Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

463 results about "Erucyl amide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonwoven fabric, process for producing the same, sanitary material and sanitary supply

InactiveUS20030157859A1Feel goodSuitable for useLayered productsAbsorbent padsStatic friction coefficientPolyolefin

Polyolefin resin-based non-woven fabric characterized by containing a fatty acid amide compound, and by having a static friction coefficient of 0.1 to 0.4. Production of such non-woven fabric is achieved by subjecting, for example, non-woven fabric containing 0.05 to 1 wt. % erucamide to an aging treatment at 30 to 60° C. for 5 to 50 hours.

Owner:IDEMITSU UNITECH CO LTD

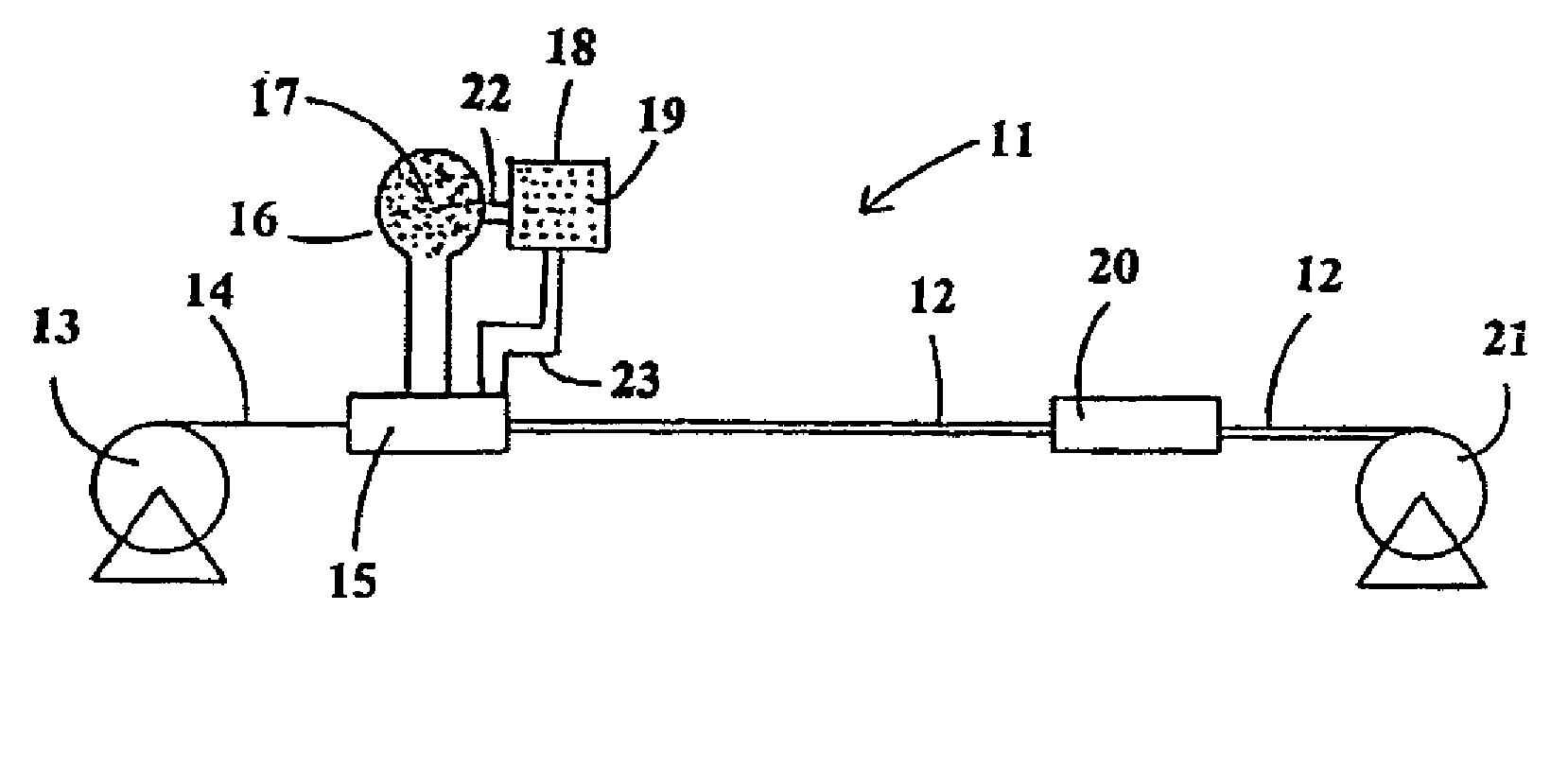

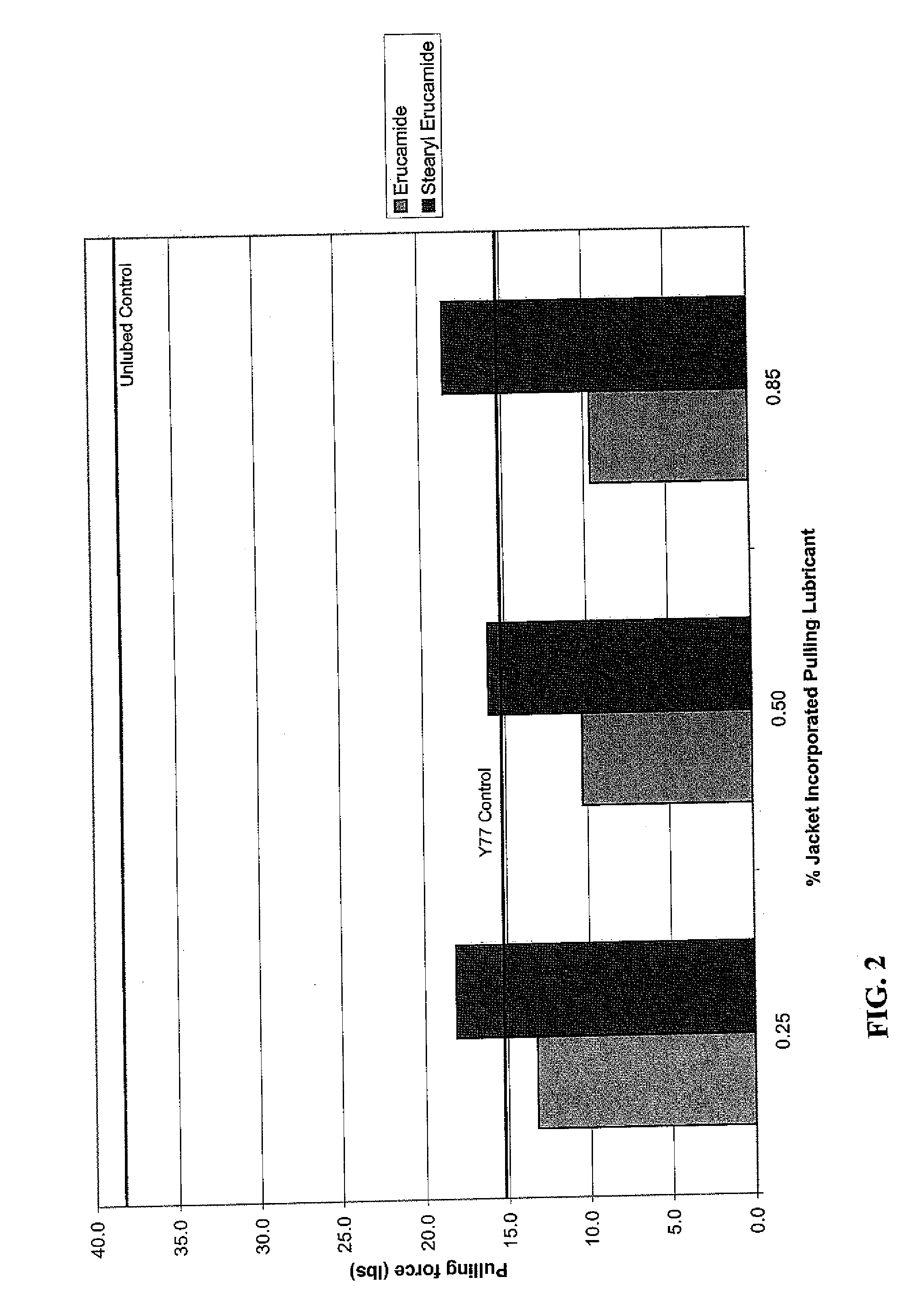

Method of manufacturing electrical cable, and resulting product, with reduced required installation pulling force

ActiveUS20100230134A1Reduce coefficient of frictionLower surfaceLine/current collector detailsLiquid organic insulatorsNylon materialElectrical conductor

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

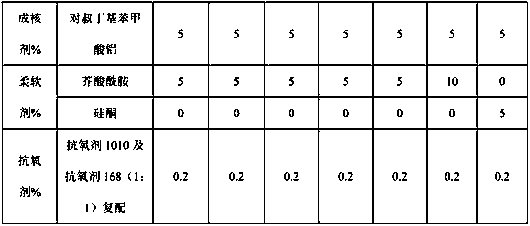

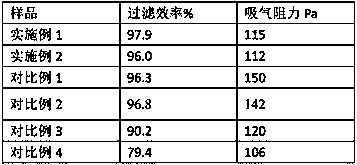

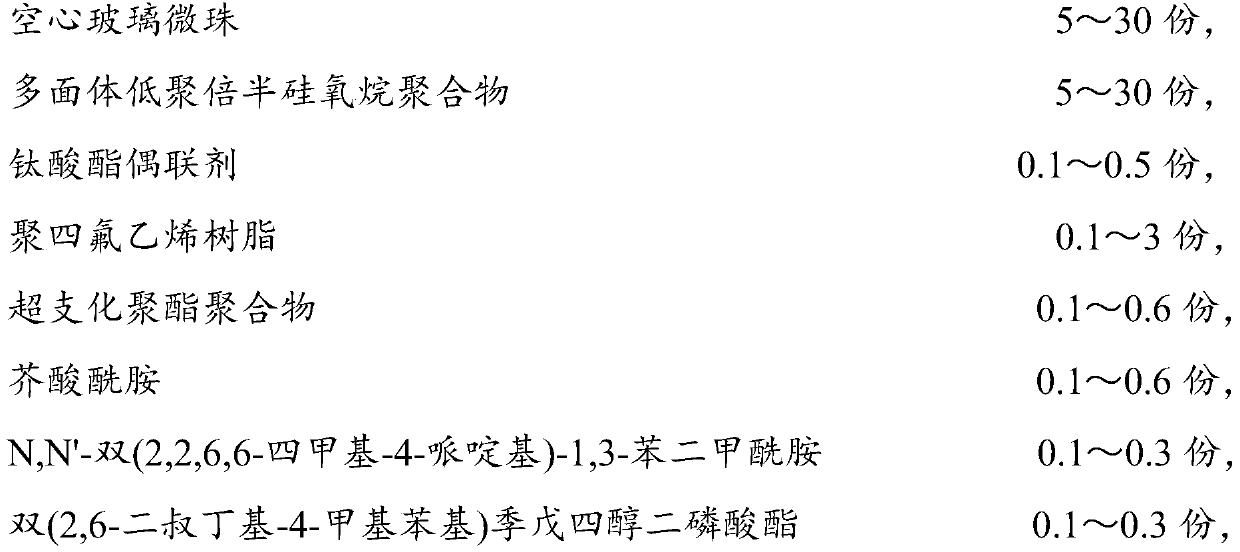

Electret master batch for melt-blown non-woven fabric for low-resistance mask and preparation method of electret master batch

ActiveCN111484678ALow breathing resistanceImprove filtration efficiencyNon-woven fabricsPolymer scienceMelt flow index

The invention discloses electret master batch for melt-blown non-woven fabric for a low-resistance mask and a preparation method of the electret master batch. The electret master batch for the melt-blown non-woven fabric for the low-resistance mask is prepared from the following components in percentage by weight: 65-85% of polypropylene resin; 1-3% of electret powder; 5-15% of a dispersant; 3-10%of a nucleating agent; 3-10% of a softening agent; 0.05%-0.5% of a processing aid; wherein the softening agent is erucyl amide; the polypropylene resin is homo-polypropylene and / or co-polypropylene,and the melt index MFI of the polypropylene resin is 230 DEG C / 2.16 kg and is not lower than 1000 g / 10 min. According to the electret master batch, the softening agent, the nucleating agent and othercomponents are added, so that when the electret master batch and the ultra-high melt index polypropylene are mixed to be used for producing the melt-blown non-woven fabric for the mask, the obtained melt-blown non-woven fabric for the mask can have low respiratory resistance while having high filtering efficiency, and therefore the electret master batch is particularly suitable for being used as amask material. The formula does not greatly adjust the formula of the existing electret master batch, and is easy to implement.

