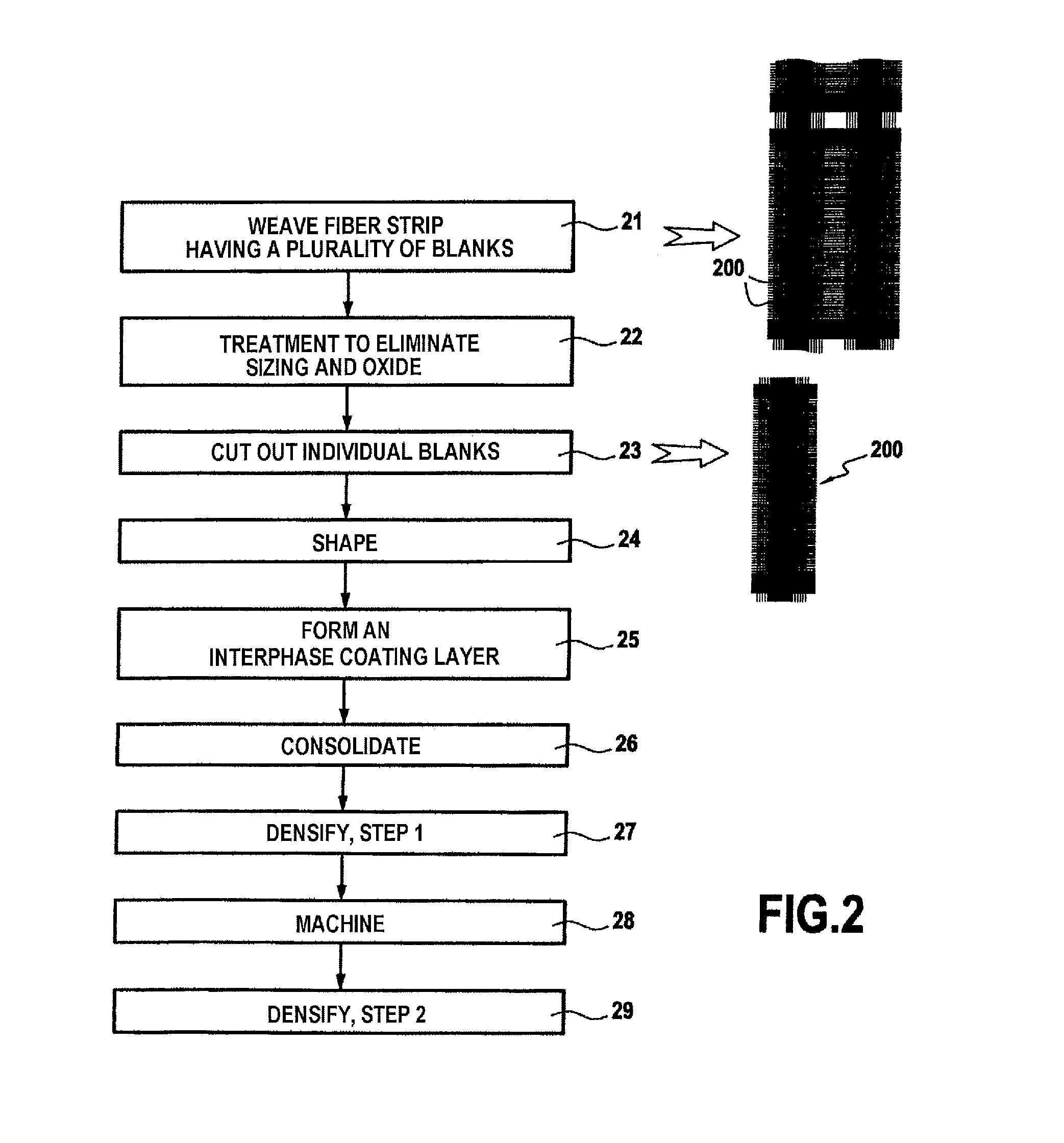

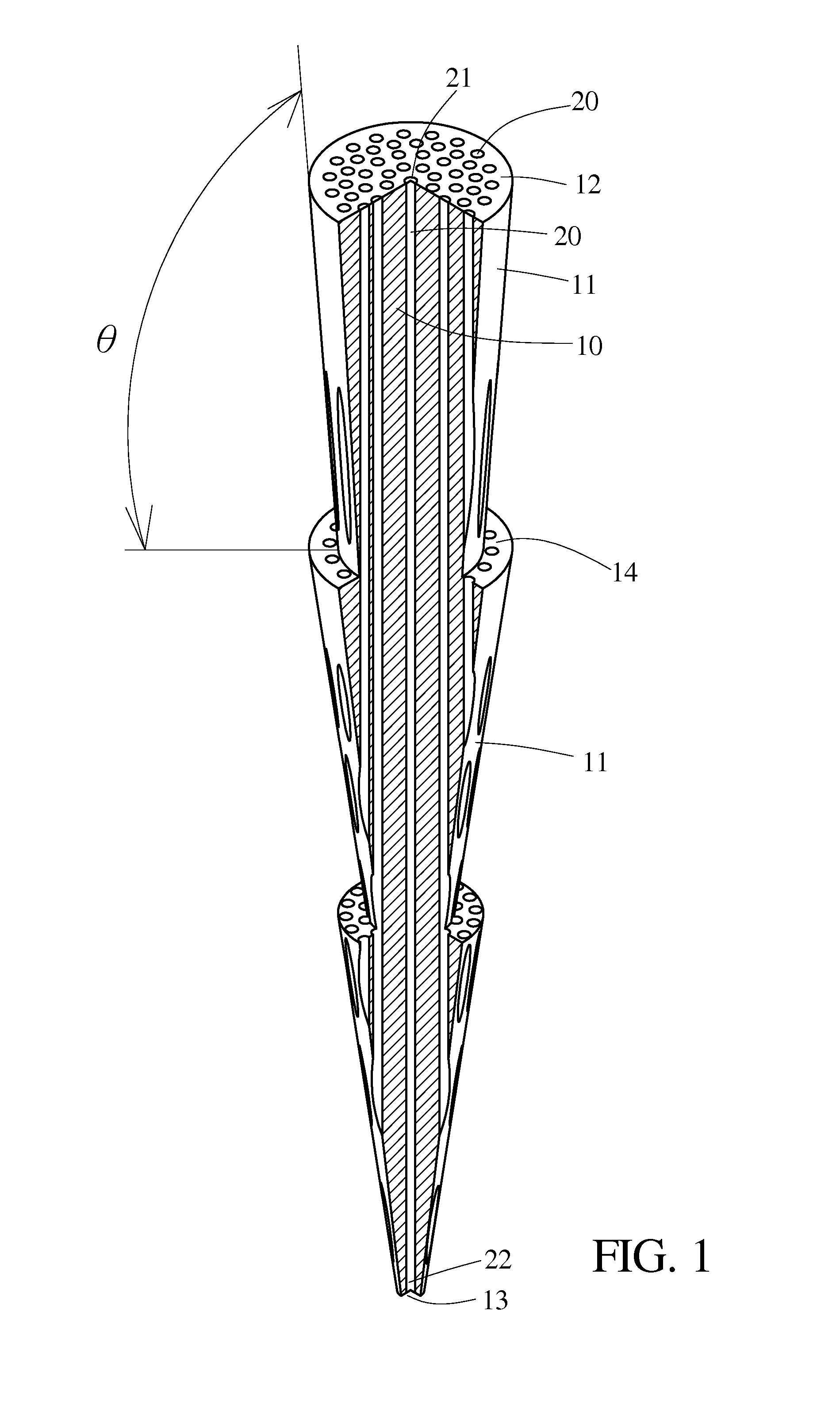

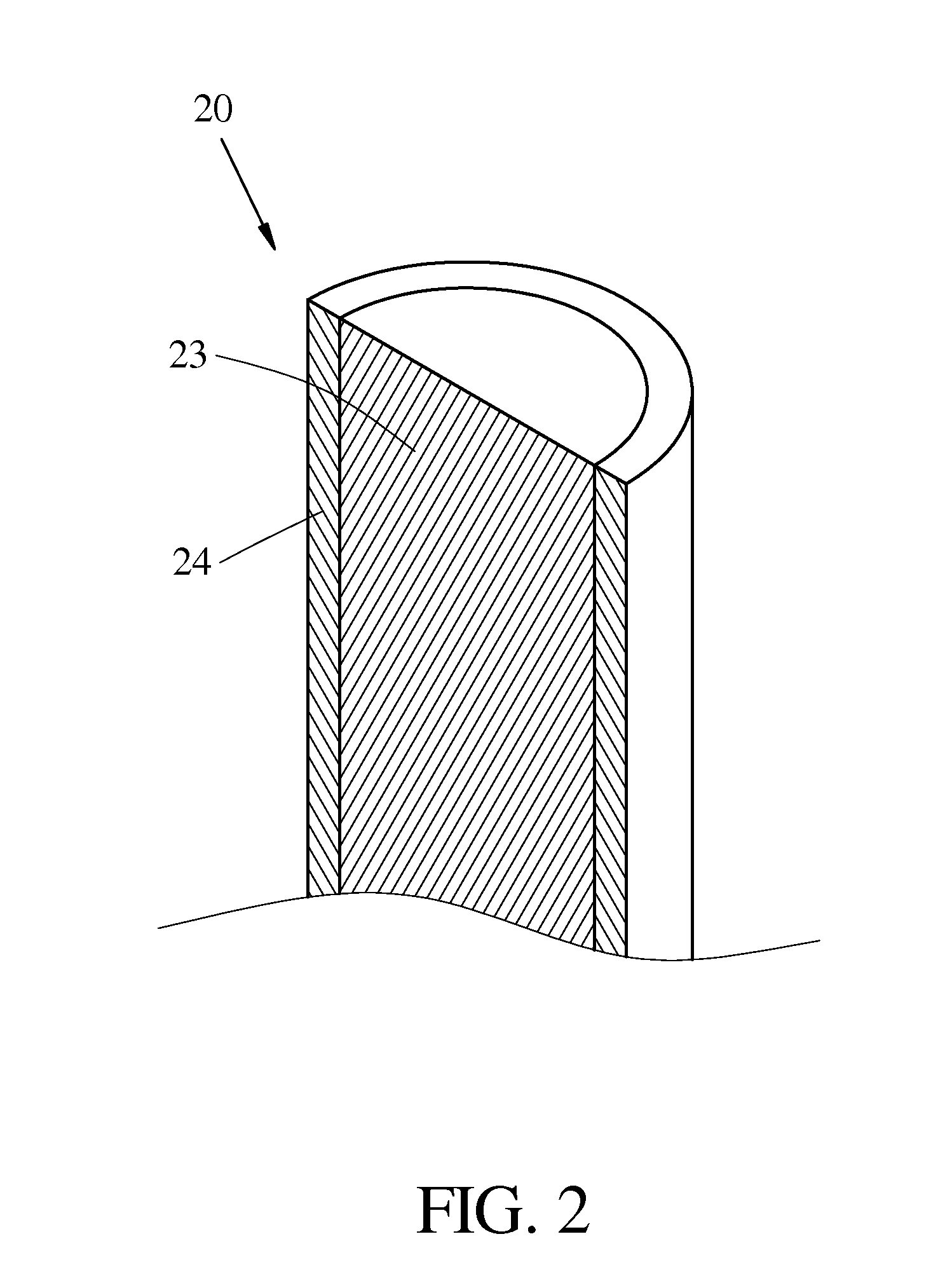

Method for manufacturing a complexly shaped composite material part

ActiveUS20110293828A1Preserve deformation capacityHigh fiber strengthBlade accessoriesEfficient propulsion technologiesGas phaseChemical vapor infiltration

A method of fabricating a complex part out of composite material including three-dimensional woven fiber reinforcement densified by a matrix, the method including three-dimensionally weaving a continuous fiber strip including a succession of fiber blanks for preforms of a plurality of parts that are to be fabricated; subsequently cutting individual fiber blanks out from the strip, each blank being a one-piece blank; shaping a cut-out blank to obtain a one-piece fiber preform having a shape that is close to the shape of a part that is to be fabricated; consolidating the preform in the desired shape; and densifying the consolidated preform by forming a matrix by chemical vapor infiltration.

Owner:SAFRAN CERAMICS SA +1

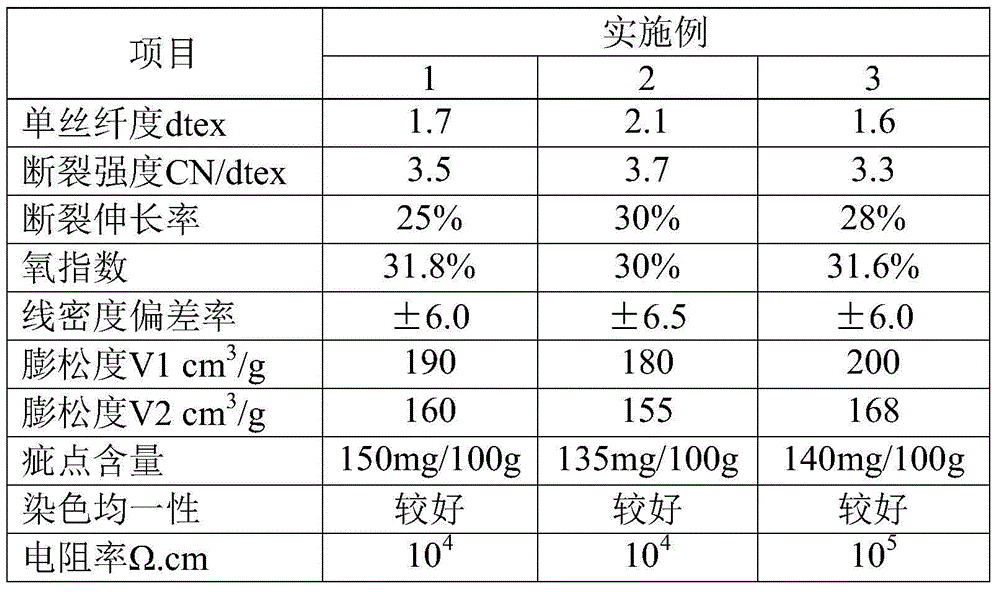

Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

ActiveCN104630928ASpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

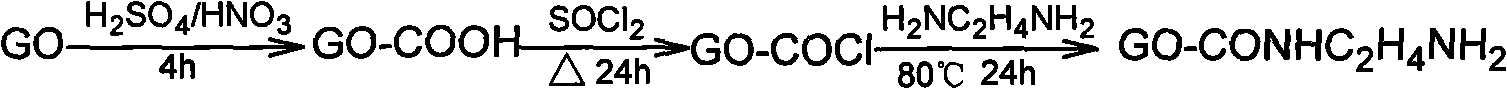

Method for preparing graphene functionalized alginate fibers

ActiveCN102181961AEffective orientationUniform and stable dispersionAlginate artificial filamentsWet spinning methodsFiberChemical reaction

The invention discloses a method for preparing graphene functionalized alginate fibers. The method comprises the following steps: firstly adding a defined amount of graphene to a sodium alginate solution to obtain a graphene / alginate spinning solution; or aminating the defined amount of graphene and then ensuring the aminated graphene to covalently bind with sodium alginate through a chemical reaction to obtain a graphene-alginate spinning solution; then ensuring the graphene / alginate spinning solution or the graphene-alginate spinning solution to respectively undergo a coagulation bath to obtain graphene / alginate as-spun fibers or graphene-alginate as-spun fibers; and then drawing, setting and oiling the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers after ensuring the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers to undergo a preheating bath and a drawing bath respectively to obtain graphene / alginate functionalized fibers or graphene-alginate functionalized fibers which are called graphene functionalized alginate fibers. The prepared graphene functionalized alginate fibers integrate the excellent performances of the graphene and the sodium alginate and have the excellent performances such as high tensile strength, good biocompatibility, antistatic performance, light weight, high elasticity, antibacterial performance and the like.

Owner:QINGDAO UNIV

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

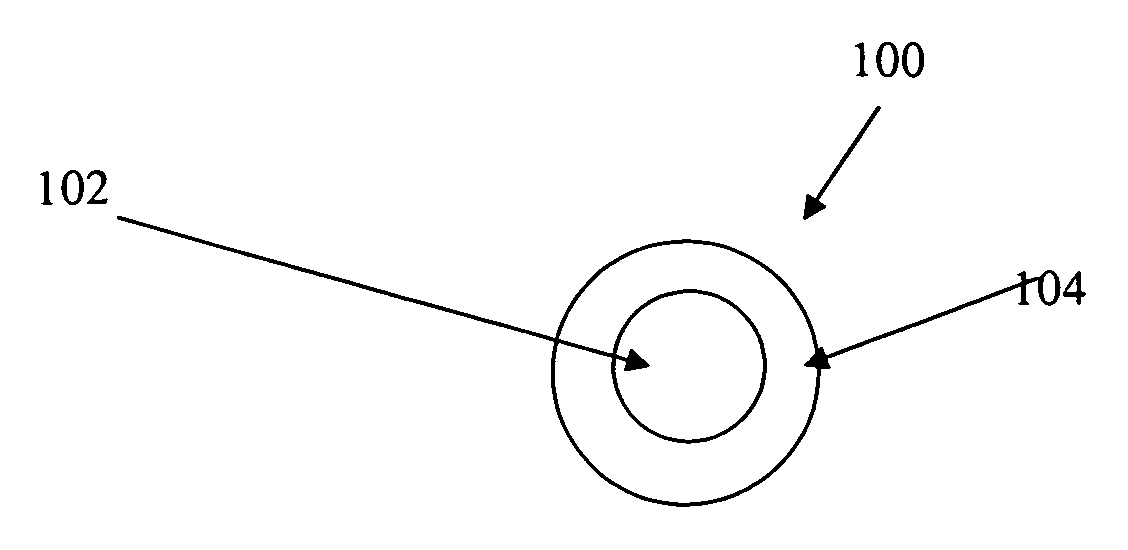

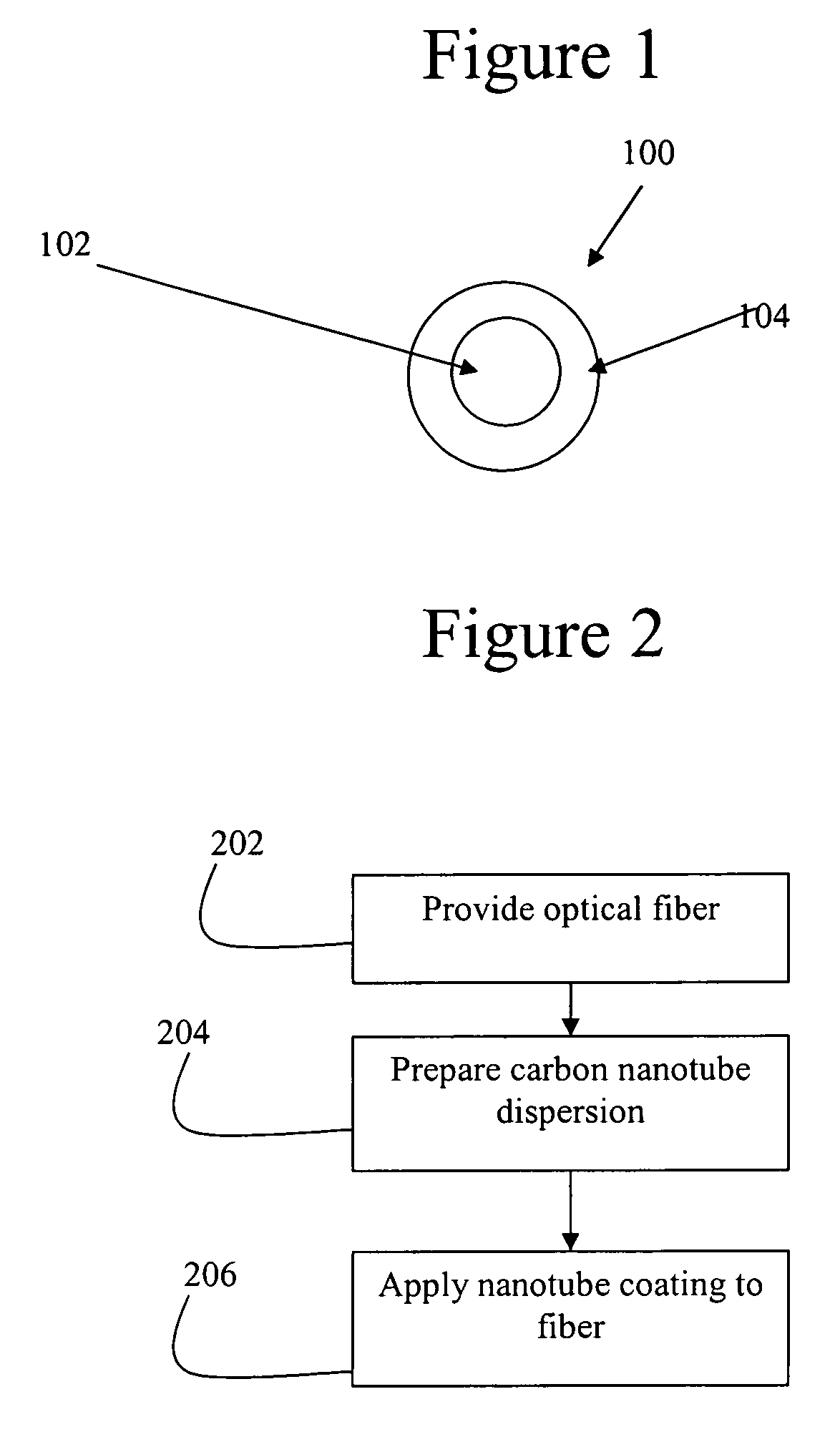

High-reliability optical fiber having a nanocomposite coating

InactiveUS20090208743A1Provide strengthGuaranteed uptimeMaterial nanotechnologyCarbon compoundsCarbon nanotubeSingle strand dna

