Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Deterioration of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molded article produced from aliphatic polyester resin composition

ActiveUS20050154148A1DistanceDeterioration of mechanical propertiesPlastic/resin/waxes insulatorsDyeing processShell moldingPolyester resin

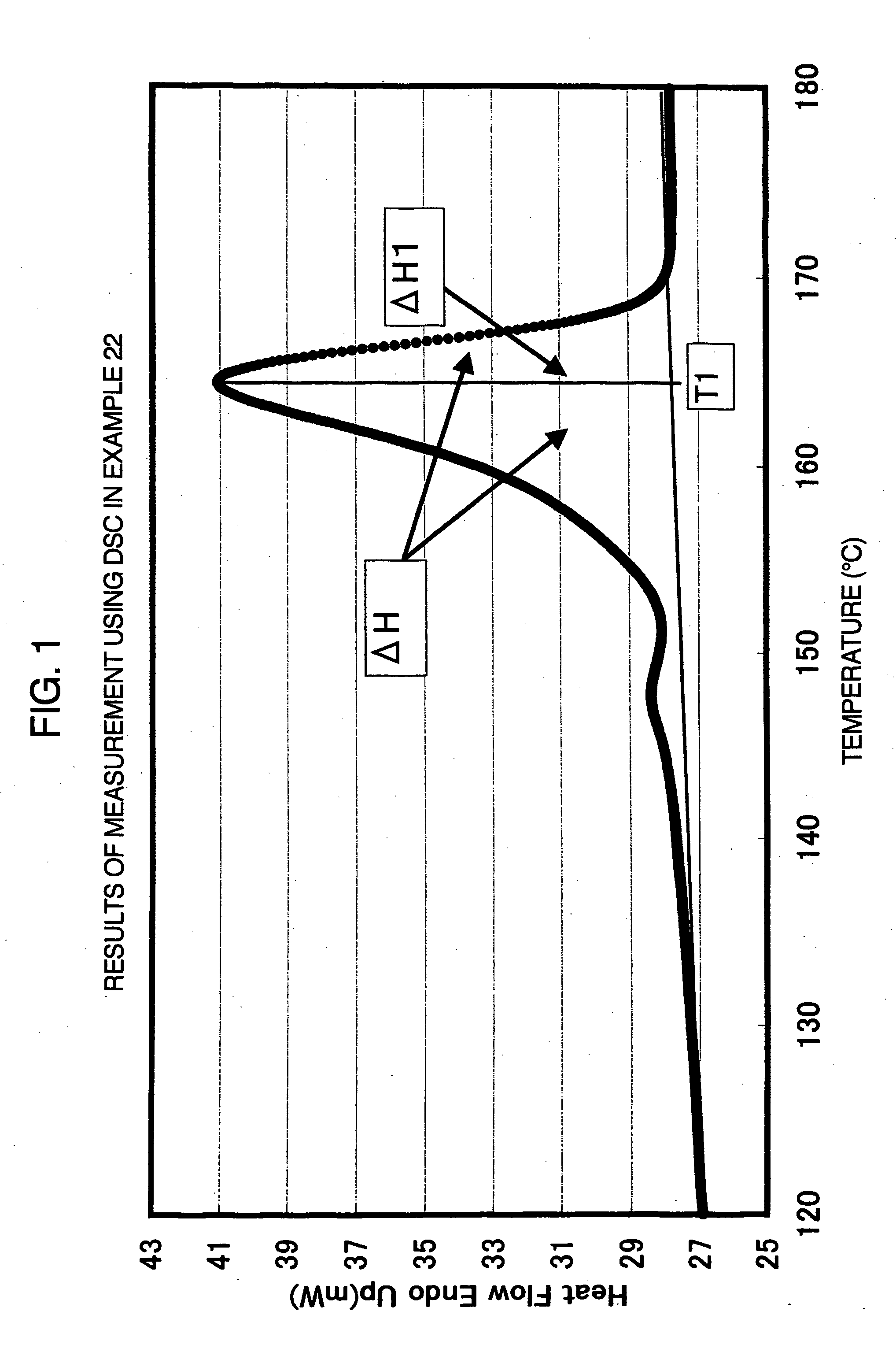

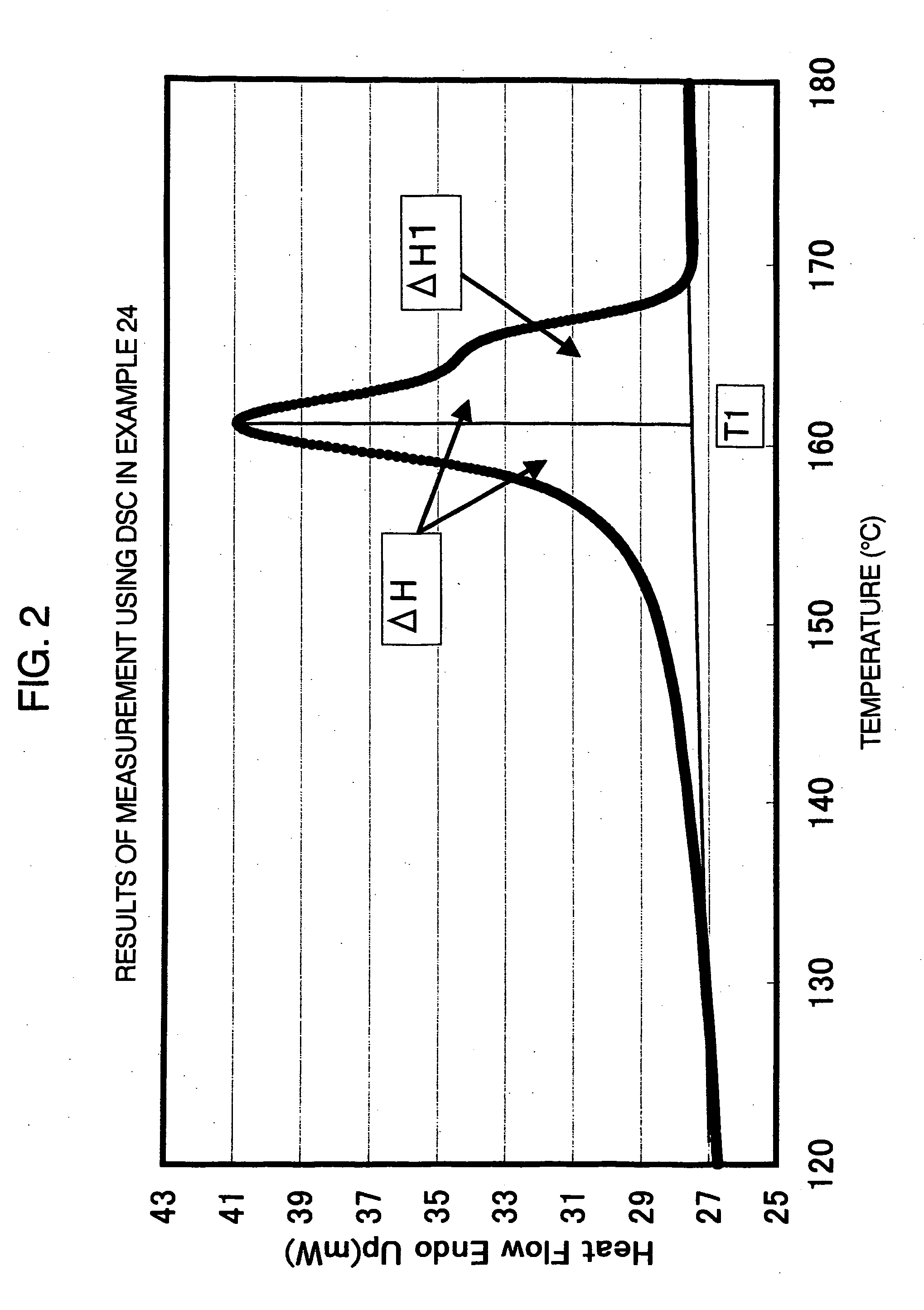

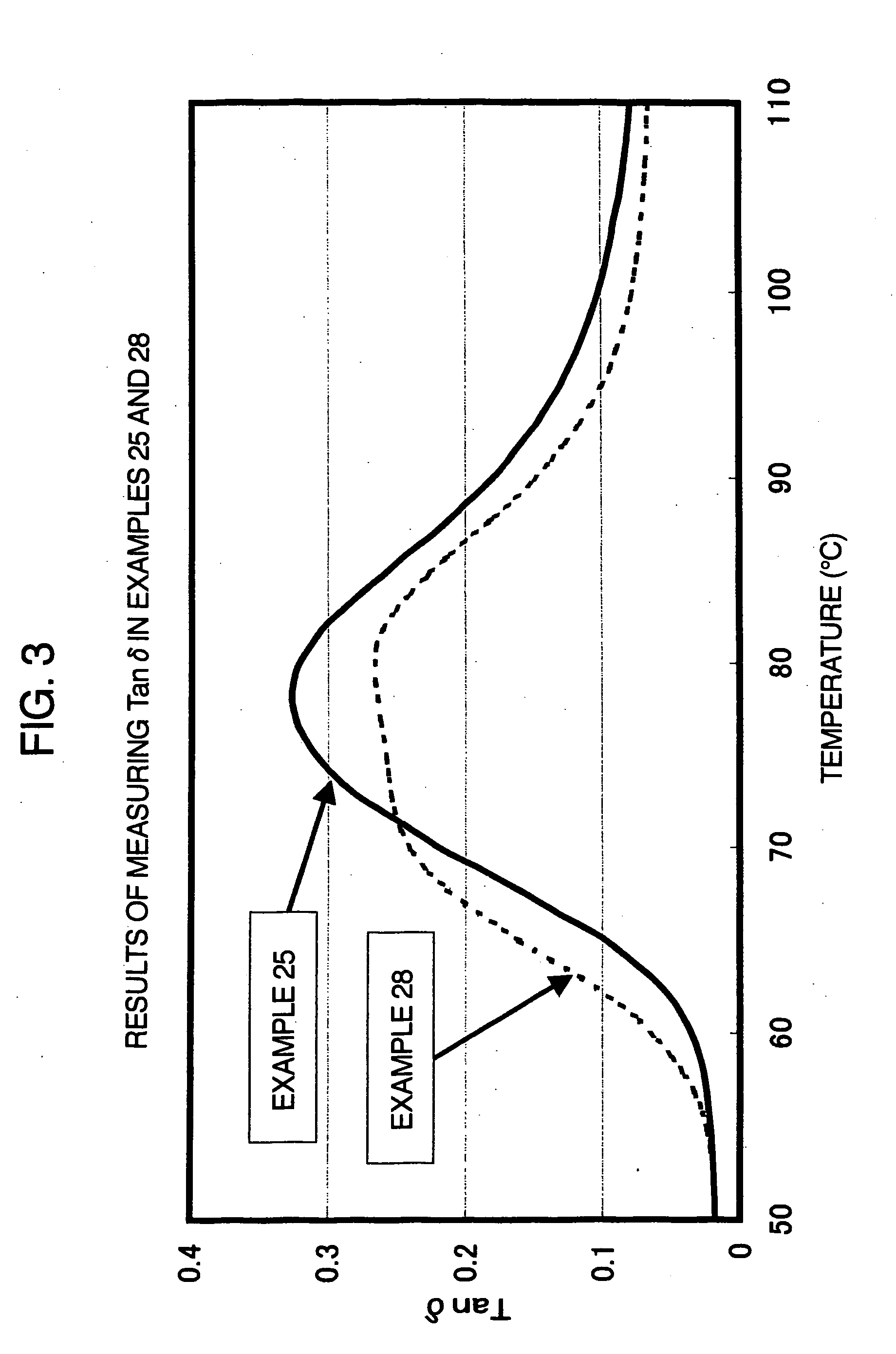

The present invention provides a molded article obtained from an aliphatic polyester resin composition comprising 60 to 99.9 parts by weight of at least one aliphatic polyester (A) and 0.1 to 40 parts by weight of at least one elastic polymer (B), provided that the total amount of the components (A) and (B) is 100 parts by weight, wherein the aliphatic polyester component in the molded article has an enthalpy of crystal fusion ΔH determined using a differential scanning calorimeter of 5 J / g or more, the molded article has a continuous phase composed of the aliphatic polyester (A) and dispersed phases composed of the elastic polymer (B), and the distance T between the walls of the dispersed phases is less than 5.0 μm.

Owner:ASAHI KASEI CHEM CORP

Flame-retardant resin composition

InactiveUS20050148701A1Increase heightDeterioration of mechanical propertiesHeat resistanceFire retardant

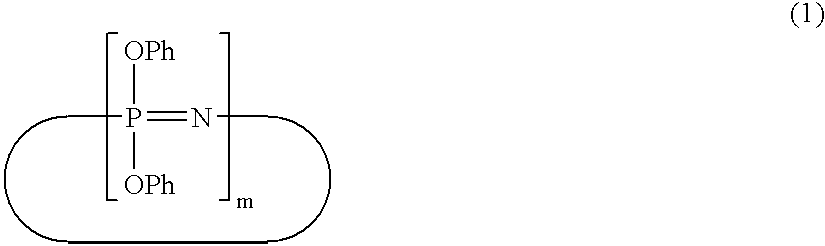

A blending of a styrenic resin, and a flame retardant comprising a phenolic resin and a phosphazene compound to a polyalkylene arylate-series resin imparts flame retardancy to a polyalkylene arylate-series resin. The phosphazene compound is a cyclic phenoxyphosphazene compound, a linear phenoxyphosphazene compound, or a crosslinked phenoxyphosphazene compound. The obtained polyalkylene arylate-series resin composition has excellent heat resistance and high flame-retardancy without bleeding out the flame retardant.

Owner:POLYPLASTICS CO LTD

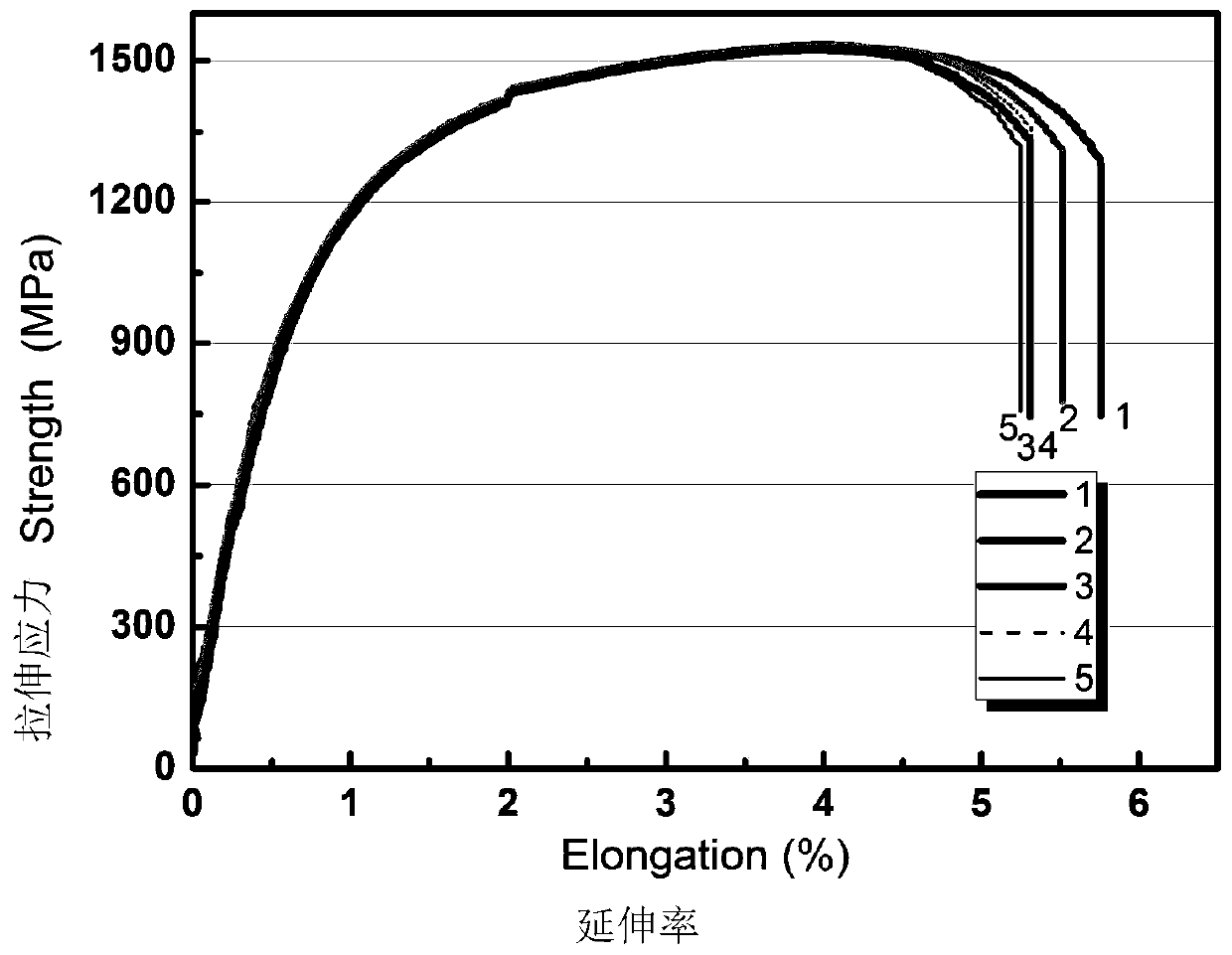

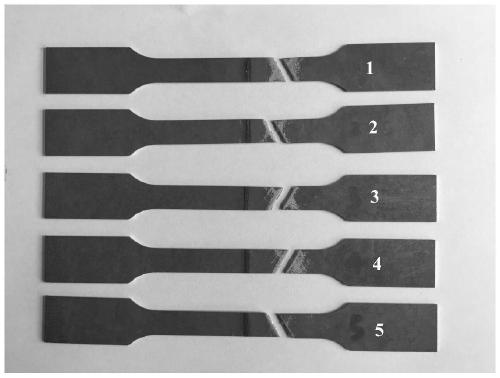

Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

ActiveCN111230301APromote homogenizationImprove hardenabilityArc welding apparatusWelding/cutting media/materialsHot stampingMetal alloy

Provided is a method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings. A steel plate to be welded comprises a base body and at least one coating on the surface of the base body. Each coating comprises an intermetallic compound alloy layer in contact with the base body and a metal alloy layer on the intermetallic compound alloy layer. Thecoatings do not need to be removed or thinned before welding or in the welding process; by presetting the welding gap and using a carbon manganese steel welding wire, a welding process and protectivegas for welding, after a welding component is subjected to hot stamping treatment, the tensile strength of a weld joint is greater than the tensile strength of a base material, the extension rate of the weld joint is greater than 4%, and the application requirement of the equal-strength welding components in the hot stamping field is met.

