Repair agent for treating compound pollution of heavy metal in soil and preparation method of repair agent

A technology for compound pollution and heavy metals, applied in the field of soil pollution remediation, can solve the problem that remediation agents cannot passivate and remediate multiple heavy metals at the same time, and achieve the effects of promoting heavy metal conversion, enhancing stability and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

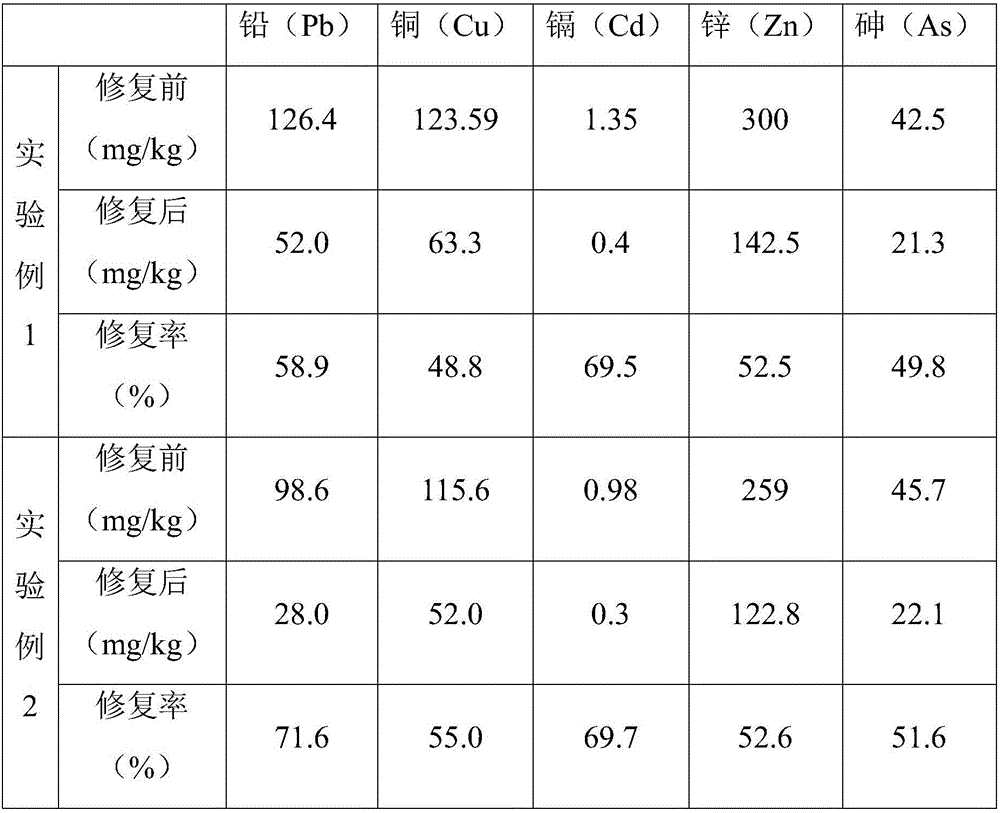

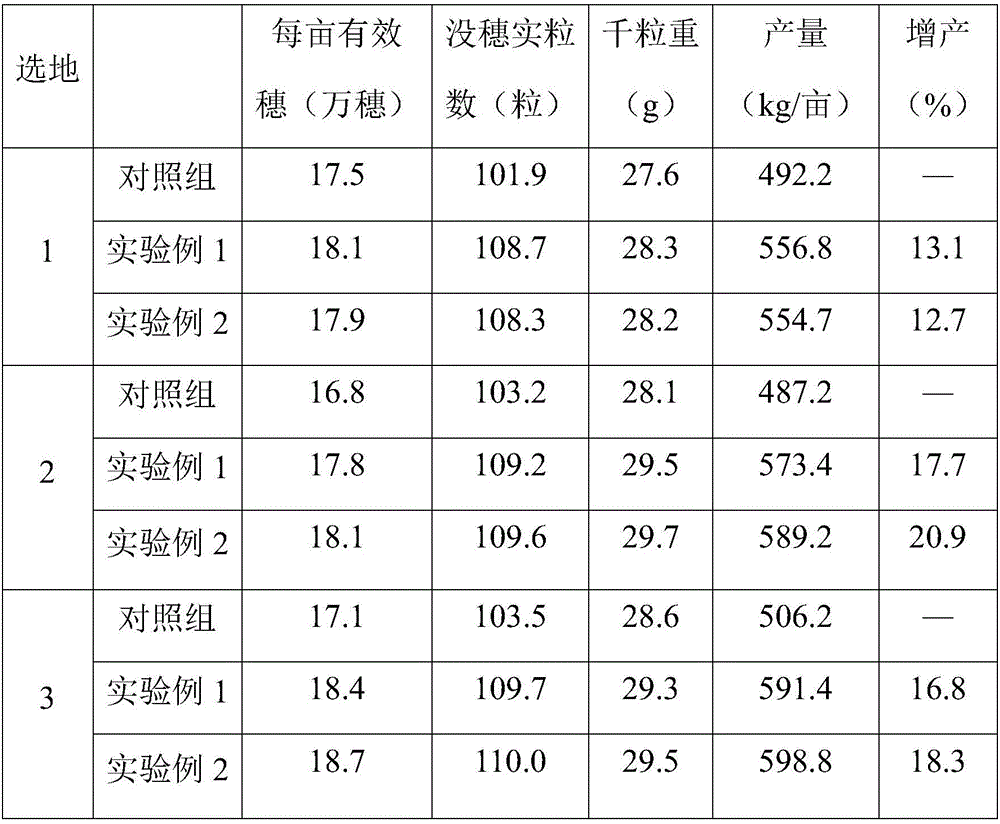

Examples

Embodiment 1

[0032] A remediation agent for treating heavy metal complex pollution in soil, comprising the following components in parts by weight: 6 parts of modified nano-carbon black, 4 parts of sodium-based bentonite-loaded nano-zero-valent iron, 2 parts of hydroxyapatite, and 8 parts of decomposed straw 2 parts and 2 parts of decomposed wine residue.

[0033] Among them, the modified nano-carbon black is prepared by the following method: Weigh 10g of nano-carbon black, wash with deionized water, dry to constant weight at 100°C, then add 200ml of concentrated nitric acid, react at 140°C for 2h, centrifuge , remove the supernatant, and then wash and centrifuge repeatedly with distilled water until the pH of the supernatant is 2 and keep it constant, then dry it at 120°C to constant weight to obtain modified nano-carbon black.

[0034] Sodium-based bentonite-loaded nano-zero-valent iron is prepared by the following method:

[0035] (1) Pulverize 100 g of calcium-based bentonite, pass th...

Embodiment 2

[0043] A remediation agent for treating heavy metal complex pollution in soil, comprising the following components in parts by weight: 8 parts of modified nano-carbon black, 5 parts of sodium-based bentonite-loaded nano-zero-valent iron, 1 part of hydroxyapatite, and 3.75 parts of decomposed straw And 1.25 parts of decomposed wine residue.

