Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

452 results about "Agricultural residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agricultural residue is the plant material remaining after the crop is harvested, including leaves, stalks and roots. For BioSAT.net, only the above ground portion of agricultural residue is considered harvestable.

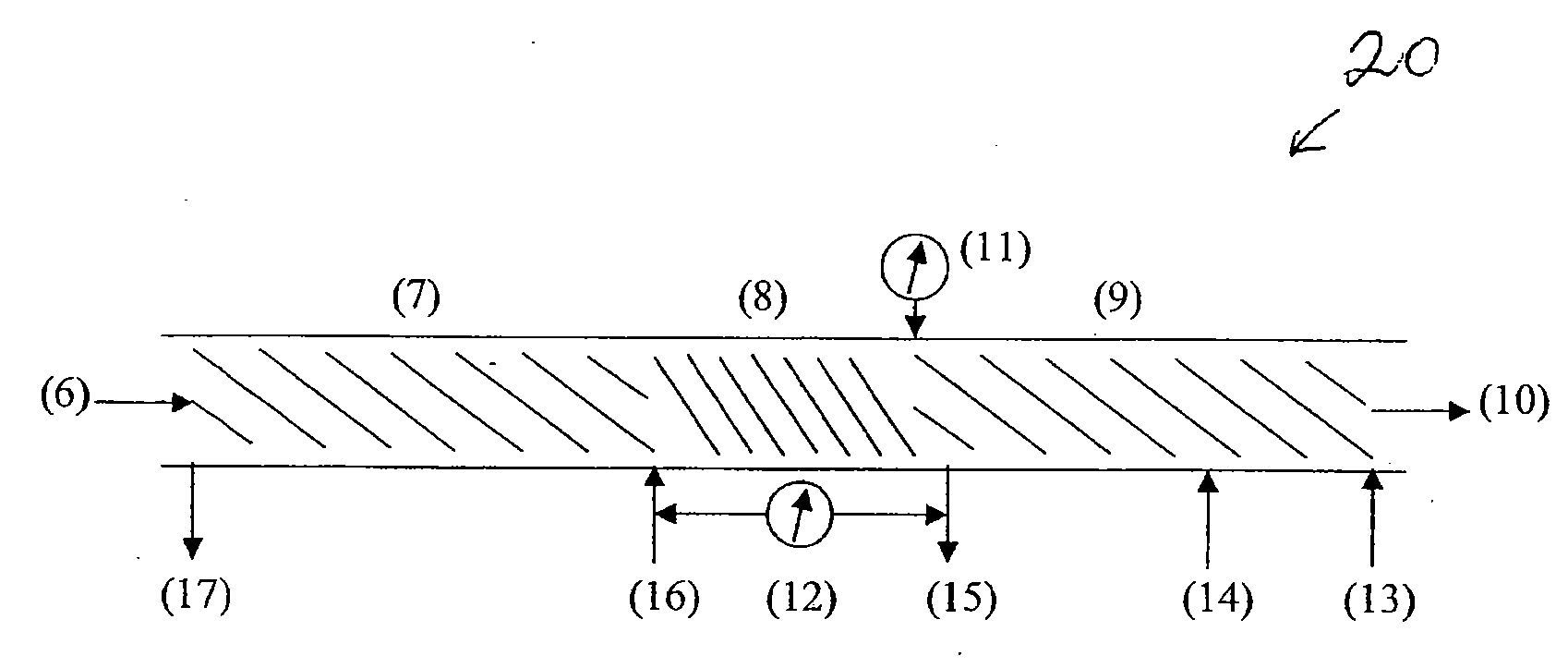

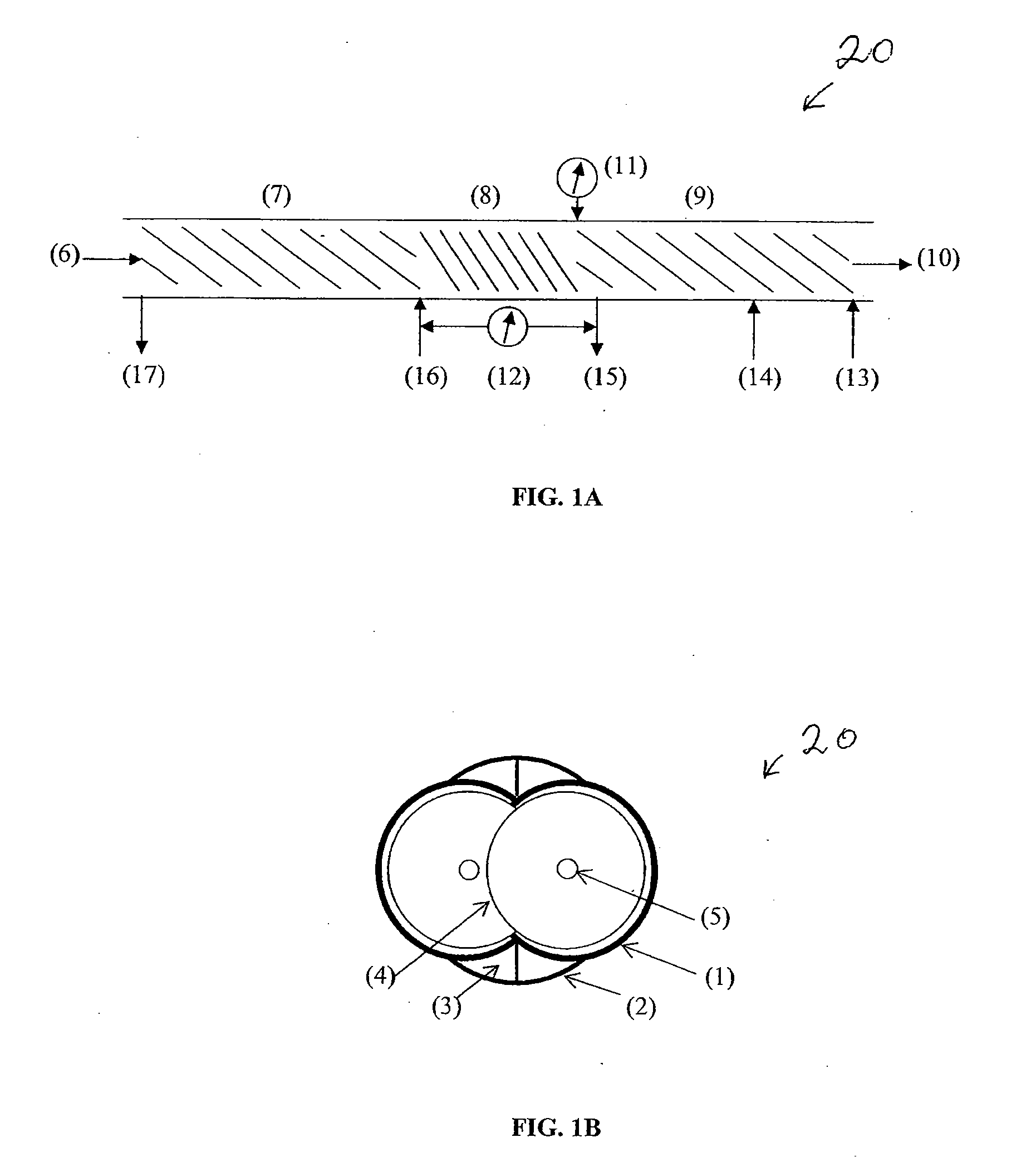

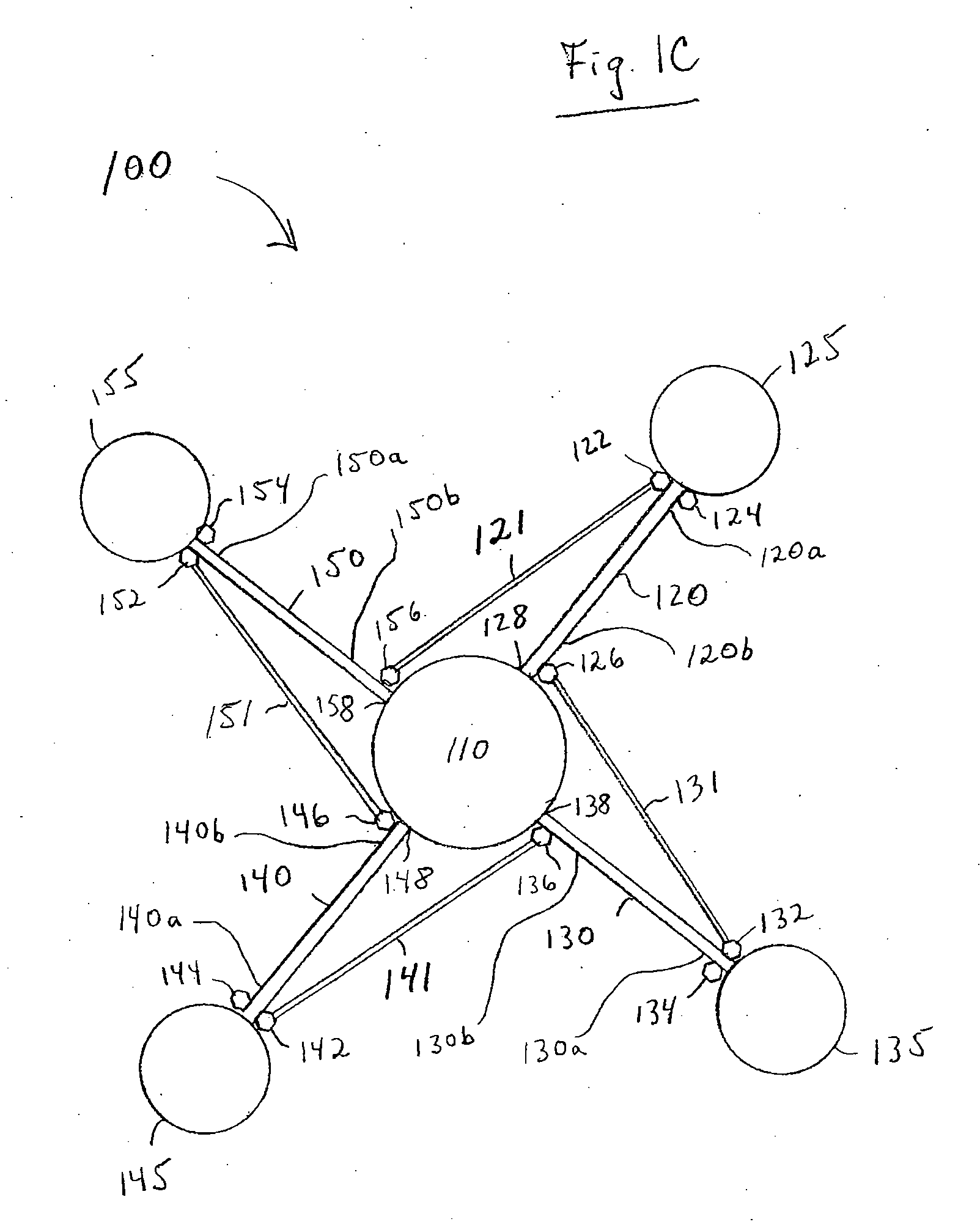

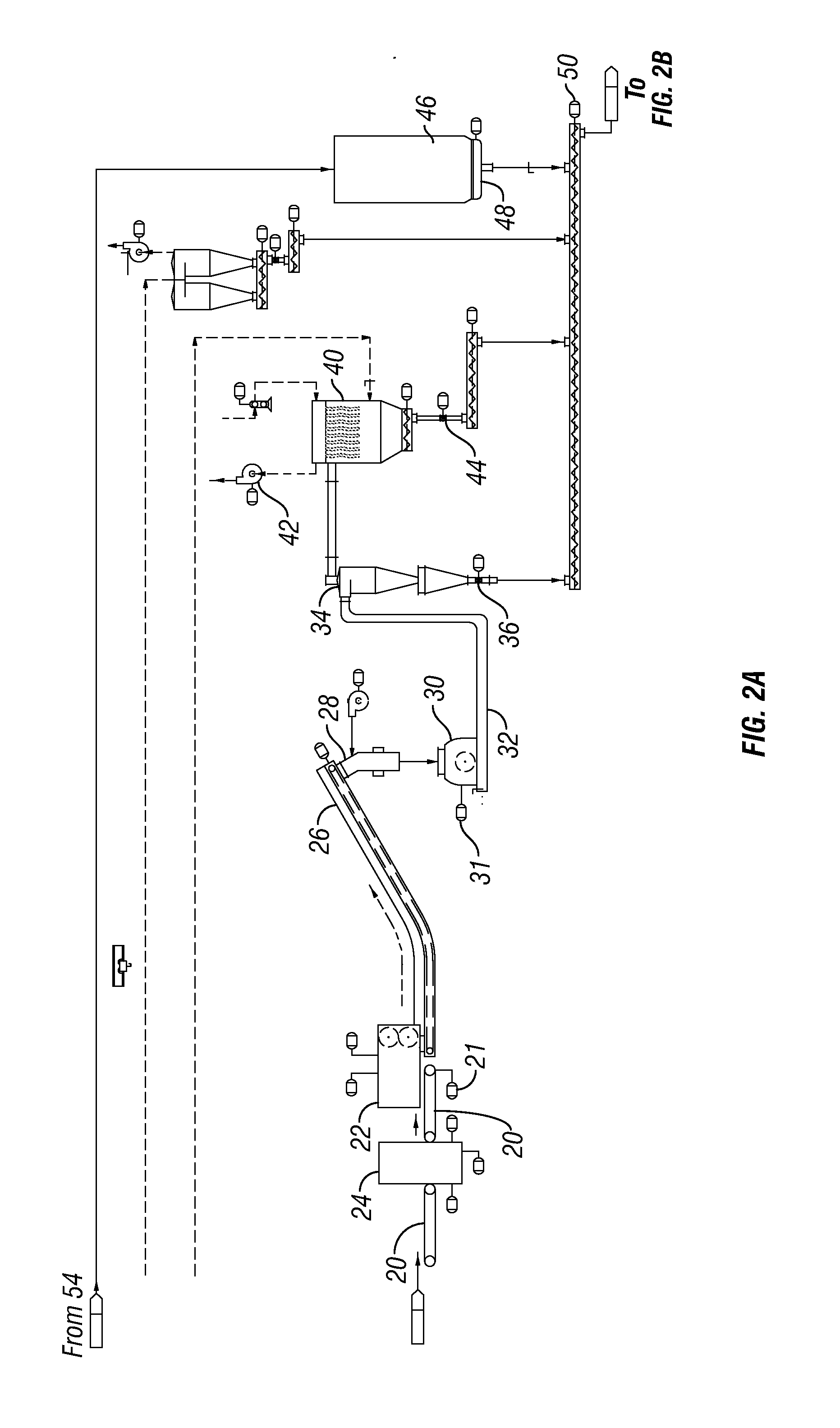

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

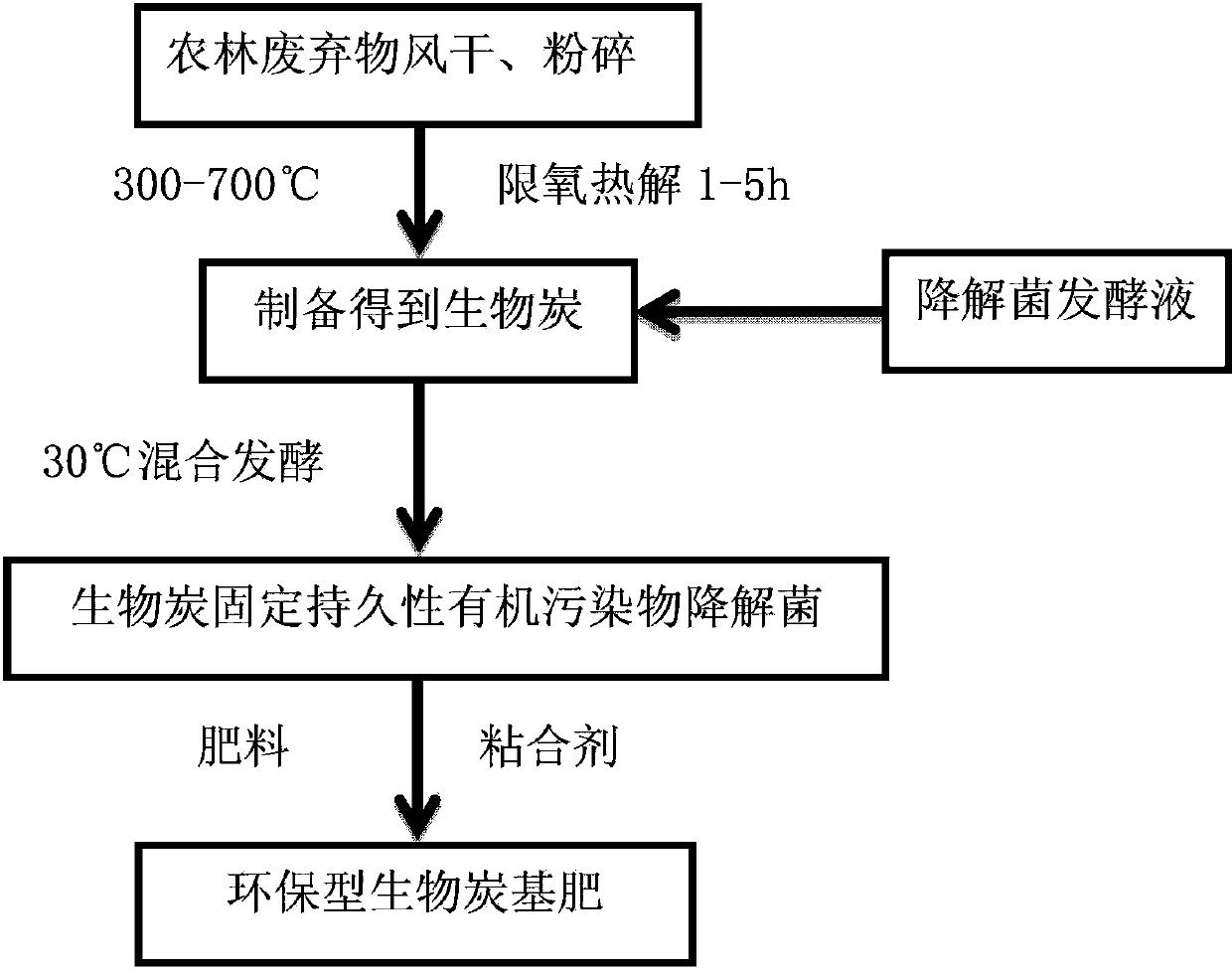

Environmentally friendly biochar-based fertilizer and application method thereof

ActiveCN103396171AGood sustained release effectHigh survival rate of live bacteriaFertilising methodsOrganic fertilisersPolycyclic aromatic hydrocarbonSurface layer

The invention discloses an environmentally friendly biochar-based fertilizer and an application method thereof. The preparation of the biochar-based fertilizer comprises the following steps of: drying and crushing forestry and agricultural residues, then performing oxygen limited pyrolysis on the crushed materials for 1-5 hours at 300 to 700 DEG C, and sieving, thereby obtaining biochar; and after the biochar is fixed with persistent organic pollutant degrading bacteria, mixing the biochar with a fertilizer, stirring the two thoroughly, and adding a binder accounting for 1wt%-4wt% of the total weight, thus obtaining the environmentally friendly biochar-based fertilizer. For application, the prepared environmentally friendly biochar-based fertilizer is applied to soil by 100-1000 kg per hectare; the surface layer of soil, to which the biochar-based fertilizer is applied previously, is turned over by 0-20 cm, so that the biochar-based fertilizer is mixed with the soil thoroughly, and then the soil can be used for planting crops. The environmentally friendly biochar-based fertilizer provided by the invention overcomes the shortcoming that present biochar-based fertilizers contain organic pollutants such as polycyclic aromatic hydrocarbon, the influence of the fertilizer on soil and environment is alleviated, and the safety risk of agricultural products is reduced; moreover, the environmentally friendly biochar-based fertilizer has the advantages of simple and practicable preparation process, low cost and the like.

