High-barrier material, plastic pipe with high barrier property and preparation method

A technology of high-barrier materials and raw materials, applied in the field of polymer materials, can solve the problems of easy detachment of adhesives, complicated improvement methods, and poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

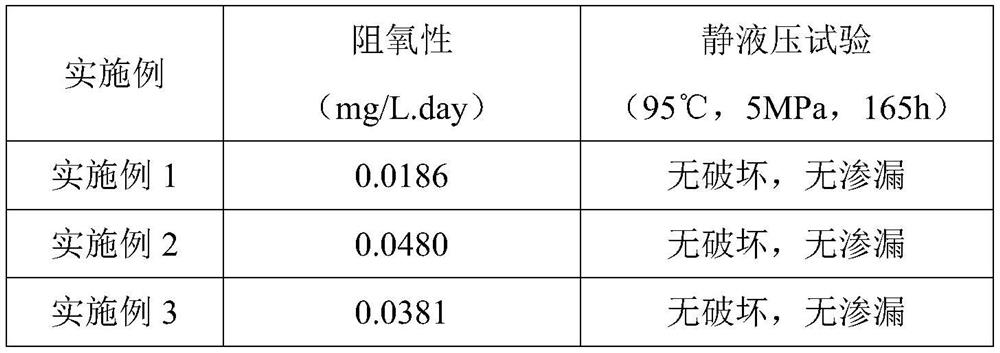

Examples

preparation example Construction

[0053] The third aspect of the present invention provides a method for preparing the plastic pipe with high barrier performance, the steps at least include: melt-mixing polyolefin resin, inorganic filler, and silane coupling agent for primary pellets, and Drying; the primary pellets are extruded through the extruder head, shaped, cooled and drawn.

[0054] In some preferred embodiments, the preparation method of the plastic pipe with high barrier performance, the steps include: carrying out melt-mixed primary pellets of polyolefin resin, inorganic filler, silane coupling agent and auxiliary agent, and drying ; The primary pellets are melted and extruded through the extruder head, shaped, cooled and drawn.

Embodiment 1

[0057] A high-barrier material. The raw materials include, by weight, 100 parts of polyolefin resin, 20 parts of inorganic filler, and 2.5 parts of silane coupling agent.

[0058] The raw material also includes an auxiliary agent; the weight ratio between the auxiliary agent and the inorganic filler is 0.5:1.

[0059] The auxiliary agent includes a combination of dispersant, antioxidant and stabilizer; the weight ratio among the dispersant, antioxidant and stabilizer is 1:2.5:1.

[0060] Described dispersant is calcium stearate.

[0061] The antioxidant is dilauryl thiodipropionate.

[0062] The stabilizer is a calcium-zinc composite stabilizer.

[0063] The polyolefin resin includes ethylene-vinyl alcohol copolymer and HDPE; the weight ratio between the ethylene-vinyl alcohol copolymer and HDPE is 1:5.

[0064] The ethylene content in the ethylene-vinyl alcohol copolymer is 38wt%; the melt flow index of the ethylene-vinyl alcohol copolymer at 190°C / 2.16kg is 1.7g / 10min. T...

Embodiment 2

[0074] A high-barrier material. The raw materials include 90 parts of polyolefin resin, 10 parts of inorganic filler and 1 part of silane coupling agent in parts by weight.

[0075] The raw material also includes an auxiliary agent; the weight ratio between the auxiliary agent and the inorganic filler is 0.01:1.

[0076] The auxiliary agent comprises a combination of dispersant, antioxidant and stabilizer; the weight ratio among the dispersant, antioxidant and stabilizer is 0.5:0.5:1.

[0077] Described dispersant is calcium stearate.

[0078] The antioxidant is dilauryl thiodipropionate.

[0079]The stabilizer is a calcium-zinc composite stabilizer.

[0080] The polyolefin resin includes ethylene-vinyl alcohol copolymer and HDPE; the weight ratio between the ethylene-vinyl alcohol copolymer and HDPE is 1:3.

[0081] The ethylene content in the ethylene-vinyl alcohol copolymer is 32wt%; the melt flow index of the ethylene-vinyl alcohol copolymer at 190°C / 2.16kg is 1.8g / 10mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com