Owner:KINGFA SCI & TECH CO LTD +1

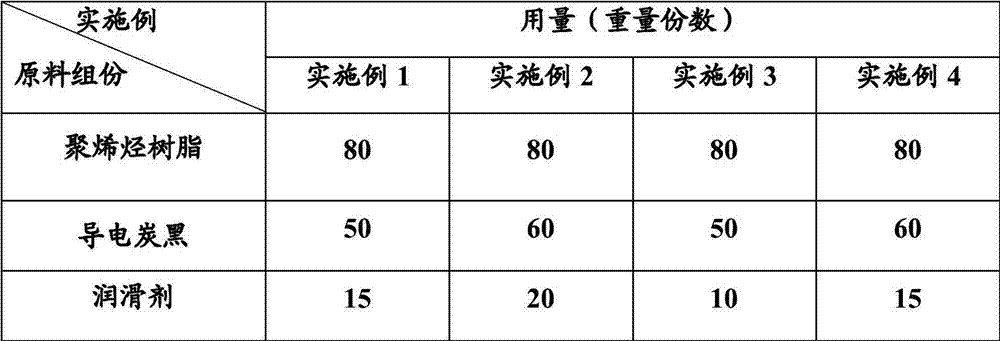

Semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material and preparation method thereof

ActiveCN102863686ADoes not affect mechanical and physical propertiesGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesPolyolefinPolymer science

The invention relates to a semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material and a preparation method thereof. The semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material is made of, by weight, 60-100 parts of polyolefin resin, 40-80 parts of conductive carbon black, 20-40 parts of flame retardant, 1-5 parts of dispersing agent, 0.1-3 parts of stearate, 0.1-3 parts of silane coupling agent, 5-20 parts of lubricant, 2-8 parts of wetting agent, 3-10 parts of antioxidant and 0-3 parts of uvioresistant agent, wherein the dispersing agent is composed of oleamide, erucyl amide or mixture of the oleamide and the erucyl amide. The improved semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material special for ultrahigh-voltage cables is advantageous in comprehensive performances, especially in electricity conductivity, flame retardation performance, low cost and the like.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

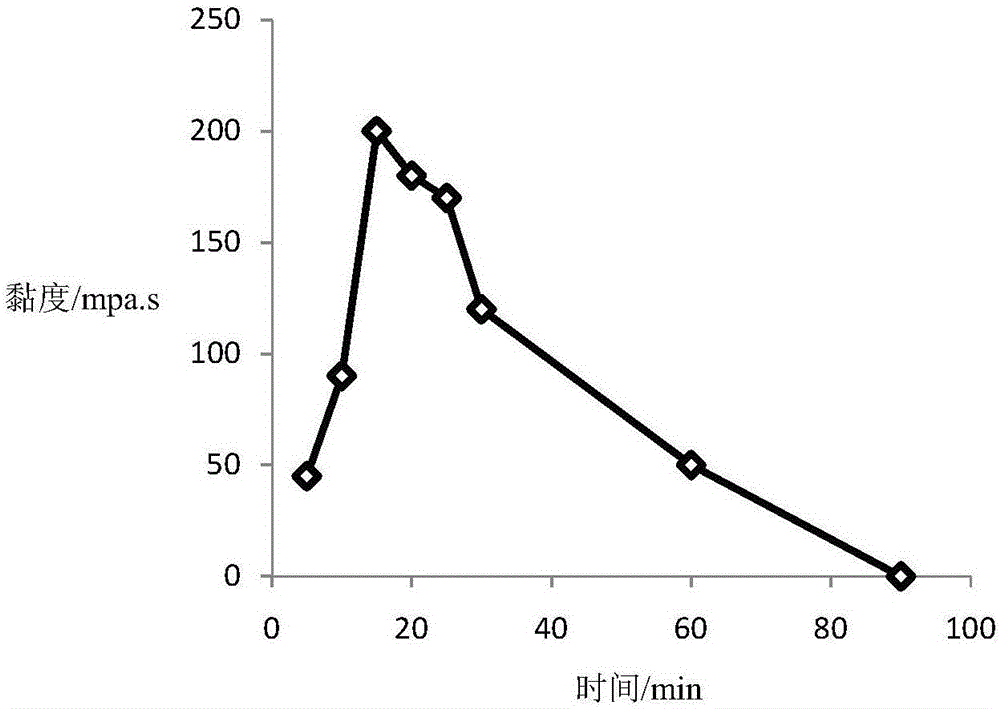

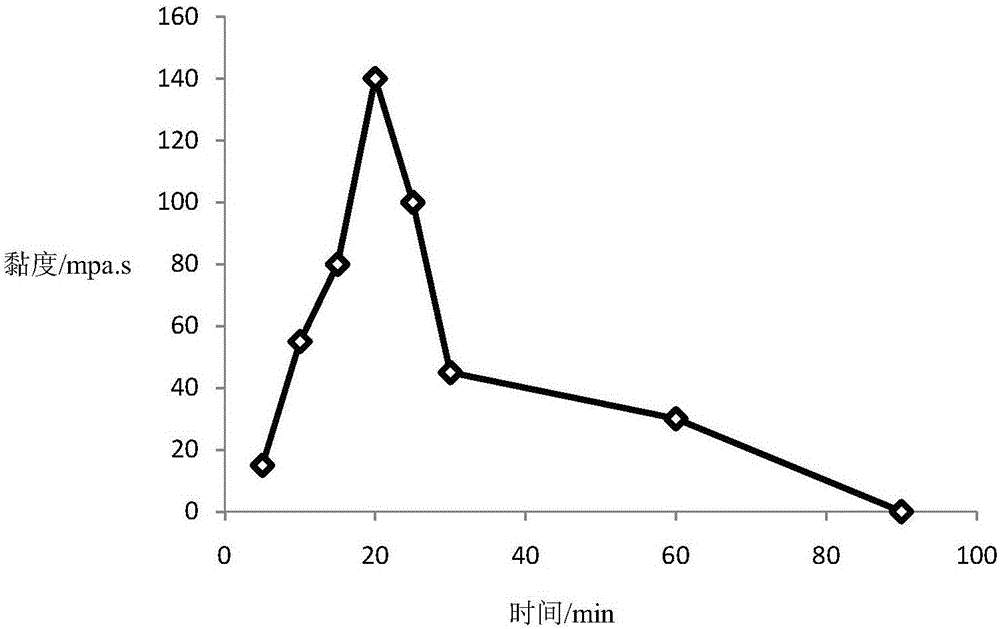

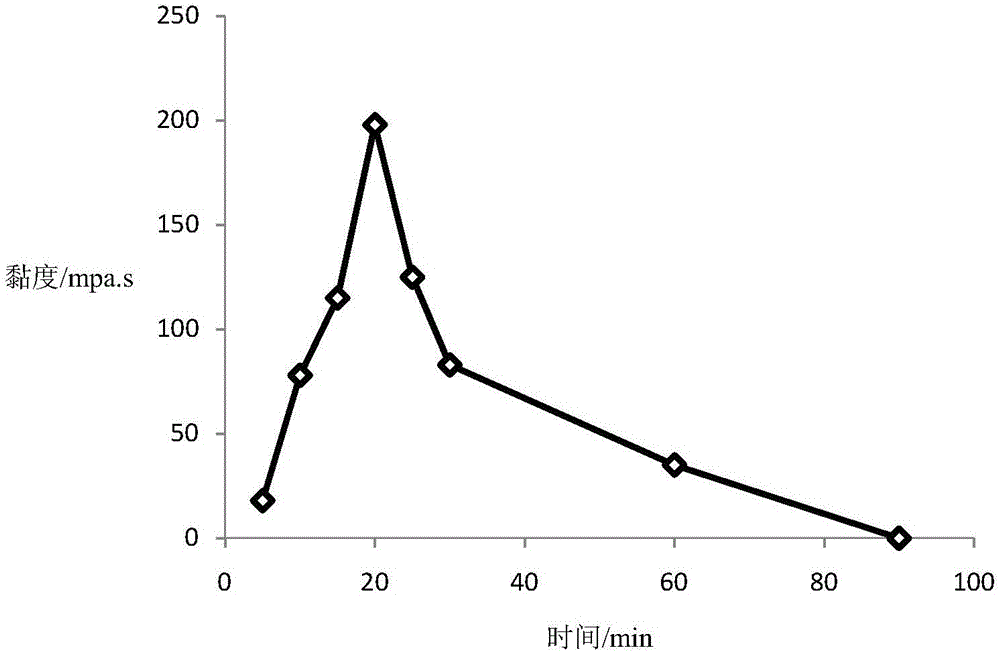

Compound type temperature-resisting viscoelastic self-diverting acid as well as preparation method and application thereof

ActiveCN106634938ACompletely broken glueReduce fluid lossFluid removalDrilling compositionCarbonate rockCocamidopropyl betaine

The invention relates to compound type temperature-resisting viscoelastic self-diverting acid as well as a preparation method and application thereof. The self-diverting acid is prepared from 1.0 to 7.5 weight percent of thickening agent A, 1.0 to 7.5 weight percent of thickening agent B, 32.2 to 75.5 weight percent of concentrated hydrochloric acid, 1.0 to 4.0 weight percent of corrosion inhibitor, 1.5 to 5.0 weight percent of ferric ion stabilizer, 1.5 to 4.0 weight percent of clay stabilizer and the balance of water; the thickening agent A is prepared from one or more of cocamidopropyl betaine, octadecyl dimethyl hydroxypropyl betaine and lauramidopropyl betaine; the thickening agent B is prepared from one or more of erucamide propyl betaine, docosyl dimethyl betaine and erucamide propylsulfobetaine. The self-diverting acid disclosed by the invention is suitable for a carbonate reservoir with the temperature of 80 to 120 DEG C.

Owner:PETROCHINA CO LTD

Fogging surface silky wax feel finishing agent for synthetic leather and preparation method thereof

InactiveCN102191689AComply with environmental standardsGood silky feelFibre treatmentWaxButyl acetate

The invention relates to a fogging surface silky wax feel finishing agent for synthetic leather and a preparation method thereof. The finishing agent comprises modified polyurethane resins, DMF (dimethyl formamide), butyl acetate, silica matting powder, modified amino siloxane, dimethicone, erucyl amide, polyurethane color beads and an organosilicon leveling agent. The finishing agent has the following advantages: the fogging surface matting effect is excellent, the silky wax feel is unique and the real leather effect of the leather surface is strong; and the synthetic leather applying the finishing agent has silky handfeel and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