Owner:BAOSHAN IRON & STEEL CO LTD

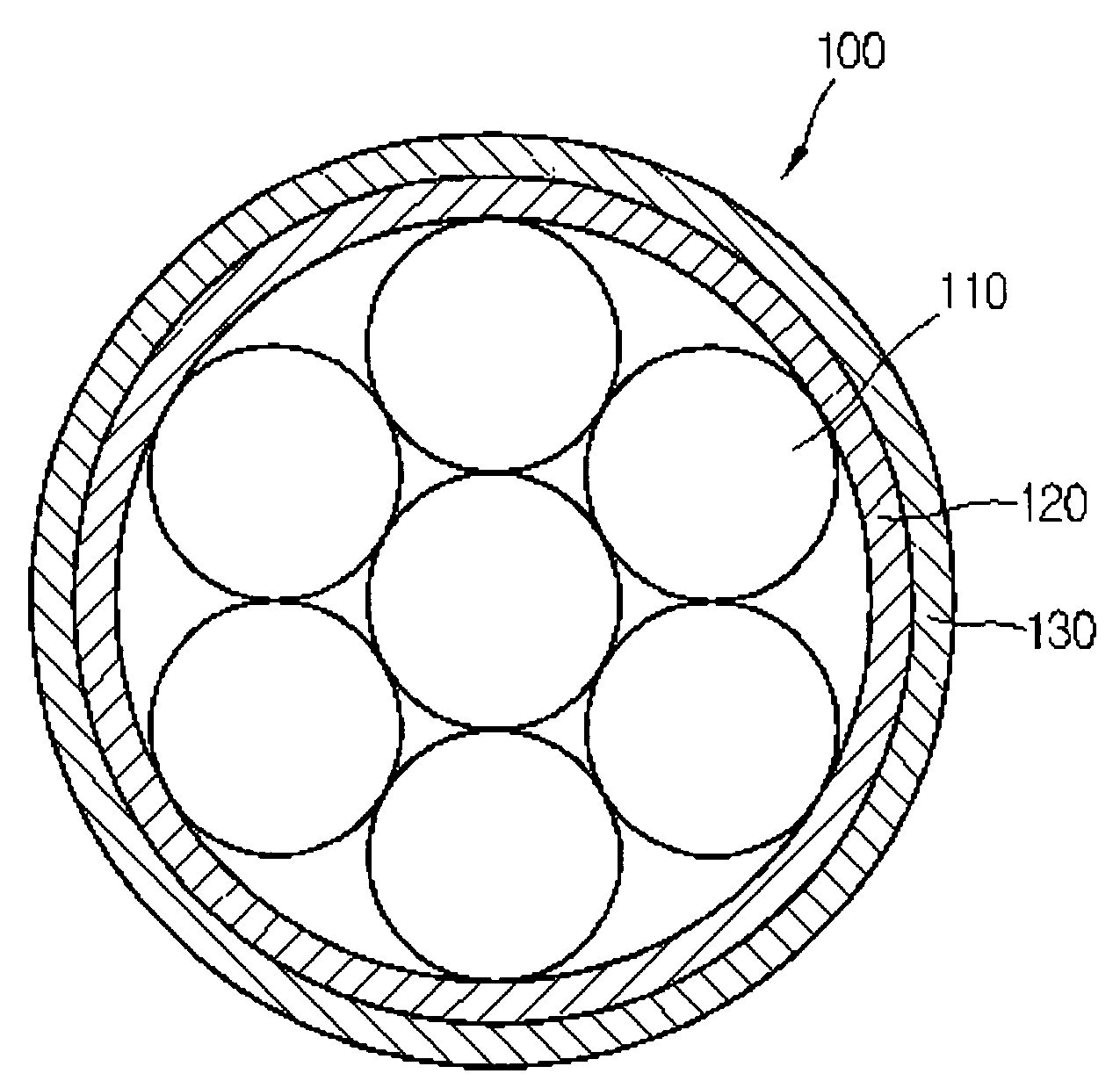

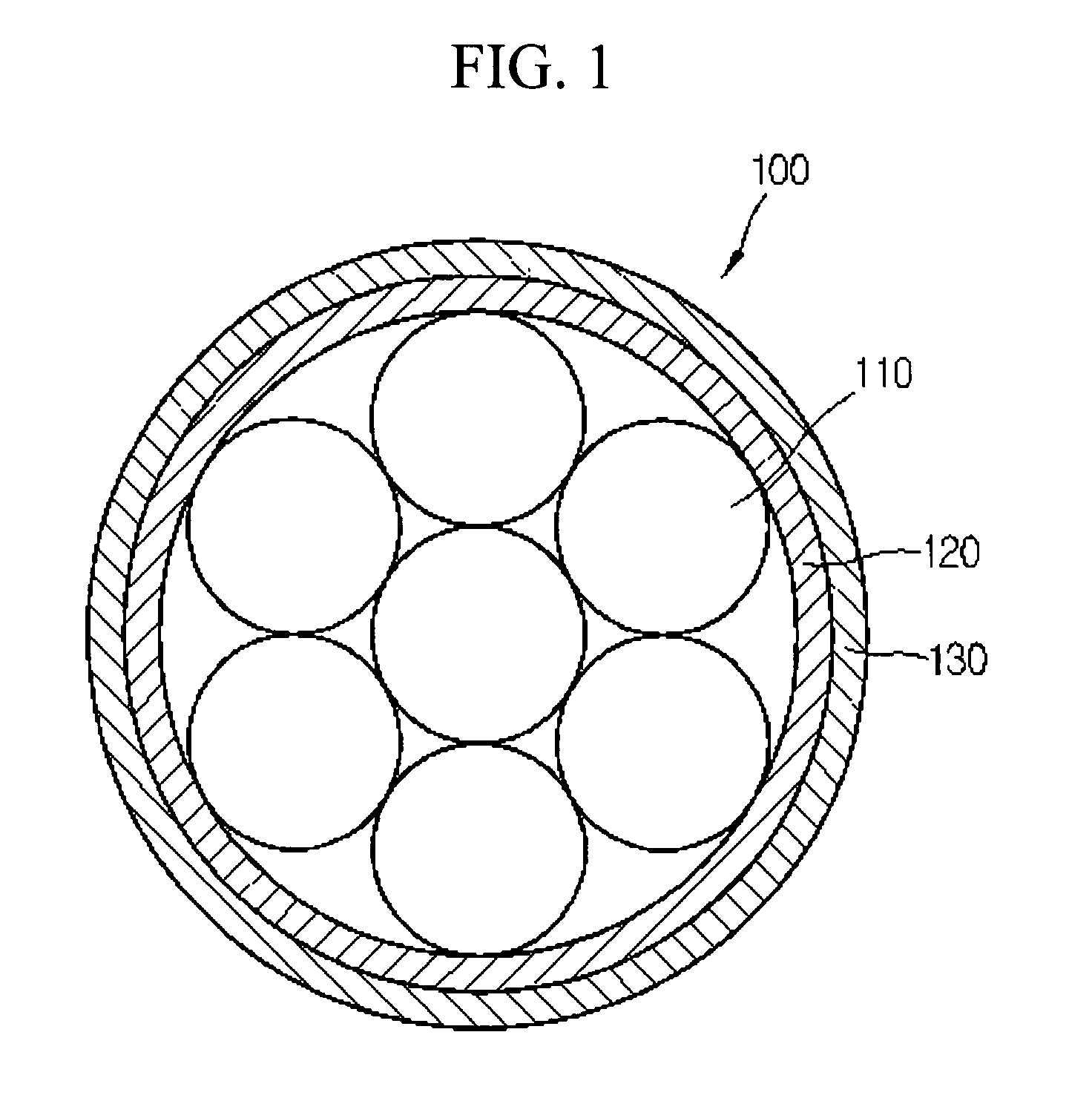

Composition for manufacturing insulation materials of electrical wire and electrical wire manufactured using the same

ActiveUS20070187130A1Withstand voltage characteristicImprove mechanical propertiesElectrical apparatusDiagnosticsElectrical conductorHeat resistance

The present invention relates to a composition for manufacturing insulation materials of an electrical wire and an electrical wire manufactured using the same. The present invention provides a composition for manufacturing insulation materials of an electrical wire having a multilayer structure, which is used for manufacturing a first insulation coating layer made of a composition including a predetermined base resin, an antioxidant and a co-crosslinking agent so as to surround a conductor or a conductor bundle for an electrical wire; a second insulation coating layer made of a composition including a base resin polyvinylidene fluoride (PVDF), a predetermined antioxidant and a co-crosslinking agent so as to surround the first insulation coating layer, and an electrical wire manufactured using the same. According to the present invention, light-weigh products may be produced, and also an electrical wire or wire products used under a high-temperature environment have advantageous properties since the composition is excellent in a mechanical property and a thermal resistance and capable of maintaining physical properties at a high temperature of at least 150° C. for a long time.

Owner:LG CABLE LTD (KR)

Low rolling resistance tire for vehicles

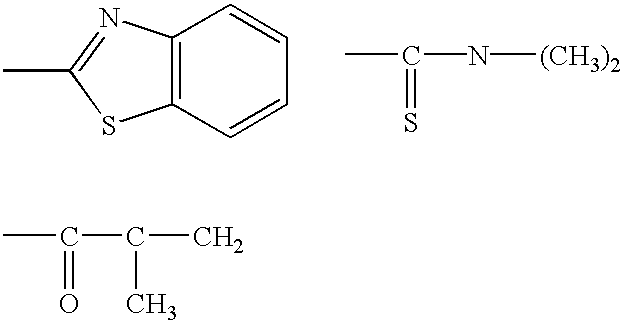

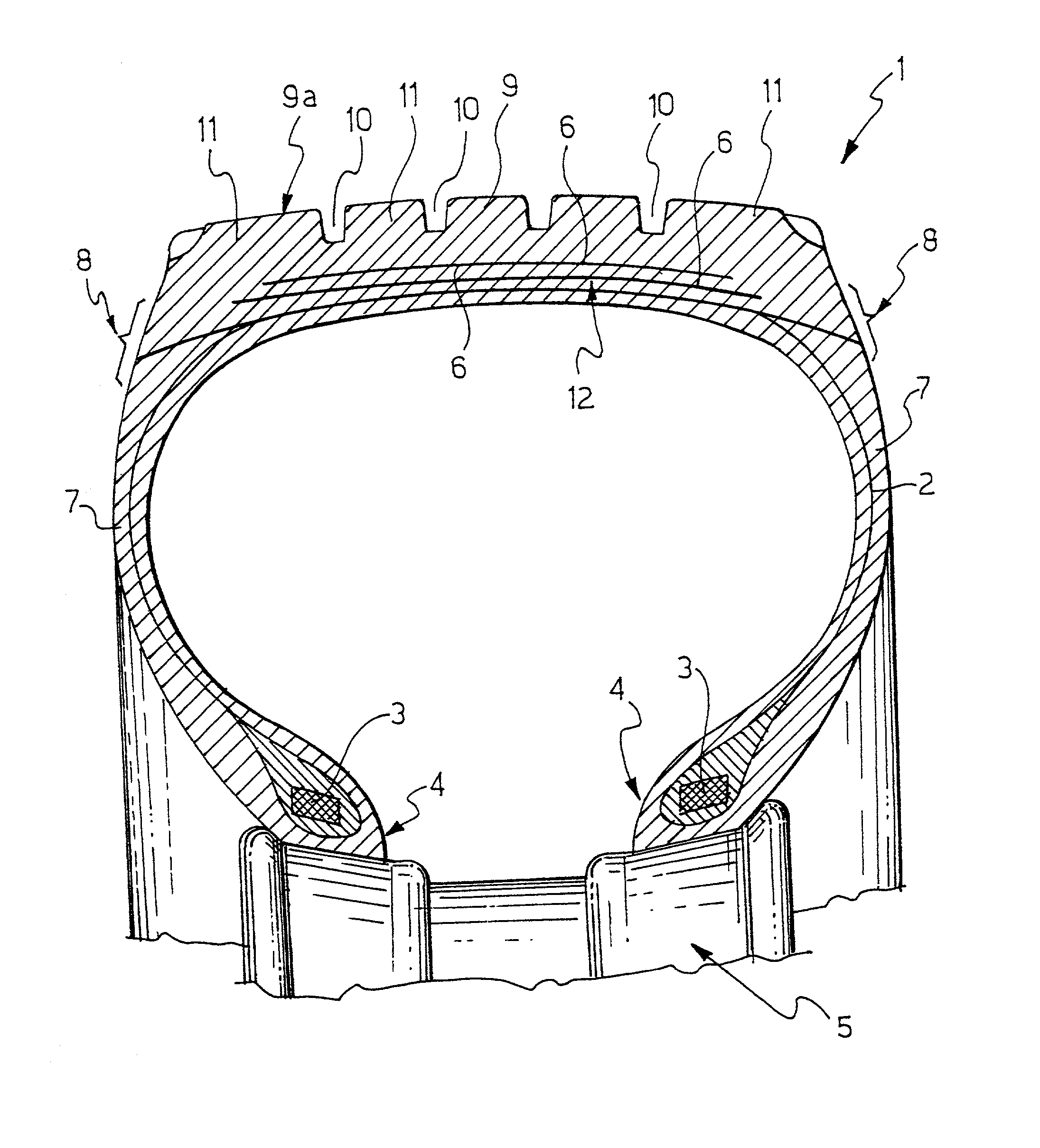

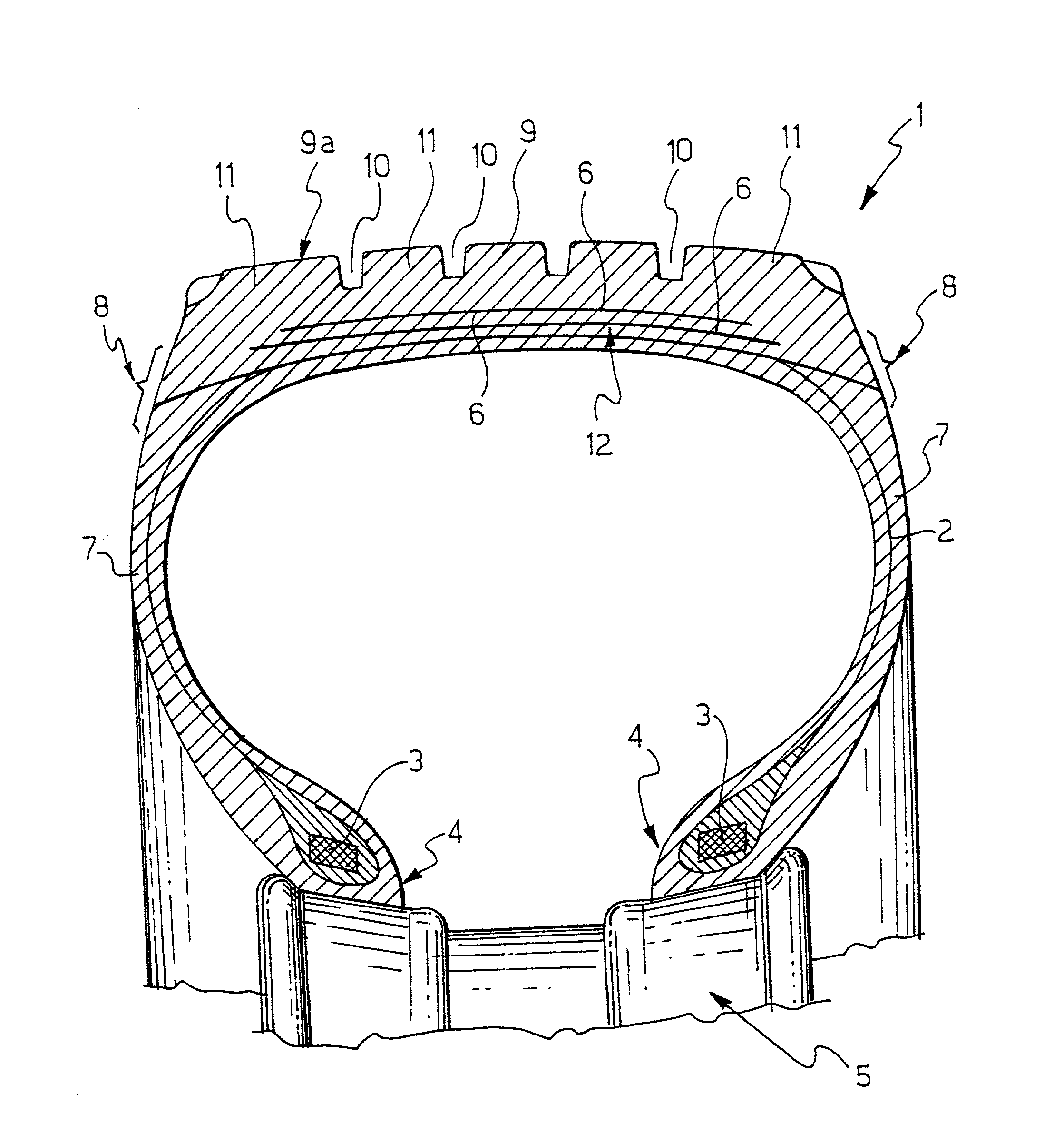

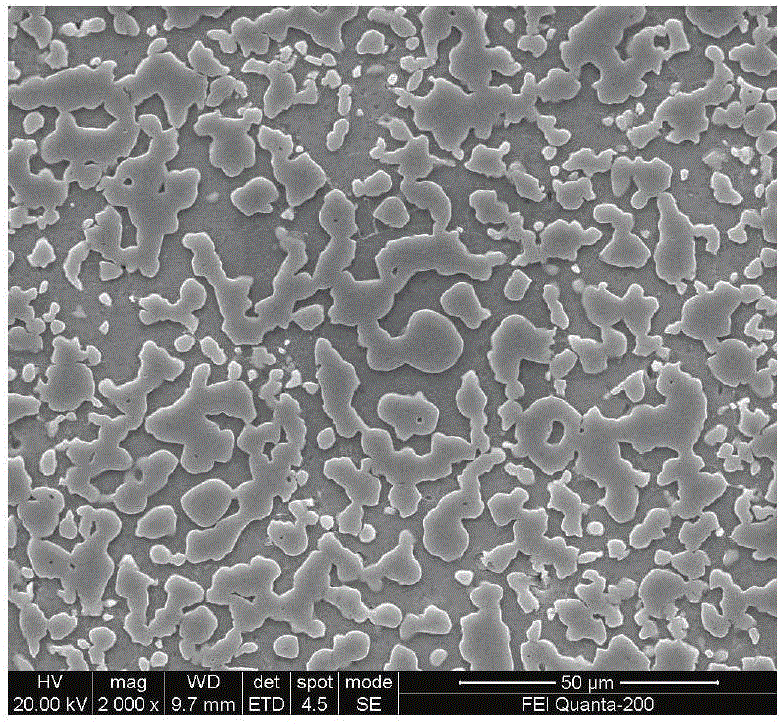

InactiveUS20020143096A1Reduce mixing actionLarge specific surface areaOther chemical processesSpecial tyresRolling resistanceProject area

A low rolling resistance tire (1) for vehicles is described which comprises a belt structure (12) coaxially extending around a carcass structure (2) and a tread (9), coaxially extending around the belt structure (12) and being externally provided with a rolling surface (9a) designed to get in touch with the ground, the tread (9) comprising a vulcanized polymer base including at least a first silica-based reinforcing filler, the tire being characterized in that the first silica-based reinforcing filler has: an average projected area of the aggregates as measured before incorporation into the polymer base lower than 20,000 nm2; a dispersion index in the vulcanized polymer base of the tread (9) not lower than 97%; and a projected area of the aggregates after incorporation into the polymer base comprised between 8500 and 18000 nm2. Advantageously, said tire has mechanical properties improved or at least comparable with respect to those of the known tires for the same type of use.