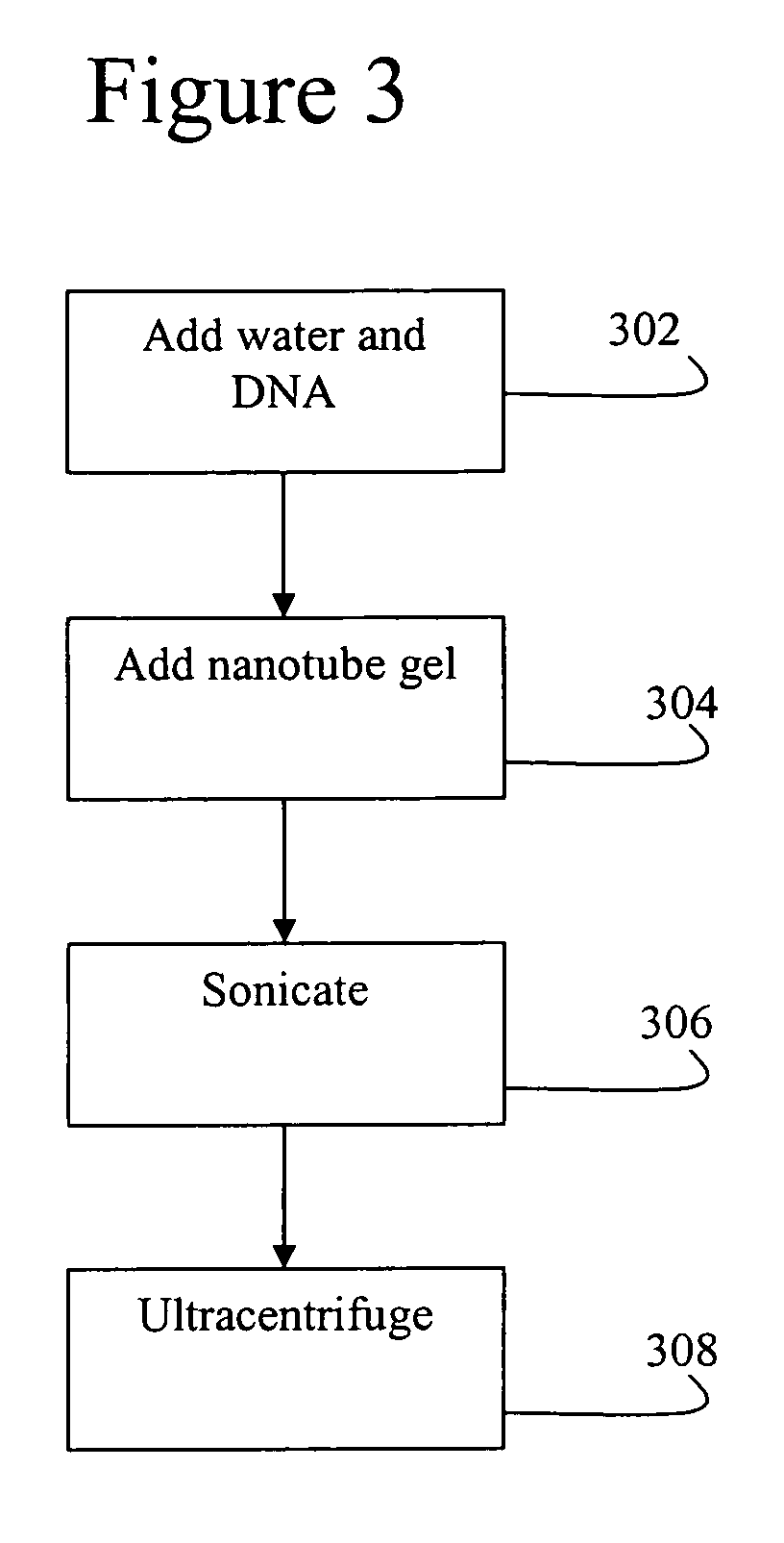

An optical fiber is coated with a super-hydrophobic carbon nanotube film, or other film containing a nanocomposite material, to increase reliability. The film is formed from a carbon nanotube dispersion, which is in turn formed from a mixture of water, carbon nanotube gel, and a polymer such as single stranded DNA of a repeating sequence of the base pairs GT with a length of 20 base pairs, which is sonicated and then ultracentrifuged.

Owner:PETTIT JOHN W

Emulated wood with pores and fibers and fabrication method thereof

ActiveUS20150376840A1Reduce surface polarityImprove compatibilityNatural cellulose pulp/paperPaper after-treatmentPolymer scienceFoaming agent

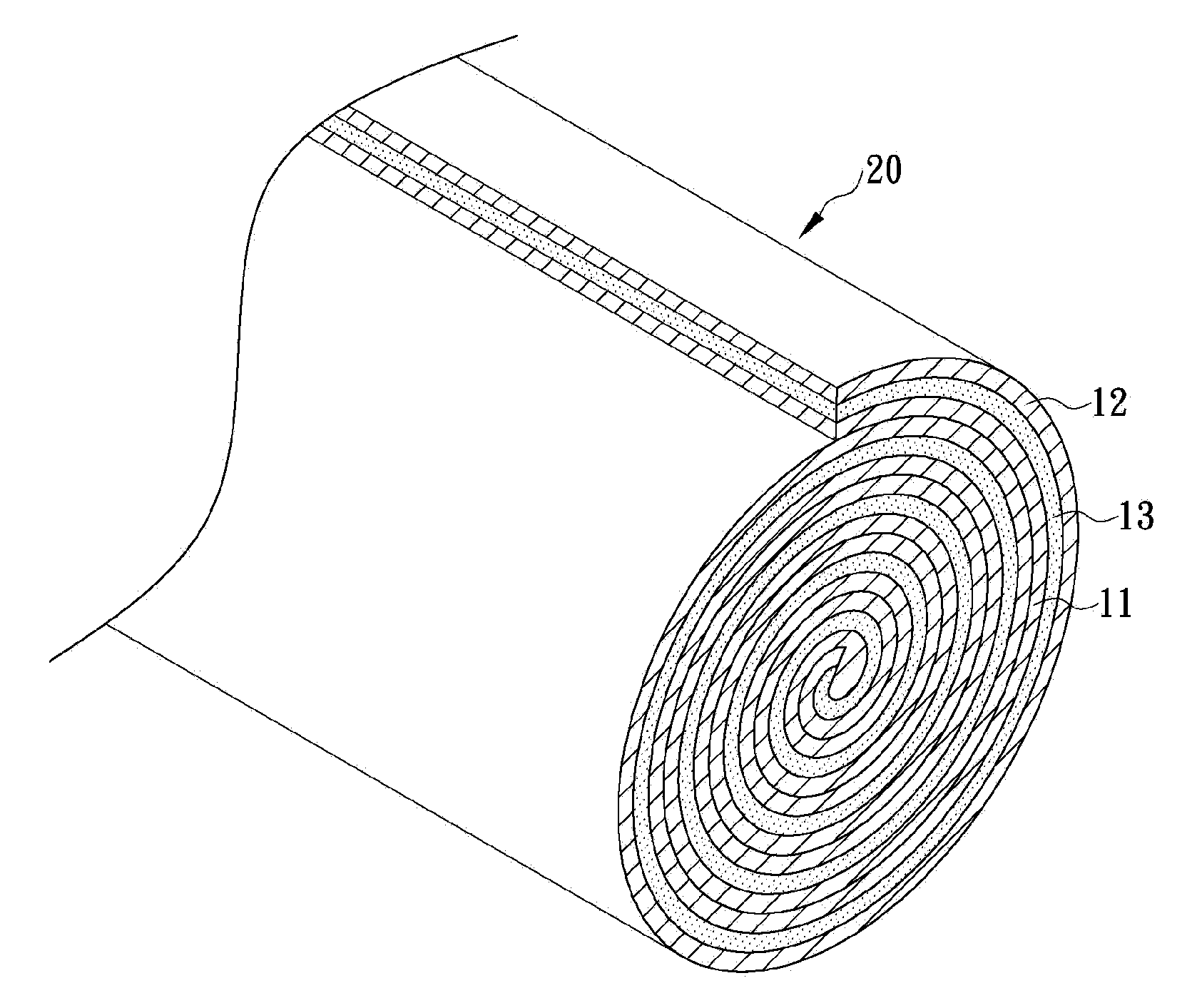

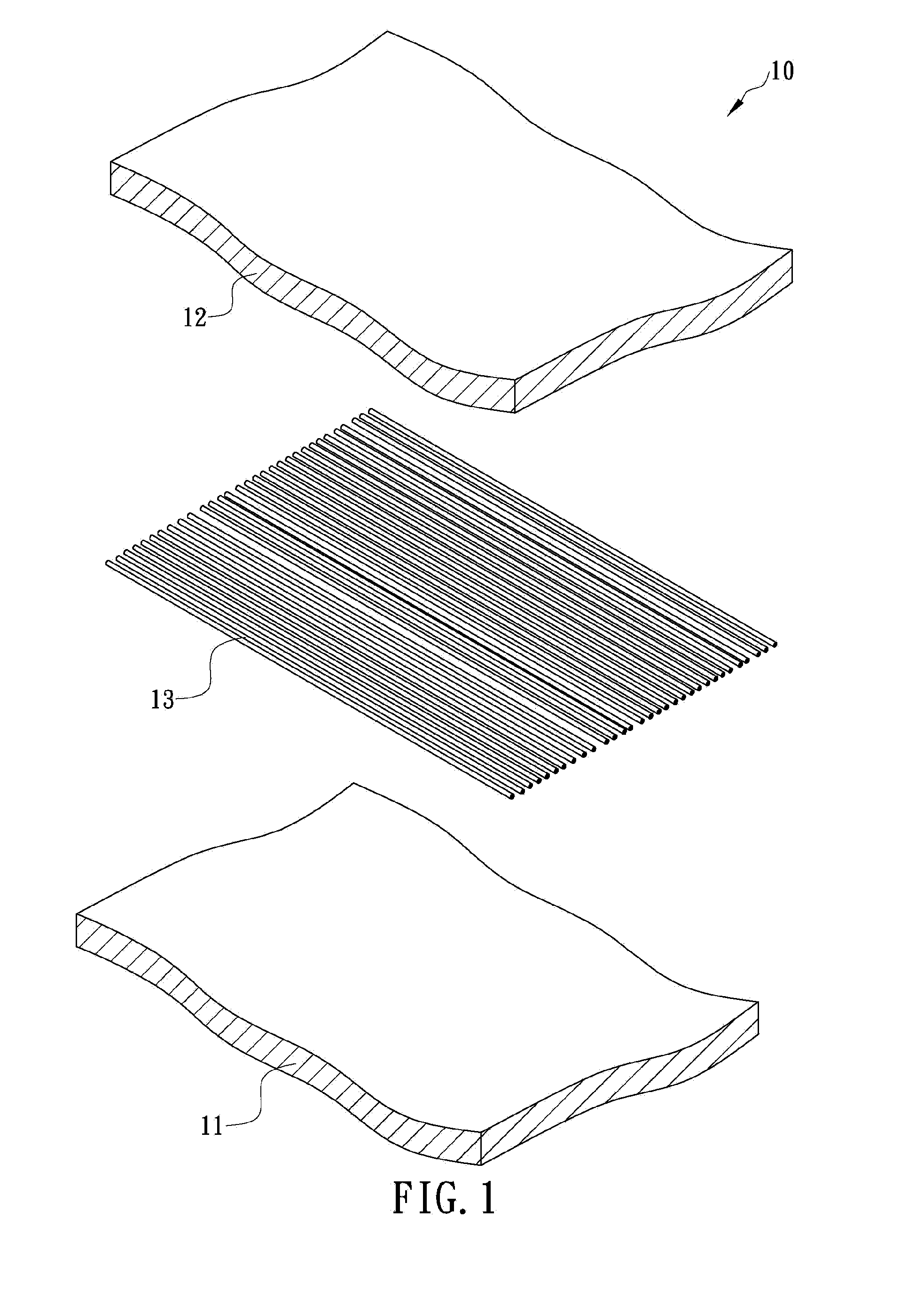

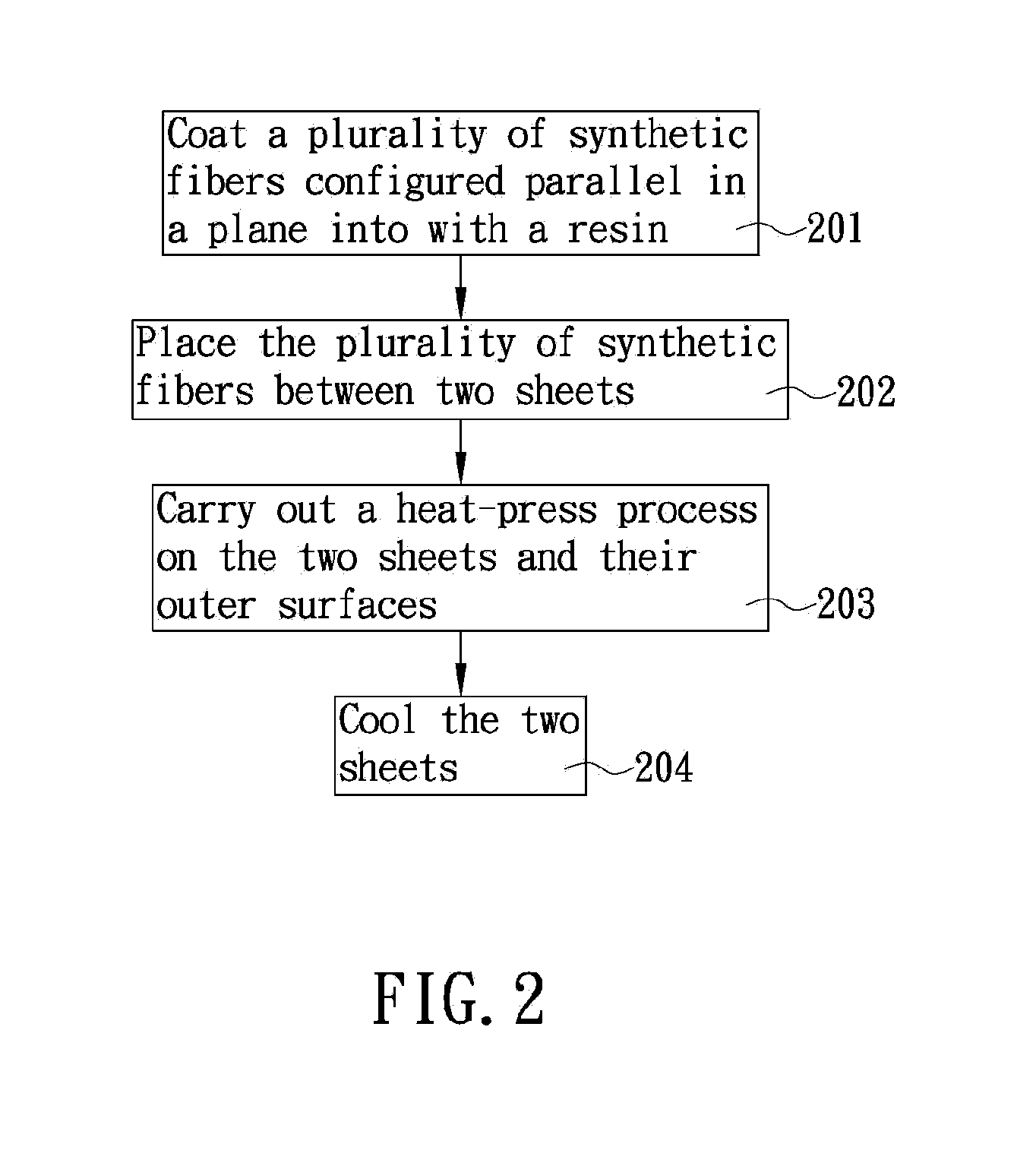

A method for fabricating emulated wood with pores and fibers, comprising: immersing a plurality of synthetic fibers configured parallel in a plane into a resin so that the resin is coated on the surfaces of the plurality of synthetic fibers and in the gaps between the plurality of synthetic fibers; placing the plurality of synthetic fibers between two sheets, wherein the two sheets are planar sheets made from a uniform composition comprising a thermoplastic elastomer, a foaming agent, and a crosslinking agent; carrying out a heat-press process on the two sheets so that the foaming agent undergoes microcellular foaming and forms dense closed pores in the two sheets, and so that the composition on inner surfaces of the two sheets expands towards the plurality of synthetic fibers and penetrates through the gaps between the plurality of synthetic fibers; and cooling the two sheets to yield an emulated wood board.