Owner:上海孚祥生态环保科技股份有限公司

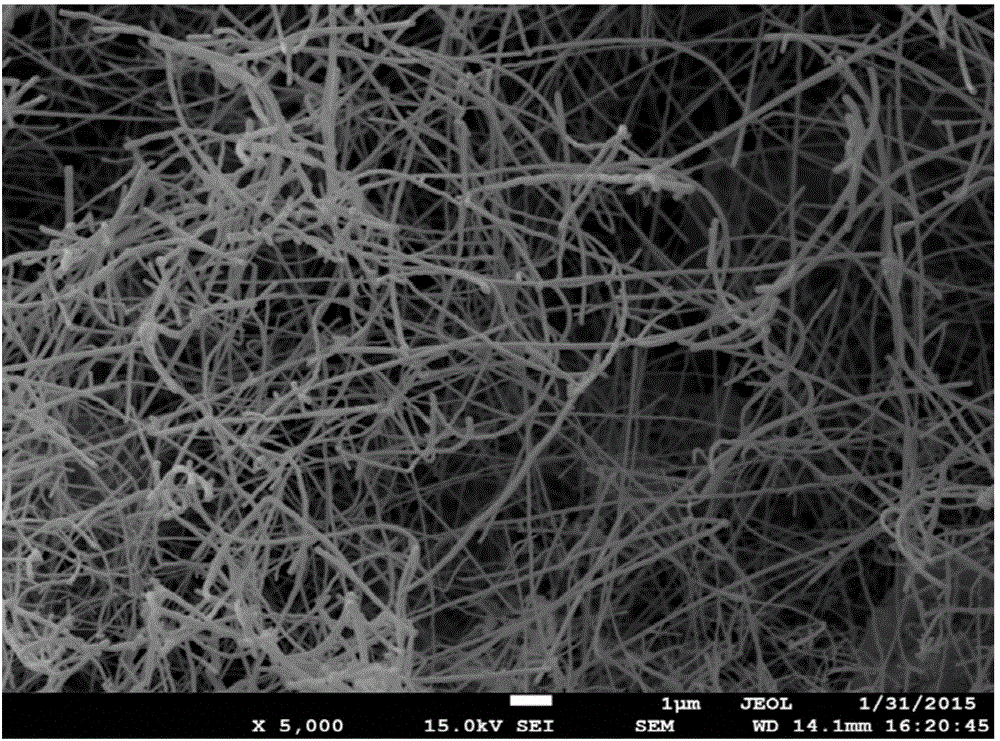

Preparation method of graphene and graphene

ActiveCN104386684ANo pollution in the processSolve the shortcomings of high cost and unfavorable large-scale industrializationMetal catalystAgricultural residue

The invention provides a preparation method of graphene. The method comprises the following steps: (A) pretreating biologic materials to obtain the pretreated biologic materials, wherein the biologic materials comprise one or several kinds of forestry and agricultural residues, tea leaves and seaweed plants; (B) mixing metal catalysts, solvents and the biologic materials pretreated in the step (A) to obtain the biologic materials loaded with the catalysts; (C) mixing pore forming agents and the biologic materials which are obtained in the step (B) and loaded with the catalysts, and heating for 0.5 to 10 hours under the temperature of 700-1200 DEG C to obtain the graphene. The preparation method for the graphene, provided by the invention, has no pollution to environment, the biologic materials are used as carbon sources, the cost of the raw materials of the carbon sources is low, and the raw materials are easy to obtain, so that the problems that the cost of existing carbon sources is high, and existing carbon sources are not beneficial to the large-scale industrialization are solved.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

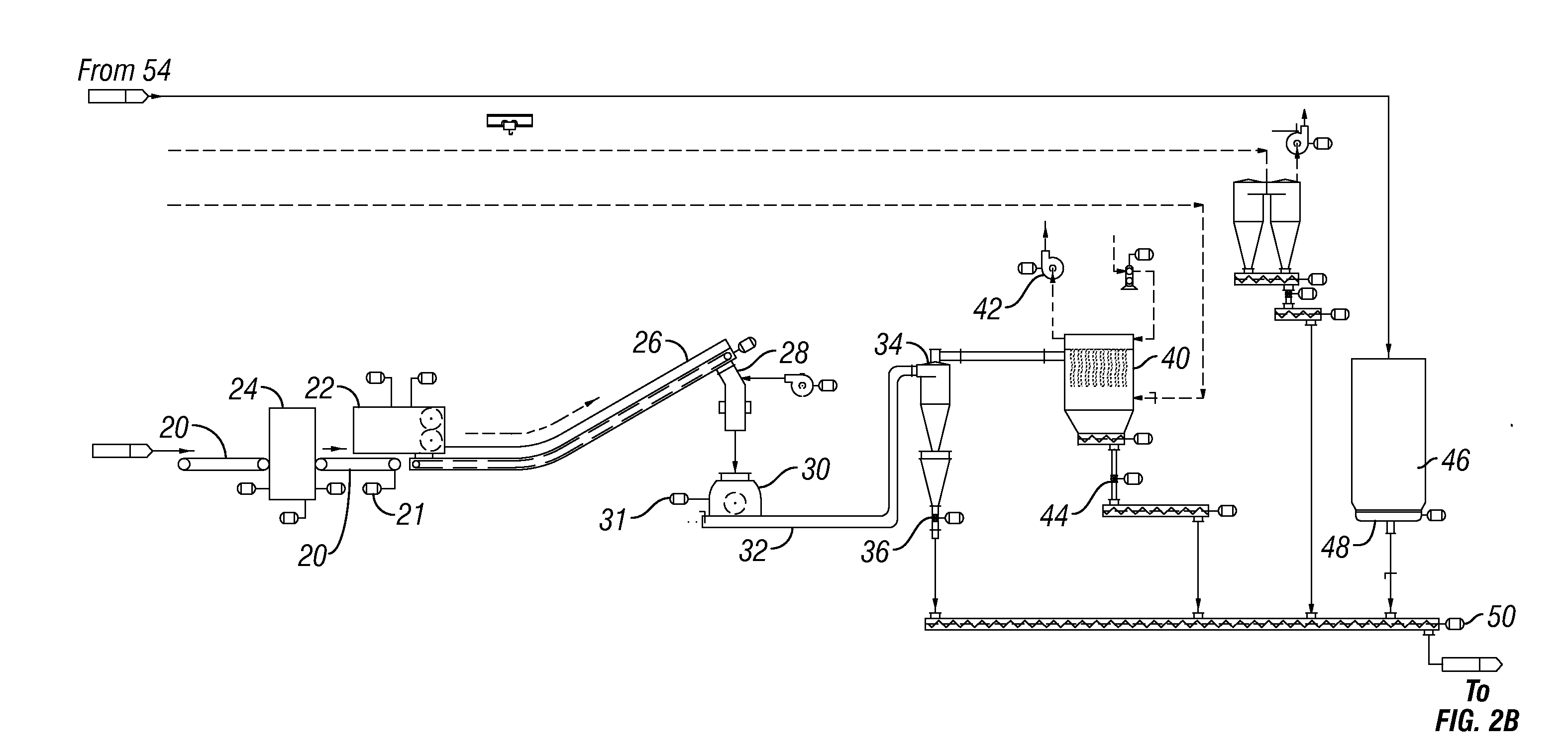

Biomass pelletizing process

ActiveUS20100281767A1Impact soil qualityImpact water useFuel feeding arrangementsSolid fuel pretreatmentAgricultural residueEngineering

A process is provided using non-food or limited-feed agricultural residue and energy crops for energy production, such as ethanol or electricity generation. The agricultural plant material is harvested and baled. The bales are transported to the processing site for storage or immediate processing. The bale strings are first removed, and then the broken bales are shredded. The shredded plant material is then ground to a small size. The ground material is then pelletized to produce densified pellets of the agricultural plant material. The pellets are cooled and then stored or transported to an end user.

