Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

346 results about "Biodegradable composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional biodegradable composite and surgical implant comprising said composite

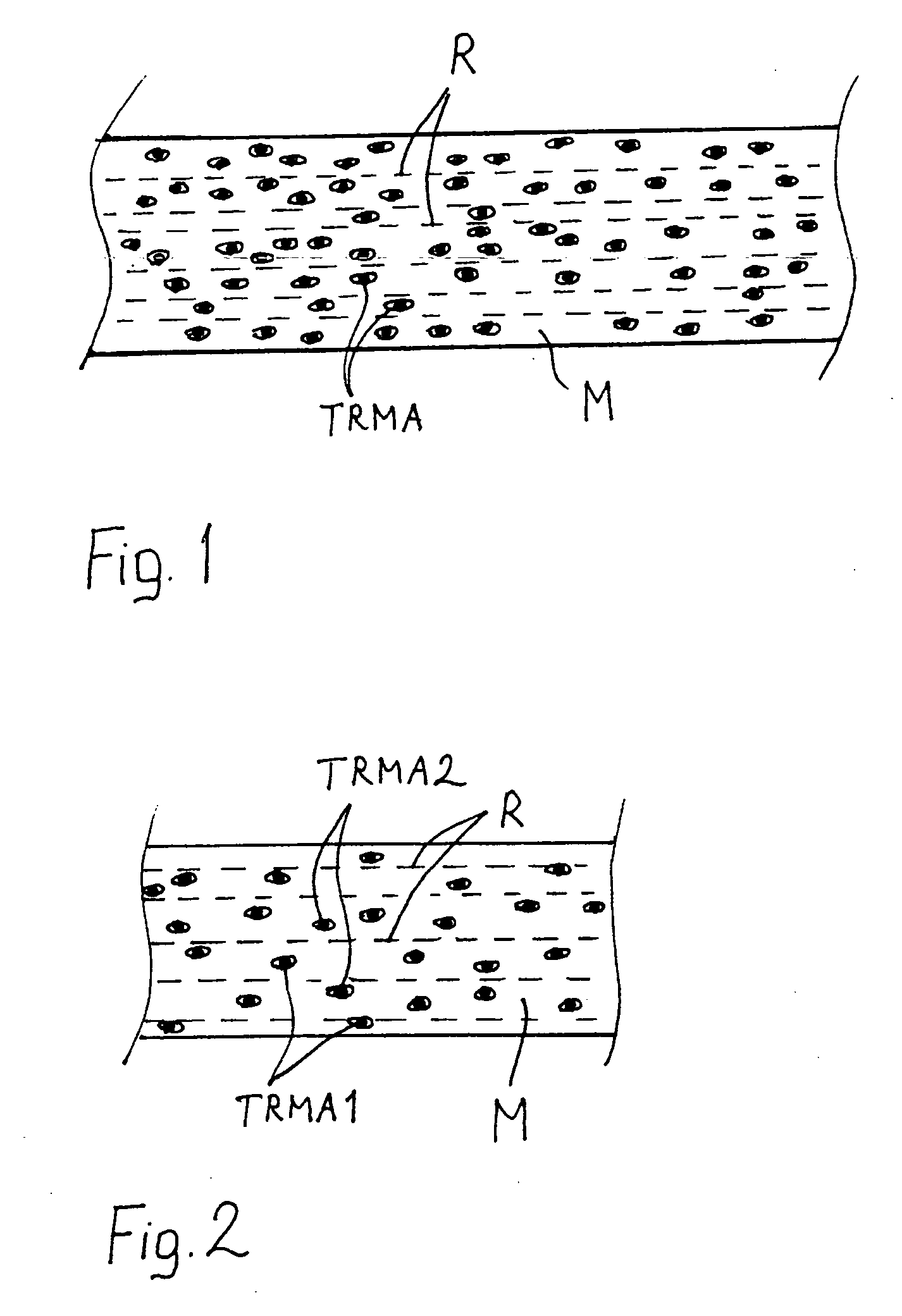

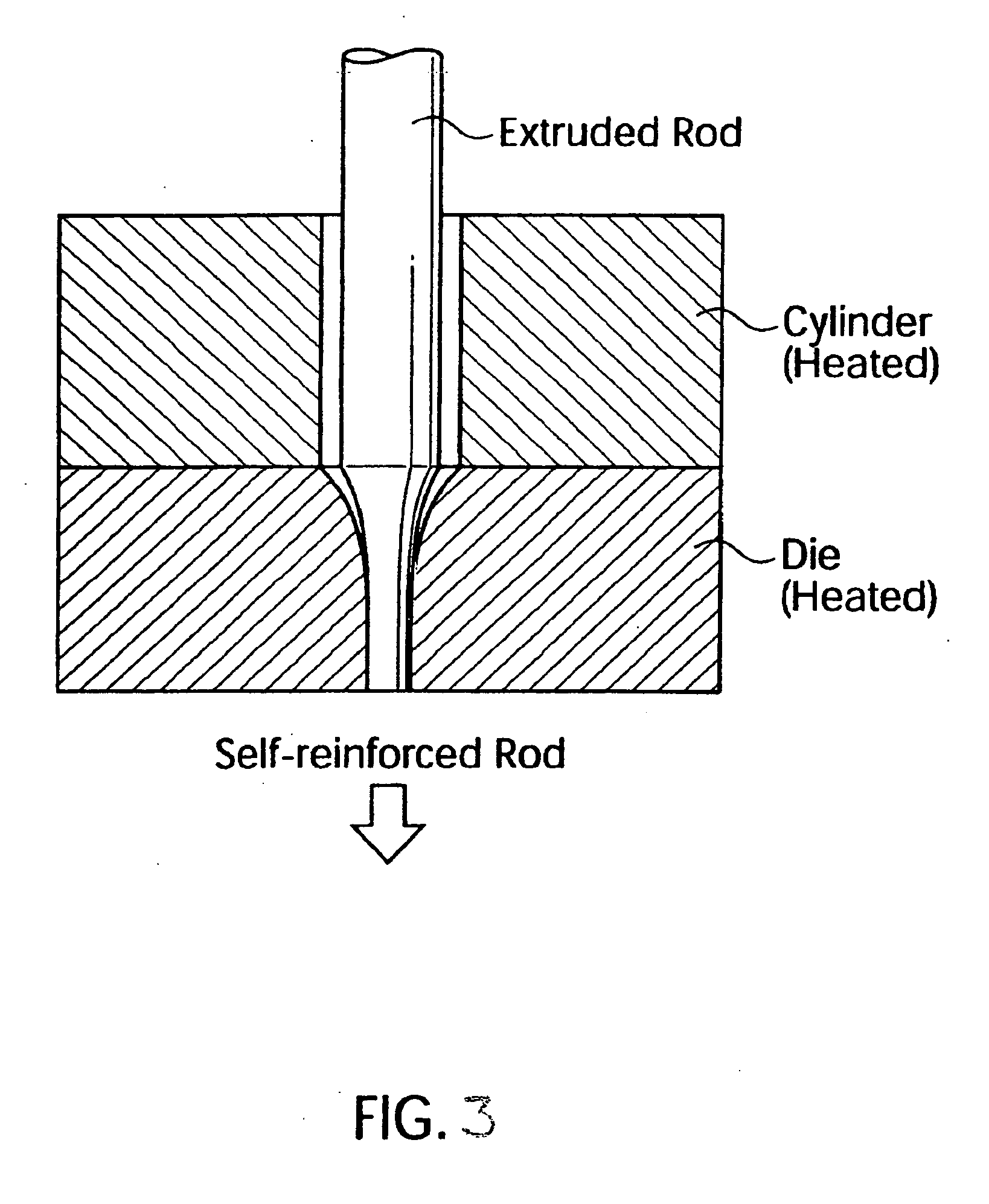

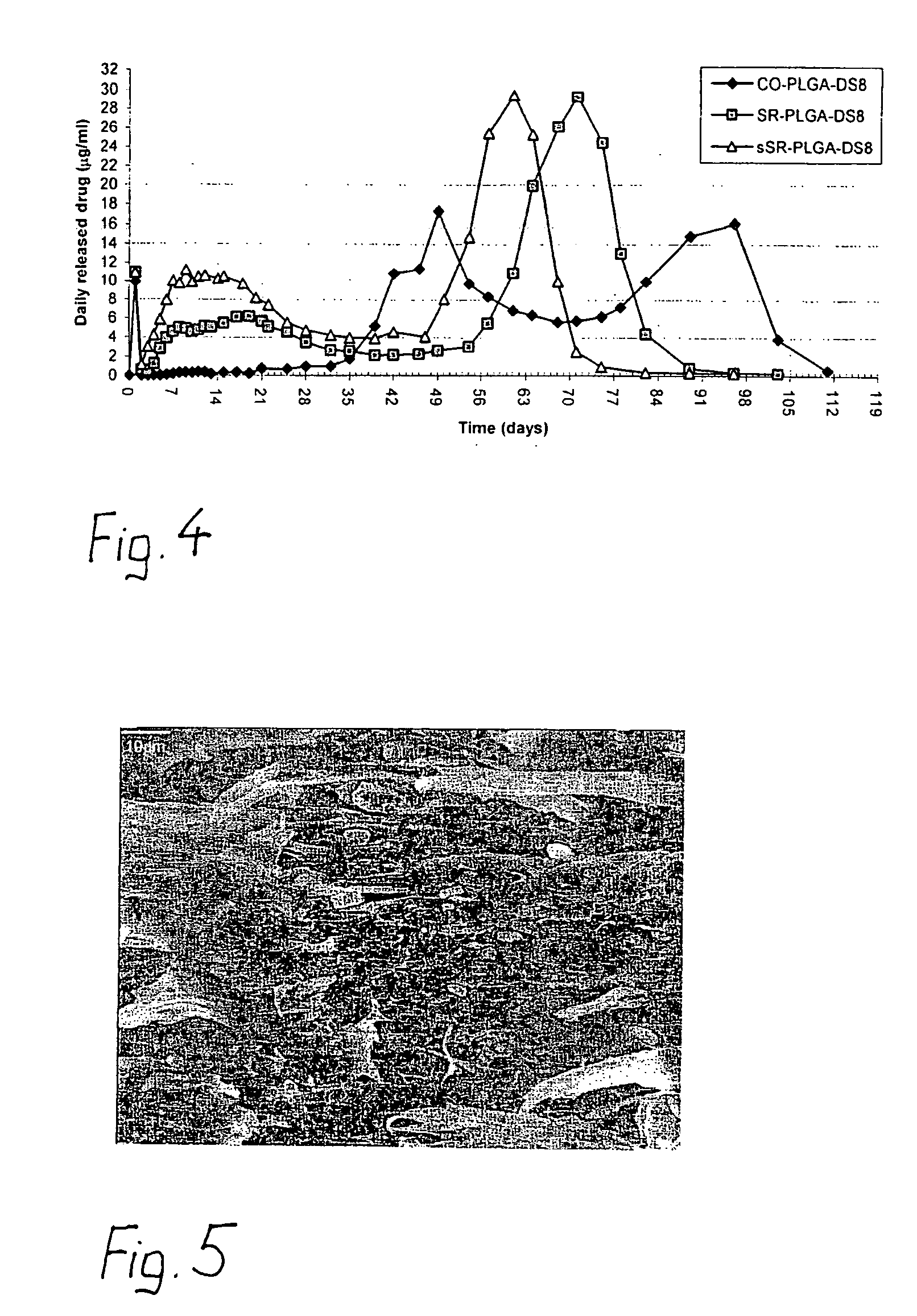

A multifunctional biodegradable composite has: a) bioabsorbable polymer matrix phase (M) b) bioabsorbable reinforcing element (R), and c) bioactive tissue / cell reaction modifying agent (TRMA) dispersed in said bioabsorbable matrix phase and selected from the group consisting of anti-inflammatory drugs and statins. Said biodegradable composite may be in a surgical implant capable of acting as a drug-delivery implant.

