Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208results about How to "Improve heat deflection temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

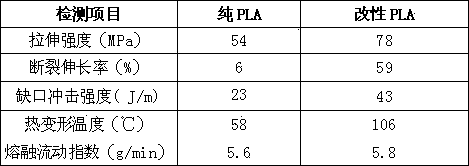

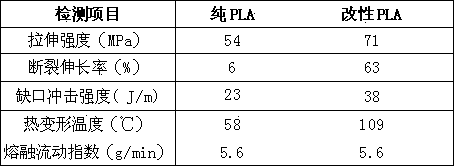

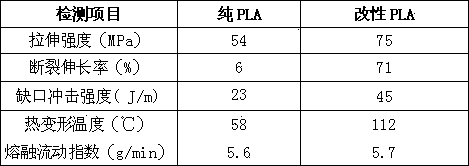

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

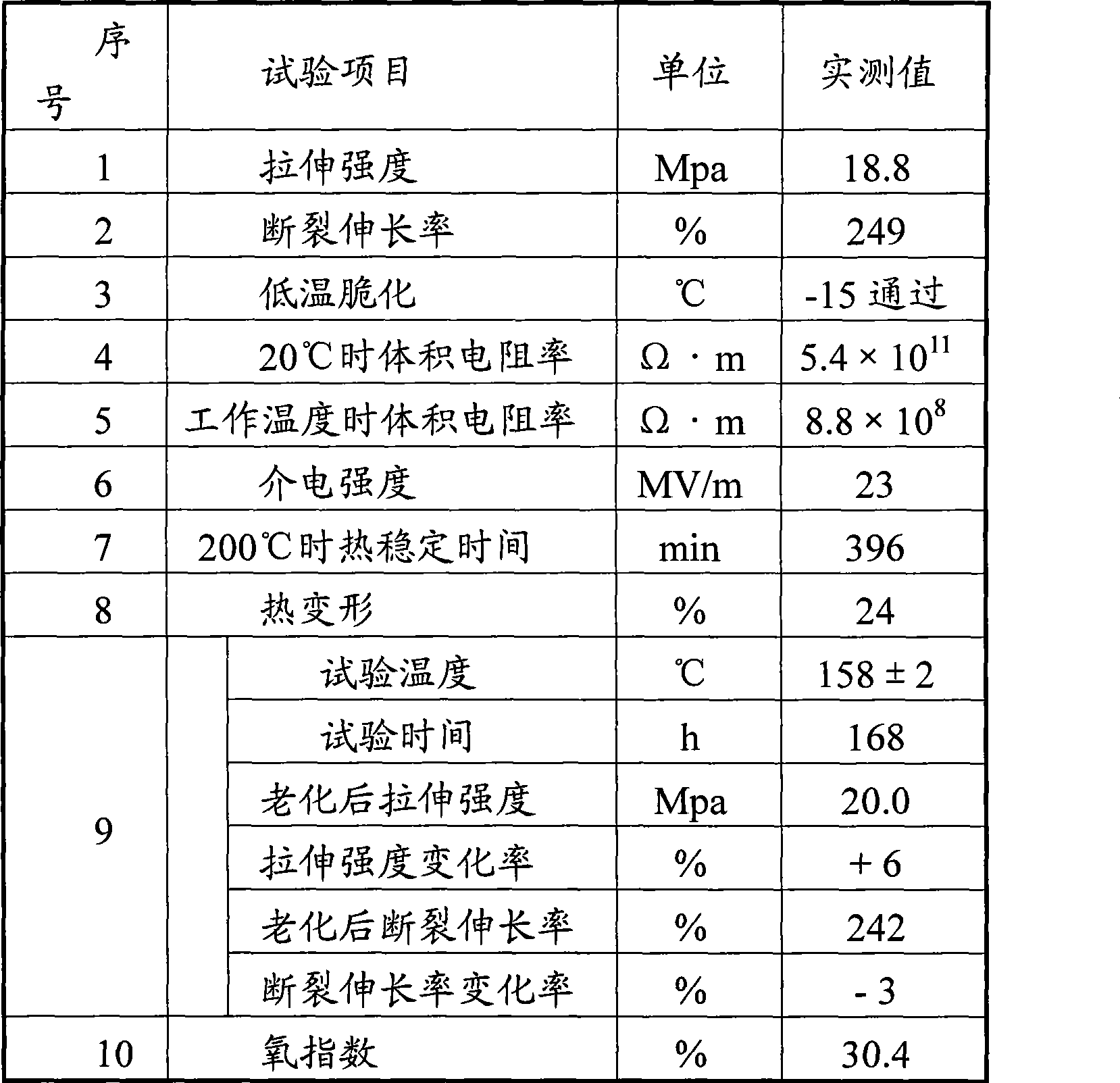

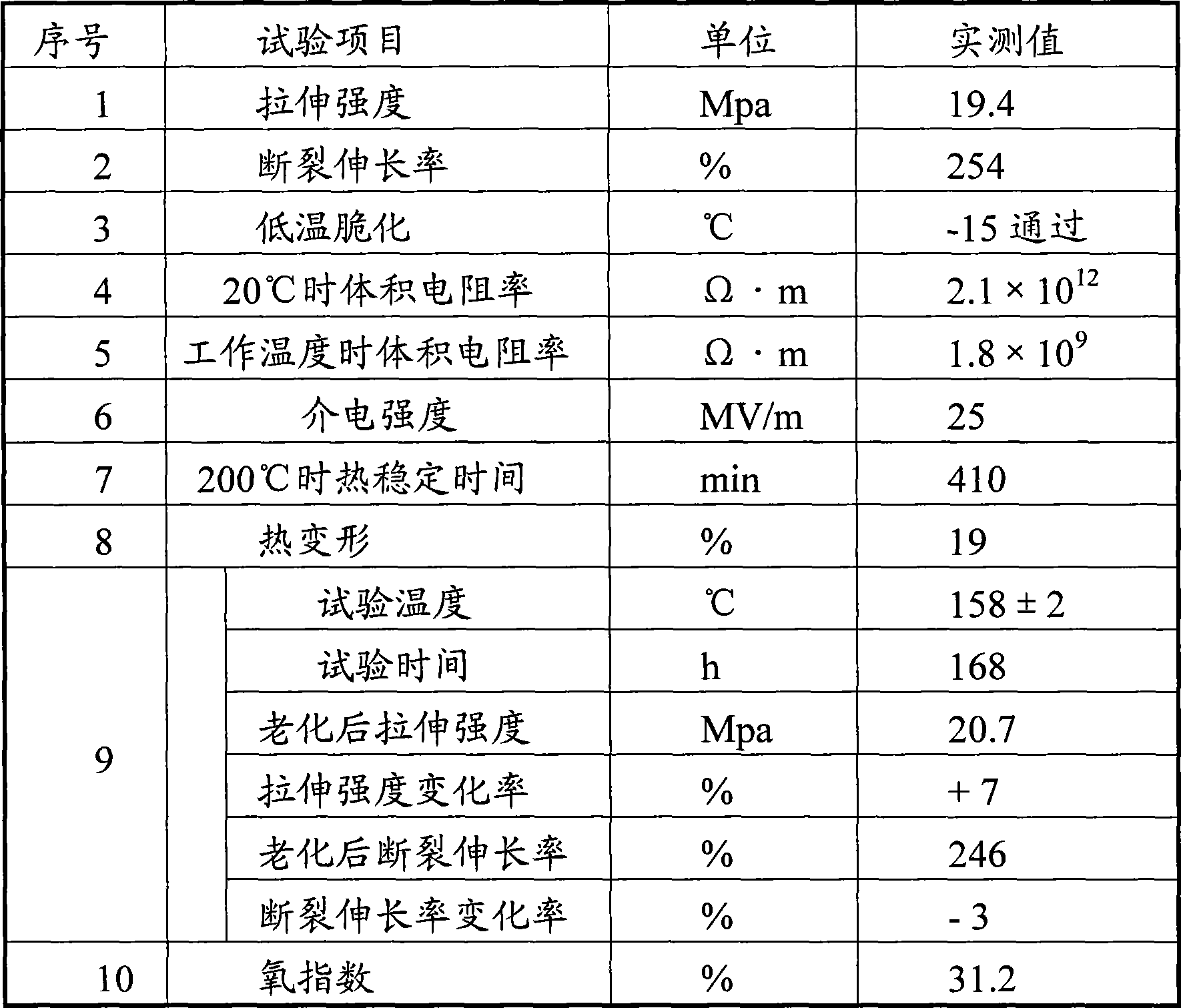

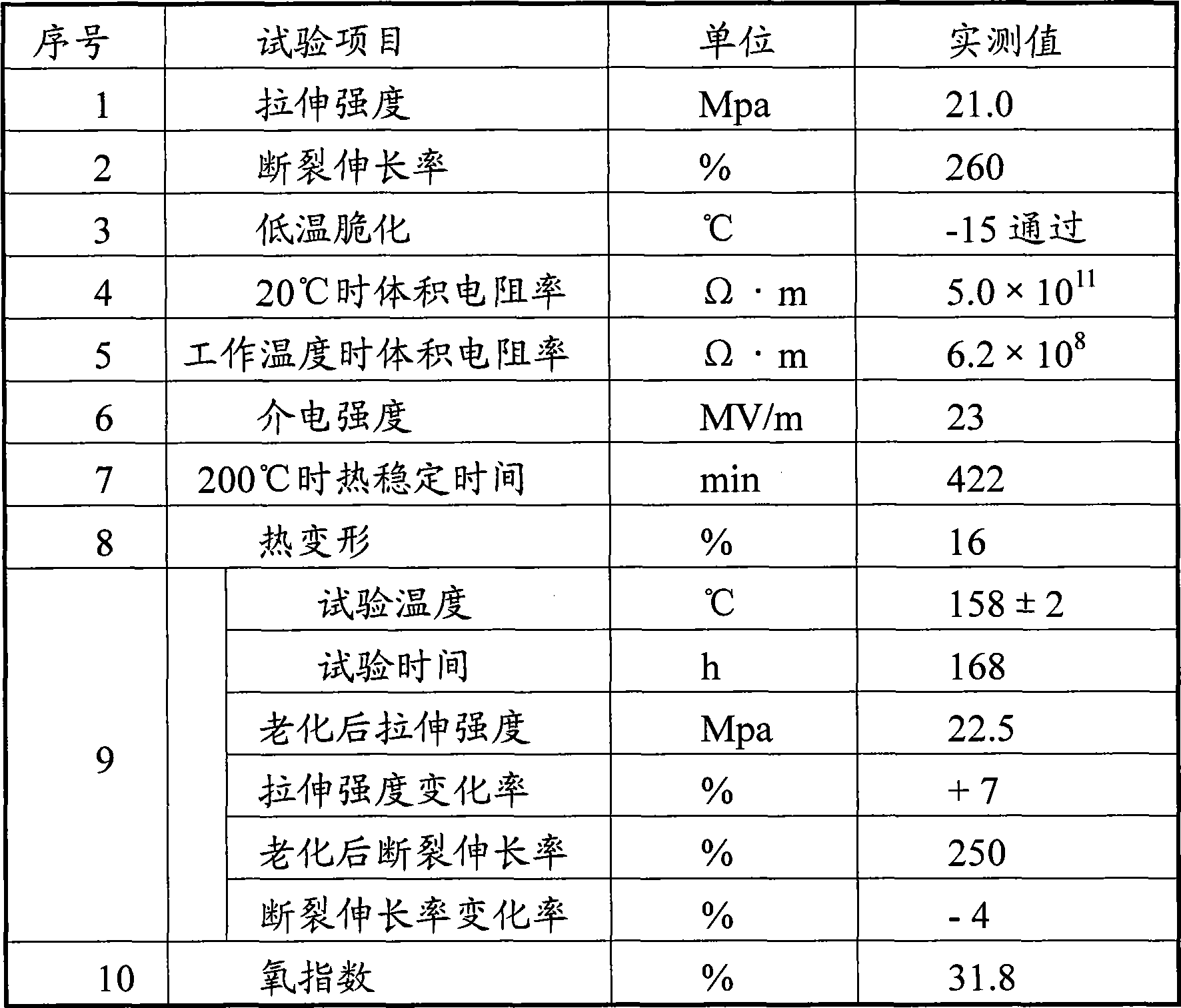

High temperature resistant environment-protective polychloroethylene material for electric wire and cable

InactiveCN101412834AImprove mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterPolyvinyl chloride

The invention provides a high-temperature resistant environment-friendly polyvinyl chloride material for wires and cables. A raw material formulation mainly comprises the following materials in weight portion: 80 to 120 portions of loose-type polyvinyl chloride resin, 20 to 55 portions of tetraoctyl pyromellitate, 5 to 35 portions of polyester plasticizer and 12 to 18 portions of calcium-zinc stabilizer, wherein the polymerization degree of the loose-type polyvinyl chloride resin is between 2,000 and 3,000; in the calcium-zinc stabilizer, the total content of lead, cadmium, mercury and hexavalent chromium is less than or equal to 10 ppm of the total weight of the calcium-zinc stabilizer; the polyester plasticizer is polypropylene-1, 2-glycol adipate or polypropylene-1, 3-butylene terephthalate; and the molecular weight of the polyester plasticizer is between 3,000 and 4,000. After the material is aged in a hot-air oven for 168 hours at 158 DEG C, the retention rate of tensile strength is up to 106 percent; the retention rate of elongation at break is 97 percent; and the material is good in mechanical physical properties and insulating property. Therefore, the material meets the temperature-resistant requirement on long-term operating temperature at 125 DEG C in UL1581.

Owner:中广核三角洲(江苏)塑化有限公司

Polymer Compositions, Method of Manufacture, and Articles Formed Therefrom

ActiveUS20080242789A1Improve ductilityIncrease modulusPigmenting treatmentCeramic shaping apparatusHeat deflection temperaturePolyester

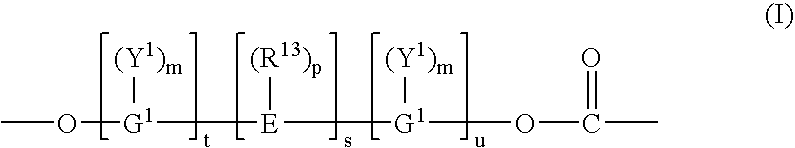

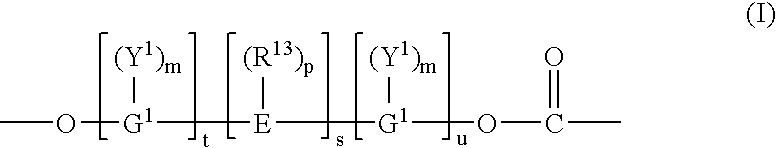

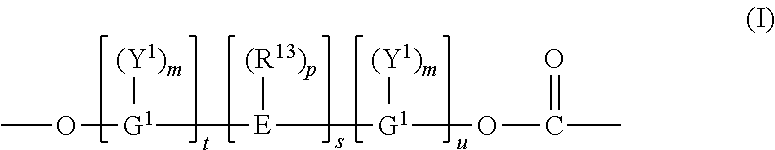

A composition comprises, based on the total weight of the composition, from 10 to 80 wt. % of a polyester; from 10 to 80 wt. % of a polycarbonate; from 0 to 20 wt. % of an impact modifier; from 1 to less than 25 wt. % of a reinforcing filler; from 0.1 to less than 2.5 wt. % of a fibrillated fluoropolymer; from 0 to 5 wt. % of an additive selected from the group consisting of antioxidants, mold release agents, colorants, quenchers, stabilizers, and combinations thereof, wherein the composition has a heat deflection temperature of at least 110° C., measured in accordance with to ASTM D648 on 3.2 mm thick molded bars at 0.455 MPa.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Polymer Compositions, Method of Manufacture, and Articles Formed Therefrom

ActiveUS20080246181A1Improve ductilityIncrease modulusMaterial nanotechnologyPigmenting treatmentPolytetramethylene terephthalateHeat deflection temperature

A composition comprises, based on the total weight of the composition: from 10 to 80 wt. % of a modified polybutylene terephthalate copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) has at least one residue derived from the polyethylene terephthalate component; from 10 to 80 wt. % of a polycarbonate; from 0 to 20 wt. % of an impact modifier; from 1 to less than 25 wt. % of a reinforcing filler; from 0.1 to less than 2.5 wt. % of a fibrillated fluoropolymer; from 0 to 5 wt. % of an additive selected from the group consisting of antioxidants, mold release agents, colorants, quenchers, stabilizers, and combinations thereof. The composition has a heat deflection temperature of at least 110° C., measured in accordance with to ASTM D648 on 3.2 mm thick molded bars at 0.455 MPa.