Owner:PELLET TECH USA

Compression-type forest tree seed cultivating substrate

InactiveCN103130573ATake advantage ofImprove germination rateFertilizer mixturesAgricultural engineeringAgricultural residue

The invention discloses a compression-type forest tree seed cultivating substrate which is made into a compression block through blending the following raw materials in percentage by weight: 10-20% of sandy soil, 75-85% of decomposed forestry and agricultural residues and 0.1-5% of peach gum. The compression-type forest tree seed cultivating substrate is low in cost and capable of achieving the effects of sufficiently utilizing a great number of cheap forestry and agricultural residues, creating economic benefits and bringing environment benefits. A product produced by using the compression-type forest tree seed cultivating substrate can be supplied to nursery stock enterprises and forestation enterprises in batch for large-scale forest tree propagation, can also be sold on the market and cultivated in a household by an individual person to enjoy the pleasure; and meanwhile, the cultivated nursery stock can also be transplanted outdoors, so that the environment is indirectly protected. The compression-type forest tree seed cultivating substrate can be used for increasing the germination rate of tree seeds and plays a role in strengthening seedlings.

Owner:HEBEI ACAD OF FORESTRY SCI

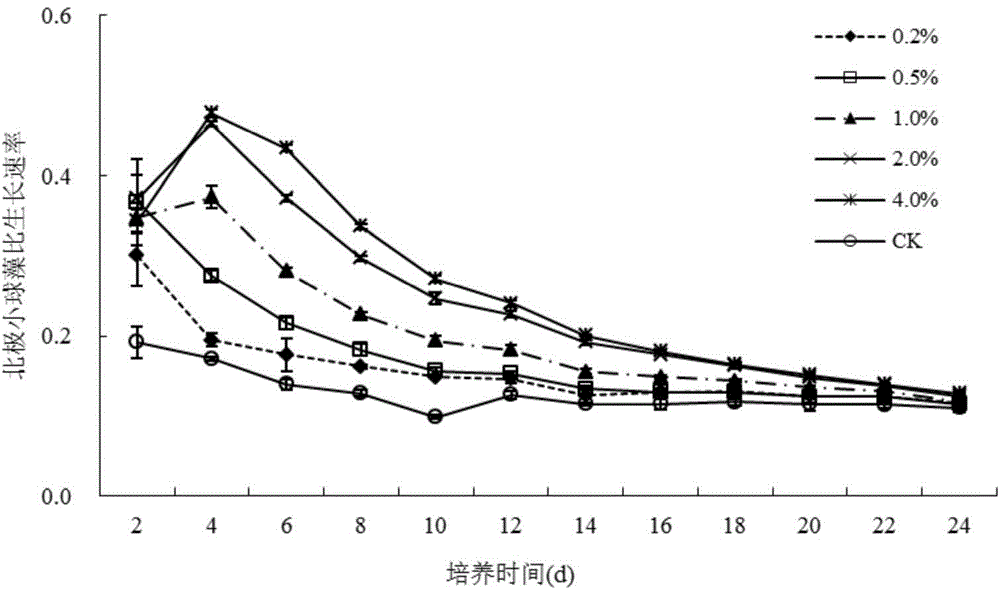

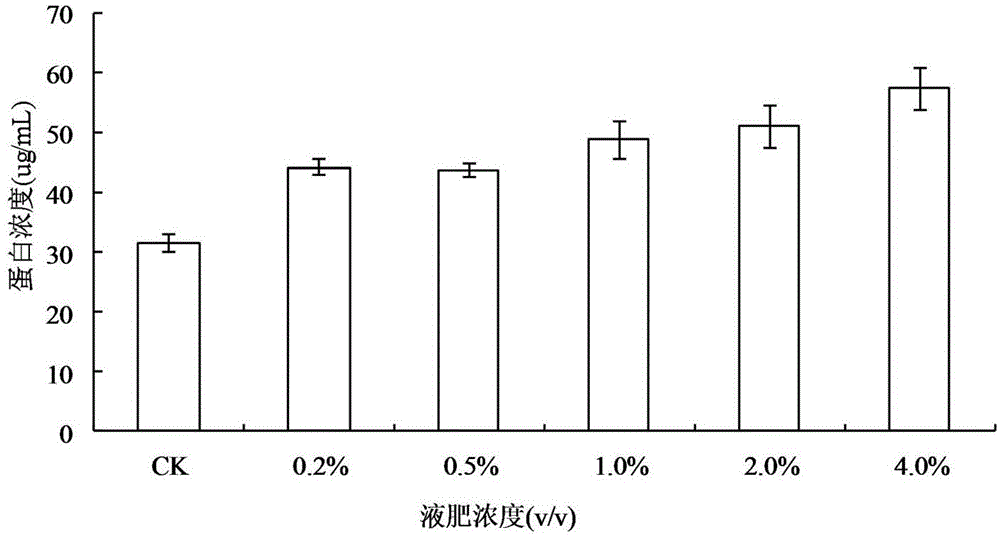

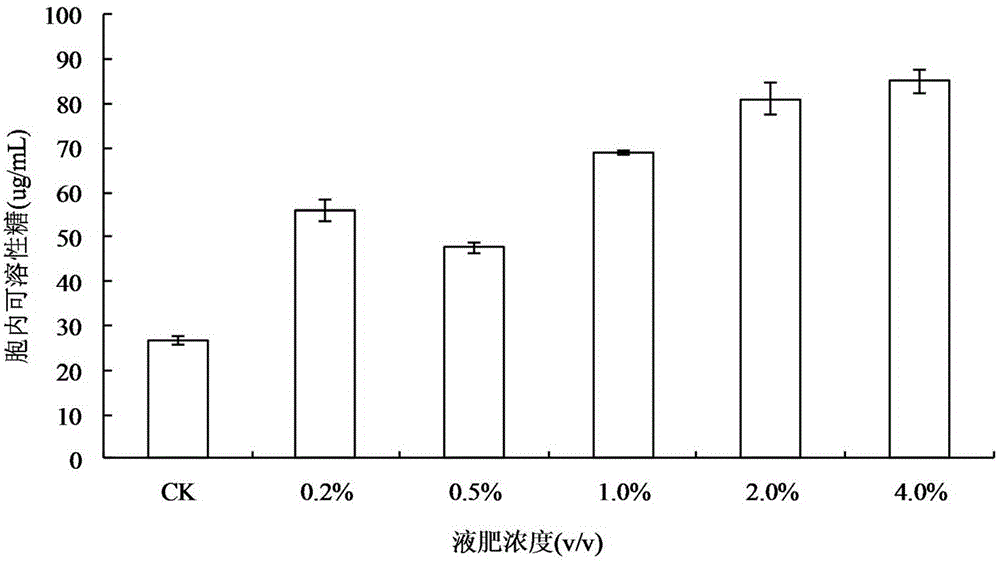

Method for producing organic seaweed fertilizer employing algae processing waste and prepared fertilizer

ActiveCN104387171ASimple and fast operationShort preparation cycleOrganic fertilisersAmmonium salt fertilisersHydrolysateAgricultural residue

The invention belongs to the fields of forestry and agricultural residue recycling and organic fertilizer production, and provides a method for producing an organic seaweed fertilizer employing an algae processing waste, and an organic seaweed fertilizer and an organic seaweed compound fertilizer prepared by the method. The method mainly comprises the following steps: crushing and evenly mixing the algae waste; decomposing an algae cell wall, polysaccharide and protein in an enzymolysis manner; carrying out solid-liquid separation on enzymatic hydrolysate, leaching enzymolysis algal residues to prepare extractum by adopting ethanol; mixing the enzymatic hydrolysate with the extractum to form an organic seaweed liquid fertilizer; mixing with a certain ratio of algae residue to form an organic seaweed granular fertilizer; and preparing the organic seaweed compound fertilizer after a proper amount of chemical fertilizer is added. The organic seaweed fertilizer is prepared by the wastes generated in macro-algae processing and micro-algae processing processes as the raw material, so that the operation is simple and convenient; the preparation cycle is short; a new idea for processing the wastes is provided for macro-algae or micro-algae processing enterprises; the environmental friendliness of enterprise production and processing is improved; and economic benefits of the enterprises are improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

Preparation method of carbon quantum dots

InactiveCN108083259ASimple preparation processEasy access to raw materialsNanotechnologyNano-carbonEnvironmental resistanceAgricultural residue

The invention provides a preparation method of carbon quantum dots and belongs to the technical field of preparation of nano luminescent materials. The preparation method comprises the following steps: weighing forestry and agricultural residues, kitchen garbage and mixture of one or more of vegetables, fruits, grains, flowers and Chinese herbal medicines in a ratio of parts by weight of 1:(1-100):(0.5-100) as raw materials; pulverizing the weighed raw materials, sieving the pulverized raw materials, performing uniform mixing, and adding organic acid or strong base or weak base to the treatedmixed liquid; and performing ultrasonic treatment, hydrothermal treatment and centrifugal treatment to obtain a solution, putting the obtained solution after centrifugal treatment into a dialysis bag,and putting the dialysis bag in a beaker filled with distilled water to be subjected to dialysis treatment so as to obtain the carbon quantum dots. The yield of the carbon quantum dots provided by the invention is 50-90%, and the sizes of the prepared carbon quantum dots are 1-2nm; and compared with the existing preparation method of the carbon quantum dots, the preparation method provided by theinvention has the advantages that the preparation process is simple, the raw materials are easy to obtain, and the preparation method is environmentally friendly and harmless.

Owner:史书亭

Method for producing charcoal fertilizer

InactiveCN103274778ASolve the problem of insufficient fertilizer efficiencyAbundant microporous structureEnergy inputResource utilizationAgricultural residue

The invention belongs to the field of resource utilization of biomass, particularly relates to a method for producing a charcoal fertilizer by using an activating agent on the basis of human and animal excreta and forestry and agricultural residues, and aims to enhance the cellular performance and fertilizer efficiency of the charcoal fertilizer through the activating agent and overcome the defects that the human and animal excreta is difficult to process and conventional charcoal has insufficient fertilizer efficiency. The method comprises the steps as follows: the human and animal excreta, ground forestry and agricultural by-products and the activating agent are mixed uniformly according to a certain proportion; moisture content of a material is reduced to 30% below by using solar energy, wind energy or bioenergy; a mixture is placed in a pyrolysis material bin and then heated to the temperature of 150-200 DEG C, so that further dehydration is performed, and residual air in the material bin is removed; the material is carbonized at the temperature of 450-550 DEG C; and cooling is performed, so that a charcoal fertilizer product can be obtained. According to the method, compared with a charcoal fertilizer which is prepared without addition of the activating agent, cellular structures are increased by more than 25%, and the total amount of phosphorus and potassium which can be used by plants is increased by more than 20%.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing bioethanol from a lignocellulosicbiomass and recycled paper sludge

A method producing ethanol by combining an plant fiber material containing calcium carbonate with at least one lignocellulosic agricultural residue into a mixture. The plant fiber material can be a paper sludge. The mixture is then hydrolyzed and the resultant hydrolysate is then fermented into ethanol.

Owner:AGBLEVOR FOSTER ARYI

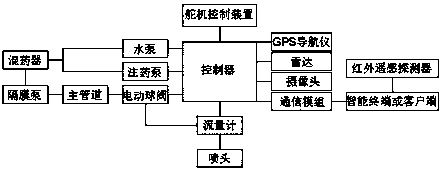

Agricultural chemical application monitoring and accurate flow rate control device and method

InactiveCN108605923APrecision medicineExpand the injection volumeControlling ratio of multiple fluid flowsFlow control using electric meansDiseaseInfrared remote sensing

The invention relates to an agricultural chemical application monitoring and accurate flow rate control device and method. The device comprises a chemical mixing device, a flow rate meter, a nozzle, acontroller and an infrared remote sensing detector, on-spot preparing and using of agricultural chemical is achieved by the chemical mixing device, the agricultural chemical is sprayed by passing through a primary pipeline to reach the nozzle, remote sensing images of a field are detected by the infrared remote sensing detector, and a corresponding application prescription map and an applicationstrategy are generated after data analysis processing is conducted; agricultural chemical spraying is controlled by the controller according to the application prescription map and the application strategy, the application concentration is adjusted by controlling a water pump and a chemical filling pump, application situation is monitored in real time according to signals transmitted by a camera,an ultrasound radar, the flow meter and a velocity sensor to adjust the application concentration and the flow rate, and therefore accurate application and flow rate control can be achieved. Accordingto the device, computation of the concentration and amount of the chemical can be conducted according to disease and pest situation of the field, feedback is conducted in real time, accurate application is conducted to improve the utilization rate of the agricultural chemical, and agricultural residue and waste caused by blindly application are prevented.

