Tire inner liner rubber, application serving as tire inner liner rubber and preparation method of tire inner liner rubber

An inner liner and tire technology, applied in the field of tire rubber, can solve the problems of uneven dispersion of carbon black and small materials, whitening of the extrusion surface, and high Mooney, and achieve uniform distribution of components, low extrusion temperature, and high temperature. The effect of ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

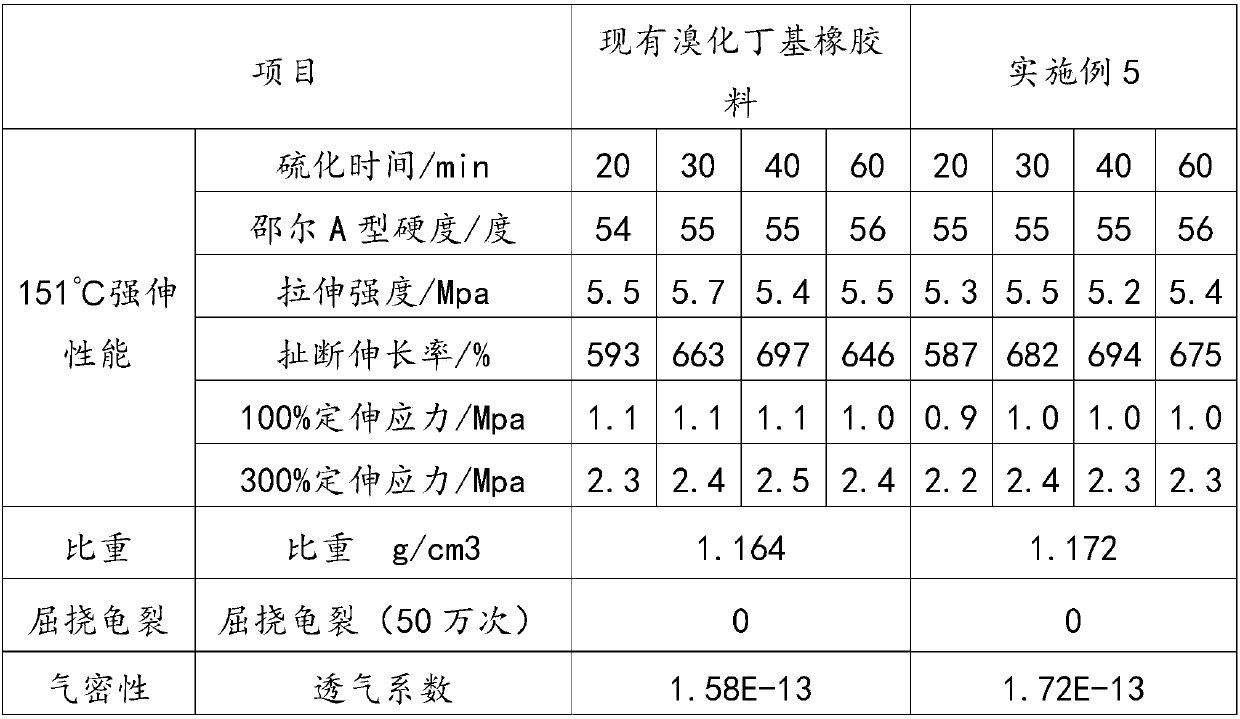

[0043]A rubber compound for tire inner liner, comprising the following raw materials in parts by weight: 32 parts of natural rubber, 65 parts of brominated butyl rubber, 22 parts of butyl reclaimed rubber, chlorinated polyethylene rubber and aromatic hydrocarbon oil according to 100:80 weight 5 parts of chlorinated polyethylene composite rubber, 2 parts of stearic acid 1801, 3 parts of tackifying resin SP1086, 0.35 parts of magnesium oxide, 7 parts of leveling agent RH-100, 13 parts of softener, 62 parts of carbon black N660, 22 parts of air blocking agent NM360, 0.6 parts of sulfur, 1.4 parts of DM and 4.0 parts of zinc oxide-80.

