Method for preparing graphene functionalized alginate fibers

A technology of seaweed fiber and ene function, applied in the chemical field, can solve the problems of high cost, seriousness, low strength of seaweed fiber, etc., and achieve the effect of improving tensile strength, high tensile strength and fiber strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

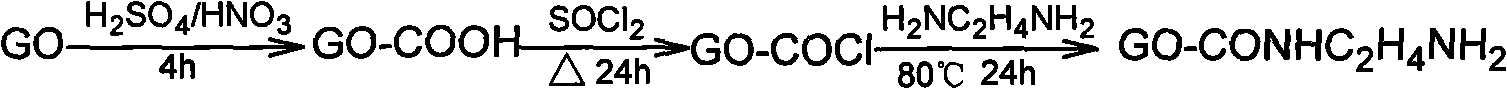

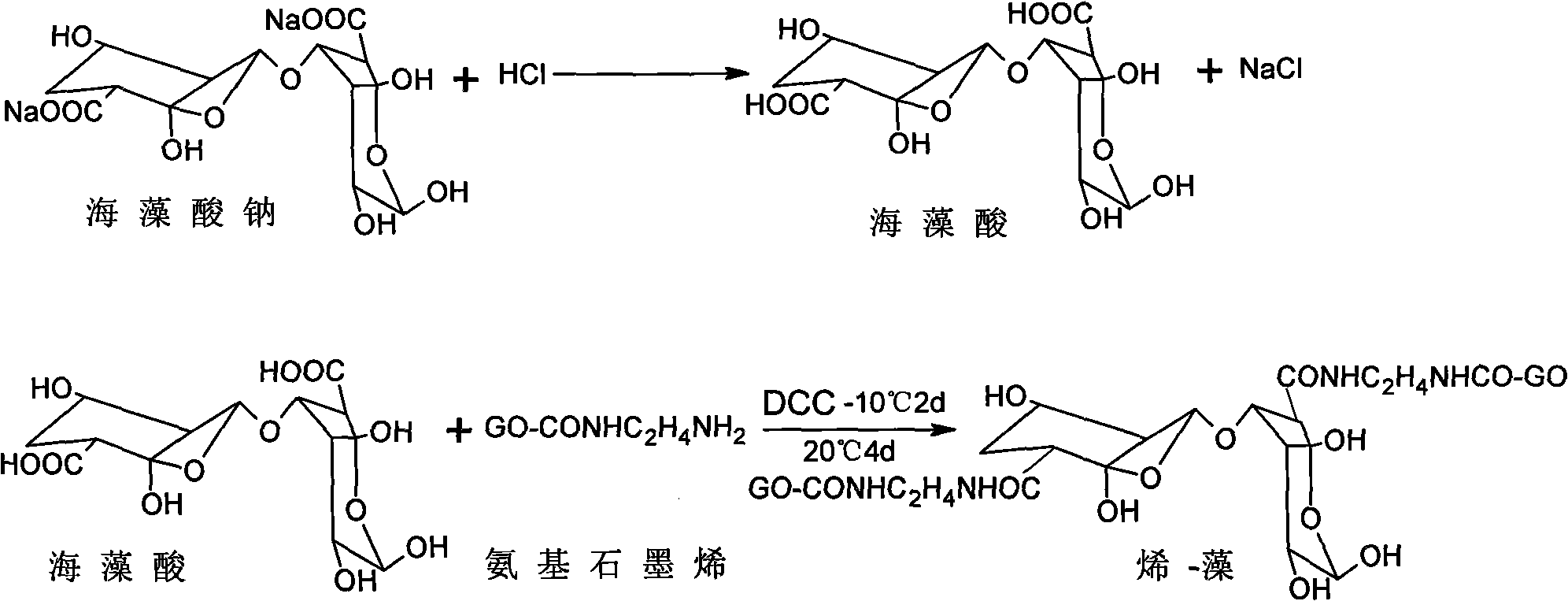

Method used

Image

Examples

Embodiment 1

[0034] Weigh 30g of sodium alginate and add it to 470ml of distilled water, fully stir and dissolve to obtain a sodium alginate solution with a mass percent concentration of 6%; weigh 0.06g of graphene and add it to the above sodium alginate solution, continue stirring for 30min, and then Sonicate in ultrasonic for 30 minutes to obtain a uniformly dispersed alkene / algae (graphene / sodium alginate) solution. Add hydrogen peroxide to the alkene / algae solution to adjust the viscosity of the solution to 2600mPa·S, then filter and vacuum defoam for 13 hours to obtain the alkene / algae spinning solution. Adjust the temperature of the algae / algae spinning solution to 50°C, use a spinneret with 70 holes and 75 microns to wet spin the spinning solution at a spinning speed of 28 m / min, and then pass the alkene / algae spinning solution through The thin stream formed by the spinneret enters the calcium chloride aqueous solution with a temperature of 40° C. and a mass percentage concentration...

Embodiment 2

[0036] Repeat Example 1, with the following differences: 0.12g of graphene is weighed and added to the sodium alginate solution.

Embodiment 3

[0038] Repeat Example 1, with the following differences: 1.5g of graphene is weighed and added to the sodium alginate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com