Owner:HENAN UNIV OF SCI & TECH

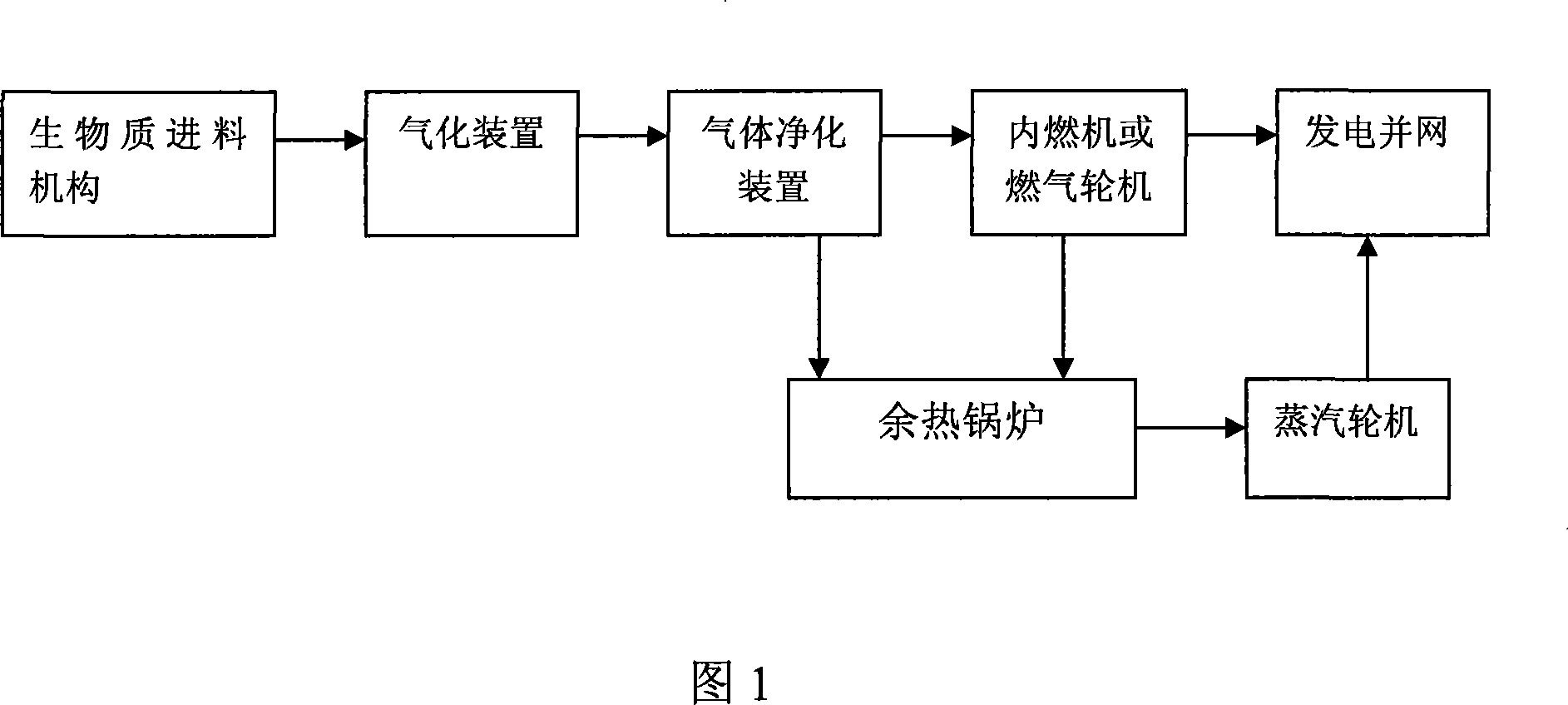

Power generation method using biomass

InactiveCN101158312AAdaptableStrong production intensityProductsInternal combustion piston enginesAgricultural residueInternal combustion engine

The invention relates to a method for generation by a biomass. The method utilizes the gasification technology, which converts the forestry and agricultural residues comprising wasted straws, sawdust, haulms, rice husks, bagasse, etc. into the flammable gas approaching the coal gas; after the dust and the tar of the flammable gas is removed by a purifier, the flammable gas is conveyed in a gas internal combustion engine or a gas turbine for generation. The invention has strong raw material adaptability, can dispose the biomass raw material of different types, and has the advantages of large production intensity, high gas heat value, little tar content, high gasification efficiency, strong load adaptability, easy start and stop, large adjustable range, stable operation, extremely high flexibility in scale. Furthermore, the generation scale depends on the quantity of the raw material and the requirement of the power, and can be designed and matched according to the requirement of the user.

Owner:WUHAN LIREN INVESTMENT

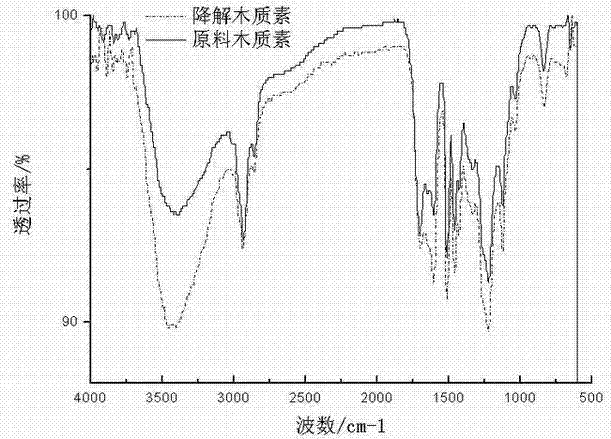

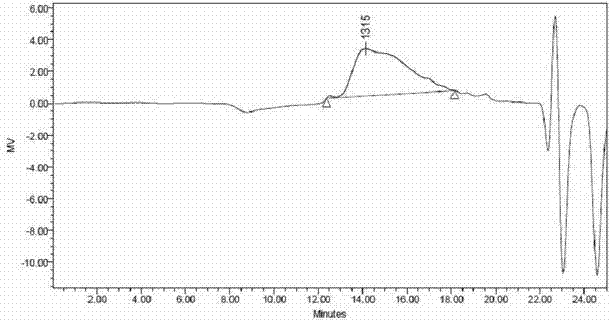

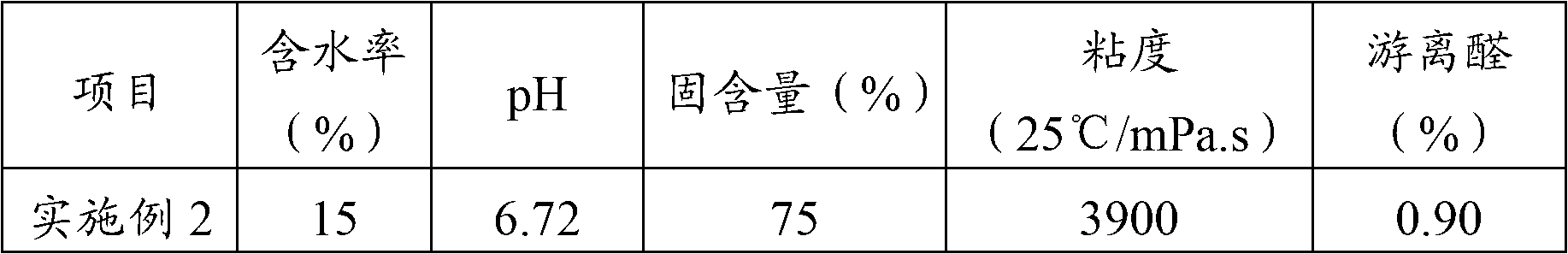

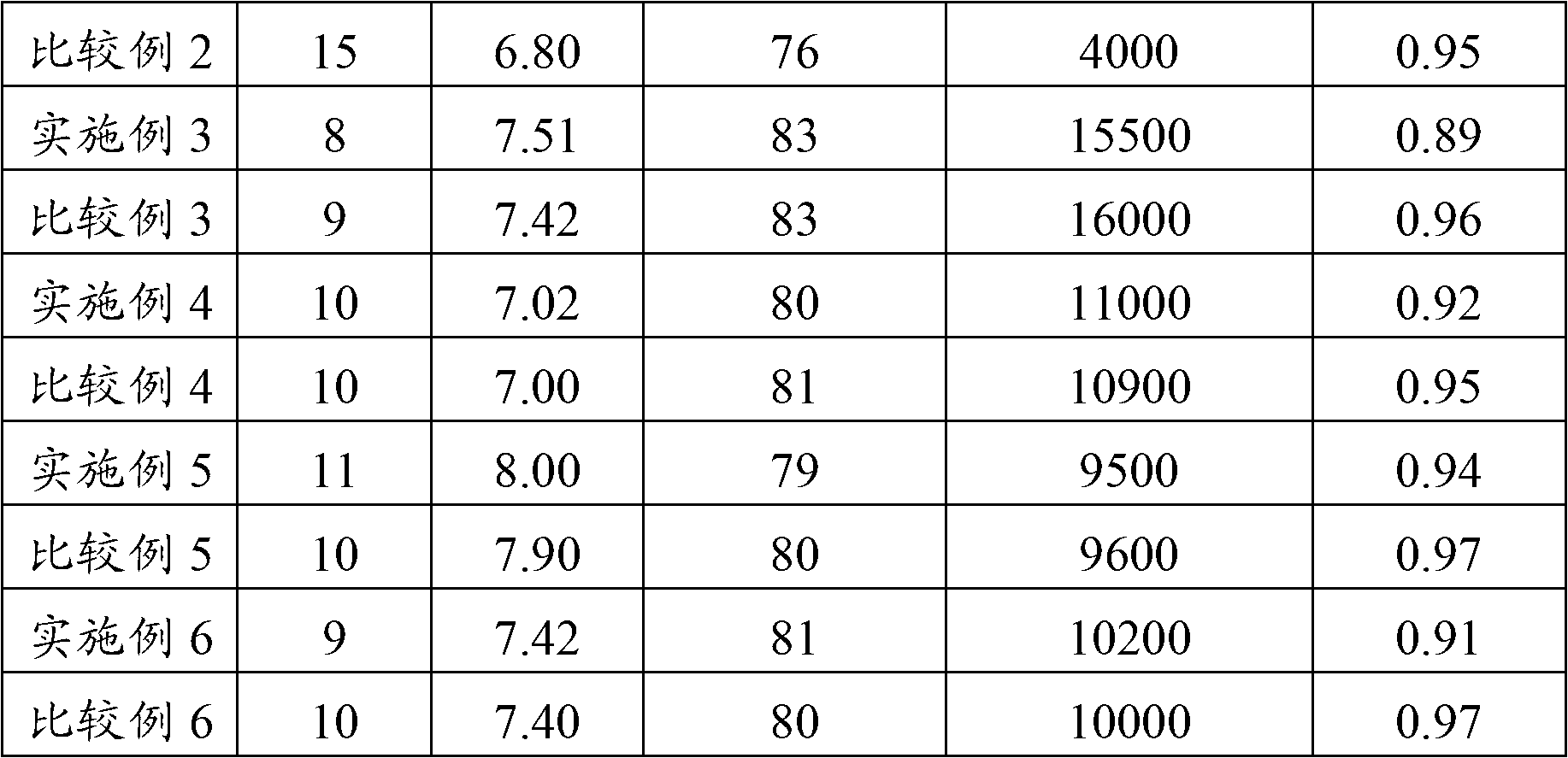

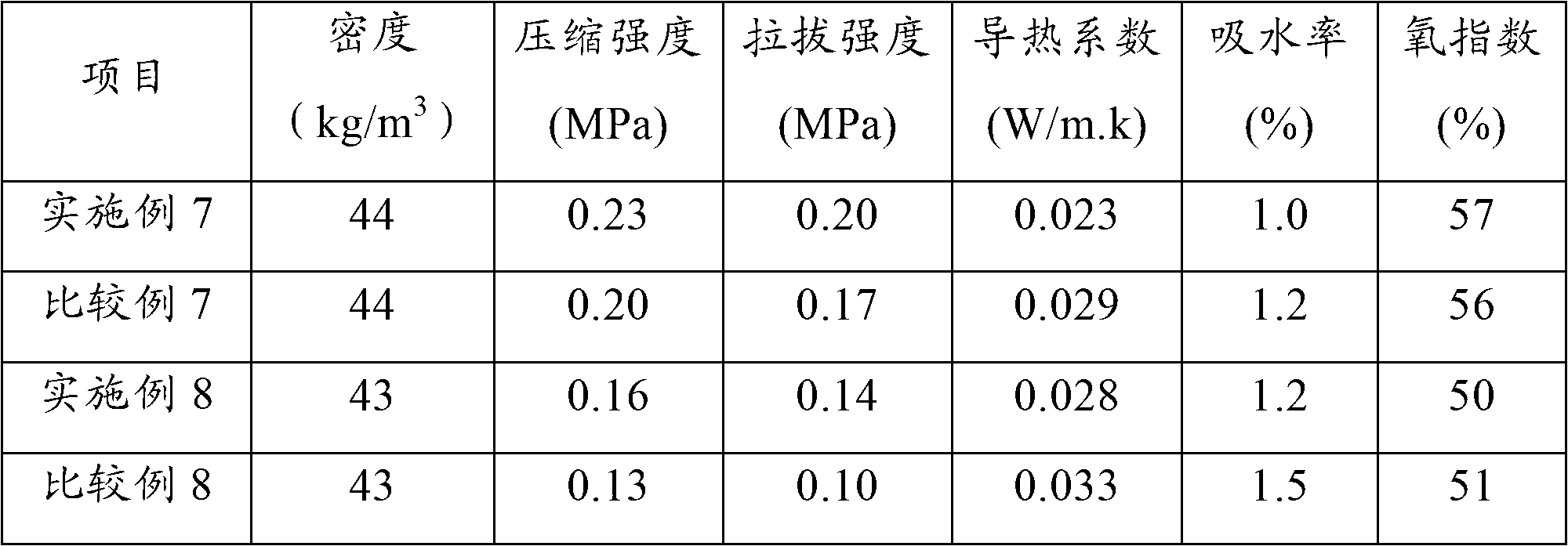

Lignin-modified phenolic foam and preparation method thereof

The invention relates to a preparation method of lignin modified phenolic foam, comprising the following steps: modifying high molecular weight lignin in order to degrade into low molecular weight lignin, wherein the activity is improved, replacing the phenol by the degraded lignin, preparing lignin modified resol, mixing with curing agent, foaming agent and surfactant, foaming at room temperature (25-30 DEG C) or in an oven of temperature 40-80 DEG C, finally the modified phenolic foam plastic is obtained after the curing process. The preparation method of the invention has the following advantages: the cost of the phenolic foam is greatly reduced, the toughness of the foam is increased and the brittles is decreased, thus the foam of the lignin modified phenolic foam has good market prospect; the preparation method of the invention provides a high-addition way to the abundant pulp paper-making waste liquid and forestry and agricultural residues, and reduces the dependency of phenolic foam industry on petrochemical raw material phenol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