Owner:BIORETEC

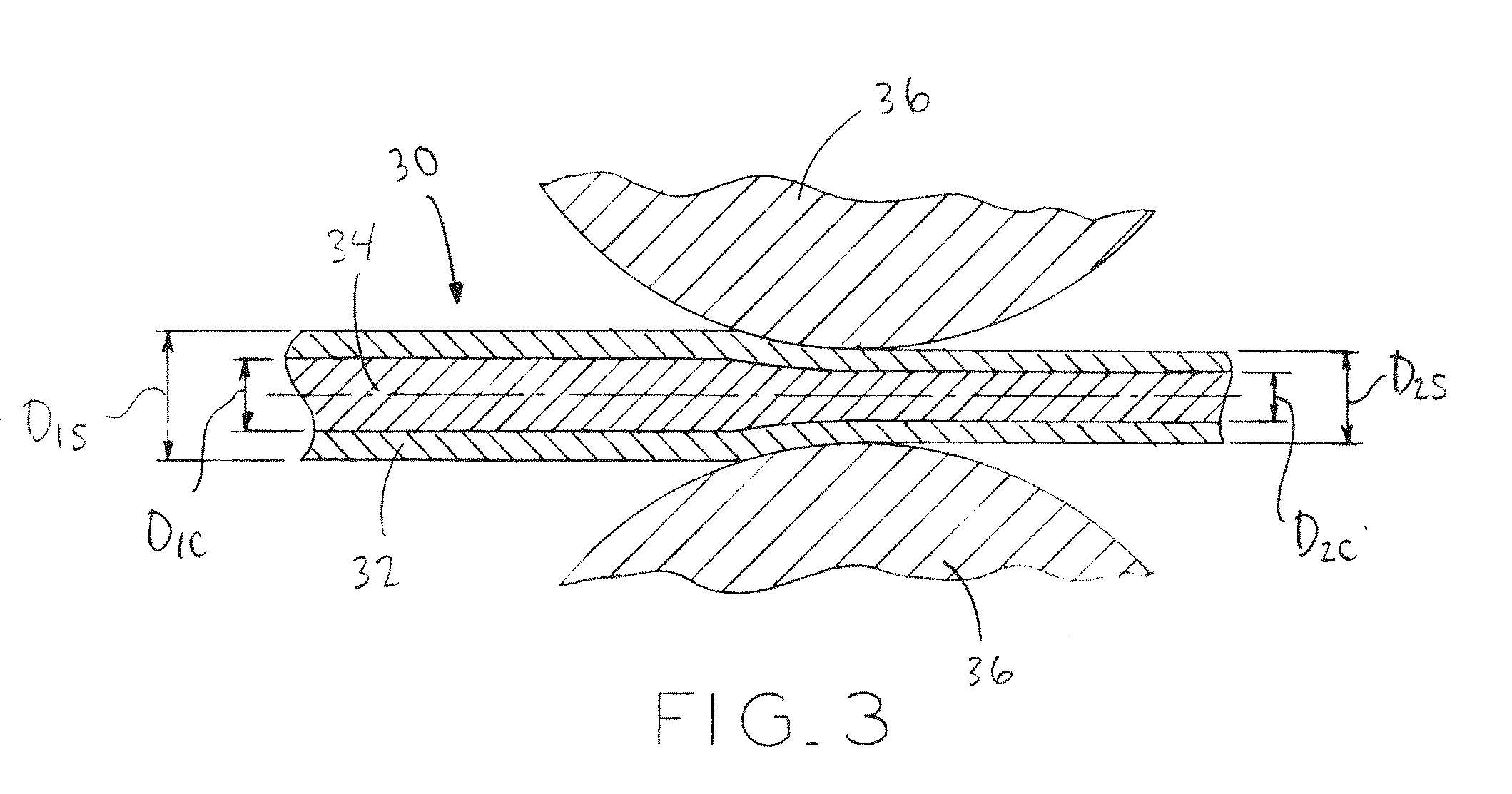

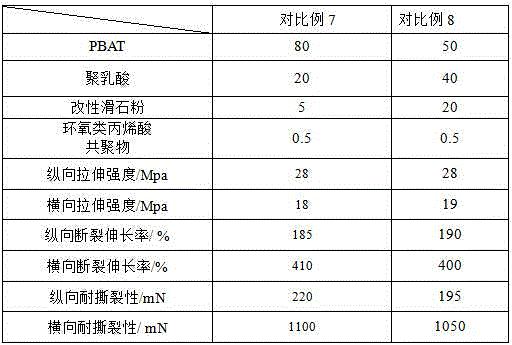

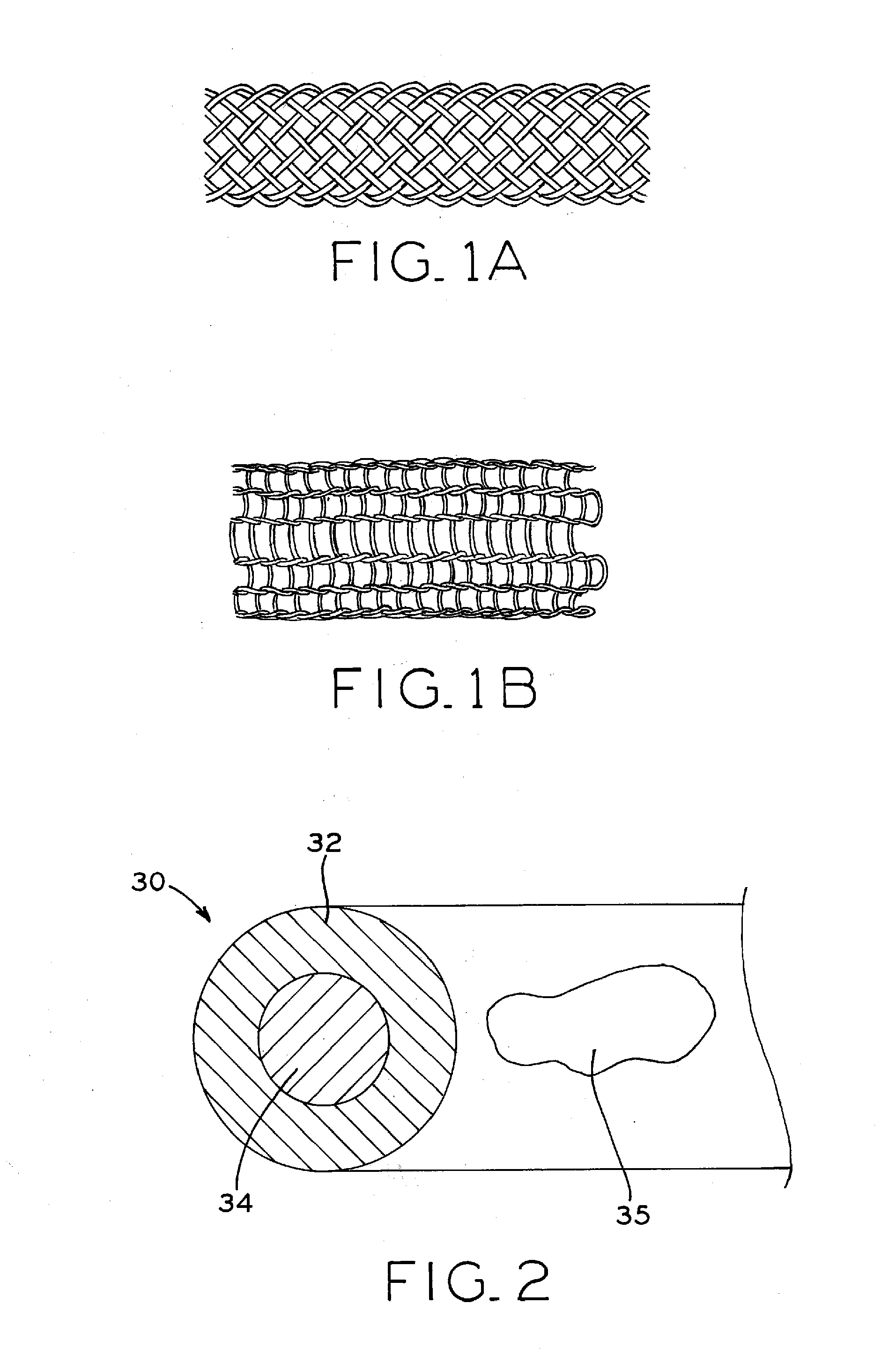

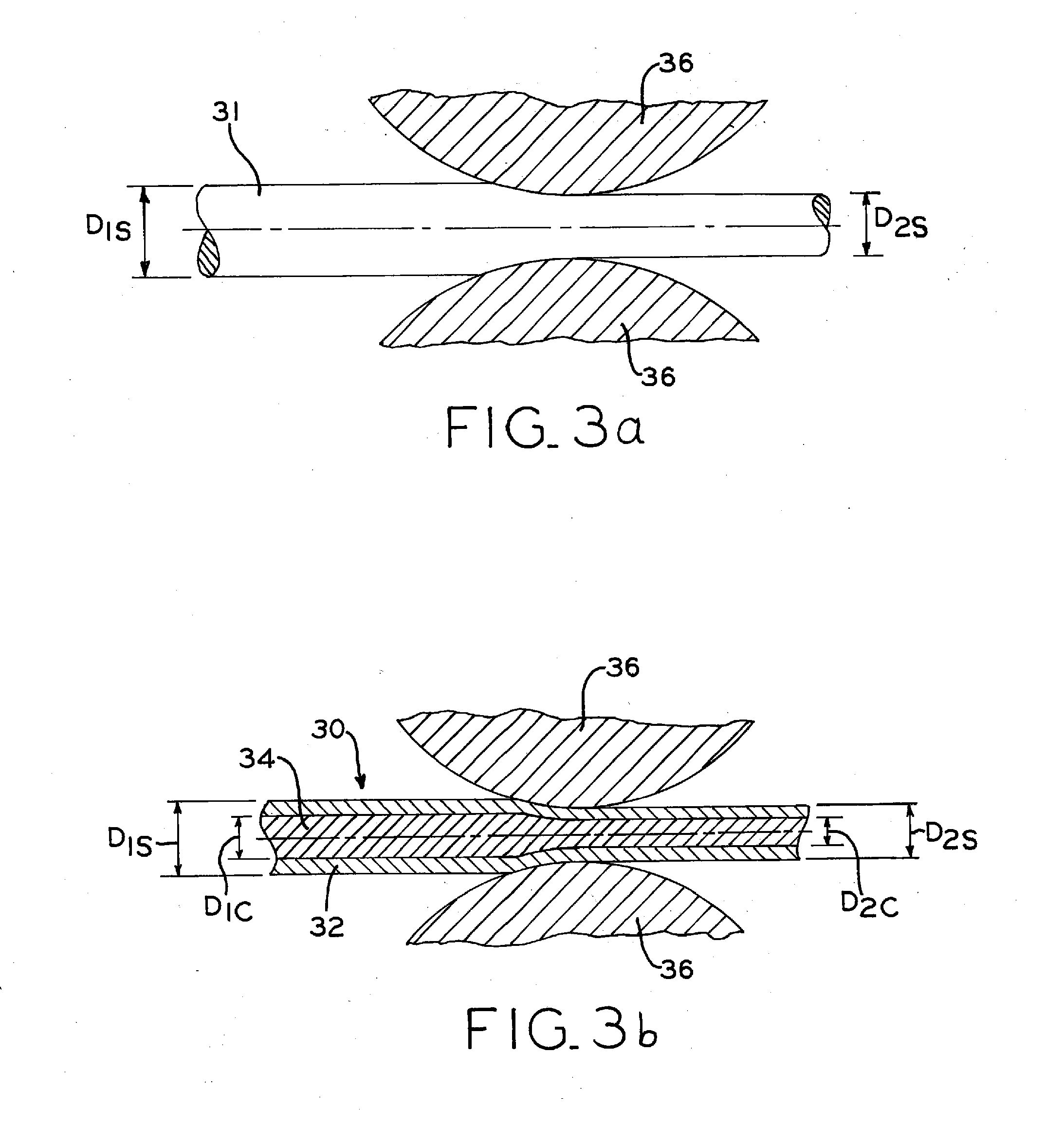

Biodegradable composite wire for medical devices

ActiveUS20110319978A1Vessel patency has been restoredDiffering biodegradation rateStentsSurgeryMechanical integrityPercent Diameter Stenosis

A bimetal composite wire including, in cross-section, an outer shell or tube formed of a first biodegradable material and an inner core formed of a second biodegradable material. When formed into a stent, for example, the first and second biodegradable materials may be different, and may have differing biodegradation rates. In a first embodiment, the first biodegradable material of the shell may degrade relatively slowly for retention of the mechanical integrity of a stent during vessel remodeling, and the second biodegradable material of the core may degrade relatively quickly. In a second embodiment, the first biodegradable material of the shell may degrade relatively quickly, leaving a thinner structure of a second biodegradable material of the core that may degrade relatively slowly. The biodegradation rates may be inherently controlled, such as by selection of materials, and also may be mechanically controlled, such as by material thicknesses and the geometric configuration of the shell, core, or overall device. In any embodiment, the metallic scaffold may also be coated with a drug-eluting, biodegradable polymer, to further inhibit neointimal proliferation and / or restenosis.

