Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219 results about "Phenolformaldehyde foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming phenolic resin preparation method and phenolic resin foam

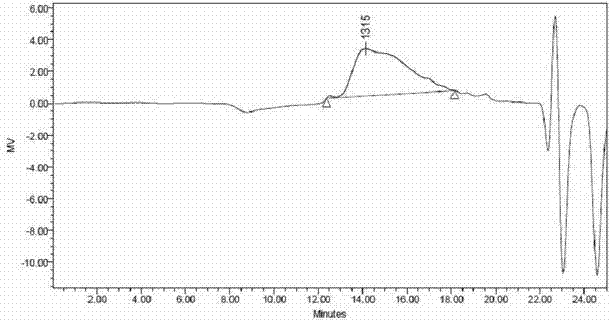

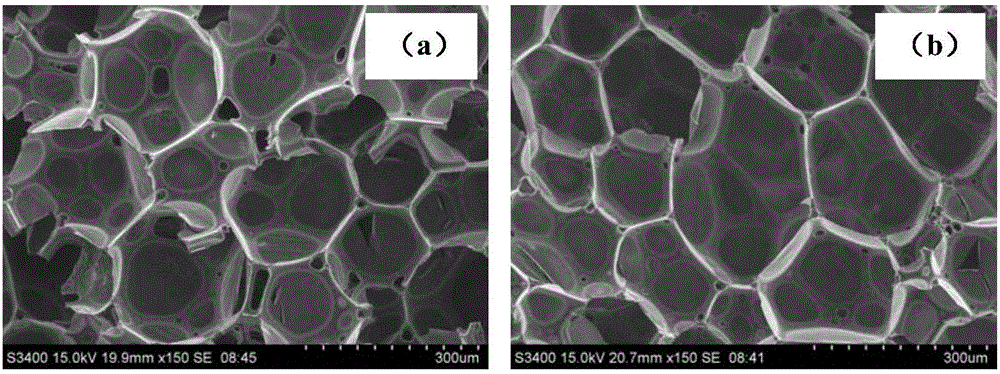

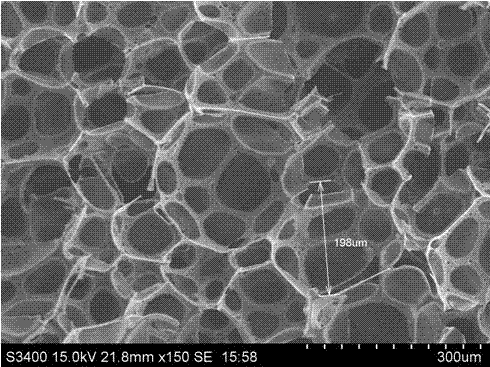

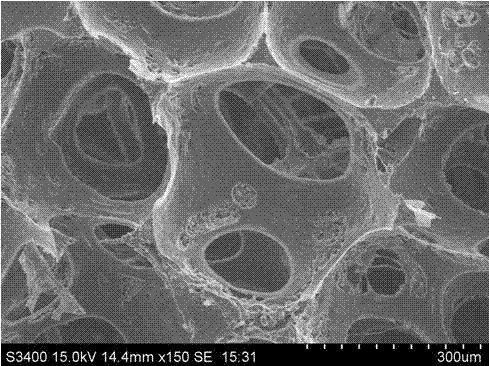

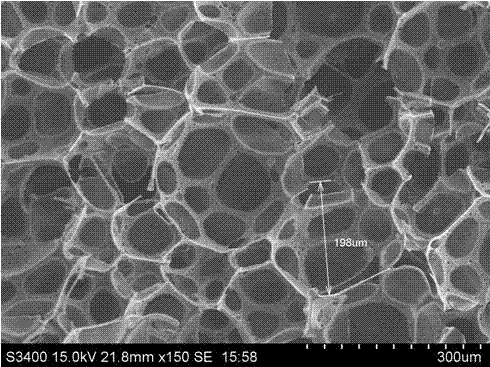

The invention discloses a foaming phenolic resin preparation method. The method comprises the following steps: A, phenol, aldehyde and alkali catalyst are added into a reactor, the mole ratio is 1 : 1-3 : 0.01-0.1, and the components are stirred for 5 to 8 hours at 70 to 90 degrees centigrade; B, the temperature of reaction liquid in step A is reduced to 50 to 60 degrees centigrade, acid is added and stirred until the pH value is 6.0 to 8.0; and C, the reaction liquid in step B is decompressed and dehydrated to 60 to 70 degrees centigrade and 2500 to 7000 m Pa.s viscosity. The invention further discloses phenolic resin foam made of the phenolic resin. The invention makes the foaming phenolic resin which can gel quickly have low free monomer content and high curing activity through controlling the synthesis technology condition accurately. The aperture of the prepared phenolic foam body is only 50 to 60 microns. The structure of the micro holes of the foam body is regular and the foam holes are fine and compact. The prepared phenolic foam body does not need any toughening modifier and no residue falls.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

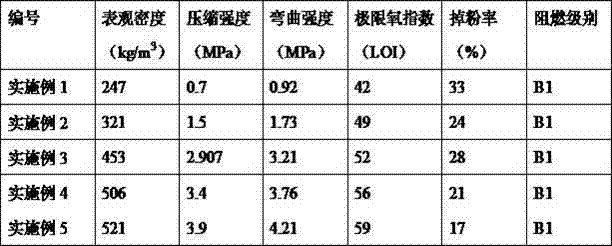

Phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and preparation method thereof

The invention relates to a phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and a preparation method thereof. The preparation method comprises the following steps: synthesizing cardanol glycidol ether from cardanol and epoxy chloropropane under alkaline conditions, and hydrolyzing under acidic conditions to generate cardanol-base dibasic alcohol; by using the cardanol-base dibasic alcohol as the raw material, dropwisely adding oxydol to react under acidic conditions to obtain the epoxy cardanol-base dibasic alcohol, carrying out reaction on the epoxy cardanol-base dibasic alcohol and a phosphorus-containing flame retardant to obtain phosphorus-containing cardanol-base polylol; carrying out reaction on the phosphorus-containing cardanol-base polylol and isocyanate to obtain a phosphorus-containing cardanol-base polyurethane prepolymer; and mixing the phosphorus-containing cardanol-base polyurethane prepolymer with a phenolic resin, and sequentially adding a surfactant, a foaming agent and a curing agent, thereby obtaining the phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam thermal-insulation material. The mechanical properties of the phenolic foam thermal-insulation material are obviously enhanced. The flame-retardant element phosphorus is introduced into the polyurethane prepolymer, thereby solving the problem of degradation of foam flame retardancy due to the carbamate introduced into the phenolic foam.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

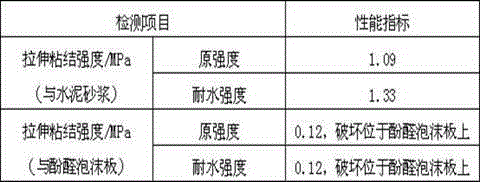

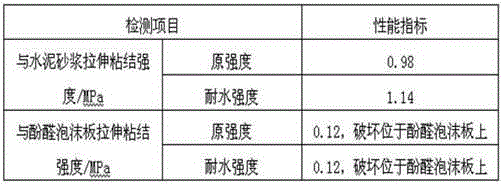

Waterproof adhesive mortar for external thermal insulation of external wall

The invention relates to the technical field of building material mortar technologies, in particular to waterproof adhesive mortar for external thermal insulation of an external wall. The waterproof adhesive mortar is prepared from the following raw materials in part by weight: 20 to 25 parts of high-alumina cement, 10 to 20 parts of Portland cement, 50 to 65 parts of sand, 2 to 8 parts of coarse whiting, 1 to 2.5 parts of re-dispersible emulsion powder, 0.1 to 0.3 part of cellulose ethers thickening agent, and 0.1 to 0.3 part of moisture repellent, wherein the Portland cement is 42.5-grade Portland cement, and the waterproof intensity of the adhesive mortar is not lower than that of the conventional adhesive mortar or is reduced slightly; the adhesive mortar is high in adhesive property and suitable for various external thermal insulation systems, and excellent in capacity of adhering cement concrete base-level wall surfaces, and thermal insulation materials such as phenolic foam, polyphenyl, extruded sheets and the like.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Preparation method of phenolic foam boards

