Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Low aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-high early-strength grouting material for repairing ballastless track structure of high speed railway

The invention discloses a super-high early-strength grouting material for repairing a ballastless track structure of a high speed railway, which is prepared by the following steps of: sequentially adding water, polymer emulsion, a water reducing agent, a rheology accessory agent and an antifoaming agent; adding admixture, cement, an expansion agent, a coagulator and a retarder, and stirring and blending the materials at a high speed. The parts by weight of the ingredients are as follows: 100 parts of superfine cement, 50-150 parts of admixture, 25-50 parts of redispersible emulsion powder, 3-10 parts of polymer emulsion, 5-25 parts of expansion agent, 0.1-1.0 part of carboxylic acid water reducing agent, 0.1-10 parts of coagulator, 0.1-5 parts of retarder, 0.001-0.005 parts of rheology accessory agent, 0.001 part of polyether-siloxane copolymer antifoaming agent and 20-70 parts of water. The material disclosed by the invention has the advantages of low viscosity, super-high early-strength, low cost, fatigue resistance, aging resistance and water erosion resistance, and the like, so that the material can be used for repairing the concrete gaps of ballastless tracks of high speed railways, gaps of cement asphalt mortar filling layers, cracks and damages.

Owner:四川昊龙高科轨道交通新材料科技股份有限公司

Silver nanowire doped conductive silver colloid and preparation method thereof

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

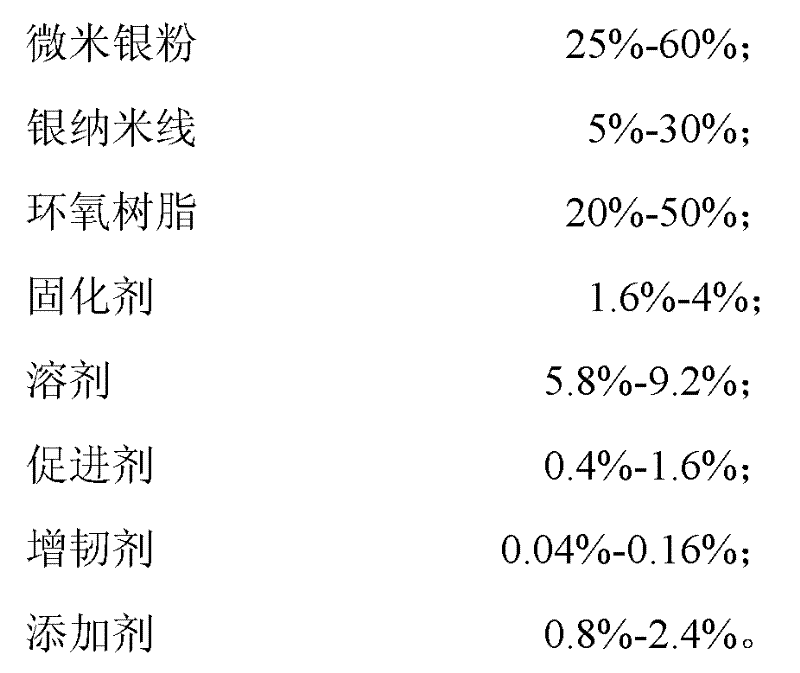

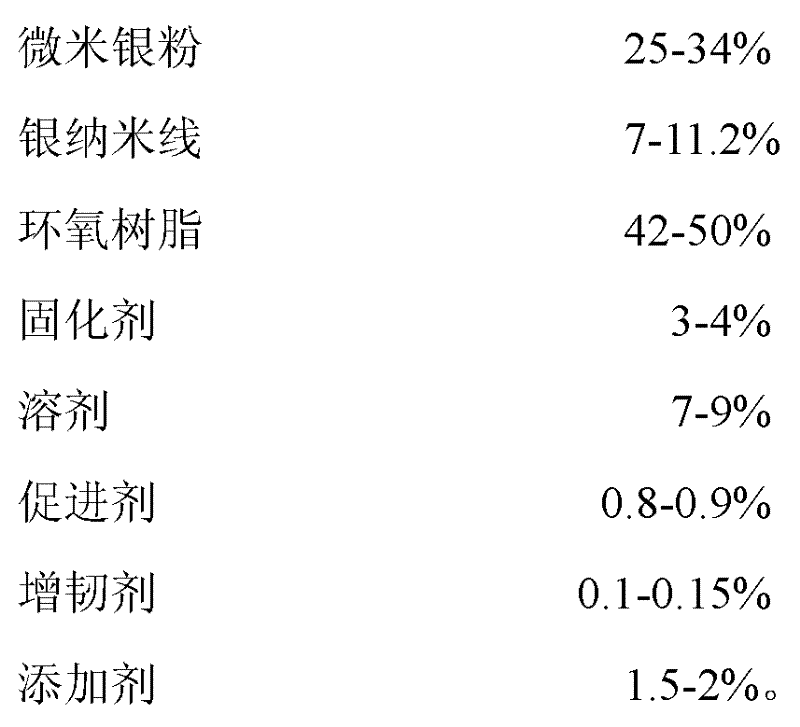

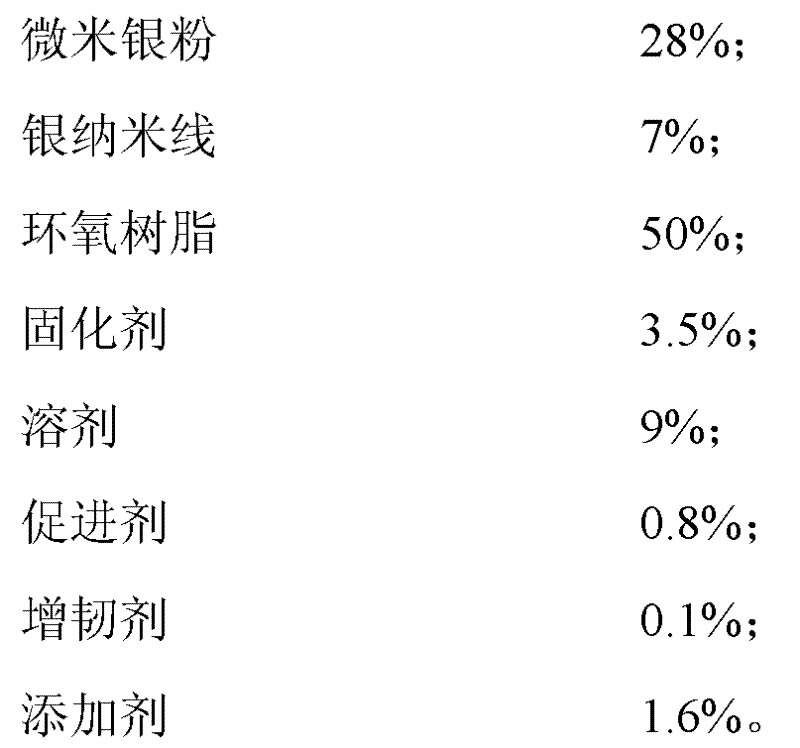

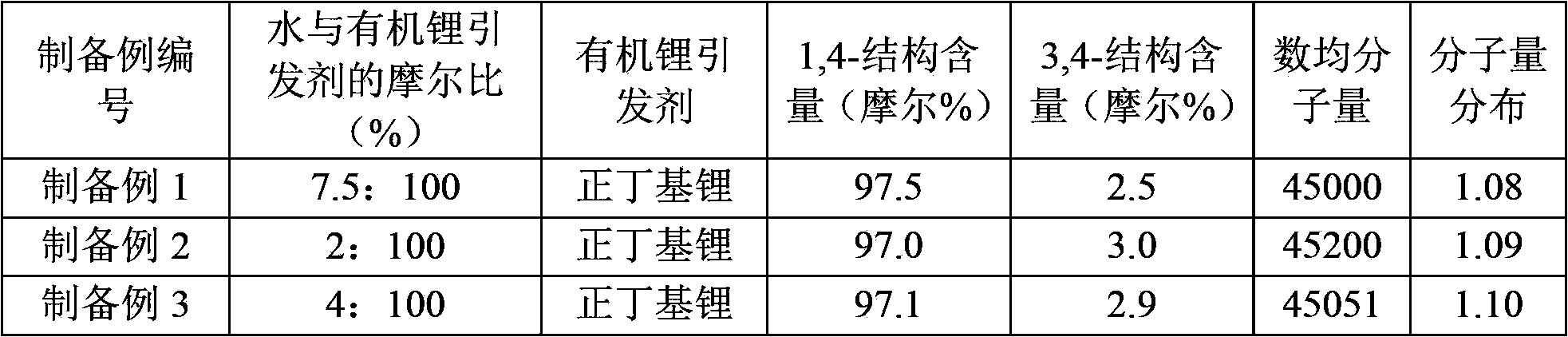

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

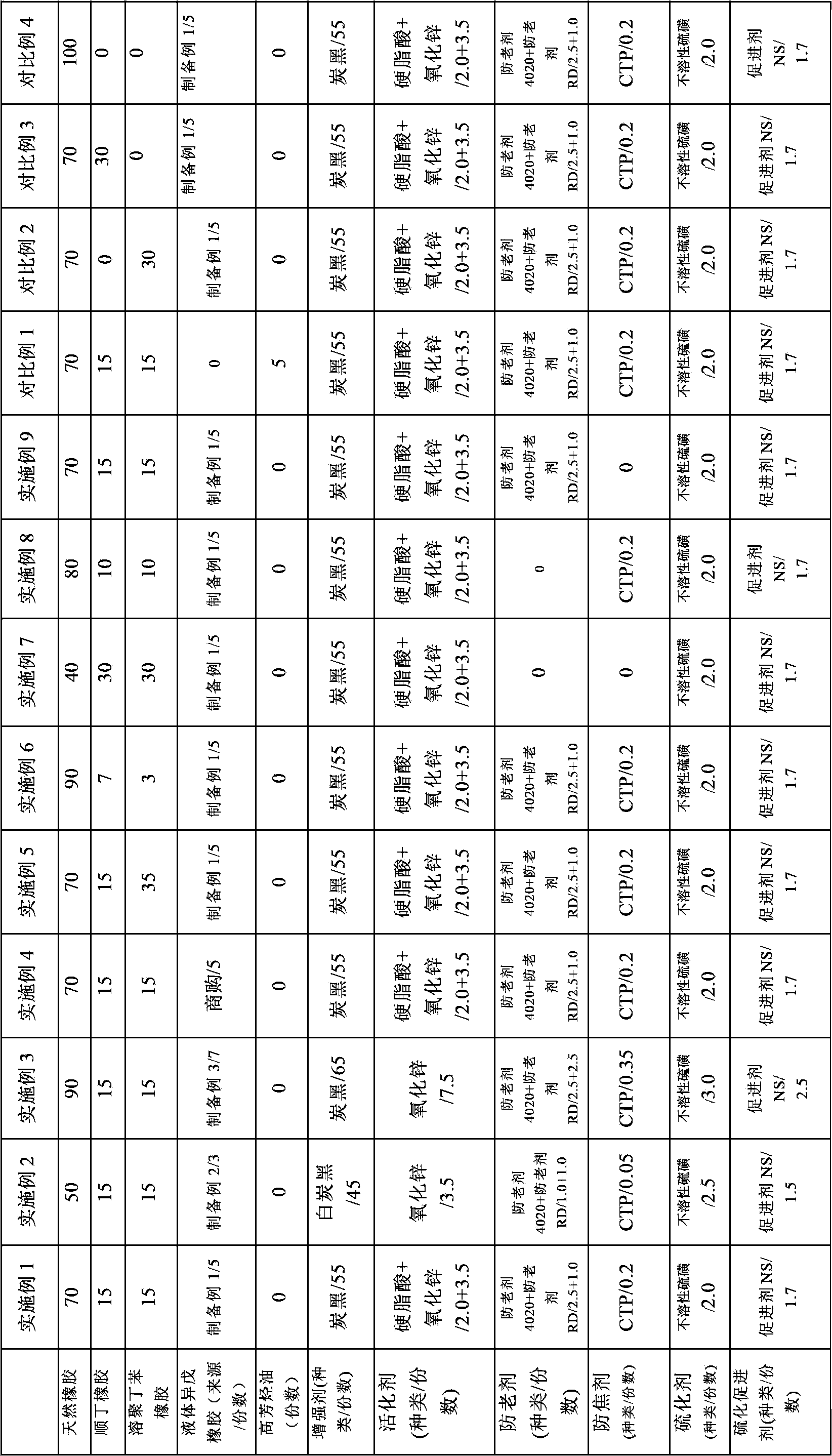

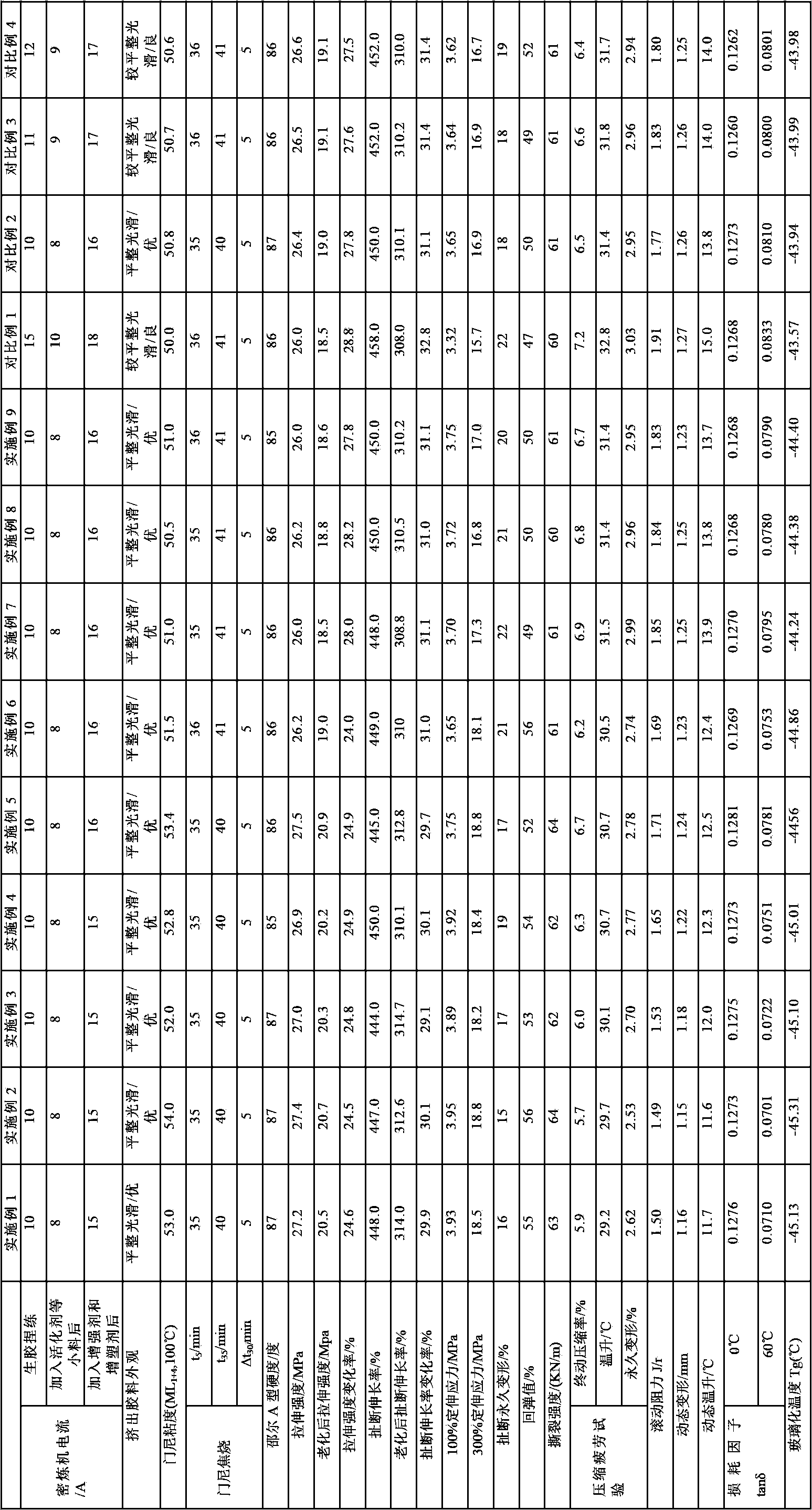

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

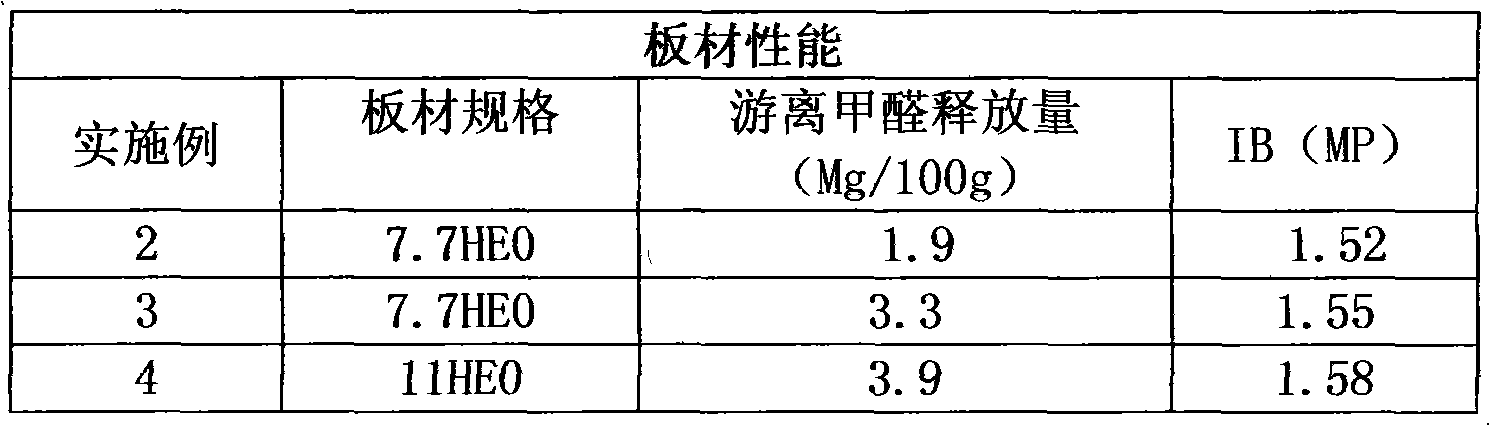

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

Single component mildew-proof flame retarded organic silicon sealing agent for machinery and preparation process thereof

InactiveCN1793271AGood effectImprove flame retardant performanceOther chemical processesSilanesSealant