Owner:FORT WAYNE METALS RES PROD CORP

Biodegradable soy protein-based compositions and composites formed therefrom

A biodegradable polymeric composition includes 99.5 wt. % to 40 wt. % soy protein and 0.5 wt. % to 60 wt. % of a first strengthening agent that consists essentially of a polysaccharide selected from the group consisting of agar, gellan, and mixtures thereof. The composition is substantially completely soluble in water at a pH of about 7.0 or higher. A biodegradable composite includes a fiber mat and the described biodegradable polymeric composition. A biodegradable molded thermoset solid article is obtained by subjecting the described biodegradable polymeric composition to conditions of temperature and pressure effective to form the thermoset solid article.

Owner:CORNELL RES FOUNDATION INC

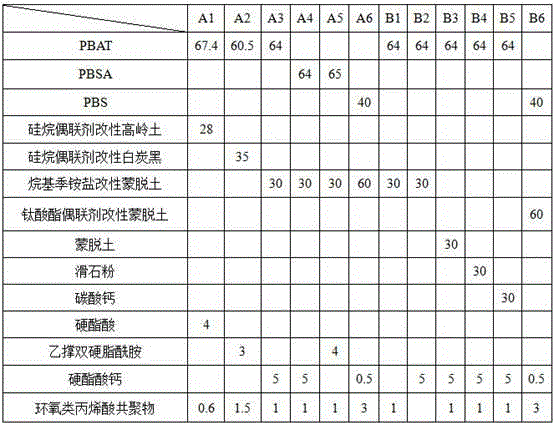

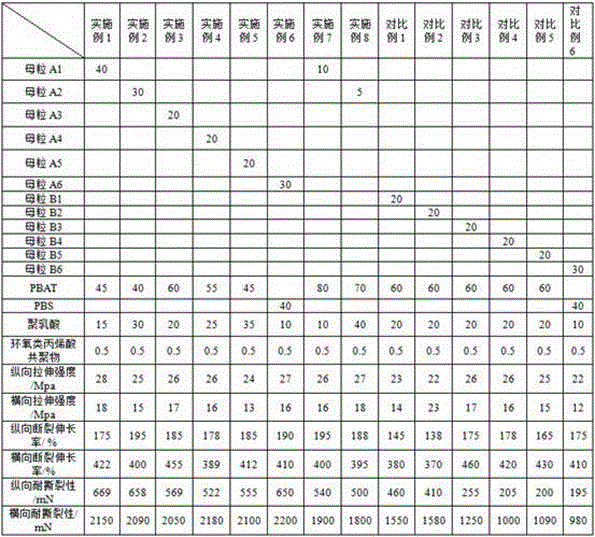

Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

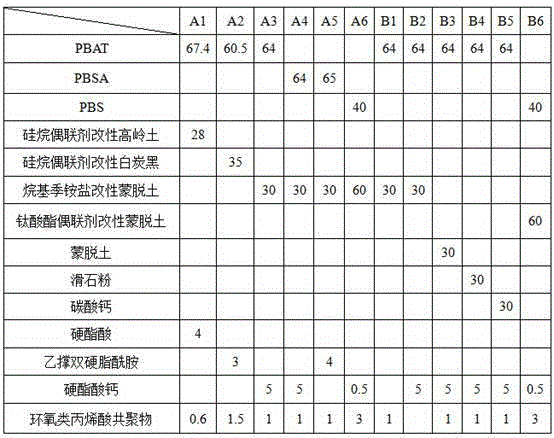

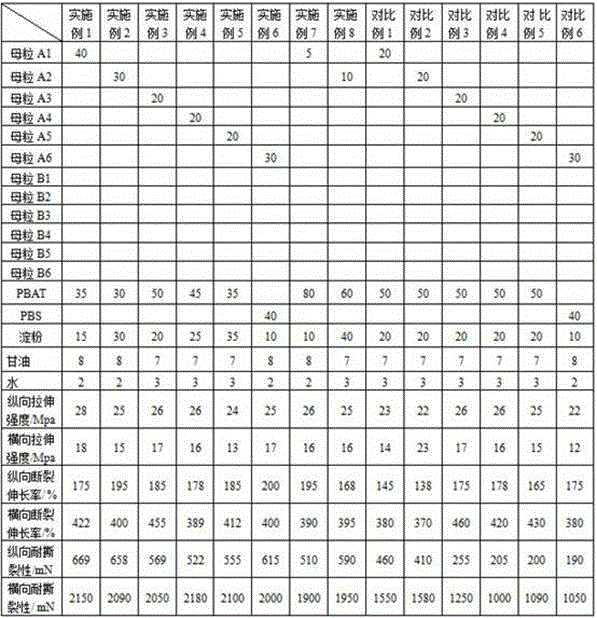

The invention discloses a full-biodegradable composite as well as a preparation method and application of the full-biodegradable composite. The full-biodegradable composite comprises the following components: 5-40 parts of inorganic filler full-biodegradable masterbatches, 40-80 parts of biodegradable copolyester, 10-40 parts of polylactic acid and 0.1-5 parts of a compatilizer, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of the biodegradable copolyester, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of the compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the matrix resin, so that the problem of relatively low tearing strength of a blend film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