The invention provides a preparation method of phenolic foam boards. The method comprises the steps as follows: mixing 90 to 120 parts by weight of alkaline phenolic resin, 4 to 15 parts by weight of foaming agents, 2 to 6 parts by weight of emulsifiers, 2 to 8 parts by weight of flexibilizers and 10 to 30 parts by weight of curing agents so as to prepare a foaming system of the phenolic foam boards; heating for foaming; solidifying for shaping; and then post-solidifying so as to prepare the phenolic foam boards. The post-solidifying treatment is performed on the conditions that temperature is 30 to 80 DEG C, the humidity is 40 to 90%, and the time is 24 to 72 hours. The preparation method provided by the invention is realized by post-solidifying boards, and adding an inorganic fire retardant and a high-activity modifier to the foaming system of the phenolic foam boards so as to prepare phenolic foam boards with the warping dimension being equal to or less than 4 mm, the wall-mounting condition is good or the boards are warped slightly, and no dropping phenomenon occurs; therefore, the boards accord with the requirements for good boards in the markets, and the method solves the warping problem of the phenolic foam boards.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

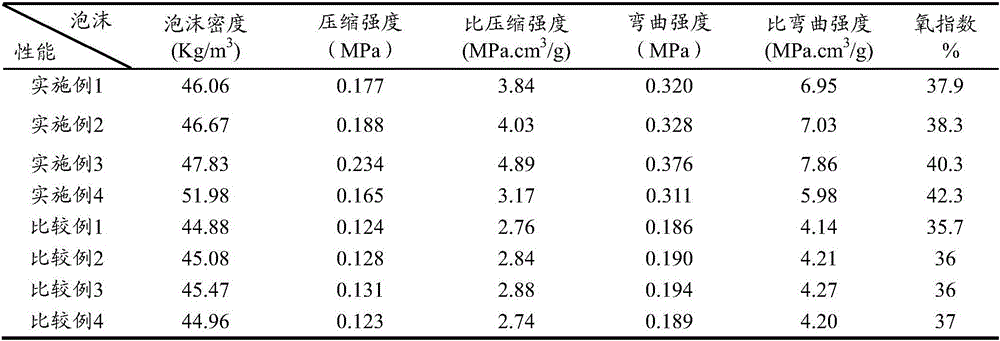

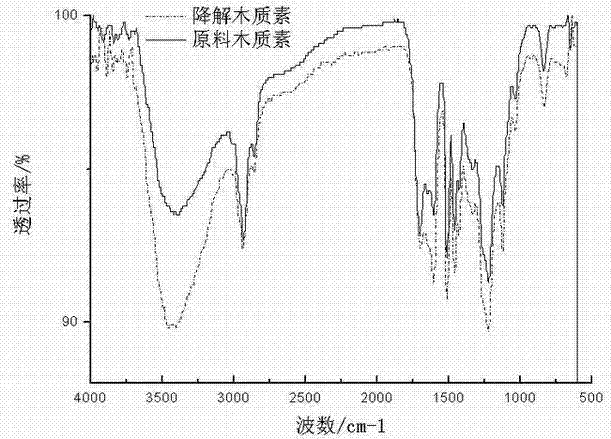

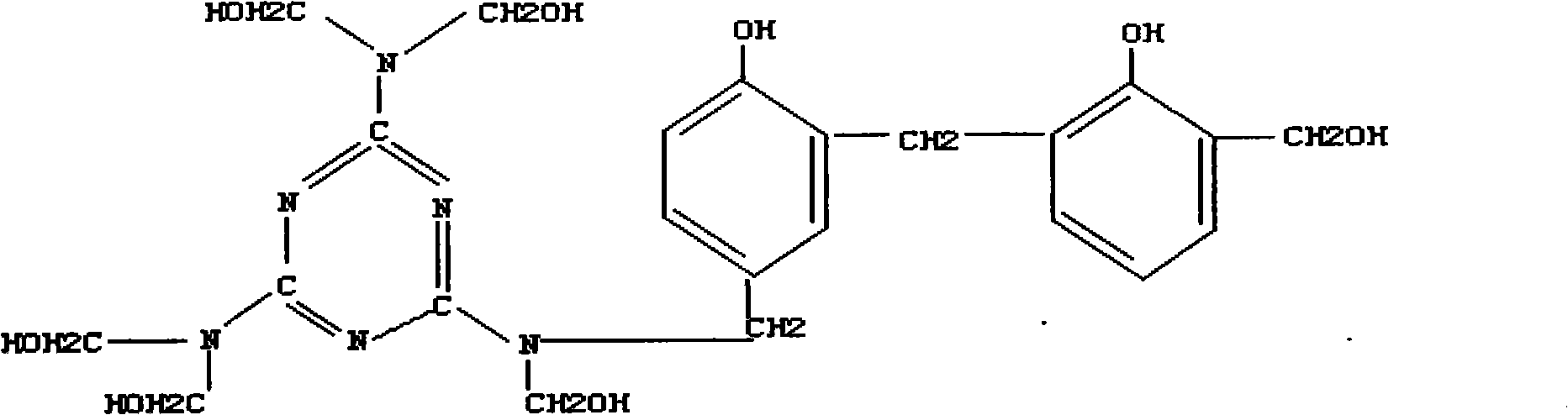

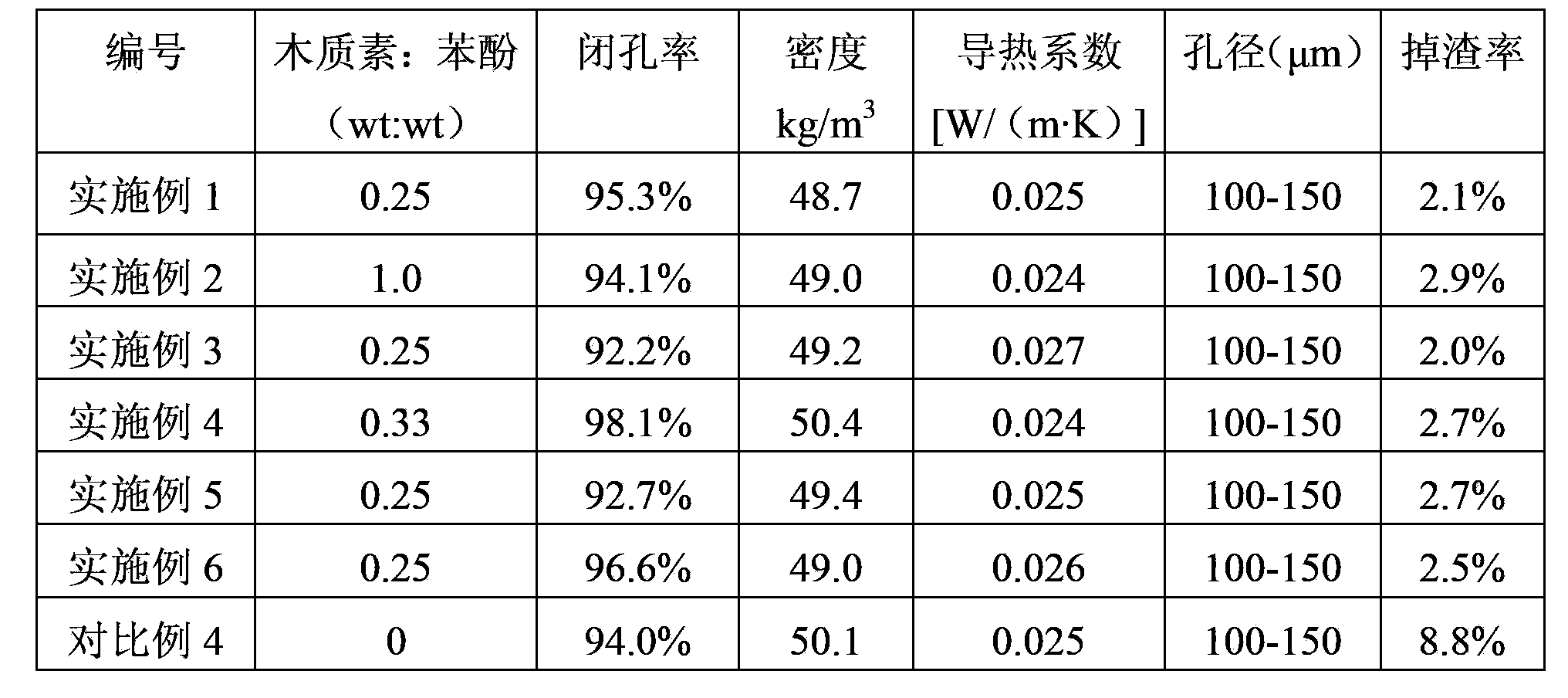

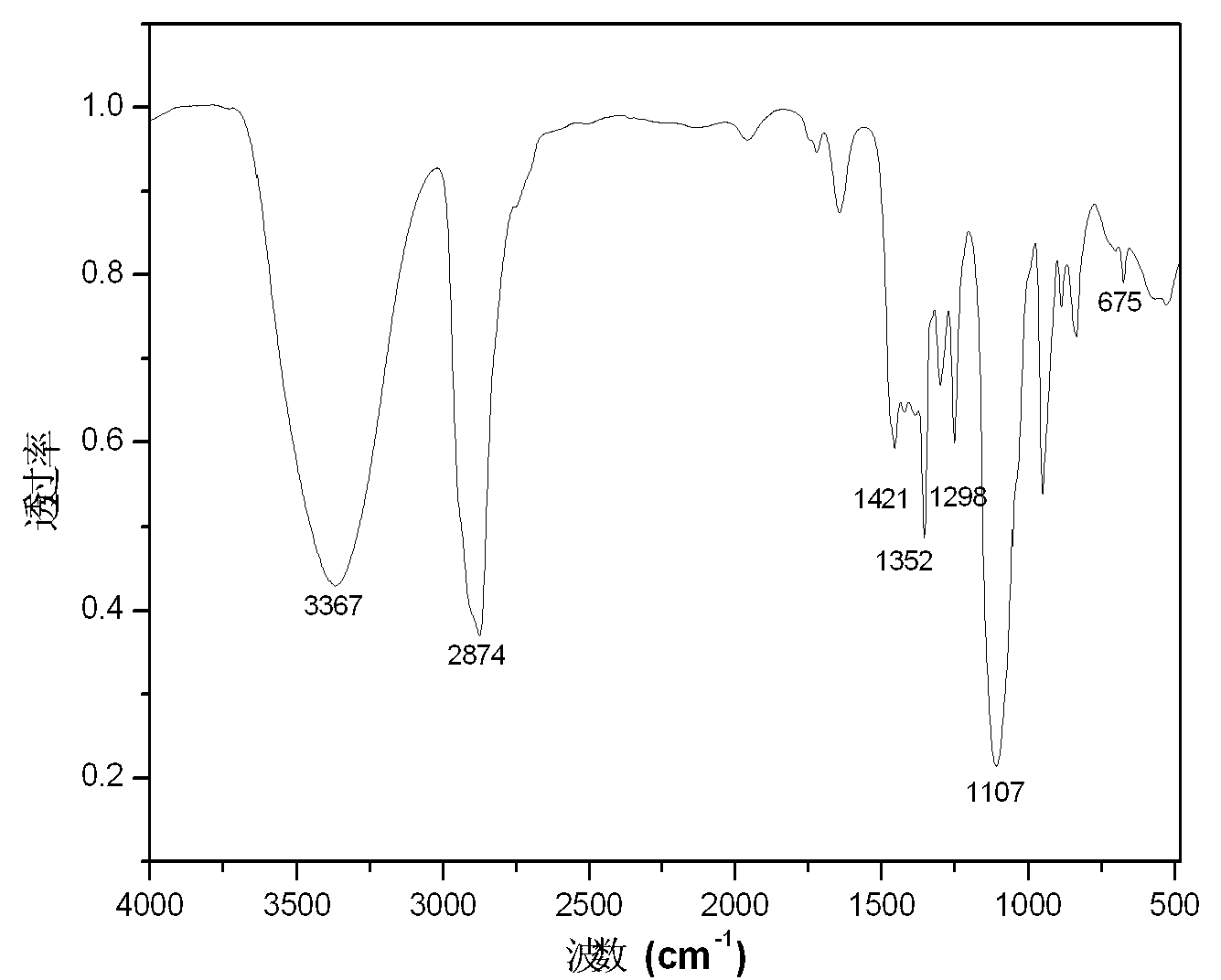

Lignin-modified phenolic foam and preparation method thereof

The invention relates to a preparation method of lignin modified phenolic foam, comprising the following steps: modifying high molecular weight lignin in order to degrade into low molecular weight lignin, wherein the activity is improved, replacing the phenol by the degraded lignin, preparing lignin modified resol, mixing with curing agent, foaming agent and surfactant, foaming at room temperature (25-30 DEG C) or in an oven of temperature 40-80 DEG C, finally the modified phenolic foam plastic is obtained after the curing process. The preparation method of the invention has the following advantages: the cost of the phenolic foam is greatly reduced, the toughness of the foam is increased and the brittles is decreased, thus the foam of the lignin modified phenolic foam has good market prospect; the preparation method of the invention provides a high-addition way to the abundant pulp paper-making waste liquid and forestry and agricultural residues, and reduces the dependency of phenolic foam industry on petrochemical raw material phenol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of polyurethane prepolymer-toughened modified phenolic foam plastic