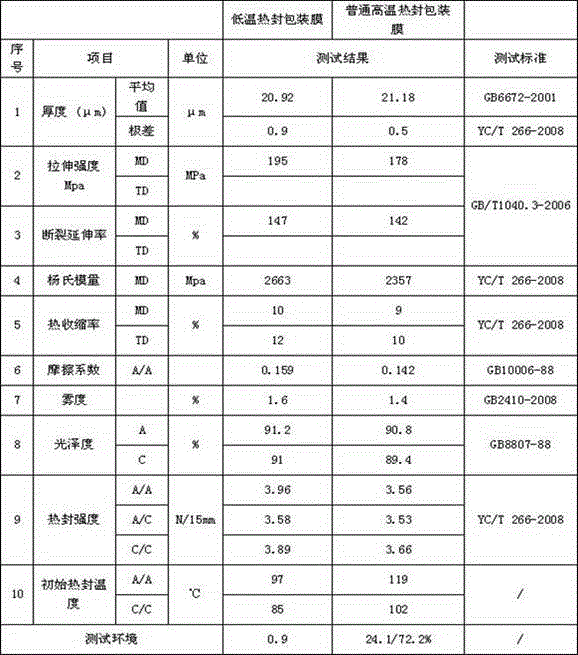

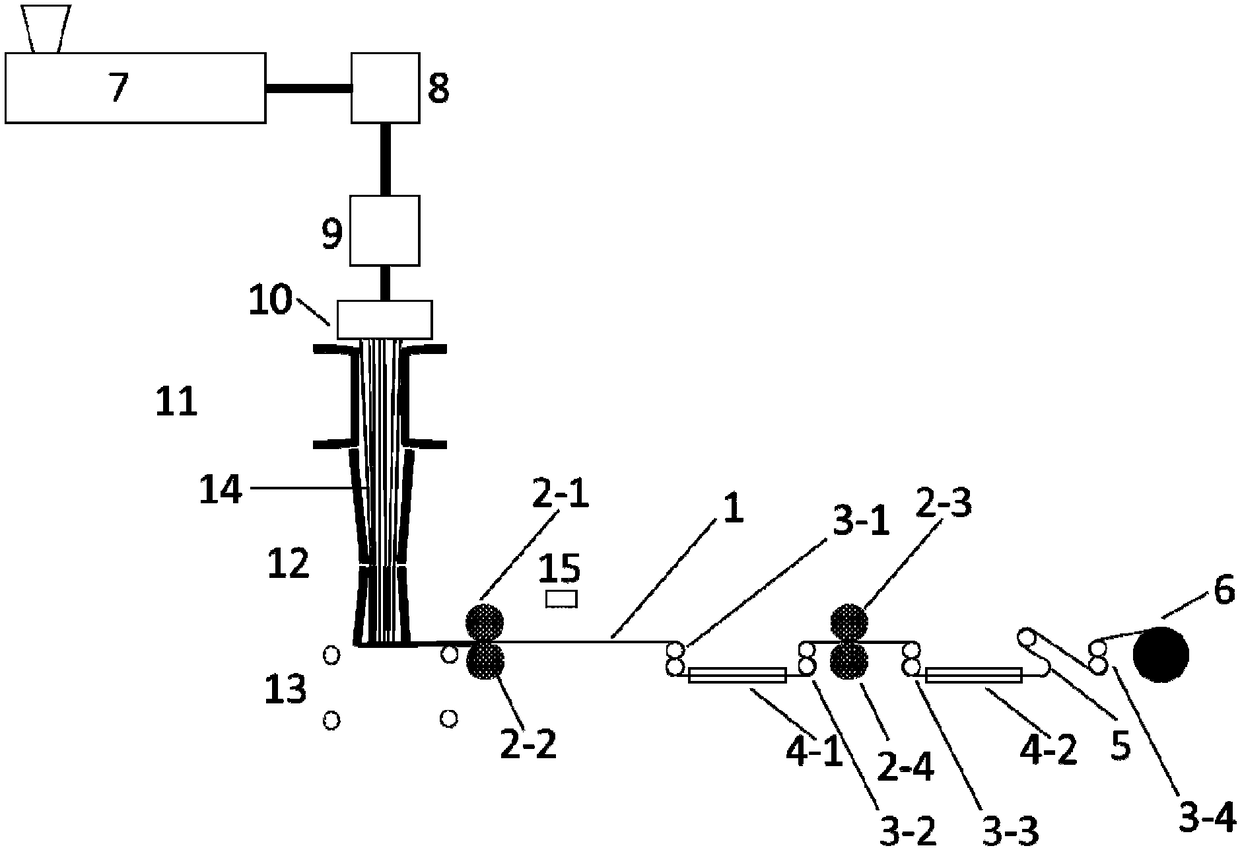

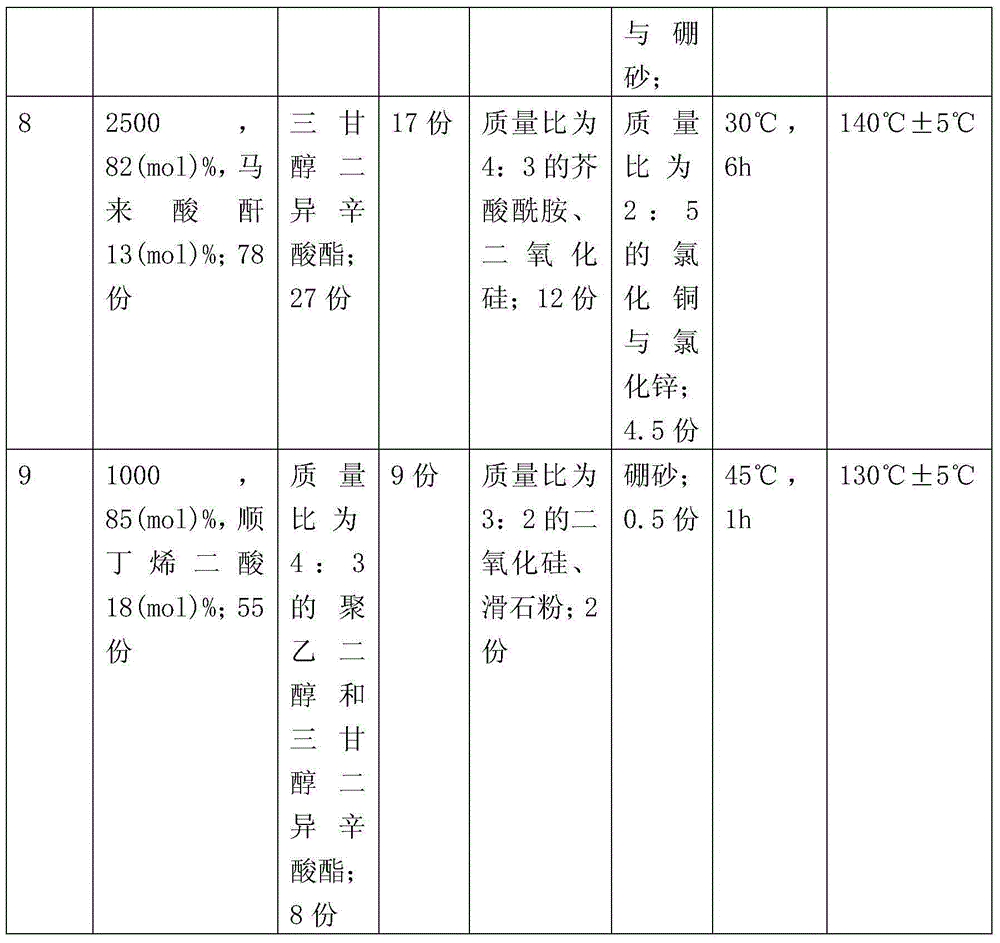

Low-temperature heat-seal shrinking packaging film used for cigarettes and manufacturing method thereof

InactiveCN105619990AReduce heat sealing temperatureReduce energy consumptionSynthetic resin layered productsLaminationElastomerMasterbatch

The invention relates to a low-temperature heat-seal shrinking packaging film used for cigarettes. The packaging film comprises a surface layer A, a core layer B and a surface layer C; the surface layer A is prepared from, by mass, 70-80 parts of an ethylene-butene-propylene terpolymer, 2-10 parts of an ethylene-butene copolymer, 12-22 parts of a slipping agent, 3-13 parts of an antisticking agent and 0.5-1.5 parts of a wear-resisting agent, wherein the slipping agent is composed of erucyl amide and dimethicone, and the antisticking agent is composed of PMMA and silicon dioxide powder; the core layer B is prepared from 65-80 parts of homo-polypropylene, 24-32 parts of stiffness improving master batch and 2-6 parts of anti-static master batch; the surface layer C is prepared from 80-90 parts of an ethylene-butene-propylene terpolymer, 5-15 parts of ethylene-butene copolymerized elastomer, 2-5 parts of a slipping agent and 3-10 parts of an antisticking agent, the slipping agent is dimethicone and the antisticking agent is PMMA. The three-layer coextruded packaging film is lower in heat-seal temperature, energy consumption is reduced, and the cigarette case packaging quality is improved.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

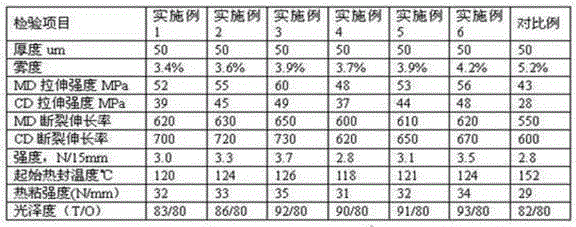

Polyvinyl alcohol wire for fused deposition molding and processing method of polyvinyl alcohol wire

ActiveCN104448641AImprove thermal stabilityImproved melt processabilityPolymer sciencePolyvinyl alcohol

The invention relates to a preparation method of high polymer materials, and particularly relates to a polyvinyl alcohol wire for fused deposition molding and a processing method of the polyvinyl alcohol wire. The polyvinyl alcohol wire comprises the following raw materials in parts by weight: 100 parts of polyvinyl alcohol resin, 20-40 parts of a plasticizer, 0.5-2 parts of an antioxidant, 5-10 parts of a heat stabilizer, 0.2-1 part of a lubricating agent and 0.1-0.5 part of an anti-blocking agent, wherein the anti-blocking agent is one of oleamide and erucyl amide. The polyvinyl alcohol wire disclosed by the invention has the advantages of high heat stability, good melt processing property, excellent mechanical property, stable wire diameter, good water solubility, simple production process, high efficiency and low cost.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Polypropylene composite material

InactiveCN101519512AImprove low temperature toughnessGood self-lubricating performanceEpoxyPolymer science

The invention relates to a polypropylene composite material, which is a functional modified material prepared by using polypropylene (PP) as a main material and using toughening agent, silver-supported nano antibacterial agent and lubricating agent as additive modifying agent. In the formulation, each 100 portions of polypropylene (PP) by weight contain 1 to 25 portions of the toughening agent, 0.1 to 2 portions of the silver-supported nano antibacterial agent, and 1 to 5 portions of the lubricating agent. The toughening agent is metallocene polyethylene, the silver-supported nano antibacterial agent is silver-supported nano titanium dioxide or silver-supported nano zinc oxide, and the lubricating agent is erucyl amide or glycerol stearate or oleic amide. The low-temperature toughness of a base material is improved by toughening and modifying, the use of epoxy ethane is reduced or avoided by adding proper antibacterial agent, and the self-lubricating property of the material is improved by adding a surface lubricating material. The composite material has the advantages of reasonable formulation and stable property; and a prepared medical injector has the functions of low temperature resistance, bacteria resistance and self lubrication.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER

Polyethylene resin composition used for preparing bottle caps

The invention discloses a polyethylene resin composition used for preparing bottle caps. The polyethylene resin composition is prepared by adding a composite smooth agent and nano zinc oxide into polyethylene resin, so that demands on smoothness are satisfied, and no peculiar smell is induced. The polyethylene resin composition comprises following ingredients: polyethylene resin, a certain proportion of a composition of erucyl amide and oleamide, polyethylene glycol, nano zinc oxide and an anti-oxidant.