Owner:PIRELLI TYRE SPA

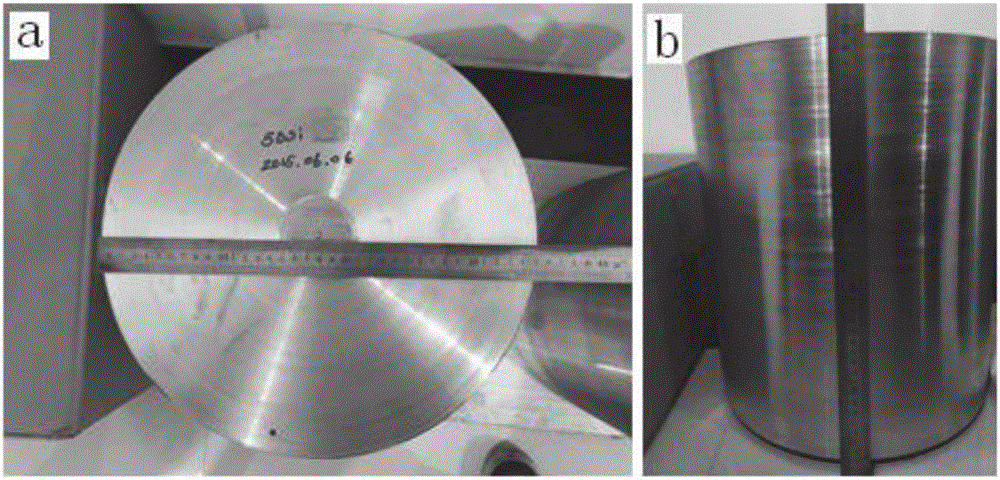

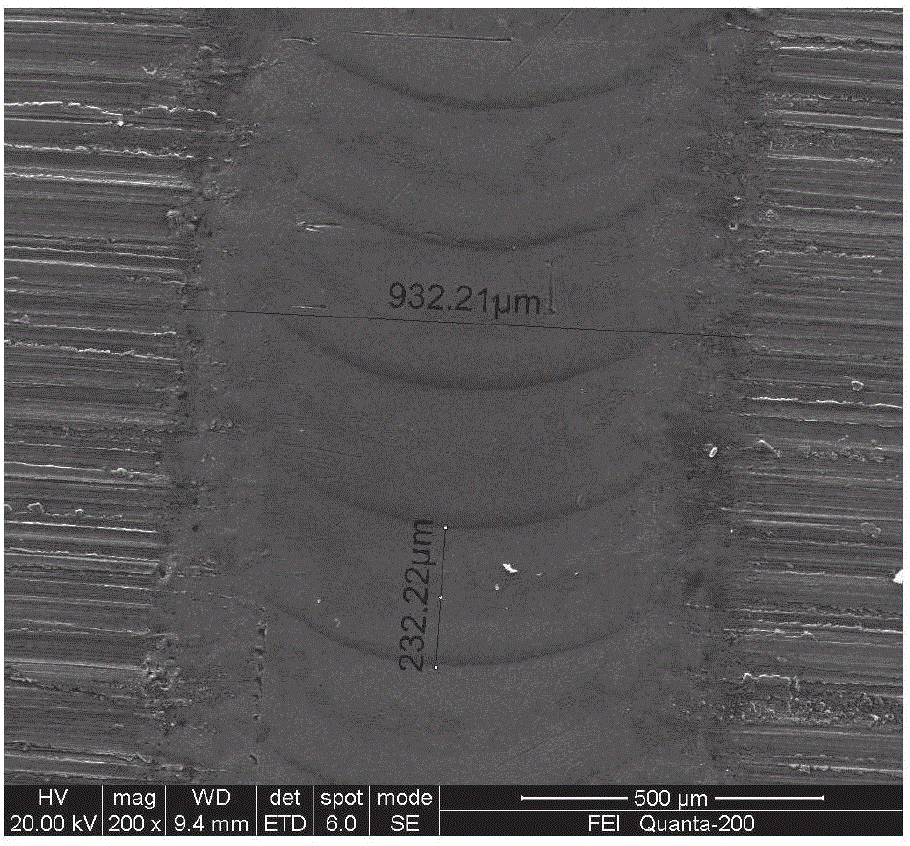

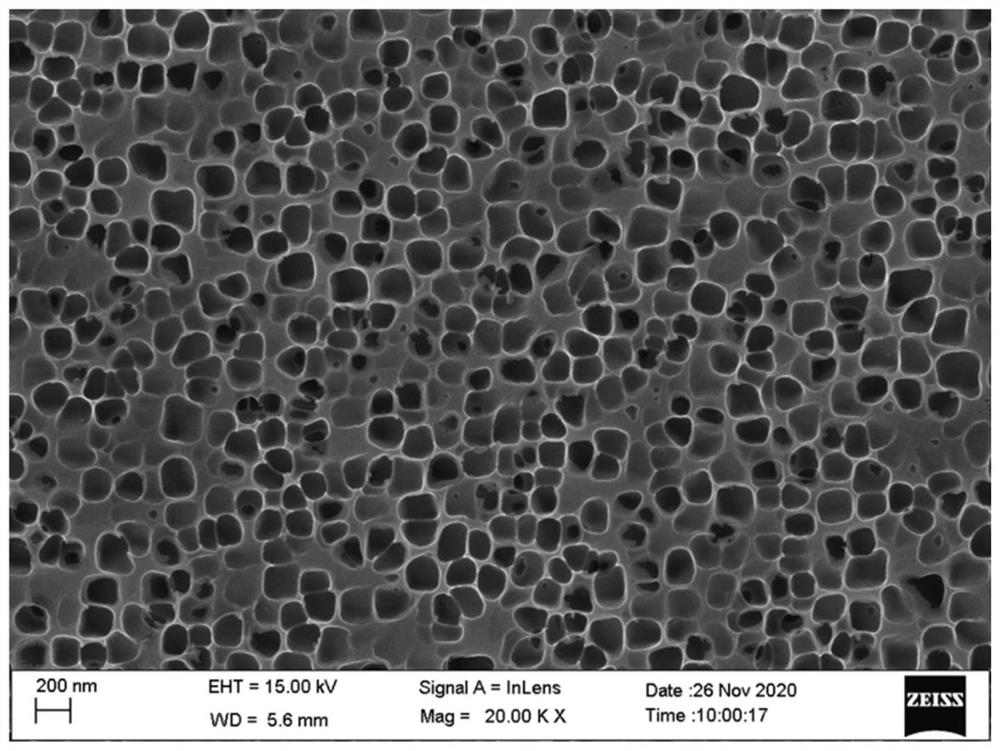

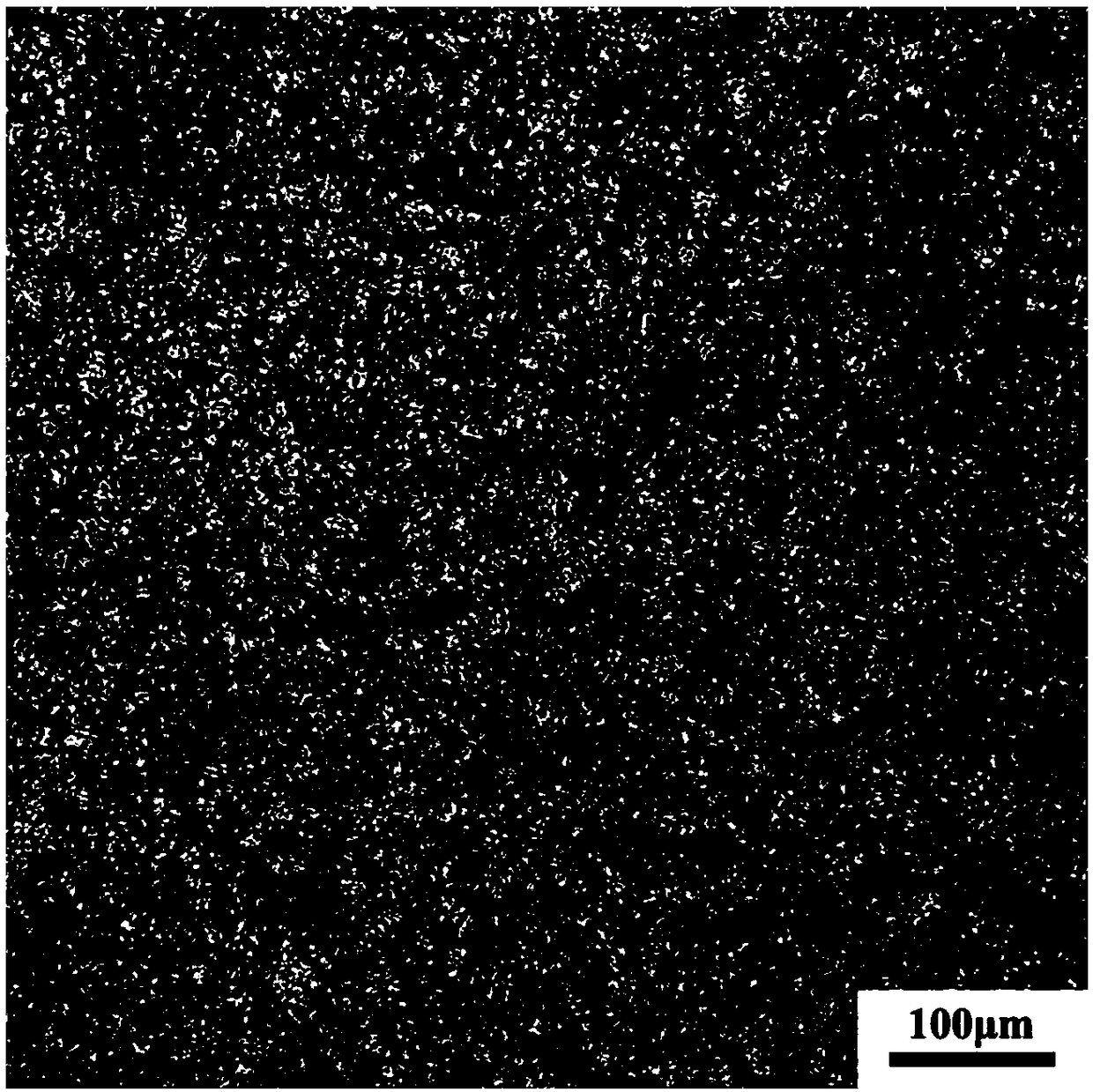

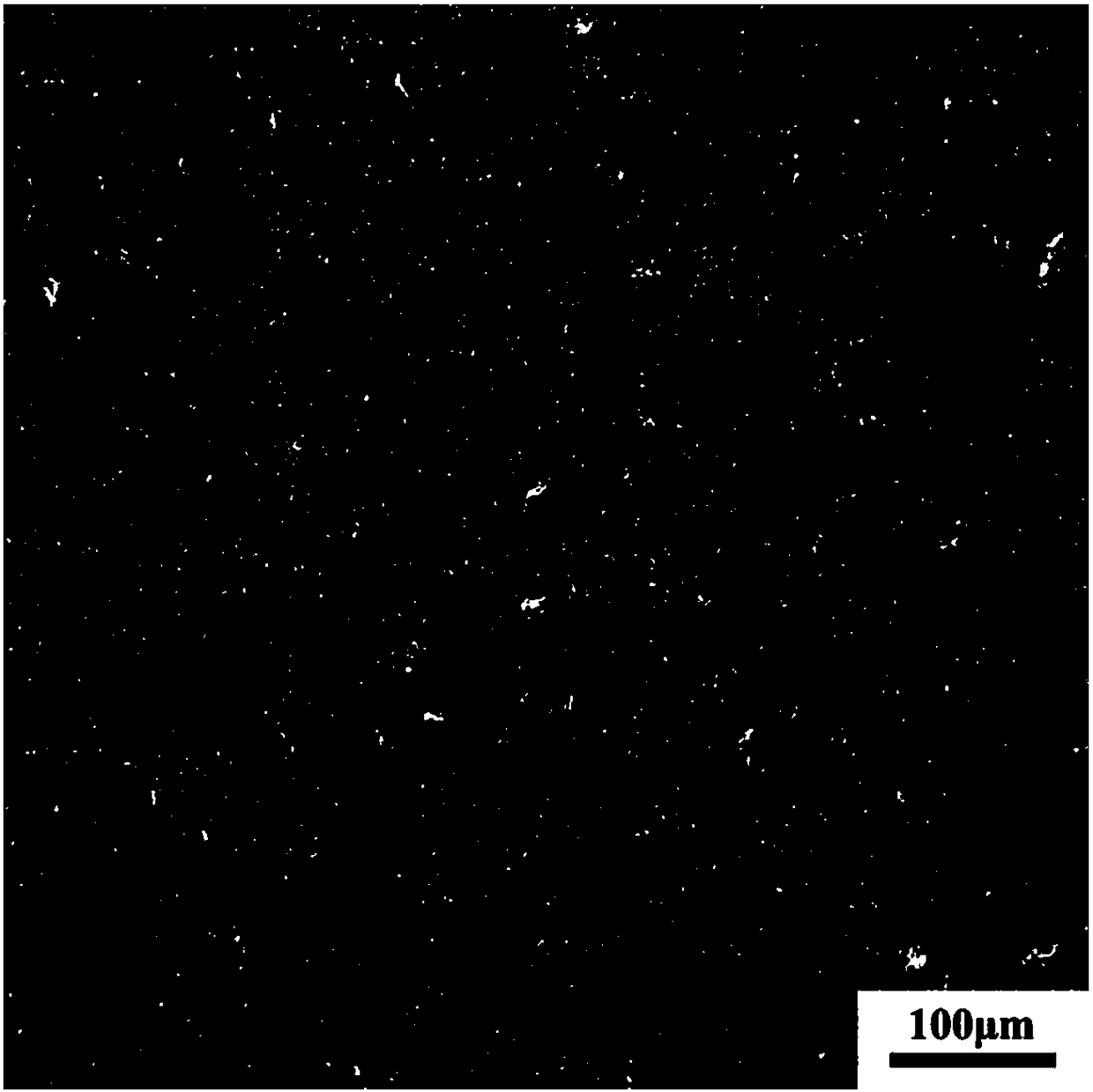

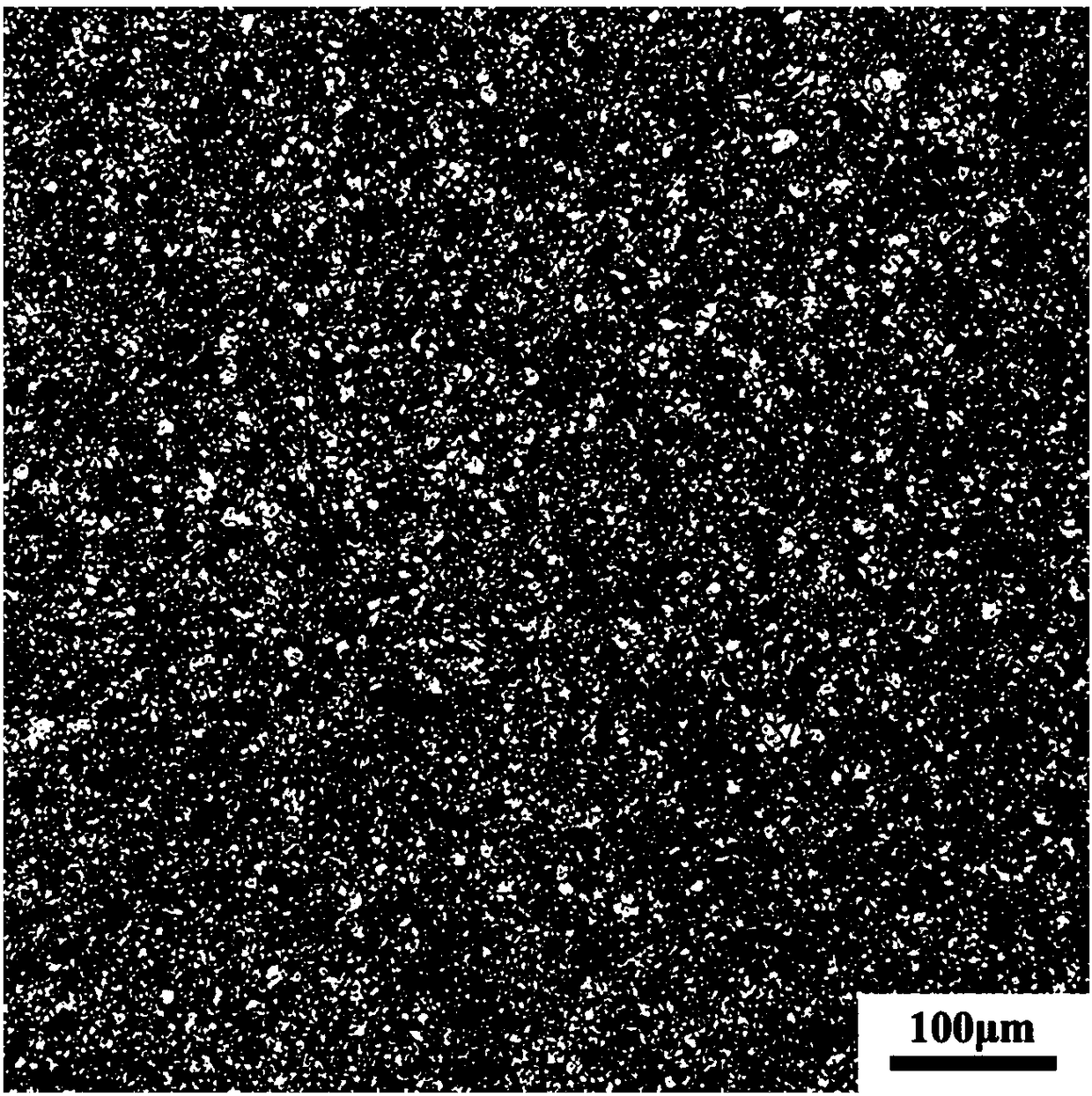

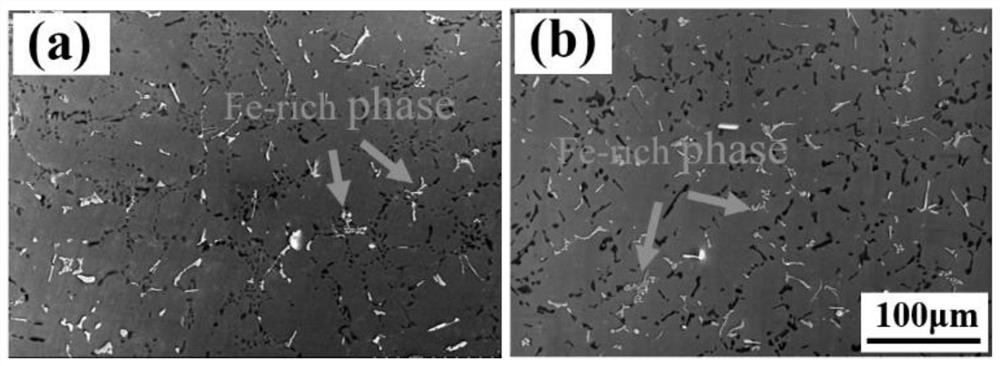

Alloying-element-strengthened high-silicon aluminum composite and preparation method thereof

The invention provides a preparation method of an alloying-element-strengthened high-silicon aluminum composite and belongs to the technical field of material preparation. The preparation method is particularly suitable for preparation of electronic packaging material. The designed alloying-element-strengthened high-silicon aluminum composite comprises, by mass percent, 48.0%-52.0% of silicon, 0.5%-4.0% of X and the balance aluminum. The X is copper and / or magnesium. The preparation method of the alloying-element-strengthened high-silicon aluminum composite comprises the steps that a silicon source, an aluminum source and an X source are prepared according to the designed components, the prepared silicon source, the prepared aluminum source and the prepared X source are smelted, and then a melt is obtained; and atomized spray deposition is conducted on the obtained melt, so that a deposition preform is obtained, hot isostatic pressing treatment is conducted on the deposition preform, and then a finished product is obtained, wherein during hot pressing pressure treatment, the temperature is controlled to be 520-600 DEG C, and the pressure is controlled to be 150-200 MPa. The designed composite has the advantages of being excellent in comprehensive performance, outstanding in mechanical property, low in preparation cost and the like and is suitable for large-scale industrial production.