Owner:MICROCELL COMPOSITE CO LTD

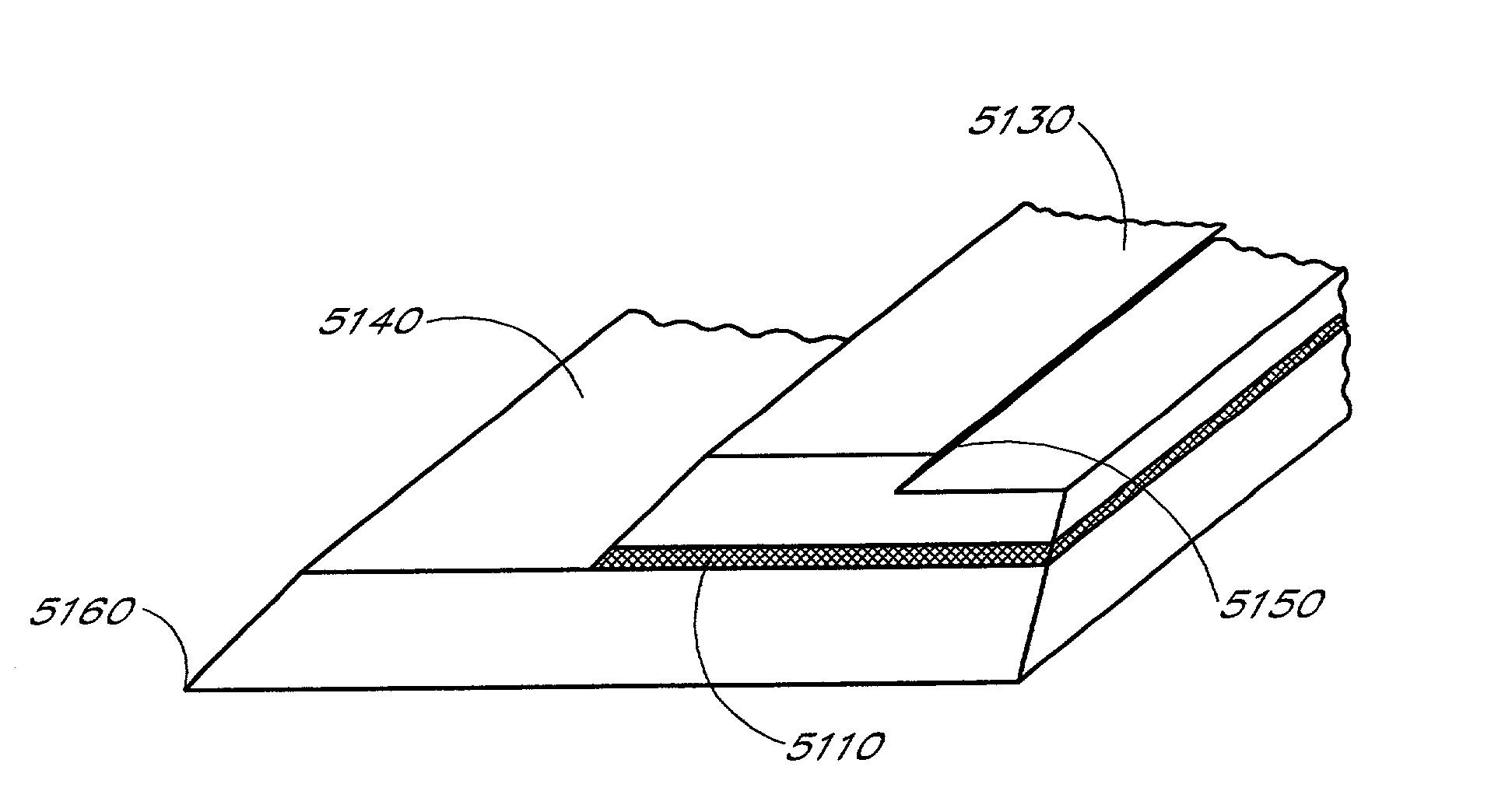

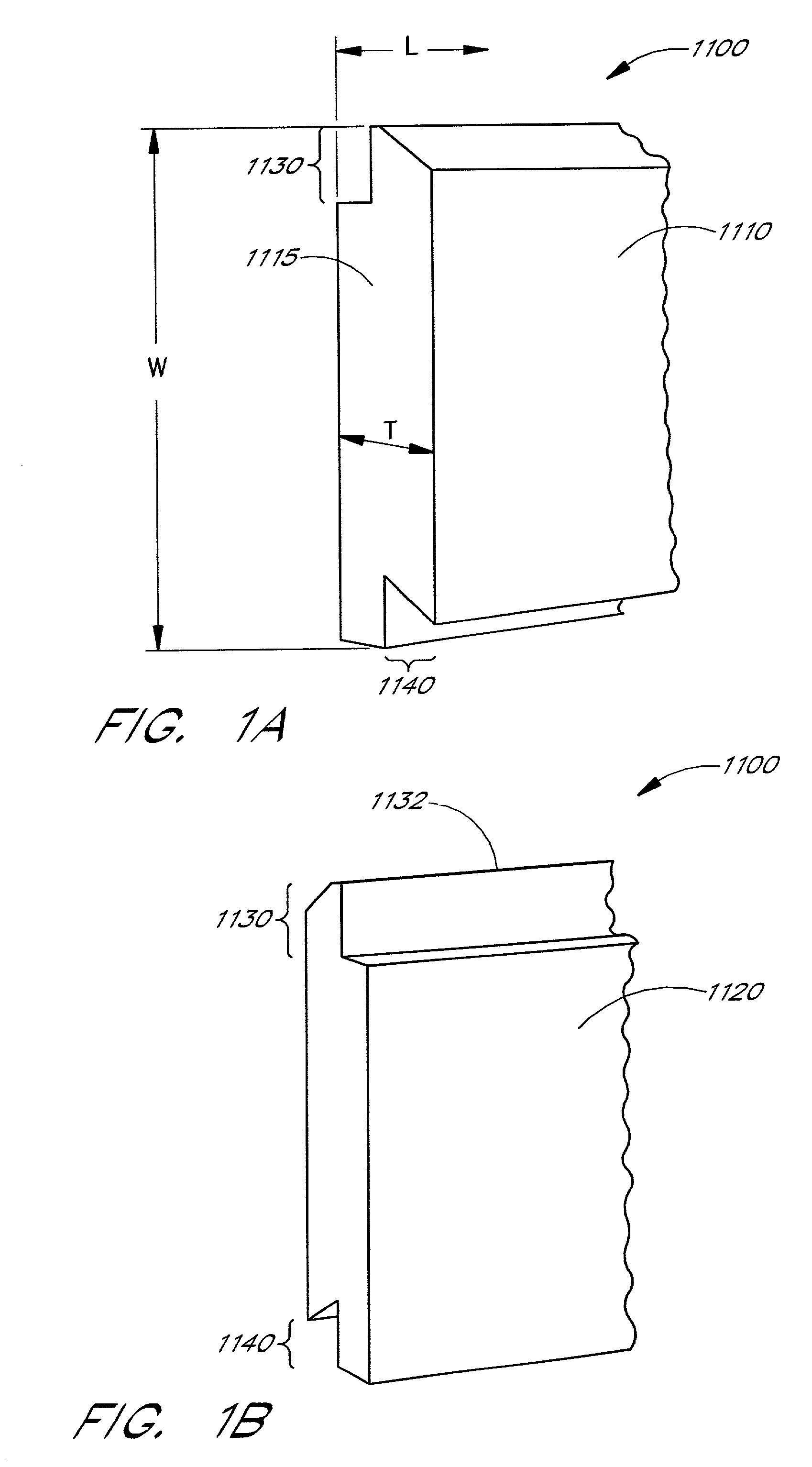

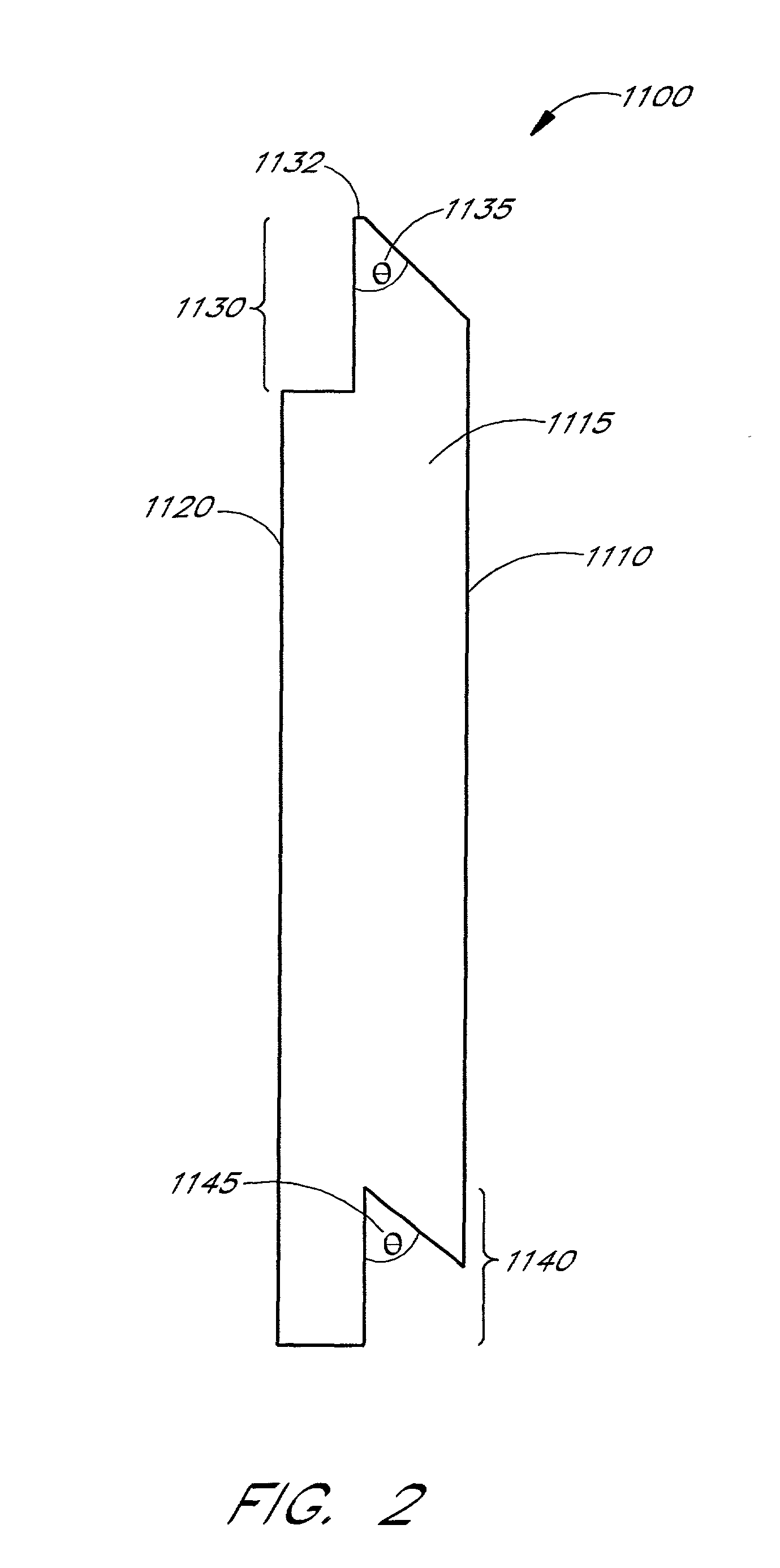

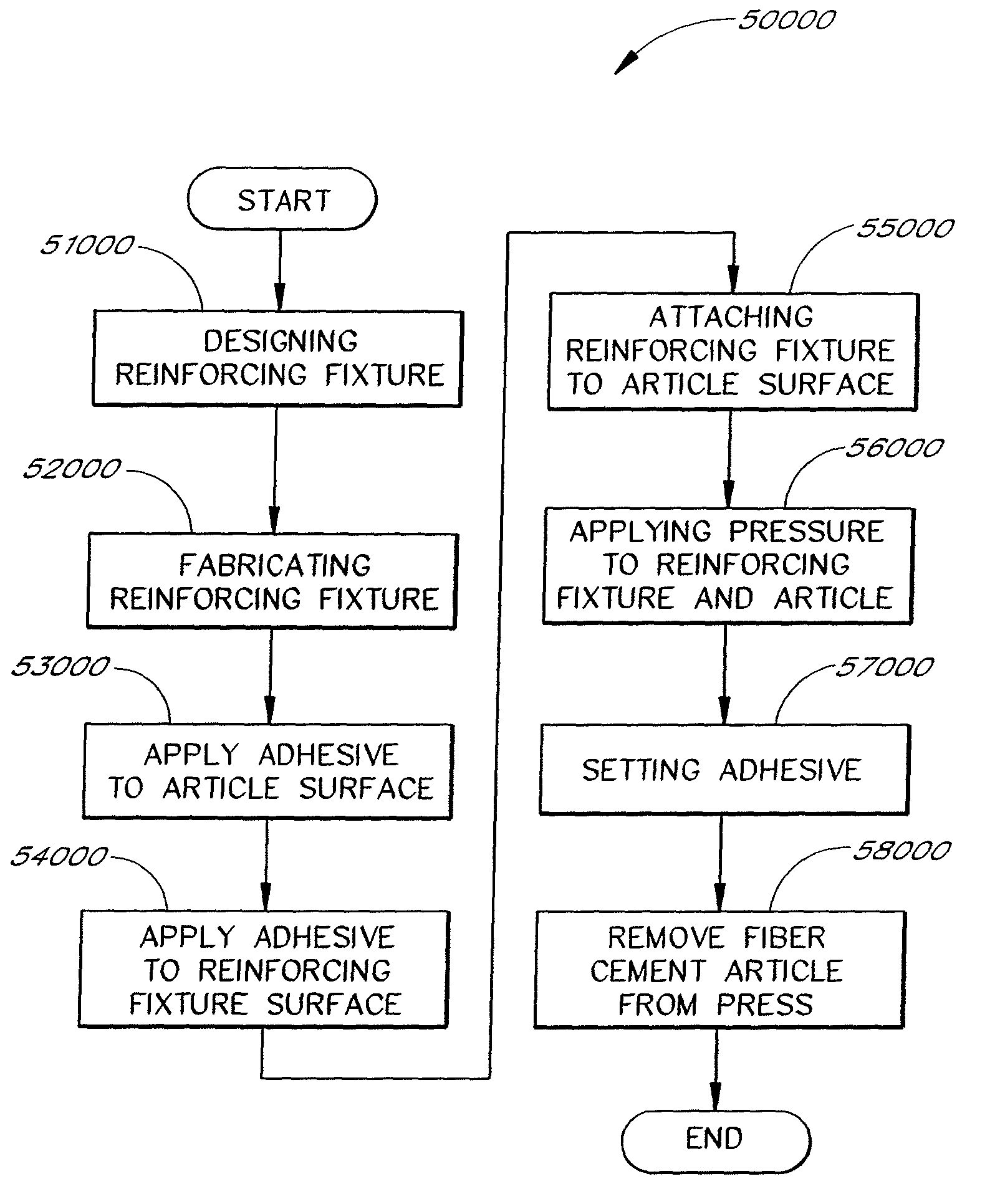

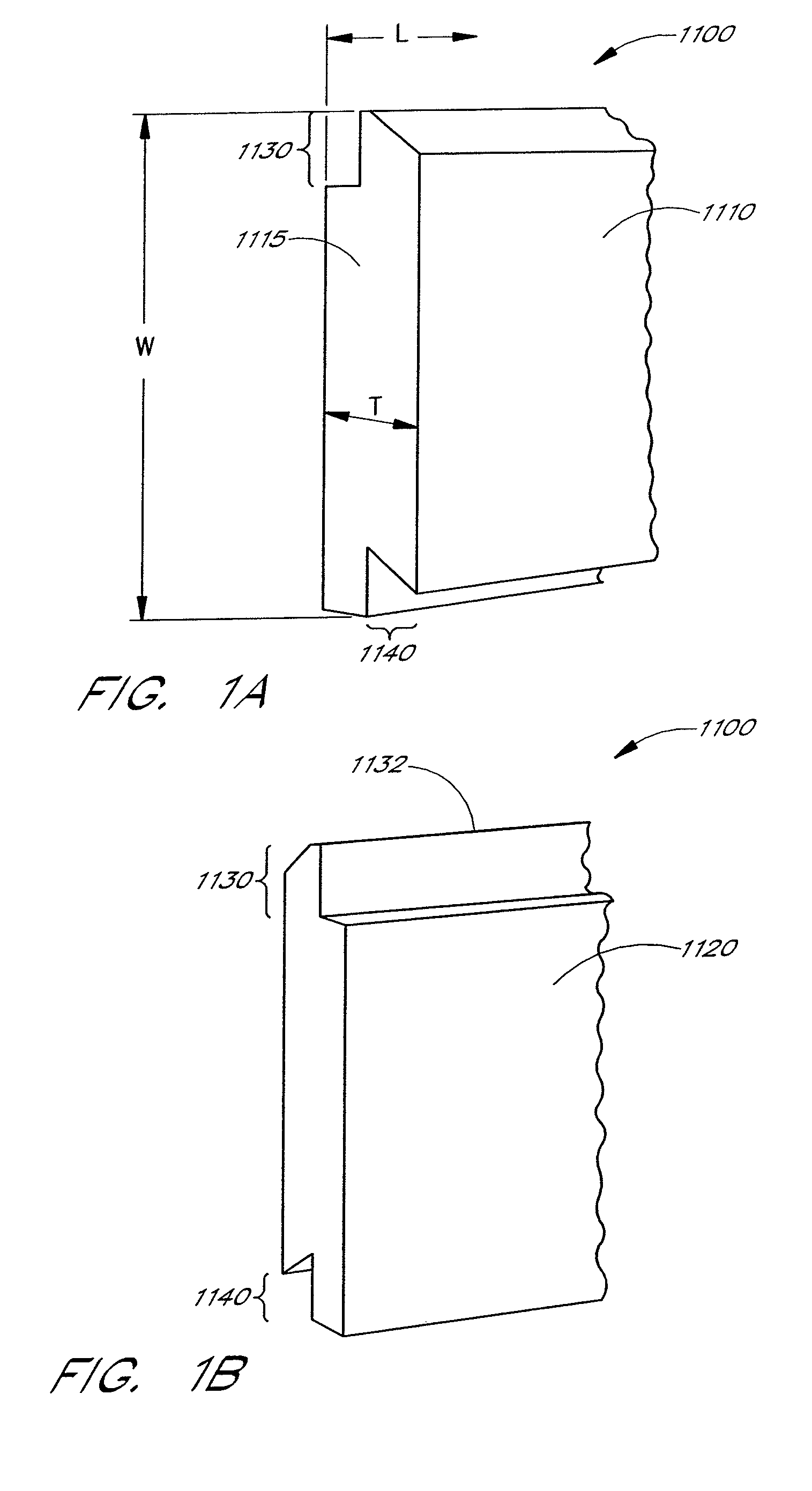

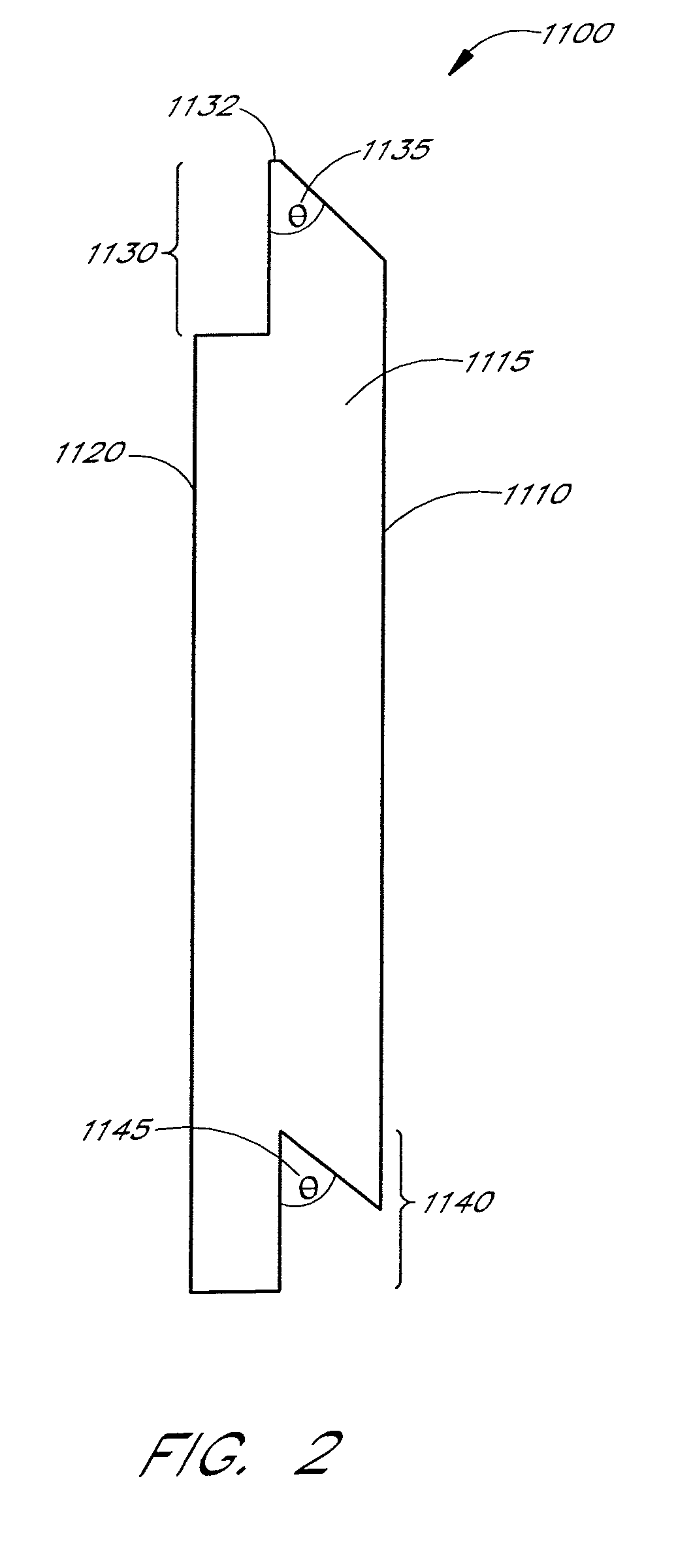

Reinforced fiber cement article and methods of making and installing the same

InactiveUS7713615B2High fiber strengthHigh tensile strengthRoof covering using tiles/slatesConstruction materialAdhesiveUltimate tensile strength

In one embodiment, a reinforced fiber cement article comprising a fiber cement piece and a reinforcing fixture bonded to a portion of the fiber cement piece for improving the performance, strength and durability of the fiber cement piece. The reinforcing fiber cement article could be used as or in conjunction with a siding plank assembly, which further comprises an interlocking feature that allows the siding plank to be stacked with other siding planks in a manner such that a uniform and deep shadow line is created. The interlocking feature sets the gauge of the exposed plank face and allows for leveling of the plank during installation. The reinforcing fixture could also serve as a thick butt piece or a plastic spline that produces a deep shadow line. A cementitious adhesive is used to bond the reinforcing fixture to the fiber cement piece.