Owner:PETROCHINA CO LTD

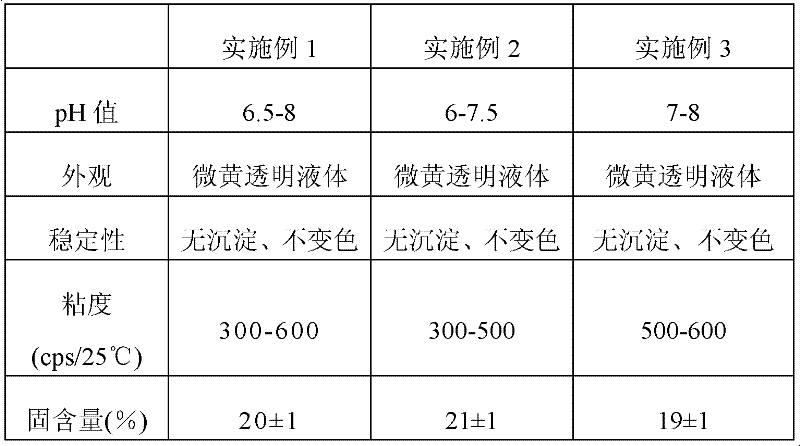

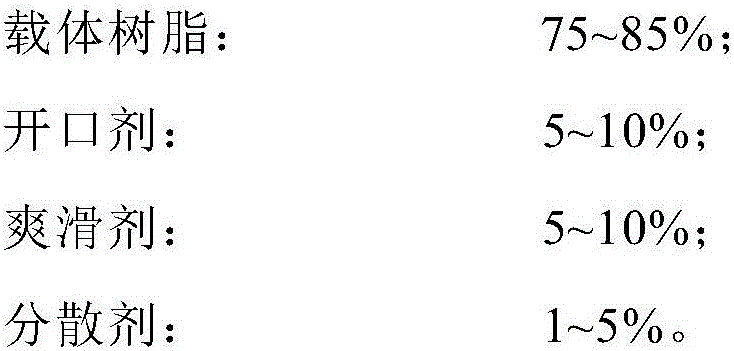

Anti-adhesion and slipping agent master batch and preparation method thereof

The invention discloses an anti-adhesion and slipping agent master batch and a preparation method thereof. The formula of the anti-adhesion slipping agent master batch is prepared from 75 to 85 percent of carrier resin, 5 to 10 percent of an anti-adhesion agent, 5 to 10 percent of a slipping agent and 1 to 5 percent of a dispersing agent, wherein the anti-adhesion agent is spherical silicon aluminum oxide with the particle size of 5 to 10 [mu]m; the slipping agent is one or two of erucyl amide and oleamide; the dispersing agent is polyethylene wax with the number-average molecular weight of 3,000 to 5,000. The master batch is produced according to a conventional blending double-screw granulation process. The anti-adhesion and slipping agents in the anti-adhesion and slipping agent master batch are excellent in anti-adhesion performance, so that the friction coefficient of a thin film can be effectively reduced; the thin film is high in transparency and low in fuzzy degree; furthermore, the slipping agent is difficult to separate out.

Owner:SHANGHAI WEIKAI CHEM +1

High elasticity nonwoven fabric and production process thereof

InactiveCN106906574ALarge deformationIncrease elasticityMelt spinning methodsConjugated synthetic polymer artificial filamentsPolymer scienceAntioxidant

The invention discloses a high elasticity nonwoven fabric and a production process thereof, wherein the high elasticity nonwoven fabric is a compound of three layers of spunbond nonwoven fabrics, each layer of the spunbond nonwoven fabrics is prepared from, by weight, 74%-96% of ethylene propylene hypocrystalline copolymer, 1.5%-24% of polypropylene, 0.029%-0.096% of polyethylene, 0.27%-1.08% of saturated erucyl amide, 0.04%-0.156% of phenols antioxidant and 0.04%-0.22% of phosphite ester antioxidant, and 0.38%-1.59% of titanium dioxide.

Owner:FOSHAN NAHAI BEAUTIFUL NONWOVEN CO LTD

PBS (Polybuthylenesuccinate) /PLA (Polylactic Acid)/PHA (Polyhydroxyalkanoate) biodegradable composite material and preparation method thereof

The invention discloses a PBS (Polybuthylenesuccinate) / PLA (Polylactic Acid) / PHA (Polyhydroxyalkanoate) biodegradable composite material and a preparation method thereof. The PBS / PLA / PHA composite material is prepared from the following components in parts by weight: the PLA, the PBS, the PHA, citric acid, rubidium benzoate, bismuth trifluoromethanesulfonate, erucyl amide, filler, a compatilizer, a plasticizer, an antioxidant and an antibacterial agent. By reasonably selecting the materials and proportioning, the PBS / PLA / PHA composite material prepared by the preparation method disclosed by the invention plays the characteristics of respective properties of the PBS, the PLA and the PHA, and has higher impact-resisting strength, tensile strength and elongation at break, good comprehensive mechanical property, long service life and wide application range.

Owner:王泽陆

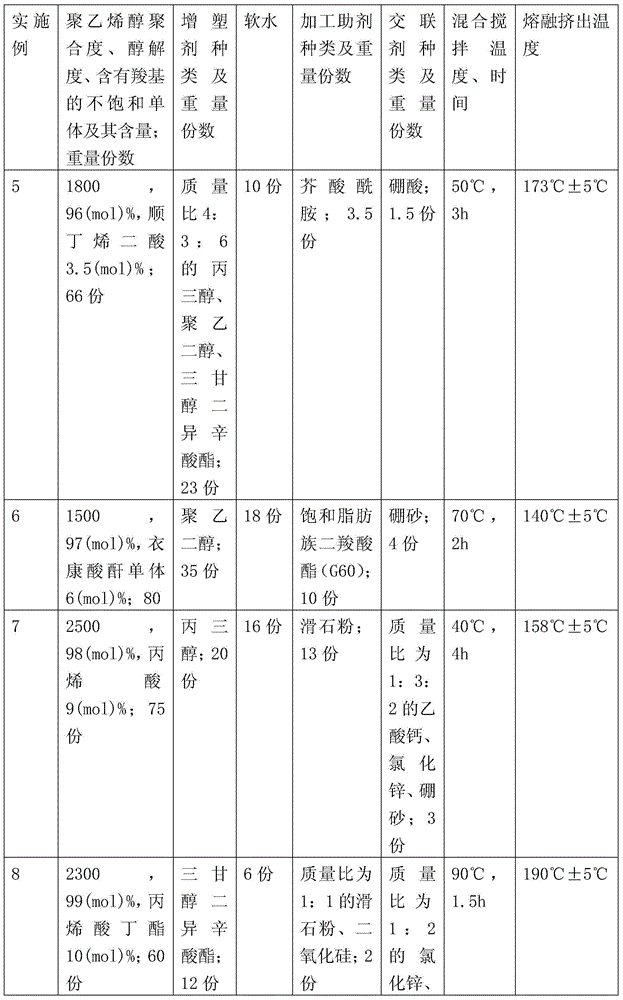

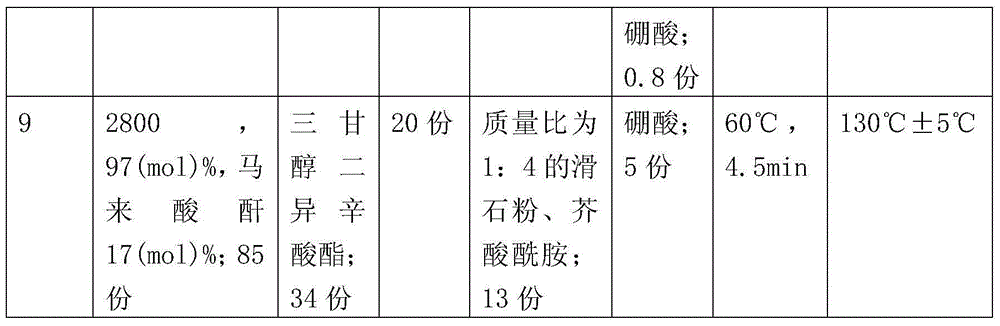

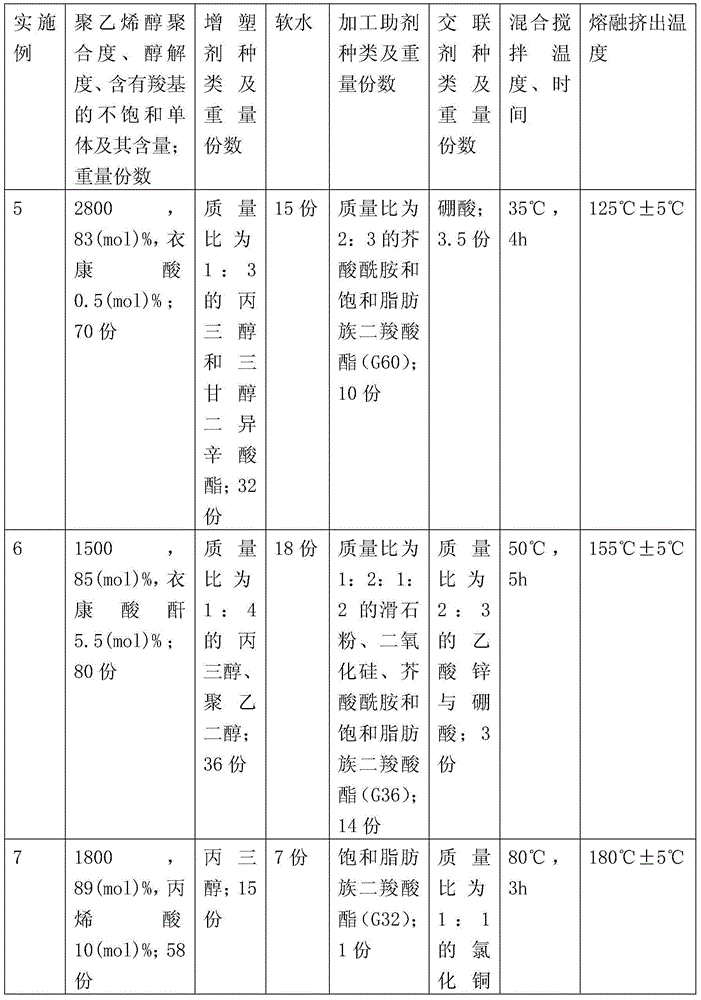

Thermoplastic modified polyvinyl alcohol resin and preparation method thereof

ActiveCN105440521ALower melting temperatureSmooth realization of thermoplastic processingThermoplasticDecomposition

The invention discloses thermoplastic modified polyvinyl alcohol resin. The thermoplastic modified polyvinyl alcohol resin comprises an effective amount of carboxyl-modified polyvinyl alcohol, a plasticizer, soft water and a processing auxiliary agent. The carboxyl-modified polyvinyl alcohol is obtained by copolymerization of a vinyl acetate monomer and an unsaturated monomer containing carboxyl and then alcoholysis and has an alcoholysis degree of 95-99.9(mol)%, a polymerization degree of 1000-3500 and carboxyl content of 0.1-20mol%. The plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate. The processing auxiliary agent is at least one of talcum powder, silica, erucyl amide and saturated aliphatic dicarboxylic acid ester. The thermoplastic carboxyl-modified high temperature water soluble polyvinyl alcohol resin has a melting temperature of 120-200 DEG C and a decomposition temperature of 300 DEG C or more, can be dissolved in water at a temperature of 80-90 DEG C, is colorless and transparent, does not produce yellowing and has excellent quality.