The invention relates to a preparation method of polyurethane-prepolymer-toughened modified phenolic foam plastic, which comprises the following steps: vacuumizing and dehydrating polyalcohol, dropwisely adding the polyalcohol into isocyanate to react in a nitrogen atmosphere, and adding a chain extender to react; regulating an alkaline A-stage phenol formaldehyde resin with acid according to parts by mass, adding a toughener polyurethane prepolymer, a surfactant, a foaming agent 1 and a curing agent into the resin to obtain a foamed system; and stirring uniformly the foamed system at room temperature, and heating to cure and form to obtain the polyurethane-prepolymer-modified flame-retardant phenol formaldehyde foam thermal-insulation material. The phenol formaldehyde foam has the advantages of less shedding, high toughness and the like; and the adopted phenol formaldehyde resin has the advantages of low viscosity and favorable compatibility with the polyurethane prepolymer, and can be easily mixed uniformly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

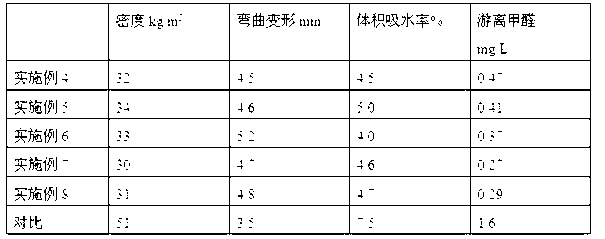

Cardanol modified phenolic aldehyde foam and preparation method thereof

The invention discloses cardanol modified phenolic aldehyde foam and a preparation method of the cardanol modified phenolic aldehyde foam. The cardanol modified phenolic aldehyde foam is prepared by the following materials in parts by weight: 100 parts of a cardanol modified phenolic aldehyde resin, 4-7 parts of a surfactant, 6-10 parts of a foaming agent and 15-20 parts of a curing agent, wherein the cardanol modified phenolic aldehyde resin is a phenolic aldehyde resin obtained by performing a first step of reaction on cardanol and liquid formaldehyde under a basic catalyst condition, then, adding phenol and paraformaldehyde, and performing a second step of reaction under the basic catalyst condition, and at last, adding a hydroxymethylurea resin to react. According to the preparation method, on the basis of not affecting the heat conductivity coefficient and high fire resistance of the phenolic aldehyde foam, the density, water absorption and free formaldehyde of phenolic aldehyde foam plastic are reduced by the cardanol, the tenacity of phenolic foam is improved, and meanwhile, renewable plant resources are adequately used. The cardanol modified phenolic aldehyde foam can be used as a building heat-insulation, heat-preservation and fire-proof material, and is a product with good market prospect.