Owner:CENT SOUTH UNIV

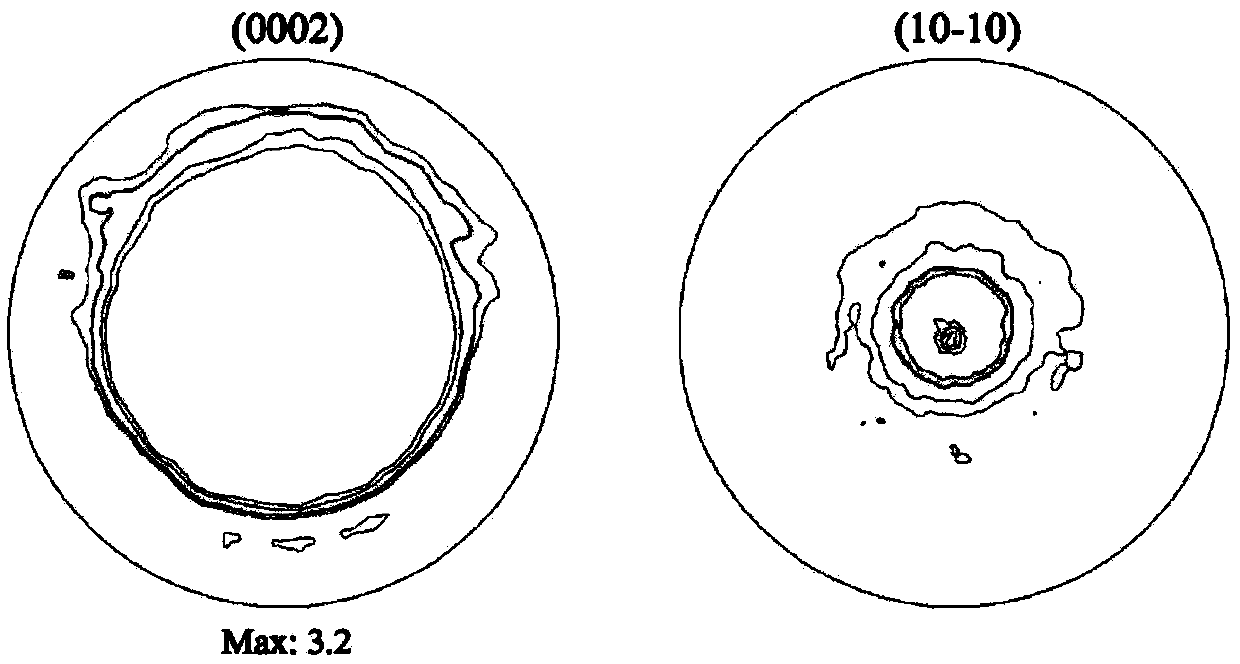

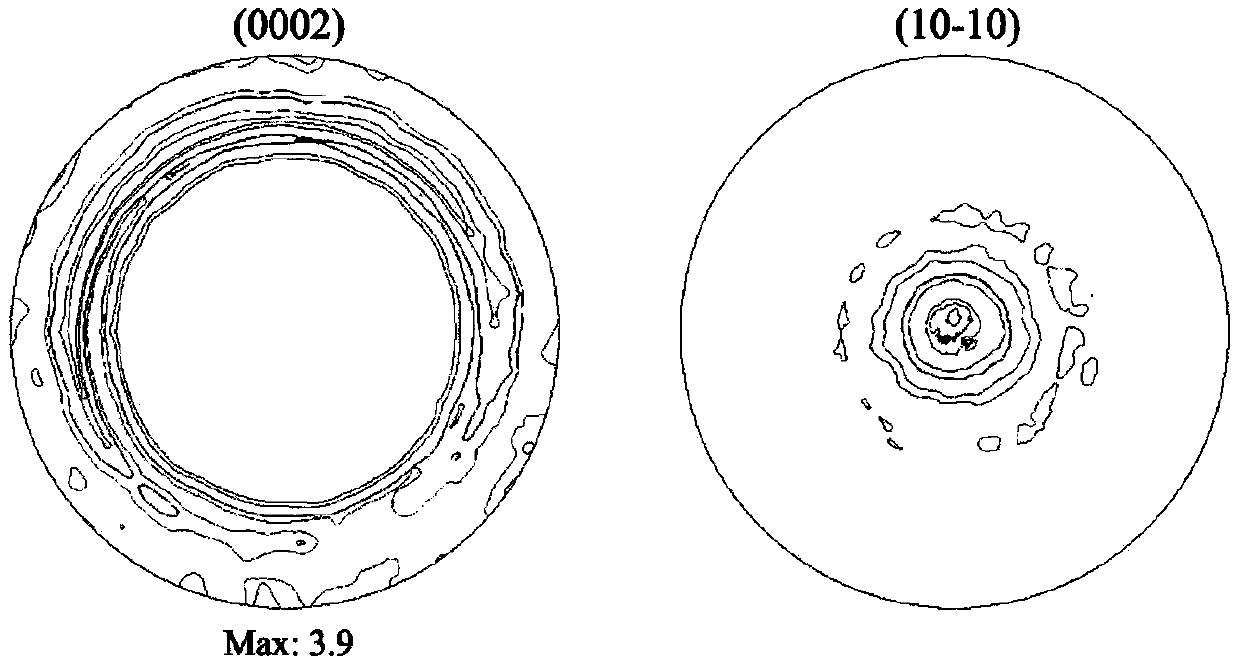

Multi-element compound reinforced weak-texture wrought magnesium alloy and preparing method thereof

The invention relates to a multi-element compound reinforced weak-texture wrought magnesium alloy and a preparing method thereof. The wrought magnesium alloy comprises the following elementary components in content: 5.5%-6.5% of Zn, 1.0%-6.5% of Al, 0.1%-0.4% of Mn, 0.1%-0.4% of Sn, 0.1%-0.4% of Ca, 0.1%-0.4% of Cu, smaller than or equal to 0.15% of unavoidable impurities and the balance of Mg. Compared with the existing non-rare-earth wrought magnesium alloy, the material of the invention has the following advantages that the alloy has high strength and great elongation after conventional extrusion treatment; the alloy has weak macro-texture and great dynamic isotropy; the alloy preparing cost is low, and the preparing technology is simple; and the application range of the wrought magnesium alloy is further increased.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Welding wire for submerged arc welding of high-manganese low-temperature steel and welding method

ActiveCN109623198AReduce welding costsLow costArc welding apparatusWelding/cutting media/materialsChemical compositionManganese

The invention discloses a welding wire for submerged arc welding of high-manganese low-temperature steel and a welding method, and relates to the technical field of welding. The welding wire is prepared from the following chemical components according to mass percent: 0.2% to 0.4% of C, 12% to 15% of Mn, 16% to 20% of Ni, 2% to 5% of Cr, less than or equal to 0.004% of P, less than or equal to 0.002% of S and the balance of Fe and inevitable impurities. The manganese-nickel composition design adopted by the welding wire has good compatibility with high-manganese low-temperature steel base metal and is suitable for a conventional welding wire manufacturing method, the composition is simple, weld metal formed by the welding wire has good impact toughness at low temperature of -196 DEG C, andthe welding requirement of the high-manganese low-temperature steel for constructing equipment like a liquefied natural gas storage tank is preferably met.

Owner:NANJING IRON & STEEL CO LTD

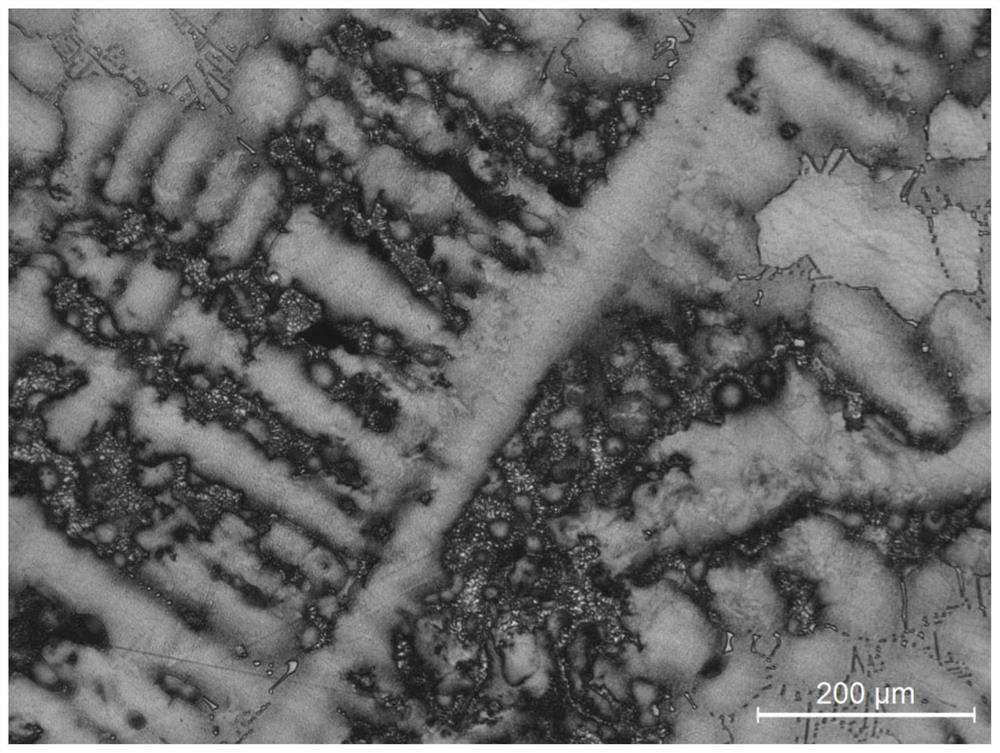

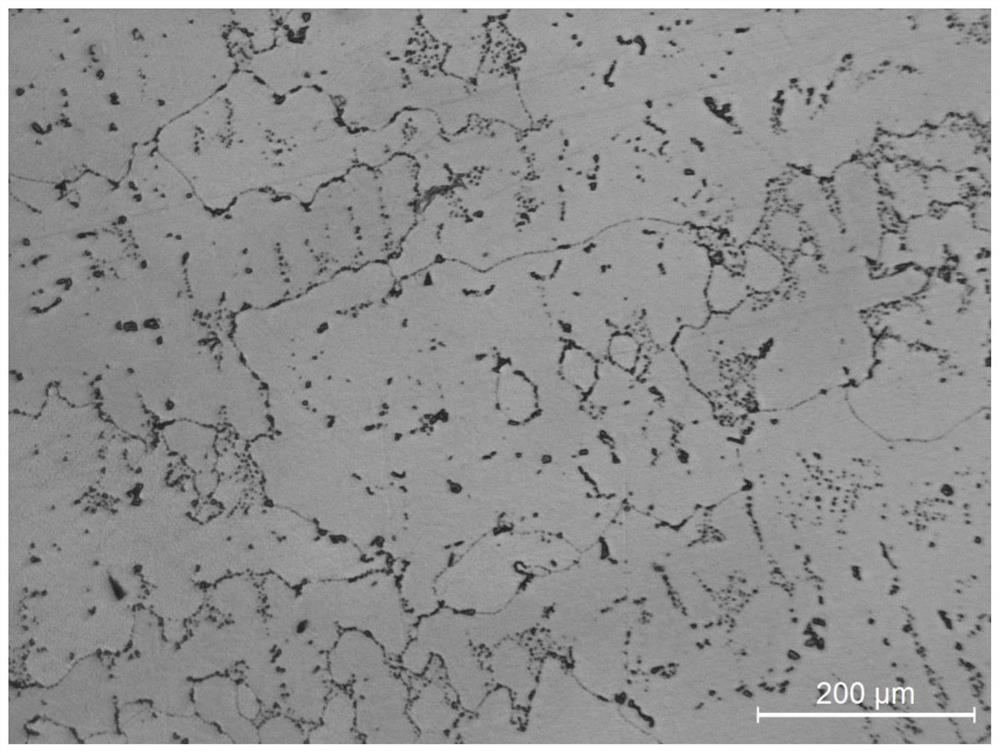

Heat treatment process for casting precipitation strengthened nickel-based superalloy

A treatment process for casting precipitation strengthened nickel-based superalloy comprises the following steps that firstly, mother alloy of the casting precipitation strengthened nickel-based superalloy is put into a vacuum induction furnace to be smelted and then drawn into an alloy bar; secondly, the temperature of the alloy bar in the first step is increased to 1205-1215 DEG C from the room temperature, heat preservation is conducted for 6-8 h, then the temperature is increased to 1220-1230 DEG C, heat preservation is conducted for 10-20 h, and then the alloy bar is cooled to the room temperature through air; thirdly, the alloy bar subjected to solid solution heat treatment in the second step is subjected to stabilizing heat treatment; and fourthly, the alloy bar subjected to heat treatment in the third step is subjected to aging heat treatment. After the alloy is treated by the process, dendritic segregation and eutectic structures are eliminated, the microstructure uniformity is remarkably improved, and the mechanical property of the alloy is greatly improved.

Owner:CHINA HUANENG GRP CO LTD +1

Chlorine ion curing agent for sea sand and preparation method and applications thereof

ActiveCN110803718AImprove mechanical propertiesRaise alkalinityIron compoundsCorrosion preventionPoly ethylene

The invention belongs to the technical field of chlorine ion curing agents, and especially relates to a chlorine ion curing agent for sea sand and a preparation method and applications thereof. The curing agent comprises following raw materials in parts by weight: 20 to 40 parts of CaFe-NO3 LDHs nano sheet, 20 to 40 parts of CaFeAl-NO3 LDHs nano sheet, 20 to 30 parts of alkaline anion exchange resin, and 5 to 10 parts of polyvinylpyrrolidone, wherein the CaFe-NO3 LDHs nano sheet and the CaFeAl-NO3 LDHs nano sheet are metal dihydroxide with a layered structure. The chlorine ion curing agent isa composite of organic substances and inorganic substances, the addition amount is little, the chlorine ion curing effect is prominent, and the mechanical properties, anti-corrosion performance, and impervious property of a cement based material are obviously enhanced at the same time.

Owner:UNIV OF JINAN

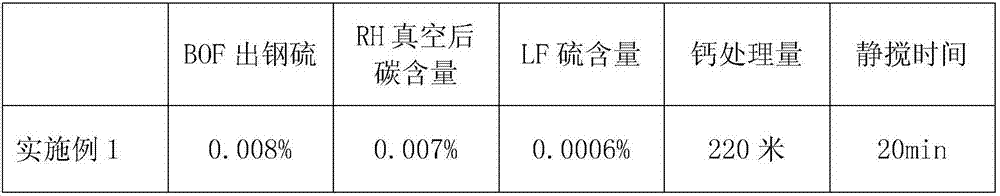

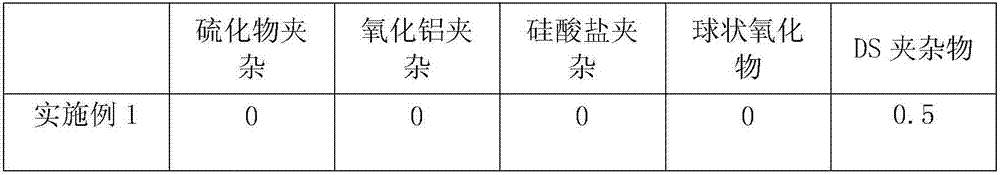

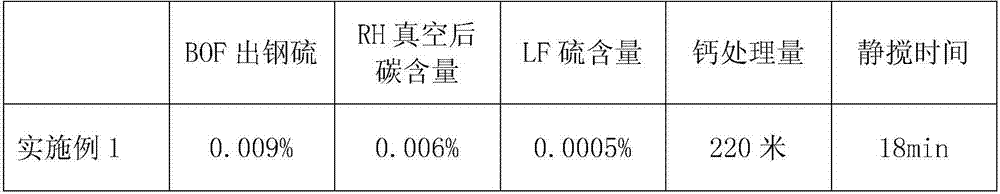

Production process for controlling large inclusions in acid-resistant pipeline steel

ActiveCN107099747AControl quantityDeterioration of mechanical propertiesProcess efficiency improvementSulfurEconomic benefits

The invention discloses a production process for controlling large inclusions in acid-resistant pipeline steel. Through systematic analysis on a pipeline steel inclusion control mechanism adopting a BOF-RH-LF production process, the component design is reasonably performed; the pipeline steel comprises the following components in percentage by weight: 0.02-0.04 percent of C, 0.10-0.30 percent of Si, 1.00-1.30 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0010 percent of S, 0.030-0.070 percent of Nb, 0.006-0.020 percent of Ti, 0.10-0.30 percent of Ni, 0.10-0.30 percent of Cr, 0.10-0.30 percent of Cu, 0.015-0.050 percent of Al and the balance of Fe. The production process disclosed by the invention has the benefits that the content of sulfurs in molten steel before calcium treatment is ensured to be less than 10 ppm; the quantitative calcium treatment is performed after the end of LF; the purpose of improving the purity of the molten steel is achieved, so that the internal quality of steels is improved, and the economic benefits are improved.

Owner:NANJING IRON & STEEL CO LTD

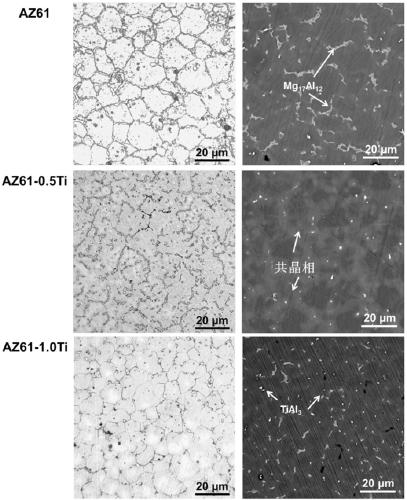

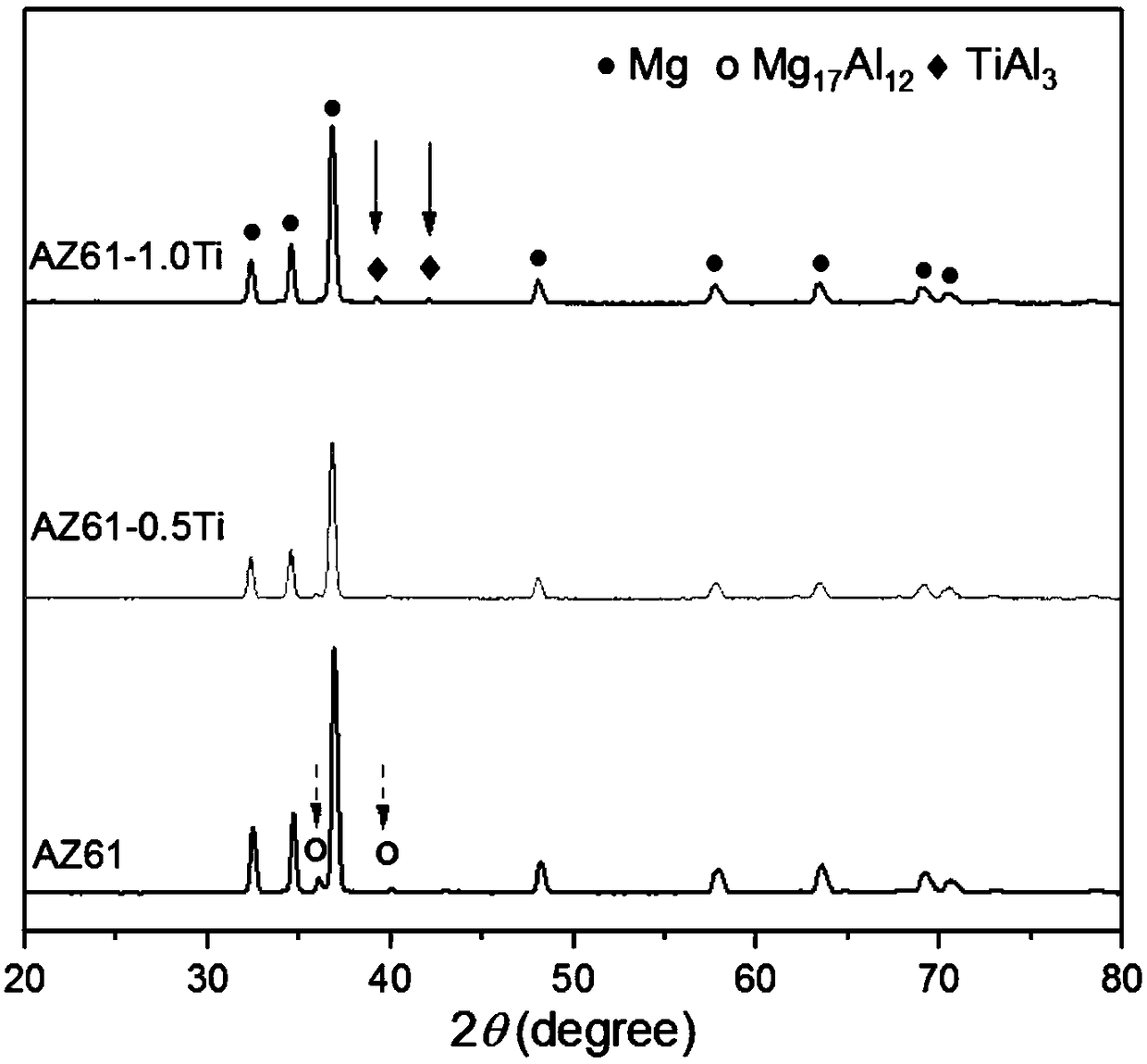

Magnesium-aluminum alloy with continuous eutectic structure and preparation method thereof

ActiveCN108950334AImprove corrosion resistanceIncrease the solidification rateSelective laser meltingMelting tank

The invention discloses a magnesium-aluminum alloy with continuous eutectic structure and a preparation method thereof, and the alloy is composed of a magnesium-aluminum alloy matrix and a continuouseutectic phase distributed at the grain edge of the matrix. The preparation method comprises the following steps that (1) nano-sized titanium powder and the magnesium-aluminum alloy powder are placedin a ball mill, and ball milling is conducted under protective atmosphere to obtain the mixed powder; and (2) the mixed powder is used as a raw material, and the magnesium-aluminum alloy with the continuous eutectic structure is prepared through selective laser melting under the protective atmosphere. According to the preparation method, the titanium is introduced in the magnesium-aluminum alloy preparation process, aluminum atoms in a molten pool are attracted to migrate, and eutectic reaction is generated on the edge of the crystal grain to generate the continuous eutectic phase; meanwhile,the characteristic that the selective laser melting solidification speed is high is utilized, the formation of the continuous eutectic phase is promoted while the content of a second phase Mg17Al12 isreduced, so that galvanic corrosion effect of the magnesium aluminum alloy is effectively weakened, and the corrosion resistance of the magnesium-aluminum alloy is improved; and meanwhile, better interface combination is achieved, so that the mechanical property of the magnesium-aluminum alloy is improved.