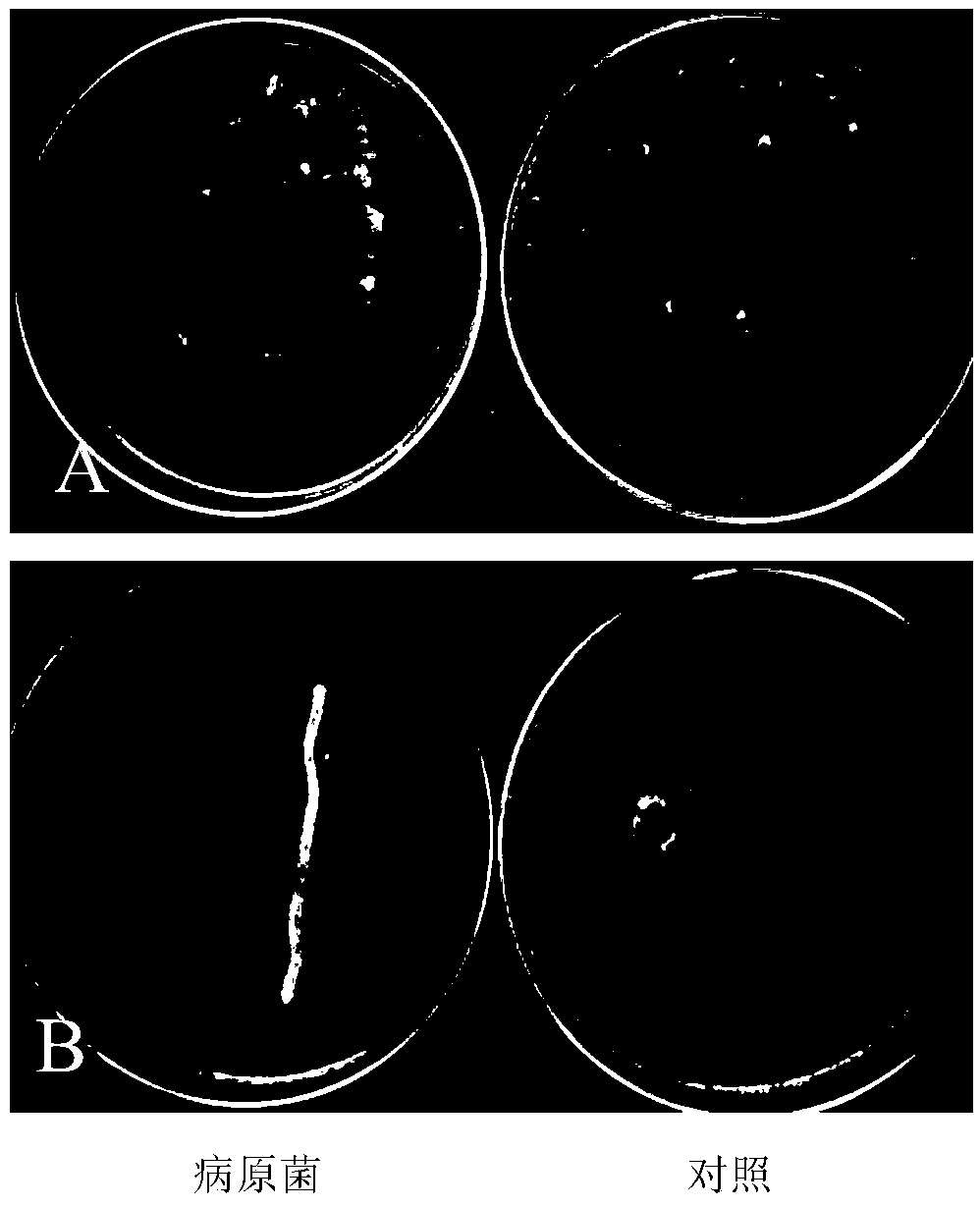

Bacillus siamensis strain for preventing and treating pear ring rot and soft rot and application thereof

InactiveCN105505834AGood control effectLow costBiocideFruit and vegetables preservationDiseaseAgricultural residue

The invention discloses a Bacillus siamensis strain for preventing and treating pear ring rot and soft rot and application thereof. The Bacillus siamensis strain is separated from peels of Laiyang pears with sterilized surfaces, the strain has broad-spectrum resistance for various types of phytopathogens and has a good effect on preventing and treating the pear fruit rot caused by pear ring rot and soft rot. The strain comes from pear fruits and is safe to pear fruits; the strain is produced on a large scale, is low in raw material cost, convenient to operate and stable in prevention and treatment effect, and can effectively solve the problems of agricultural residues and environment pollutions caused by pear fruit disease and insect pesticide prevention and treatment. The strain has huge application potential on the aspects of biological prevention and treatment of after-harvest diseases and insects of pears, and the excellent basic strain is provided for research and development of microbial pesticides.

Owner:北京市辐射中心

Fertilizer for fruit trees and production method of fertilizer

InactiveCN105254452ARich in nutrientsHigh in nutrientsBio-organic fraction processingOrganic fertiliser preparationSucroseNutrition

The invention discloses a fertilizer for fruit trees and a production method of the fertilizer. The fertilizer is prepared from raw materials in parts by weight: 35 to 45 parts of chicken manure, 30 to 40 parts of filter mud in sugar factory, 20 to 30 parts of agricultural residues powder, 20 to 25 parts of tea seed cake, 10 to 15 parts of rice husk powder, 10 to 20 parts of vinegar residue, 5 to 8 parts of fulvic acid potassium, 155 to 175 parts of urea, 125 to 135 parts of potassium sulfate, 55 to 65 parts of potassic-magnesian fertilizer, 85 to 90 parts of calcium superphosphate, 2 to 3 parts of ammonium molybdate, 10 to 15 parts of lignin, 6 to 8 parts of animo acid chelated copper and boron, 7 to 9 parts of sucrose complexed manganese and calcium, 3 to 5 parts of diaminoferric xanthohumate and 4 to 6 parts of zinc lignosulfonate. The fertilizer prepared by the production method disclosed by the invention is abundant in nutrition, can be used for meeting nutrient requirement of the fruit trees, improving growth speed of the fruit trees and improving the yield and the quality of the fruit trees, and is beneficial for promoting the growth of the fruit trees; in addition, by using the fertilizer, the properties of soil can be improved, and soil loosening is promoted; after the fertilizer is applied, a good control effect for diseases and insect pests of the fruit trees can be realized.

Owner:DAXIN PRODIVITY PROMOTING CENT

Method for preparing biological carbon with high nitrogen-phosphorus adsorption properties

ActiveCN103611497AFast adsorption rateHigh recovery rateOther chemical processesRare-earth elementAgricultural residue

The invention discloses a method for preparing biological carbon with high nitrogen-phosphorus adsorption properties. According to the method, forestry and agricultural residues are taken as raw materials to prepare the biological carbon with the high nitrogen-phosphorus adsorption property by carrying out high-temperature oxygen-deficient themolysis by utilizing the catalytic performance of light rare earth elements. The sources of the utilized raw materials are wide, the cost of a rare earth catalyst is low, and the prepared biological carbon is high in nitrogen-phosphorus adsorption speed and large in nitrogen-phosphorus adsorption capacity; the largest adsorbing capacities of NO3<->, NH4<+> and PO4<3-> can respectively reach 38.44mg / g, 15.58mg / g and 19.74mg / g. The method is simple in process operation, low in investment requirement and cost and high in product recovery rate and application value.

Owner:四川发展环境科学技术研究院有限公司

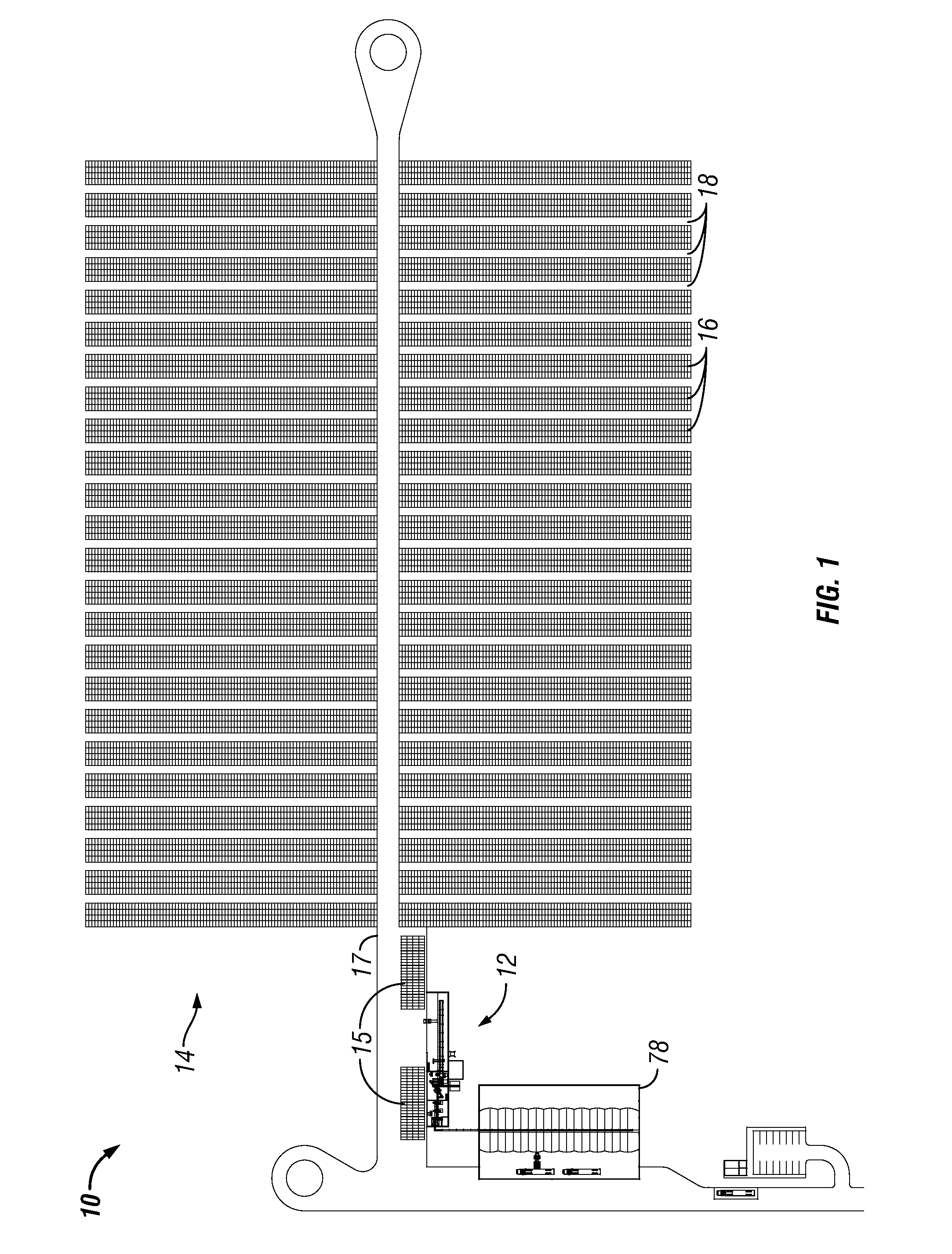

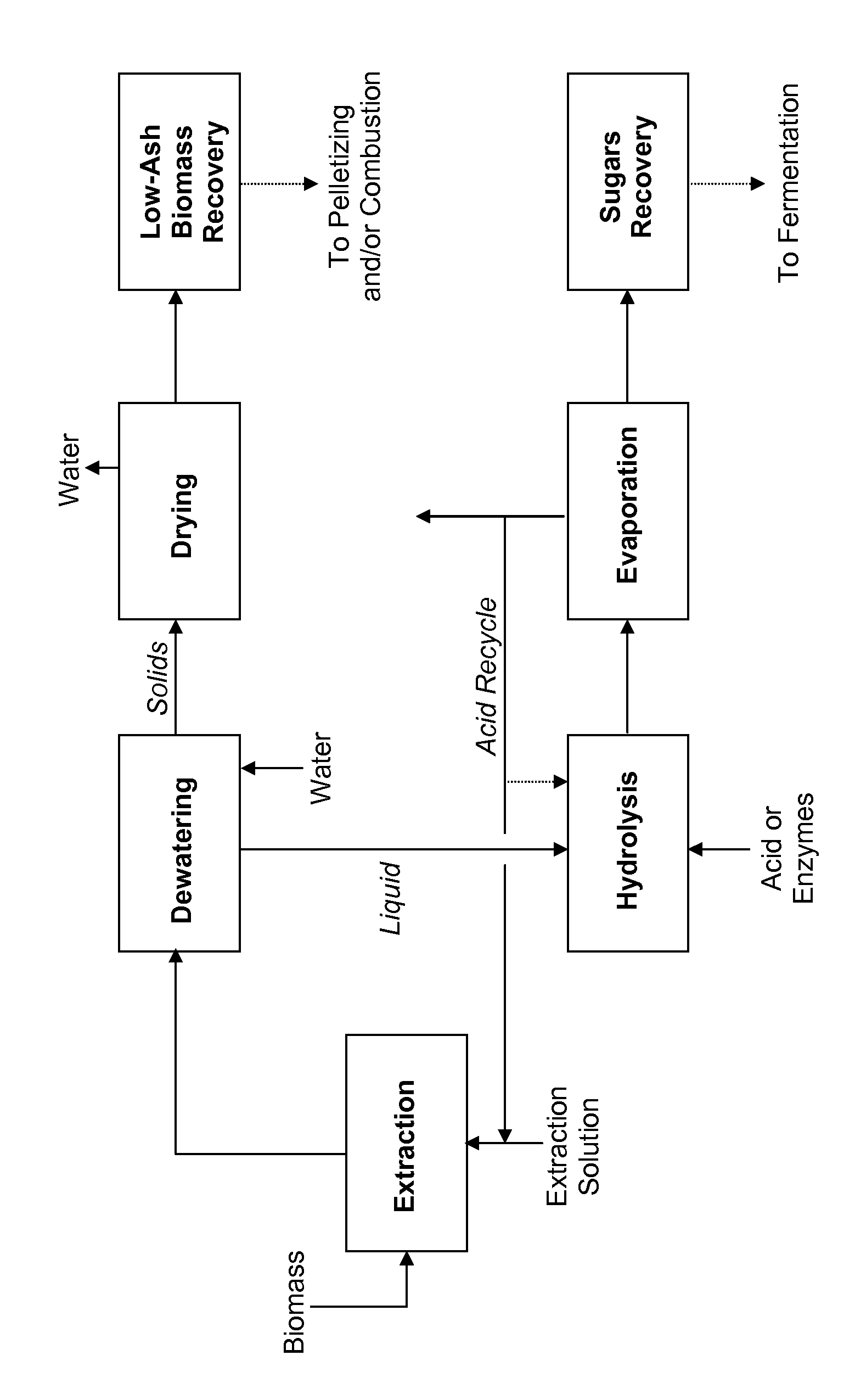

Processes for producing fermentable sugars and low-ash biomass for combustion or pellets