Owner:SHPP GLOBAL TECH BV

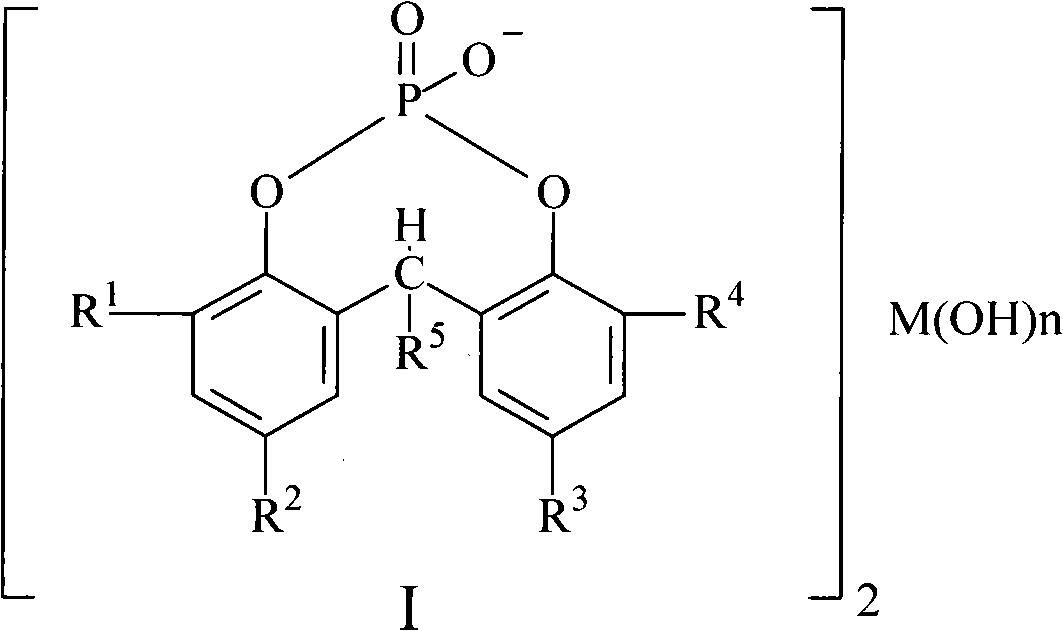

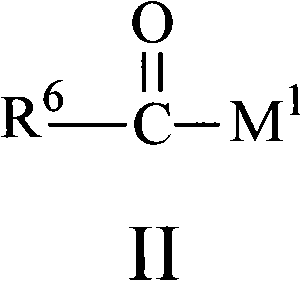

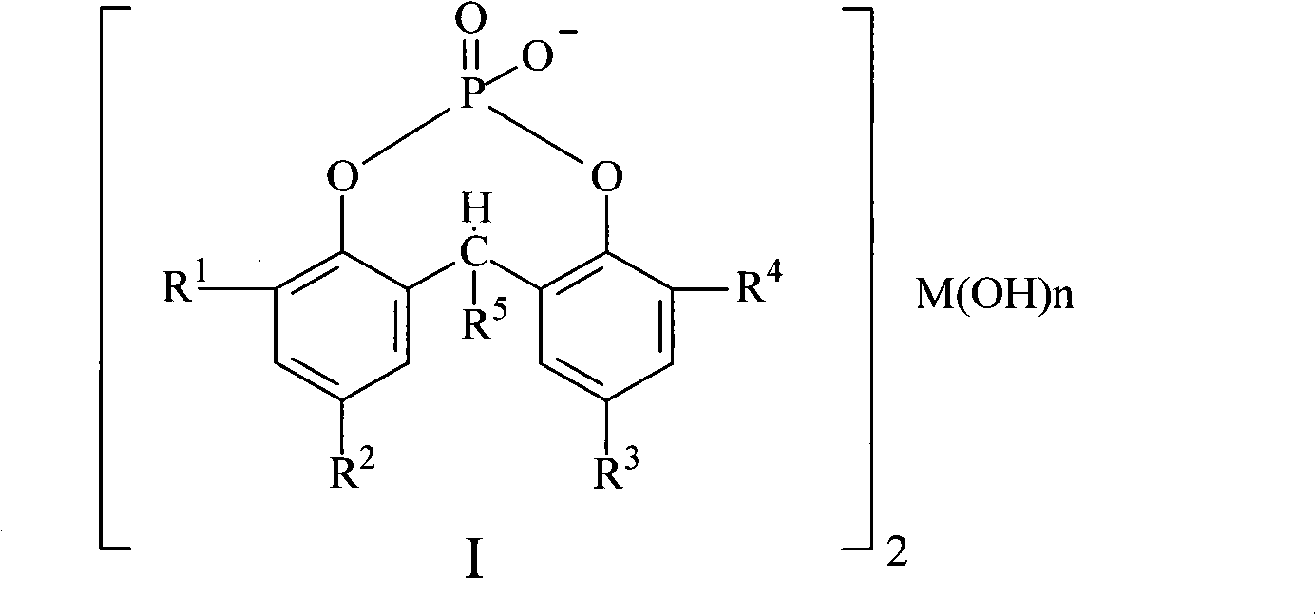

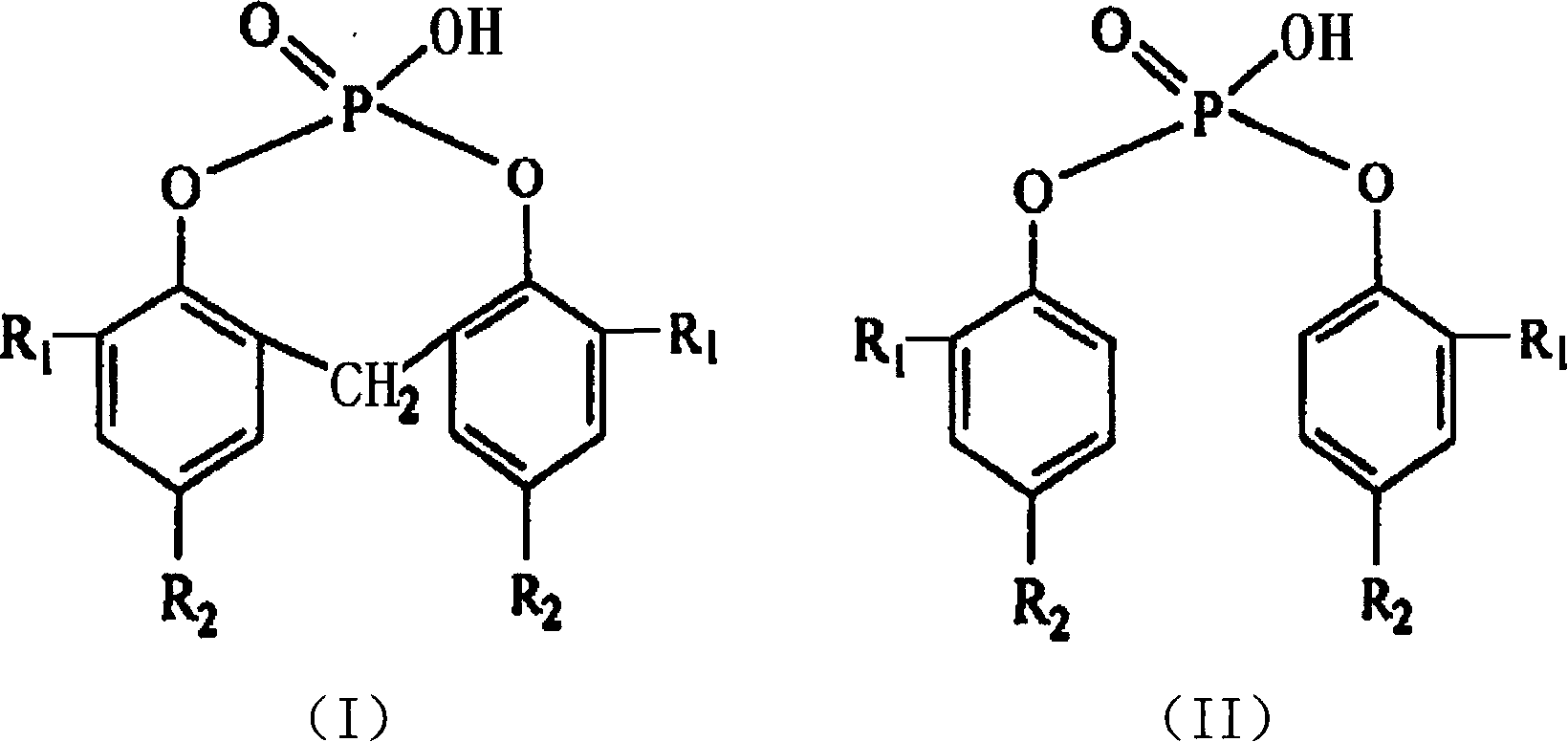

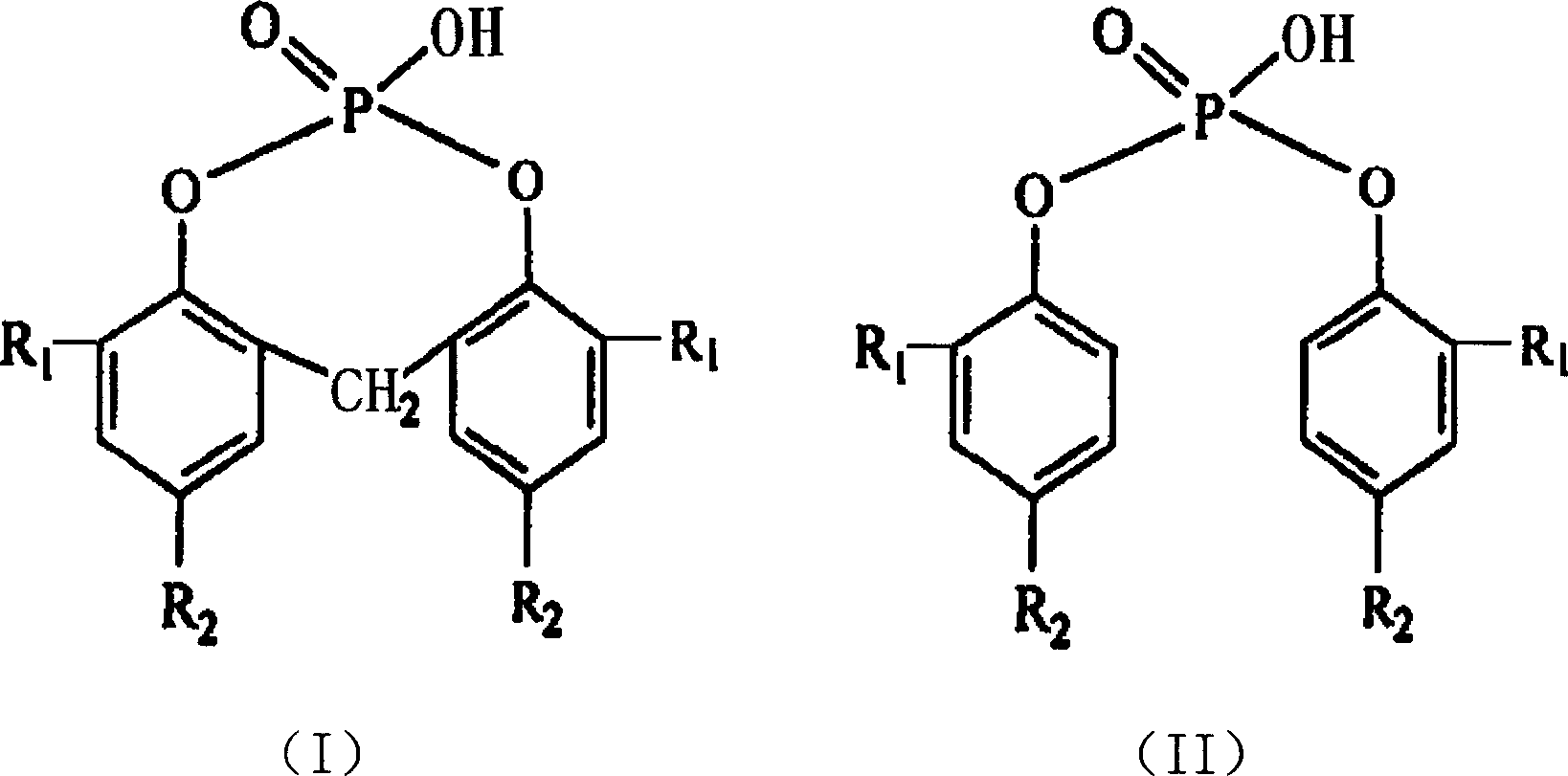

Polypropylene transparent nucleater

The invention discloses a polypropylene transparent nucleating agent, which consists of one or two compounds in category A accounting for 90 to 10 percent by weight and one or two compounds in category B accounting for 10 to 90 percent by weight. The compound(s) in category A is (are) multivalent metal salt(s) substituting for diaryl phosphoric acid; and the compound(s) in category B is (are) alkali metal salt(s) of monobasic fatty acid. The polypropylene transparent nucleating agent disclosed by the invention overwhelms the defects of organic phosphates in use, such as too high melting point, limited compatibleness with resin, poor dispersibility, causing flaws on the surfaces of products easily and so on. By adopting the invention, the polypropylene transparent nucleating agent improves the rigidity, the tensile strength, the creep resistance, the heat distortion temperature of polypropylene and so on, brings high transparency to polypropylene, and reducing the forming cycle. Products got by adopting the invention are of high quality.

Owner:JIANGSU TAIHU CHEM

Transparent polypropylene and preparing method thereof

The invention relates to transparent polypropylene, which is prepared from the following raw materials by weight part: 100 parts of polypropylene, 0.1-0.4 parts of nucleating agent, 0.1-0.2 parts of antioxidant, 0.05-0.2 parts of acid-acceptor, 0.05-0.1 parts of lubricant and 0.05-0.15 parts of dispersant, wherein the nucleating agent is prepared by compounding a phosphate transparent agent with a sorbitol transparent agent, and the weight ratio of the phosphate transparent agent to the sorbitol transparent agent is 0.1 to 100. The preparation method of the transparent polypropylene comprises the following steps: premixing the nucleating agent, the antioxidant, the acid-acceptor, the lubricant and the dispersant, and then extruding the premixed material and the polypropylene at the temperature of 160-240 DEG C to be pelletized.