The invention disclose mono-component mould proof anti-flaming organosilicon mechanical seal agent and its manufacturing method. Its component and part by weight proportioning are as follows: hexagonal crystal type magnesium hydroxide 20-40, end hydroxyl dimethyl polysiloxane 40-60, 40% weight percentage organosilicon quaternary ammonium salt antibacterial agent alcohol solution 3-6, vapour phase process reinforcing silica 5-7, silane coupler 2-5, and catalyst 2-3. The grain size of the hexagonal crystal type magnesium hydroxide is 1000-1500nm. The water content is lower than 0.1% weight percentage. The viscosity of the end hydroxyl dimethyl polysiloxane is 2000-10000mPa.S. It has the advantages of high flame retardancy, antibiosis, ageing resistance, wide using temperature range, and low cost. It expands organosilicon seal agent using range, and has important meaning in our country mechanism industry.

Owner:SHANDONG UNIV

Wall body placing heat-insulating mortar dry material and preparing method thereof

The invention relates to thermal insulation mortar dry material for wall masonry, which is prepared by the following materials by weight proportion: 40-80 portion of silicon ore sintered material, 10-30 portion of shell-enwrapped aggregate, 18-20 portion of cement and 3-6 portion of additive. The thermal insulation mortar dry material has low thermal conductivity which is below 0.25W / (m.k) and can avoid the produce of cold-hot bridge on block joint, thus effectively forming a self-thermal insulation effect of building wall. At the same time, the thermal insulation mortar dry material had good cohesiveness and well anti-aging performance and can have the same life with the building; furthermore, the thermal insulation mortar dry material has the advantages of no poison, no pollution, no harm to human body, wide material source, low construction cost and simple construction which is ideal material for wall masonry.

Owner:南阳天意保温耐火材料有限公司

Preparation of organic cobalt salt adhesion promotion agent

ActiveCN101481591AHigh activityQuality improvementNon-macromolecular adhesive additivesCarboxylic acid salt preparationOrganic acidOrganic solvent

The invention discloses a method for preparing an organic cobalt salt adhesion promoter. The method comprises the following steps: cobalt solution, sodium hydroxide solution and sodium carbonate solution, which respectively have certain concentration, are respectively prepared; after the cobalt solution is heated, the sodium hydroxide solution is slowly added till the pH value of the reactant liquid reaches 7, and then the sodium carbonate solution is slowly added till the