This invention provides processes and apparatus to convert biomass, including wood and agricultural residues, into low-ash biomass pellets for combustion, alone or in combination with another solid fuel. Some embodiments provide processes for producing hemicellulosic sugars and low-ash biomass from cellulosic biomass, comprising providing an aqueous extraction solution with acetic acid; extracting the feedstock to produce an extract liquor containing soluble ash, hemicellulosic oligomers, acetic acid, dissolved lignin, and cellulose-rich solids; dewatering and drying the cellulose-rich, lignin-rich solids to produce a low-ash biomass; hydrolyzing the hemicellulosic oligomers to produce fermentable hemicellulosic sugars, wherein additional acetic acid is generated; removing a vapor stream comprising vaporized acetic acid from the extract; recycling the vapor or its condensate to provide some starting acetic acid for the extraction solution; and recovering fermentable hemicellulosic sugars. The disclosed processes can produce clean power from biomass. Co-products include fermentation products such as ethanol, fertilizers, and lignin.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Isocyanate strengthened agricultural residue fiber/plastic composite material and its preparation method

This invention relates to a agricultural remainder / plastic composite enhanced by isocyanate. The weight percentage of its components is that agricultural remainder fabric material 10-60%, plastic 10-60%, couplant 0.3-10% which is percentage weighed by bone dry weight of agricultural remainder fabric material. It is complex made by the technology of wood based panel. Its preparation is that at first agricultural remainder fabric material is pretreated into paring, fiber or powder and dried with water content 0-25%, and then thermoplastic is classified and shattered into lamellar or granular; At last, two kinds of materials, together with 0.3-10% couplant, are mixed for pretreatment in ordinary temperature, then a mixed powder is made. Pavement and thermocompression are conducted at 130-223DEG C and 1-20MPa about 1-20min, then the plate is received by cutting-edge at ordinary temperature.

Owner:LANGFANG HUARI FURNITURE CO LTD

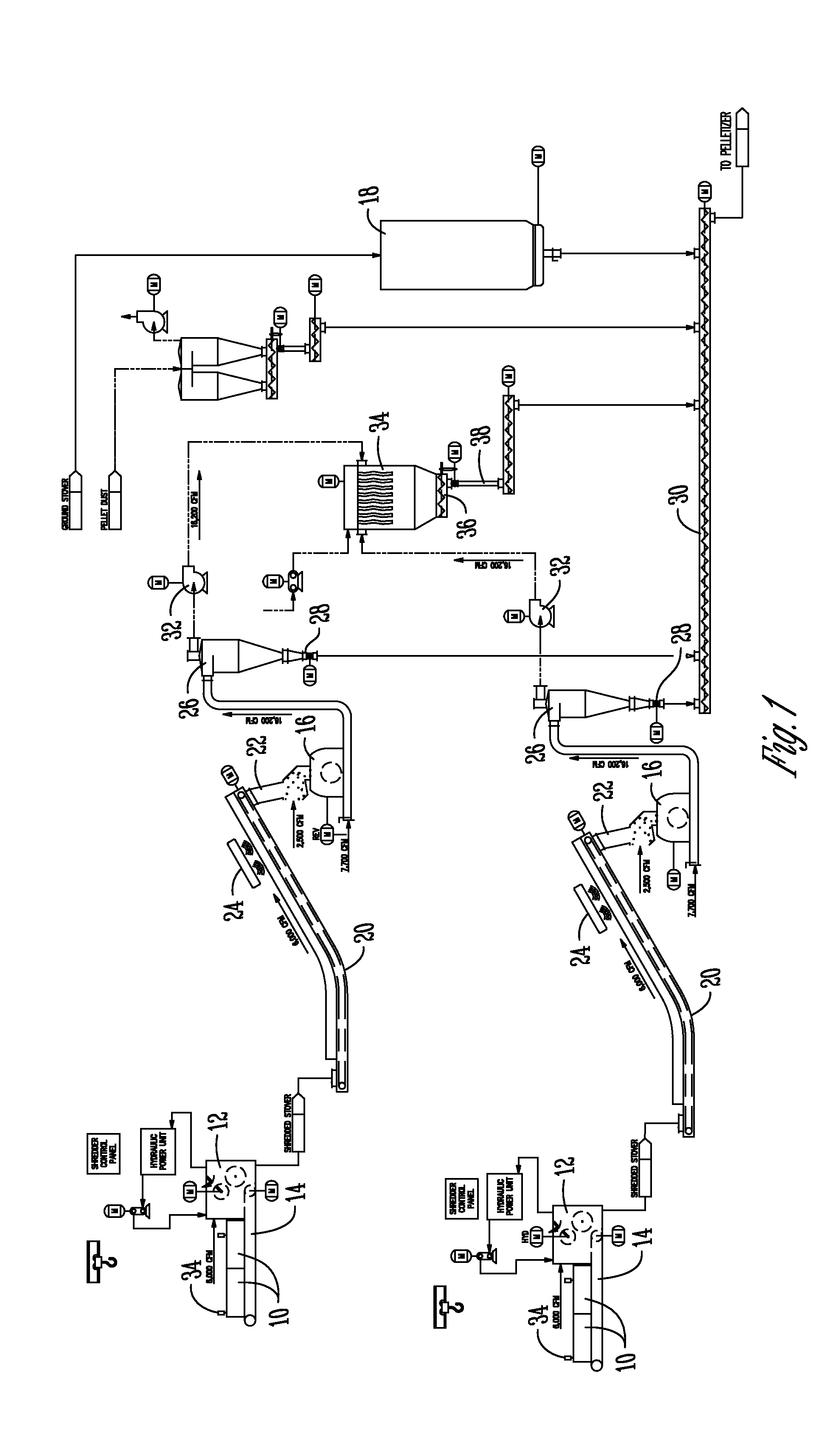

System for shredding and grinding biomass

InactiveUS20140014748A1Efficiently economically shred grindRapid and economic and sustainable developmentFuel feeding arrangementsSolid fuel pretreatmentAgricultural residuePulp and paper industry

A method and system for processing biomass material from harvest to pelletizing includes a continuous shredding stage and grinding stage to reduce the size of the material. A fan pulls air through the shredder and the grinder to assist the movement of the biomass material through the shredder and the grinder. Due to the light weight of the biomass material, the material is transported between the shredding and grinding stages mechanically and pneumatically by a combination auger with air assist. The biomass material may include agricultural residues, such as corn stover. The process and equipment eliminates or minimizes damage to the carbohydrates in the biomass so as to maintain pre-grinding cellulose and hemi-cellulose levels.

Owner:PELLET TECH USA

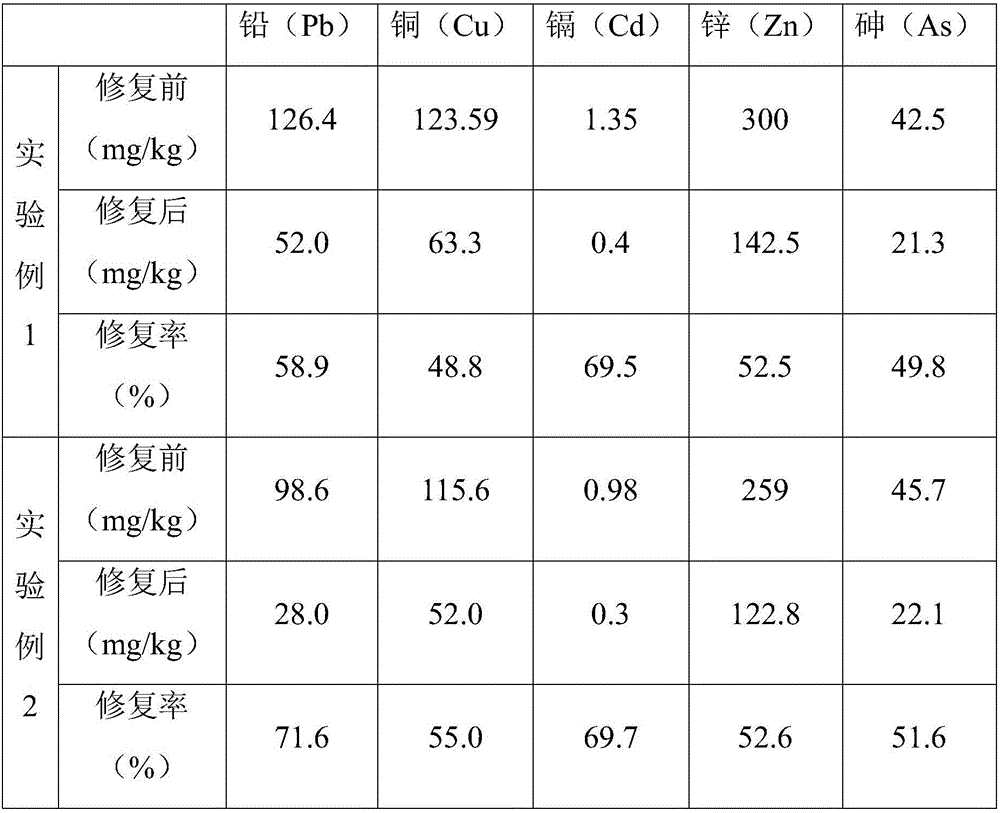

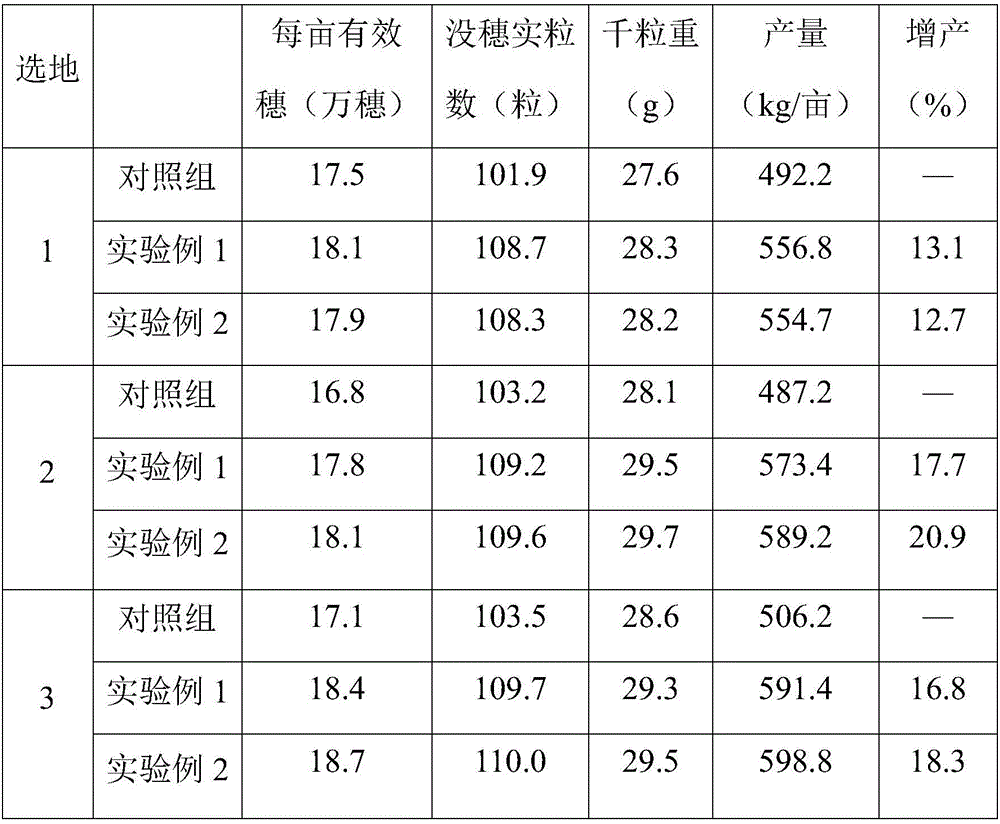

Ferric-carbon biologic particle and preparation method and application thereof

InactiveCN106268635ALarge specific surface areaModerate pHOther chemical processesContaminated soil reclamationGlutaric acidAgricultural residue

The invention discloses a ferric-carbon biologic particle and a preparation method and application thereof. The preparation method of the ferric-carbon biologic particle comprises the following steps: 1) drying, smashing, pyrolyzing, grinding, sieving and washing forestry and agricultural residues to obtain charcoal; 2) soaking the charcoal in a NaOH solution to perform surface activation treatment; 3) sequentially utilizing a polyethyleneimine / ethanol solution and a glutaric acid solution to treat the charcoal with the surface activated to obtain a charcoal particle with amino grafted on the surface, 4) dispersing a soluble molysite solution or a ferrite solution into absolute ethyl alcohol, adding the charcoal particle and a NaBH4 solution, loading nanometer zero-valent iron generated in reaction on the charcoal particle to obtain the ferric-carbon biologic particle. The ferric-carbon biologic particle is good in dispersibility, high in load rate of the nanometer zero-valent iron, good in soil remediation effect, stable in effect, simple in preparation technology, low in energy consumption, low in cost, economical, practical and suitable for being widely used as a remediation material of soil which is polluted by heavy metal.