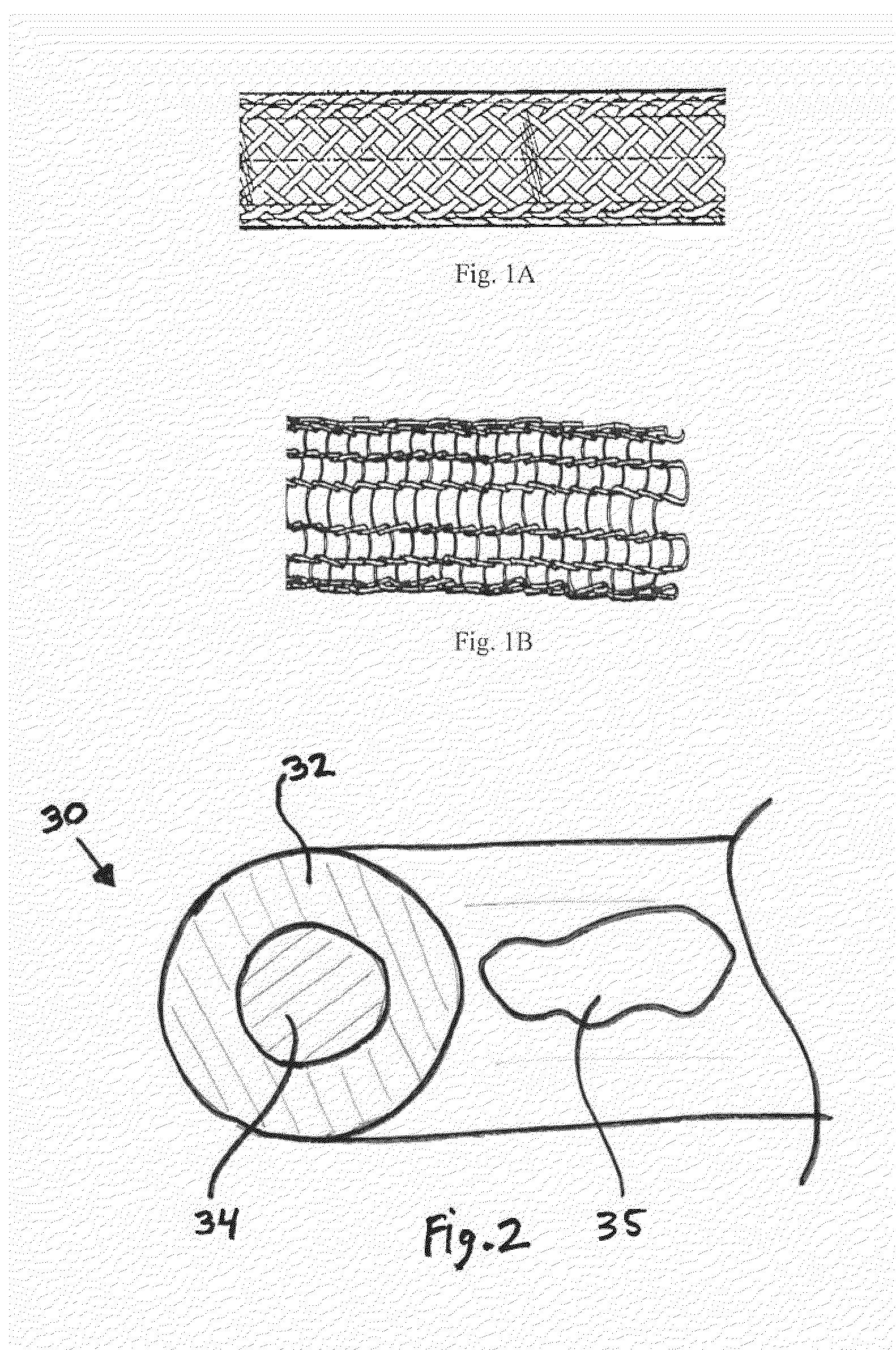

Absorbable / biodegradable composite yarn constructs and applicatons thereof

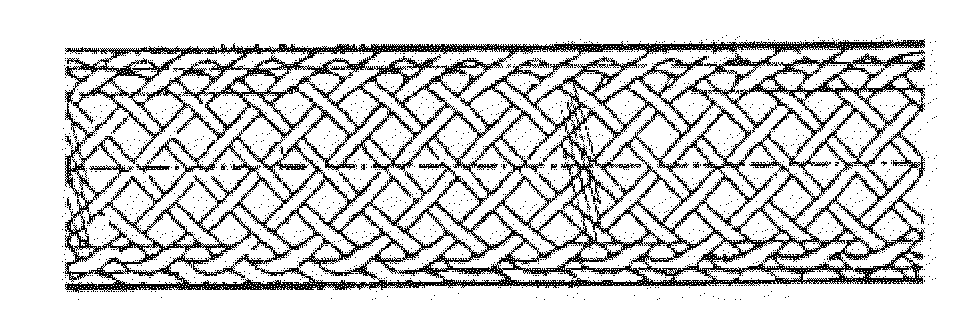

Absorbable composite medical devices such as surgical meshes and braided sutures, which display two or more absorption / biodegradation and breaking strength retention profiles and exhibit unique