Owner:PETROCHINA CO LTD

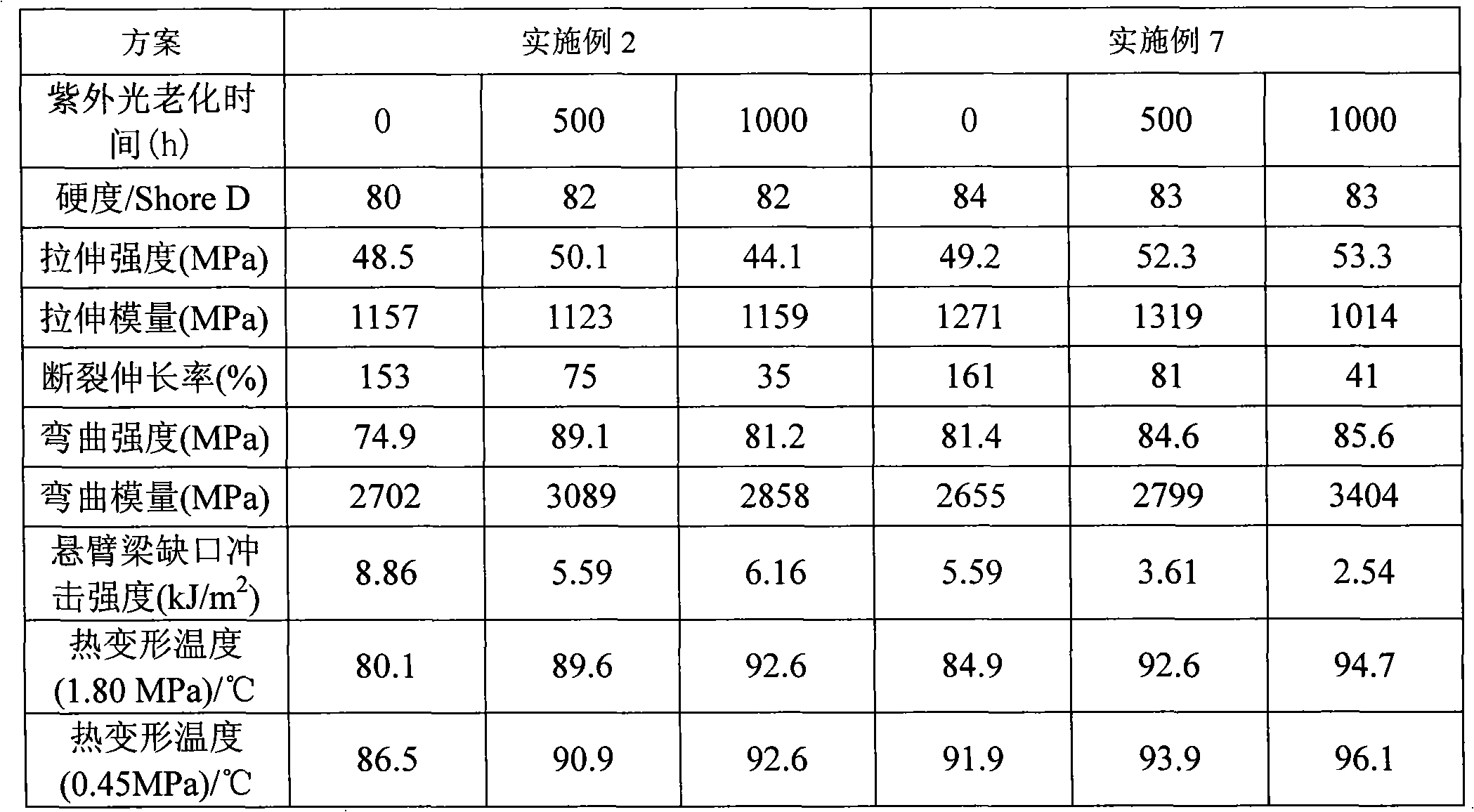

High temperature resistant PVC profile outer cover used in base station antenna and preparation method thereof

InactiveCN101635386AHigh tensile strengthImprove bending strengthRadiating element housingsUltravioletAcrylonitrile

The invention discloses a high temperature resistant PVC profile outer cover used in a base station antenna and a preparation method thereof, which can not only improve the mechanical property, but also greatly improve high and low temperature resistant ageing property and ultraviolet ray resistant property, and greatly improve the electrical property of the material simultaneously, and what's more, the resisted high temperature can reach 90 DEG C. The outer cover of the invention is manufactured by the following raw materials according to the mass ratio: 100 parts of PVC, 30-100 parts of heat resistant modified resin, 4-10 parts of inorganic modified padding, 0-10 parts of calcium carbonate, 1-2 parts of organic stannum stabilizing agent; 1-2 parts of metal soap stabilizing agent, 0.5-1.5 parts of lubricating agent, 4-12 parts of impact modifier, 1-3 parts of acrylic ester processing agent and 0-0.6 part of light stabilizer, wherein, the heat resistant modified resin is one or two or the emulsion blend of ABS resin and alpha-methyl styrene-acrylonitrile copolymer; the inorganic padding is one of titanium dioxide and mica or the mixture of the two.

Owner:NANJING UNIV OF TECH +1

Modified phenolic resin material for 3D printing and preparation method thereof

ActiveCN103980657AThe degree of cross-linking can be controlledIncrease profitHeat deflection temperaturePhenol formaldehyde resin

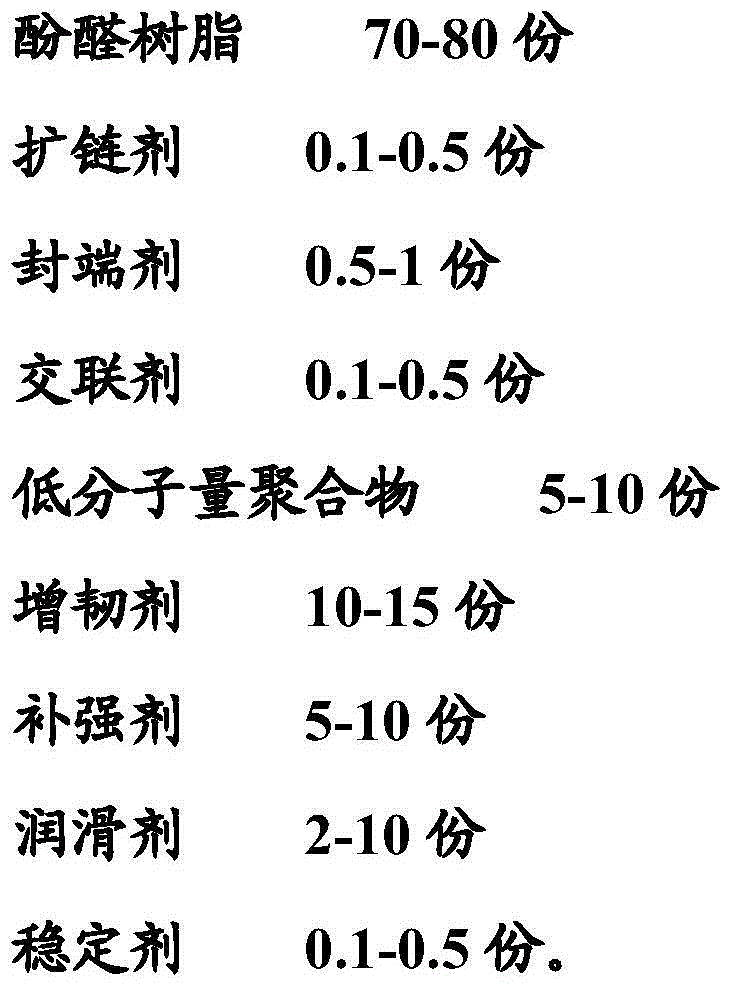

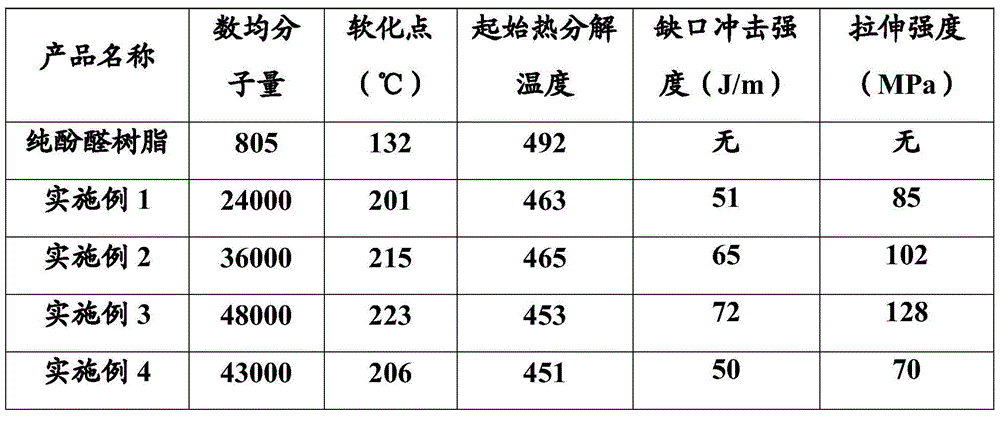

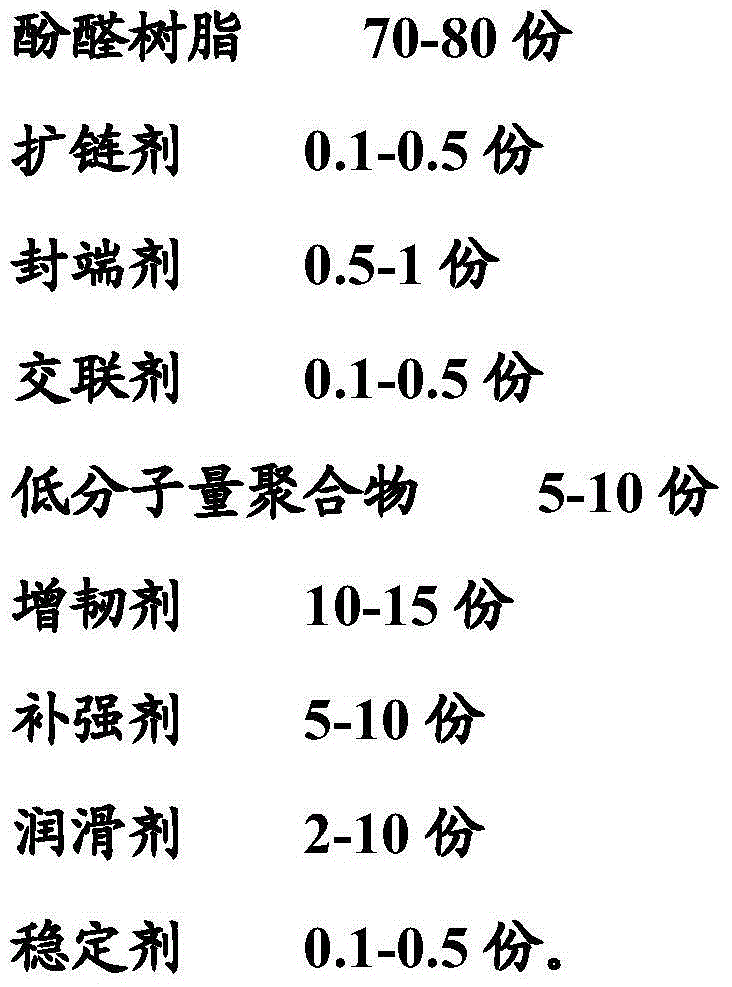

The invention relates to a modified phenolic resin material for 3D printing. Raw materials of the modified phenolic resin material comprises, by weight, 70-80 parts of phenolic resin, 0.1-0.5 parts of a chain extender, 0.5-1 part of an end-capping agent, 0.1-0.5 parts of a cross-linking agent, 5-10 parts of a low-molecular polymer, 10-15 parts of a flexibilizer, 5-10 parts of a reinforcing agent, 2-10 parts of a lubricant and 0.1-0.5 parts of a heat stabilizer. Through a simple material mixing and extruding technology, the phenolic resin is subjected to a modification process so that flexibility, impact intensity and thermal deformation temperature of the phenolic resin are increased greatly. In addition, the phenolic resin material can be processed into various forms, is suitable for various 3D-printing moulding technologies and has a wide application prospect in the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