Owner:JAMES HARDIE TECH LTD

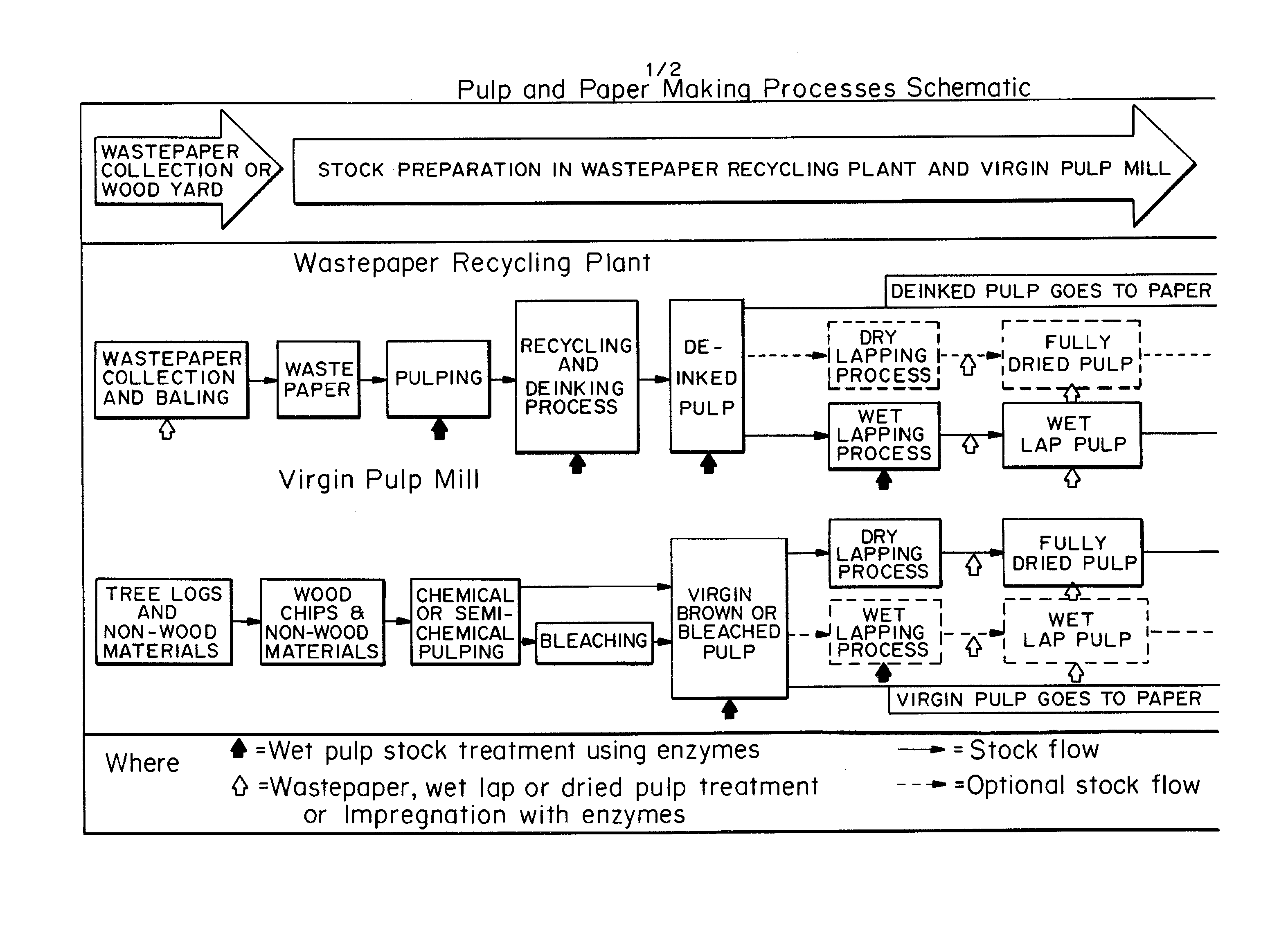

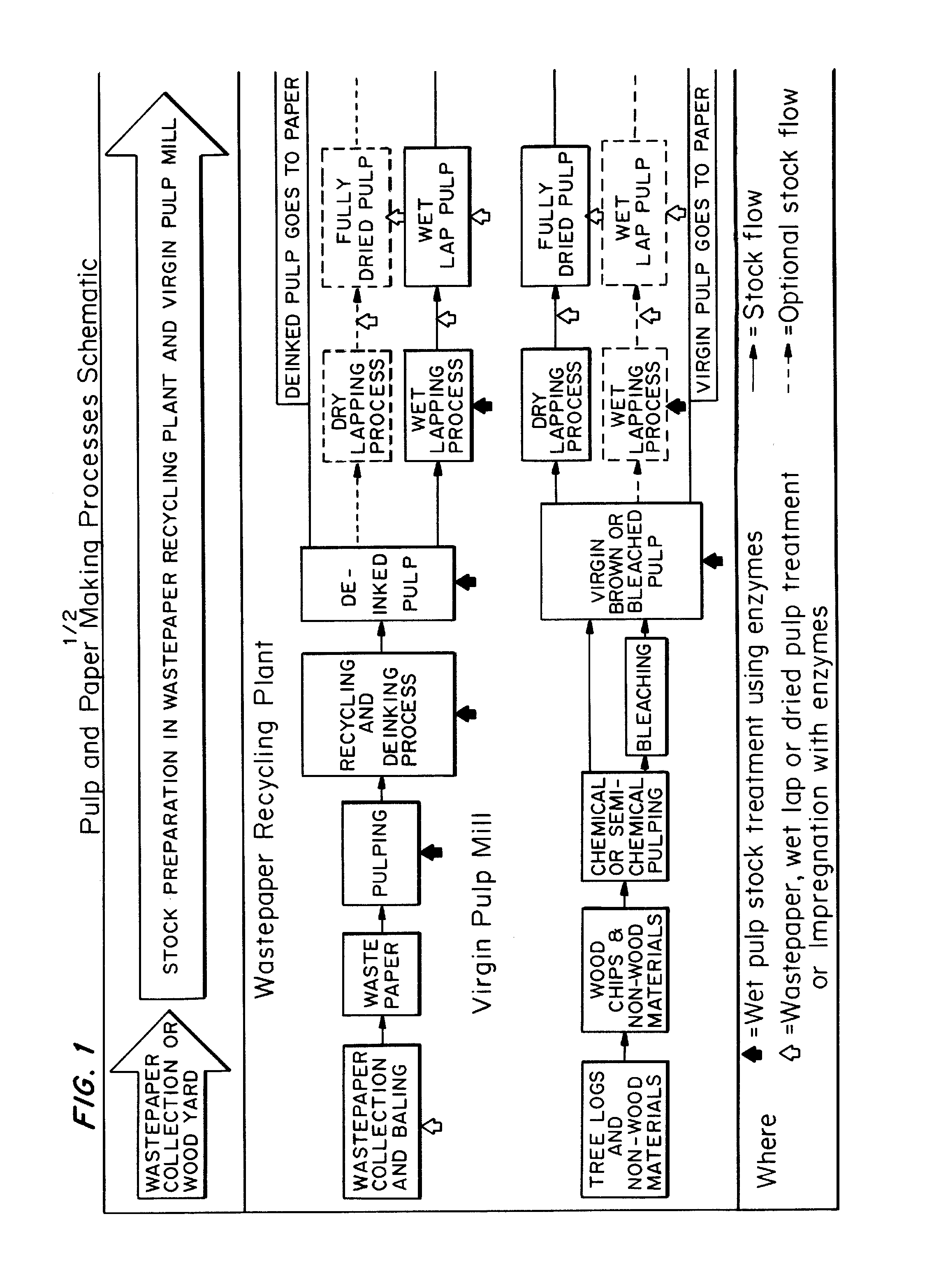

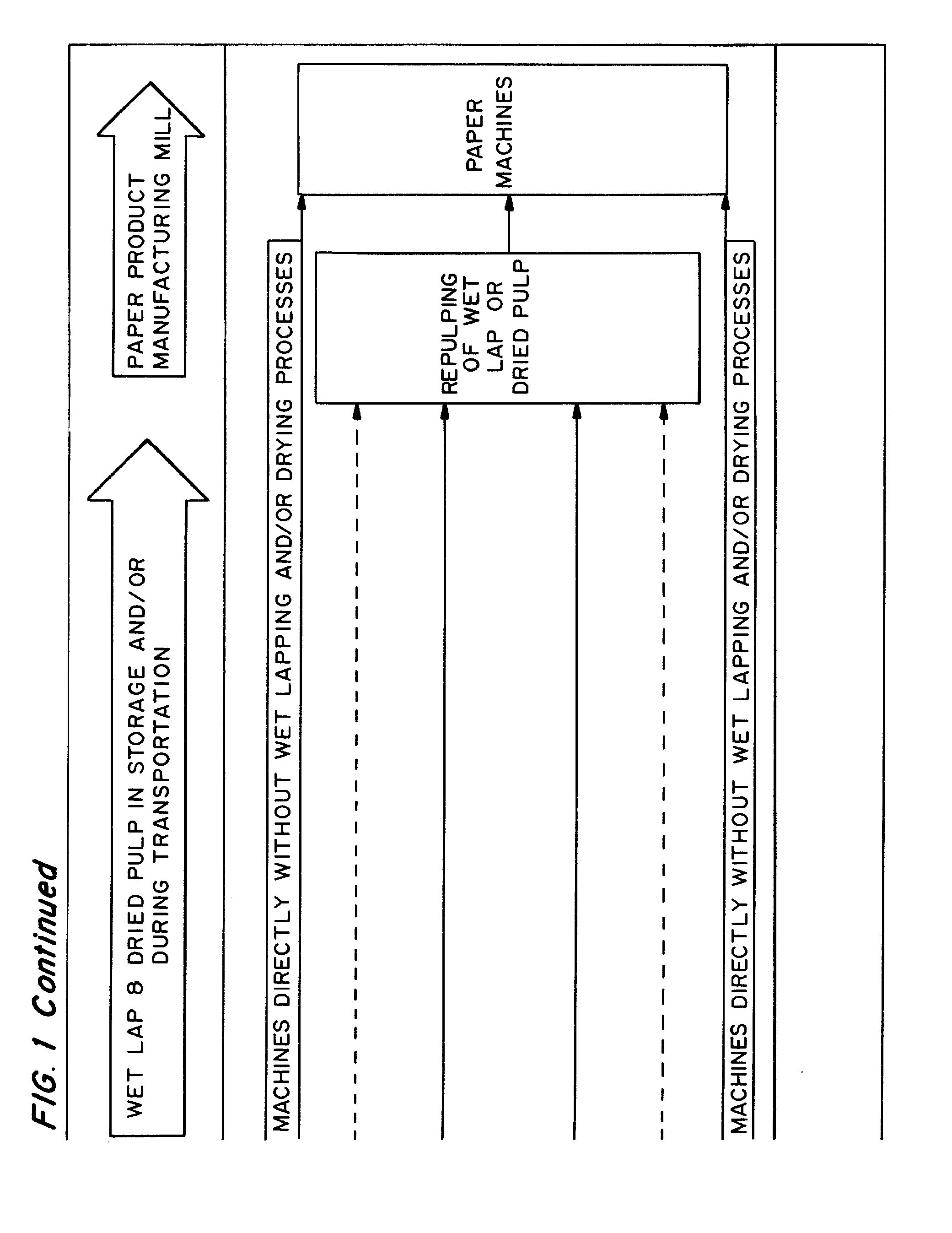

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20130146239A1Increasing pulp drainageImprove strength propertiesMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Methods for reducing the effects of wetlapping, drying, and hornification of pulp fibers and consequently increasing the pulp drainage and strength properties in the final product (i.e., paper) are provided. The method which has been developed creates a “value-added” product by the wastepaper supplier or at the pulp and / or deinking (recycled paper) mill—a wastepaper load / bale, wet pulp stock or wet lap, or dried pulp treated with or impregnated with enzymes that enhance the quality of the pulp or paper product when it is repulped and processed at the paper mill.

Owner:ENZYMATIC DEINKING TECH LLC

Production method of carbon fiber

InactiveCN103409854AHigh yieldHigh crystallinityWet spinning methodsMonocomponent synthetic polymer artificial filamentCarbon fibersCarbonization

The invention relates to a production method of a carbon fiber. The production method comprises the following steps of: preparing a spinning solution; carrying out wet spinning; solidifying; previously oxidizing primary polyacrylonitrile resin fibers; carrying out low-temperature carbonization; carrying out high-temperature carbonization, and the like. The production method disclosed by the invention can be used for enhancing the regularity of a fiber molecular chain by mixing high-regularity polyacrylonitrile resin and common polyacrylonitrile resin, thereby enhancing the fiber crystallinity, enhancing the fiber compact degree, increasing the carbon network length of the final fiber molecular chain and enhancing the fiber strength. Compared with the carbon fiber in the prior art, the carbon fiber obtained by adopting the production method has the advantage that the tensile strength and the carbonization yield are respectively improved by more than 19.7% and 26.0%.

Owner:THE NORTHWEST RES INST OF CHEM IND

Modified polyphenylene sulfide fiber and method for making same

InactiveCN101187088AHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsUltimate tensile strengthSilicon dioxide

The invention provides a modified polyphenylene sulfide fiber and process for preparing, whose components and parts by weight comprise 100 parts of polyphenylene sulfide and 0.2-2 parts of nano-silica whose surface is treated, the particle size of the silica is 20-60 nanometer, and the denier of the fiber is 85-91 dtax. The invention prepares the polyphenylene sulfide fiber through modifying polyphenylene sulfide resins and using special spinning process, the fiber strength and tension toughness are all improved, simultaneously, the glossiness of the fiber is further improved, the spinning is capable of being done by a common spinning device, the cost of spinning is reduced, the fluidity of substrate is changed better during spinning, the temperature of spinning is reduced by 5-10 DGE C, the draft multiple of as-spun fiber is improved, and the mechanical properties of the fiber are capable of being improved.

Owner:DONGHUA UNIV

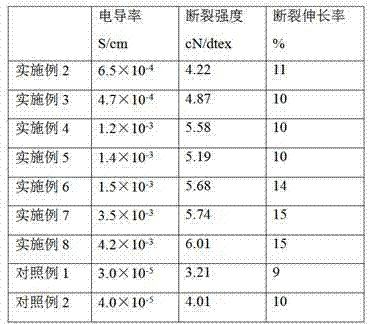

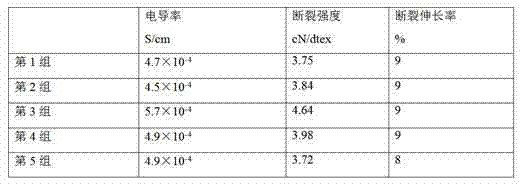

Preparation method of graphene-doped conductive composite fiber

ActiveCN104278360AImprove conductivityHigh fiber strengthElectroconductive/antistatic filament manufactureArtificial thread manufacturing machinesPolymer scienceDoped graphene

The invention relates to a preparation method of a graphene-doped conductive composite fiber and belongs to the technical field of composite materials. The preparation method of the graphene-doped conductive composite fiber comprises the following steps: step one, mixing and stirring 10-15 parts of graphene, 2-4 parts of a dispersing agent and 100-150 parts of a high-molecular polymer in parts by weight, wherein the high-molecular polymer is prepared by mixing 1,2-polybutadiene, acrylic resin, chlorinated polypropylene and polypropylene according to any weight ratio; and step two, fusing, filtering, spinning, cooling and molding, drawing and thermally shaping a mixture prepared by the step one by a twin-screw extruder to obtain the conductive composite fiber. The graphene-doped conductive composite fiber prepared by the method is relatively high in conductivity and fiber strength.

Owner:江苏悠谷未来科技有限公司

Reinforced fiber cement article and methods of making and installing the same

InactiveUS8409380B2High fiber strengthHigh tensile strengthCovering/liningsCeramic shaping apparatusAdhesiveCombined use

In one embodiment, a reinforced fiber cement article comprising a fiber cement piece and a reinforcing fixture bonded to a portion of the fiber cement piece for improving the performance, strength and durability of the fiber cement piece. The reinforcing fiber cement article could be used as or in conjunction with a siding plank assembly, which further comprises an interlocking feature that allows the siding plank to be stacked with other siding planks in a manner such that a uniform and deep shadow line is created. The interlocking feature sets the gauge of the exposed plank face and allows for leveling of the plank during installation. The reinforcing fixture could also serve as a thick butt piece or a plastic spline that produces a deep shadow line. A cementitious adhesive is used to bond the reinforcing fixture to the fiber cement piece.

