High-impact-resistance heat-resistant polylactic acid alloy material and preparation method thereof

A high-impact, alloy material technology, applied in the field of high-impact and heat-resistant polylactic acid alloy material and its preparation, can solve the problems of low thermal deformation temperature, poor impact resistance, etc., and achieves low cost, impact resistance and resistance. The effect of improved thermal properties and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

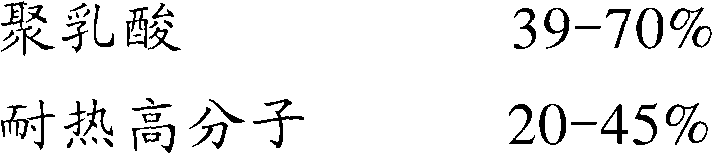

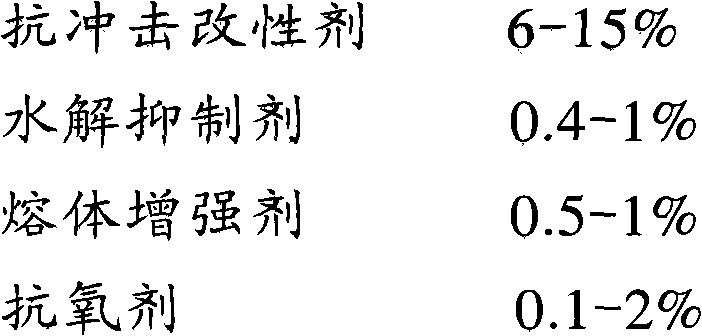

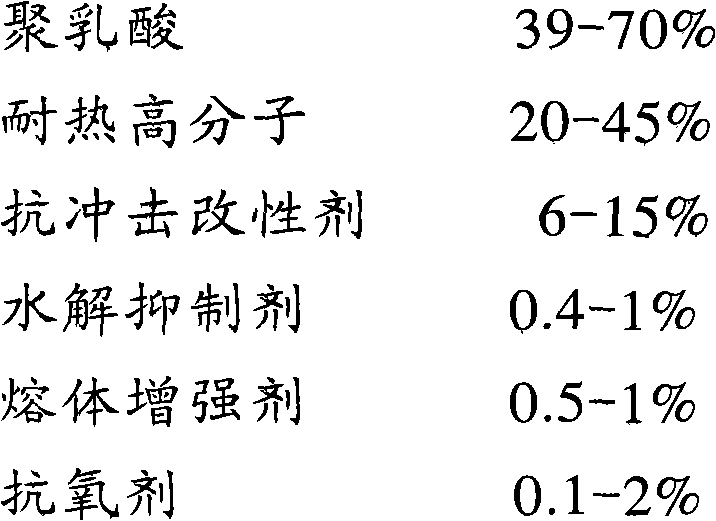

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the above-mentioned high-impact heat-resistant polylactic acid alloy material, the method includes the following steps: polylactic acid, heat-resistant polymer, impact modifier and hydrolysis inhibitor, melt reinforcing agent and anti-corrosion The oxygen agent is placed in the mixer according to the above-mentioned ratio and stirred to make it evenly mixed, and then the mixed components are put into the twin-screw extruder for reaction and extruded. A polylactic acid alloy material with high impact resistance and heat resistance.

[0031] Specifically, the above-mentioned vacuum drying condition is 0.5×10 -2 MPa-2.0×10 -2 Dry at 50-80°C for 3-8 hours under MPa.

[0032] The above polylactic acid, heat-resistant polymer, and impact modifier were vacuum-dried at 50-80°C for 3-8 hours before stirring to remove moisture, and the vacuum degree was 0.5×10 -2 MPa-2.0×10 -2 MPa.

[0033] The screw speed of the tw...

Embodiment 1

[0038] Weigh 39 parts of polylactic acid (molecular weight is 100000), 35 parts of polycarbonate, 10 parts of polymethyl methacrylate, 15 parts of ABS, 0.4 part of hydrolysis inhibitor DIC, 0.5 part of melt enhancer PO, 0.1 part of antioxidant Tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)pentaerythritol ester. Among them, polylactic acid, polycarbonate, polymethyl methacrylate, and ABS need to be vacuum-dried at 50°C for 8 hours to remove moisture before use, and the vacuum degree is 2.0×10 -2 MPa.

[0039] Put each component in a mixer and stir for 3 minutes to make it evenly mixed, then react and extrude in a twin-screw extruder, the screw speed is 180rpm, and the temperature of each zone of the twin-screw extruder is: the first zone: 250 ℃, the second zone: 270℃, the third zone: 270℃, the fourth zone: 260℃, the fifth zone: 240℃, the sixth zone: 230℃, the seventh zone: 210℃, the eighth zone: 200℃ , Ninth Zone: 200°C, Tenth Zone: 200°C, Eleventh Zone: 200°C. Th...

Embodiment 2

[0042] Weigh 48 parts of polylactic acid (molecular weight is 200000), 40 parts of polyoxymethylene, 10 parts of acrylate polymer, 0.8 part of hydrolysis inhibitor DCC, 0.7 part of melt enhancer XDI, 0.5 part of antioxidant (3,5-di Octadecyl tert-butyl-4-hydroxyphenyl)propionate. Among them, polylactic acid, polyoxymethylene, and acrylate polymers need to be vacuum-dried at 70°C for 5 hours to remove moisture before use, and the vacuum degree is 0.9×10 -2 MPa.

[0043] Put each component in a mixer and stir for 3 minutes to make it evenly mixed, then react and extrude in a twin-screw extruder, the screw speed is 100rpm, the temperature of each zone of the twin-screw extruder is: the first zone: 160 ℃, the second zone: 160℃, the third zone: 165℃, the fourth zone: 165℃, the fifth zone: 165℃, the sixth zone: 165℃, the seventh zone: 165℃, the eighth zone: 170℃ , Ninth Zone: 170°C, Tenth Zone: 165°C, Eleventh Zone: 160°C. The extruded product is cooled and diced, in a vacuum of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com