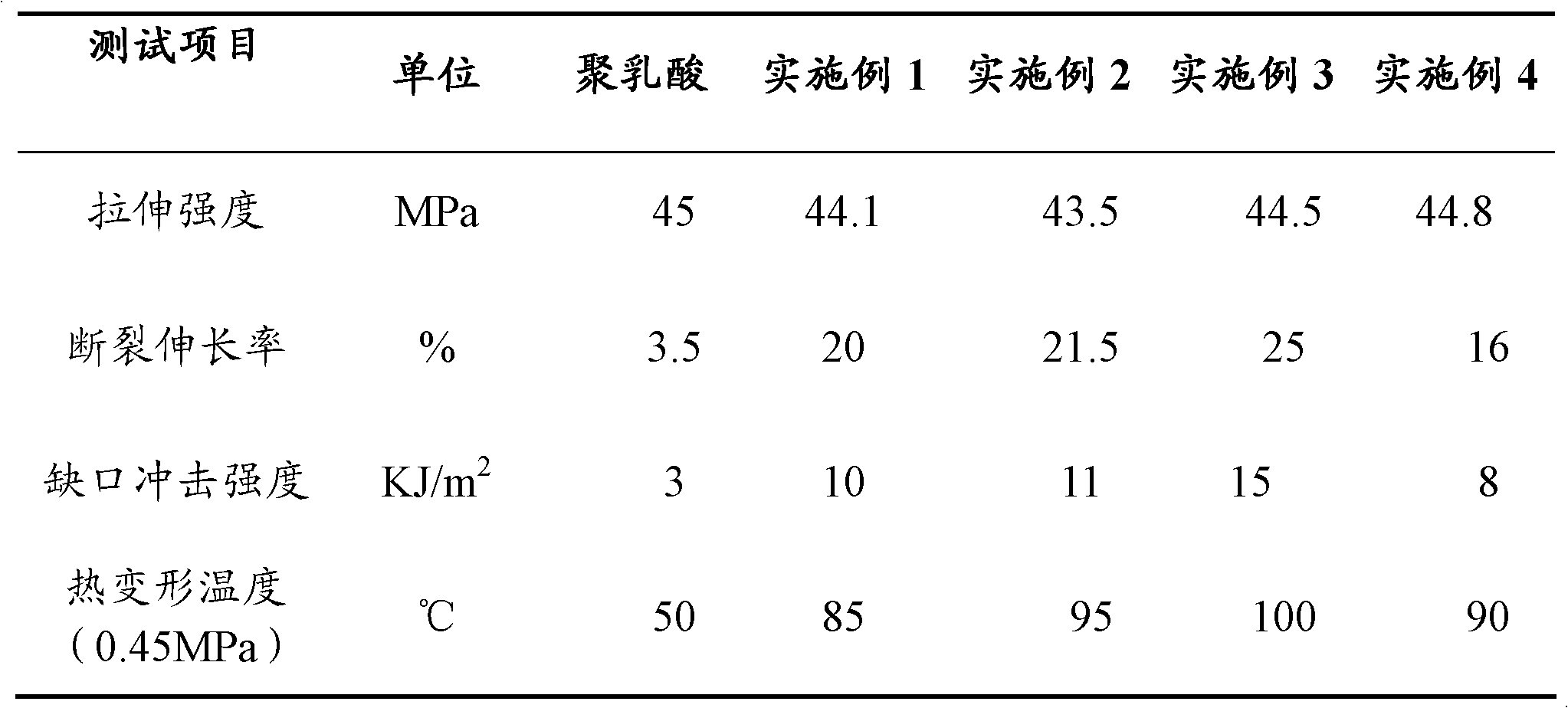

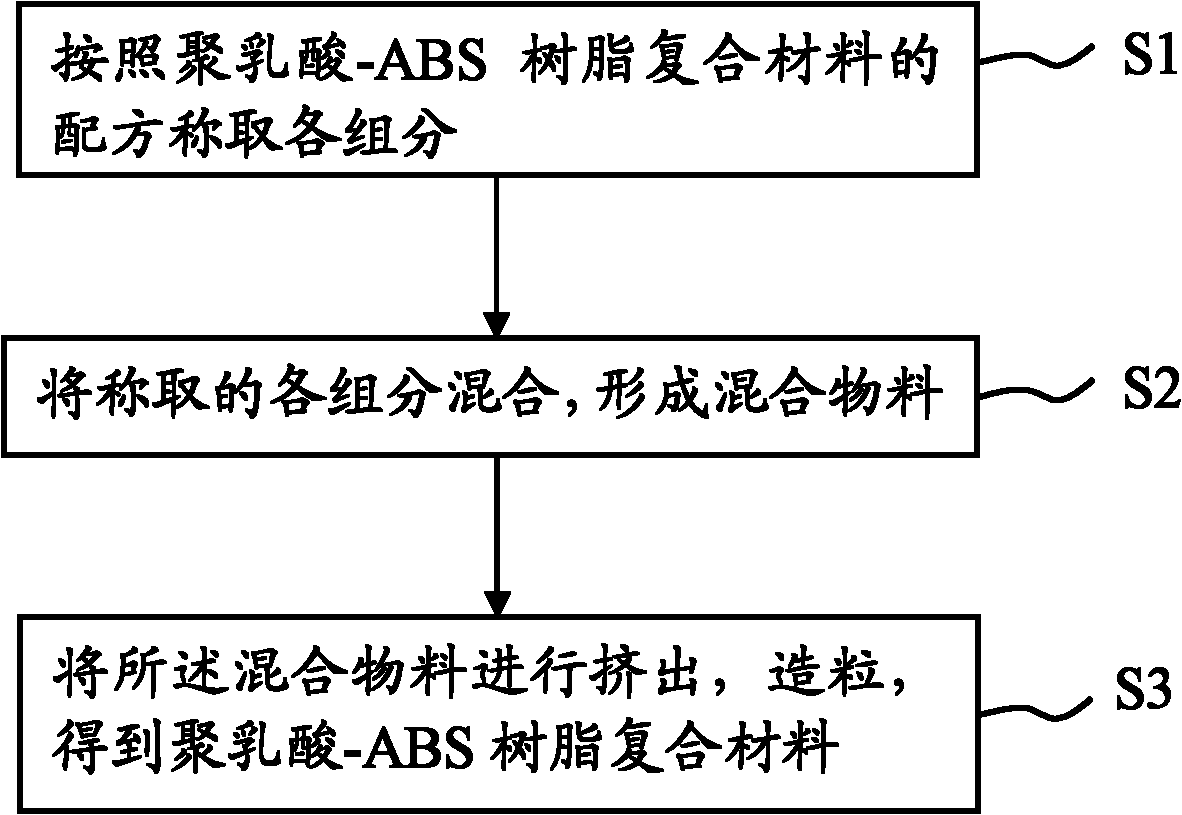

PLA (polylactic acid) resin-ABS (acrylonitrile-butadiene-styrene) resin composite material and method for preparing same

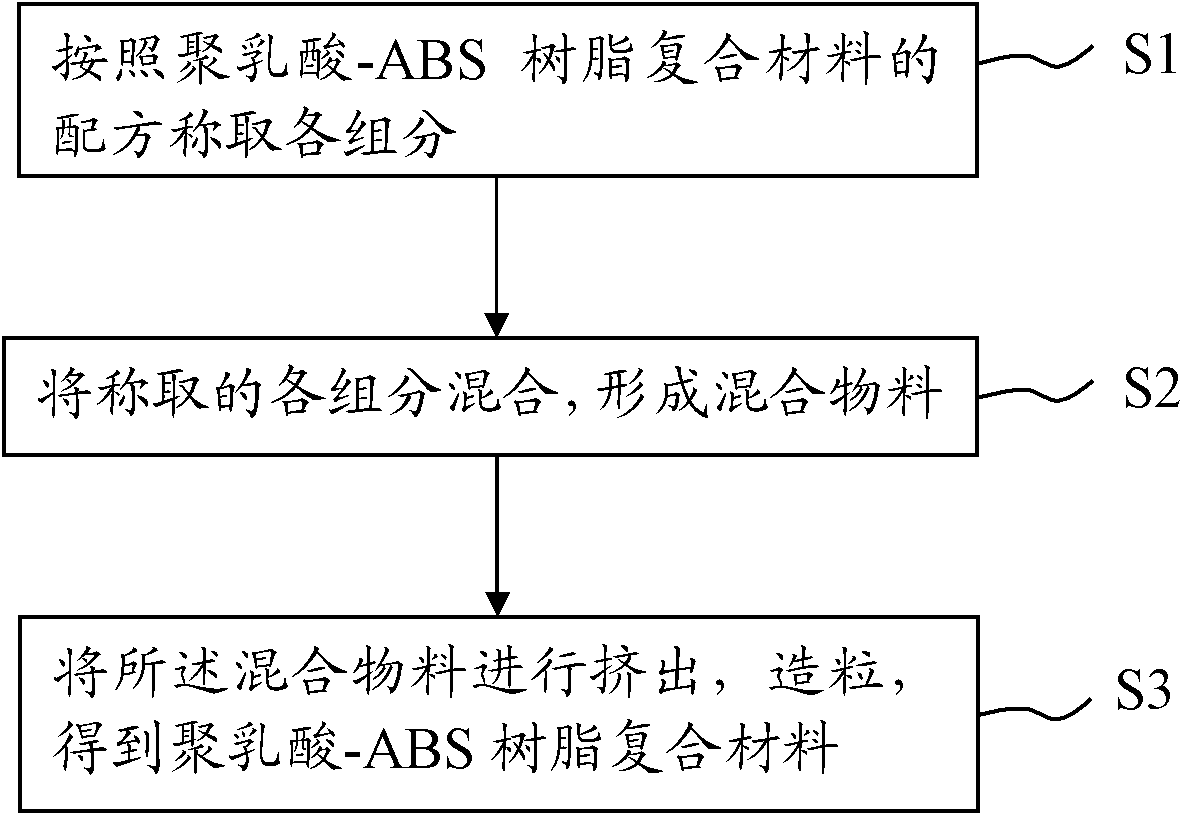

InactiveCN102040813AStrong impact resistanceImprove impact resistanceHeat deflection temperatureExtrusion Granulation

The invention discloses a PLA (polylactic acid) resin-ABS (acrylonitrile-butadiene-styrene) resin composite material and a method for preparing the same. The PLA resin-ABS resin composite material is prepared form the following components by weight percent: 60-80% of PLA resin and copolymer thereof, 10-30% of ABS resin, 3-5% of compatibilizer, 5-10% of toughening agent, 0.5-2% of talcum powder and 0.5-1.5% of coupling agent. The components in proper content range interact mutually during extrusion, thus the PLA resin and ABS resin composite material has advantages of excellent impact strength, heat distortion temperature and biodegradable properties. The method for preparing the PLA resin and ABS resin composite material adopts the simple one-step mixing reaction-extrusion-granulation process, is convenient to operate, has high benefit and low cost and is suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

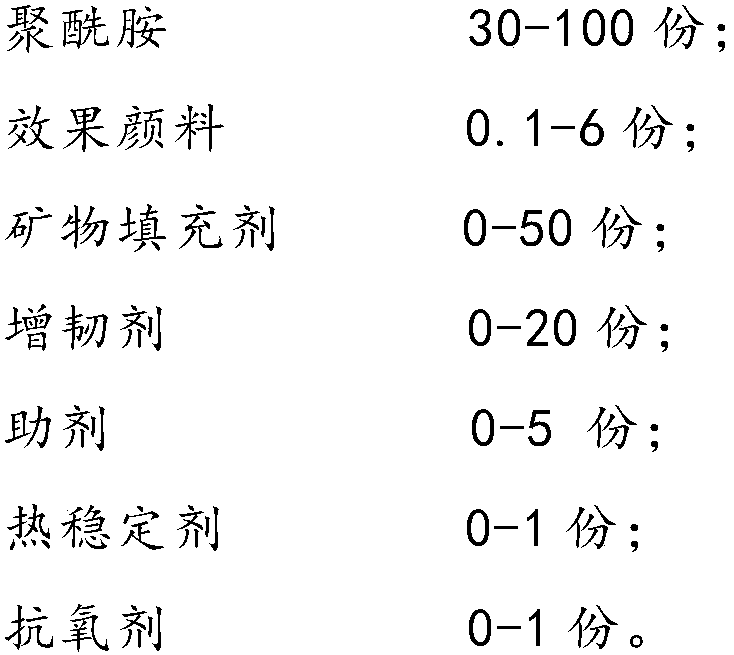

Low-smell high-gloss free-spraying polyamide composition and preparation method thereof

The invention discloses a low-smell high-gloss free-spraying polyamide composition which comprises, by weight, 30-100 parts of polyamide, 0.1-6 parts of effect pigments, 0-50 parts of mineral fillers,0-20 parts of flexibilizers, 0-5 parts of auxiliaries, 0-1 part of heat stabilizers and 0-1 part of antioxidants. Monomers and low-polymer components remaining in the production process of polyamideare eliminated by reaction in the preparation process, and the smell of a low-smell nylon composition is improved. Besides, surface defects of free-spraying workpieces are decreased, brightness is improved, the free-spraying workpieces are closer to appearance effects of painted parts, the smell of the nylon composition is further removed by a smell removal process, and glossiness and tensile strength are further improved by introducing the mineral fillers and the flexibilizers.

Owner:SHANGHAI KINGFA SCI & TECH +2

Polymer compositions, method of manufacture, and articles formed therefrom

ActiveUS8067493B2Improve ductilityIncrease modulusMaterial nanotechnologyPigmenting treatmentPolytetramethylene terephthalateHeat deflection temperature

Owner:SHPP GLOBAL TECH BV

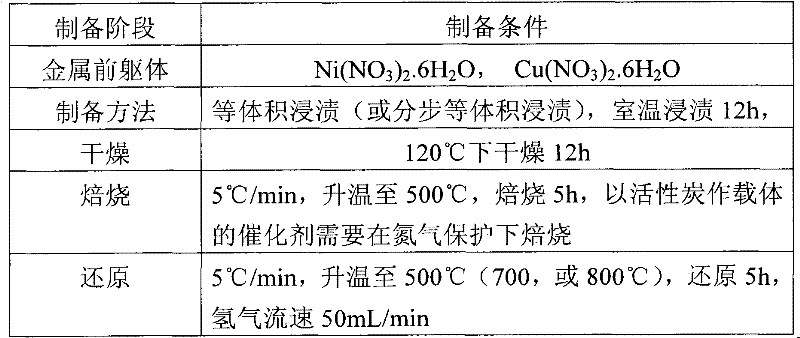

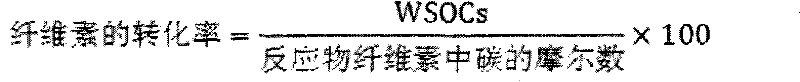

Method for directly preparing glycols from biological cellulosan

InactiveCN102442886AWide variety of sourcesWidely distributedOrganic compound preparationHydroxy compound preparationCelluloseAlcohol sugars

The invention discloses a method for directly preparing glycols from biological cellulosan, comprising the following steps: using cellulose cellulose as a raw material and a polar solvent as a reaction solvent, adding a catalyst in the raw material solution, and reacting for 0.5-72 h at a temperature of 150-300 DEG C under the condition of hydrogenation to obtain a mixture of glycols and sugar alcohol, wherein, the catalyst is a supported nickel-based catalyst, copper-based catalyst, nickel-copper, copper-zinc, nickel-copper-zinc dual metal of poly metal catalyst. According to the invention, various glycols can be obtained simultaneously; the product can be used individually by separation, and can be directly used for producing unsaturated polyester resin, polyurethane, fuel additive, surfactant, emulsifier, motor vehicle antifreeze fluid and the like without deep separation.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

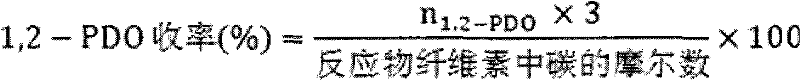

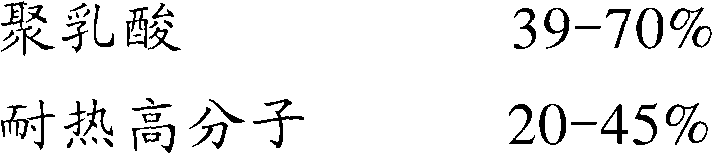

High-impact-resistance heat-resistant polylactic acid alloy material and preparation method thereof

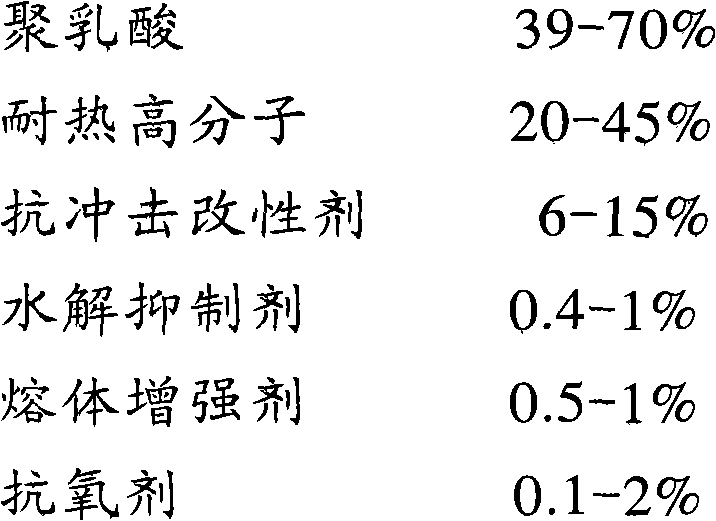

The invention provides a high-impact-resistance heat-resistant polylactic acid alloy material and a preparation method thereof. The alloy material comprises the following components in percentage by weight: 39-70 percent of polylactic acid, 20-45 percent of heat-resistant macromolecules, 6-15 percent of an impact-resistant modifier, 0.4-1 percent of a hydrolysis inhibitor, 0.5-1 percent of melt reinforcing agent and 0.1-2 percent of an antioxidant. The high-impact-resistance heat-resistant polylactic acid alloy material is obtained by uniformly mixing the components with a stirrer, putting a mixture into a double screw extruder, and extruding and pelletizing. The method has the advantages of simple process, high benefit and low cost. The prepared alloy material can be applied in the fieldof engineering plastic for automobiles, buildings, aviation and the like.