Owner:JAMES HARDIE TECH LTD

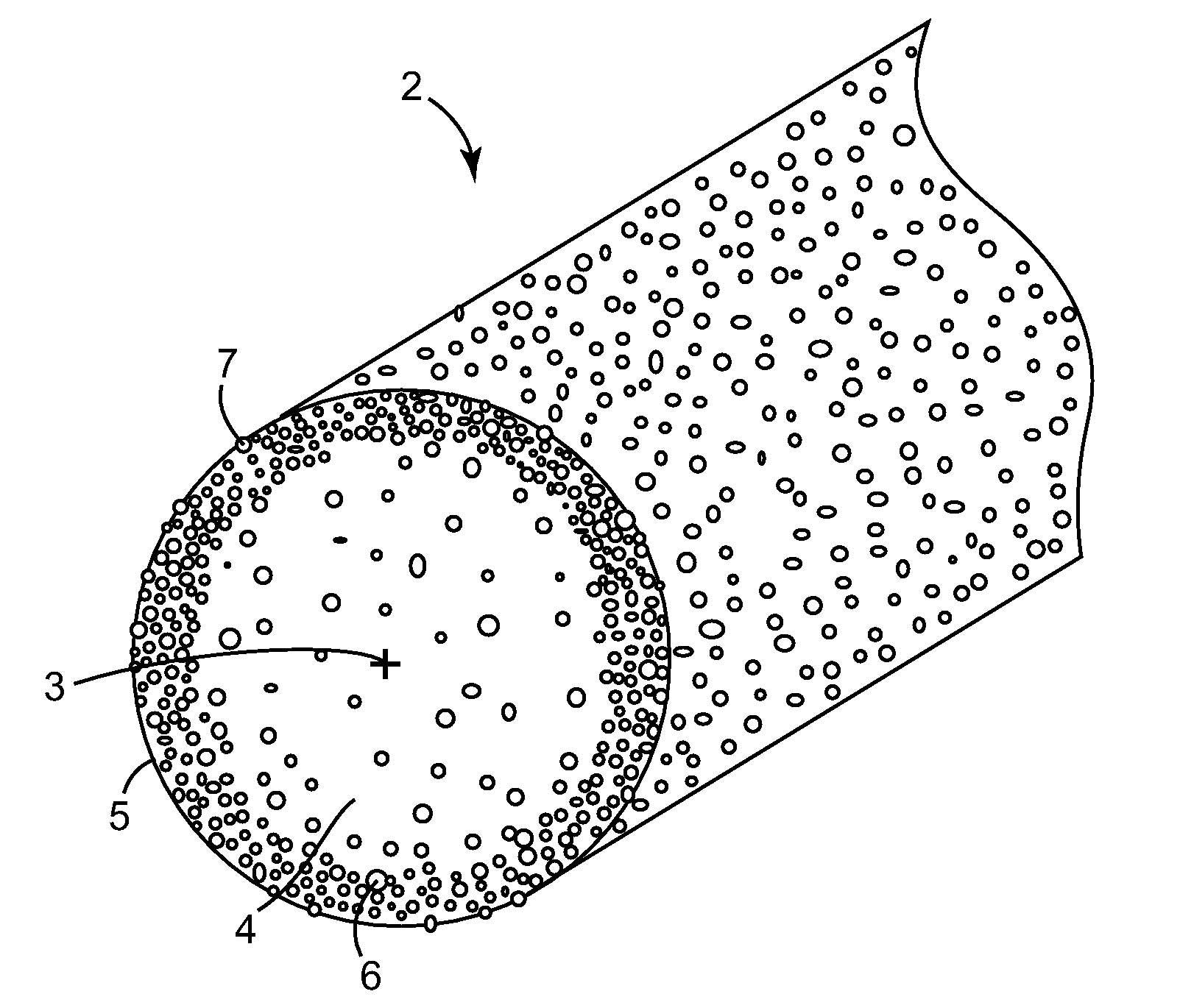

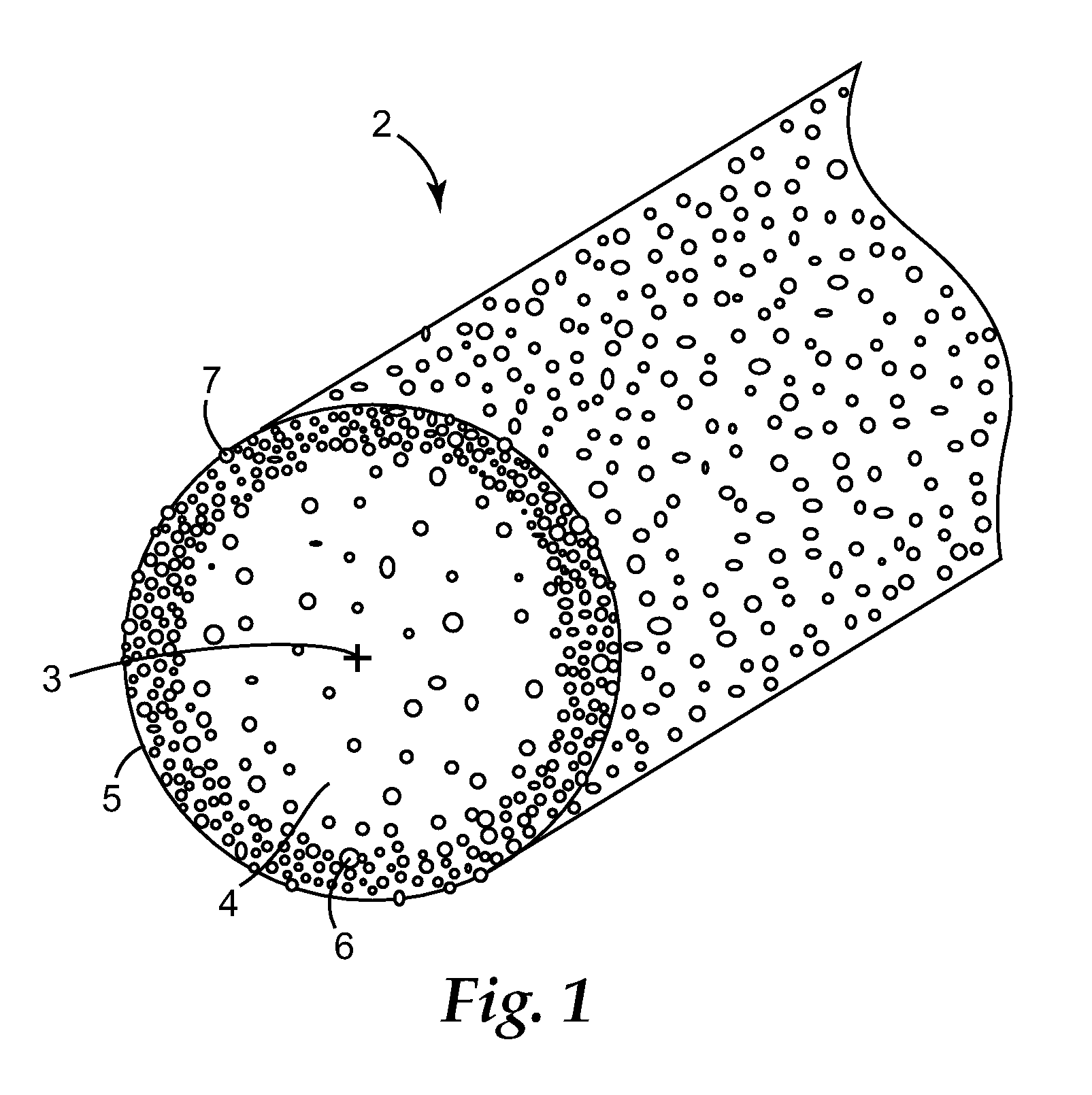

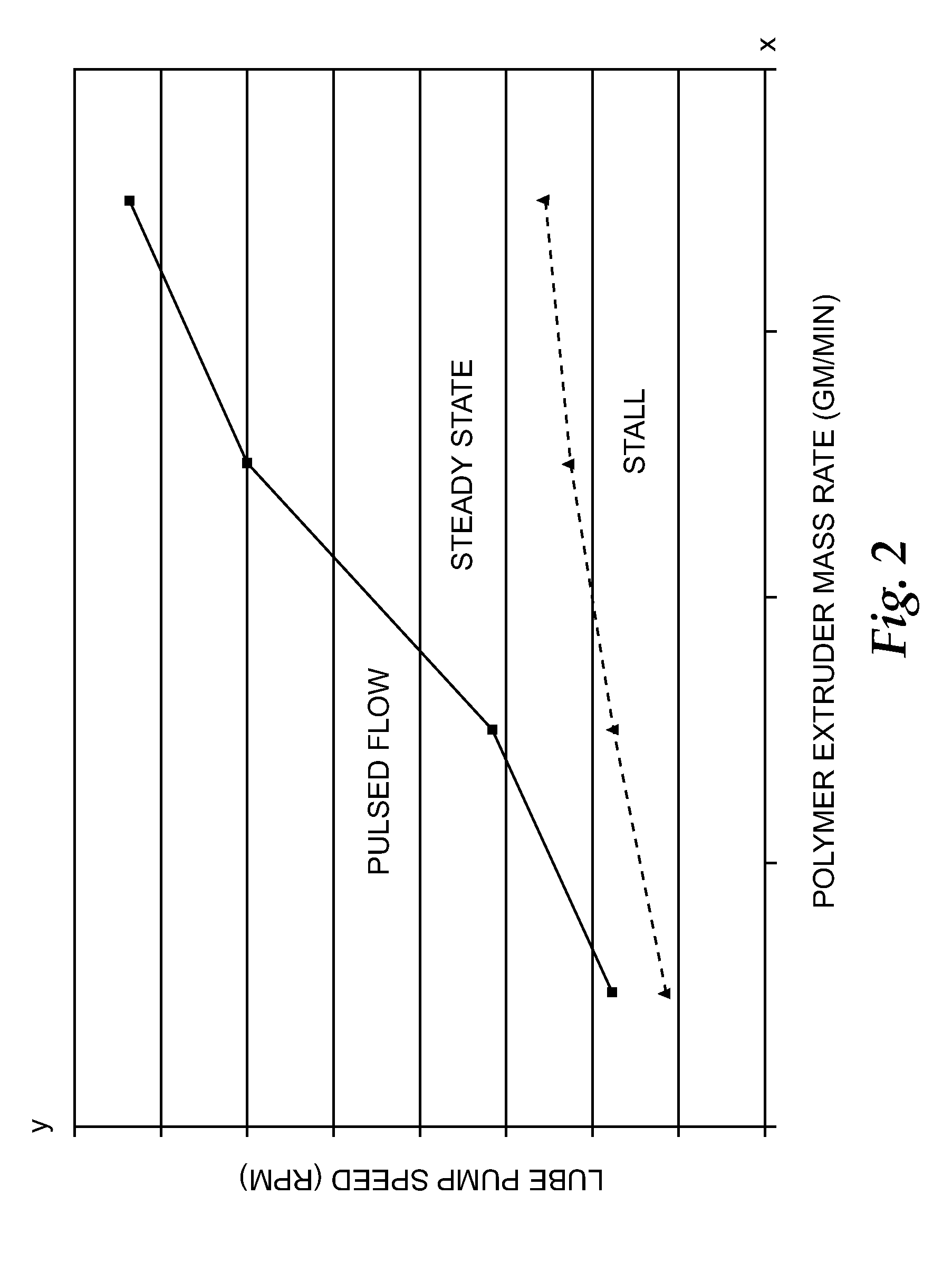

Particulate-loaded polymer fibers and extrusion methods

InactiveUS20080003430A1High fiber strengthImprove distributionSpinnerette packsYarnFiberParticulates

Particulate-loaded polymer fibers along with methods and systems for extruding polymeric fibers are disclosed. The particulate-loaded polymer fibers have a fiber body that includes a polymeric binder with a plurality of particles distributed within the polymeric binder. Some of the particles are completely encapsulated within the polymeric binder and others may be embedded such that they are partially exposed on the outer surface of the fiber body. The polymers used in the fibers may be of high molecular weight and the encapsulated particles may be preferentially distributed towards the outer surfaces of the fibers.

Owner:3M INNOVATIVE PROPERTIES CO

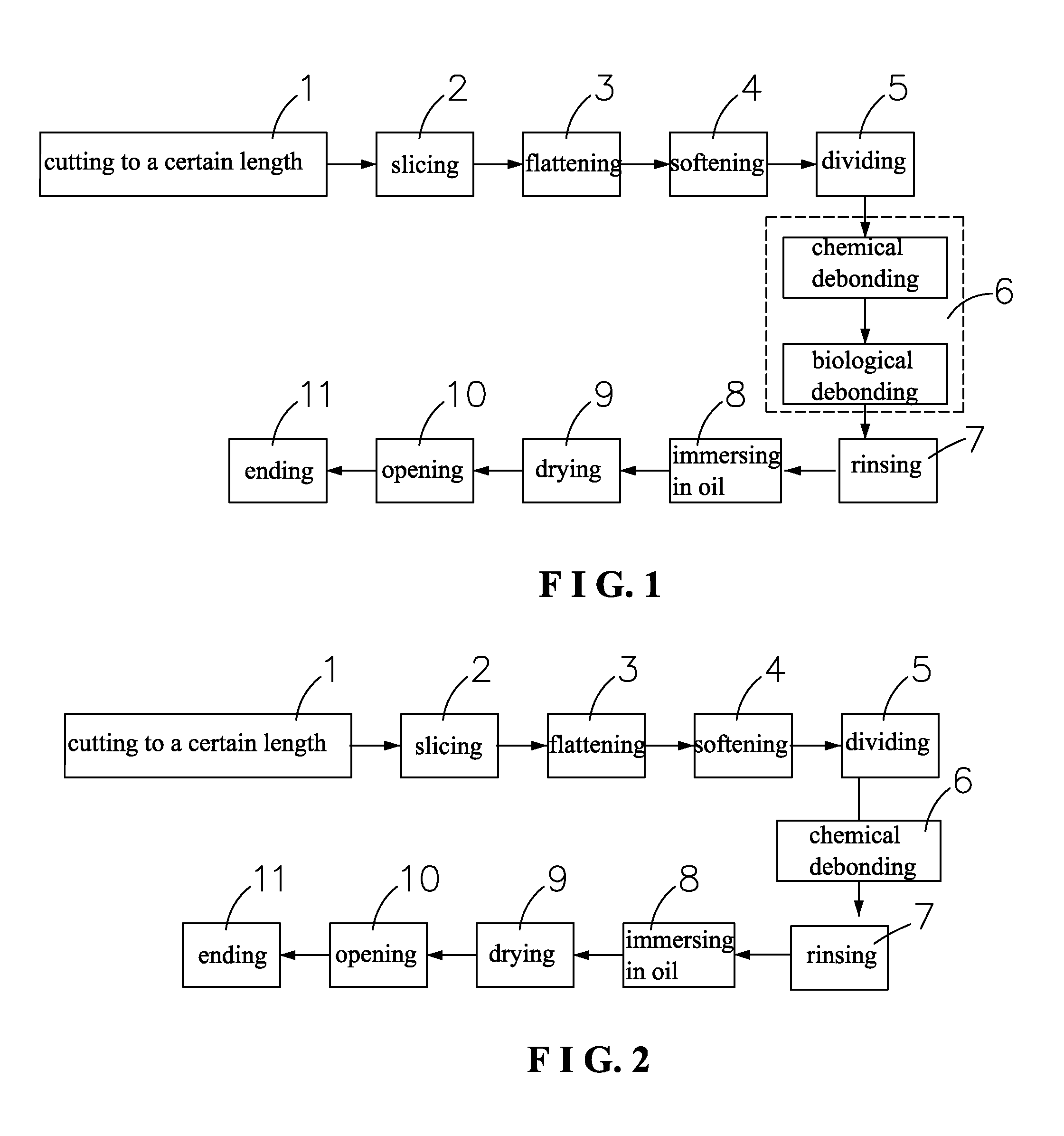

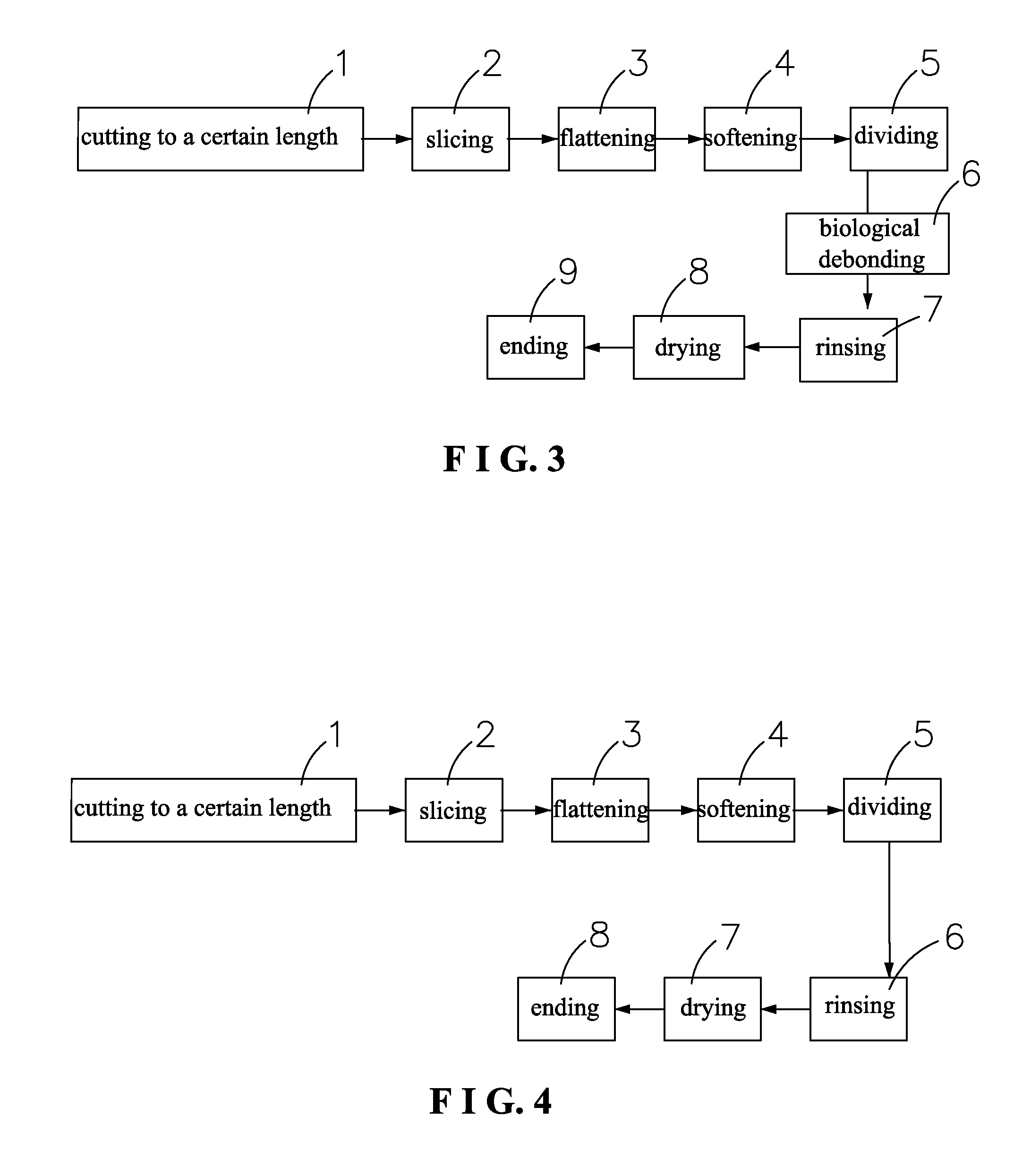

Production technology for natural bamboo fibers

ActiveUS20140000761A1Simple and high-efficient producing methodImprove adaptabilityWood working apparatusPlant material mechanical workingFiberMaterials science

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

Microorganism retting flax method for crudefiber crops

InactiveCN101285211AShort fermentation timeHigh rate of numbnessBacteriaMicroorganism based processesFiber cropMicroorganism

The invention provides a method for retting flax with microbe mild water for bast-fiber crops, belonging to a retting technology for the bast-fiber crops. The method comprises the following steps of: adding degumming bacteria into a retting vessel according to 0.5 to 1.0 per thousand of the total weight of aqueous solution; heating up to 30 to 40 DEG C after injecting water to 100 percent of the total weight of the aqueous solution; and finishing retting after 40 to 50 hours. The industrial production of the degumming bacteria is completed via primary strain culture, secondary strain culture and industrial production. The method has the characteristics of short retting fermentation period, high percentage of fiber extraction, high fiber stress, small water consumption, low energy consumption, retting water economization, zero drainage of retting water and no environmental pollution.