Owner:CENT SOUTH UNIV

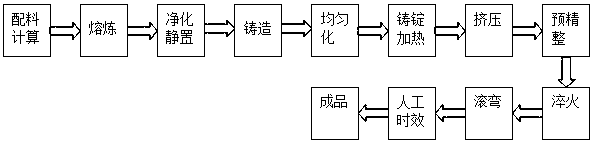

Aviation aluminium alloy U-shaped frame section bar and preparation method thereof

The invention discloses an aviation aluminium alloy U-shaped frame section bar and a preparation method thereof. The aviation aluminium alloy U-shaped frame section bar is prepared from the followingelements in percentage by weight: 5.6-6.5% of Zn, 1.4-2.4% of Cu, less than 0.1% of Mn, 1.8-2.6% of Mg, 0.2-0.25% of Cr, 0.25-0.35% of Fe, equal to or less than 0.1% of Si, less than 0.08% of Ti and the balance of Al. According to the preparation method, through the set alloy composition and the specific preparation technology including extruding, rolling and bending, the aviation aluminium alloyU-shaped frame section bar formed at one time is obtained, on one hand, the tensile strength and yield strength of U-shaped frame section bar are greatly improved, finally, the tensile strength can reach 550-609 MPa, the yield strength can reach 490-546 MPa, the elongation is 7-11%, the planar clearance is equal to or less than 1 mm, the perpendicularity is equal to or less than 1 degree, which are much better than the using standard, and on the other hand, the precision of the U-shaped frame section bar is greatly improved, the prepared U-shaped frame section bar has excellent planar flatnessto ensure stability consistency of quality, can completely meet the using requirement of aviation aluminium alloy section bar, and provides material guarantee for research of a novel spaceflight carrier rocket in China.

Owner:西北铝业有限责任公司

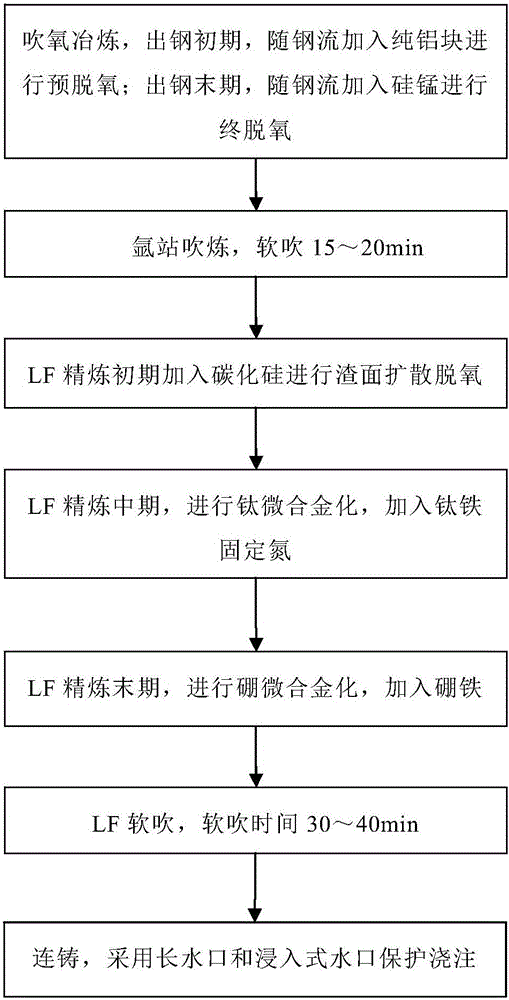

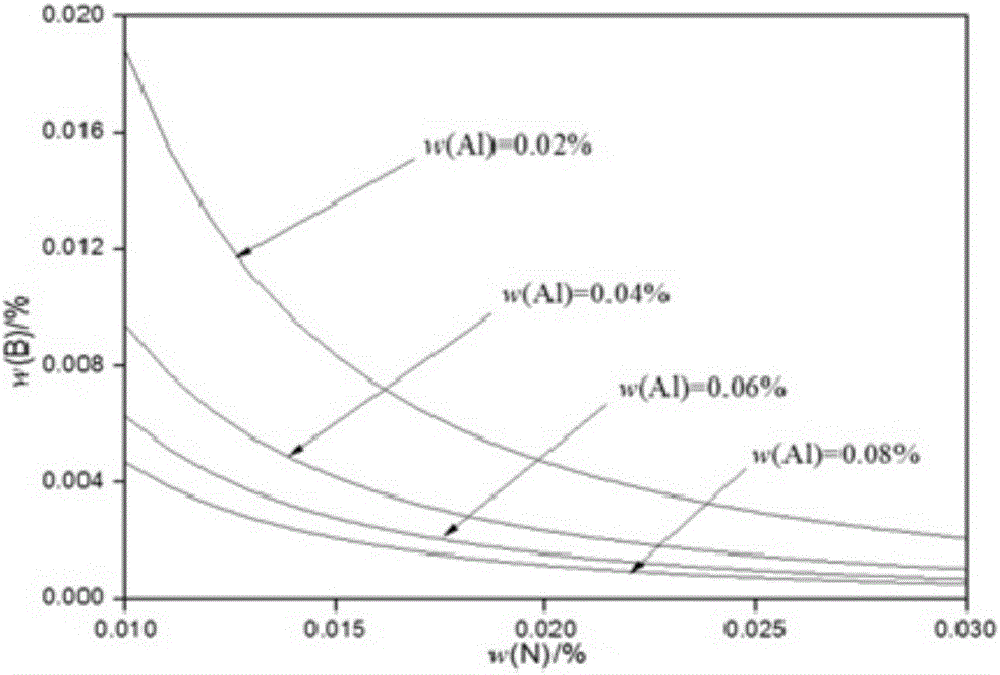

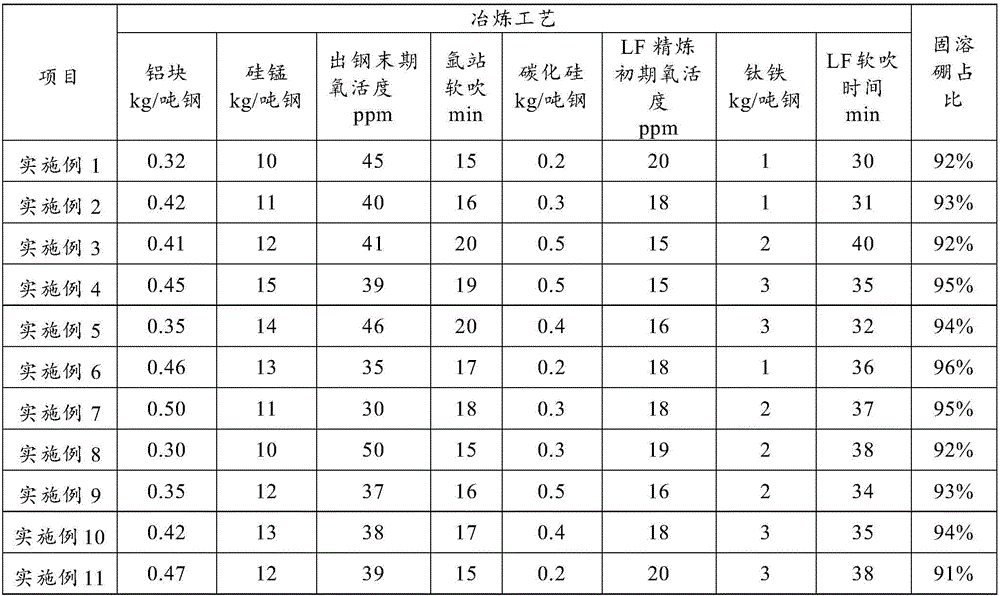

Smelting method for controlling existing form of boron in steel

The invention belongs to the technical field of steelmaking, and discloses a smelting method for controlling an existing form of boron in steel. The smelting method comprises the following steps of blowing oxygen and smelting: at the early stage of steel tapping, pure aluminum blocks are added along with the flow of steel for pre-deoxidation, and at the final stage of steel tapping, silicomanganese is added along with the flow of steel for final deoxidation; blowing at an argon station: soft blowing is performed for 15 to 20 min; adding silicon carbide for slag surface diffusion deoxidation at the early stage of LF refining; performing titanium micro alloying, and adding ferrotitanium for fixing nitrogen at the middle stage of LF refining; performing boron micro alloying, and adding ferroboron at the final stage of LF refining; performing LF soft blowing for 30 to 40 min; performing continuous casting: casting is protected by adopting a long nozzle and a submersed nozzle. The invention provides the smelting method for increasing the duty cycle of solid solution boron.

Owner:武汉钢铁有限公司

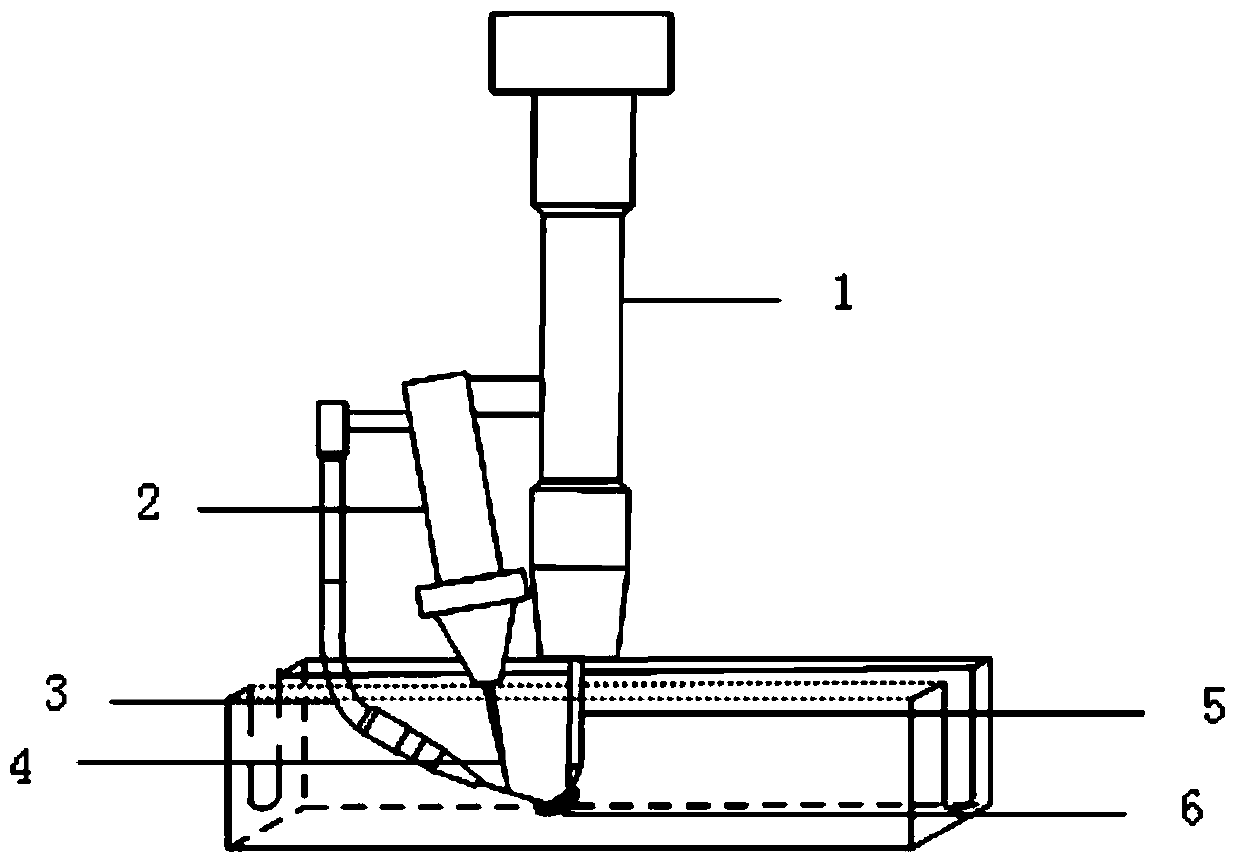

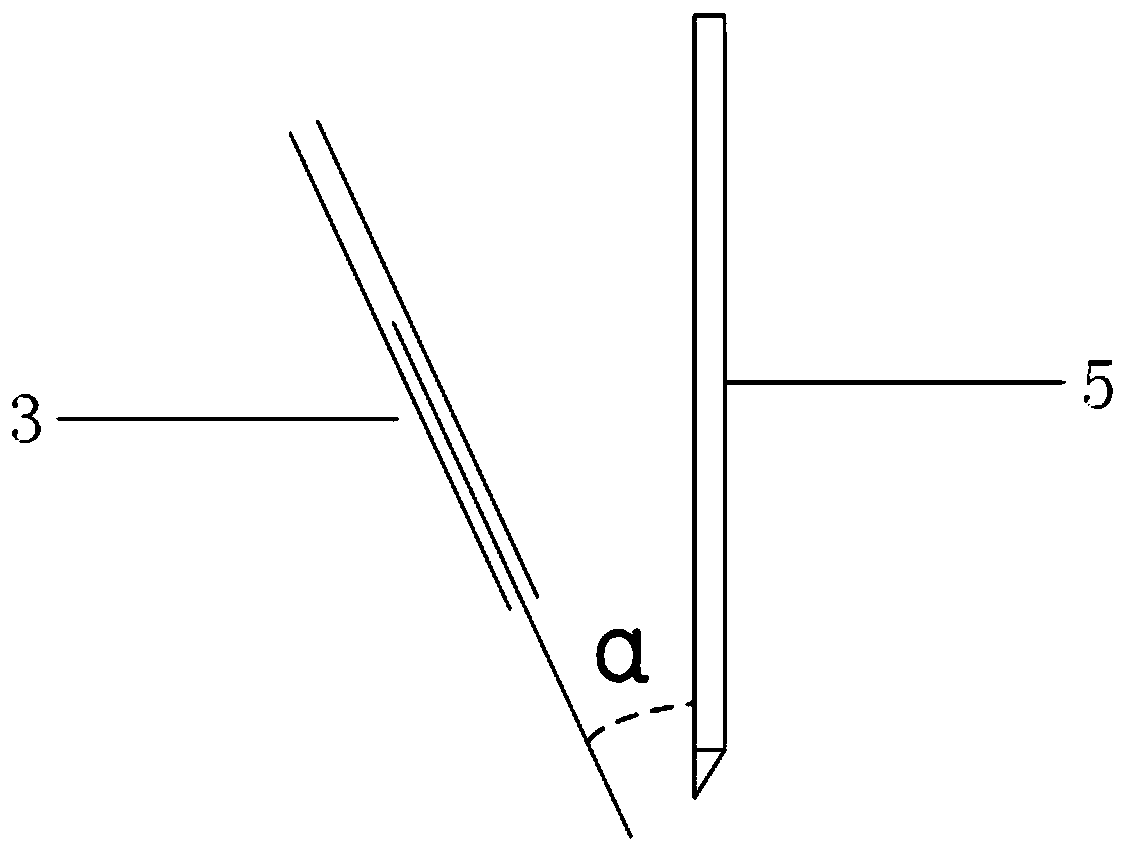

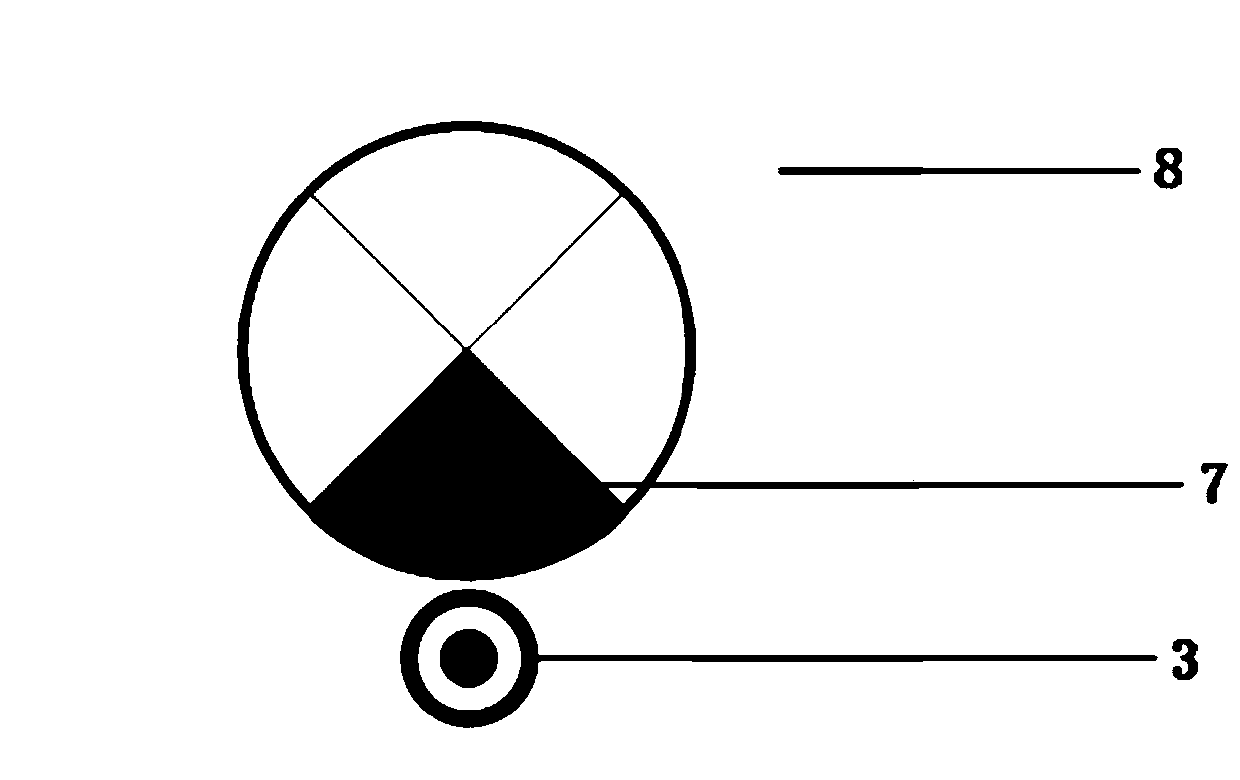

Non-axisymmetric rotary tungsten electrode GTAW and pulse laser composite welding method

ActiveCN110052712AIncrease the volume of deposited metalImprove welding quality and manufacturing efficiencyLaser beam welding apparatusElectric arcOptoelectronics

The invention relates to a non-axisymmetric rotary tungsten electrode GTAW and pulse laser composite welding method, and belongs to the technical field of GTAW welding. A based welding system comprises a pulse laser system, a welding gun system and a wire feeding device. The method comprises the following steps: providing pulse laser by the pulse laser system, arranging a laser unit between the wire feeding device and a welding gun, periodically providing pulse laser to irradiate a welding wire by matching with rotation of a non-axisymmetric tungsten electrode. The problems such as uneven smelting for non-axisymmetric rotary electric-arc welding wires are solved, thermal input of welding is reduced, quality of welding seams is improved, and deposition efficiency is remarkably improved.