Owner:CHERY AUTOMOBILE CO LTD

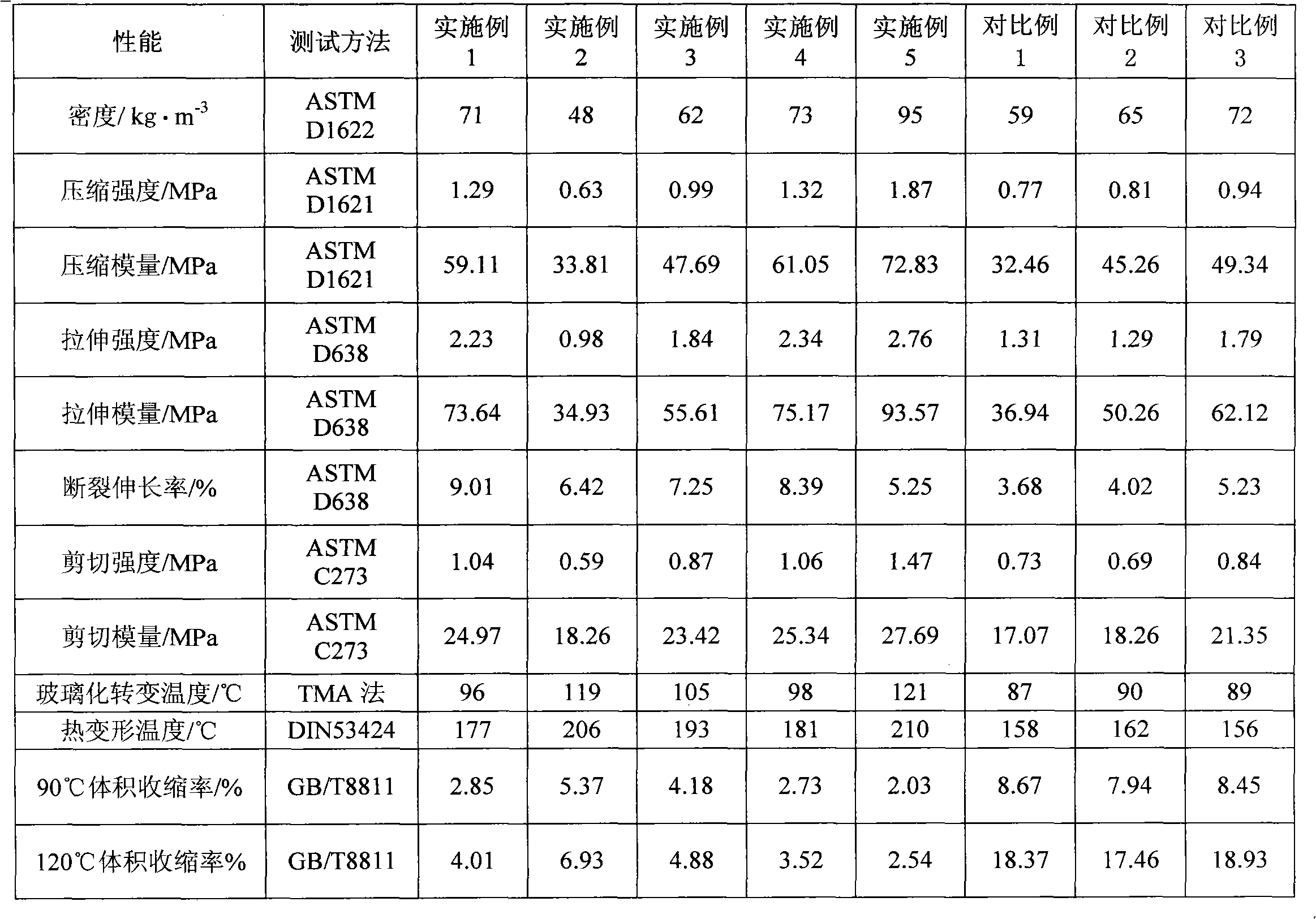

Modified rigid cross-linked polyvinyl chloride foam and preparation method thereof

ActiveCN103509273AGood dimensional stabilityImprove heat deflection temperatureCross-linkHeat deflection temperature

The invention discloses a modified rigid cross-linked polyvinyl chloride foam, which is prepared from the following raw materials in parts by weight: 90-99 parts of polyvinyl chloride paste resin, 1-10 parts of chlorinated polyvinyl chloride resin, 3-15 parts of cross-linking agent, 30-70 parts of isocyanate, 9-24 parts of anhydride, 4-8 parts of azo foaming agent, 2-15 parts of epoxidized soybean oil, and 2-6 parts of filler, wherein the filler is any one or combination of more of hollow glass beads, titanium dioxide, a carbon nano tube or montmorillonoid. Meanwhile, a preparation method of the foam is also provided. The form has better dimensional stability and higher distortion temperature; the highest distortion temperature can be up to 120 DEG C.

Owner:威海维赛新材料科技有限公司

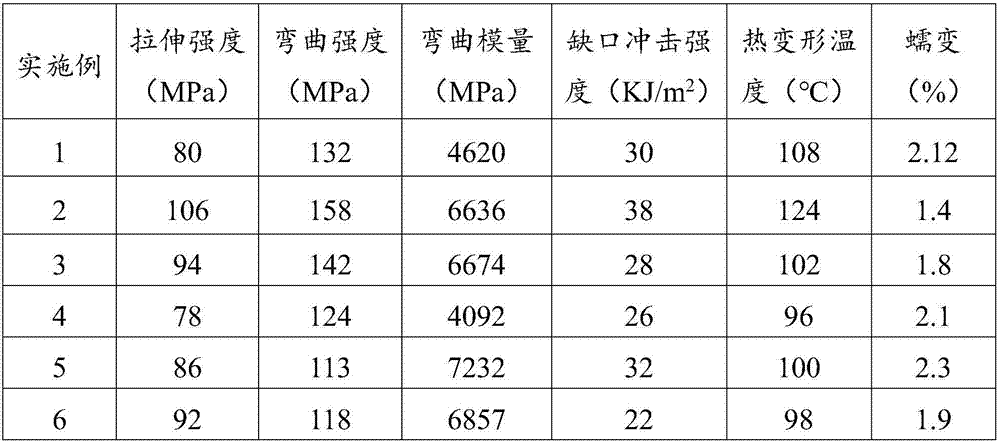

Modified polypropylene composite material and preparation method of same

ActiveCN108034147AImprove scratch resistanceLow costHeat deflection temperaturePolypropylene composites

The invention discloses a modified polypropylene composite material which includes, by weight, 35-90 parts of polypropylene resin, 8-35 parts of basalt fibers, 0.1-5 parts of a scratch resistant agent, 0.5-5 parts of a coupling agent, and 0.2-5 parts of a compatibilizer. The basalt fibers are selected from at least one of non-twist continuous basalt fibers and short-cut basalt fibers. The non-twist continuous basalt fibers are 1200-2400 tex non-twist continuous basalt fibers and the short-cut basalt fibers are 0.2-10 mm short-cut basalt fibers; preferably, the basalt fibers are pre-treated inacetic acid being 1.0-3.0 mol / L for 1-3 h. The modified polypropylene composite material has low cost, high thermal deformation temperature, good tensile strength, high bending modulus and excellent damp-heat-resistance, anti-aging property and scratch resistance, and can satisfy demands on vehicle-use modified polypropylene composite materials.

Owner:WUHAN JINFA TECH CO LTD +1

High-gloss, high-hardness and spraying-free ABS (acrylonitrile butadiene styrene) plastic modified material and preparation method thereof

The invention relates to a high-gloss, high-hardness and spraying-free ABS (acrylonitrile butadiene styrene) plastic modified material and a preparation method thereof. The high-gloss, high-hardness and spraying-free ABS plastic modified material comprises the following raw materials in parts by weight: 55-64 parts of ABS resin, 15-20 parts of AS (acrylonitrile styrene) resin, 15-25 parts of PMMA (polymethyl methacrylate) resin, 0.2-0.5 part of plasticizer, 0.2-0.5 part of lubricant, 1-2 parts of high color black, 0.2-0.4 part of antioxidant and 0.1-0.2 part of methyl silicone oil. The high-gloss, high-hardness and spraying-free ABS plastic modified material disclosed by the invention has very high hardness, the surface hardness can be above the H level, and the high-gloss, high-hardness and spraying-free ABS plastic modified material further has strong anti-scratch performance during the using process and is less prone to being scratched; the high-gloss, high-hardness and spraying-free ABS plastic modified material has very high gloss, high black and bright degree, stable quality, good using effects and good tensile strength, anti-impact strength and other performances, and housings of televisions, refrigerators and washing machines applying the high-gloss, high-hardness and spraying-free ABS plastic modified material have stronger anti-impact performance and long service life; and the preparation method disclosed by the invention has the advantages of simplicity in operation, few required equipment and low production cost.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

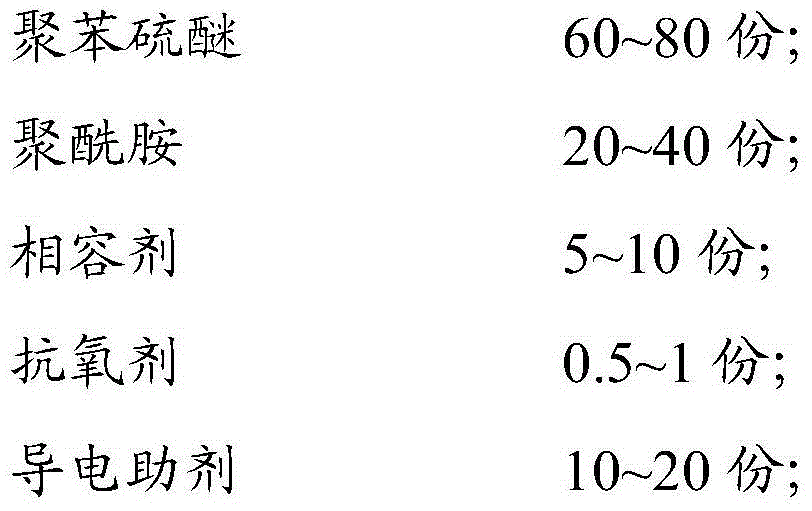

Polyphenylene sulfide composite material and preparation method thereof

The invention relates to a polyphenylene sulfide composite material and a preparation method thereof. The polyphenylene sulfide composite material is prepared from the following raw materials in parts by weight: 60-80 parts of polyphenylene sulfide, 20-40 parts of polyamide, 5-10 parts of a compatilizer, 0.5-1 part of an antioxidant, 10-20 parts of a conductivity improver, 20-40 parts of filler, 0.5-1 part of a coupling agent and 0.4-0.8 part of a lubricant, wherein the compatilizer is a styrene-vinyl-butadiene-styrene segmented copolymer grafted maleic anhydride. The polyphenylene sulfide composite material has relatively good rigidity, heat resistance and anti-static performance.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

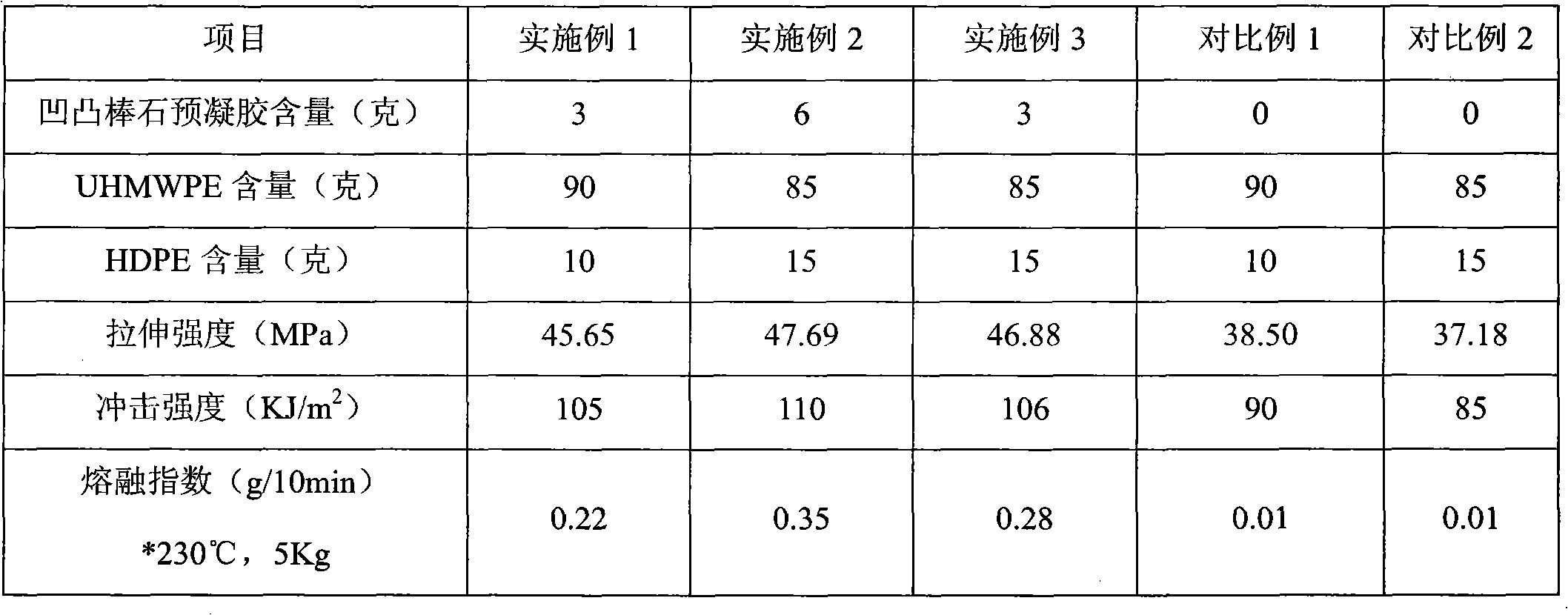

Method for preparing extrusion-grade ultrahigh molecular weight polyethylene-high density polyethylene-attapulgite pregel composite material

The invention discloses a method for preparing an extrusion-grade ultrahigh molecular weight polyethylene-high density polyethylene-attapulgite pregel composite material. The method comprises the following steps: adding 15-10 parts by weight of high density polyethylene, 1-10 parts by weight of attapulgite pregel, 0.5-30 parts by weight of flow modifier and 0.1-1 part by weight of antioxygen into 85-90 parts by weight of ultrahigh molecular weight polyethylene, mixing at the temperature of 20-30 DEG C at a high speed, feeding the mixture in a double-screw extruder at the extrusion temperature of 180-240 DEGC, and extruding and pelletizing to obtain the extrusion-grade ultrahigh molecular weight polyethylene special material which has the characteristic of excellent mechanical performance, and can meet requirements of certain occasions and special products.

Owner:HUAFENG PIPE IND CO LTD GANSU

Organophosphate polypropylene nucleation agent and its preparation method

The invention discloses the organophosphorus ester polypropylene nucleation agent and its preparation method. The method comprises the following steps: using the replacement diaryl phosphoric acid and alcohols as reactants, spraying the water, organic solvent and alcohols into the replacement diaryl phosphoric acid separately, controlling the moisture content at 3-22úÑ, with the esterification catalysts, stirring and reacting. The said replacement diaryl organophosphorus ester can be used as nucleation improver of profax, improving the processing property of profax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass fibre reinforced polypropylene-nylon composite material and preparation method thereof

The invention discloses a glass fibre reinforced polypropylene-nylon composite material. The glass fibre reinforced polypropylene-nylon composite material comprises the following components in parts by weight: 40 to 60 parts of polypropylene, 20 to 50 parts of nylon, 5 to 40 parts of glass fibres, 2 to 10 parts of a compatilizer, 1 to 4 parts of a coupling agent, 0.5 to 2 parts of an antioxidant, and 0.1 to 0.2 part of an auxiliary agent. The invention also discloses a preparation method for the glass fibre reinforced polypropylene-nylon composite material. Glass fibres disclosed by the invention can be uniformly dispersed in a molten mixture; the lengths of the glass fibres are effectively prevented from being damaged; the preparation method is simple and is safe to operate; the prepared composite material is good in mechanical properties and high in impact resistance, and has good thermal deformation temperature resistance, creep resistance and size stability.

Owner:JIANGSU SHENXIANG ELECTROMECHANICAL

Coupling agent modified silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive

InactiveCN102838957AExtended service lifeReduce absorptionNon-macromolecular adhesive additivesOther chemical processesAntioxidantAdhesive

The invention relates to a coupling agent modified silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive. The adhesive is characterized in that: it is composed of component A and component B that are mixed in a ratio of 1: (0.9-1) for construction. Specifically, the component A consists of cycloaliphatic epoxy resin, an active diluent, a transparent blue-violet purple dye color paste, a defoaming agent and a softening agent. The component B consists of a curing agent, an accelerator, a silane coupling agent modified nano-ultraviolet absorbent, polyol and an antioxidant. The nano-silicon dioxide doped cycloaliphatic epoxy resin LED packaging adhesive provided in the invention has the advantages of good ageing resistance, strong binding power, fast curing, low viscosity and moisture absorption, so that employment of organosilicone with a high cost can be avoided. Meanwhile, the defects of high moisture absorption, poor ultraviolet resistance and low shortwave transmittance and the like of existing bisphenol A type epoxy resin can be overcome. The LED packaging adhesive provided in the invention is more suitable to be used as a high-end LED packaging adhesive, a high power LED packaging adhesive or an ultraviolet light-based white light and blue light LED packaging adhesive.