Owner:黑龙江省科学院亚麻综合利用研究所

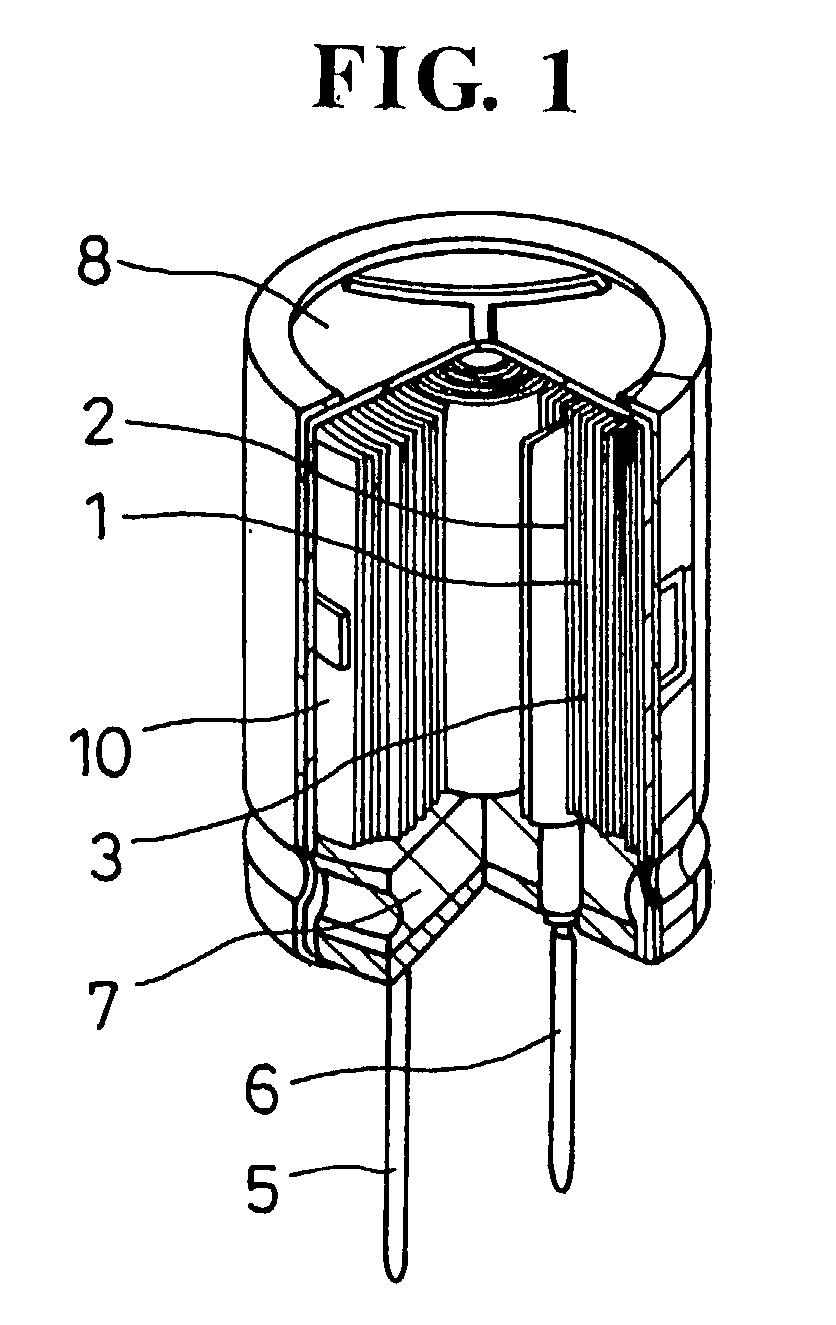

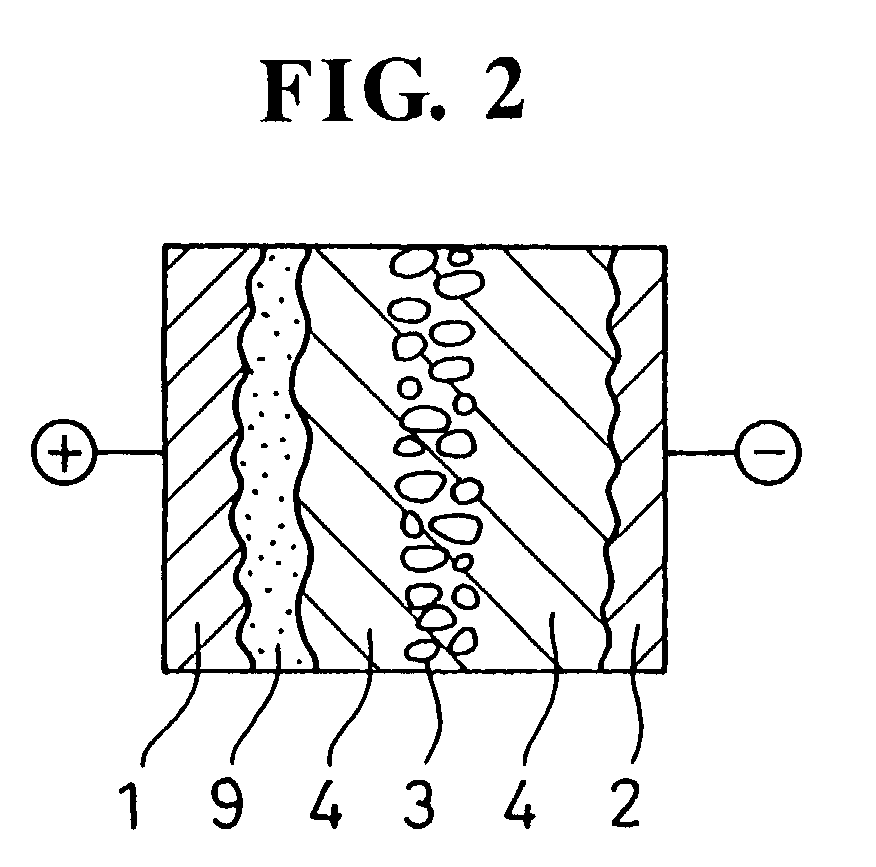

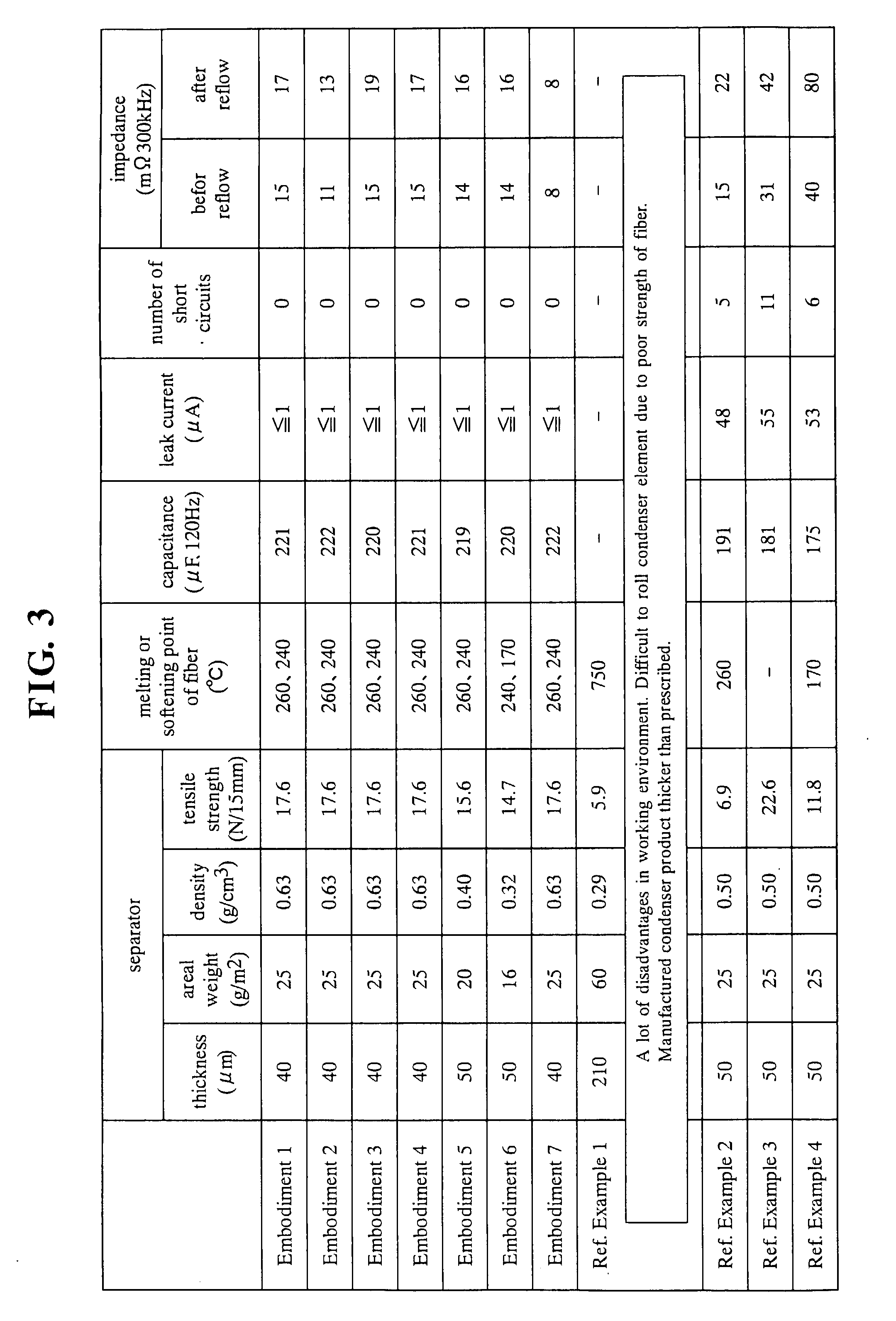

Separator for solid electrolyte condenser and solid electrolyte condenser using the same

ActiveUS20020117394A1High frequencyReduce resistanceHybrid capacitor separatorsHybrid capacitor electrolytesChemistryElectrolyte

An object of the present invention is to provide a separator which is excellent in sticking and adhesion capability with the solid electrolyte, physically strong and highly heat-resistive and to provide a solid electrolyte condenser which is excellent in the impedance characteristic and leak current characteristic. In a solid electrolyte condenser comprising an anode foil, a cathode foil, a separator, the separator is made of a nonwoven fabric containing polyester resin or its derivative manufactured by the wet method. The condenser element is formed by rolling the anode foil and the cathode foil together with the separator between them. The solid electrolyte is provided between the anode foil and the cathode foil of the condenser element.

Owner:NIPPON KODOSHI +1

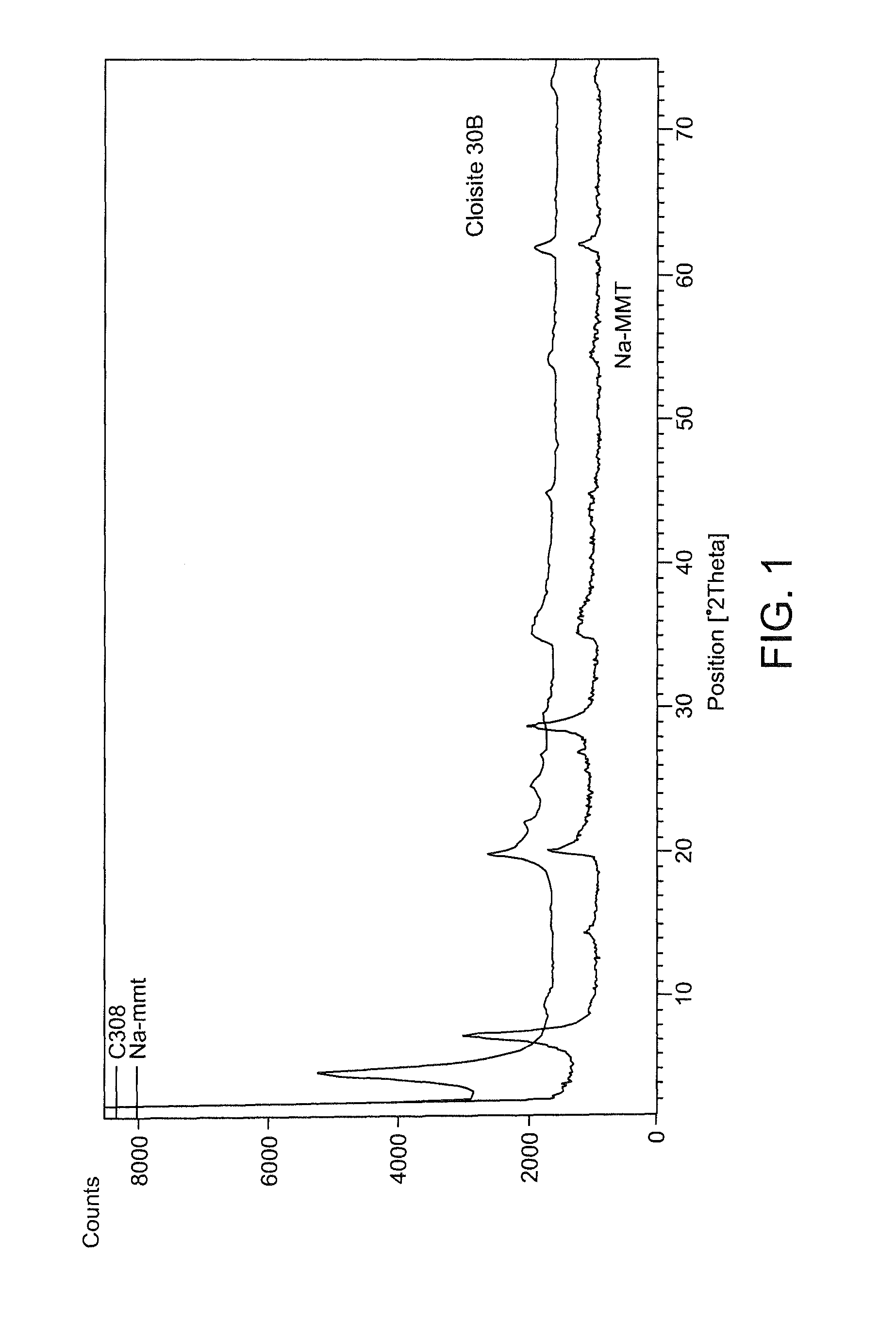

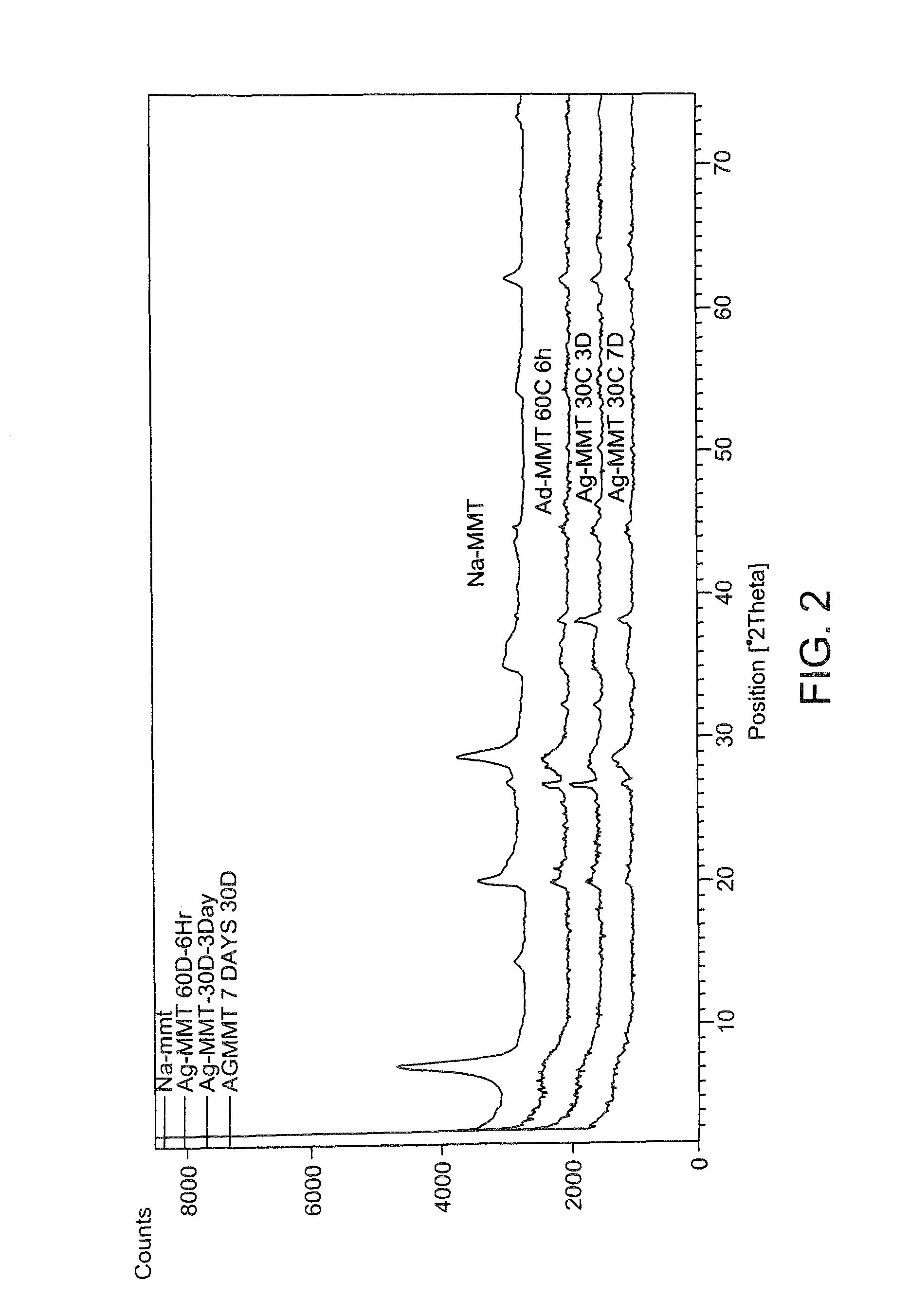

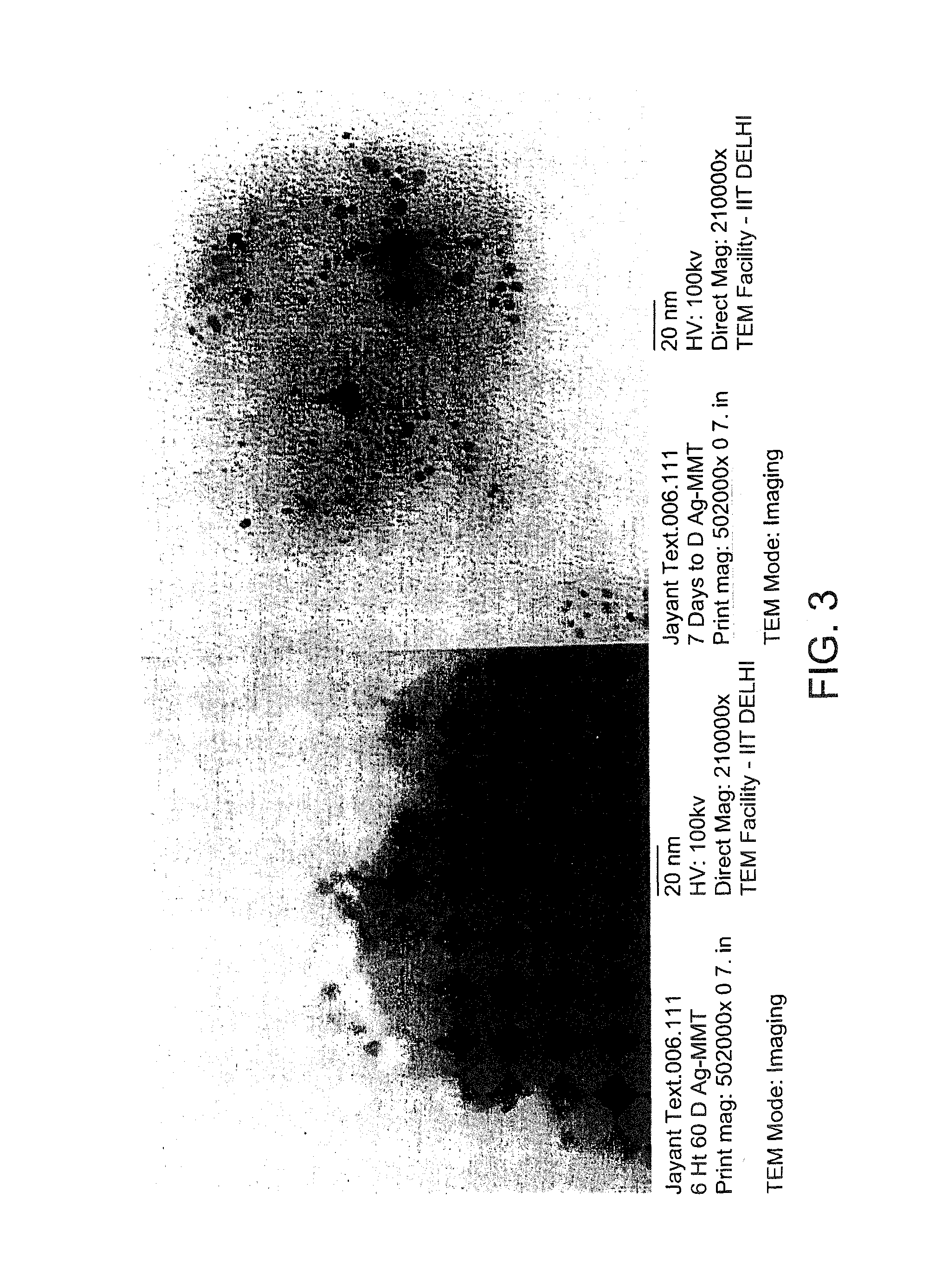

Antimicrobial nanocomposite compositions, fibers and films

ActiveUS9192625B1Prevent bacterial growthImprove thermal stabilityAluminium/calcium/magnesium active ingredientsNon-woven fabricsEscherichia coliFiber

In the present disclosure, silver ions, copper ions, quaternary ammonium compounds and cationic drugs such as sulphanilamide, chlorhexidine acetate, etc., used as antibacterial agents are incorporated into fibers, filaments and films through nanoclays. The nanoclays serve as a carrier for the antimicrobial agents and are incorporated into the fiber-forming polymer. In one embodiment, the biocidal metals and organic compounds are incorporated into the clay structure via an ion exchange reaction. Nylon nanocomposite filaments and films based on copper and quaternary ammonium ion modified clays provide 100% antibacterial activity against Gram positive Staphylococcus aureus and Gram negative Escherichia coli bacteria at an optimum clay loading of 0.75% (by weight), and the activity is retained up to 50 washes. The resulting filaments show enhanced mechanical properties such as tensile strength and modulus, and find application in areas of medical textiles like sutures, wound dressings and health & hygiene textiles. In addition, they can be integrated into protective clothing, body garments, sportswear and upholstery.