Owner:重庆川维科技有限公司 +1

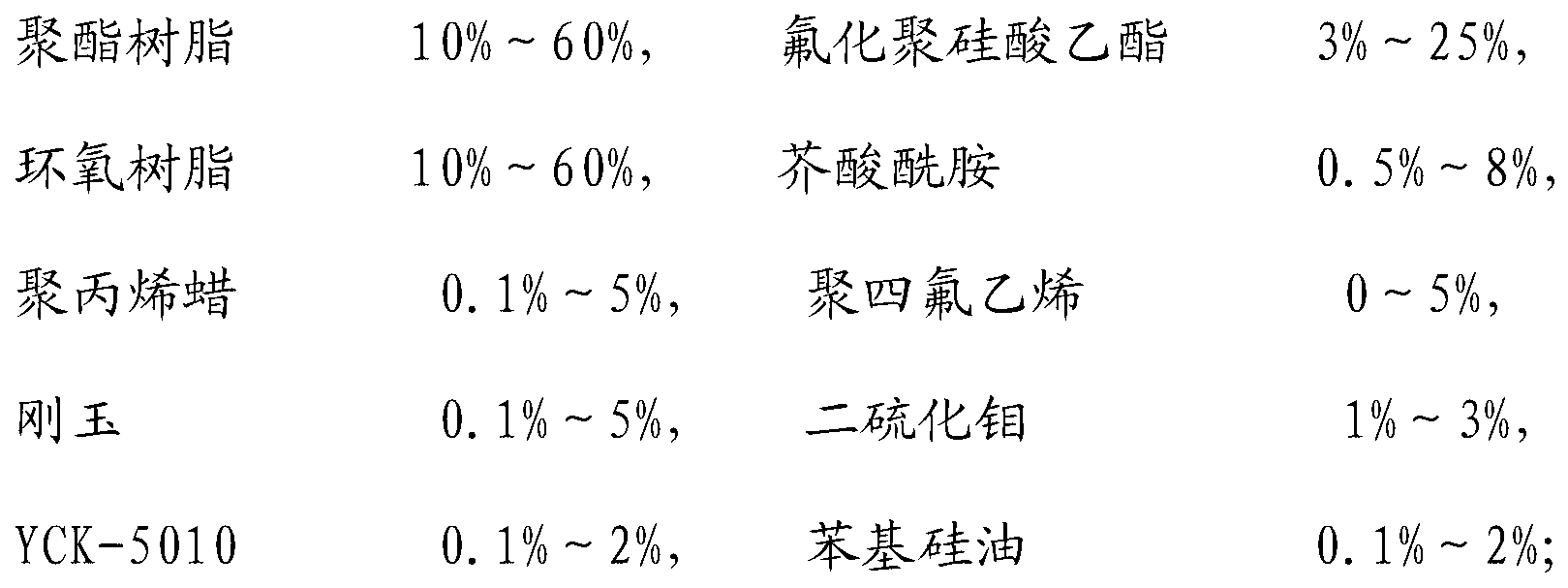

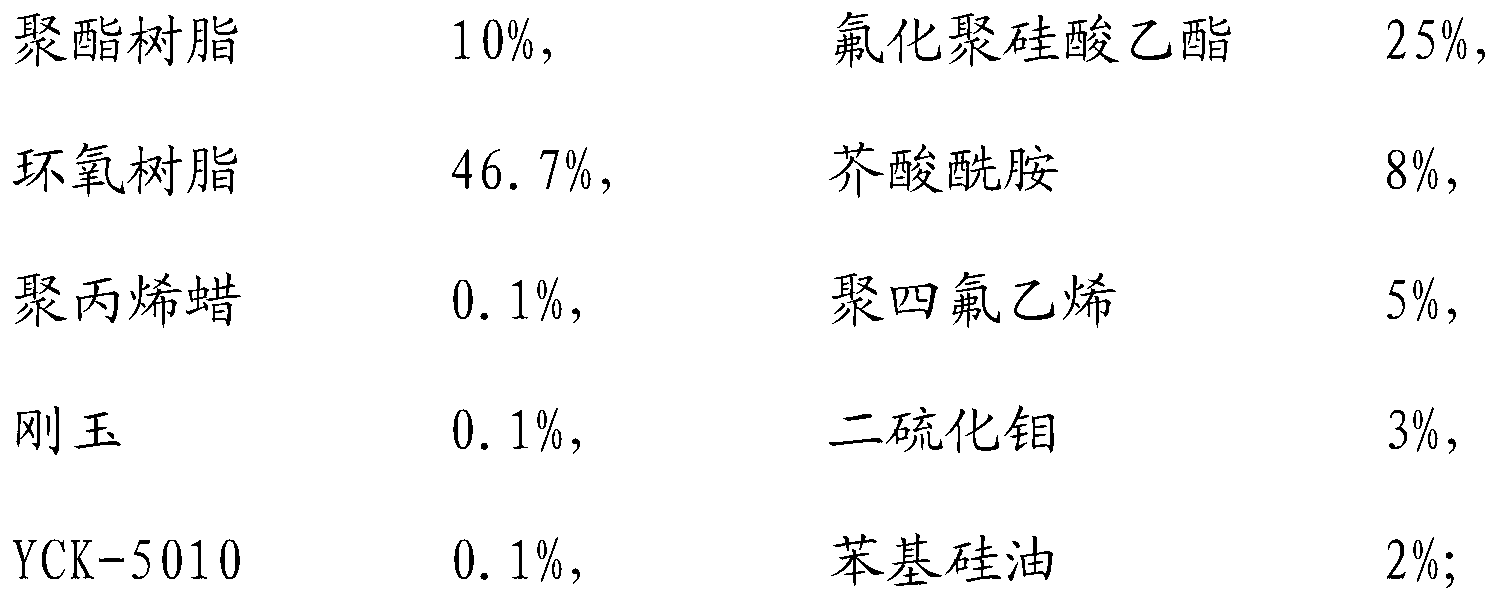

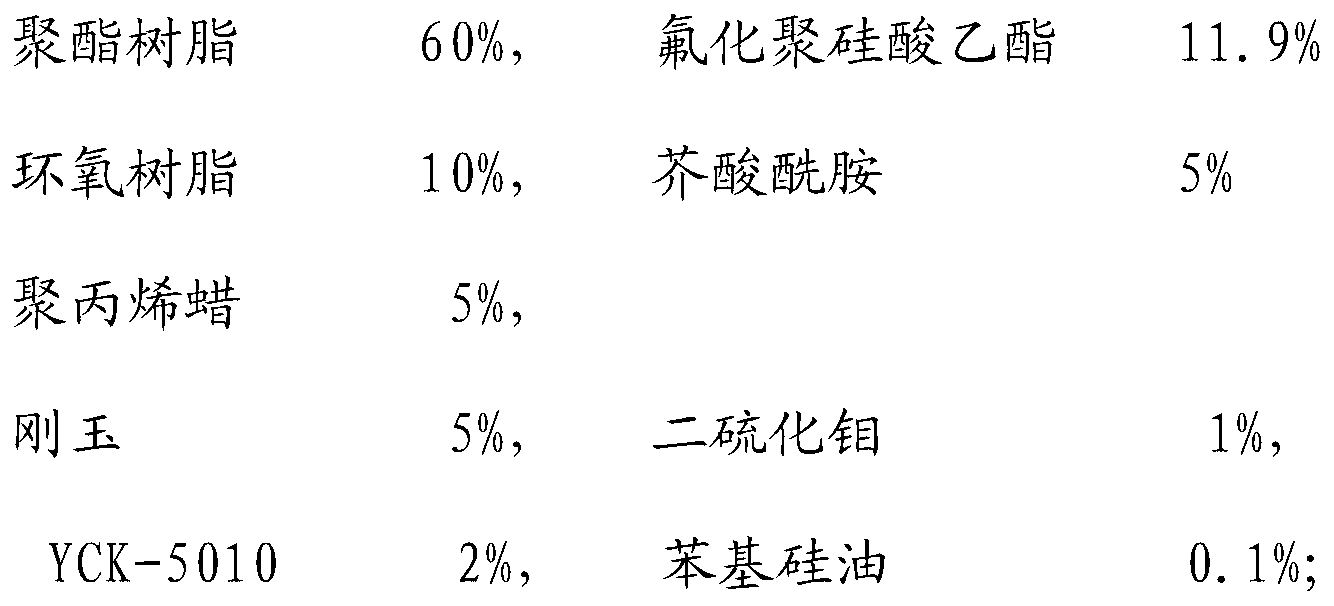

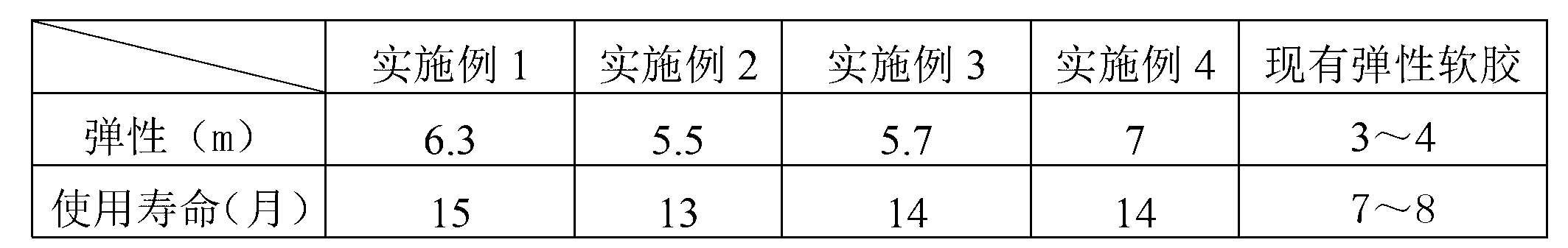

PU (Poly Urethane) wear-resistant coating

ActiveCN103305109AImprove toughnessExtended service lifePolyurea/polyurethane coatingsEpoxyWear resistant

The invention discloses a PU (Poly Urethane) wear-resistant coating. The PU wear-resistant coating comprises a component A and a component B which are respectively packaged, wherein the component A is composed of the following materials: polyester resin, fluorinated ethyl silicate, epoxy resin, erucyl amide, polypropylene wax, teflon, corundum, molybdenum disulfide, YCK-5010 and phenyl silicone oil; the component B is a polyurethane prepolymer; the ratio of the component A to the component B is 2:(0.5-1). Because the epoxy resin, the polyester resin and the polyurethane prepolymer which are excellent in toughness are selected, a film-forming material has excellent toughness, and an organically modified inorganic material-fluorinated ethyl silicate is adopted for modification, the hardness and strength of the PU wear-resistant coating are also greatly increased. In the invention, wear-resistant agents including corundum and molybdenum disulfide are used, and various surface lubricating and anti-wear additives such as erucyl amide, YCK-5010 wax, polypropylene wax, teflon and phenyl silicone oil are added into the coating, so that the PU wear-resistant coating disclosed by the invention has excellent wear resistance and bearing and lubrication properties, and can have the effects of protecting surfaces, reducing the friction coefficient and prolonging the service lives of parts.

Owner:GUANGDONG DEKANG CHEM IND

Elastic flexible glue and preparation method thereof

The invention relates to elastic material for preparing elastic and flexible toys, and particularly relates to elastic flexible glue. The elastic flexible glue comprises the following components by weight percentage: simethicone, super fine calcium carbonate, boric acid, TPR (thermal plastic rubber), zinc stearate, silicon resin, bentonite, barium carbonate, linseed oil and erucyl amide. The elastic flexible glue provided by the invention has good elasticity and proper bulking intensity; the surface of the elastic flexible glue is smooth, good in hand feel, adhesive, and tough, and has good aging resistance, high stability and long service life that is from 13 to 15 months; and the elastic and flexible toys made of the elastic flexible glue have high quality, and are playable and durable.

Owner:杜京财

Aging-resistant PVC tubular product and preparation method thereof

InactiveCN104140617AGood anti-ultraviolet aging performanceImprove mechanical propertiesPhosphateCadmium Cation

The invention discloses an aging-resistant PVC tubular product and a preparation method thereof. The aging-resistant PVC tubular product is prepared from the following raw materials in parts by weight: 100-150 parts of SG-3 PVC, 30-60 parts of an acrylonitrile-styrene-acrylate copolymer, 2-4 parts of triglycidyl isocyanurate, 10-15 parts of titanium dioxide, 15-20 parts of sericite in powder, 25-45 parts of polyether sulfone, 3-6 parts of polytetrafluoroethylene micropowder, 2-3 parts of tribasic aluminum sulfate, 1.5-2.5 parts of a barium cadmium zinc liquid compound stabilizer, 3-5 parts of erucyl amide, 4-7 parts of Fischer Tropsch wax, 1-2 parts of pyrithione zinc, 1-2 parts of bisphenol A phosphate, 5-10 parts of caustic-burned magnesia powder and 3-4 parts of auxiliaries. The PVC tubular product prepared by the preparation method disclosed by the invention not only has excellent ultraviolet aging resistance and mechanical property, but also has good heat resistance, corrosion resistance, wear resistance, impact resistance, environmental stress crack resistance and the like, and is free from deformation and cracking when being exposed to the sun for a long time and durable.

Owner:安徽玉发塑业有限公司

Polypropylene-based filament elastic super-soft non-woven material and production method thereof

InactiveCN108179549AStable structureReduce distortionHeating/cooling textile fabricsTextile treatment by spraying/projectingPolyolefinPolyethylene glycol

The invention relates to a polypropylene-based filament elastic super-soft non-woven material and a production method thereof. The production method of the polypropylene-based filament elastic super-soft non-woven material comprises the following steps: (1) elastic and super-soft blending modification of a thermoplastic copolymer: carrying out melt blending modification on 40 to 80 weight percentof polypropylene with 0.01 to 2 weight percent of erucyl amide and 5 to 15 weight percent of polyethylene glycol by using a screw pelletizer, thus preparing polymer particles; blending the polymer particles with 18 to 40 weight percent of polyolefin elastic copolymer and 8 to 12 weight percent of UHMWPE (Ultra-high Molecular Weight Polyethylene) slice; (2) spun-bond forming of a polypropylene-based filament net; (3) hot rolling and pre-curing of the polypropylene-based filament net; (4) pre-wetting; (5) first-stage hot drawing; (6) secondary forming through hot rolling; (7) second-stage hot drawing; (8) cooling; (9) coiling. The polypropylene-based filament net prepared by the invention is relatively excellent in elasticity, softness and fluffiness, does not contain substances having adverse effects on a human body and is safe to use.