pH value of the reactant liquid reaches 9.5; the reaction liquid undergoes standing, and precipitates are rinsed with water; and the rinsed precipitate inorganic cobalt salt undergoes twice dehydration and then the reaction with weak organic acid in an organic solution so as to obtain the organic cobalt salt adhesion promoter product. The highly-active basic cobaltous carbonate powder produced according to the method has requirement-meeting indexes such as appearance, cobalt content, water content, trivalent cobalt content, impurity content, grain size, stacking density, and the like; and more importantly, the basic cobaltous carbonate powder has good reactive behavior. After the basic cobaltous carbonate powder undergoes neutralization reaction with the weak organic acid, the organic cobalt salt adhesion promoter product with high quality can be obtained.

Owner:JIANGSU KAOU CHEM

Resin glue adhesive for E0 grade fibre board

InactiveCN101307215ALow water resistanceLow aging resistanceAldehyde/ketone condensation polymer adhesivesDomestic articlesFirming agentUltimate tensile strength

The invention discloses a synthetic resin cementing compound used for an EO-stage fiberboard. The synthetic resin cementing compound consists of melamine modified urea resin and a firming agent and is characterized in that the compositions of reaction material of the urea resin by weight percentage are: 4.0 to 6.0 percent of the melamine, 40.0 to 42.0 percent of urea, 52.0 to 56.0 percent of formaldehyde, and 0.4 to 0.6 percent of an accelerating agent; acid and alkali are appropriate and the total mol ratio is between 0.90 and 0.93; and the cementing compound is obtained by the systemization and reaction of the materials. The cementing compound has good cementation strength, appropriate curing time, and the content of 0.06 to 0.08 percent of free formaldehyde, etc. E1 and the E0-stage fiberboard with good quality can be produced stably and have the advantages of low glue feeding amount, strong adaptability to the hot press molding technology and high curing speed in the hot press molding process, etc., thereby meeting the need of the market on products of high environmental performance fiberboards.

Owner:DARE TECH

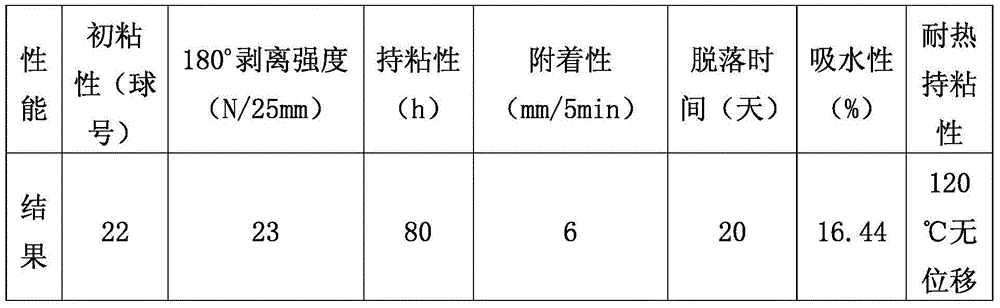

Preparation method of emulsion type polyacrylate pressure-sensitive adhesive for reflecting film

ActiveCN104449485AHigh bond strengthImprove aging resistanceFilm/foil adhesivesEster polymer adhesivesChemistryEmulsion