Owner:INDIAN INST OF TECH DELHI

Production method of anti-myopia paper

ActiveCN102154925AIncrease productivityHigh mechanical strengthWater-repelling agents additionPaper coatingFiberChemical products

The invention provides a production method of an anti-myopia paper. The method comprises the steps of: impregnating a wheat straw raw material by chemical medical liquid; pretreating under a normal-pressure and low-temperature condition; separating and thinning fiber by a mechanical twisting, grinding and fiber-separating method; and copying into a paper on a paper maker. The directly-obtained color of the paper is yellow, the yellow fiber paper with different depth degrees can be produced according to the difference of the chemical products and the treatment conditions, the paper is used for the book for the school children or the reading magazine, and the paper has the function of myopia resistance without dazzling. The paper produced by the method is higher in yield and better in mechanical strength, wherein the yield of the paper is more than 60%, the rupturing length of the paper is more than 6.0km, the rupturing-resistant index is more than 4.2kPa.m<2> / g, the rupturing index is more than 3.20mN.m<2> / g, and the folding strength of the paper is more than 100 times.

Owner:SHAANXI UNIV OF SCI & TECH

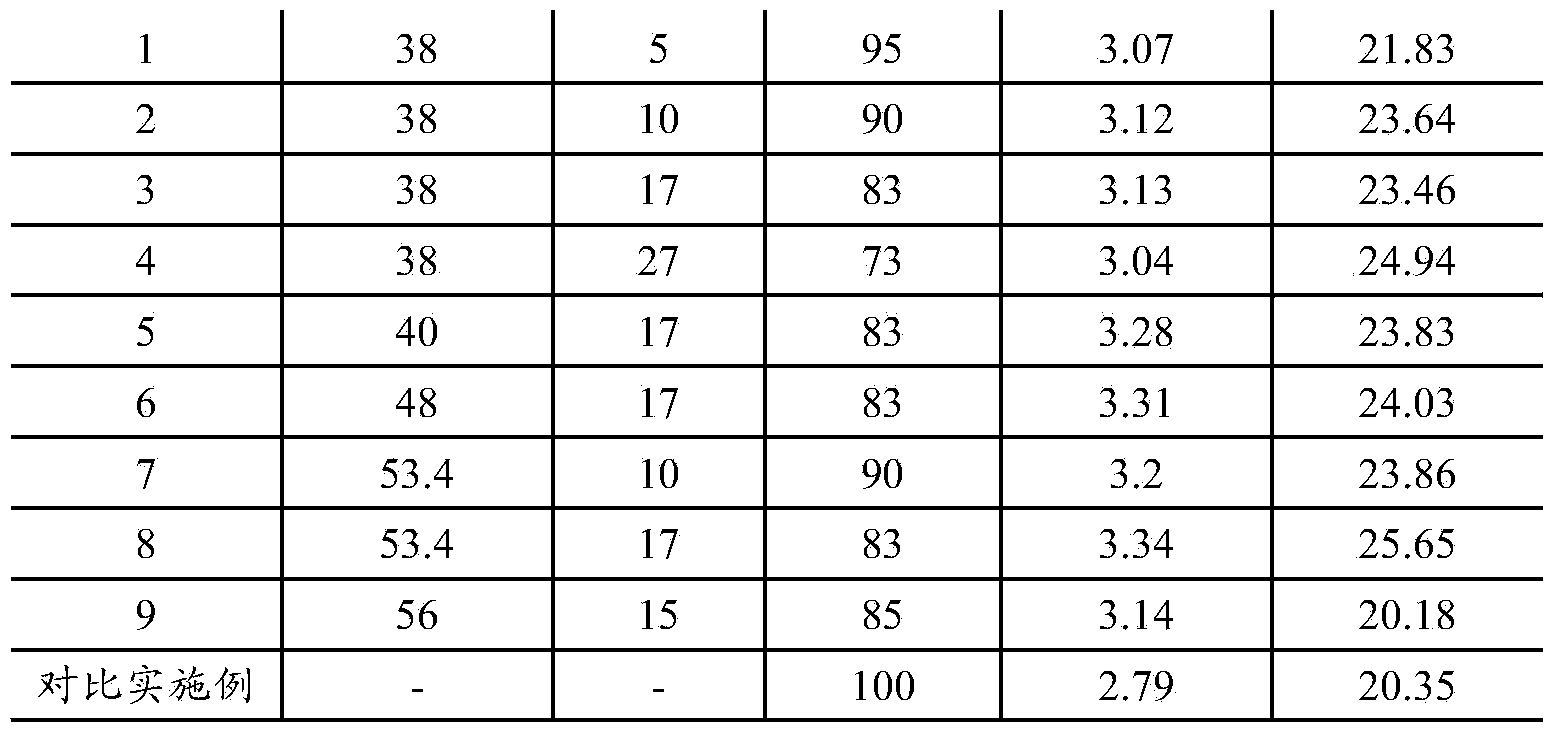

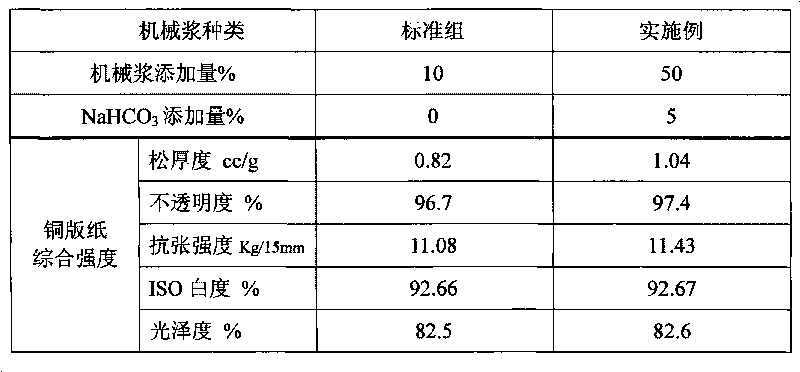

Method for manufacturing art paper with high content of mechanical pulp and art paper manufactured therefrom

ActiveCN101698985AHigh fiber strengthIncrease mechanical pulp contentPaper/cardboardChemical and mechanical pulp mixturePre treatmentSizing

The invention discloses a method for manufacturing art paper with high content of mechanical pulp and the art paper manufactured therefrom, the art paper comprises base paper made from paper pulp, the base paper contains 50%-60% of the mechanical pulp. The manufacturing method comprises the steps: pretreating the refined paper pulp by adding pretreating auxiliary agent with the concentration of sizing agent controlled between 1.5% and 6%, the addition amount of the pretreating auxiliary agent being 0.1-10% in relation to absolute dry pulp, the preteating time being 20-60 minutes and the pretreating time being 30-70 DEG C, resulting in the pretreating sizing agent, mixing the preteating sizing agent with untreated sizing agent, and applying the mixture to the manufacturing of the art paper directly, wherein the content of the mechanical pulp is 50%-60%. The manufacturing method is simple, safe and reliable. The manufacturing method can dramatically promote the content of the mechanical pulp in the art paper and economize on the consumption of wood in the process of papermaking. Meanwhile, the increased content of the mechanical pulp is favorable for lowering the production cost of papermaking industry.

Owner:GOLD EAST PAPER JIANGSU

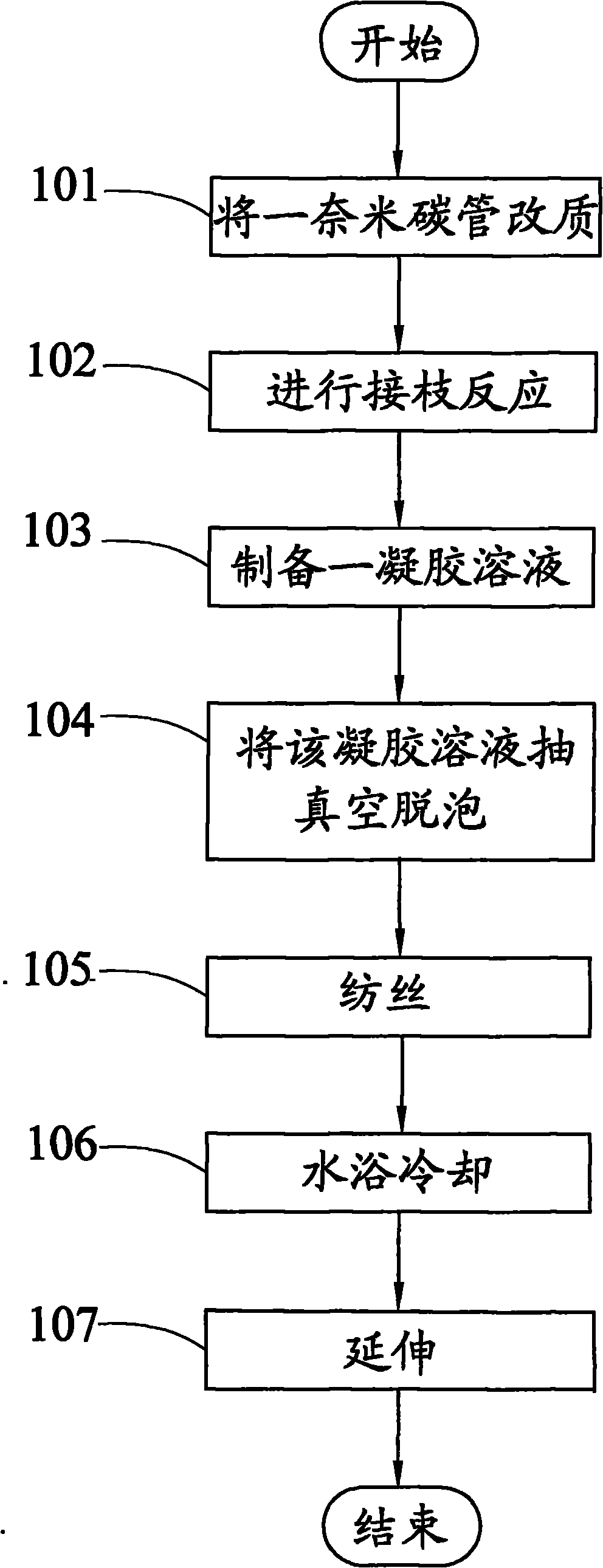

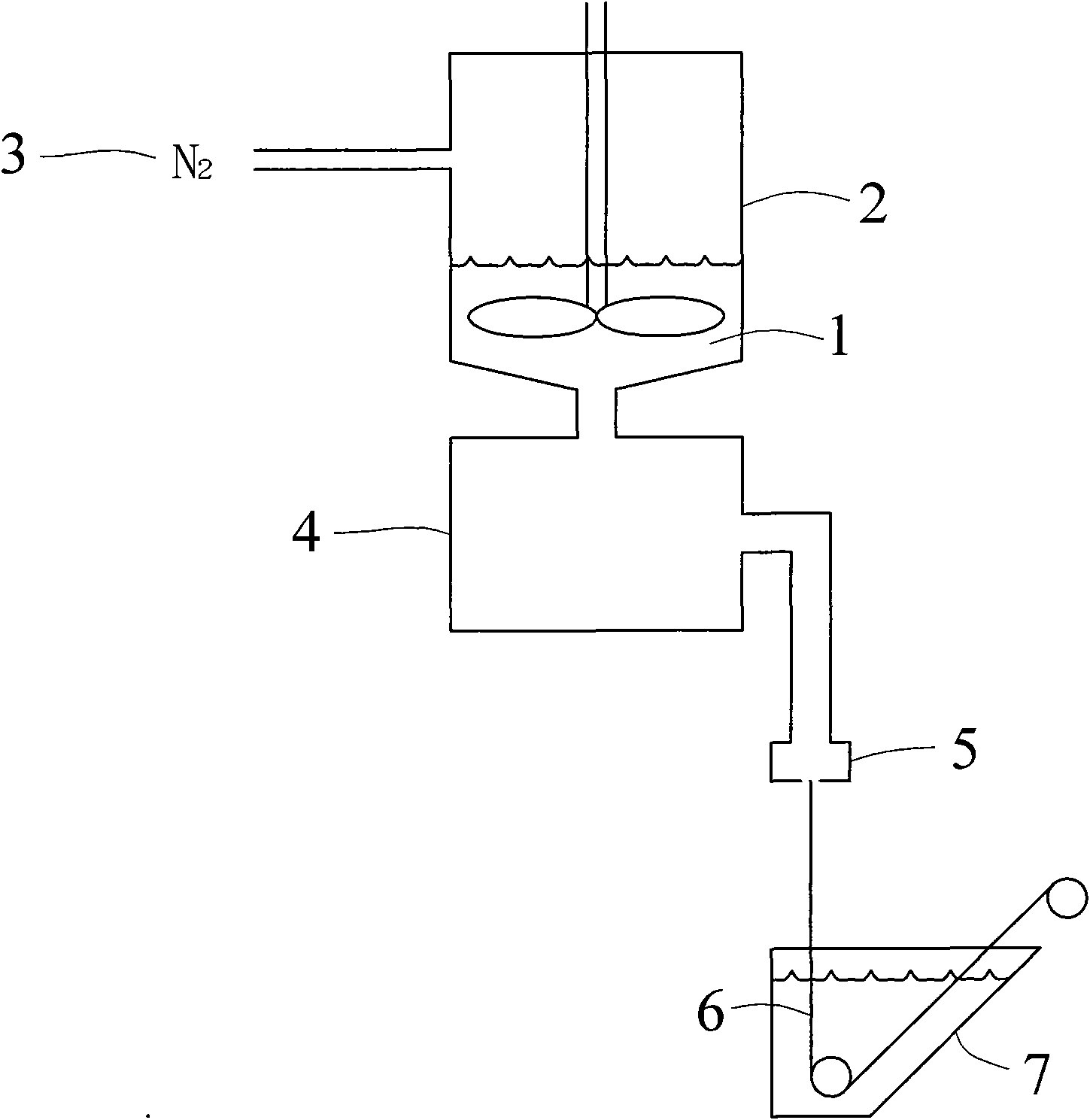

Ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and manufacturing method of high-performance fiber thereof

InactiveCN101988221AHigh fiber strengthLess frizzMelt spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses an ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and a manufacturing method of high-performance fiber thereof, belonging to the field of a composite material.The manufacturing method of the composite material comprises the following steps: preparing UHMPE and a nano-inorganic substance, such as attapulgite, a carbon nanotube, sepiolite, wollastonite, montmorillonite and the like into gel solution; in the case of light transmittance close to zero under certain concentration, heating the gel solution for dissolving; and vacuumizing, defoaming, spinning with different spinneret boards containing various spinneret angles as well as feed length and discharge length, carrying out air-quenching, carrying out aqueous-phase curing, performing multi-segment temperature change extension and the like to finally obtain the composite material for the ultra-high strength fiber the light transmittance of which is close to zero. The obtained composite material can increase the strength and modulus of UHMPE fiber and solve the defects of the UHMPE fiber, such as high crimp, high creep, light transmittance and the like.

Owner:叶正涛 +1

Method for utilizing graphene to modify filter-material fiber of bag-type deduster

A related method for utilizing graphene to modify filter-material fiber of a bag-type deduster comprises the following steps: 1) taking graphite as a raw material, using an oxidation-reduction method to prepare graphene, dispersing graphene in water or an organic solvent; 2) mixing 3-aminopropyltriethoxysilane and the like as a coupling agent with ethanol according to a volume ratio of 1:3, and uniformly spraying the mixture on the surface of the filter-fiber filter material; 3) employing an immersing or spraying manner to coat the surface of the filter-fiber filter material obtained in the step (2) with the graphene sol prepared in the step (1); and 4) performing natural-placing stabilization on the filter-material fiber obtained in the step (3) for 24 h, then utilizing water or a light solvent to clean, and putting the filter-fiber filter material in a vacuum drying box and baking at 110 DEG C for 10 h. Compared with the prior art, the method helps to substantially improve performances of the filter-material fiber by utilizing modification of graphene to the filter material of the bag-type deduster, and has extremely good industrial utilization value.