Owner:苏州多瑈新材料科技有限公司

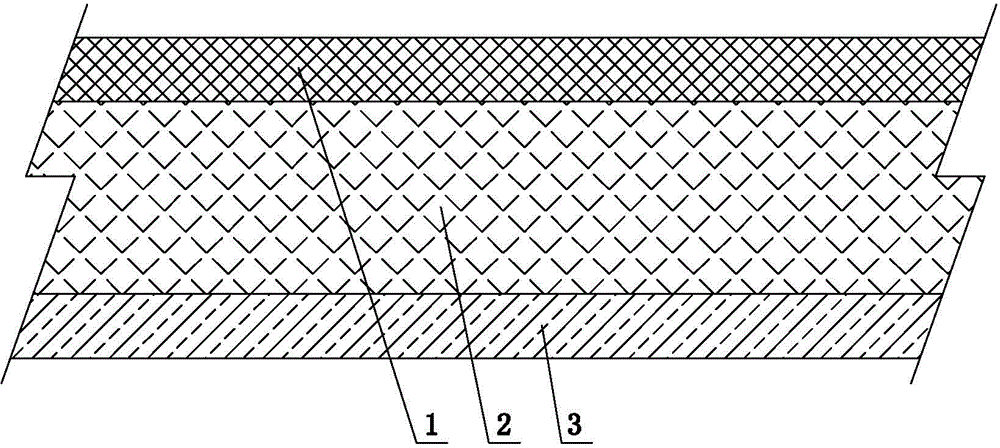

Modified polyamide composite membrane and preparation method thereof

InactiveCN103182821AGood hot tack propertiesImprove thickness uniformityFlexible coversWrappersErucyl amidePolypropylene

A modified polyamide composite membrane is formed by compounding a corona layer, a core layer and a heat seal layer, wherein the corona layer is prepared from polypropylene homopolymers, and is arranged on the upper surface of the core layer; the heat seal layer is arranged on the lower surface of the core layer; the core layer is prepared from modified polyamide, polypropylene copolymers, propylene-alpha olefin copolymers and an erucyl amide slipping agent; and the heat seal layer is prepared from copolypropylene resin, an erucyl amide slipping agent and a synthetic wollastonite anti-adhesion agent. Materials of all the layers are respectively added into a screw extruder to be melted, then are subjected to co-extrusion, tape casting and cooling molding by a connector and a die head, and next the materials are subjected to corona treatment, rolling, aging treatment, slitting and packing to obtain the finished product modified polyamide composite membrane. The compatibility of modified polyamide and polypropylene is good, the binding force among membrane layers is very strong, adhesive is not required, the production process is simplified, and the production cost is saved.

Owner:湖北慧狮塑业股份有限公司

Gas-phase anti-rust composite packaging film for industry and preparation method thereof

ActiveCN101319067AHigh mechanical strengthIncrease elasticityFlat articlesLow-density polyethyleneBenzoic acid

The invention relates to a rust proofing packaging film, in particular to a gas phase rust proofing industrial composite packaging film and a preparation method thereof. The gas phase rust proofing industrial composite packaging film comprises the compositions by weight proportion: 0 to 0.53 of drewamine, 0.12 to 0.42 of cyclohexane, 0.13 to 0.4 of dicyclohexylamine, 0.09 to 0.28 of phenylformic acid, 0.22 to 0.55 of tert-Butyl benzoic acid, 0 to 0.12 of cinnamylate, 29.5 to 45.1 of low density polyethylente, 29.5 to 45.1 of linear low density polyethylene, 0 to 0.02 of oleamide or erucyl amide and 0 to 0.12 of a diffusing impurity EB-FF. The gas phase rust proofing film has good barrier property and high intensity, saves cost, is nonpoisonous and harmless, prevents the pollution, and can be reused. The preparation method is simple and convenient, the process is easy to control and the production cost is low.

Owner:金荣范

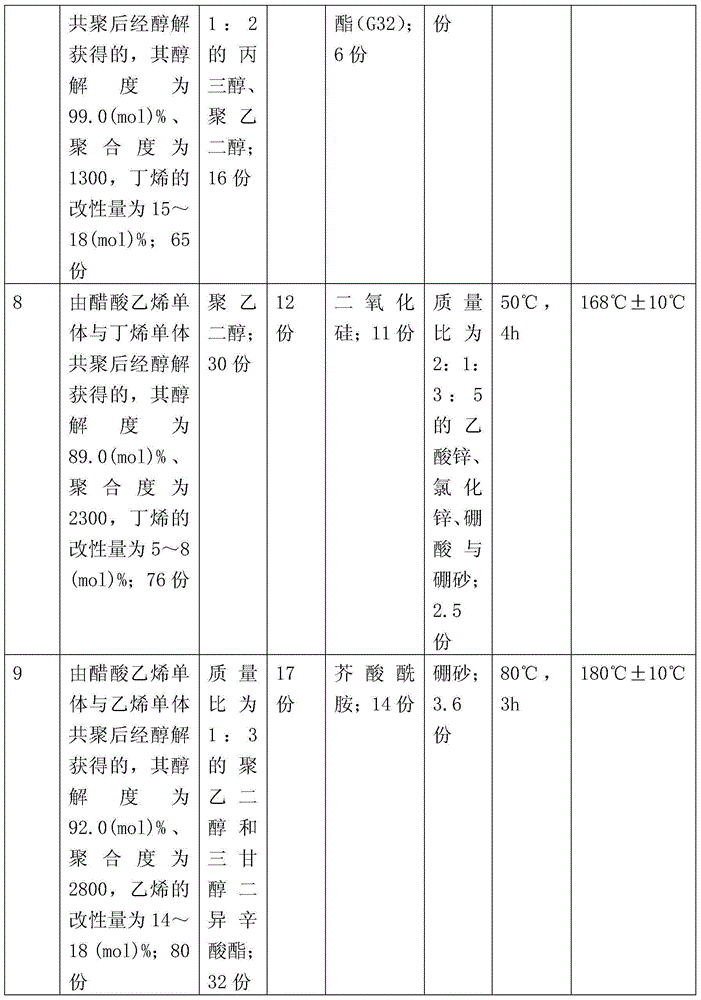

Thermoplastic modified polyvinyl alcohol resin and preparation method thereof

ActiveCN105440523ALower melt processing temperatureReduce processing temperatureThermoplasticProcedure Agents

The invention discloses thermoplastic modified polyvinyl alcohol resin. The thermoplastic modified polyvinyl alcohol resin comprises vinyl-modified polyvinyl alcohol, a plasticizer, soft water and a processing auxiliary agent. The vinyl-modified polyvinyl alcohol is obtained by copolymerization of a vinyl acetate monomer and an unsaturated monomer containing vinyl and then alcoholysis and has an alcoholysis degree of 80.0-99.9(mol)%, a polymerization degree of 1000-3000 and a vinyl-containing unsaturated monomer modification amount of 0.1-20(mol)%. The plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate. The processing auxiliary agent is at least one of talcum powder, silica, erucyl amide and saturated aliphatic dicarboxylic acid ester. The thermoplastic vinyl-modified polyvinyl alcohol resin has a melting temperature of 160-220 DEG C and a decomposition temperature of 320 DEG C or more, is colorless and transparent, does not produce yellowing and has excellent quality.

Owner:CHINA PETROCHEMICAL CORP +1

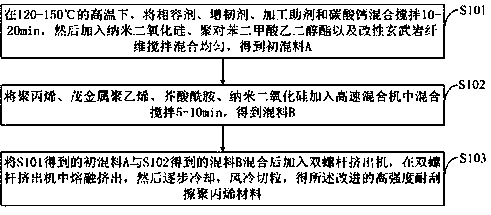

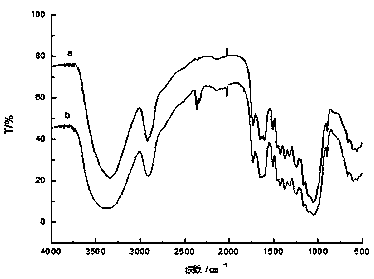

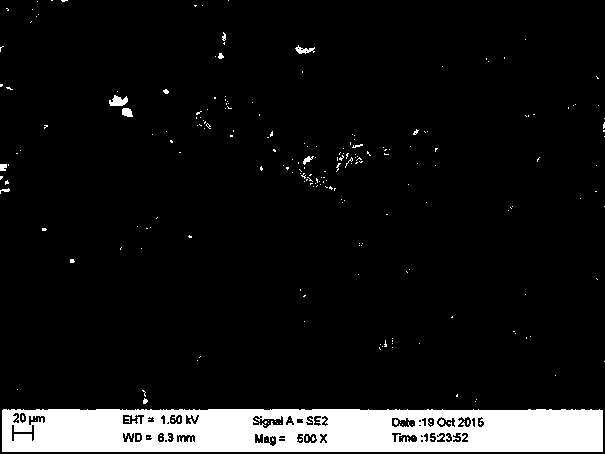

Improved high strength scratch-resistant polypropylene material and preparation method thereof

The invention belongs to the technical field of polypropylene materials, and discloses an improved high strength scratch-resistant polypropylene material and a preparation method thereof. The improvedhigh strength scratch-resistant polypropylene material is composed of polypropylene, polyethylene glycol terephthalate, metallocene polyethylene, calcium carbonate, erucyl amide, modified basalt fibers, a toughening agent, a compatilizer, nano silicon dioxide, and a processing aid. The strength of polypropylene is enhanced. High activity calcium carbonate can be prepared by a provided calcium carbonate preparation method, and thus the polypropylene preparation efficiency is improved. The surface of basalt fibers is modified so that the binding force of the interface between basalt fibers anda polypropylene matrix is strengthened. An LFT fiber infiltration preparation technology is applied to basalt fiber modified polypropylene, the length of fibers is controlled in a range of 10 to 15 mm, the length of fibers in the polypropylene matrix is long, and thus the mechanical strength of a product is enhanced.