Owner:SHANDONG UNIV

A production process for controlling large inclusions in acid-resistant pipeline steel

ActiveCN107099747BControl quantityDeterioration of mechanical propertiesProcess efficiency improvementCalcium handlingMetallurgy

The invention discloses a production process for controlling large inclusions in acid-resistant pipeline steel. Through systematic analysis on a pipeline steel inclusion control mechanism adopting a BOF-RH-LF production process, the component design is reasonably performed; the pipeline steel comprises the following components in percentage by weight: 0.02-0.04 percent of C, 0.10-0.30 percent of Si, 1.00-1.30 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0010 percent of S, 0.030-0.070 percent of Nb, 0.006-0.020 percent of Ti, 0.10-0.30 percent of Ni, 0.10-0.30 percent of Cr, 0.10-0.30 percent of Cu, 0.015-0.050 percent of Al and the balance of Fe. The production process disclosed by the invention has the benefits that the content of sulfurs in molten steel before calcium treatment is ensured to be less than 10 ppm; the quantitative calcium treatment is performed after the end of LF; the purpose of improving the purity of the molten steel is achieved, so that the internal quality of steels is improved, and the economic benefits are improved.

Owner:NANJING IRON & STEEL CO LTD

Magnesium-zinc-germanium alloy with cathode inhibition effect and preparation method thereof

The invention discloses a magnesium-zinc-germanium alloy with a cathode inhibition effect and a preparation method thereof. The magnesium-zinc-germanium alloy comprises a magnesium matrix and a magnesium-zinc-germanium second phase, the preparation method comprises the following steps that (1), the magnesium-zinc alloy and a nano-germanium powder are placed in a ball mill, and the magnesium-zinc alloy and the nano-germanium powder are subjected to ball milling under a protective atmosphere to obtain a magnesium-zinc-germanium mixed power; (2), the mixed powder is taken as a raw material, and the magnesium-zinc-germanium alloy is prepared by performing selective laser melting under a protective atmosphere. According to the magnesium-zinc-germanium alloy with a cathode inhibition effect andthe preparation method, the germanium is introduced into the magnesium-zinc alloy, and the second phase containing germanium is generated in the alloy, so that the aggregation of medium hydrogen atomsin the solution on the cathode can be inhibited, the generation rate of hydrogen is reduced by weakening the recombination of the hydrogen atoms, so that the corrosion resistance of the magnesium-zinc alloy is improved; and on the other hand, the mechanical property of the magnesium-zinc alloy is improved through solid solution strengthening, fine grain strengthening and second phase strengthening.

Owner:JIANGXI UNIV OF SCI & TECH +1

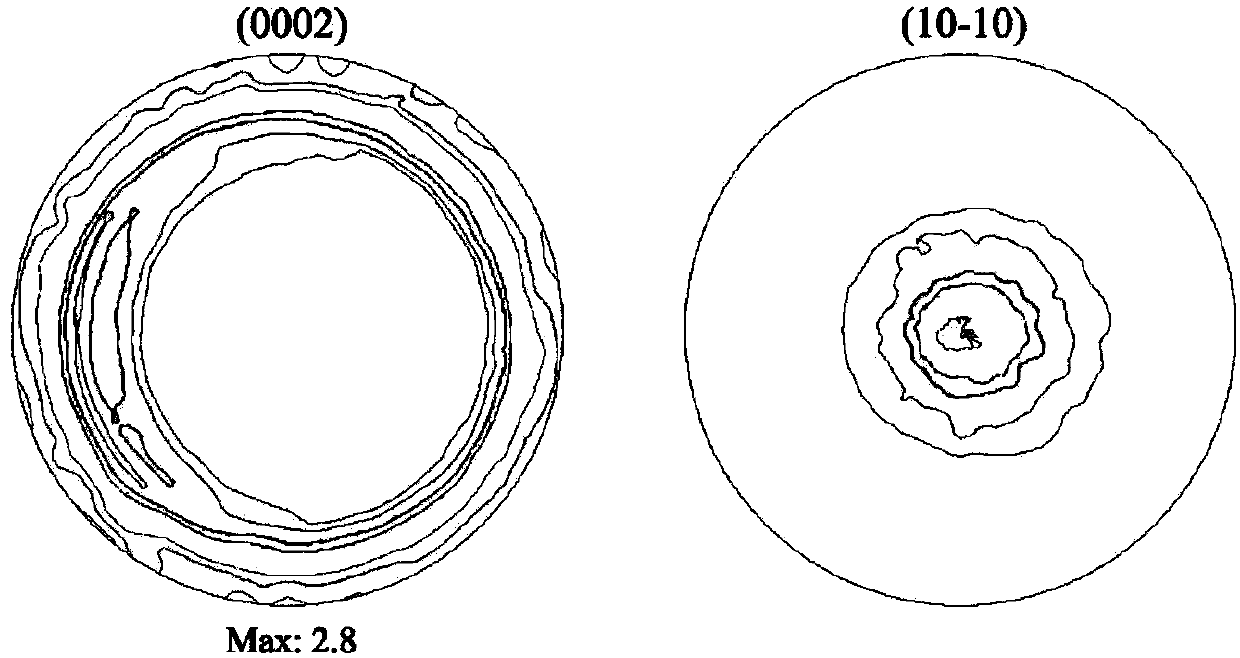

Multi-element composite enhanced magnesium alloy with high strength and low cost and preparation method thereof

The invention relates to a multi-element composite enhanced magnesium alloy with high strength and low cost and a preparation method thereof. The multi-element composite enhanced magnesium alloy is prepared from the following elements of 2.5% to 6.5% of Al (aluminum), 0.6% to 1.5% of Zn (zinc), 0.1% to 0.4% of Mn (manganese), 0.1% to 0.4% of Sn (stannum), 0.1% to 0.4% of Ca (calcium), 0.1% to 0.4%of Cu (copper), 0.15% or less of unavoidable impurities, and the balance of Mg (magnesium). The prepared multi-element composite enhanced magnesium alloy has the advantages that the tensile strengthand compressive strength are greatly improved, and the deterioration of elongation rate is avoided; the magnesium alloy material can be prepared through alloying by adding a small amount of alloy elements, the deformation is completed on common deformation processing equipment, the alloy cost is not obviously increased, the property is high, and the commercial value is high; the application rangeof magnesium alloy is effectively expanded.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sn-Ag-Cu lead-free solder with high interface bonding strength and a preparation method thereof

InactiveCN109848606AInhibited DiffusionLow aging resistanceWelding/cutting media/materialsSoldering mediaSurface oxidationMechanical property

The invention discloses improved Sn-Ag-Cu lead-free solder and a preparation method thereof. Zr and Ni are added in Sn-Ag-Cu lead-free solder, the amount of the Zr and the amount of the Ni are controlled, addition of the Ni can further promote the dispersion distribution of the Zr so as to further refine the microstructure of the solder; the surface tension of a molten pool is reduced, a wetting and spreading area is expanded, and the welding wettability and the oxidation resistance of a solder alloy are improved; and formation of the defects such as cavities and bridging in the welding process is inhibited, surface oxidation of welding spots during the long-term use process is prevented, and the welding spots still have excellent electricity and heat conduction performance in long-term use. By means of the synergistic effect of the two elements, the welding wettability as well as the mechanical property, the high-temperature anti-aging performance and the electricity conduction and heat conduction performance of the welding spots are comprehensively improved, and the development requirements of electronic components are met.

Owner:CENT SOUTH UNIV +1

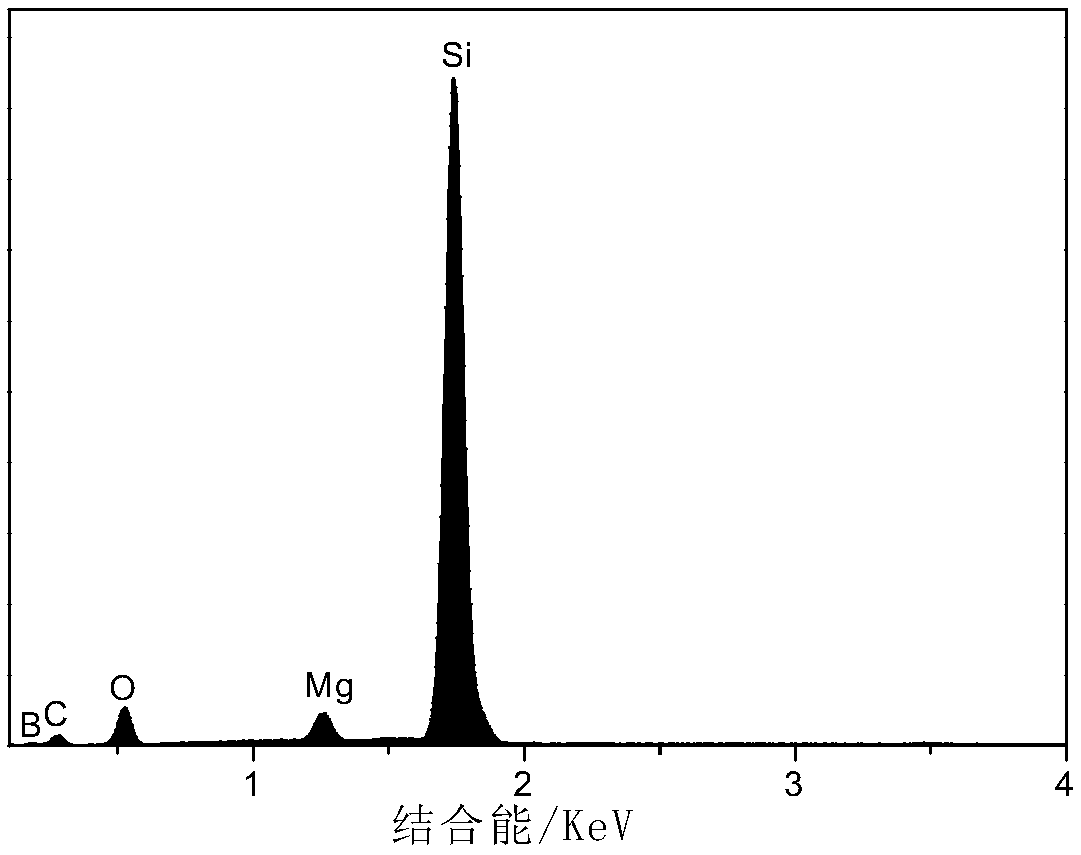

High-performance low-carbon aluminum alloy and preparation method

The invention provides a high-performance low-carbon aluminum alloy and a preparation method, and belongs to the technical field of aluminum alloy materials. The aluminum alloy comprises the following chemical components in percentage by mass: 6%-8% of Si, 3%-5% of Cu, 0.2%-0.6% of Mg, less than or equal to 0.8% of Fe, 0.3%-0.6% of Mn, 0.02%-0.04% of Ti, 0.05%-0.15% of La and the balance of Al and inevitable impurities. Through component optimization and process parameter adjustment, the yield strength of a casting reaches 400 MPa or above, the tensile strength reaches 430 MPa or above, the hardness reaches 155 HV or above, and the ductility reaches 4.0% or above. The method serves the major strategy of carbon peak reaching and carbon neutralization in China, the manufacturing process is free of pollution, the carbon emission is only 5% of that of a high-performance aluminum alloy structural part produced by electrolytic aluminum, and the bottleneck problem that regenerated aluminum alloy cannot be applied to high-end products is thoroughly solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Solid core wire for gas protection welding of high manganese low temperature steel

ActiveCN109623202AReduce the content of expensive elements and alloy costsImprove performanceWelding/cutting media/materialsSoldering mediaLiquefied natural gasMetallic Nickel

The invention discloses a solid core wire for gas protection welding of high manganese low temperature steel. The solid core wire is characterized by comprising the following chemical composition in percentage by mass: 0.2-0.4% of C, 12-15% of Mn, 14-18% of Ni, 1.5-4.5% of Cr, 0.1-0.6% of Mo, 0.005-0.040% of Ti, no more than 0.004% of P, no more than 0.002% of S and the balance Fe and inevitable impurity elements. The solid core wire adopts the alloy design of composite manganese and nickel adding, the content of expensive elements such as nickel and the cost of alloy are reduced, the fact that the excessive amount of manganese forms excessive toxic manganese evaporation in the welding process is avoided, the use performance of the wire is improved, the weld metal formed by the solid corewire at low temperature of minus 196 DEG C has excellent impact toughness, and the welding requirements of the high manganese low temperature steel for the construction of liquefied natural gas storage tanks and other equipment are well met.

Owner:NANJING IRON & STEEL CO LTD +1

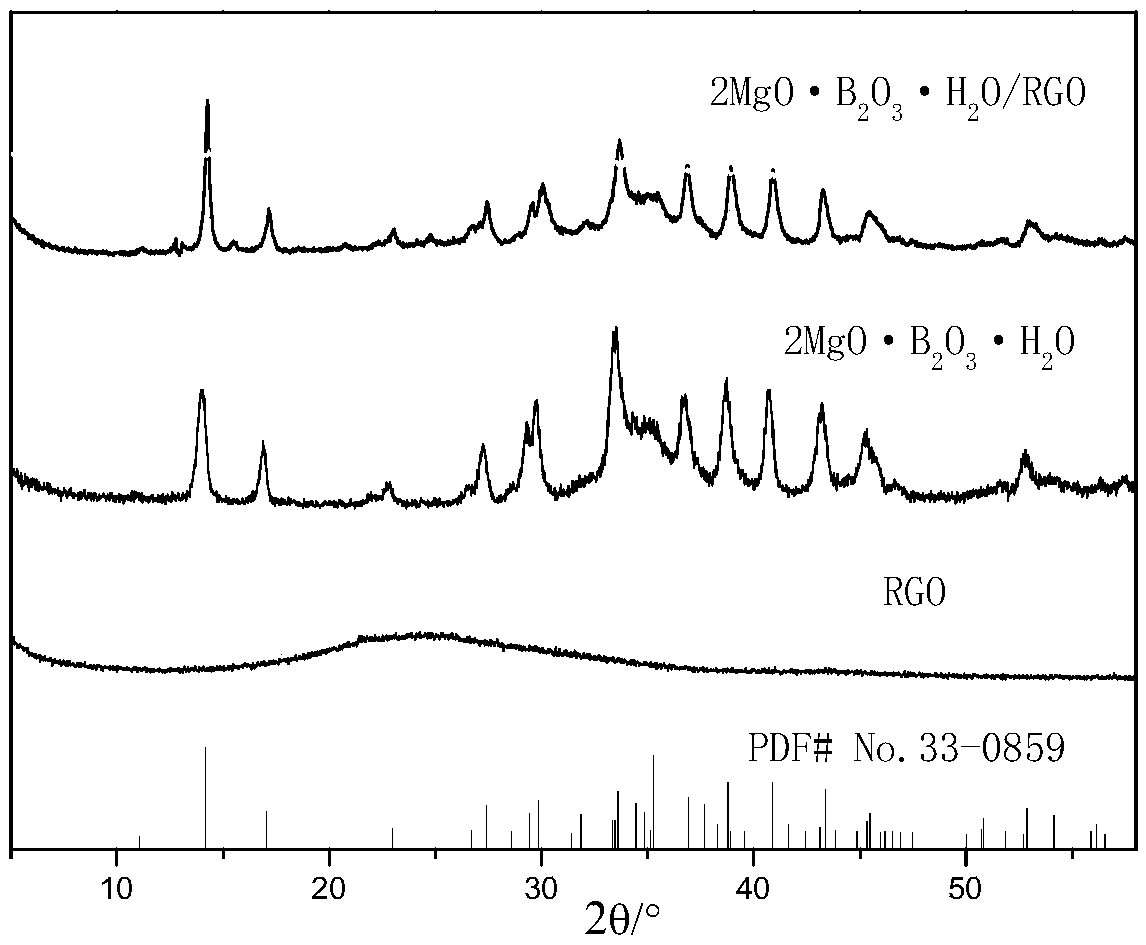

2MgO.B2O3.H2O/RGO nano-composite flame retardant

InactiveCN109575363AStrong mechanical propertiesImprove mechanical propertiesPolymer scienceMass content

The invention discloses a 2MgO.B2O3.H2O / RGO nano-composite flame retardant. The composite flame retardant is prepared by loading 2MgO.B2O3.H2O nano-ribbons on the surface of RGO (Reduced Graphene Oxide); and the mass content of the RGO is 5 to 20 percent. According to the 2MgO.B2O3.H2O / RGO nano-composite flame retardant, GO is added in the process of preparing the 2MgO.B2O3.H2O nano-ribbons by a hydrothermal method; the nano-composite flame retardant of the RGO loaded with 2MgO.B2O3.H2O nano-ribbons is prepared by reacting in situ; the preparation method is simple and low in cost; and the prepared 2MgO.B2O3.H2O / RGO nano-composite flame retardant material is good in disparity and small in particle size, moreover, has good flame retarding effect and mechanical properties, and has a potentialapplication prospect.