Owner:JIANGSU TETRA NEW MATERIAL TECH

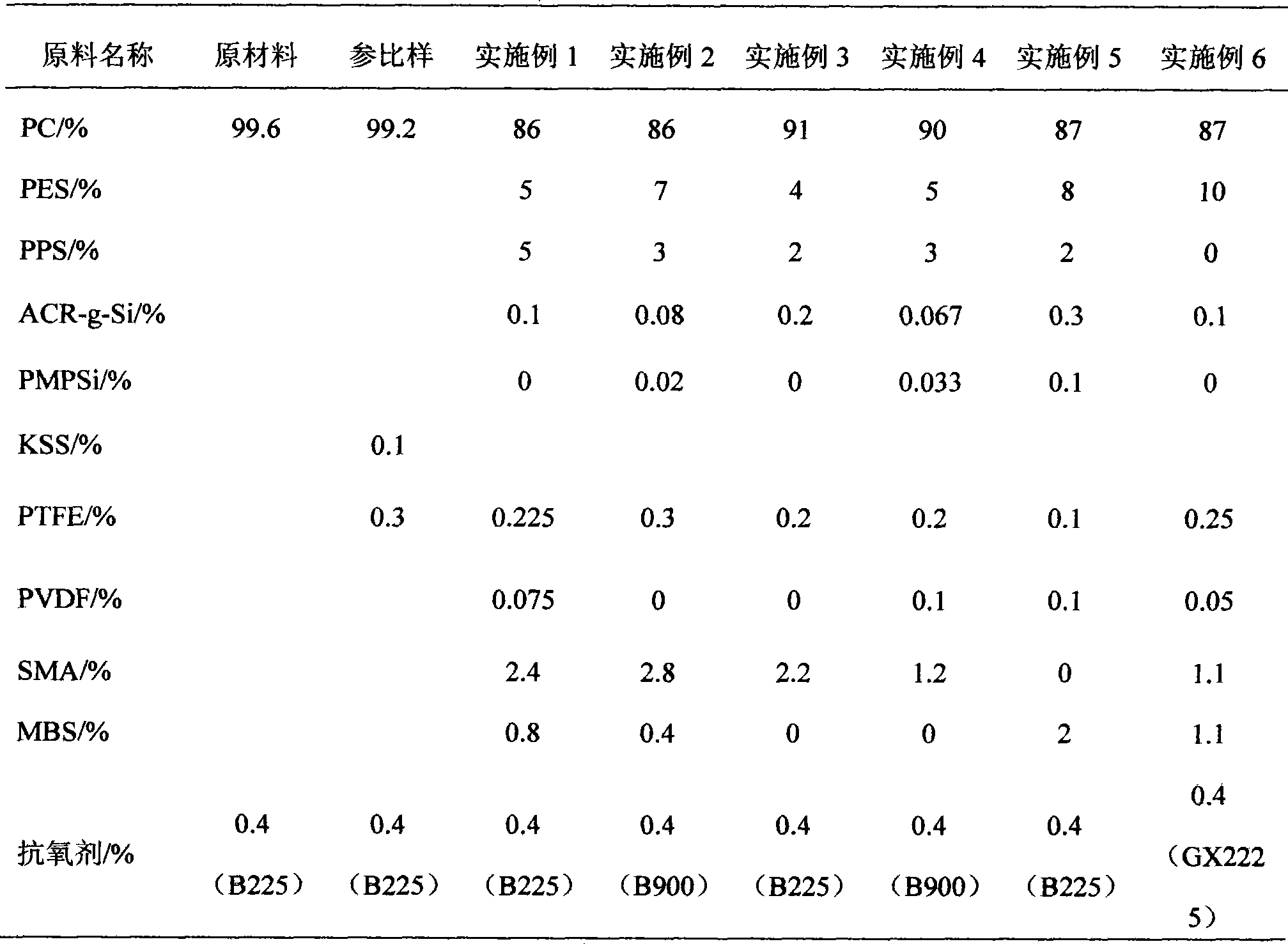

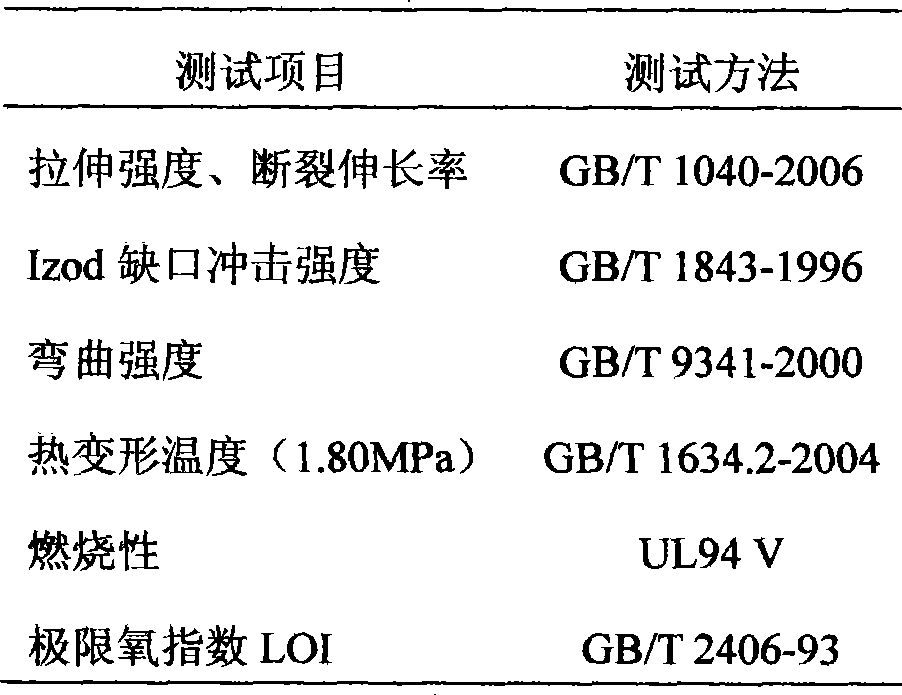

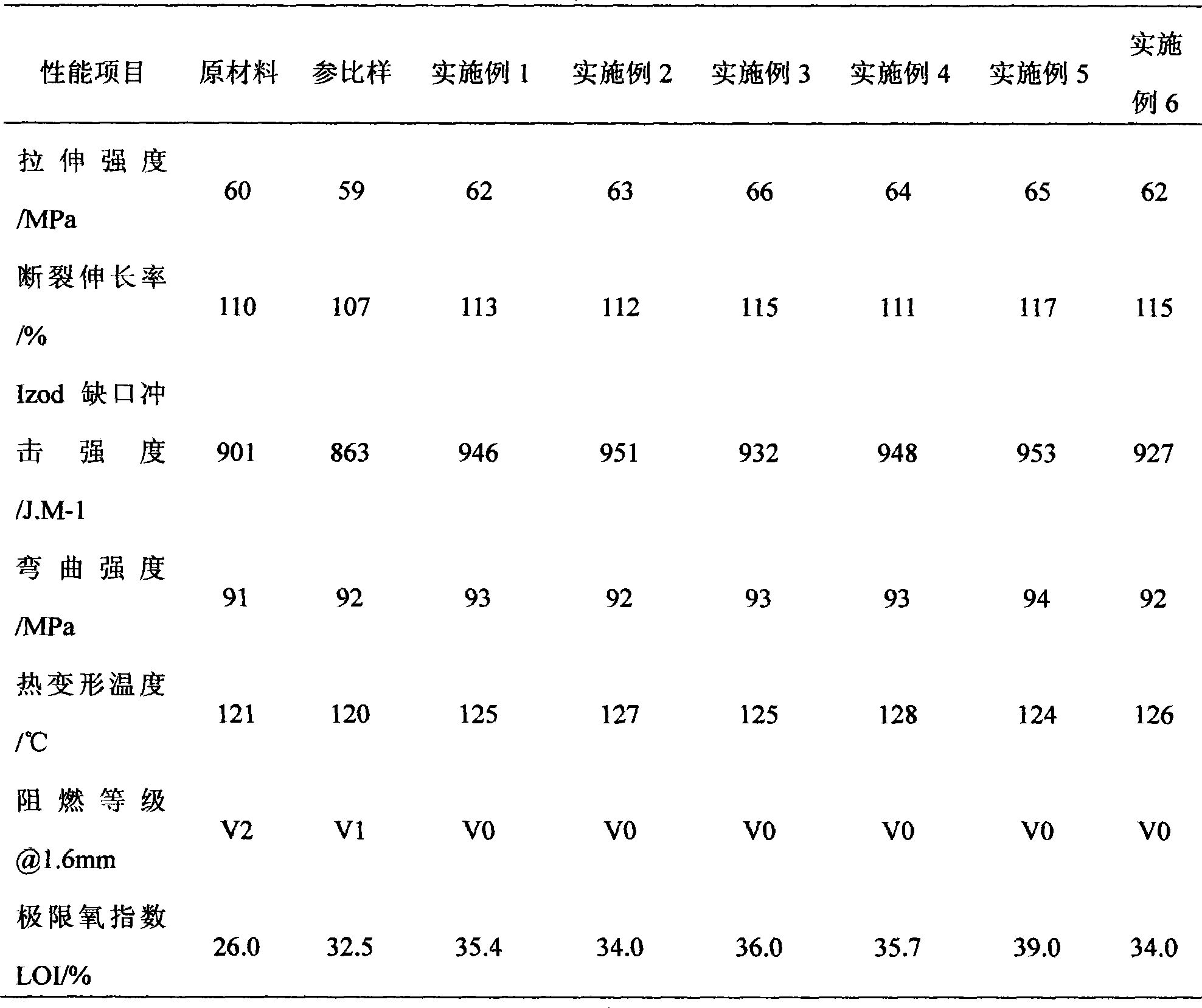

Non-halogen flame-retarding high performance polycarbonate engineering plastics and preparation method thereof

The invention relates to a halogen-free inflaming retarding high-performance polycarbonate engineering plastic and a preparation method thereof. Counted in weight percentage, the components of the engineering plastic include as follows: 78 to 92 percent of PC resin, 5 to 10 percent of sulfur-bearing super engineering plastics, 0.1 to 3 percent of flame retardant containing silicon, 0.1 to 1 percent of anti-dropping agent, 1 to 5 percent of compatilizers and 0.1 to 1 percent of chemical inhibitors; wherein, the sulfur-bearing engineering resin is polyethersulfone or the composition of the polyethersulfone and polyphenyl thioether; the flame retardant containing silicon is acrylic ester graft modification polysiloxane or the composition of the acrylic ester graft modification polysiloxane and poly methyl phenyl siloxane. The preparation method includes as follows: the materials of the prescription are fully mixed in a high speed mixer; then is fed into a co-rotating meshed double-screw extruder to melt, blend and extrude. In the invention, the sulfur-bearing super engineering plastics and the flame retardant containing silicon are matched and used, thus endowing the polycarbonate with excellent flame retardation and higher heat resistance as well as excellent compatibility, improving the mechanical property of the composite material and overcoming the defects of being easily separated out and absorbing moisture of a micromolecule flame retardant containing silicon.