Owner:SHANGHAI JIAO TONG UNIV +1

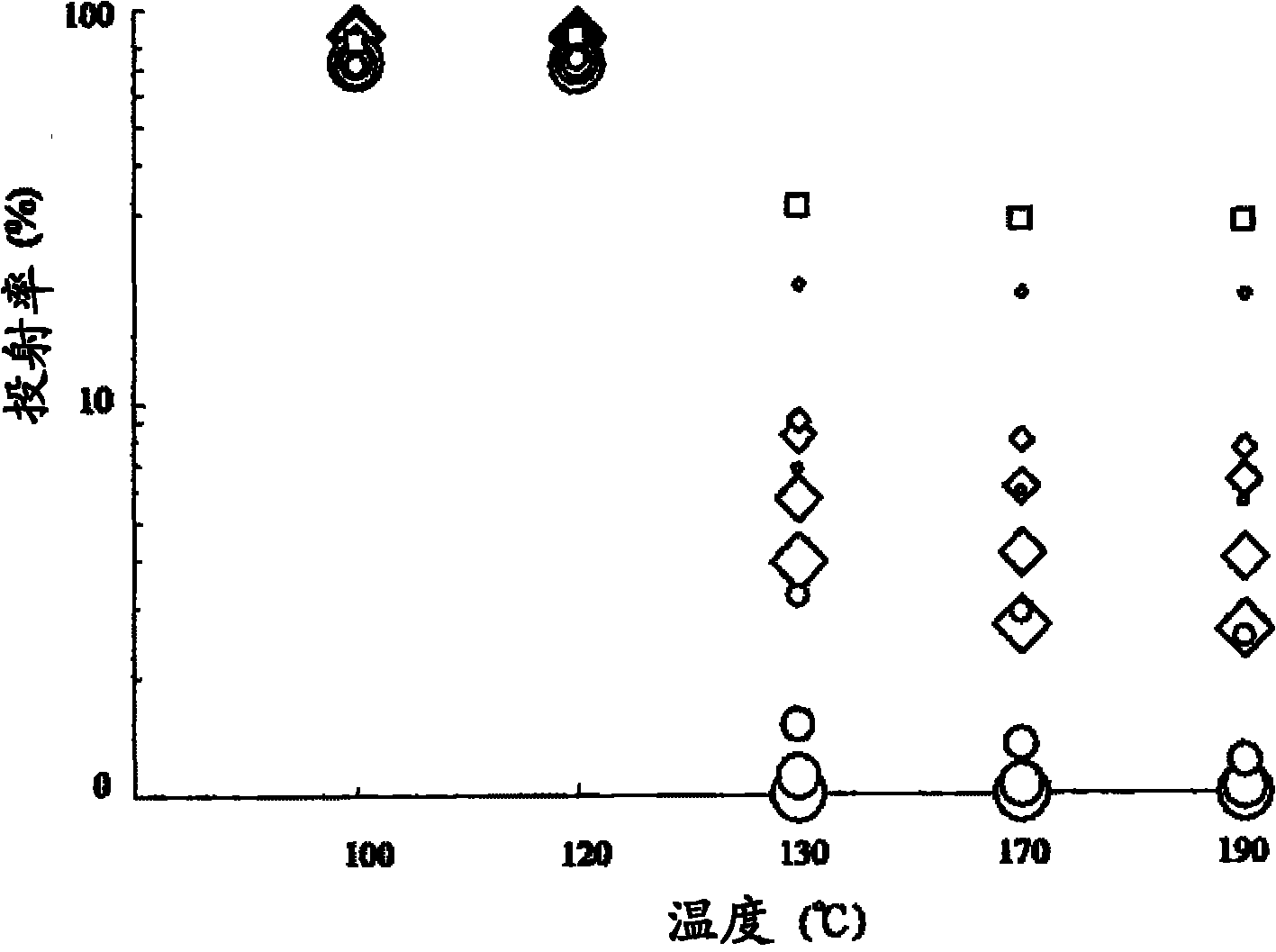

Photochromic composite fiber

ActiveCN109402780ADecay of Photochromic PerformancePhotochromic performance does not attenuateFilament/thread formingConjugated synthetic polymer artificial filamentsAntioxidantUltraviolet

The invention provides photochromic composite fiber. The fiber comprises a skin layer and a core layer, wherein the skin layer is a fiber-forming polymer, a proper flame retardant, a proper softener and a proper air tightness enhancer are added, the core layer is a thermoplastic fiber-forming polymer, and photochromic dye, an antioxidant, a spinning aid, a thermal stability and a sensitizer are added in a certain proportion. A photochromic material and functional additives are doped in the core layer material of the fiber, then, a skin-core composite structure is constructed through melt spinning, the core layer is packaged by the skin layer containing the functional aids, so that the stability of the photochromic material in the core layer material is improved, accelerated aging tests areconducted under the conditions that ultraviolet rays are higher than 4000 muW / cm<2>, the temperature is 40 DEG C and the humidity is normal, the photochromic capacity of the fiber can be kept for 70-110 h, and meanwhile, the fiber has excellent photochromism, short response time, high repeatability, long service life, excellent mechanical performance and the like.

Owner:TIANJIN UVOS TECH CO LTD

Biodegradable graphene oxide biocomposite fibrous membrane, preparation method and uses thereof

PendingUS20200330641A1Good chemical stabilityImprove mechanical propertiesSuture equipmentsPharmaceutical delivery mechanismFiberPolymer science

The invention relates to a biodegradable graphene oxide biocomposite fibrous membrane and a preparation method and uses thereof. The composite fibrous membrane comprises biodegradable graphene oxide biocomposite fibers, each fiber has an outer layer consisting of graphene oxide-biodegradable polymer nanofibers and an inner layer consisting of sodium alginate / polyvinyl alcohol nanocomposite fibers. The biodegradable graphene oxide biocomposite fibrous membrane of the invention has the advantages of good biocompatibility, biodegradability, swellability, bacteriostasis and good mechanical properties and chemical stability.

Owner:JIANG SHULAN

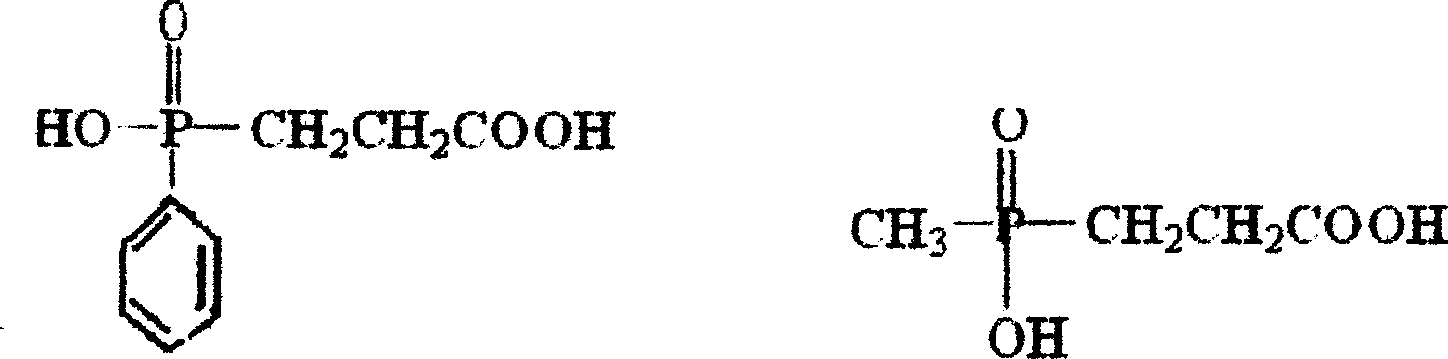

Flame retardance poly- p-benzene dicarboxylic acid trimethylene glycol ester and method for producing the same

The invention discloses a flame-proof polyytrimethylene terephthalate alcohol and preparing method, which is characterized by the following: incorporating phosphoric system combustion inhibitor element; counting with phosphorus content; making up 0. 3%-1% polyytrimethylene terephthalate alcohol; preparing methyl glycol solution of phosphate ester; adding into terephthalic acid; proceeding esterification and polycondensation reaction with 1, 3 methyl glycol; getting the product. This product possesses simple course and good property, which fibre intensity is high.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Preparation technology of far-infrared cotton fiber

ActiveCN104695227AGood antibacterial effectImprove adsorption capacityBiochemical fibre treatmentVegetal fibresCross-linkApocynum venetum

The invention discloses a preparation technology of far-infrared cotton fiber. The preparation technology comprises the steps of preparing raw materials, treating the raw materials, preparing a far-infrared mixed solution, carrying out coating treatment and spinning. The preparation technology is simple in method; the far-infrared coating mixed solution is prepared by mixing far-infrared ceramic powder with a resin bonding agent, a cross-linking agent, a dispersing agent and the like; the treated raw material fiber is coated with the far-infrared coating mixed solution, and the far-infrared coating mixed solution is firmly combined with the raw material fiber, so that the far-infrared fiber is good in effect. An ultraviolet light absorber is also added to the far-infrared coating mixed solution and is dipped into the cotton fiber, so that the finished product fiber has an ultraviolet resistant function. The cotton fiber is refined by alkaline biological enzyme, and alkali treatment is replaced, so that the preparation technology is low in damage to fiber and is beneficial to maintaining fiber strength; apocynum venetum fiber and activated carbon fiber are added into the raw material fiber for use, so that the finished product fiber also has a good antibacterial effect.

Owner:浙江世纪晨星纤维科技有限公司

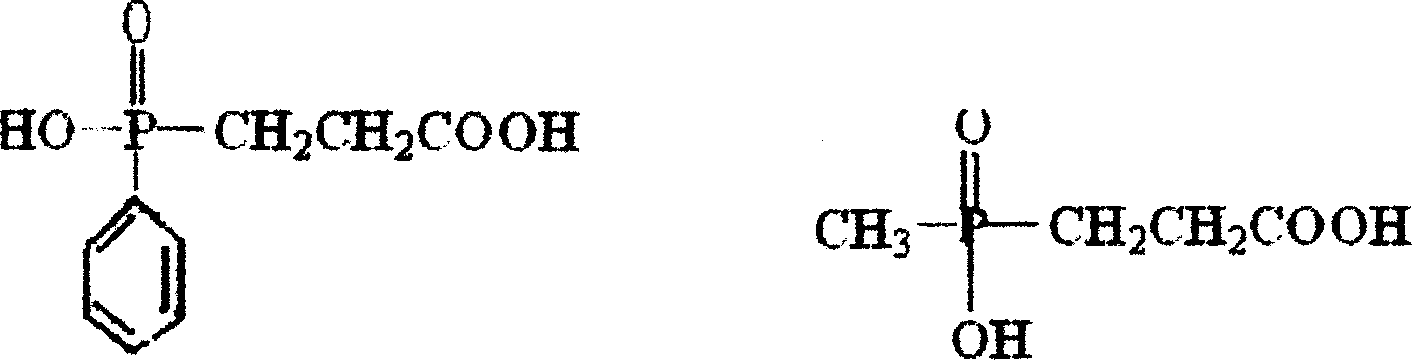

Double-fibre compact spinning device

The invention provides a novel double-fiber close spinning device, consisting of two main parts of a double top roller subassembly and a hollow roller subassembly, wherein in the double top roller subassembly, a top roller(2) and a top roller(4) are arranged on a top roller frame(5), on which an airflow orientation block(11) is arranged by a positioning board(10), a spring(3) is arranged on the top roller frame(5), a permanent magnet(12) is arranged on the airflow orientation block(11); in the hollow roller subassembly, a wide vacuum nozzle(7), an air suction base(9) and a baffle board(6) are jointly assembled in hollow roller rings(8), which are arranged on a main shaft(14) in pairs; the double top roller subassembly is arranged on a cradle(1) and exerts pressure on the hollow roller subassembly. The yarn spun by the device has few hairy feathers and little fly waste and is low in fiber strength.

Owner:陆节 +1

Method for manufacturing a complexly shaped composite material part

ActiveUS8846147B2Preserve deformation capacityHigh fiber strengthBlade accessoriesPretreated surfacesGas phaseChemical vapor infiltration

A method of fabricating a complex part out of composite material including three-dimensional woven fiber reinforcement densified by a matrix, the method including three-dimensionally weaving a continuous fiber strip including a succession of fiber blanks for preforms of a plurality of parts that are to be fabricated; subsequently cutting individual fiber blanks out from the strip, each blank being a one-piece blank; shaping a cut-out blank to obtain a one-piece fiber preform having a shape that is close to the shape of a part that is to be fabricated; consolidating the preform in the desired shape; and densifying the consolidated preform by forming a matrix by chemical vapor infiltration.

Owner:SAFRAN CERAMICS SA +1

Impregnating compound for basalt fibers

The invention discloses a special impregnating compound for basalt fibers and a preparation method of the impregnating compound. The impregnating compound comprises raw materials in percentage by weight as follows: 2%-10% of water-soluble epoxy resin, 1%-8% of polyvinyl alcohol, 0.5%-1.0% of a coupling agent, 0.2%-0.8% of an antistatic agent, 0.08%-0.25% of a pH regulating agent and the balance of deionized water. The impregnating compound for surface modification of the basalt fibers is prepared in the rated weight proportion and directly coats surfaces of the basalt fibers during basalt production drawing, surface modification is completed after drying, and the impregnating compound is more convenient to use and has the good adhesion and film-forming property.

Owner:晏玲莉

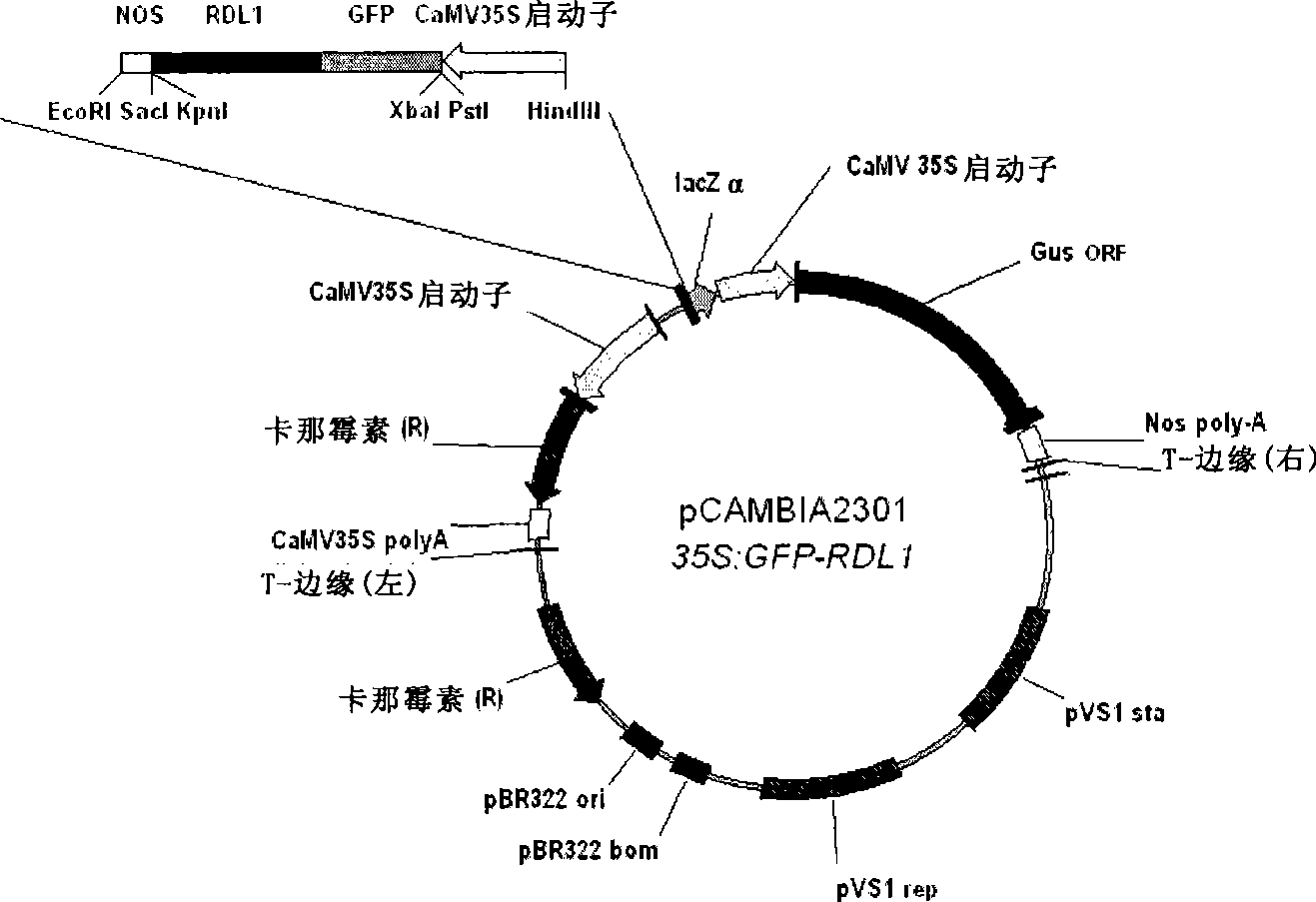

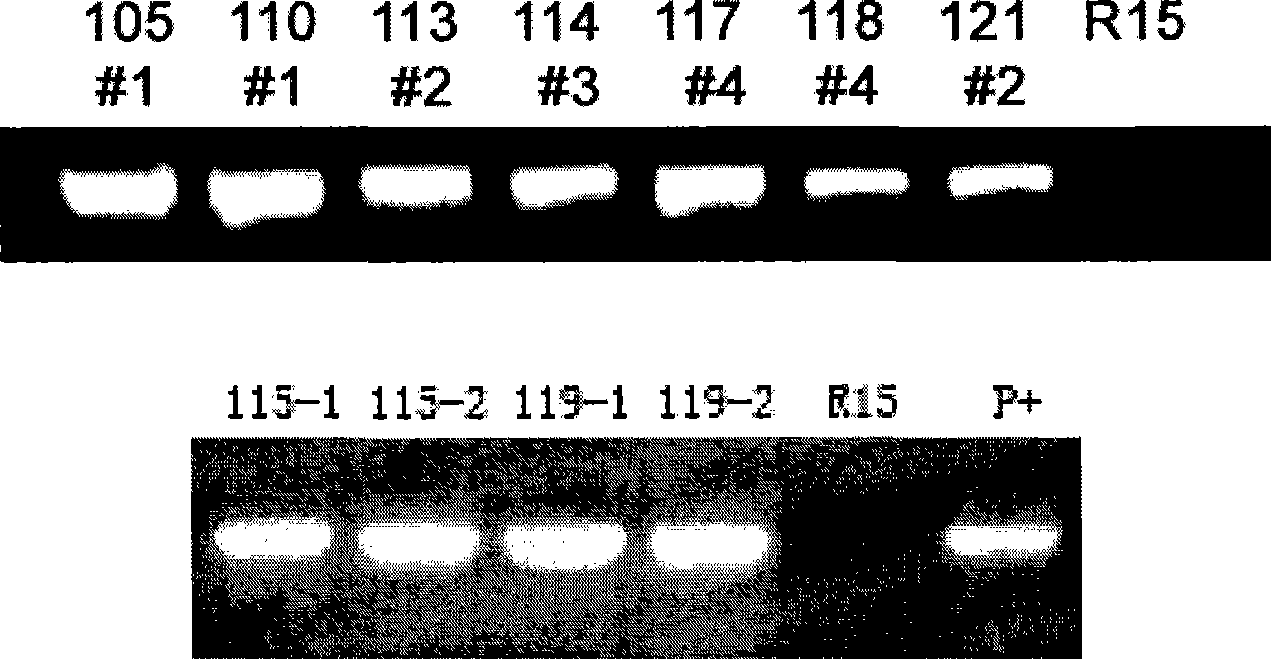

Method for promoting plant seed augmentation and cotton fibre growth by using RDL1 gene

The invention provides application of a plant RDL1 gene or RDL1 protein in improving properties of crops seeds, and a method for improving properties of crops seeds. Particularly, the invention provides a gene engineering method for promoting the crops seeds to enlarge and cotton fiber to lengthen by utilizing the plant RDL1 gene. The invention also provides a vector containing the RDL1 gene, a host cell, a method for preparing transgenic plants and a method for obtaining seeds with improved properties through the transgenic plants. The method can increase the volume of the seeds and the weight of the seeds, and lengthen seed fiber and / or increase the strength of the seed fiber, plays a positive role in improving the yield and properties of crops, and has extensive application prospects.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

Fiber optics dental post

A fiber optics dental post includes a resin body and plural fiber optics center shafts; wherein the resin body includes an outer peripheral face, a receiving irradiation portion, and a bottom; each of the fiber optics center shafts pierces through and is fixed in the resin body, and has a receiving irradiation end and a light-guide irradiation end; each receiving irradiation end placed on the receiving irradiation portion of the resin body is used to receive the light irradiating on the receiving irradiation portion, and each light-guide irradiation end is respectively placed on the outer peripheral face and at the bottom of the resin body, thus the light received by each receiving irradiation end is propagated to the outer peripheral face and the bottom of the resin body through the light-guide irradiation end for irradiation, so as to effectively enhance the adhesion strength of the dental post.

Owner:TAIWAN FIBER OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com