Owner:苏州炜隆灿科技有限公司

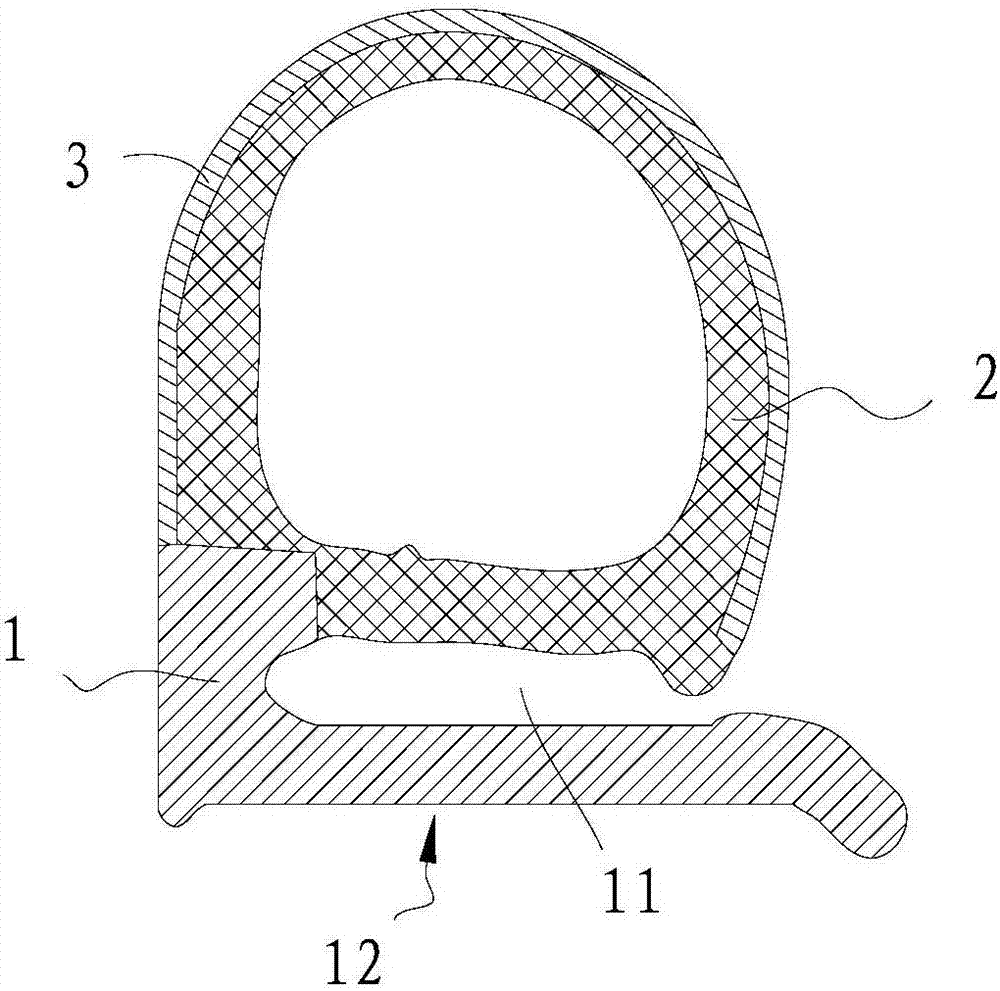

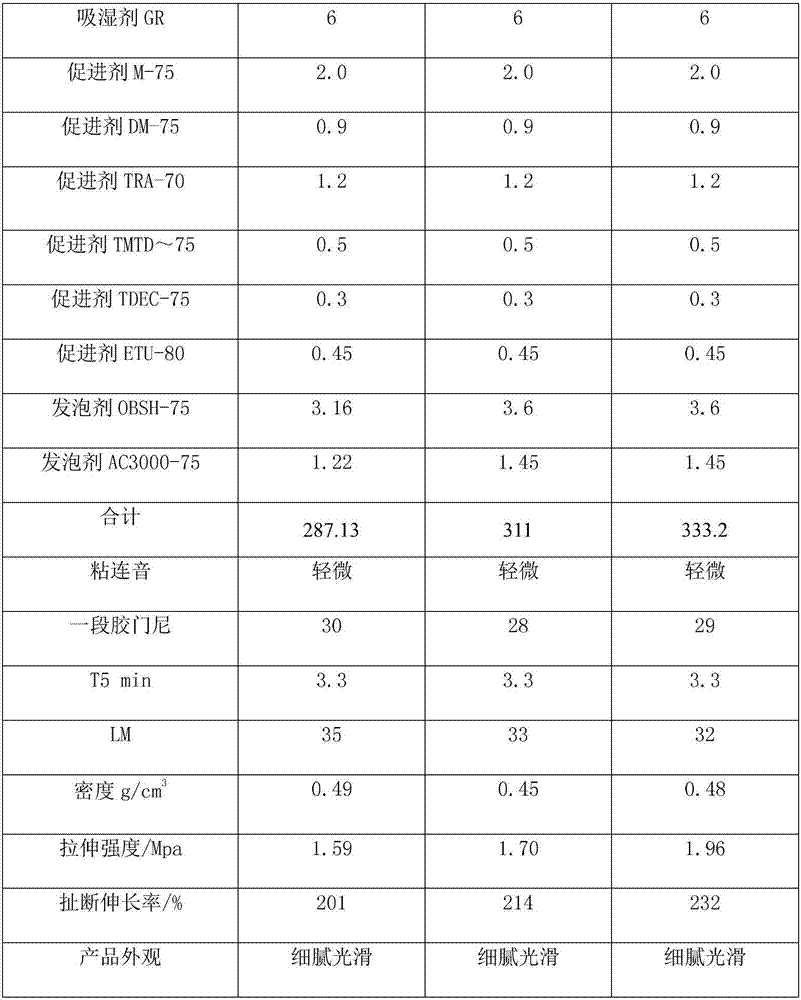

Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

InactiveCN107418061ALow viscosityConducive to lightweight designEngine sealsVehicle sealing arrangementsElastomerPolyolefin

The invention provides sponge foaming rubber for a car door sealing strip and a preparation method thereof, a car door sealing strip and a preparation method thereof. The sponge foaming rubber for the car door sealing strip, provided by the invention, is prepared from the following components in parts by weight: 20 to 40 parts of ethylene-propylene-diene monomer 9090M, 69 to 92 parts of ethylene-propylene-diene monomer V8800, 5 to 7 parts of active zinc oxide, 1 to 2 parts of stearic acid, 1 to 3 parts of a dispersant, 0.8 to 1.4 parts of erucamide, 1 to 2 parts of PEG-4000 (Polyethylene Glycol-4000), 5 to 10 parts of POE (Polyolefin Elastomer), 60 to 77 parts of paraffin oil R-2291, 30 to 50 parts of carbon black N550, 50 to 70 parts of carbon black SP5000, 1.5 to 2.5 parts of sulfur S-80, 6 to 10 parts of a moisture absorbent GR, 3 to 6.4 parts of an accelerant, 3 to 3.6 parts of a foaming agent OBSH-75 (Oxydibenzenesulfonyl Hydrazide-75) and 1.1 to 1.5 parts of a foaming agent AC3000-75. By adopting a formula of the sponge foaming rubber for the car door sealing strip, provided by the invention, the prepared sponge rubber has relatively low density and can meet a lightweight design; meanwhile, the obtained rubber also can have relatively good physical performance, so that the utilization quality of the car door sealing strip utilizing the sponge foaming rubber can also be improved.

Owner:NUOBO RUBBER PRODION

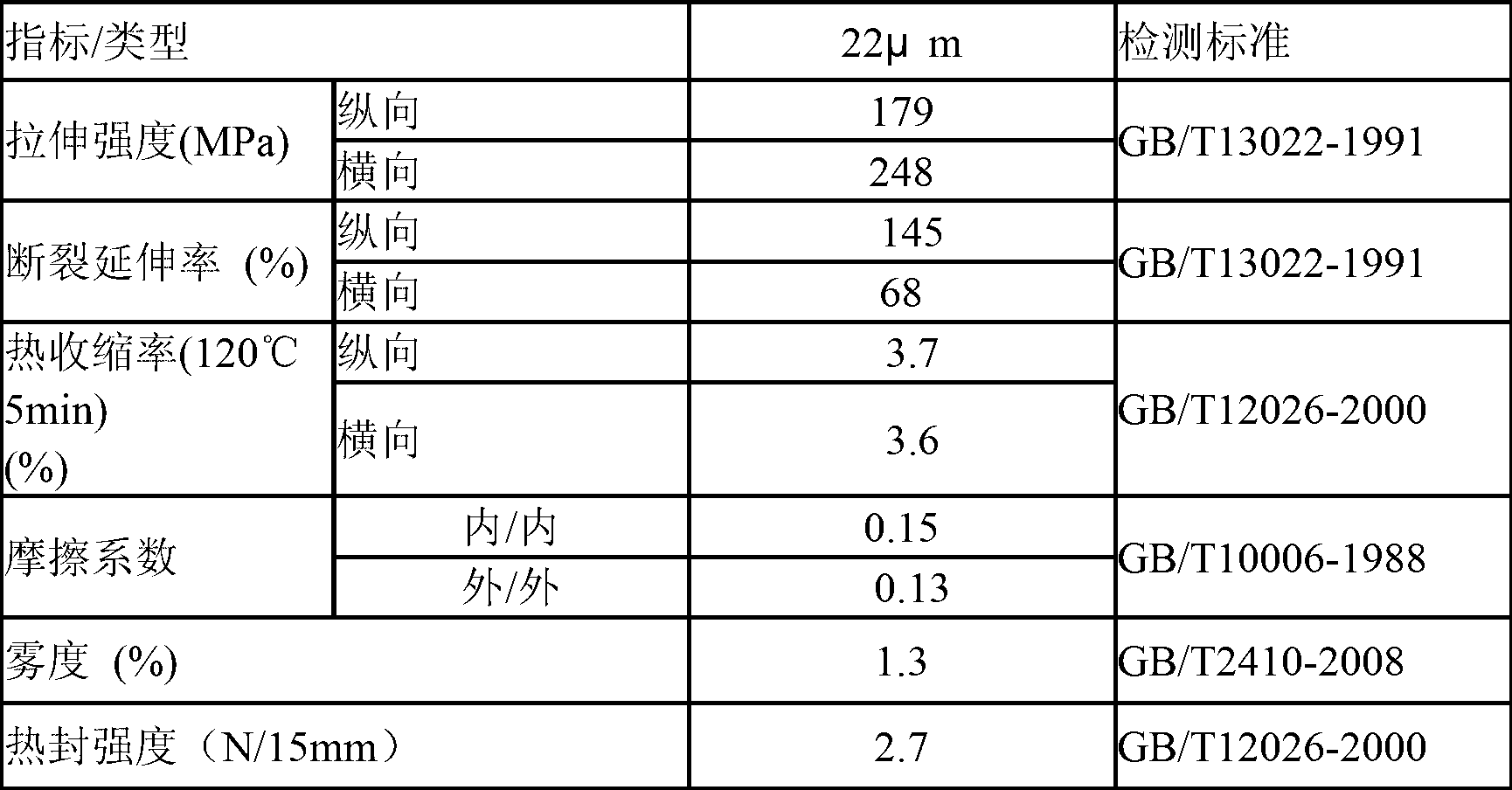

Low-friction and biaxially oriented polypropylene heat-sealing membrane and manufacturing method thereof

ActiveCN103009748AFulfil requirementsReduce coefficient of frictionFlexible coversWrappersPolytetramethylene terephthalatePolymer science

The invention discloses a low-friction and biaxially oriented polypropylene heat-sealing membrane and a manufacturing method thereof. Aiming at the problem of high friction coefficient of a conventional polypropylene heat-sealing membrane, the silicone is used as a high temperature slipping agent to make the membrane keep relatively low friction coefficient at various temperature, polybutylene terephthalate with the particle size of 2-3 [mu]m is used as an anti-blocking agent to make the membrane have an anti-blocking effect and to reduce the friction coefficient, and erucyl amide of a mixed antistatic agent is used in an interlayer which can be migrated to a surface layer so as to play a slipping role. The obtained low-friction and biaxially oriented polypropylene heat-sealing membrane has very good physical properties, with the friction coefficient of 0.12-0.15, and can meet the requirements of a high speed packaging machine.

Owner:HAINAN SHINER IND

Thermoplastic modified polyvinyl alcohol resin and preparation method therefor

ActiveCN105440524ALower melt processing temperatureReduce processing temperatureThermoplasticProcedure Agents

The invention relates to thermoplastic carboxyl-modified normal-temperature-water-soluble polyvinyl alcohol resin. The polyvinyl alcohol resin is prepared from an effective quantity of carboxyl-modified polyvinyl alcohol, plasticizer, soft water and processing aid, wherein the carboxyl-modified polyvinyl alcohol is prepared through copolymerizing a vinyl acetate monomer and a carboxyl-containing unsaturated monomer and then carrying out alcoholysis and has the alcoholysis degree of 80.0-90.0(mol)%, the polymerization degree of 1,000-3,500 and the carboxyl content of 0.1-20mol%, the plasticizer is at least one of glycerol, polyglycol and triglycol diisooctoate, and the processing aid is at least one of talcum powder, silicon dioxide, erucyl amide and saturated aliphatic dicarboxylic ester. The prepared thermoplastic carboxyl-modified polyvinyl alcohol resin has the melting temperature of 120-200 DEG C, is soluble to water of 5-30 DEG C, has the decomposition temperature above 300 DEG C, is colorless and transparent, is free of yellowing and is excellent in quality.