The invention relates to a preparation method of an emulsion type polyacrylate pressure-sensitive adhesive for a reflecting film. Hard monomers (5-15 parts of vinyl acetate and 5-15 parts of methyl methacrylate) and soft monomers (30-50 parts of ethylhexyl acrylate and 10-30 parts of ethyl acrylate) are subjected to quaternary monomer copolymerization, and consequently, the bonding strength of the pressure-sensitive adhesive is improved obviously. In addition, 0.3-1 part of lauryl sodium sulfate and 1-3 parts of sodium allyloxyhydroxypropyl sulfonate are taken as emulsifying agents; a substance with a surfactant is polymerized to a macromolecular chain to take the place of a part of the micromolecular emulsifying agent lauryl sodium sulfate, and therefore, the aging resistance and the water resistance of the pressure-sensitive adhesive are improved. The emulsion type pressure-sensitive adhesive prepared by use of the preparation method is high in permanent adhesion, high in peel strength, and high in combination properties such as aging resistance, high temperature resistance, water resistance and acid rain resistance, and capable of meeting the requirement on long-term use of the reflecting film. In addition, the preparation method is simple in process, free from environment pollution, low in cost, and suitable for large-scale industrial production.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Material used for manufacturing handle of refrigerator door and preparation method thereof

ActiveCN103044862AIncrease the number of door openingsImprove mechanical propertiesRefrigerator carAcrylonitrile

The invention relates to a material used for manufacturing a handle of a refrigerator door and a preparation method thereof. The material composition comprises the following components in parts by weight: 40-83 parts of polybutylene terephthalate, 5-25 parts of acrylonitrile- styrene-acrylonitrile composition, 10-35 parts of glass fiber, 3-20 parts of crystal whisker, 2-10 parts of a compatilizer, 0.03-2 parts of an antibacterial agent, 0.01-2 parts of a lubricating agent and 0.01-2 parts of other auxiliaries; and the components are mixed in the formula, and then extrusion pelleting is carried out by virtue of an extruding machine, so that the material composition product is obtained. Compared with the prior art, the material composition provided by the invention is subjected to moulding and processing, the prepared handle of the refrigerator door is smooth and produces no warpage on the surface, no glass fiber is exposed, dimensional stability is good, and the prepared handle of the refrigerator door is resistant to scraping and has excellent antibacterial property.

Owner:HEFEI GENIUS NEW MATERIALS

Ultraviolet ray and infrared ray adsorption blue transparent glass

The invention relates to ultraviolet ray and infrared ray adsorption blue transparent glass, which is formed by that Fe2O3 and CeO2 are added in dry SiO2 and other auxiliary materials, and then the glass is directly fired under the high-temperature melting and low-temperature annealing processes, and the glass is blue and transparent; Visible light transmittance of the glass with 2mm is more than 70 percent, the transmittance of the ultraviolet rays with 200nm-390nm can be reduced to 10-7, the transmittance of the infrared rays with 780nm-1300nm is reduced to 10-6, and the transmittance of the infrared rays with 1300nm-2000nm is reduced to 10-5. The ultraviolet ray and infrared ray adsorption blue transparent glass has low cost, can completely achieve the technical data of vacuum coated glass with Europe and America technology, which is applied to eyesight protection glass products, and can thoroughly overcome the low oxidation resistance, ageing resistance and friction resistance of the vacuum coated glass and is mainly applied to the eyesight protection glass products such as arc welding mask lens, spectacle lens, computer screens, television screens and the like.

Owner:蔡绪忠 +5

Resin with mixing and solidification functions and synthetic method thereof

The invention provides a synthetic method of resin with mixing and solidification functions. The synthetic method of the resin with the mixing and the solidification functions comprises the steps that 80-110 g of polyisoprene dibasic alcohol, 4-10 g of 3-ethyl-3-hydroxymethyleneoxetane, 5-12 g of hydroxyl acrylate, 0.1 g of polymerization inhibitor para hydroxybenzene methyl ether and 0.01 g of catalyst dibutyltin dilaurate are added into a three-mouth flask with a thermometer, the temperature is raised to 65 degrees, then 18-32 g of diisocyanate starts to be dropwise added, the temperature is controlled to be 70-75 degrees, and reaction is performed for 2-3 h. The content of NCO perssad is analyzed by an infrared spectrometer, until the NCO peak disappears completely, the heating reaction is stopped, and the urethane acrylate modified by oxetane can be obtained. The resin with the mixing and the solidification functions can manufacture three-dimensional products with low shrinking percentage, low warping, good flexibility, ageing resistance, high machining precision, good photocuring performance and excellent mechanical strength; in addition, the synthetic reaction is simple in technology and easy to control, no special equipment is needed to be used, no solvent is needed, and the production cost is low.

Owner:YANTAI DARBOND TECH

Liquid silicone rubber composition having low permanent compression deformation and preparation method thereof

The invention discloses a liquid silicone rubber composition having low permanent compression deformation, which comprises the following components in parts by mass: 100 parts of vinyl polydimethylsiloxane, 1-50 parts of inorganic filler, 1-30 parts of structurized control agent, 0.01-10 parts of crosslinking agent, 0.01-2 parts of platinum catalyst, 0.001-1 part of inhibitor, 0.1-20 parts of magnesium oxide and 0.01-10 parts of compression deformation improver. The invention also discloses a preparation method of the liquid silicone rubber composition having low permanent compression deformation. According to the invention, after the compression deformation improver is introduced into the vinyl polydimethylsiloxane, the permanent compression deformation performance can be obviously reduced; and the liquid silicone rubber composition still has very good processability and is suitable for being used as liquid silicone rubber of a spark plug sheath of an automobile.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

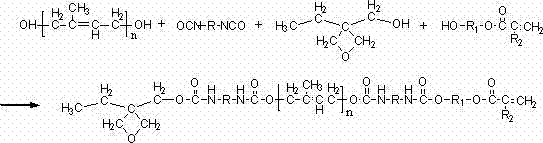

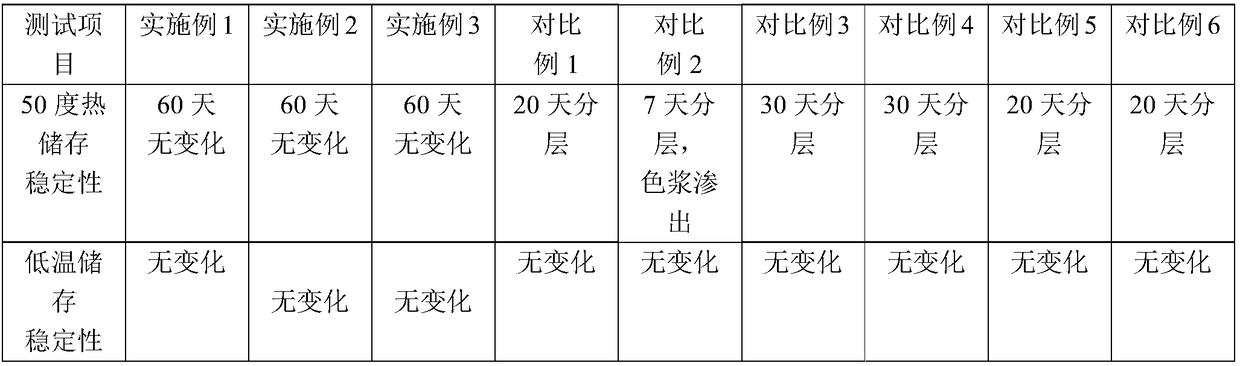

Stone-imitating coating and preparation method thereof

The invention provides a stone-imitating coating and a preparation method thereof. The stone-imitating coating includes, by weight, 300-500 parts of deionized water, 2-3 parts of a sterilizing agent,2-5 parts of cellulose, 1-2 parts of a dispersant, 2-4 parts of a defoaming agent, 7-10 parts of a film forming additive, 7-10 parts of propylene glycol, 1-3 parts of a pH regulator, 150-200 parts ofa binder, 2-4 parts of a thickener, 300-500 parts of sintered colored sand, and 5-15 parts of protective glue. The sintered colored sand is made from quartz sands in 40-120 meshes, toner percentage being 0.8-1.2%. By using the sintered colored sand instead of calcium carbonate sand, regulating raw material ratio and optimizing process parameters, the coating has excellent performance, good stability and good anti-aging effect. The preparation method has simple process and can achieve industrial large-scale production; the product brings excellent economic benefit to enterprises and has extensive prospect.