Owner:SOUTH CHINA UNIV OF TECH

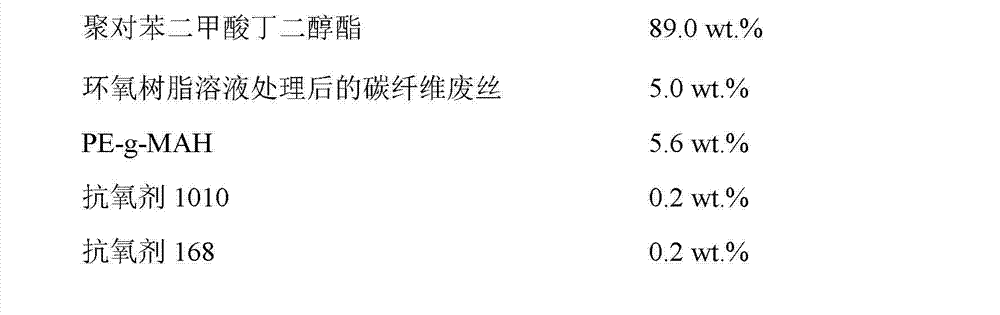

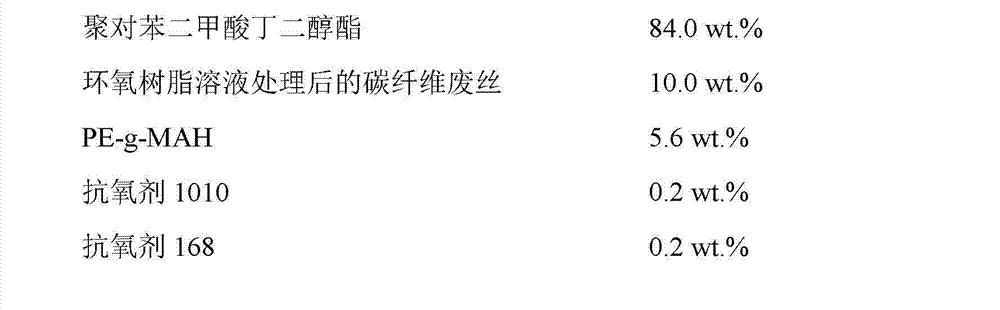

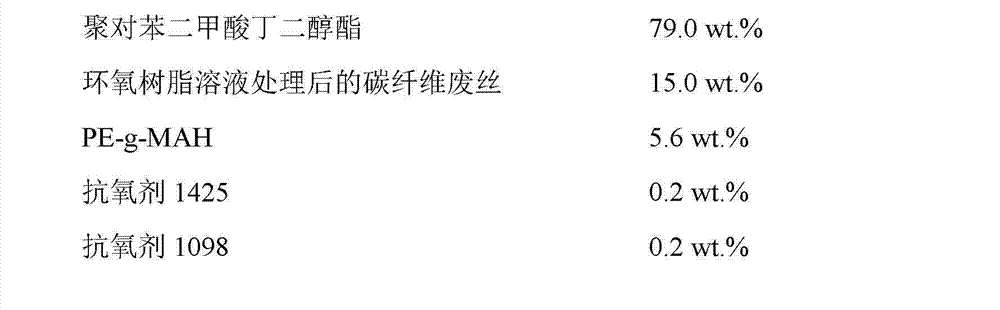

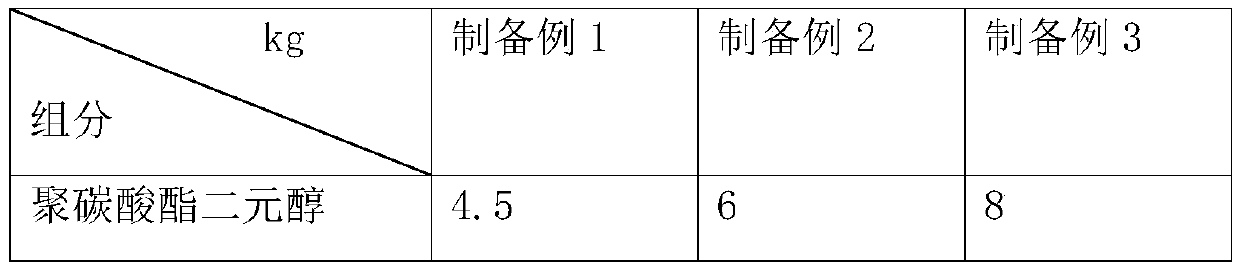

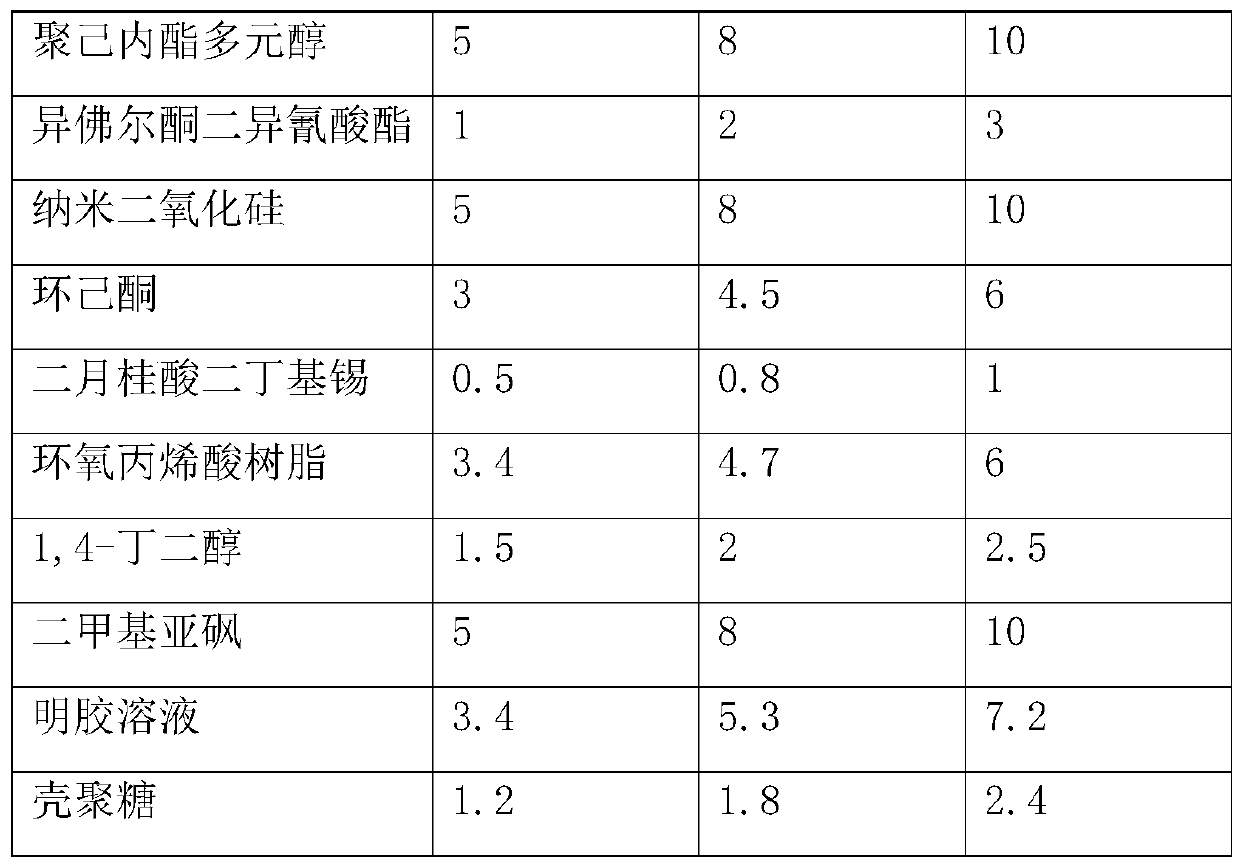

Waste-carbon-fiber-reinforced polybutylene terephthalate composite material and preparation method thereof

The invention relates to a waste-carbon-fiber-reinforced polybutylene terephthalate composite material and a preparation method thereof, belonging to the field of polymer-base composite material. The composite material is prepared from 65.0-90.0 wt.% of reinforced polybutylene terephthalate, 5.0-30 wt.% of waste carbon fiber subjected to surface treatment, 0.1-0.3 wt.% of antioxidant and 3.0-8.0 wt.% of toughener. The preparation method comprises the following steps: cleaning the surface of waste carbon fibers, activating and drying; adding the waste carbon fibers into a double screw extruder through a side feed port; carrying out melt blending extrusion on the waste carbon fibers with polybutylene terephthalate, a toughener and an antioxidant by using the double screw extruder; and drawing the extruded melt, cooling with water, screening, granulating and drying. The composite material has the characteristics of high strength, high modulus, high toughness, high heat deformation temperature, favorable heat resistance, favorable static resistance, wear resistance and creep resistance; and the product has the advantages high cost performance and simple preparation method, and can be widely used in the fields of electronic and electric parts, automobile accessories, household appliances and the like.

Owner:BEIJING UNIV OF CHEM TECH

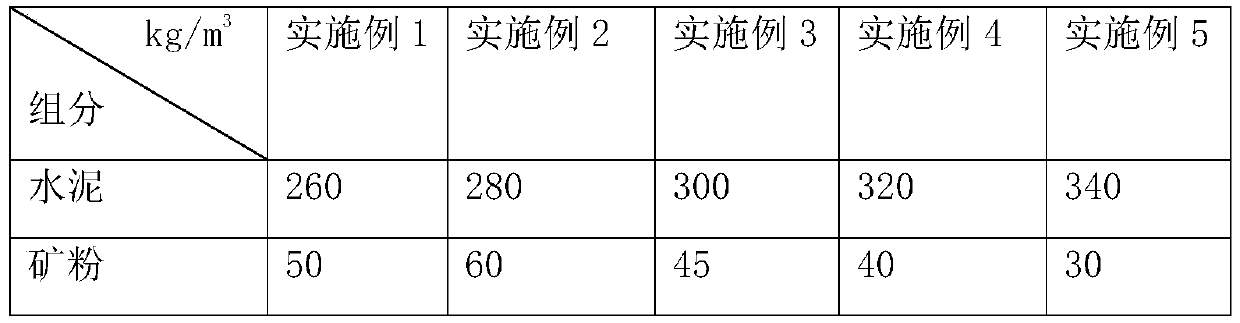

Colored pervious concrete and preparation process thereof

The invention discloses a colored pervious concrete and a preparation process thereof. The colored pervious concrete is prepared from the following raw materials in parts by weight: 260 to 340 parts of cement; 30 to 60 parts of mineral powder; 60 to 90 parts of fly ash, 20 to 45 parts of silica fume, 150 to 200 parts of water, 700 to 900 parts of a fine aggregate, 800 to 1200 parts of a coarse aggregate, 10 to 20 parts of a pigment, 8 to 16 parts of an early strength accelerator, 45 to 80 parts of bisphenol A epoxy resin, 35 to 55 parts of polyurethane modified gelatin and 60 to 90 parts of acuring accelerator; wherein the curing accelerator is prepared from 2-ethyl-4-methylimidazole, a modified anhydride curing agent and a cardanol modified polyamide in a mass ratio of 1 to (1.3 to 1.5)to (0.7 to 1). The colored pervious concrete has the advantages of being high in pervious coefficient, high in early compressive strength and breaking strength, short in curing time, capable of shortening open traffic time and good in thermal aging resistance and freezing and thawing resistance.

Owner:成都新豪鼎盛建材有限公司

Heat-resistant and flame-retardant nylon tube

InactiveCN105482448AImprove the disadvantage of high water absorptionImprove water absorptionPolymer scienceMagnesium borate

The invention discloses a heat-resistant and flame-retardant nylon tube. The heat-resistant and flame-retardant nylon tube is prepared from nylon 66, nylon 6, polymethylhydrosiloxane, epoxy resin, titanate coupling agent modification nano-zinc oxide, modification needle-like wollastonite, an amination carbon nano-tube, nano-silicon dioxide, red phosphorus, melamine cyanurate, organic nano-montmorillonite, glass fibers, magnesium borate whiskers, basic zinc carbonate nanofibers, ethylene-propylene-diene monomer, ethylene-bis-stearamide, calcium pimelate, zinc pimelate, silane coupling agent, aluminum diethylphosphinate and lanthanum stearate. The heat-resistant and flame-retardant nylon tube is good in heat resistance and flame retardancy, high in strength and excellent in impact resistance, and a nylon tube formed by the heat-resistant and flame-retardant nylon tube is good in overall performance and long in service life.

Owner:安徽都邦电器有限公司

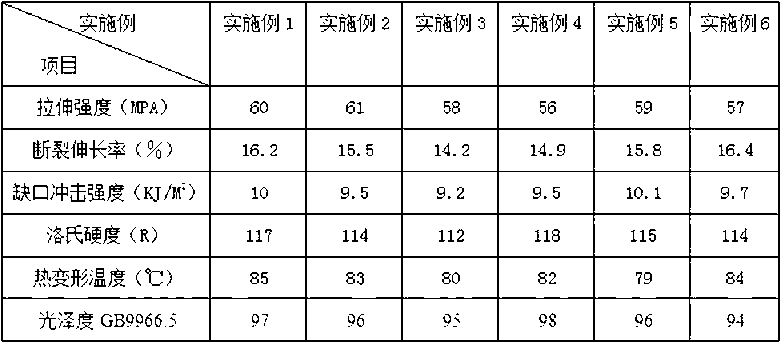

Coupling agent modified calcium carbonate filled polypropylene plastic and preparation method thereof

The invention discloses a coupling agent modified calcium carbonate filled polypropylene plastic and a preparation method thereof. The coupling agent modified calcium carbonate filled polypropylene plastic comprises the following components in parts by weight: 100 parts of polypropylene, 10-20 parts of calcium carbonate, and 0.1-0.3 part of coupling agent, wherein the coupling agent preferably consists of 10-30 parts of gamma-chloropropyltriethoxysilane, 50-70 parts of isopropyl tri(dioctylphosphate)titanate and 10-30 parts of Polyethyleneglycol trimethoxysilylpropyl ether. According to the invention, calcium carbonate is modified by adding the coupling agent so that the surface of calcium carbonate changes from hydrophilicity into lipophilicity and then can be tightly combined with polypropylene, and the performances of a plastic material are improved; furthermore, the coupling agent is preferable so that the viscosity is reduced, and each mechanical property is better; and the coupling agent modified calcium carbonate filled polypropylene plastic has the advantages of good tensile strength, elongation at break, notch impact strength, thermal deformation temperature and Rockwell hardness.

Owner:河北立信化工有限公司

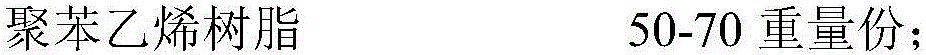

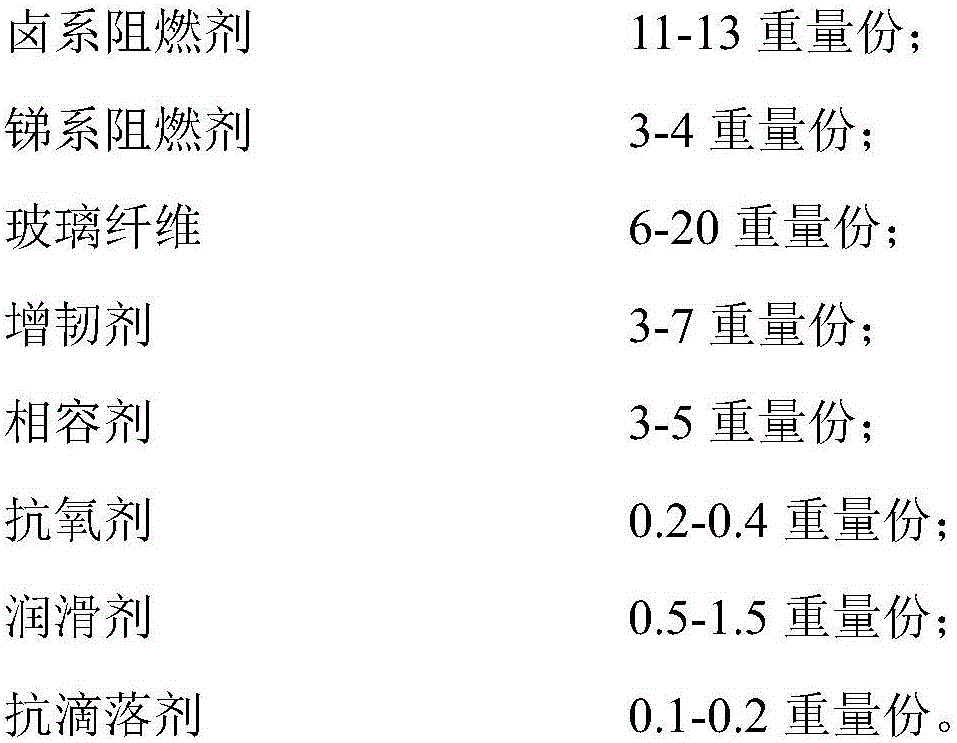

Glass fiber-reinforced flame-retardant polystyrene resin composition and preparation method thereof

The invention relates to a glass fiber-reinforced flame-retardant polystyrene resin composition, which comprises the following components in weight part: 50-70 parts of polystyrene resin, 11-13 parts of halogenated flame retardant, 3-4 parts of antimonic flame retardant, 6-20 parts of glass fibers, 3-7 parts of flexibilizer, 3-5 parts of compatilizer, 0.2-0.4 part of anti-oxidant, 0.5-1.5 parts of lubricant, and 0.1-0.2 part of anti-dripping agent. According to the technical scheme of the invention, the impact strength of the resin composition is greatly improved. Meanwhile, the defect that the existing glass fiber-reinforced flame-retardant polystyrene resin is poor in impact strength can be overcome. The application range of glass fiber reinforced flame-retardant polystyrene is expanded. The glass fiber-reinforced flame-retardant polystyrene resin provided by the invention is high in impact strength, high in rigidity, high in flame-retardant efficiency, good in flowability, and the like. Meanwhile, the glass fiber-reinforced flame-retardant polystyrene resin has a wide application prospect to meet the market requirements of light weight and thin wall upside to the current trend.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

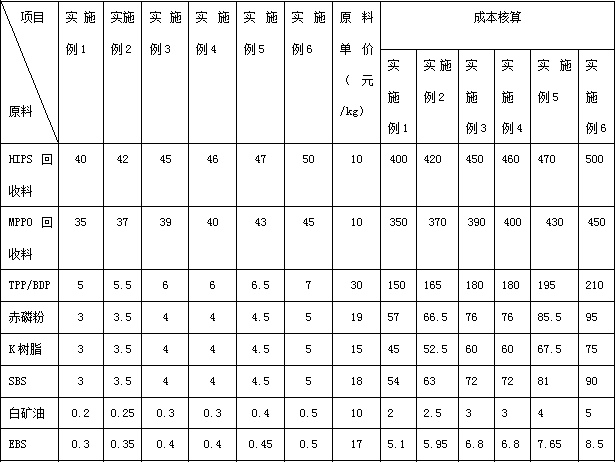

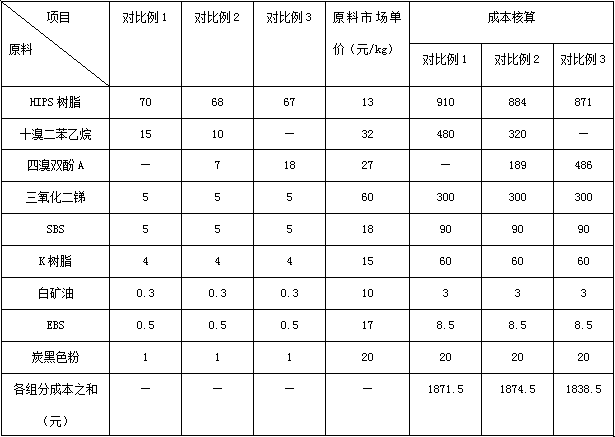

Halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and preparation method thereof

ActiveCN103242614AImprove flame retardant performanceImprove securityPlastic materialsUltimate tensile strength

The invention relates to a halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and a preparation method thereof. The halogen-free flame retardant HIPS plastic modified material comprises the following materials in parts by weight: 40-45 parts of HIPS, 35-40 parts of MPPO (Modified Polyphenylene Oxide), 5-7 parts of halogen-free flame retardant, 3-5 parts of red phosphorus powder, 3-5 parts of K resin, 3-5 parts of SBS (Styrene Butadiene Styrene), 0.3-0.5 part of lubricating agent, 0.2-0.5 part of white mineral oil and 0.5-2 parts of carbon black powder. The halogen-free flame retardant HIPS plastic modified material not only has good flame retardation and strong safety, but also has good mechanical performances including tensile strength and the like; a television enclosure, which is manufactured by the halogen-free flame retardant HIPS plastic modified material, has stronger impact resistance and a long service life, and can be recycled. The processing materials MPPO and HIPS are mainly reclaimed materials, so that the cost of the modified HIPS plastic material is greatly lowered. The halogen-free flame retardant HIPS plastic modified material is free of halogen, environment-friendly and capable of generating great environment-friendly benefits. Besides, the preparation method of the halogen-free flame retardant HIPS plastic modified material is simple to operate, less in needed equipment and low in production cost.