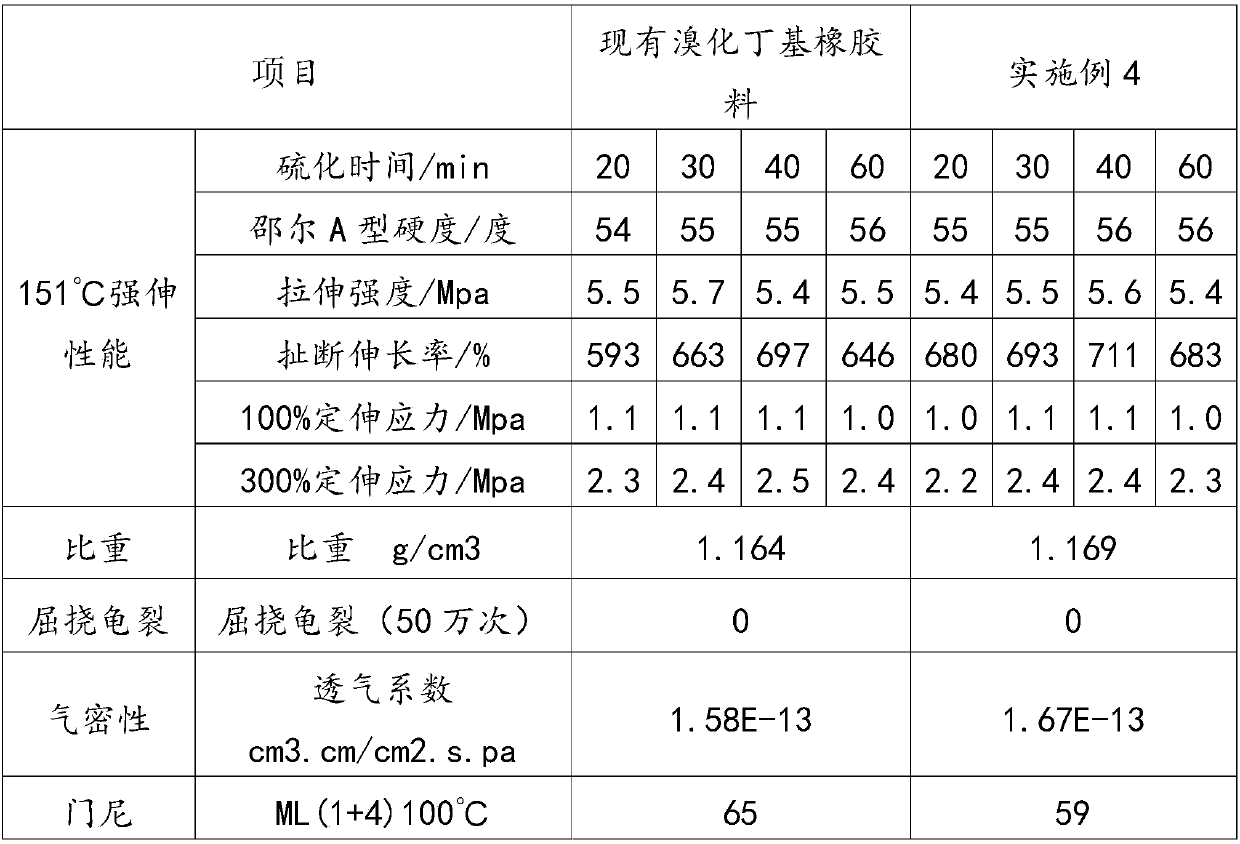

Embodiment 2

[0045] A rubber compound for tire inner liner, comprising the following raw materials in parts by weight: 30 parts of natural rubber, 60 parts of brominated butyl rubber, 20 parts of butyl reclaimed rubber, chlorinated polyethylene rubber and aromatic hydrocarbon oil according to 100:80 weight 10 parts of chlorinated polyethylene composite rubber, 2 parts of stearic acid 1801, 3 parts of tackifying resin, 0.3 part of magnesium oxide, 8 parts of leveling agent RH-100, 12 parts of softener, carbon 60 parts of black N660, 25 parts of air blocking agent NM360, 0.7 parts of sulfur, 1.45 parts of DM, 3.75 parts of zinc oxide-803.75 parts.