Owner:重庆川维科技有限公司 +1

Super-transparent EVA film and production method thereof

The invention relates to the technical field of film materials, in particular to a super-transparent EVA film and a production method thereof. The super-transparent EVA film comprises, by weight, 100 parts of EVA particles and 2-5 parts of EVA opening smooth master batch. The EVA opening smooth master batch comprises, by weight, 100 parts of EVA particles, 5-10 parts of erucyl amide, 3-10 parts of smoothing agent, 3-5 parts of nano-silica, and 1-3 parts of fluoropolymer processing agent. The production method includes the steps of firstly, preparing the EVA opening smooth master batch; secondly, extrusion casting forming; thirdly, cooling and shaping. The super-transparent EVA film has the advantages that the EVA particles, the high-purity erucyl amide, the organic silicone smoothing agent, the nano-silica and the fluoropolymer processing agent of the super-transparent EVA film are complementary and have combined action, one-step extrusion forming is used, later surface processing is not needed, and when the produced super-transparent EVA film is 0.10-0.50 in thickness, the light transmittance of the EVA film can reach above 97%, the haze of the EVA film can reach below 7%, and the service life of the EVA film can reach more than 24 months.

Owner:FUJIAN HUIYIMEI ENVIRONMENTAL PROTECTION MATERIALTECH CO LTD

Heat-resistant modified polylactic acid composite material

The invention discloses a heat-resistant modified polylactic acid composite material composed of the following raw material components: polylactic acid, polybutylene succinate, polyadipic acid / butylene terephthalate, erucyl amide, acetyl tributyl citrate, a glycidyl methacrylate grafted ethyl methacrylate copolymer, an antioxidant 10760 and talcum powder. The heat resistance of the polylactic acidcomposite material is improved by three modes of introducing the fully biodegradable polybutylene succinate component with excellent temperature resistance, carrying out toughening treatment by adopting polyadipic acid / butylene terephthalate and promoting the crystallization behavior of a composite system by adopting superfine talcum powder; therefore, the application of the polylactic acid composite material in the field of disposable articles is adapted. A straw formed by extrusion molding of the composite material can be used for processing and preparation of hot drink packaging, and the application of the full-biomass degradable composite material in the field of disposable articles is expanded.

Owner:湖南省菱越新材料有限公司

Novel electronic package composite material and fabrication method thereof

ActiveCN105789145AHigh thermal conductivityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesPolyvinyl alcoholAluminium alloy

The invention provides a novel electronic package composite material and a fabrication method thereof. The fabrication method comprises the following steps of firstly, mixing silicon carbide, corn starch, maltodextrin powder, carbamide, natural japan tallow, erucyl amide, nanometer silicon dioxide, thermoplastic polyimide, polyvinyl formal, waterborne polyurethane, tertiary butylhydroquinone, calcium carbonate and water, ball-milling the mixture by a ball milling machine, placing the mixture in a baking oven for drying after stirring the mixture by a high-speed agitator, and sieving the mixture to remove blocks and large particles; secondly, placing the obtained product in a die, carrying out compression molding, and placing the product in a muffle furnace for sintering to obtain a pre-fabricated member; and finally, carrying out vacuum press infiltration on the pre-fabricated member, 6061 aluminum alloy and high-purity aluminum to obtain the novel electronic package composite material. The novel electronic package composite material provided by the invention is high in heat conductivity and has high heat dissipation performance, meanwhile, the novel electronic package composite material is relatively low in thermal expansion coefficient and stable in structure and performance.

Owner:JIANGSU TETRA NEW MATERIAL TECH

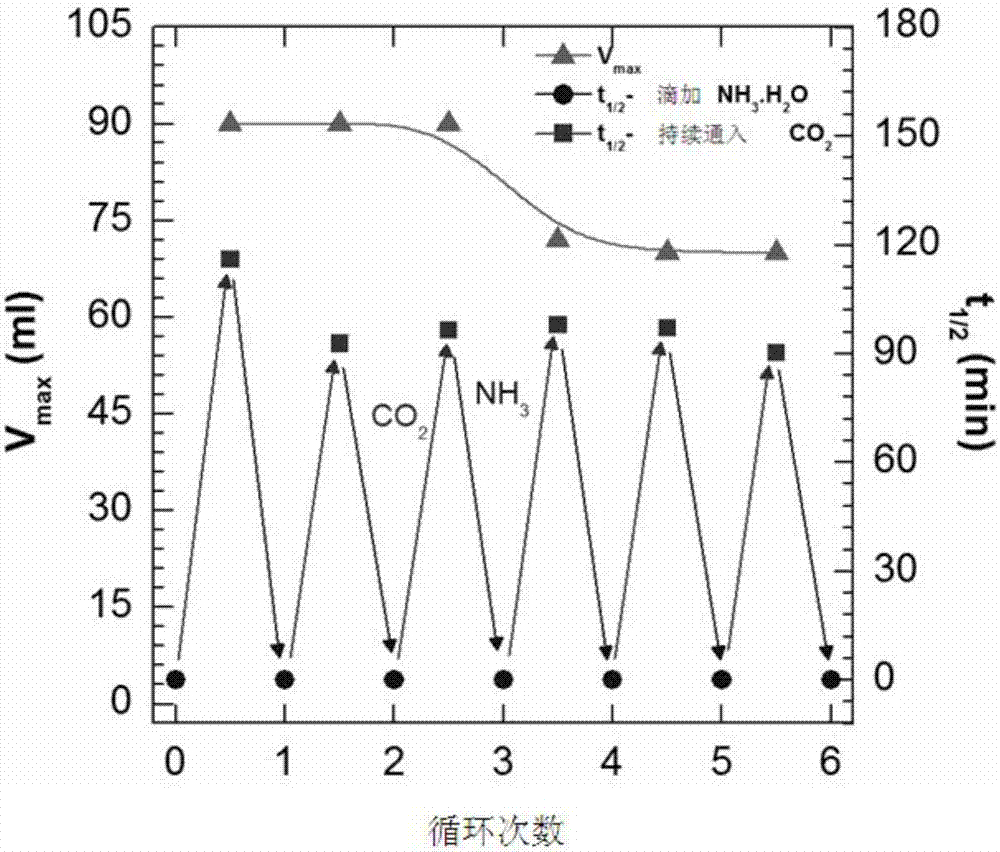

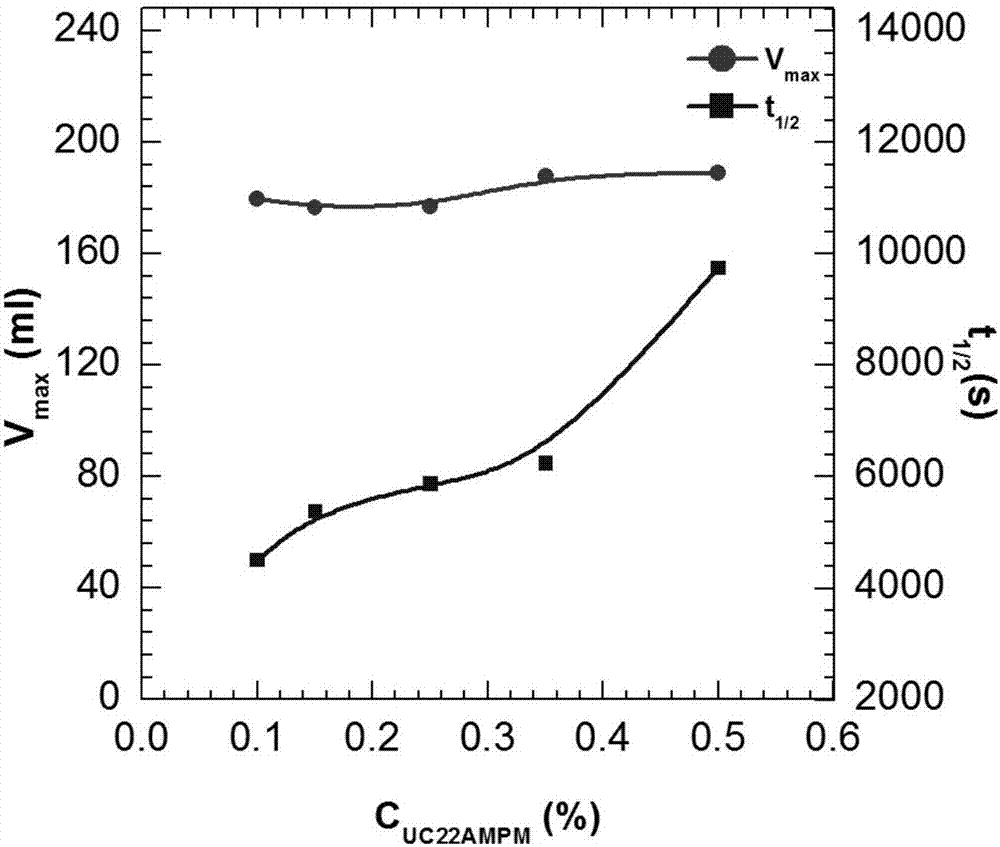

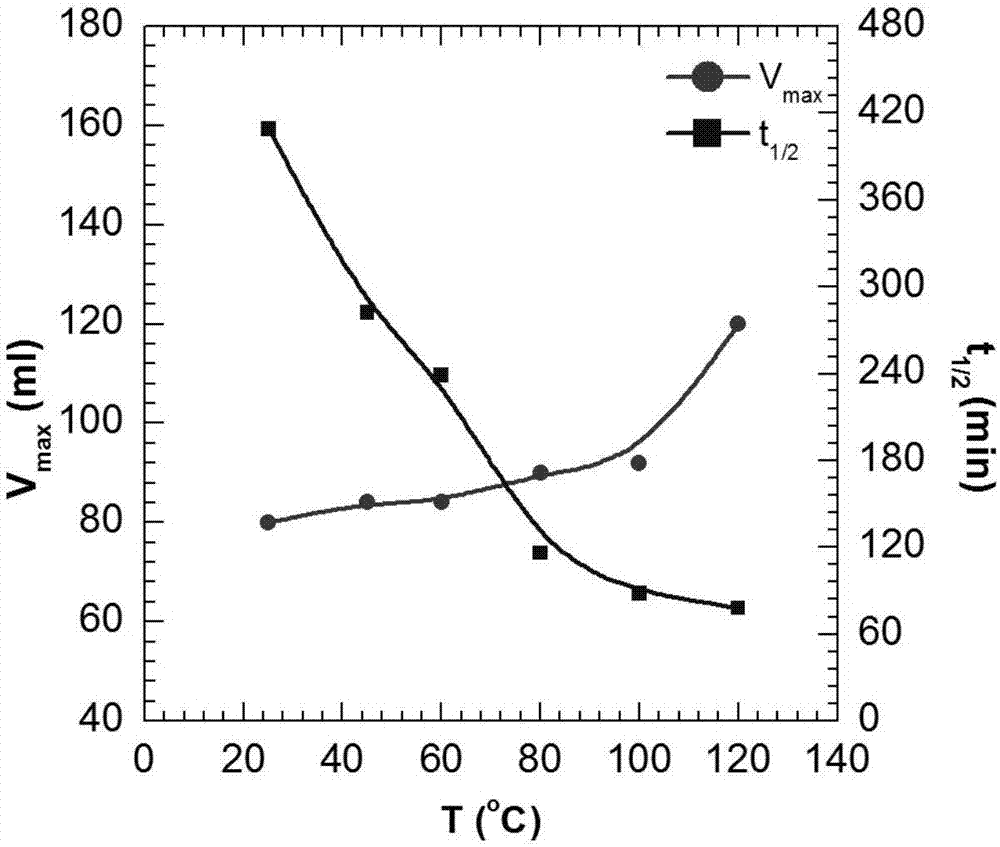

Self-stabilized carbon dioxide/ammonia water switch foam system

The invention relates to a self-stabilized carbon dioxide / ammonia water switch foam system which is composed of CO2, a bubbling liquid and ammonia water. The CO2 is stimulating factors and bubbling gas, the ammonia water is a defoaming liquid, the bubbling liquid is prepared from a bubbling agent and deionized water, the bubbling agent accounts for 0.1-1% by mass of the bubbling liquid, and the bubbling agent is erucyl amide propyl-N,N-dimethyl tertiary amine or oleic amide propyl-N,N-dimethyl tertiary amine. The foam system is simple in component and sensitive in foam switching property, and still has relatively good foaming property and switching property in a high-temperature and high-pressure environment.

Owner:SICHUAN UNIV

Low-dielectric-constant liquid crystal polymer composition and preparation method thereof

InactiveCN111320848AImprove heat deflection temperatureEasy to processLiquid crystal compositionsPolymer scienceTert butyl

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com