Owner:SHAANXI NORMAL UNIV

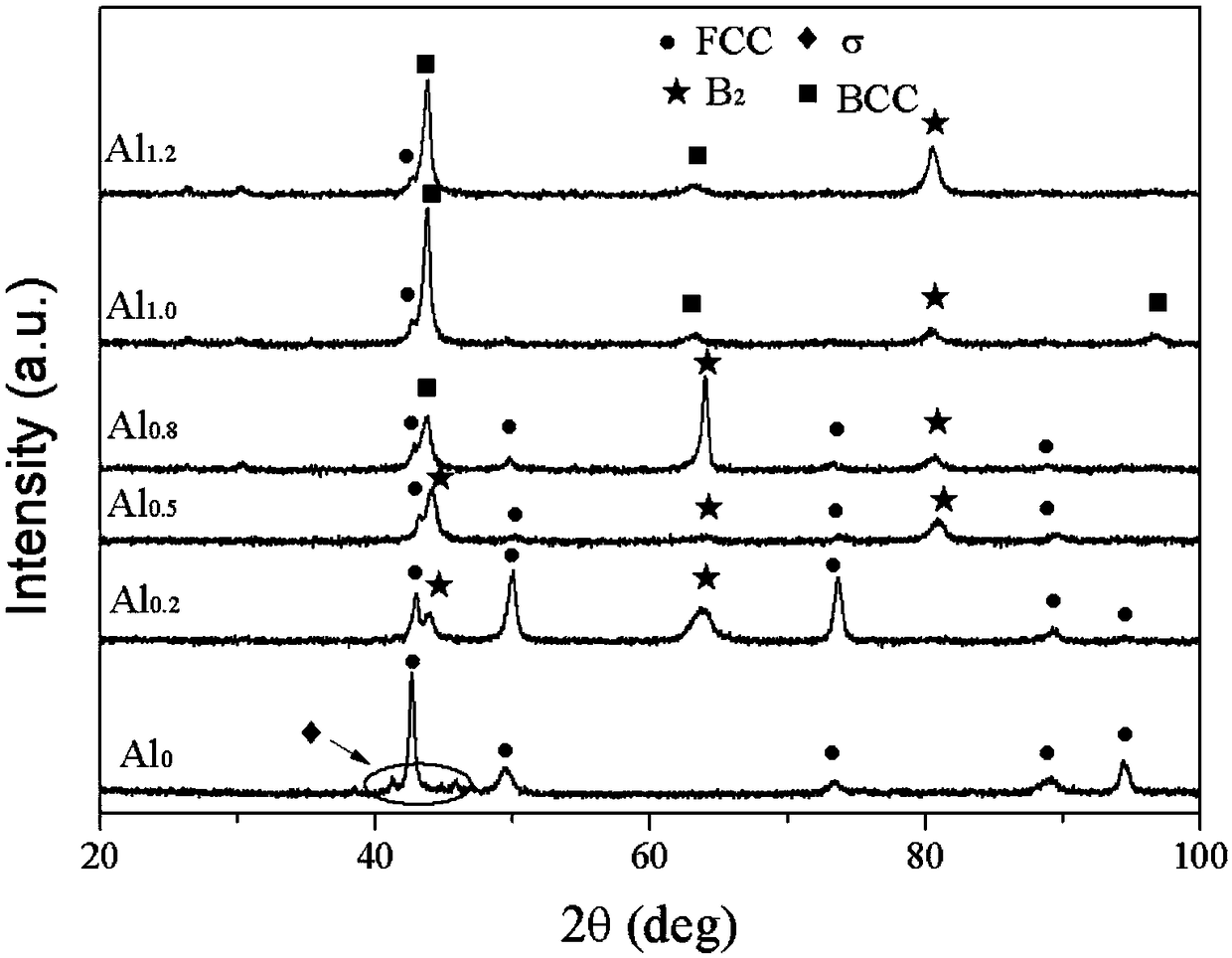

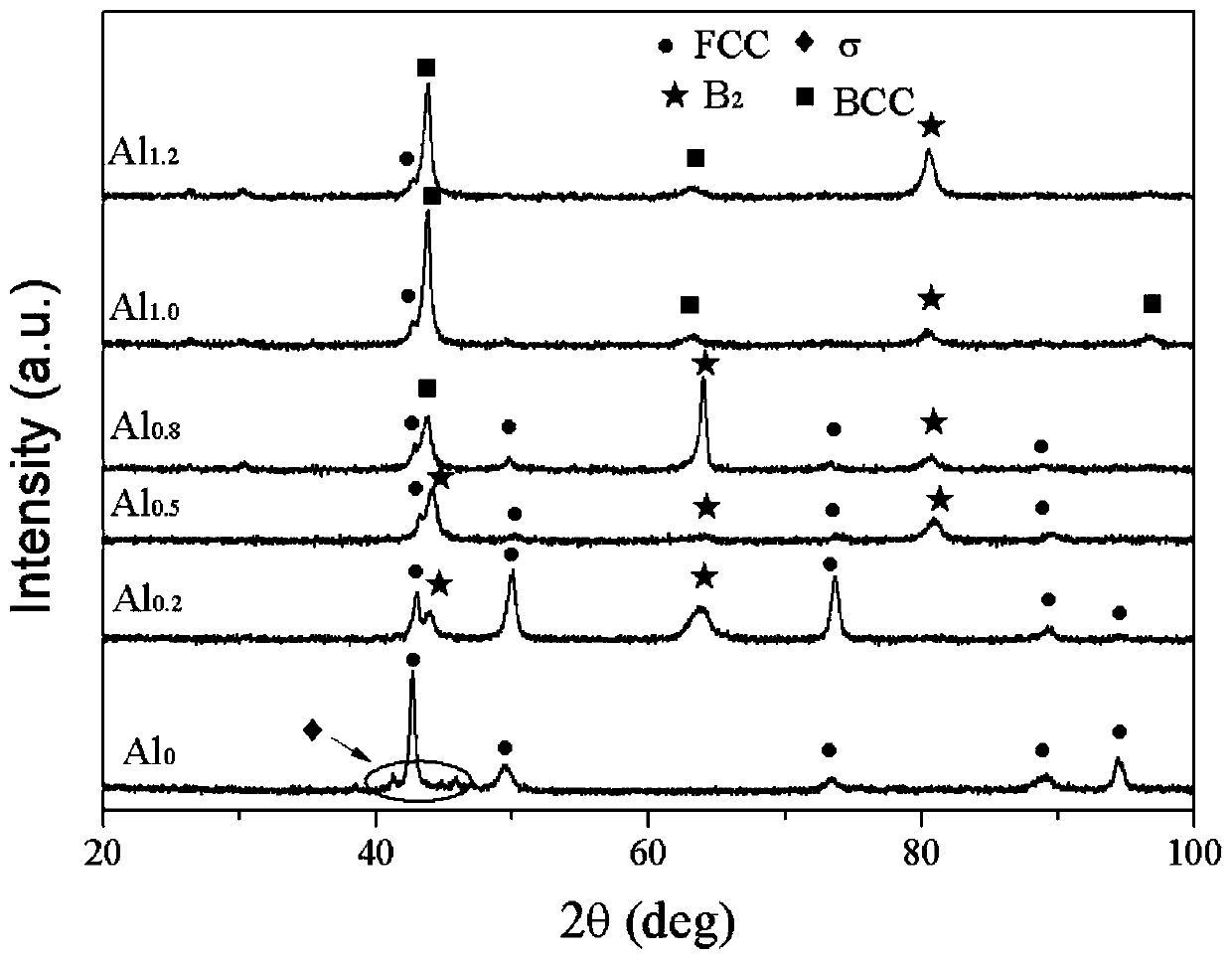

Five-element high-entropy alloy Cu0.5FeNiVAlx and strength and hardness improvement method thereof

ActiveCN108467984AIncrease the scope of applicationGood application prospectHigh entropy alloysMuffle furnace

The invention discloses five-element high-entropy alloy Cu0.5FeNiVAlx and a strength and hardness improvement method thereof. The five-element high-entropy alloy Cu0.5FeNiVAlx mainly comprises Cu, Fe,Ni, V and Al with purities greater than or equal to 99.9%. The five-element high-entropy alloy Cu0.5FeNiVAlx comprises, by atomic percent, 10 to 15 at% of the Cu, 20 to 30 at% of the Fe, 20 to 30 at%of the Ni, 20 to 30 at% of the V, and 0 to 26 at% of the Al. A preparation method of the five-element high-entropy alloy Cu0.5FeNiVAlx is as follows: performing arc-strike smelting in a vacuum environment protected by argon gas on the alloy raw materials Cu, Fe, Ni, V and Al for repeated several times. The strength and hardness improvement method of the five-element high-entropy alloy Cu0.5FeNiVAlx is as follows: using a quartz tube for vacuum sealing of a prepared Cu0.5FeNiVAlx ingot, then using a muffle furnace at 500 DEG C, 750 DEG C and 1000 DEG C respectively for annealing treatment, andfinally thermally-insulating and cooling to room temperature. The five-element high-entropy alloy Cu0.5FeNiVAlx obtained by the method has an effective improvement in strength and hardness, and contributes to broadening the application range of a high-entropy alloy and improving the economic value.

Owner:GUANGXI UNIV

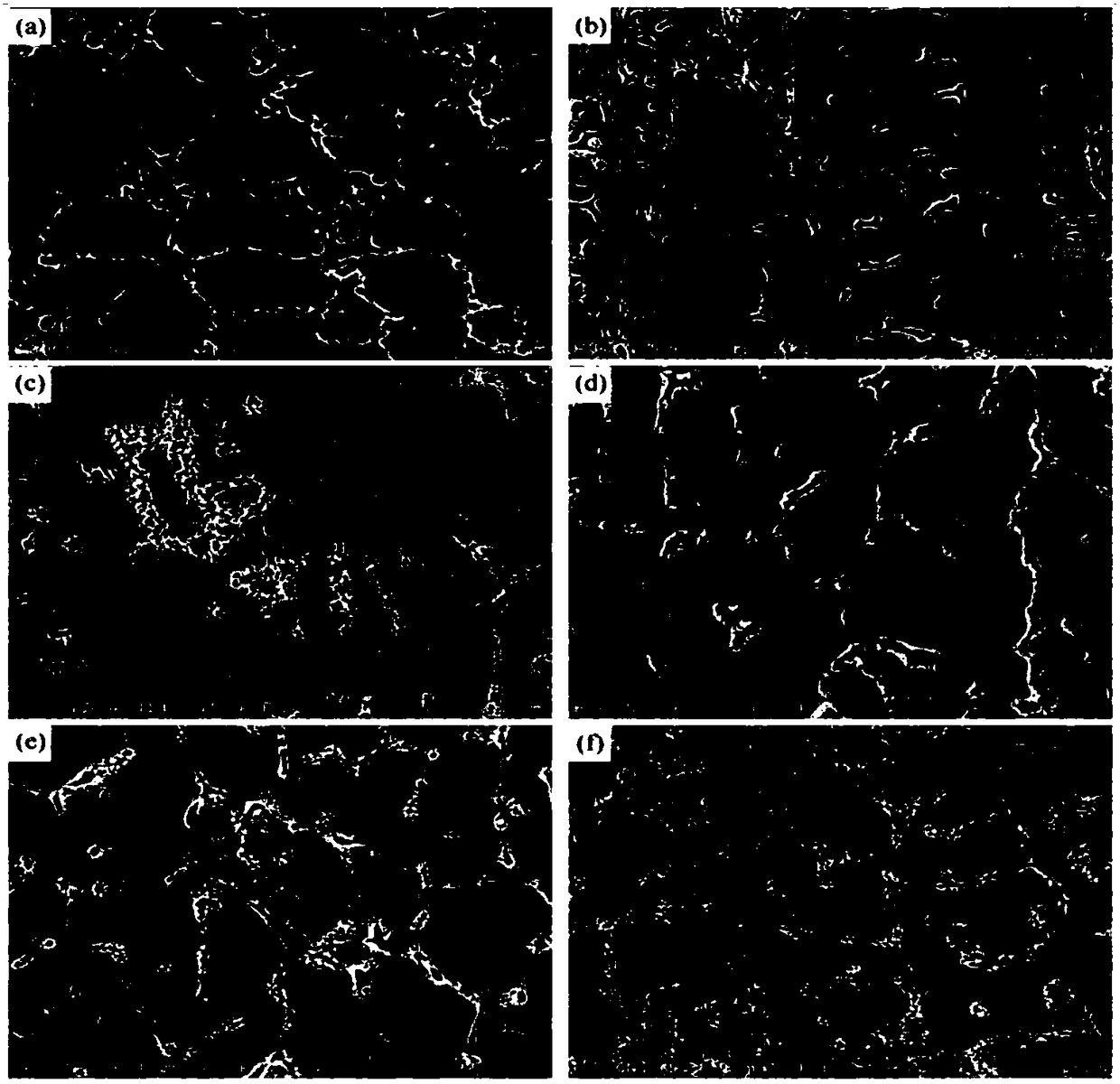

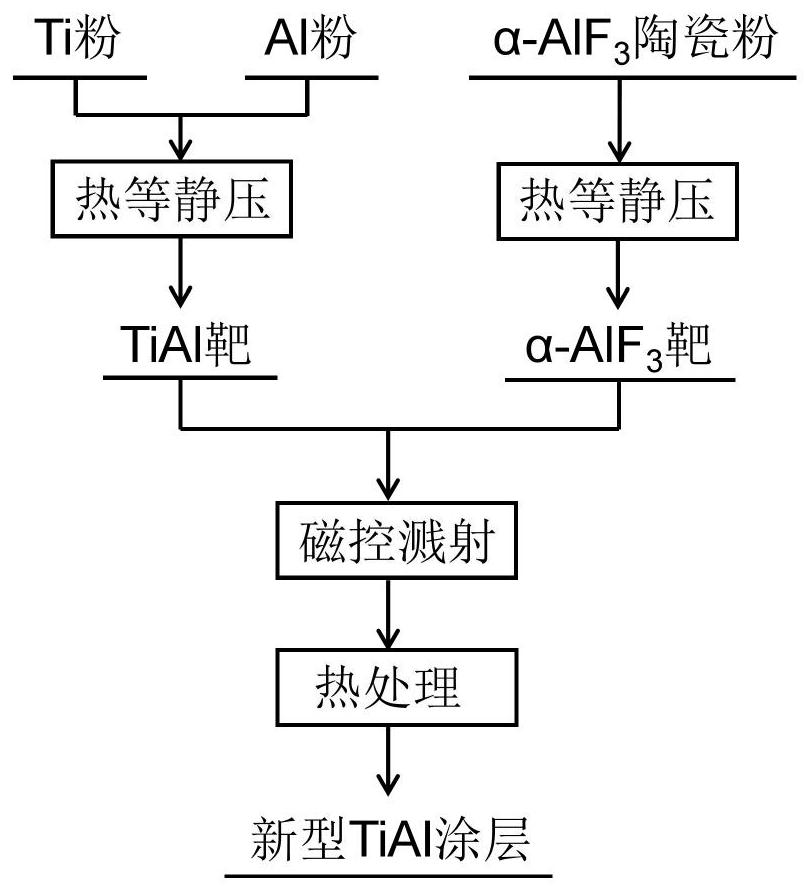

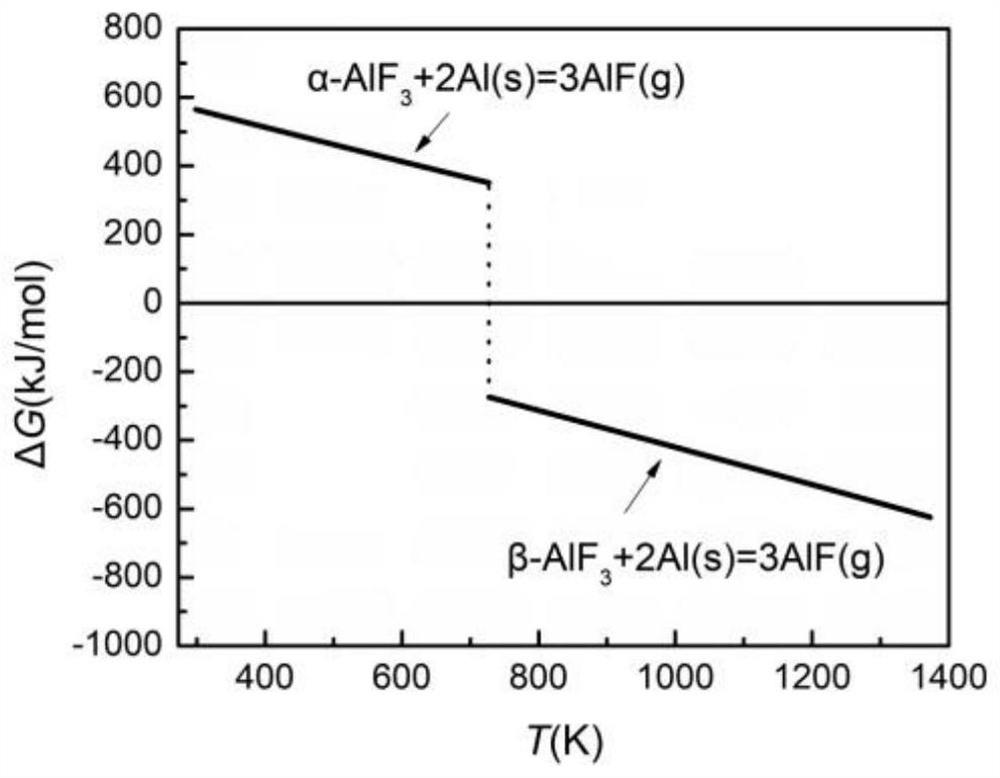

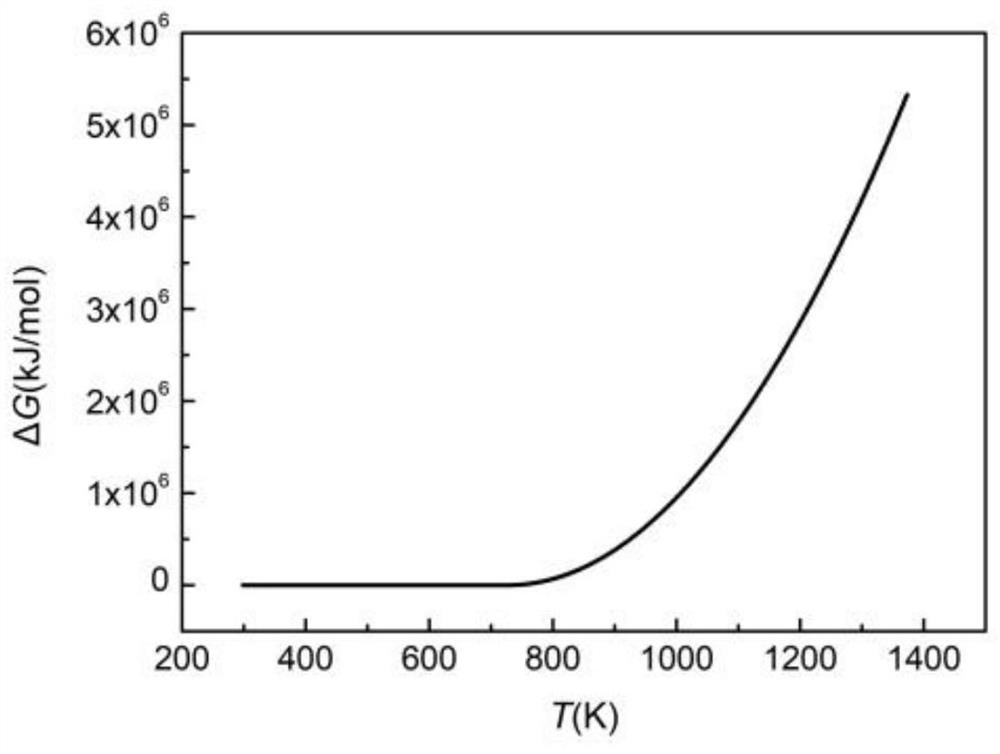

TiAl coating capable of improving high-temperature oxidation resistance of titanium alloy and preparation method of TiAl coating

ActiveCN113652644AReduce thermal stressImprove oxidation resistanceVacuum evaporation coatingSputtering coatingNanoparticleRadio frequency sputtering

The invention discloses a TiAl coating capable of improving the high-temperature oxidation resistance of a titanium alloy and a preparation method of the TiAl coating. The TiAl coating comprises alpha-AlF3 nanoparticles, and the content of the alpha-AlF3 nanoparticles accounts for 5 to 30 vol. percent of the TiAl coating. According to the preparation method of the TiAl coating, a TiAl alloy target material and an alpha-AlF3 target material serve as raw materials, and magnetron sputtering deposition is conducted on the surface of a base material to prepare the coating; the magnetron sputtering is double-target co-sputtering, the base material temperature during sputtering is 150 DEG C, the TiAl alloy target material adopts direct current sputtering, the power is 0.5 to 2 kW, the alpha-AlF3 target material adopts radio frequency sputtering, and the power is 0.07 to 0.2 kW; and after the coating is obtained through double-target co-sputtering, heat treatment is conducted on the obtained coating at 600 to 800 DEG C for 5 to 20 hours to obtain a final coating.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