Owner:上海贝塔建筑科技有限公司

Organic-silicon-modified polyurethane sealant and processing technology thereof

InactiveCN101864165AImprove performanceIncrease elasticityNon-macromolecular adhesive additivesOther chemical processesSilanesTemperature resistance

The invention relates to organic-silicon-modified polyurethane sealant and processing technology thereof. The organic-silicon-modified polyurethane sealant is prepared by mixing the following components: polyether glycol, hydroxyl-terminated polymethyl siloxane with 6 to 18 degrees of polymerization, isocyanate, a catalyst, namely benzoyl chloride, an active hydrogen compound, a catalyst, namely dibutyltin dilaurate and filler. The process comprises the following steps of: 1, preparing a component A, wherein the step is divided into the following steps of: firstly, adding the polyether glycol and the isocyanate into a flask provided with a thermometer, a condenser, a stirring device and a vent pipe; secondly, heating the materials slowly; and thirdly, slowly adding silane into a reaction system dropwise, measuring the NCO group content by a titration method and storing tightly; and 2, preparing a component B, wherein the step is divided into the following steps of: mixing the materials, stirring and dispersing the materials, and grinding the materials by using a grinding machine for later use; and pouring the dispersed component B into another reactor, stirring the component to dehydrate, and storing tightly to obtain the component B. The organic-silicon-modified polyurethane sealant has the advantages of high elasticity, low-temperature flexibility, wear resistance, temperature resistance, water resistance and aging resistance.

Owner:陕西浩瀚新宇科技发展有限公司

Preparation method of OCA (Optical Clear Adhesive)

InactiveCN108822759ALower glass transition temperatureHigh loss tangentEster polymer adhesivesFilm/foil adhesives without carriersElastomerAdhesive

The invention discloses a preparation method of an OCA (Optical Clear Adhesive). The preparation method comprises the following steps: step (1), weighing the following components in percentage by mass: 90 to 99 percent of an acrylic prepolymer, 0 to 10 percent of an acrylic monomer, 0.1 to 0.5 percent of a cross-linking agent, 0.1 to 0.5 percent of a photoinitiator and 0.1 to 1 percent of a chaintransfer agent; step (2), putting and stirring the acrylic prepolymer, the acrylic monomer, the cross-linking agent, the photoinitiator and the chain transfer agent in a container, and carrying out primary curing under an ultraviolet lamp after introducing nitrogen, thus obtaining a prepolymer; step (3), defoaming the prepolymer obtained in step (2), coating a PET (Polyethylene Terephthalate) lining sheet, and carrying out secondary curing under the ultraviolet lamp, thus obtaining the OCA. According to the preparation method disclosed by the invention, incompletely cured OCA in low gel fraction can be obtained through once UV curing, and gaps between adhered objects can be effectively wetted and filled, so that the range difference of printing ink can be filled; secondary curing is carried out after adhesion, the dissipation factor value is increased, and a product is more partial to an elastomer, so that good aging resistance and good reworking performance are obtained.

Owner:新纶电子材料(常州)有限公司

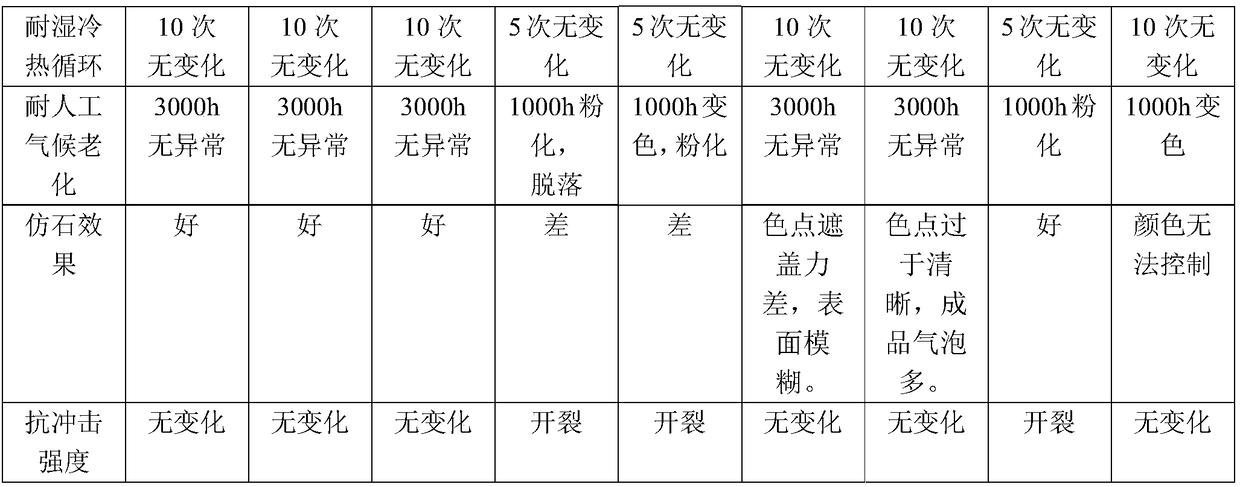

Light-curing colored paint

InactiveCN101967343AFast initial light curing effectCatalyzed Decomposition to AminesPolyurea/polyurethane coatingsEpoxy resin coatingsAcetoacetatesAcetic acid

The invention relates to a light-curing colored paint. The light-curing colored paint is technically characterized by comprising the following components in percentage by weight: 0.2 to 8 percent of light amine-producing agent, 0.5 to 10 percent of amine proliferation agent, 5 to 30 percent of acetoacetic ester compound, 30 to 65 percent of acrylate light-curing resin, 10 to 40 percent of acrylate activated thinner, 0.1 to 8 percent of photoinitiator and 4 to 8 percent of pigment. The light amine-producing agent contained in the system generates amine catalysts under ultraviolet irradiation, further catalyzes to start the amine-producing proliferation reaction of the amine proliferation agent, rapidly generates massive amines in a coating and automatically spreads to the whole coating system to generate amines along regional chemistry. Therefore, a crosslinked curing film is formed, and an invisible region on the surface or at the bottom of a film layer can be rapidly cured.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