Owner:北京傲德新材料科技有限公司

Wood fiber reinforced flame retardant foam composite plate and manufacturing method thereof

InactiveCN102114659AImprove use valueSolve the "Three Rural Issues"Wood working apparatusDomestic articlesAdhesive cementPhenolformaldehyde foam

The invention relates to a wood fiber reinforced flame retardant foam composite plate and a preparation method thereof. The external layer of the composite plate is a wood panel, and the foam core plate in the internal layer is a wood fiber reinforced phenol formaldehyde foam material or a melamine modified formaldehyde foam material. The wood fiber is treated by a coupling agent. The invention further relates to a manufacturing method of the plate. The wood panel is adhered to the external layer panel of the foam core plate. The plate can be manufactured by performing lamination thermal composition on the materials by using an adhesive, and also can be manufactured by directly foaming between fixed dual-layer panels. The foam core plate uses wood fiber reinforced phenol formaldehyde foam or melamine modified formaldehyde foam material. The flame retardant performance can accord with the specified standard. The foam core plate is flame retardant and small in smoke amount, generates no harmful gas, and meets requirement of environmental friendliness, so that the composite plate has excellent sound absorption and heat insulation properties. The fiber reinforced foam base material has an excellent mechanical property.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Resin for high-flame-retardant phenol formaldehyde foam and production method thereof

InactiveCN101781393AExtended burn timeNon-flammableDust removalFire preventionPlasticizerSurface-active agents

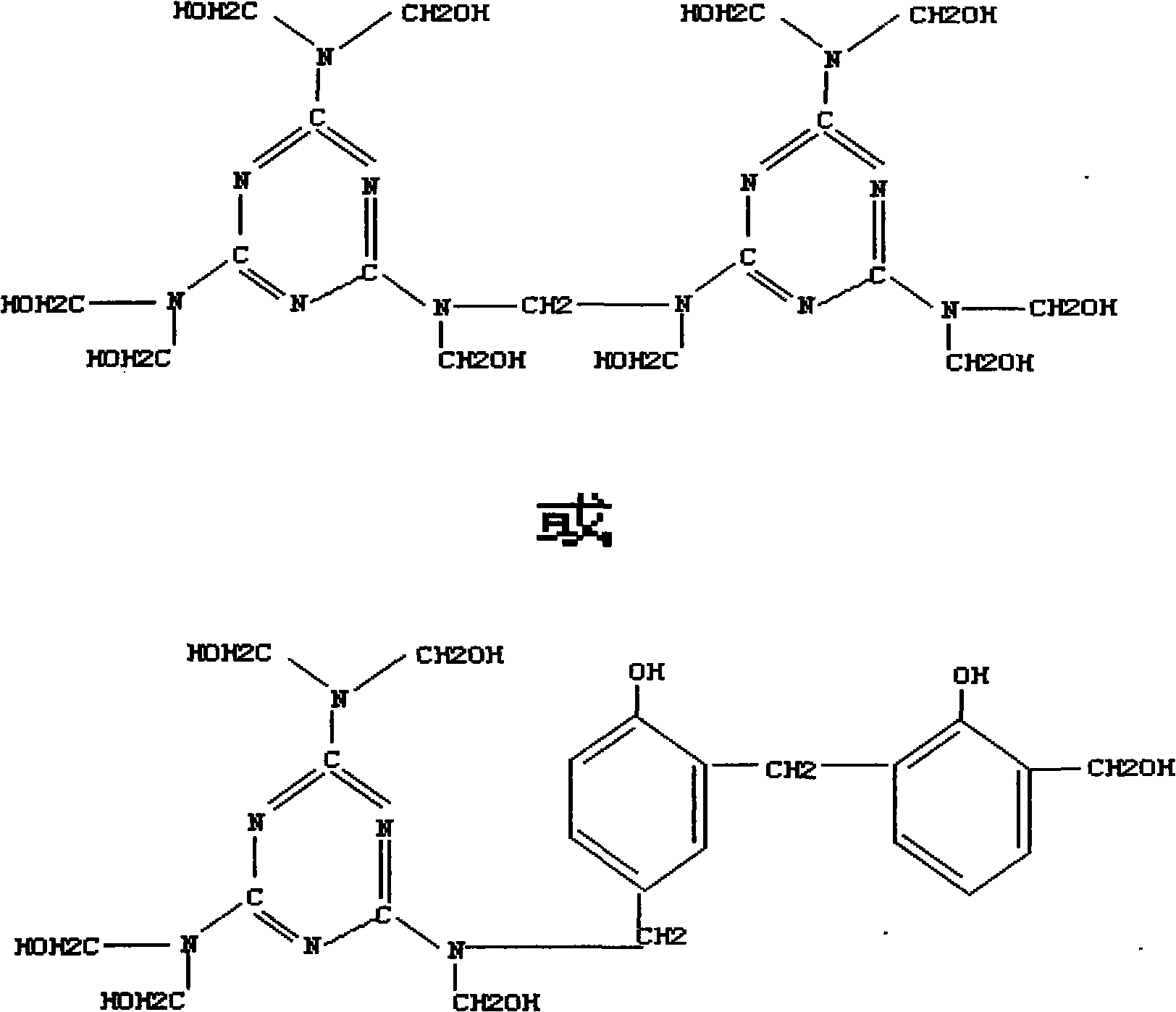

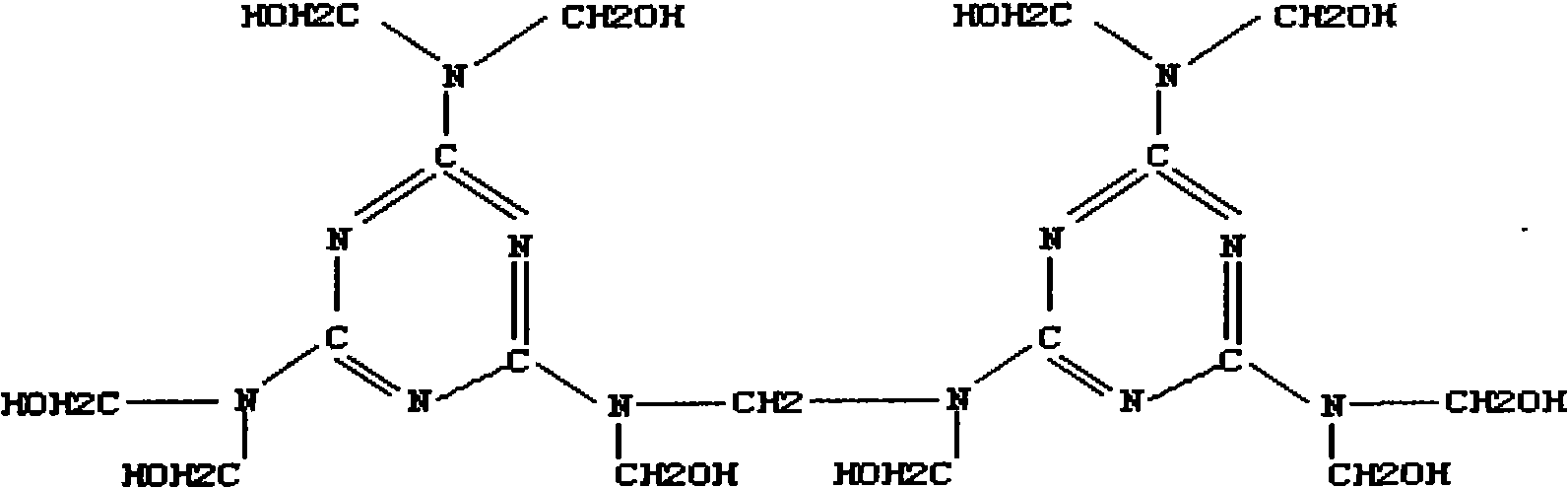

The invention discloses resin for high-flame-retardant phenol formaldehyde foam and a production method thereof. The production method comprises the following steps of: adding melamine to resin for common phenol formaldehyde foam to react or adding a melamine resin polymer to mix, wherein the addition of the melamine is 0.5-8 percent of the total weight of resin for high-flame-retardant phenol formaldehyde foam; then, adjusting a pH value to 6.0-8.5 with acid, dewatering and concentrating; and adding a plasticizer and a surface active agent. The invention has simple production process, improves the flame-retardant performance of the phenol formaldehyde foam by the triple-nitrogen heterocyclic structure characteristics of the melamine so as to satisfy the requirement of an industry standard MT113-1995, i.e. a testing method and a judgment rule for the flame-resistant antistatic property of polymer products used under a coal mime, and the storage process is stable without generating sediment. The resin for the high-flame-retardant phenol formaldehyde foam can be used in occasions needing extinguishing materials, such as filling empties during the safe production of a mine preventing air leaking from coal cracks, making closed walls and fireproof walls on buildings and enhancing broken roofs and stratums.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Low-density low-acidicity phenol formaldehyde foam board and preparation technique thereof

The invention relates to the technical field of foam thermal-insulation materials, particularly a low-density low-acidicity phenol formaldehyde foam board which is composed of the following components in parts by weight: 100 parts of phenol aldehyde resin, 1-10 parts of emulsifier, 1-10 parts of toughener, 7-12 parts of foaming agent, 3-10 parts of inorganic filler, 3-10 parts of flame retardant and 15-25 parts of organic acid curing agent. The organic acid curing agent is composed of more than one of p-toluenesulfonic acid, dimethyl benzenesulfonic acid, sulfocarbolic acid and benzenesulfonic acid. The high-proportion resin is combined with organic mixed acid into which an inorganic filler is added, and two surfaces are respectively coated with a glass fiber felt layer. The density of the prepared phenol formaldehyde foam board is 25-40 kg / m<3>, the pull strength is higher than 0.1 MPa, the close-pore ratio is higher than 90%, the heat conductivity coefficient is 0.023W / (m.k), and the pH value is higher than 4.5.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