Owner:广州市金龙峰环保设备工程股份有限公司

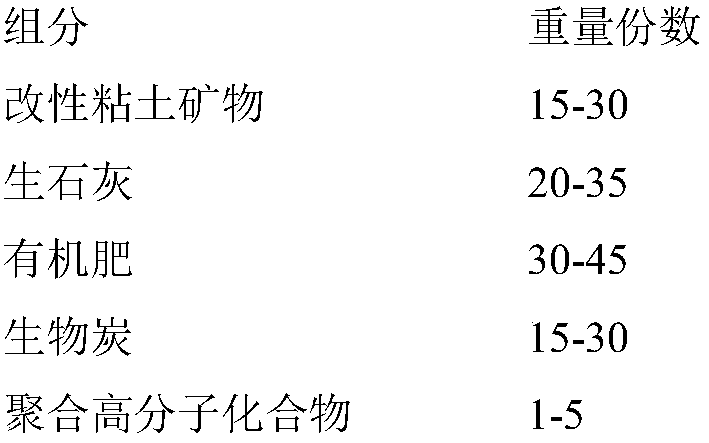

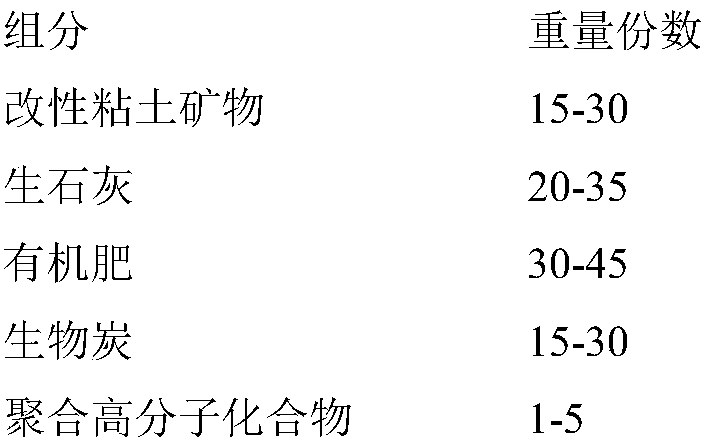

Cadmium contaminated mine soil remediation agent as well as preparation and application method thereof

InactiveCN108889773ALarge specific surface areaImprove adsorption capacityAgriculture tools and machinesContaminated soil reclamationClay mineralsFeces

The invention provides a cadmium contaminated mine soil remediation agent as well as preparation and application methods thereof. The remediation agent contains the following components in parts by weight: 15-30 parts of modified clay minerals, 20-35 parts of quick lime, 30-45 parts of organic fertilizers, 15-30 parts of charcoal and 1-5 parts of polymerized high molecular compounds. The preparation method of the remediation agent comprises the following steps: grinding and crushing clay minerals to 100 meshes, calcining at a high temperature, cooling, and grinding into granules or powder; taking forestry and agricultural residues as main raw materials, adding feces of livestock and poultry, externally inoculating a source inoculant, and fermenting by 5-15 days; taking crop straws as raw materials, performing high temperature pyrolysis, cooling to the room temperature, grinding, and passing through a 100-mesh sieve; and finally, uniformly mixing the modified clay minerals, quick lime,organic fertilizers, charcoal and polymerized high molecular compounds according to a certain ratio. The cadmium contaminated mine soil remediation agent is applied at a dose of 1-2 tonnages per mu, can achieve effects of effectively reducing the available cadmium in mine soil, regulating the pH value and ensuring normal growth of mine vegetation, and has great significance for restoring the minevegetation.

Owner:SHENZHEN WENKE GARDENING IND

Rice-husk-based porous silicon carbide ceramic material and preparing method thereof

The invention discloses a rice-husk-based porous silicon carbide ceramic material and a preparing method thereof. The rice-husk-based porous silicon carbide ceramic material is mainly prepared from rice husks and a mixture, and mass of the mixture is 30%-70% of that of the rice husks; the mixture is prepared from, by mass, 1%-30% silicon powder, 5%-40% carbon source, 1%-15% catalyst and 30%-70% binding agent. Agricultural residue rice husk serves as the main raw material of the rice-husk-based porous silicon carbide ceramic material, and is mixed with silicon powder, carbon source, catalyst and binder to prepare a semi-finished product after formation, drying and calcination; the source of the raw material which are used has wide source and low cost, the prepared product has the advantages of high porosity, big mechanical strength, good filtering effect, excellent thermal shock resistance, micro and fine hole diameter of pore, adjustable micro-morphology and the like, has wide development space and application prospect, and is suitable for industrial popularization and application.

Owner:马琰珂

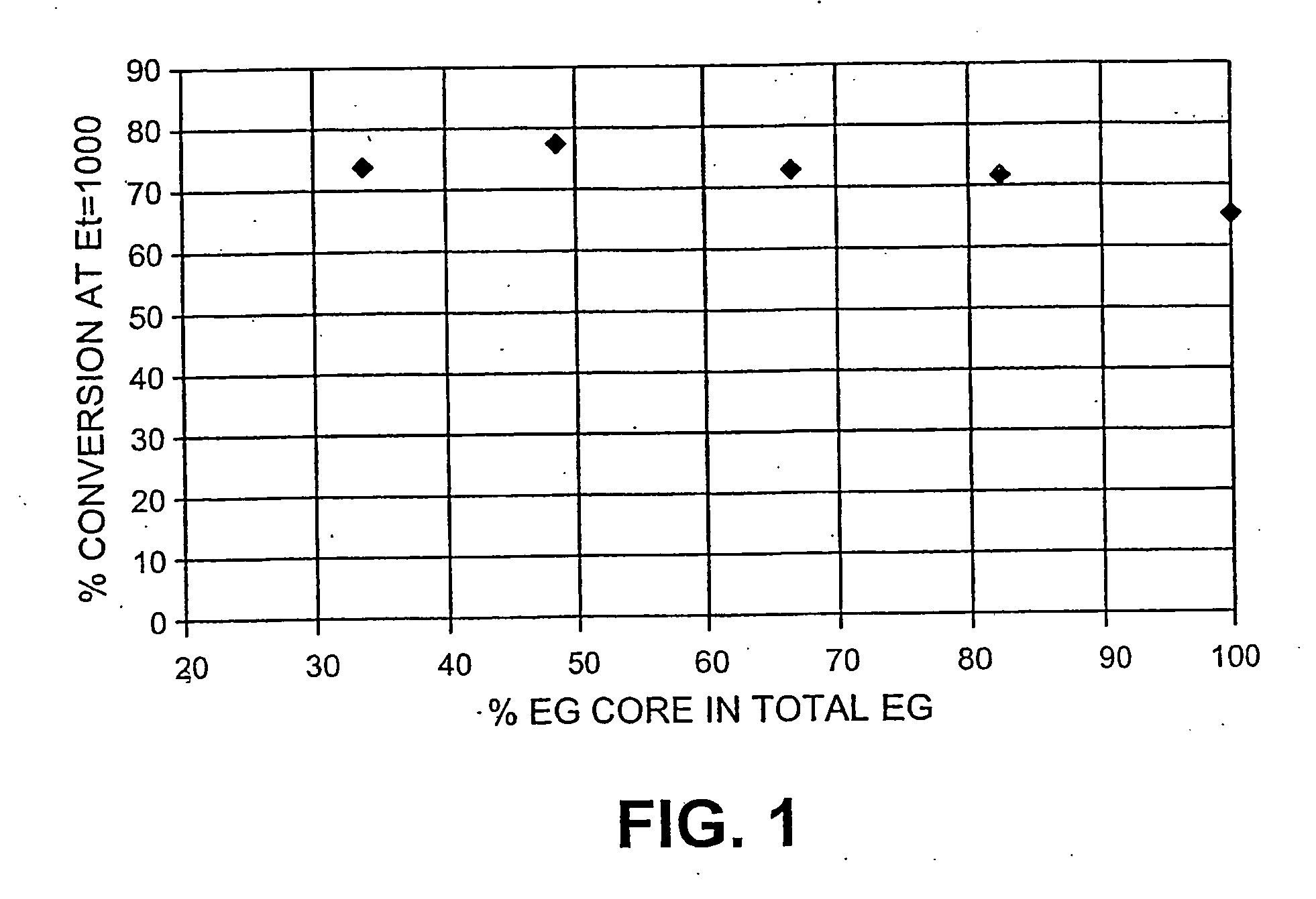

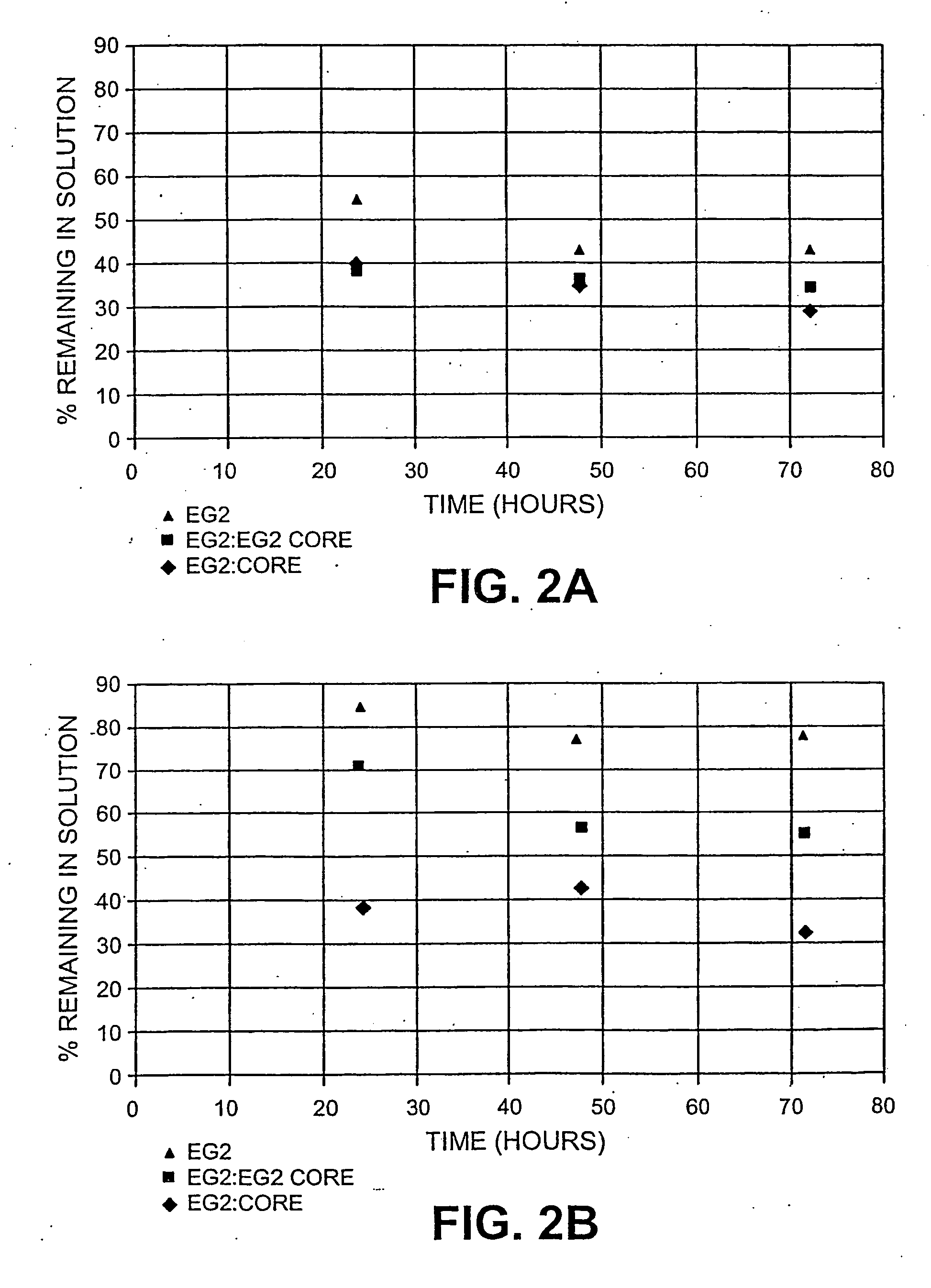

Method for glucose production using endoglucanase core protein for improved recovery and reuse of enzyme

The present invention pertains to a method of converting cellulose to glucose by treating a pretreated lignocellulosic substrate with an enzyme mixture comprising cellulase enzyme and endoglucanase core proteins, wherein the endoglucanase core proteins are present in the enzyme mixture at an amount relative to all endoglucanases from about 35 wt. % to about 100 wt. % and wherein the endoglucanase cellulase enzymes are present in the enzyme mixture at an amount relative to the amount of CBH and EG enzymes from about 2 wt. % to about 50 wt. %. The pretreated lignocellulosic substrate is selected from the group consisting of agricultural residues, residues after starch or sugar removal, dedicated ethanol crops, forestry products, and pulp and paper products, or combinations thereof.