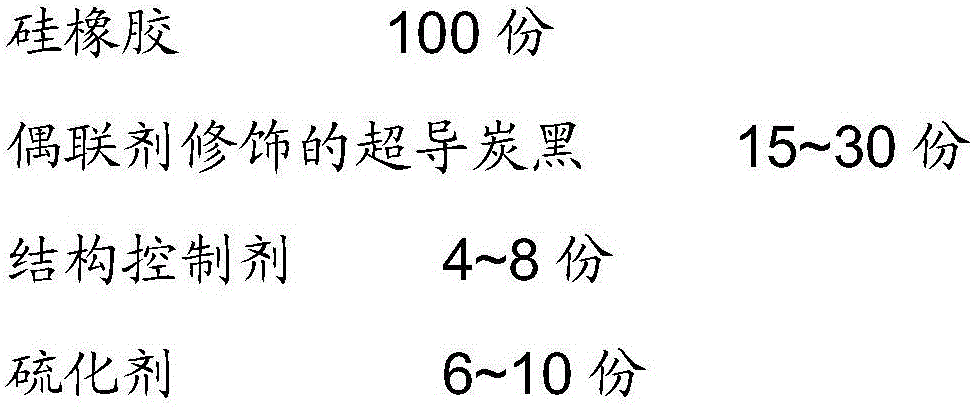

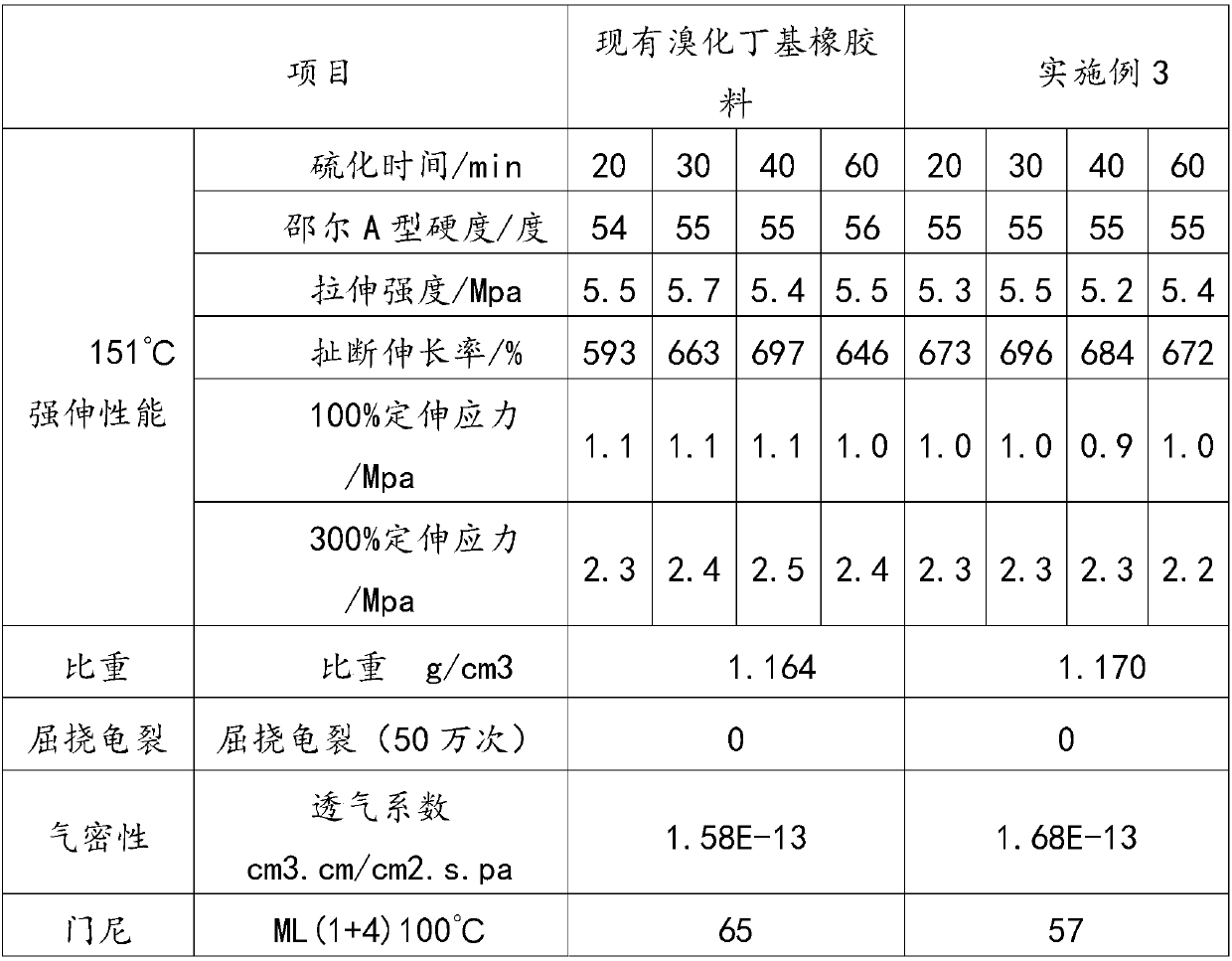

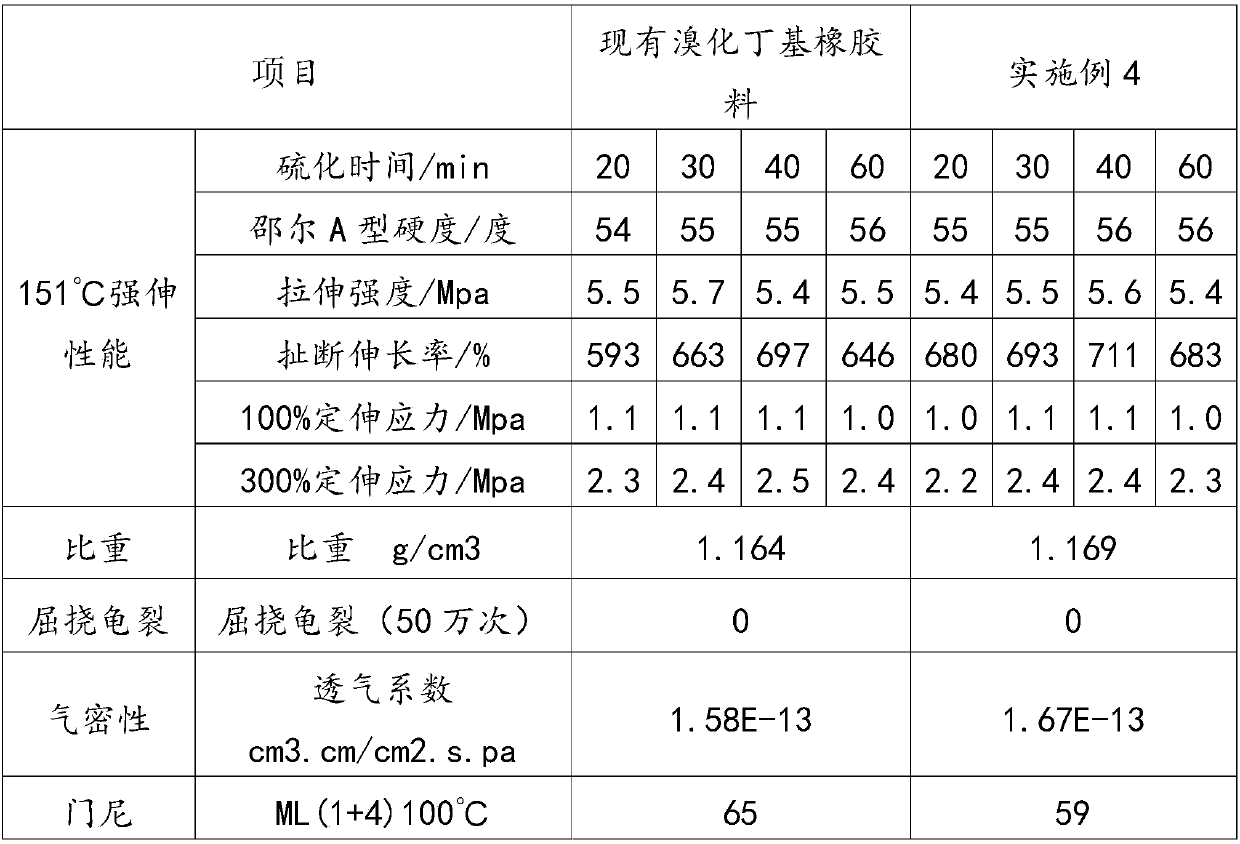

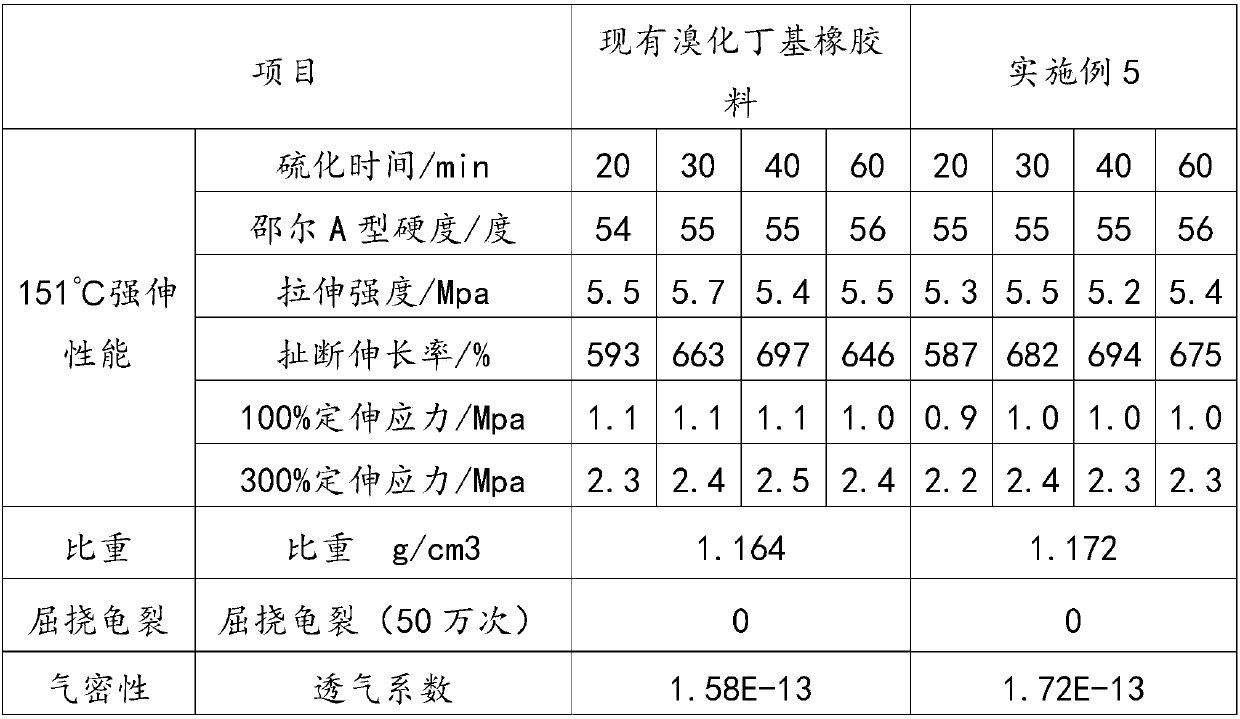

Preparation method of ageing-resistant and high-resilience extruded carbon black filled conductive shielding silicone rubber

The invention discloses a preparation method of ageing-resistant and high-resilience extruded carbon black filled conductive shielding silicone rubber. The preparation method comprises the steps that 1, 100 parts of silicone rubber, 15-30 parts of coupling agent modified superconductive carbon black, 4-8 parts of a structure control agent and 6-10 parts of vulcanizing agent are prepared by mass; 2, the raw materials in the step 1 are mixed on a mixing mill or a kneading machine at room temperature; 3, the rubber material obtained in the step 2 is subjected to vulcanization treatment, and the vulcanization treatment process is divided into two stages. The prepared conductive shielding silicone rubber has good extrusion processing performance. A preparation process is simple, and the costs are low. The silicone rubber prepared by means of the preparation method has good ageing-resistant performance and elasticity and is suitable for use by serving as a high-performance sealant material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Sulfochlorination polyvinyl sizing material for power steering pipe

The invention discloses a sulfochlorination polyvinyl sizing material for a power steering pipe, and a preparation method thereof. The sulfochlorination polyvinyl sizing material comprises the following raw materials in parts by weight: 100 parts of chlorosulfonated polyethylene rubber, 50-60 parts of carbon black, 20-30 parts of a reinforcing agent GC666, 0.3-0.7 part of stearic acid, 0.8-1.2 parts of a flowable agent WB212, 3-7 parts of C9 petroleum resin, 11-19 parts of an acid accepter, 10-20 parts of a plasticiser TOTM, 1.4-2.2 parts of an antiager, 1-3 parts of an internal release agent WS180, 4-6 parts of a vulcanizator BIPB, and 5-7 parts of a crosslinking additive Activator-70P. The sulfochlorination polyvinyl sizing material is prepared by the steps of material preparation, seal smelting, cooling and open milling, and has the characteristics of high strength, low permanent compression set, low temperature resistance, aging resistance, oil resistance and the like, can completely meet the requirements of the power steering pipe, and meanwhile is nontoxic, flavourless and stable in storage.

Owner:浙江久运汽车零部件有限公司

Foaming chameleon sole and preparation method thereof