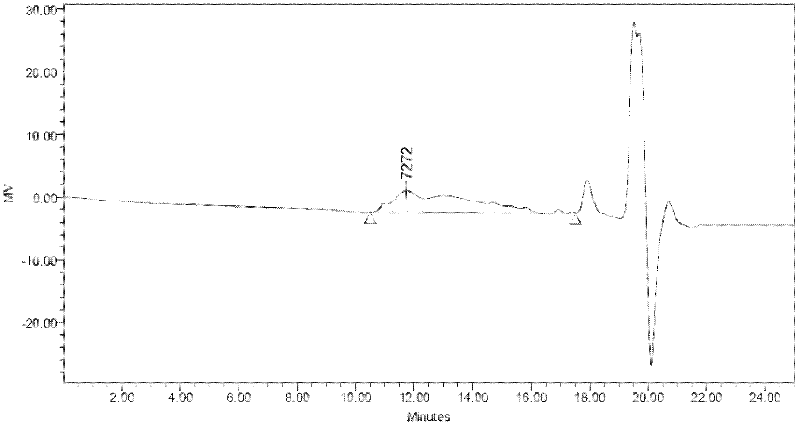

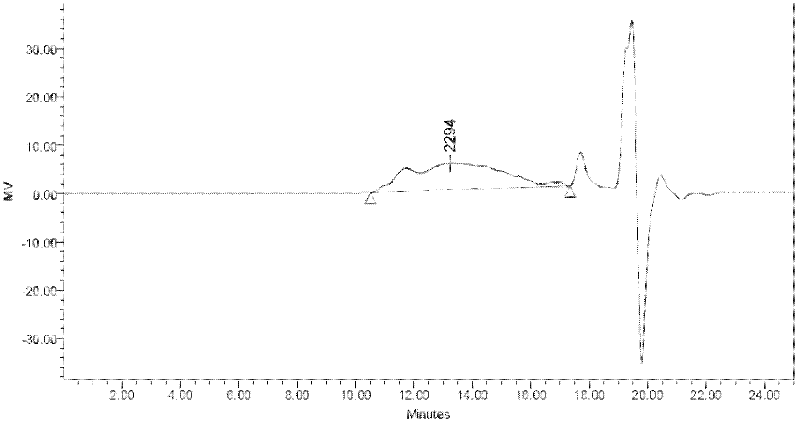

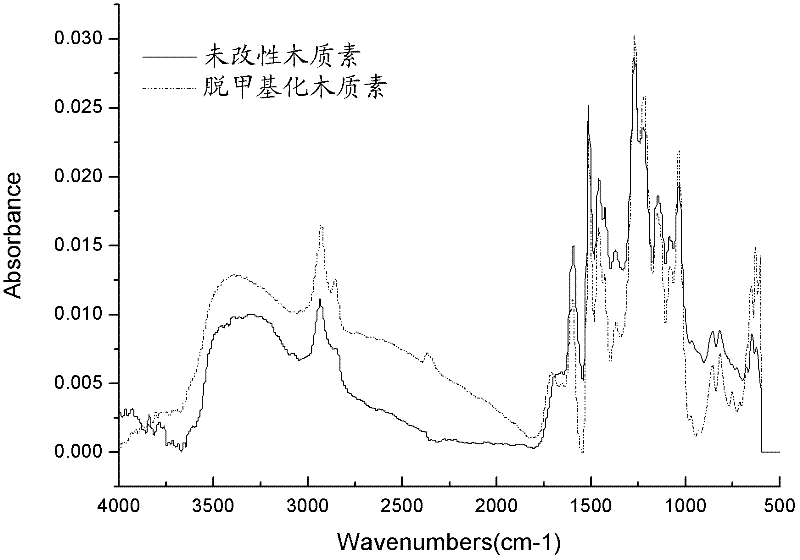

Modification method of lignin

The invention relates to a modification method of lignin. The modification method comprises: adding and dissolving lignin in an organic solvent in which a thiol and a basic catalyst are dissolved, carrying out a demethylation reaction, centrifuging, washing and drying to obtain pure demethylated lignin, wherein the mass ratio of lignin to the catalyst to the thiol to dimethyl formamide is 1: (0.2-0.6): (0.5-2): (5-10). The lignin provided by the invention has the advantages that the free radicals are not polymerized in the modification process, the molecular weight of the lignin is reduced and the polarity is simultaneously improved, the reaction activity with formaldehyde is improved, and the lignin can replace phenol at a high ratio. The lignin modified by the modification method is in a shape of powder, can be used for preparing thermoplastic phenolic resins and thermosetting phenolic resins, and can also be used for adhesives, phenolic foam plastics, polyurethane foam plastics, phenolic molding materials, carbonization functional materials, polyurethane films and other multiple novel polymer materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Composite phenolic aldehyde building energy-saving heat-insulating board and its manufacturing method and application

InactiveCN101191371AImprove thermal insulationImprove thermal insulation performanceCovering/liningsLaminationProduction lineInsulation layer

A composite phenolic aldehyde construction energy saving insulation plate and manufacturing method and application thereof relate to an insulation plate. The invention aims to provide the composite phenolic aldehyde construction energy saving insulation plate and the manufacturing method and application thereof with excellent insulation effect, convenient use and high construction efficiency. The invention comprises a phenolic aldehyde insulation layer, a bonding layer and an inorganic material composite board, wherein, the bonding layer is arranged between the phenolic aldehyde insulation layer and the inorganic material composite board; the thickness of the phenolic aldehyde insulation layer is 20-100mm, the thickness of the bonding layer is 0.1-1mm, and the thickness of the inorganic material composite board is 3-10mm. The inorganic material composite board is continuously produced for reserving; the inorganic material composite board is applied with bonding treatment agent; phenolic aldehyde resin which is prepared pro rata is frothed and solidified into shaping with the continuous production line of the composite board, and a target product can be received.

Owner:厦门高特高新材料有限公司

Preparation method for halogen-free flame-retardant toughened phenolic foamed plastics

InactiveCN102746612AImprove flame retardant performanceLow combustion smokePhenolformaldehyde foamPolymer science

The invention specifically relates to a preparation method for halogen-free flame-retardant toughened phenolic foamed plastics, which belongs to the technical field of materials. The method comprises the following steps: weighing 100 parts of resol resin and then respectively adding a plasticizer, a surfactant, a curing agent, a foaming agent and a halogen-free flame retardant; and evenly mixing the above mentioned components under rapid stirring, pouring an obtained mixture into a die, closing the die and carrying out foaming at a temperature of 60 to 100 DEG C for 30 to 60 min so as to obtain the flame-retardant toughened phenolic foamed plastics. The prepared flame-retardant toughened phenolic foamed plastics have the advantages of a good flame retardant effect (wherein an oxygen index is as high as 40%), a small smoke volume in combustion, no production of toxic and corrosive gas and good mechanical properties.

Owner:TONGJI UNIV

Preparation method of hollow glass microbead-reinforced phenolic foam composite material

The invention discloses a preparation method of a hollow glass microbead-reinforced phenolic foam composite material, belonging to the field of foam materials. The preparation method comprises the following steps: copolymerizing phenol and formaldehyde serving as comonomers and hollow glass microbeads serving as reinforcing materials so as to get modified A-stage phenolic resin in the presence of an alkaline catalyst; and further mixing the A-stage phenolic resin with a surfactant, a foaming agent, a nano-nucleating agent and an acid curing agent according to a formula, adding into a mold, and performing hot-pressing, foaming and molding to prepare the hollow glass microbead-reinforced phenolic foam. According to the preparation method disclosed by the invention, by reinforcing the hollow glass microbeads, the compressive strength, the bending strength and the impact strength of the phenolic foam are improved; the bubble hole structure of the phenolic foam is improved, the bubble hole size is reduced; and bubble holes are more uniform; and the fire resistance of the phenolic foam can not be reduced. The prepared foam can be applied to high-tech technical fields of aerospace, high-speed trains, building heat insulation, ships and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fiber reinforced phenolic foam composite material and preparation method thereof

ActiveCN104497473AImprove fire performanceControllable cell sizePhenolformaldehyde foamFoaming agent

The invention discloses a fiber reinforced phenolic foam composite material. The fiber reinforced phenolic foam composite material is prepared from the following components in parts by weight: 10-100 parts of fiber felts, 100 parts of phenolic resin, 5-20 parts of a foaming agent, 1-6 parts of a modifier, 5-18 parts of a curing agent and 0-200 parts of a solvent. Interaction of a microsphere foaming agent, fiber felts and the modifier is adopted, so that the phenolic resin foam composite material obtained by the preparation method disclosed by the invention is not only relatively excellent in fireproof performance, but also controllable in hole diameter of foam holes; the obtained composite material is high in strength, not prone to drop powder and capable of being bent into various shapes. Domestic requirements such as fire resistance, water resistance and heat resistance can be completely satisfied, the material strength is greatly improved, and the application field of the fiber reinforced phenolic foam composite material is expanded.