[0044] Among them, the modified nano-carbon black is prepared by the following method: Weigh 12g of nano-carbon black, wash it with deionized water, dry it to constant weight at 120°C, add 210ml of concentrated nitric acid, react at 140°C for 2h, and centrifuge , remove the supernatant, and then wash and centrifuge repeatedly with distilled water until the pH of the supernatant is 5 and keep it constant, and then dry at 120°C to constant weight to obtain modified nano-carbon black.

[0045] Sodium-based bentonite-loaded nano-zero-valent iron is prepared by the following method:

[0046] (1) Pulverize 120 g of calcium-based bentonite, pass...

Embodiment 3

[0054] A remediation agent for treating heavy metal complex pollution in soil, comprising the following components in parts by weight: 8 parts of modified nano-carbon black, 5 parts of sodium-based bentonite-loaded nano-zero-valent iron, 2 parts of hydroxyapatite, and 4 parts of decomposed straw And 2 parts of decomposed wine residue.

[0055] Among them, the modified nano-carbon black is prepared by the following method: Weigh 12g of nano-carbon black, wash it with deionized water, dry it to constant weight at 110°C, add 220ml of concentrated nitric acid, and react at 120°C for 2.5h. Centrifuge to remove the supernatant, then wash and centrifuge repeatedly with distilled water until the pH of the supernatant is 4 and keep it constant, then dry at 100°C to constant weight to obtain modified nano carbon black.

[0056] Sodium-based bentonite-loaded nano-zero-valent iron is prepared by the following method:

[0057] (1) Pulverize 120g of calcium-based bentonite, pass through a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com