The invention relates to the technical field of sole, and in particular to a foaming chameleon sole and a preparation method thereof. The foaming chameleon sole consists of the following raw materials by weight: 20-30 parts of natural rubber, 30-40 parts of EVA resin, 10-20 parts of silicon dioxide, 8-15 parts of nano calcium carbonate, 1-3 parts of zinc oxide, 0.6-1 part of stearic acid, 1.5 parts of a vulcanizing agent, 0.5-2 parts of an accelerator, 1-2.5 parts of a foaming agent, 0.2-0.6 part of other additives and 1-3 parts of a pigment. The preparation method of the foaming chameleon sole of the present invention uses the above-described materials, and strictly controls the weight ratio of the raw materials; the prepared foam chameleon sole has the characteristics of wear resistance, water resistance, aging resistance, low production cost, light weight, good cushioning performance, high comfort, and ventilation effect; and a laser machining machine can be used in processing for arbitrarily design of the desired patterns and colors.

Owner:GUANGDONG LIYU YIBAO RUBBER SHEET CO LTD

Tire inner liner rubber, application serving as tire inner liner rubber and preparation method of tire inner liner rubber

InactiveCN109517284AReduced ozone resistanceExcellent ozone resistanceSpecial tyresChlorinated polyethyleneButyl rubber

The invention discloses tire inner liner rubber, application serving as tire inner liner rubber and a preparation method of the tire inner liner rubber. The tire inner liner rubber comprises the following raw materials in relative parts by weight: 30-40 parts of natural rubber, 65-75 parts of brominated butyl rubber, 20-30 parts of butyl reclaimed rubber, 5-20 parts of chlorinated polyethylene composite rubber, 2-5 parts of a dispersing agent, 3-5 parts of a tackifier, 0.2-0.5 part of magnesium oxide, 5-10 parts of a homogenizing agent, 10-15 parts of a softening agent, 60-70 parts of a filling agent, 20-30 parts of an air stopper, 0.5-1 part of a vulcanizing agent, 1-1.5 parts of an accelerant and 3-5 parts of an activating agent. The tire inner liner rubber disclosed by the invention canreplace brominated butyl rubber, the performance is improved, and the cost is greatly reduced.

Owner:SHANDONG RIKE CHEM

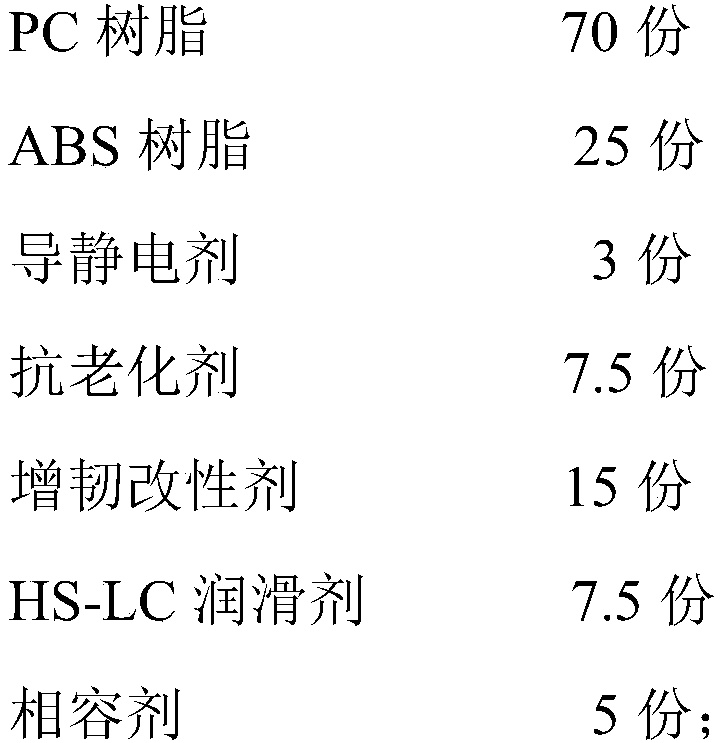

Antistatic PC-ABS (polycarbonate-acrylonitrile butadiene styrene) alloy material and preparation method thereof

The invention relates to the technical field of alloy materials, in particular to an antistatic PC-ABS (polycarbonate-acrylonitrile butadiene styrene) alloy material and a preparation method thereof.The antistatic PC-ABS alloy material is prepared from the following raw materials in parts by weight: 60 to 80 parts of PC resin, 20 to 30 parts of ABS resin, 2 to 4 parts of a static conducting agent, 5 to 10 parts of an anti-aging agent, 12 to 18 parts of a toughening modifier, 6 to 9 parts of a lubricant, and 2 to 8 parts of a compatilizer, wherein the static conducting agent adopts graphene with 1 to 20 layers. The antistatic PC-ABS alloy material has the advantages that the surface resistivity can reach 104 ohm, the antistatic property is excellent, the antistatic effect is lasting, and the anti-impact property and tensile strength are good.