Owner:镇江三阳装饰材料有限公司

Composite reinforced pnenolic aldehyde foam insulating board and its preparation method

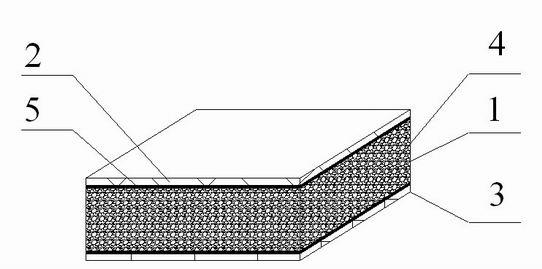

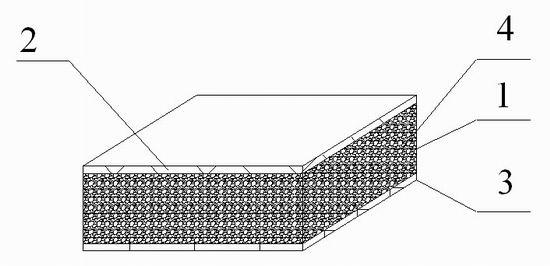

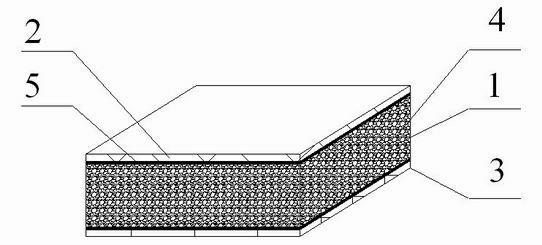

InactiveCN101144559AImprove physical strengthGood adhesionThermal insulationLayered productsSurface layerUltimate tensile strength

The invention provides a composite type reinforced phenol formaldehyde foam insulating sheet and a preparing method thereof. The insulating sheet comprises an upper surface layer (1), a middle layer (2) and a lower surface layer (3) which are mutually combined in sequence, the materials of the middle layer (2) are phenol formaldehyde foams, and the upper surface layer (1) and the lower surface layer (3) comprise a reinforced layer (101) made of fiber mat. The composite type reinforced phenol formaldehyde foam insulating sheet of the invention greatly improves the physical strength and the adhering performance through combining fiber reinforced materials on the surface of the phenol formaldehyde foam sheet, and widens the application area of the phenol formaldehyde foam insulating sheet.

Owner:SHANGHAI HAOHAI CHEM

Phenolic foam plate containing nanometer aerogel and production method of phenolic foam plate

The invention relates to the technical field of phenolic foam plates and in particular relates to a phenolic foam plate containing nanometer aerogel. The phenolic foam plate containing nanometer aerogel comprises the following raw materials: phenolic resin, an emulsifying agent, a toughening agent, a foaming agent, nanometer aerogel, a fire retardant and a curing agent according to a weight ratio of 100: (1-10): (1-10): (7-12): (2-15): (2-15): (15-25). The toughening agent is prepared by mixing polyvinyl pyrrolidone with ethylene glycol according to a weight ratio being 1: (1-5). A production method of the phenolic foam plate containing nanometer aerogel comprises the following steps: evenly mixing and stirring the raw materials and pouring the raw materials into a preheated die to foam and cure. By taking the nanometer aerogel as filler and adding the special toughening agent, the strength of the plate can be improved; a compression strength is increased from about 0.14 to be greater than 0.18; a pulling strength is increased from about 0.07 to be greater than 0.12; a heat conductivity coefficient of the plate is reduced to be less than 0.022; an oxygen index is increased from about 45 to be 55.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Neutral obturator phenolic aldehyde foam plastic and preparation method thereof

ActiveCN102558757AAvoid corrosionExtended service lifeSynthetic resin layered productsSurface layerFoaming agent

The invention discloses neutral obturator phenolic aldehyde foam plastic and a preparation method thereof and relates to phenolic aldehyde foam plastic. The invention provides the neutral obturator phenolic aldehyde foam plastic and the preparation method thereof. The neutral obturator phenolic aldehyde foam plastic is neutral on the premise of no influencing properties, such as heat insulation, fire resistance and the like, of the phenolic aldehyde foam plastic and is modified by alkaline sustained-release microcapsules. The neutral obturator phenolic aldehyde foam plastic consists of the following raw materials in part by mass: 100 parts of expandable phenolic resin, 3 to 5 parts of surfactant, 3 to 15 parts of foaming agent, 5 to 40 parts of alkaline sustained-release microcapsule and 3 to 30 parts of acid curing agent. The preparation method comprises the following steps: mixing the expandable phenolic resin, the surfactant, the alkaline sustained-release microcapsule and the hydrocarbon foaming agent; adding the acid curing agent; conveying the mixture to a base plane which can move continuously and is paved with a surface layer material; and preparing the neutral obturator phenolic aldehyde foam plastic with the required shapes by using the heated double-caterpillar type laminating machine conveying machine unit. The obtained neutral obturator phenolic aldehyde foam plastic is modified by the alkaline sustained-release microcapsules.

Owner:福建天利高新材料有限公司

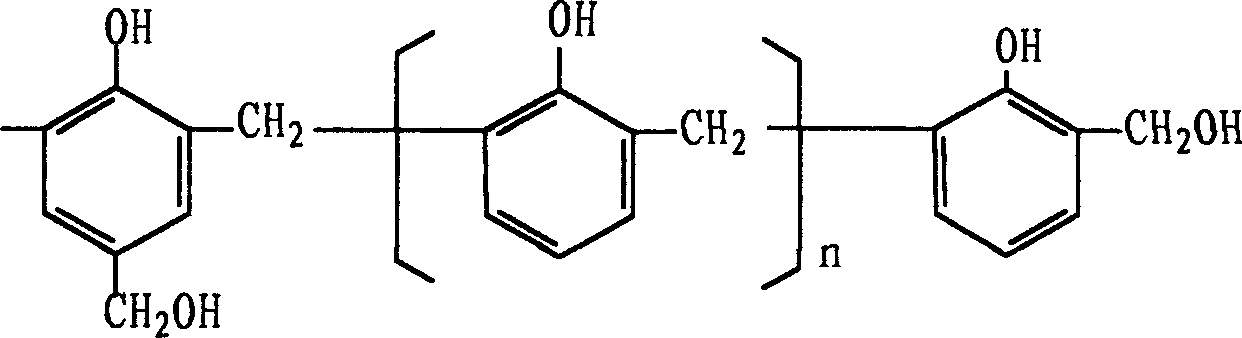

Lignin modified phenolic resin, foam thereof, preparation method of resin, and preparation method of foam

The invention belongs to the technical field of organic composite materials, and especially relates to a lignin modified phenolic resin, a foam thereof, a preparation method of the resin, and a preparation method of the foam. The preparation method of the lignin modified phenolic resin comprises the following steps: 1, mixing an acid catalyst with phenol and lignin, and reacting at 230-300DEG C under 2-5MPa to obtain a lignin phenolation product solution; and 2, adding formaldehyde, and reacting to obtain the lignin modified phenolic resin, wherein phenol can be added or not added to the lignin phenolation product solution obtained in step 1 before the addition of formaldehyde. The lignin modified phenolic resin synthesized through the method has a high curing activity, and has a shorter gelling time and a lower content of free formaldehyde than low temperature phenolated lignin modified phenolic resin. The phenolic foam prepared by using the lignin modified phenolic resin has the advantages of good toughness, high percentage of close area, and good thermal insulation performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Steel face type phenolic aldehyde heat preserving composite board and manufacturing method and application thereof

InactiveCN101275704AImprove thermal insulationReduced service lifeThermal insulationPipe protection by thermal insulationInsulation layerComposite plate

A steel face type phenolic aldehyde heat preservation composite board and the manufacturing method and application thereof relate to a warming plate, particularly a steel face type phenolic aldehyde heat preservation composite board and the manufacturing method and application thereof, which combines the advantages of the traditional galvanized sheet iron wind pipe and combined wind pipe, have good heat preservation effect, widely used in the pipe of the central air conditioner, such as the heat preservation work shop, the clean air condition house, the large exhibition hall, the gymnasium, the high-rise building, the high level villa, which are provided with an upper layer, a tackified layer, the phenol formaldehyde foam insulation layer and the metal lower layer. The tackified layer is arranged between the upper layer and the phenol formaldehyde foam insulation layer, the thickness of the upper layer is 0.1-0.5 mm, the thickness of the phenol formaldehyde foam insulation layer is 20-100mm, the thickness of the metal lower layer is 0.05-0.5 mm. The continuous production method or the batch production method is used.