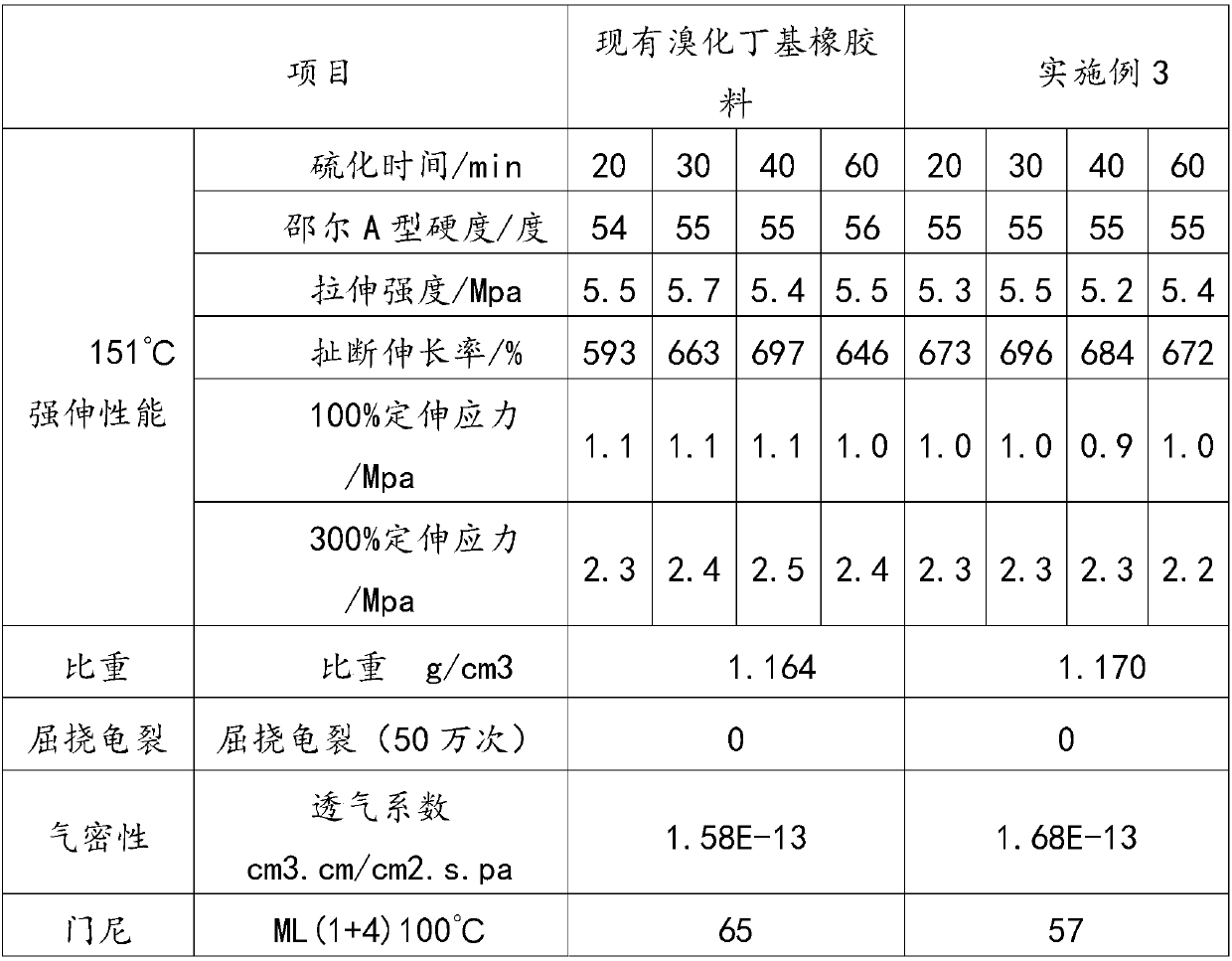

Embodiment 3

[0047] A rubber compound for tire inner liner, comprising the following raw materials in parts by weight: 35 parts of natural rubber, 70 parts of brominated butyl rubber, 25 parts of butyl reclaimed rubber, chlorinated polyethylene rubber and naphthenic oil according to 100:70 12 parts by weight of the prepared chlorinated polyethylene composite rubber, 3.5 parts of stearic acid 1801, 3.5 parts of tackifying resin, 0.4 part of magnesium oxide, 7 parts of leveling agent RH-100, 13 parts of softener, 65 parts of carbon black N660, 25 parts of air blocking agent NM360, 0.7 parts of sulfur, 1.2 parts of DM and 4 parts of zinc oxide-80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com