Owner:GUANGDONG GERUI NEW MATERIALS CO LTD

Process of synthesizing heat resistant copolymer

The improved emulsion polymerization process of preparing heat resistant alpha-methylstyrene-acrylonitrile copolymer features that 30-50 wt% of the monomers, emulsion and initiator are pre-emulsified; and the rest monomers, emulsion and initiator are emulsified, heated to 65-70 deg.c and polymerized while adding the pre-emulsion until to obtain solid content higher than 36 %, where, the initiator is oil soluble azo diisobutyronitrile or azo diisoheptonitrile. The present invention has stable emulsion system, complete and homogeneous copolymerization, copolymerizing conversion rate as high as 98 %, low residual monomer rate, high Vicat temperature and other advantages.

Owner:LILAI CHEM YIXING

Bladder rubber and its preparation method

A bladder rubber and its preparation method are provided. The bladder rubber contains brominated butyl rubber 45-60, carbon black 20-30, talcum powder 5-15, oil material 1-5, anti-aging agent 1-2, and vulcanizing agent 1-3 wt%. The inventive bladder rubber has performances of butyl rubber and active bromine, effectively improves gas tightness of bladder, accelerates vulcanizing speed, ensures adhesion property, and improves service life of bladder.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Halogen-free flame-retardant wood-plastic co-extrusion composite material and preparation method thereof

InactiveCN111070824AImprove flame retardant performanceHigh strengthSynthetic resin layered productsWood layered productsZinc boratePlant fibre

The invention discloses a halogen-free flame-retardant wood-plastic co-extrusion composite material and a preparation method thereof. The halogen-free flame-retardant wood-plastic co-extrusion composite material comprises a core layer and a halogen-free flame-retardant surface layer for coating the core layer, wherein the core layer comprises plant fibers, PE plastic, a compatilizer, an antioxidant, a lubricant and an inorganic filler, and the halogen-free flame-retardant surface layer comprises PE plastic, modified polypropylene fibers, an ethylene-methacrylic acid copolymer, hypophosphite, zinc borate, an interface modifier, a light stabilizer, an antioxidant and other auxiliaries. The halogen-free flame-retardant wood-plastic co-extrusion composite material disclosed by the invention isvery simple to prepare, the core layer granules and the halogen-free flame-retardant surface layer granules are firstly prepared respectively, and then co-extrusion molding is carried out. The halogen-free flame-retardant wood-plastic co-extrusion composite material has the advantages of excellent flame retardancy, high strength, excellent impact resistance, high hardness, favorable wear resistance, low water absorptivity, favorable aging resistance, favorable wear resistance, favorable scratch resistance, high wood texture and favorable antiskid effect, and is not easy to fade or mildew whenbeing used outdoors.

Owner:广州康森新材料科技有限公司 +1

Spray hard phenolic foam

InactiveCN102268172ASmooth surface High tensile strengthHigh compressive strengthFireproof paintsPhenolformaldehyde foamPolymer science

The invention discloses a hard phenolic foam composition, a sprayed hard phenolic foam coating, a preparation process and an application. The rigid phenolic foam composition is obtained by mixing composite phenolic resin and mixed acid in a mass ratio of 1-10:1. The above-mentioned hard phenolic foam composition is completely atomized and mixed uniformly at a pressure of 100-200kg and a temperature of 20-50°C, sprayed from a spray gun, and evenly sprayed on the wall to form a spray-coated hard phenolic foam Insulation. The obtained spraying hard phenolic foam coating can be applied to the field of waterproof, fireproof or thermal insulation materials.

Owner:田瑞军

Wood splicing adhesive

ActiveCN108018006ALow costLow aging resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyvinyl alcoholDefoaming Agents

The invention discloses a wood splicing adhesive and belongs to the field of adhesives. The wood splicing adhesive comprises the components in percentage by mass: 20-30% of styrene-acrylate emulsion,20-30% of ground calcium carbonate, 13-20% of polyvinyl alcohol emulsion, 9-15% of vinyl acetate-acrylate emulsion, 9-15% of vinyl acetate-ethylene copolymer emulsion, 5-9% of water, 0.6-1.0% of plasticizer and 0.05-0.1% of defoaming agent. The production process of the wood splicing adhesive disclosed by the scheme is safe, easy to implement and low in cost; and the wood splicing adhesive productis high in bonding strength and ageing resistance as well as better in environment protection property.

Owner:山东凯源木业有限公司

Corrosion-resistant and antistatic coating material and preparation method thereof

InactiveCN108441088ALow aging resistanceGood dispersionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyethylene glycol

The invention provides a corrosion-resistant and antistatic coating material and a preparation method thereof. The corrosion-resistant and antistatic coating material is prepared from the following raw materials in parts by weight: 20-50 parts of epoxy modified acrylate, 10-20 parts of polyaniline, 11-18 parts of polycarbonate, 8-15 parts of acrylonitrile-butadiene-styrene copolymer, 7-15 parts ofpolyethylene glycol terephthalate, 6-12 parts of carbon nanotube, 4-8 parts of silane coupling agent, 3-6 parts of hexadecyl trimethyl ammonium bromide, 2-5 parts of polyethylene glycol octylphenol ether, 3-7 parts of acryloxyethyl trimethylammonium chloride, 2-5 parts of polyepoxysuccinic acid, 5-10 parts of corrosion-resistant and antistatic pigment, 1-2 parts of coalescent, 1-3 parts of leveling agent and 0.5-2 parts of defoaming agent. The coating material prepared by using the preparation method has good mechanical strength, corrosion resistance and weather resistance, and the surface resistivity is not higher than 8.48*105ohm and conforms to the standard of the coating material, so that the corrosion-resistant and antistatic coating material has a wide application prospect in corrosion-resistant and antistatic materials.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Reflective heat-insulation polyvinyl chloride (PVC) waterproof coiled material and preparation method thereof

ActiveCN110423416AHigh infrared reflectivityLow thermal conductivityRoof covering using flexible materialsPressure sensitive film/foil adhesivesPolyvinyl chloridePotassium

The invention discloses a reflective heat-insulation polyvinyl chloride (PVC) waterproof coiled material and a preparation method thereof. The PVC waterproof coiled material comprises the following components in parts by weight: 100 parts of PVC resin powder, 20-60 parts of a plasticizer, 10-30 parts of a toughening agent, 4-6 parts of epoxidized soybean oil, 2-5 parts of a heat stabilizer, 3-12 parts of potassium hexatitanate and / or sodium hexatitanate, 3-5 parts of titanium dioxide, 0.2-0.5 part of stearic acid, 0.1-0.4 part of calcium stearate, 0.2-2 parts of an antioxidant, 0.2-2 parts ofa light stabilizer, 20-40 parts of calcium carbonate and 0.1-0.5 part of a coupling agent. The coiled material has excellent dimensional stability, reflection heat insulation performance, good mechanical property, good low-temperature toughness, good aging resistance, long service life of the product, energy conservation and environment friendliness, and is particularly suitable for being used onexposed roofs.

Owner:HUNAN SHENYU NEW MATERIAL CO LTD

High-barrier material, plastic pipe with high barrier property and preparation method

The invention relates to the technical field of plastic pipes, and particularly provides a high-barrier material which at least comprises the following raw materials in parts by weight: 80-120 parts of polyolefin resin, 5-30 parts of inorganic filler and 0.1-5 parts of silane coupling agent, wherein the polyolefin resin comprises at least one of an ethylene-vinyl alcohol copolymer, HDPE, PP, PET and PC. The high-barrie material is mainly used for products with barrier property requirements on oxygen molecules, and the material can remarkably reduce the oxygen barrier property of humidity and the stability of pipe strength.

Owner:赵志勇 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com