Owner:厦门高特高新材料有限公司

Method for preparing safe environment-friendly phenolic foam

InactiveCN102229706ALow thermal conductivityImprove thermal conductivityAlkaneSimple Organic Compounds

The invention discloses a method for preparing safe environment-friendly phenolic foam. The foam is prepared by a reaction after mixing the following ingredients: 100 weight portions of expandable phenolic resin, 8-15 weight portions of curing agent, 4-8 weight portions of surfactant and 20-50 weight portions of packing. The preparation method comprises the following steps: putting the ingredients in a reaction container in proportion, stirring with high speed, after mixing uniformly, transferring the ingredients to a preheated mould, foaming at the temperature of 60-80 DEG C and under the pressure of 15-40kg / cm<2>, cooling and demoulding. According to the method, because inflammable CFCs, low-carbon alkane and other lower-boiling organic compounds are not used as foaming agent, the production cost is reduced. The prepared phenolic foam has uniform quality, small aperture, low coefficient of thermal conductivity, and good thermal insulation performance, can be widely used in exterior wall, roofing, air-conditioning bellow and other thermal insulation materials, and improves thermal insulation performance and fireproof performance greatly.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Production method of phenol formaldehyde resin used for normal temperature continuous casting and foaming and resin made by said method

A water-soluble phenolic resin for continuous casing and foaming at ordinary temp is composed of phenol and formaldehyde through low-temp prepolycondensation reaction, heating to 95 deg.c, high-temp polycondensation reaction, medium-temp polycondensation reaction, and low-temp polycondensation reaction while adding amino organosilicon compound as reaction activity regulator. Its advantages are high foaming uniformity, and high adhesion to panel.