Owner:东莞国立高分子材料有限公司

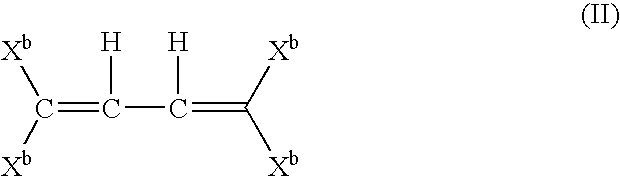

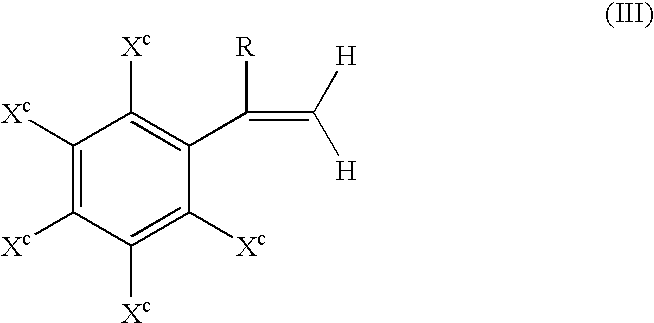

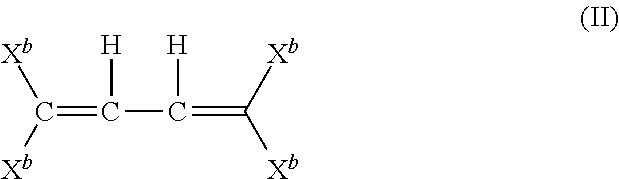

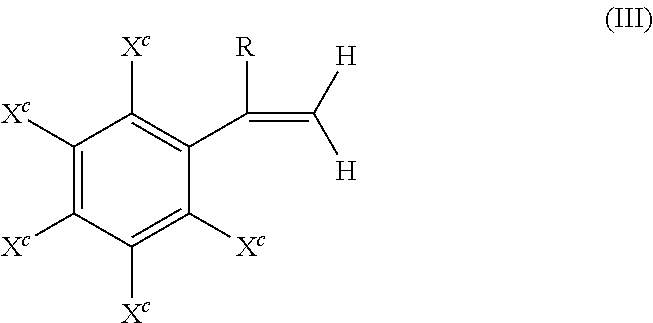

Polydicyclopentadiene/polystyrene interpenetrating polymer network and preparation method thereof

ActiveCN102558731APromote aggregationMake up tensile strengthHeat deflection temperaturePolymer science

The invention discloses a polydicyclopentadiene / polystyrene interpenetrating polymer network and a preparation method thereof. A compound material is formed through simultaneous polymerization of polymeric monomers in part by weight: 60 to 99 part of dicyclopentadiene, 1 to 40 parts of styrene or benzene ring substitution styrene and 0.01 to 10 parts of divinylbenzene, wherein a substitution group in the benzene ring substitution styrene is an alkyl substitution group with halogen or carbon number ranging from 1 to 6; dicyclopentadiene is polymerized by a ring-opening translocation catalytic body; and styrene and divinylbenzene are polymerized by a free radical. Heat generated by ring-opening polymerization of polydicyclopentadiene causes the polymerization of styrene to form an interpenetrating polymer network type compound material taking polydicyclopentadiene as a first network and polystyrene as a second network, as compared with the single polydicyclopentadiene material, the tensile strength is improved by 3 to 15%, the heat distortion temperature is increased by 5 to 13 DEG C, the polymerization conversion rate of the polydicyclopentadiene is increased from 97.2% to 99.5%, and the styrene adopting halogen can enhance the flame retardance of the material.

Owner:HENAN UNIV OF SCI & TECH

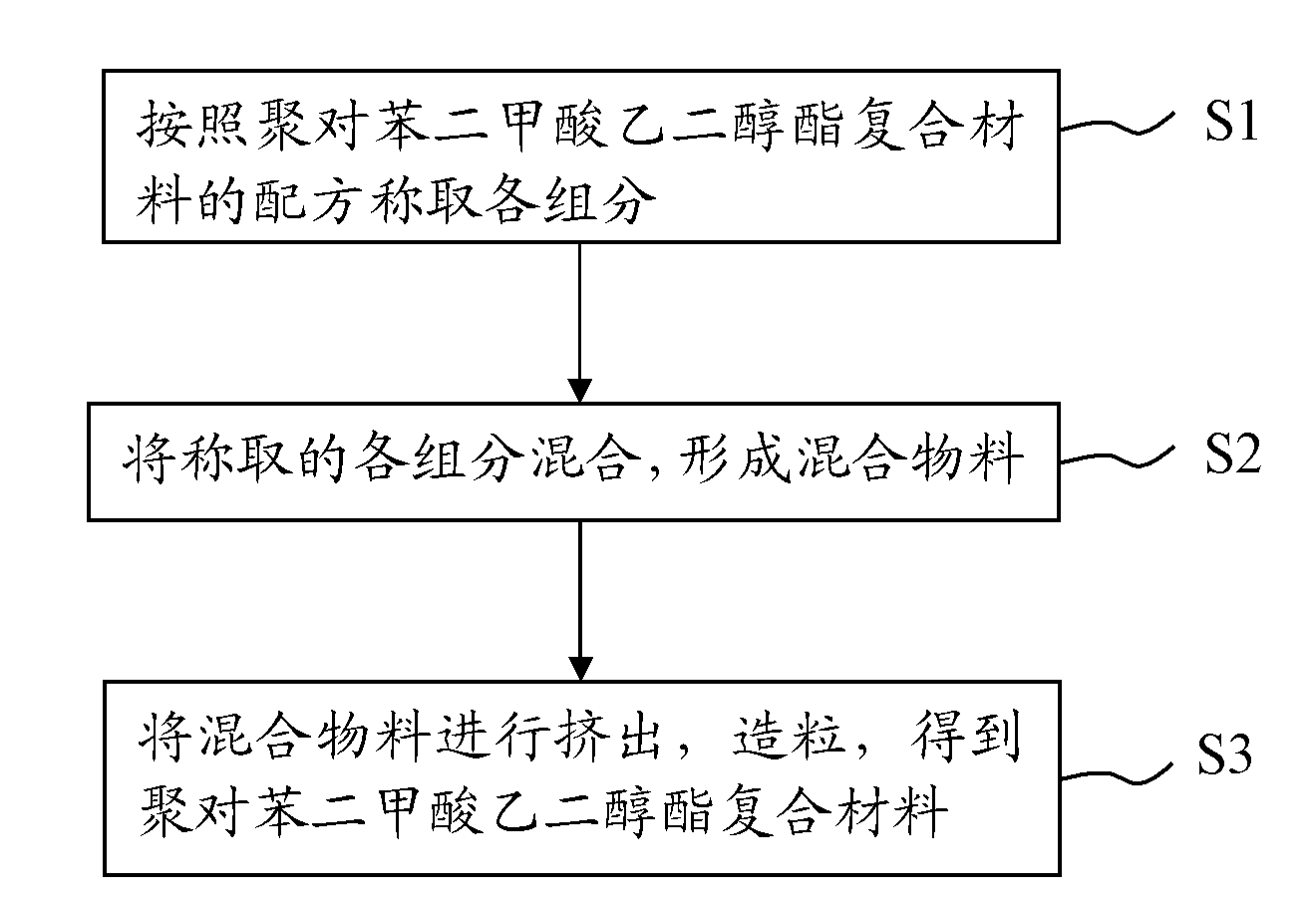

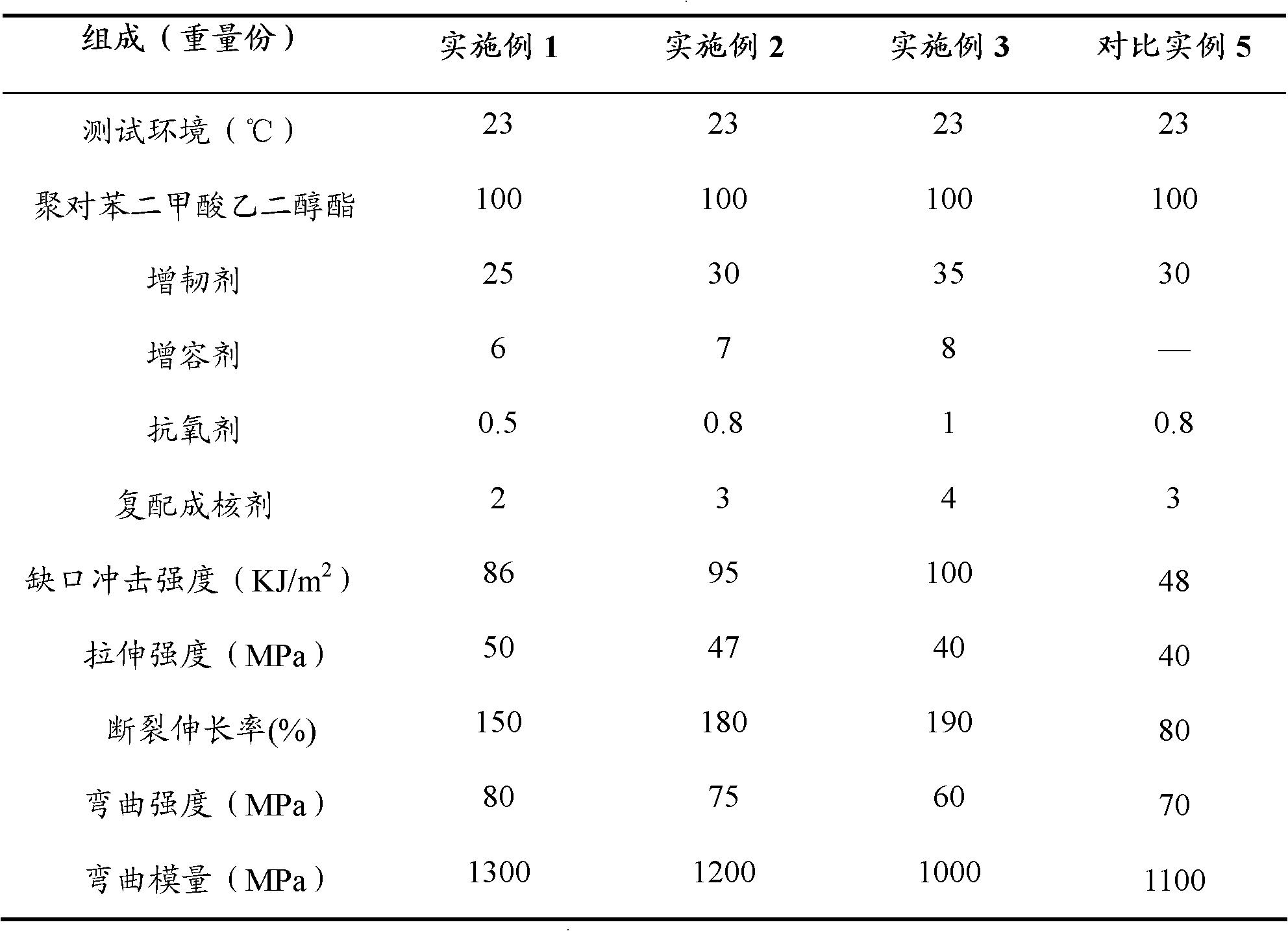

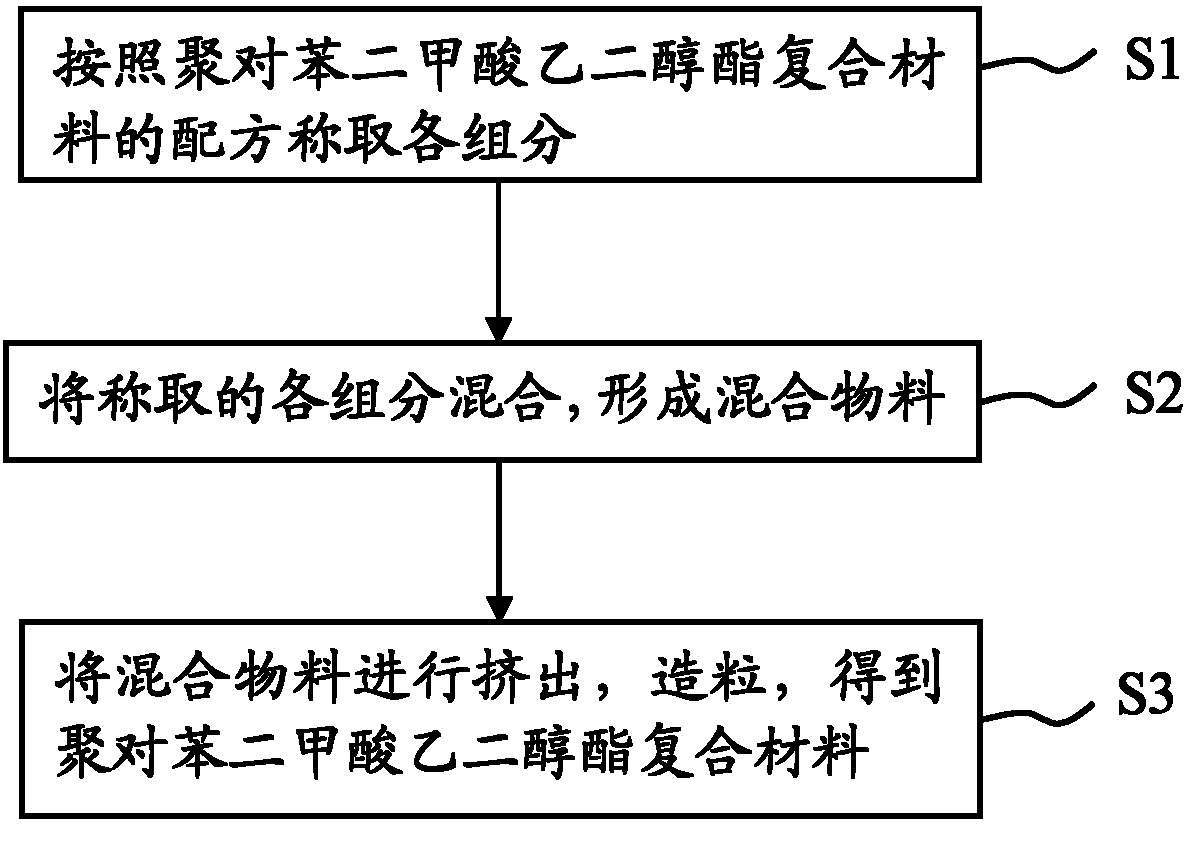

Polyethylene terephthalate composite material and method for preparing same

InactiveCN102040809AHigh impact strengthImprove heat deflection temperatureHeat deflection temperaturePolyethylene terephthalate glycol

The invention discloses a polyethylene terephthalate composite material and a method for preparing the same. The polyethylene terephthalate composite material is prepared from the following components in parts by weight: 100 parts of polyethylene terephthalate, 25-35 parts of plasticizer, 6-8 parts of compatibilizer and 2-4 parts of compound nucleating agent. The components in proper content range interact mutually during extrusion, thus the polyethylene terephthalate composite material has advantages of excellent impact strength, heat distortion temperature, gloss, ultrasonic welding performance, dimensional stability and chemical resistance. The method for preparing the polyethylene terephthalate composite preparation adopts the simple one-step mixing reaction-extrusion-granulation process, is convenient to operate, has high benefit and low cost and is suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com