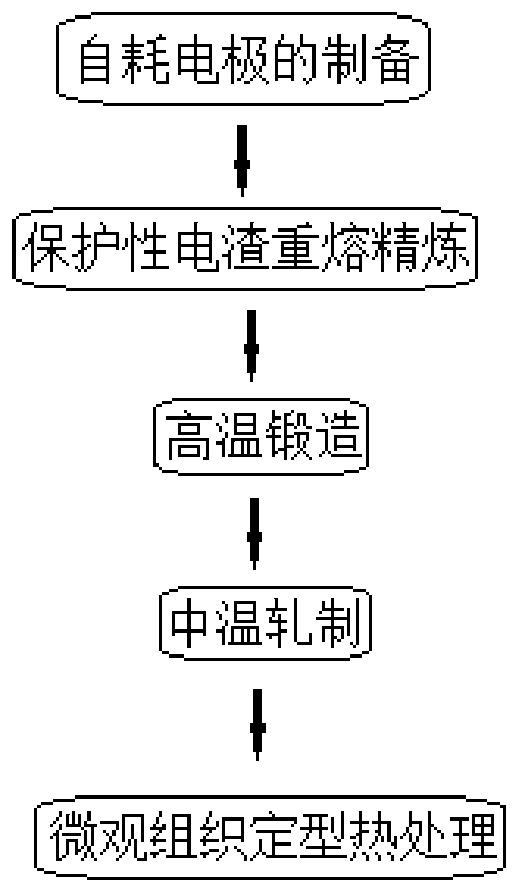

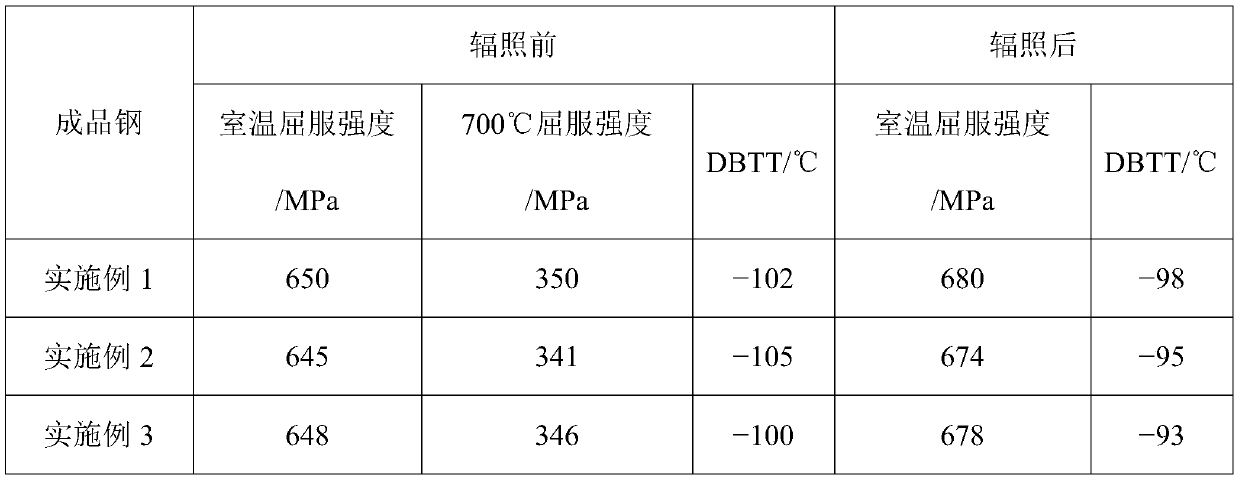

Nano-structure low-activation martensitic steel and preparation method thereof

ActiveCN111593265AAvoid sharp risesAvoid comprehensive mechanical propertiesForgingStructural material

The invention discloses nano-structure low-activation martensitic steel and a preparation method thereof. The nano-structure low-activation martensitic steel comprises the following chemical elementsof, in percentage by mass, 0.08%-0.012% of C, 0.1%-0.25% of Si, 0.4%-0.5% of Mn, 8.5%-9.5% of Cr, 1%-1.5% of W, 0.18%-0.22% of V, 0.01%-0.05% of Ti, 0.0050%-0.01% of N, and the balance Fe. The preparation process comprises the steps of consumable electrode preparation, protective electroslag remelting refining, high-temperature forging, medium-temperature rolling and microstructure shaping heat treatment. According to the nano-structure low-activation martensitic steel and the preparation method thereof, and the use performance of the low-activation steel structure material can be improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

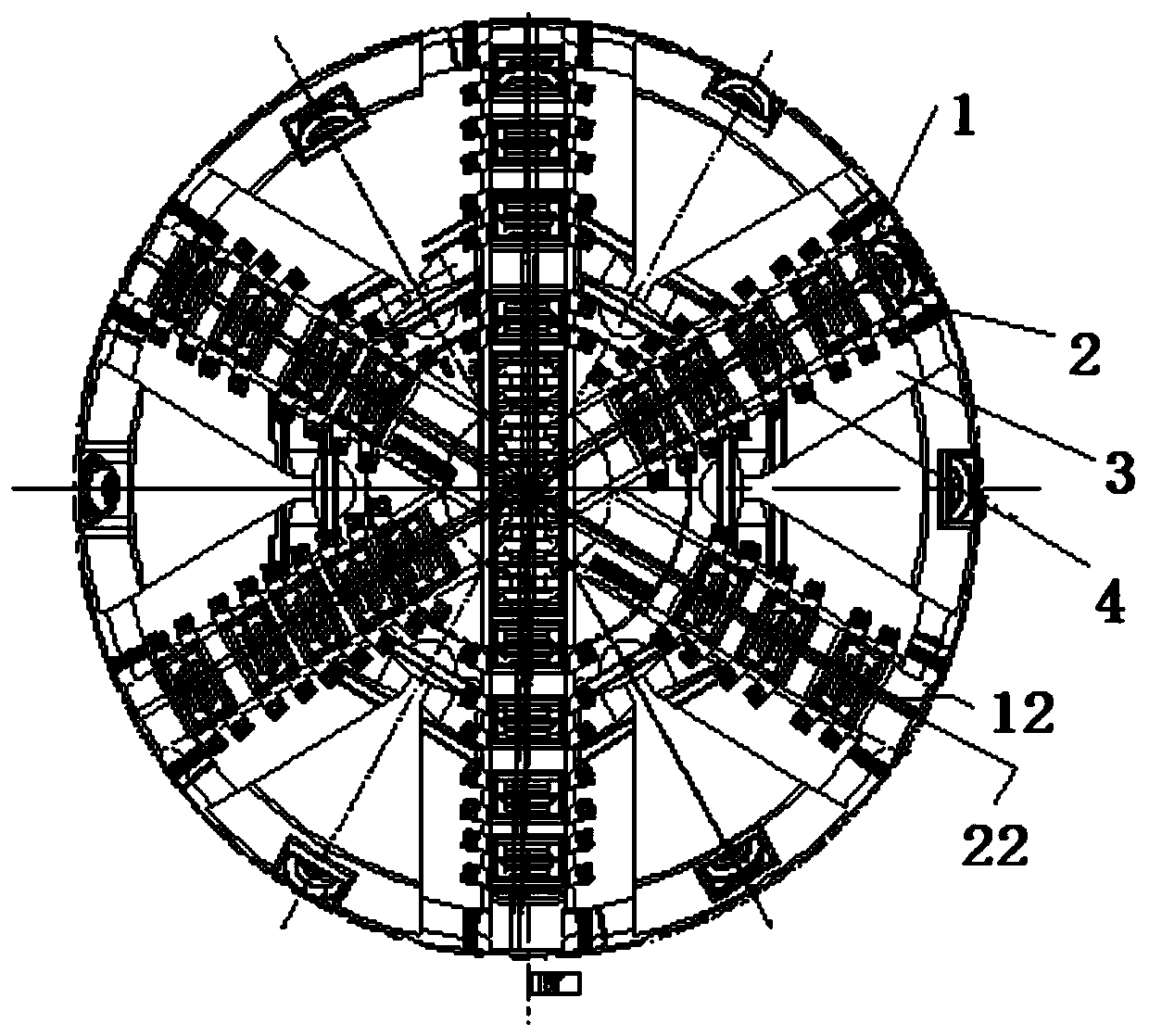

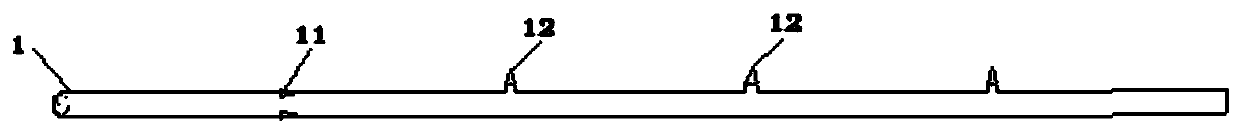

Thermal shock device and method for shield tunneling machine

InactiveCN111101959ADeterioration of mechanical propertiesImprove permeabilityTunnelsEngineeringShield tunneling

The invention relates to a thermal shock device and method for a shield tunneling machine, and belongs to the technical field of shield construction. The thermal shock device comprises a temperature measuring device arranged on a cutter head, heating pipelines and cooling pipelines, wherein the heating pipelines and the cooling pipelines are parallelly arranged on the end surface of the cutter head of the shield tunneling machine and uniformly distributed in the circumferential direction of the cutter head; the position, away from the end surface of the cutter head, of each heating pipeline isprovided a plurality of ignition devices which are sequentially distributed in the length direction of the heating pipeline, and heating switches used for controlling the ignition devices; the position away from the end surface of the cutter head, of each cooling pipeline is provided a plurality of cooling spray heads sequentially distributed in the length direction of the cooling pipeline, and cooling switches used for controlling the cooling spray heads; and the ignition devices and the cooling spray heads are lower than cutters on the cutter head. By utilizing a thermal shock principle, aspecial competent formation is rapidly heated and cooled, a lot of heat exchange is quickly generated, shock thermal stress is generated inside, and shock fracturing is caused, the mechanical propertyof the special competent formation is reduced, the rock breaking speed is increased, and cutter head abrasion is reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A kind of alloying element reinforced high-silicon-aluminum composite material and preparation method thereof

Owner:CENT SOUTH UNIV

Manufacturing method of porous thermal insulation coating layer

InactiveUS20180161807A1Low thermal conductivityReduce volumePiston ringsBlade accessoriesThermal insulationInternal combustion engine

Disclosed herein is a manufacturing method of a porous thermal insulation coating layer. In the manufacturing method, a porous thermal insulation coating layer having excellent close adhesion may be uniformly formed within a shorter time and the porous thermal insulation coating layer may be applied to an internal combustion engine, thereby making it possible to secure low thermal conductivity and low volume thermal capacity.

Owner:HYUNDAI MOTOR CO LTD

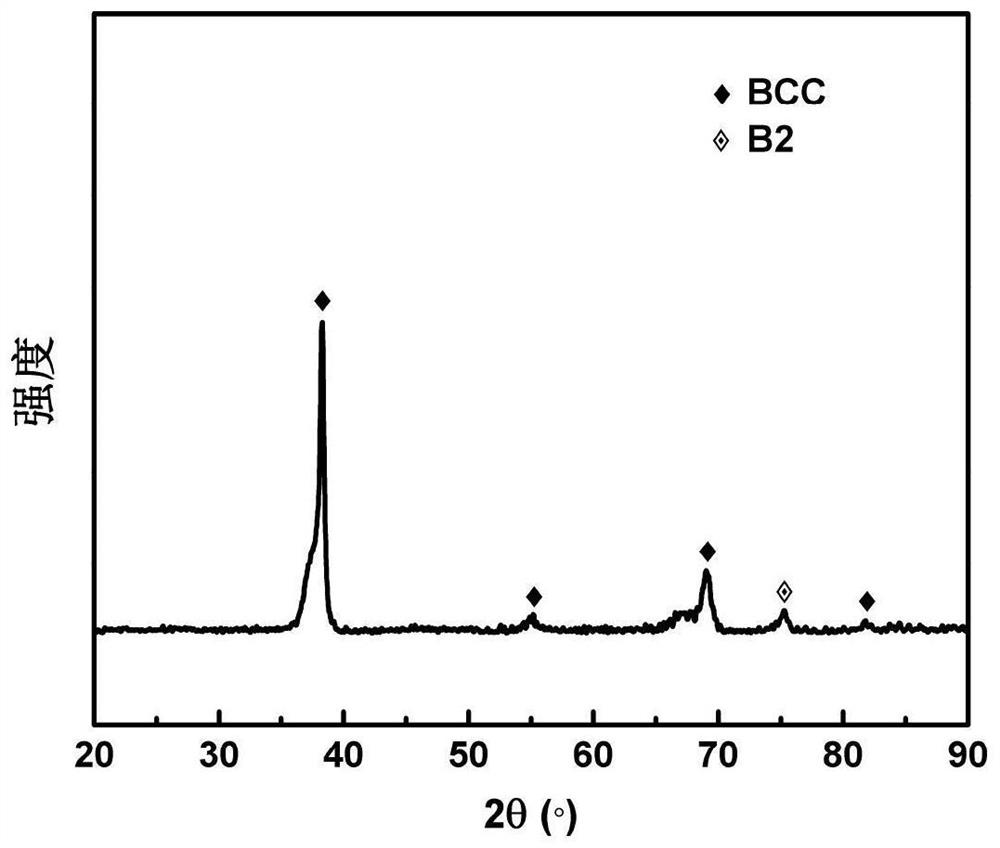

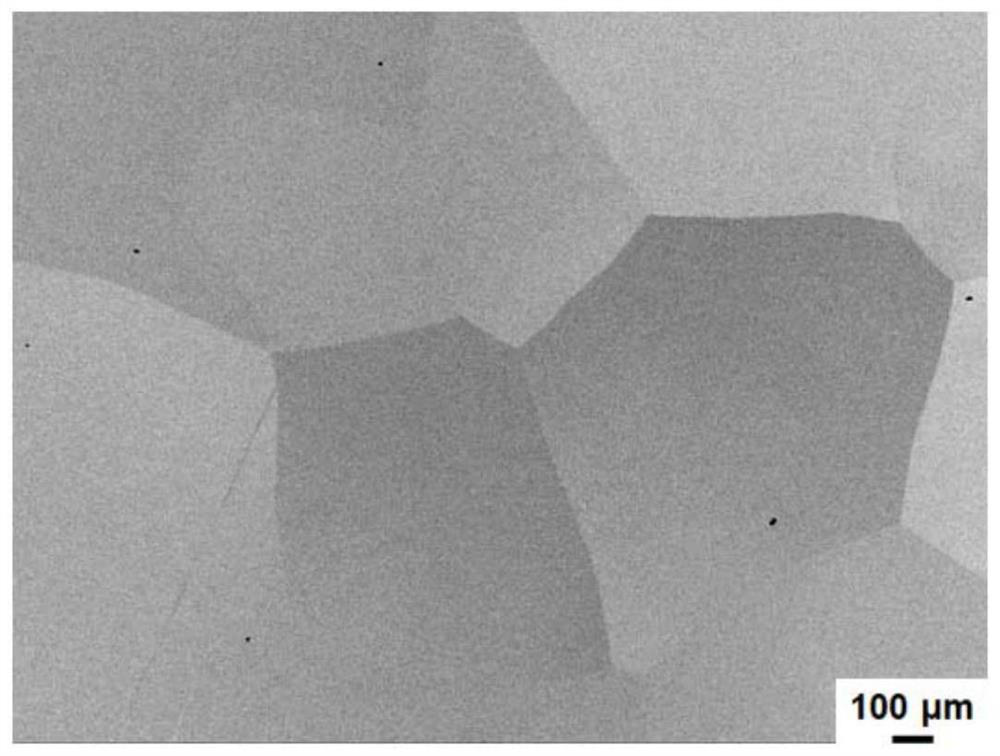

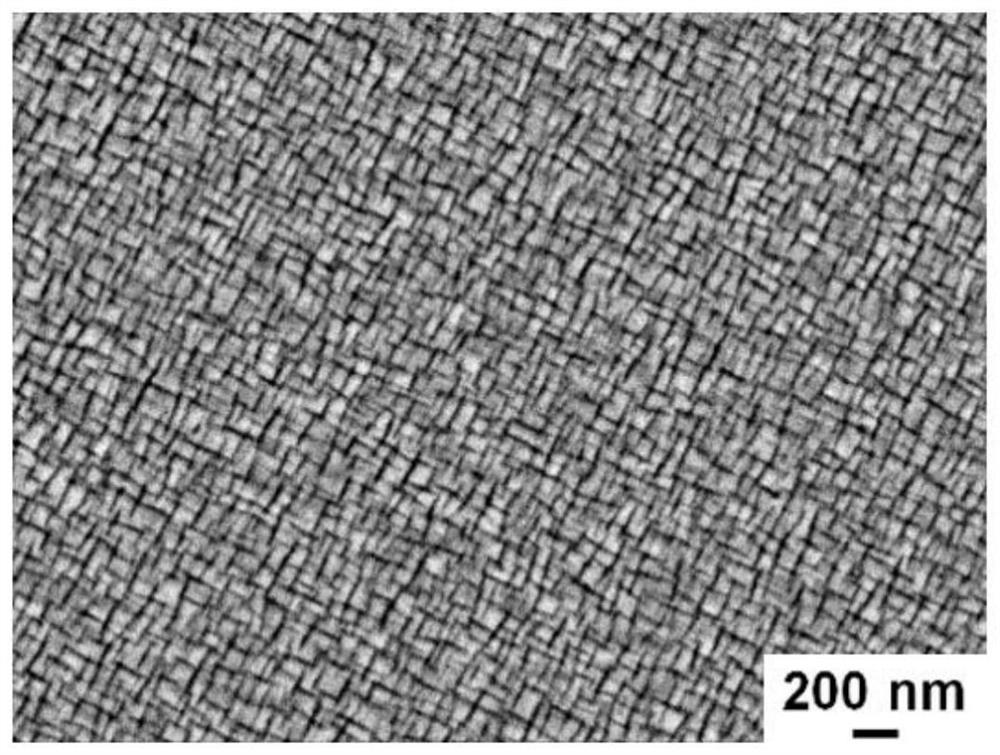

Multi-principal-element alloy containing BCC/B2 double-phase structure and preparation method of multi-principal-element alloy

The invention relates to a multi-principal-element alloy containing a BCC / B2 double-phase structure and a preparation method of the multi-principal-element alloy and belongs to the technical field of metal materials. The multi-principal-element alloy is of a woven BCC / B2 double-phase structure, the chemical formula of the multi-principal-element alloy is recorded as TiaTabNbcZrdAleMf according to the atomic percentage content of all elements, M is at least one of V, Cr, Ni, Cu, Fe, Si, Mg, Y, B, C and O, a is greater than 30 and less than or equal to 60, b is greater than 0 and less than or equal to 15, c is greater than or equal to 5 and less than or equal to 50, d is greater than or equal to 5 and less than or equal to 40, e is greater than or equal to 5 and less than 15, f is greater than or equal to 0 and less than or equal to 10, b+c+d is greater than or equal to 40 and less than or equal to 75, b / d is greater than or equal to 0.3 and less than or equal to 0.6, and the multi-principal-element alloy has good plasticity and high strength by optimizing the composition elements of the multi-principal-element alloy, the content of all the elements and the microstructure. In addition, the multi-principal-element alloy can be obtained through alloy smelting and annealing treatment, the preparation method is simple, safe and reliable, and good application prospects are achieved.

Owner:浙江省科创新材料研究院

A five-element high-entropy alloy cu 0.5 fenival x And its strength and hardness improvement method

The invention discloses five-element high-entropy alloy Cu0.5FeNiVAlx and a strength and hardness improvement method thereof. The five-element high-entropy alloy Cu0.5FeNiVAlx mainly comprises Cu, Fe,Ni, V and Al with purities greater than or equal to 99.9%. The five-element high-entropy alloy Cu0.5FeNiVAlx comprises, by atomic percent, 10 to 15 at% of the Cu, 20 to 30 at% of the Fe, 20 to 30 at%of the Ni, 20 to 30 at% of the V, and 0 to 26 at% of the Al. A preparation method of the five-element high-entropy alloy Cu0.5FeNiVAlx is as follows: performing arc-strike smelting in a vacuum environment protected by argon gas on the alloy raw materials Cu, Fe, Ni, V and Al for repeated several times. The strength and hardness improvement method of the five-element high-entropy alloy Cu0.5FeNiVAlx is as follows: using a quartz tube for vacuum sealing of a prepared Cu0.5FeNiVAlx ingot, then using a muffle furnace at 500 DEG C, 750 DEG C and 1000 DEG C respectively for annealing treatment, andfinally thermally-insulating and cooling to room temperature. The five-element high-entropy alloy Cu0.5FeNiVAlx obtained by the method has an effective improvement in strength and hardness, and contributes to broadening the application range of a high-entropy alloy and improving the economic value.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com