Owner:孙维钧

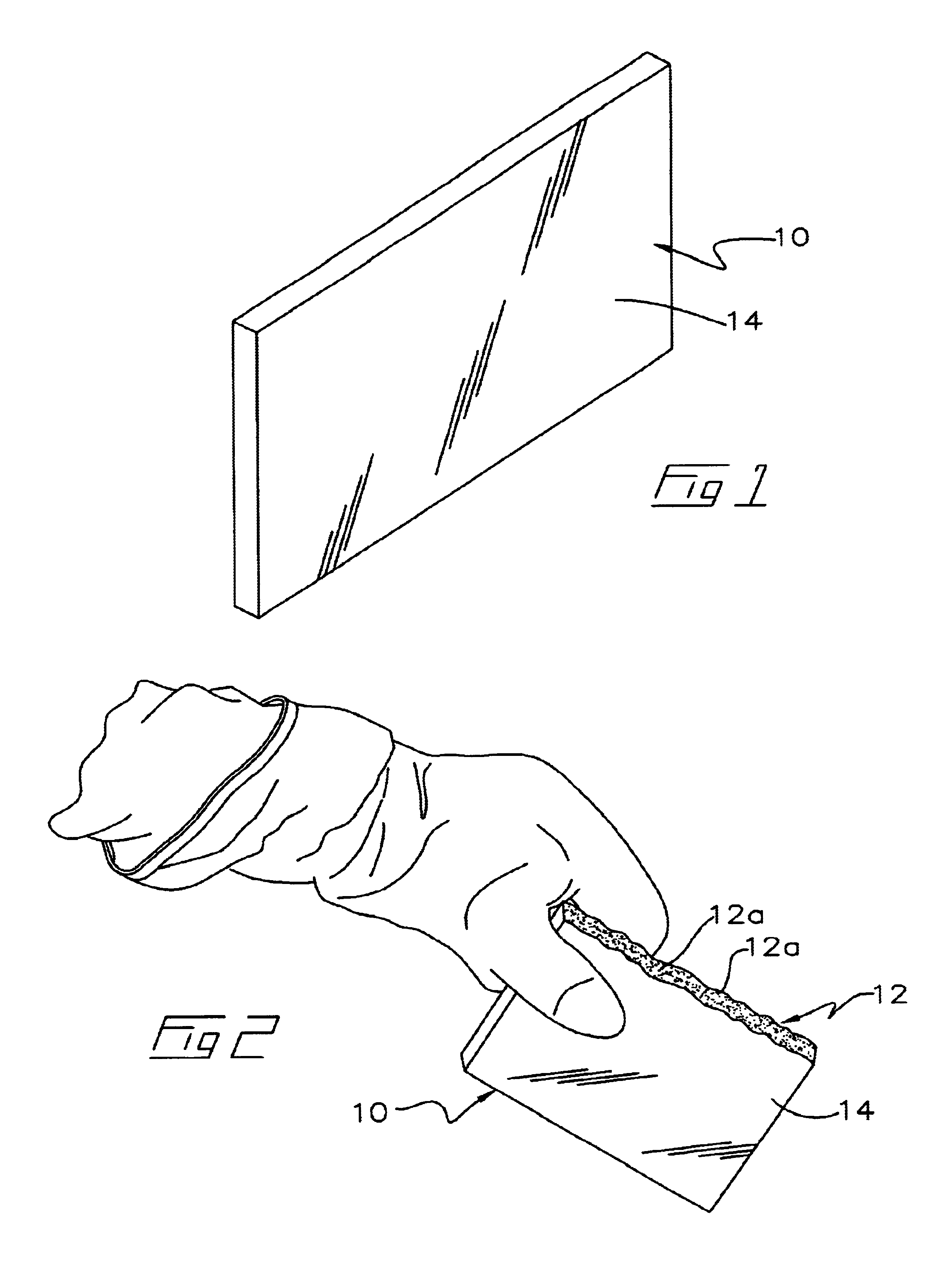

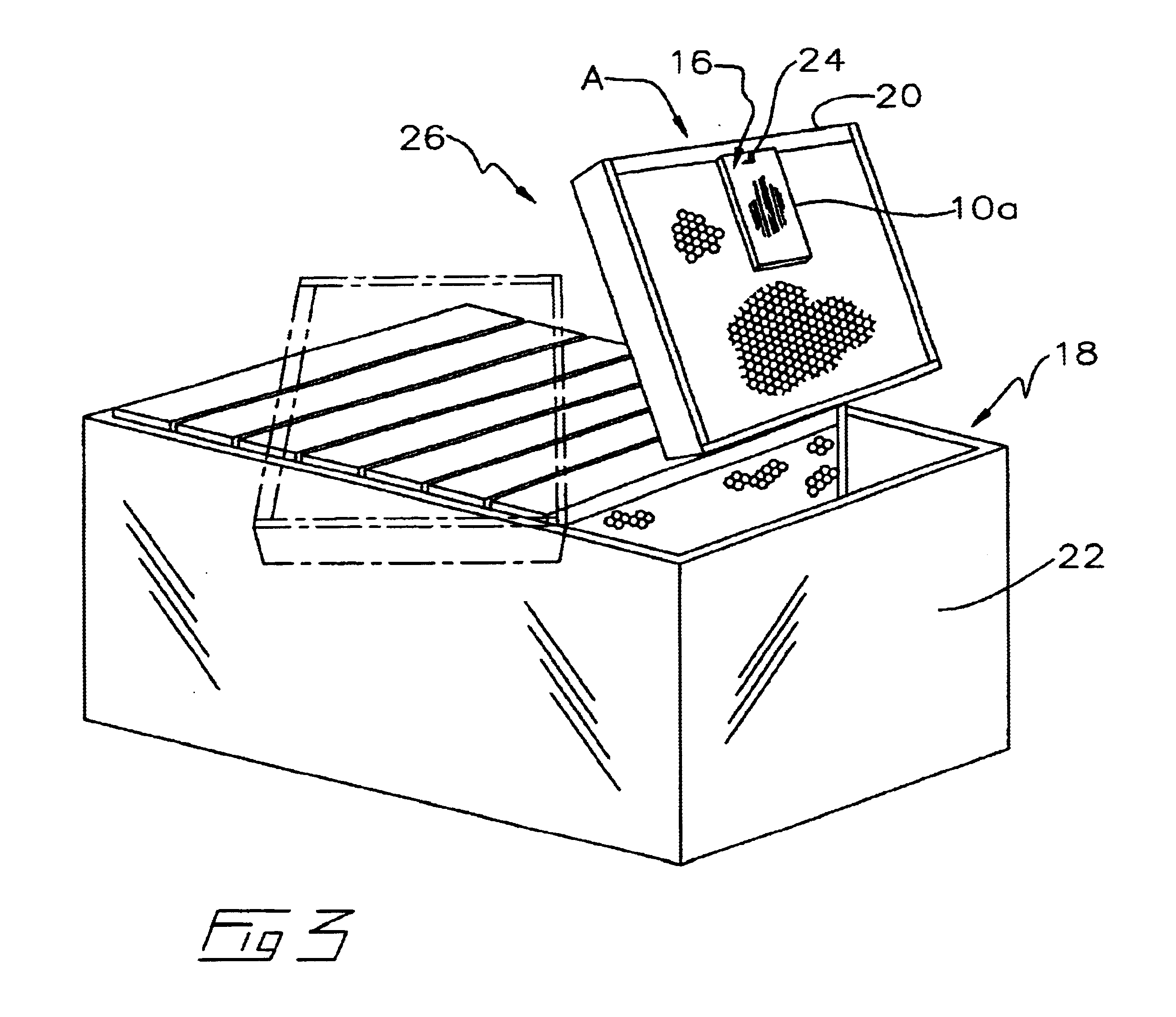

Treatment fluid dispenser for control of mites

InactiveUS6837770B2Increase humidityIncrease temperatureInsect catchers and killersBeehivesMedicineFoamcore

A treatment fluid dispenser pad includes a phenolic foam core encased in a fluid impervious skin or sheath. The fluid impervious skin or sheath is sealed about the phenolic foam core. The pad is cut in one or more sections and soaked in formic acid fluid. Each section of pad is vertically hung in a bee space so as to downwardly dispose an exposed surface of the phenolic foam core to thereby evaporate acid at a uniform rate.

Owner:RUZICKA VACLAV

Lignin-based phenolic foam material and preparation method thereof

The invention discloses a lignin-based phenolic heat insulating material and a preparation method thereof. The preparation method comprises the following steps of: uniformly stirring expandable lignin basic phenolic resin with the conventional pH adjusting agent and a surfactant; adding a foaming agent and rapidly and uniformly stirring; adding a curing agent lastly; and uniformly stirring, and rapidly pouring into a specified enclosed container for foaming to the obtain lignin-based phenolic heat insulating material, wherein the used curing agent is a compound curing agent obtained by mixing toluenesulfonic acid and phosphoric acid in the mass ratio of 1.5:1. The foaming multiplying power of the lignin-based phenolic foam material is adjustable, the form hole fineness uniform density is 40-60 kg / m<3>, the compression strength is 0.07-0.45MPa, and the water absorbing rate is 7-15.5 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Lignin phenolic foam and preparation method thereof

The invention relates to lignin phenolic foam and a preparation method thereof. The preparation method comprises the following step: liquefying lignin to obtain biomass phenol to obtain lignin flowing phenolic resin under the catalyst effect of formaldehyde. The lignin phenolic foam is prepared from the following components in parts by mass: 100 parts of lignin flowing phenolic resin, 4-8 parts of a surfactant, 10-32 parts of a curing agent and 5-20 parts of a foamer. According to the lignin phenolic foam provided by the invention, dependency of phenolic resin on petrochemical materials is reduced, and the foam is uniformly foamed, has good heat-preserving and fire resisting performances and biodegradability, belongs to an environment-friendly product, and has huge social, economic and biological benefits.

Owner:SHANDONG YUSHIJU CHEM CO LTD

Low water absorption and high flame retardant composite phenolic foam thermal insulation material and production method thereof

The invention relates to a low water absorption and high flame retardant composite phenolic foam thermal insulation material and a production method thereof. The thermal insulation material is composed of phenolic resin foam and flame retardant expandable polystyrene foamed particles of different sizes. The flame retardant expandable polystyrene foamed particles of different sizes are uniformly dispersed in a phenolic resin foam matrix, the particles are mutually isolated, and the phenolic resin foam and the particles are closely combined together. The production method of the thermal insulation material includes: mixing A-stage resin, a surface active agent, a foaming agent, and a toughening agent evenly, adding a curing catalyst and conducting mixing again, and finally adding the flame retardant expandable polystyrene foamed particles of different sizes to undergo mixed foaming curing molding. The thermal insulation material provided in the invention has very low water absorption and good fireproof performance, as well as good mechanical strength.

Owner:蓝云飞 +2

Easily degradable phenolic foam and preparation method thereof

The invention discloses easily degradable phenolic foam which is obtained through a mixed reaction and foaming by raw materials which comprise, by weight, 100 parts of biomass phenolic resin, 4-8 parts of surface active agents, 24-44 parts of curing agents and 10-15 parts of foaming agents. The biomass phenolic resin is obtained through the mixed reaction and foaming by raw materials which comprise, by weight, 100 parts of biomass phenol, 15-20 parts of alkali, 90-130 parts of aldehyde and 40-75 parts of water. The biomass phenol is obtained through the mixed reaction by raw materials which comprise, by weight, 100 parts of phenol, 3-4 parts of catalyst acid and 25-33 parts of agriculture and forestry wastes. Further disclosed is a preparation method of the easily degradable phenolic foam. According to the easily degradable phenolic foam and the preparation method thereof, the agriculture and forestry wastes are translated into a flow state in a complete component mode under a specified condition, and used for replacing of partial petroleum base chemical products to prepare high polymer materials with high additional value. On one hand, the wastes are used, the product has biodegradability, and environment pollution is eliminated. On the other hand, production cost of the product is reduced.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Paint preparation technology

ActiveCN103540198AReasonable standardImprove standardsUnspecified rubber coatingsPolystyreneWaste rubber

The invention discloses a paint preparation technology, which is characterized by comprising the technological steps of: (1) raw material selection, wherein by weight percent, polystyrene foam, phenolic foamed plastics, waste rubber and nitrocellulose account for 65%, industrial alcohol, coal tar, acetone and water solvent account for 15%, pigment and filler account for 15%, and a wet dispersing agent, a defoaming agent, a delustering agent and a plasticizer account for 5%; (2) fusion refining; (3) primary fining; (4) dispersing; (5) blending and color modulation; (6) filtering; (7) packaging. The technology disclosed by the invention is reasonable and compact, technological process is reduced greatly, paint source is wide, the technology belongs to waste reuse, and production cost is reduced; meanwhile, according to the raw material ratio, the technology is convenient for preparing various functional paints and can meet the requirement of production technology of the paints, dosage and ratio are accurate, deviation is small, product quality is guaranteed, and yield of enterprises is improved effectively.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Preparation method of borate modified phenolic foam material

InactiveCN103289305ASimple processReduced powder shedding ratePhenolformaldehyde foamPolymer science

The invention belongs to the technical field of materials, and relates to a preparation method of borate modified phenolic foam material. The borate is prepared by esterification reaction of boric acid and polyethylene glycol under certain temperature. The preparation method of the borate modified phenolic foam material comprises the following steps of: firstly, weighing 100 mass parts of A-stage phenolic resin, then, respectively adding 2-14 mass parts of borate, 3-6 mass parts of surface active agent, 8-11 mass parts of curing agent and 6-14 parts of foaming agent, stirring and mixing evenly, pouring the mixture into a die, closing the die, foaming for 30-60min under 70-90 DEG C, and sequentially obtaining the borate modified phenolic foam. The phenolic foam material is high in flame retardant efficiency, low in powdery rate and low in smoke development, and generates no toxic and corrosive gases.

Owner:TONGJI UNIV

Toughened enhanced phenolic foam insulation material and preparation method thereof

The invention relates to a toughened enhanced phenolic foam insulation material. The material is characterized by mainly comprising the following raw materials: 100 parts of phenolic resin, 2-10 parts of phenolic resin fluidity improver, 5-15 parts of emulsifying agent, 4-8 parts of foaming agent, 1-10 parts of toughening-enhancing agent, and 6-55 parts of reactivity acid curing agent. The reactivity acid curing agent in high additive amount is adopted so that the cost is lowered, and the system residual acid is small and the corrosivity is small. The glass fiber powder and diatomite are used as the toughening-enhancing agent so that the foam flame retardation is improved, and the production cost is lowered.

Owner:LIAOCHENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com