Owner:IOGEN ENERGY CORP

Preparation method of seaweed organic fertilizer and organic fertilizer prepared by using method

ActiveCN104261981AReduce pollutionReduce manufacturing costBio-organic fraction processingMagnesium fertilisersChemical industryAgricultural residue

The invention belongs to the fields of forestry and agricultural residues recycling and organic fertilizer production, and provides a preparation method of a seaweed organic fertilizer, a seaweed organic composite mixed fertilizer and a seaweed organic liquid fertilizer, and three fertilizers. The preparation method of the seaweed organic fertilizer comprises the following steps: (1) processing ingredients; (2) carrying out aerobic and anaerobic mixed fermentation; (3) screening and crushing an organic seaweed fertilizer; and (4) pelleting. The composite mixed fertilizer and the organic liquid fertilizer are improved on the basis of the method. Seaweed slag, a microalgae culture medium and microalgae slag in the chemical industry production are taken as raw materials; composting fermentation is carried out on the raw materials and activated sludge; waste is changed into treasures; pollution to the environment is reduced; the production cost is low; no hazardous substance is generated in fermentation preparation; water resources are saved; and no secondary pollution is generated. The seaweed contains a lot of natural active ingredients such as cytokinin and phytohormone; and the fertilizer produced from the raw materials can promote the growth of plants, enhances the ability of resisting adverse environments, and can improve the fertilizer-conserving and water-holding capacities of the soil after being used for a long period of time.

Owner:NANJING AGRICULTURAL UNIVERSITY

Biodegradable composite, product made therefrom, and method of manufacture thereof

Biodegradable composites and products, and methods of their manufacture are presented. The composites typically comprise 10 wt % to 80 wt % of a lignocellulosic material derived from an agricultural residue or obtained from a natural source, 20 wt % to 80 wt % of a polymer binder, 5 wt % to 20 wt % of a compatibilizer, and an effective amount of a processing aid. One method of manufacture of a product is by injection molding.

Owner:CITY UNIVERSITY OF HONG KONG

Preparation method of lignin-phenol-formaldehyde resin and preparation method of lignin-phenol-formaldehyde resin foam

The invention provides a preparation method of lignin-phenol-formaldehyde resin and a preparation method of lignin-phenol-formaldehyde resin foam. The preparation method of the lignin-phenol-formaldehyde resin comprises the following steps: mixing and reacting lignin and a phenolic compound with a nucleophilic reagent to obtain a lignin phenol compound; adjusting the pH (Potential of Hydrogen) of the lignin phenol compound to reach alkalinity; then mixing and reacting the lignin phenol compound with formaldehyde, so as to obtain the lignin-phenol-formaldehyde resin. The preparation method of the lignin-phenol-formaldehyde resin foam comprises the following steps: mixing the obtained lignin-phenol-formaldehyde resin with a foaming agent, a curing agent and a surface active agent; and foaming and curing to obtain the lignin-phenol-formaldehyde resin foam. According to the preparation methods, the phenol compound serves as a solvent, and the ether bonds in the Alpha-aryl ether, Alpha-alkyl ether, phenol type Beta-aryl ether, non-phenol type Beta-aryl ether containing Alpha-alcoholic hydroxyl, and methyl aryl ether in the lignin are broken, so that lignin macromolecule can be degraded well, and as a result, the activity of the lignin and the strength of the lignin-phenol-formaldehyde resin foam are improved. By adopting the preparation methods, the existing forestry and agricultural residues which have no economic value and bring pollution to the environment are used as the environment-friendly new bio-based polymer materials, and remarkable economic benefits, social benefits and eco-environment benefits are brought thereby.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

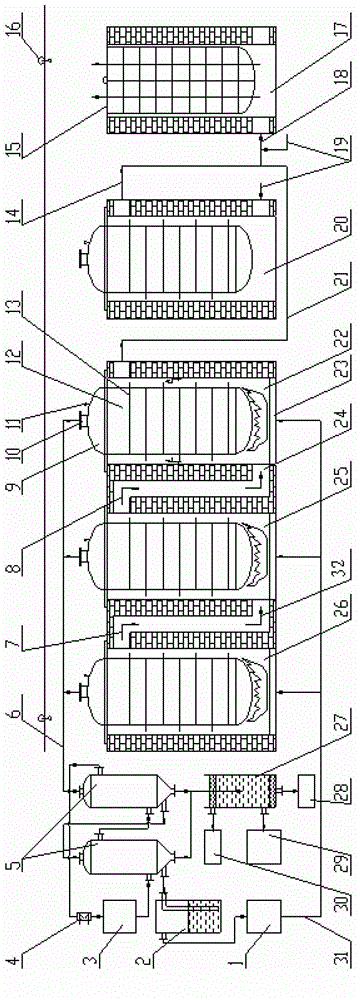

Carbonizing system and carbonizing process of wood materials

ActiveCN102911683AQuality improvementIncrease the heat exchange areaBiofuelsEnergy inputCooling chamberAgricultural residue

The invention discloses a carbonizing system of wood materials. The carbonizing system of wood materials comprises a carbonizing device and a by-product recovery device, wherein the carbonizing device comprises a reaction vessel and a reaction chamber for putting the reaction vessel; the reaction vessel comprises a material shelf and a destructive distillation kettle for putting the material shelf; the destructive distillation kettle is composed of a destructive distillation kettle body and a destructive distillation kettle cover; an exhaust hole and a temperature measuring hole are arranged on the destructive distillation kettle cover; the reaction chamber comprises a calcining chamber with a combustion area, a carbonizing chamber, a pre-heating chamber which are sequentially arranged, a drying chamber and a cooling chamber for pre-treatment and post-treatment of wood materials respectively. The pre-heating chamber, the carbonizing chamber and / or the exhaust hole on the destructive distillation kettle cover in the calcining chamber are connected with the by-product recovery device. The system is suitable for carbonizing production of all wood materials such as tree wood, hard weed tree, bamboo material, forestry and agricultural residues (straw, shell, sawdust and on the like). The invention is scientific and rational in process, none in emission and pollution, short in production period and low in cost, thereby being suitable for popularization and application.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Green and quick method for preparing lignin-nanosilver sol

The invention discloses a green and quick method for preparing lignin-nanosilver sol. The nanosilver sol is obtained by reacting lignin serving as a reducer and stabilizer with ammoniacal silver nitrate under the condition of microwave radiation. The preparation method comprises the following steps of obtaining [Ag(NH3)2] <+> through coactions of AgNO3, NaOH and ammonia water; reacting the [Ag(NH3)2]<+> with the lignin under the condition of microwave radiation to obtain the nanosilver sol. The concentration and the particle size of the nanosilver are controlled by adjusting the temperature and time for microwave reaction and a ratio of the lignin to the AgNO3, and the obtained nanosilver can be wrapped by the lignin, and is uniformly dispersed and difficultly agglomerated. The preparation method accords with the concept of 'green chemistry'. The method provides a technology orientation for utilizing forestry and agricultural residues at high values, and provides a new way for compounding nanocrystalline metal. Meanwhile, the nanosilver has a great application prospect in the fields of medical treatment and biology.

Owner:SOUTH CHINA UNIV OF TECH

Method for conversing agricultural and forest residues to be fermentable sugars

InactiveCN101338333ADecreased non-productive adsorptionIncrease the effective concentrationEnzymesFermentationFermentable sugarAgricultural residue

The invention belongs to the field of cellulase hydrolysis and discloses a method for converting forestry and agricultural residues into fermentability sugar. The method includes adopting steam explosion pre-treatment and washing on the forestry and agricultural residues after being cracked; then zymohydrolysis and saccharification is carried out. An activator is used during the zymohydrolysis and saccharification process. Compared with the prior method, as the activator is added to stop the lignin to generate non-productability absorption to the cellulose, the method of the invention improves the effective concentration of the cellulose and solves the problem of more consumption of the cellulose during the traditional hydrolyzing technique. The method of the invention has the characteristics of low cellulose consumption, simple technique, high sugar conversion rate, etc.

Owner:NANJING FORESTRY UNIV

Repair agent for treating compound pollution of heavy metal in soil and preparation method of repair agent

InactiveCN106800939AIncrease surface areaReduce agglomerationAgriculture tools and machinesOther chemical processesSoil heavy metalsAgricultural residue

The invention discloses a repair agent for treating compound pollution of a heavy metal in soil and a preparation method of the repair agent. The repair agent is prepared from the following components in parts by weight: 6-8 parts of modified nano-carbon black, 2-5 parts of sodium bentonite-loaded nano zero-valent iron, 1-2 parts of phosphate mineral and 5-10 parts of decomposed forestry and agricultural residues. The preparation method comprises the steps of (1) crushing the phosphate mineral and the decomposed forestry and agricultural residues into powder of which the particle size is 100-200 meshes separately and drying for later use; and (2) mixing the modified nano-carbon black, the phosphate mineral, the sodium bentonite-loaded nano zero-valent iron and the decomposed forestry and agricultural residues according to the formula, and stirring in a closed container to prepare the repair agent for treating compound pollution of the heavy metal in the soil.

Owner:四川省有色冶金研究院有限公司

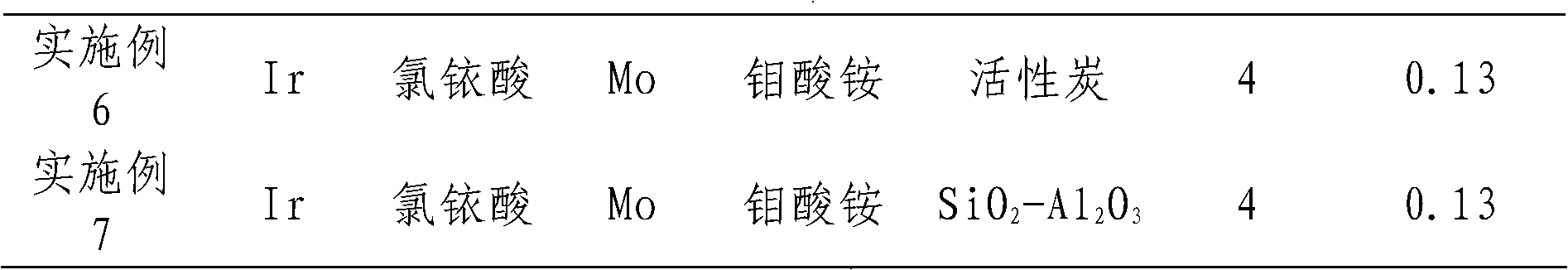

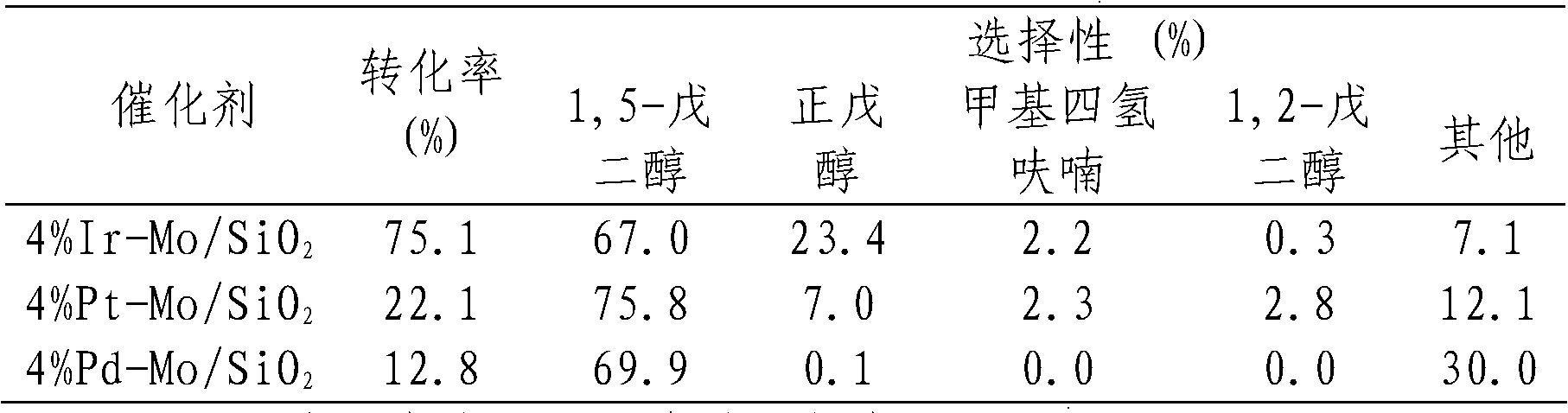

Method for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol

InactiveCN102911011APreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonHydrogen

The invention relates to a novel A-B / X or A / X supported catalyst for preparing 1,5-pentadiol by means of selective hydrogenolysis of tetrahydrofurfuryl alcohol obtained from forestry and agricultural residues. The component A refers to one or more of precious metals Ir, Pt and Pd, the auxiliary B refers to one or more of Mo, Re and W, and the carrier X refers to any one of SiO2, activated carbon and SiO2-Al2O3. The capacity of the precious metal A in the catalyst is 0.5-10%, the molar ratio of the auxiliary B to the precious metal A is 0.0-1.0, the reaction pressure is 2-20MPa, and the reaction temperature is 80-150 DEG C. The catalyst has the advantages of mild reaction conditions, high reactivity and high selectivity, and a novel effective way for preparation of 1,5-pentadiol from biomass of forestry and agricultural residues is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com