properties in different clinical settings, are made using combinations of at least two types of yarns having distinctly different physicochemical and biological properties and incorporate in the subject construct special designs to provide a range of unique properties as clinically useful implants.

Owner:POLY MED

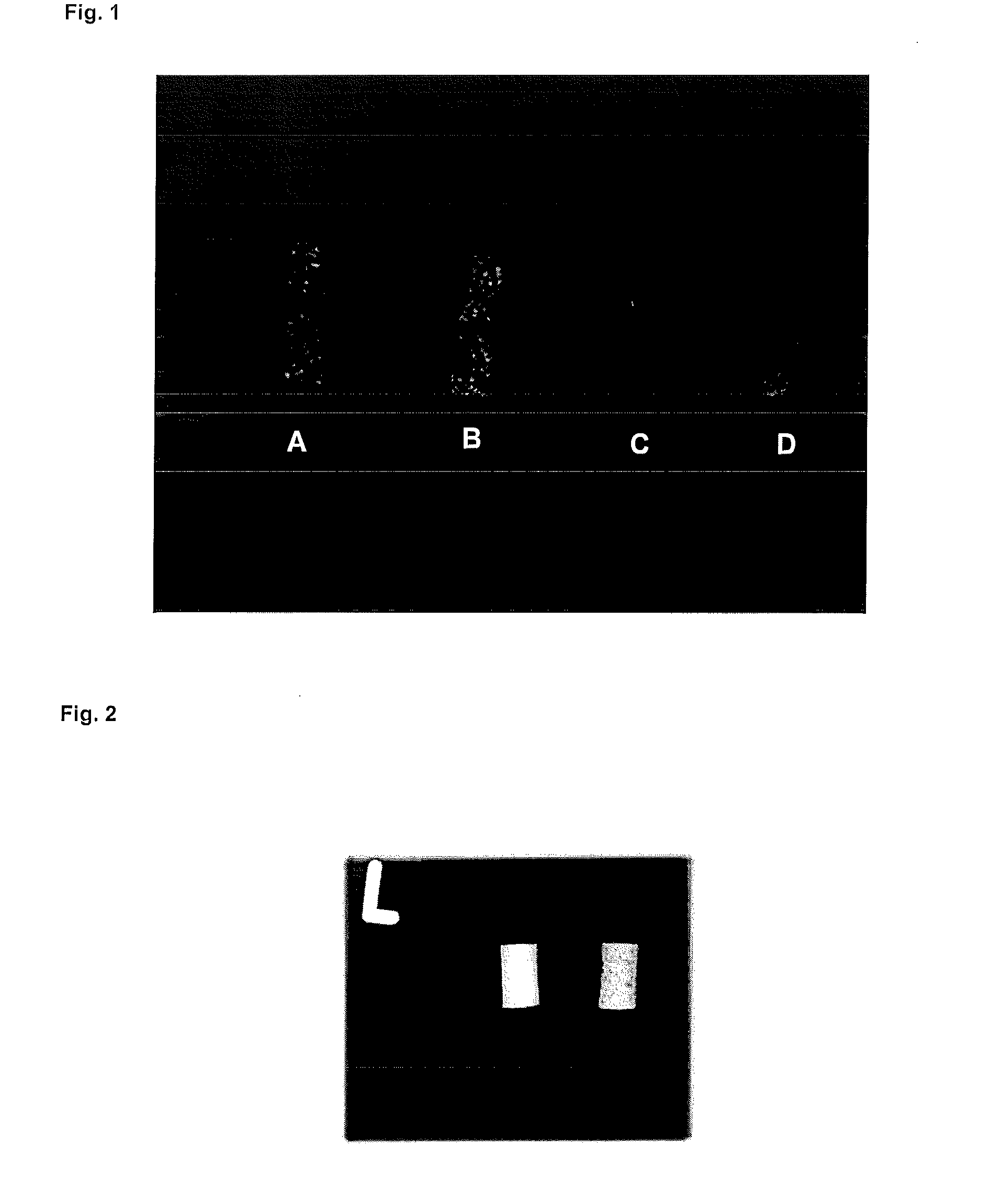

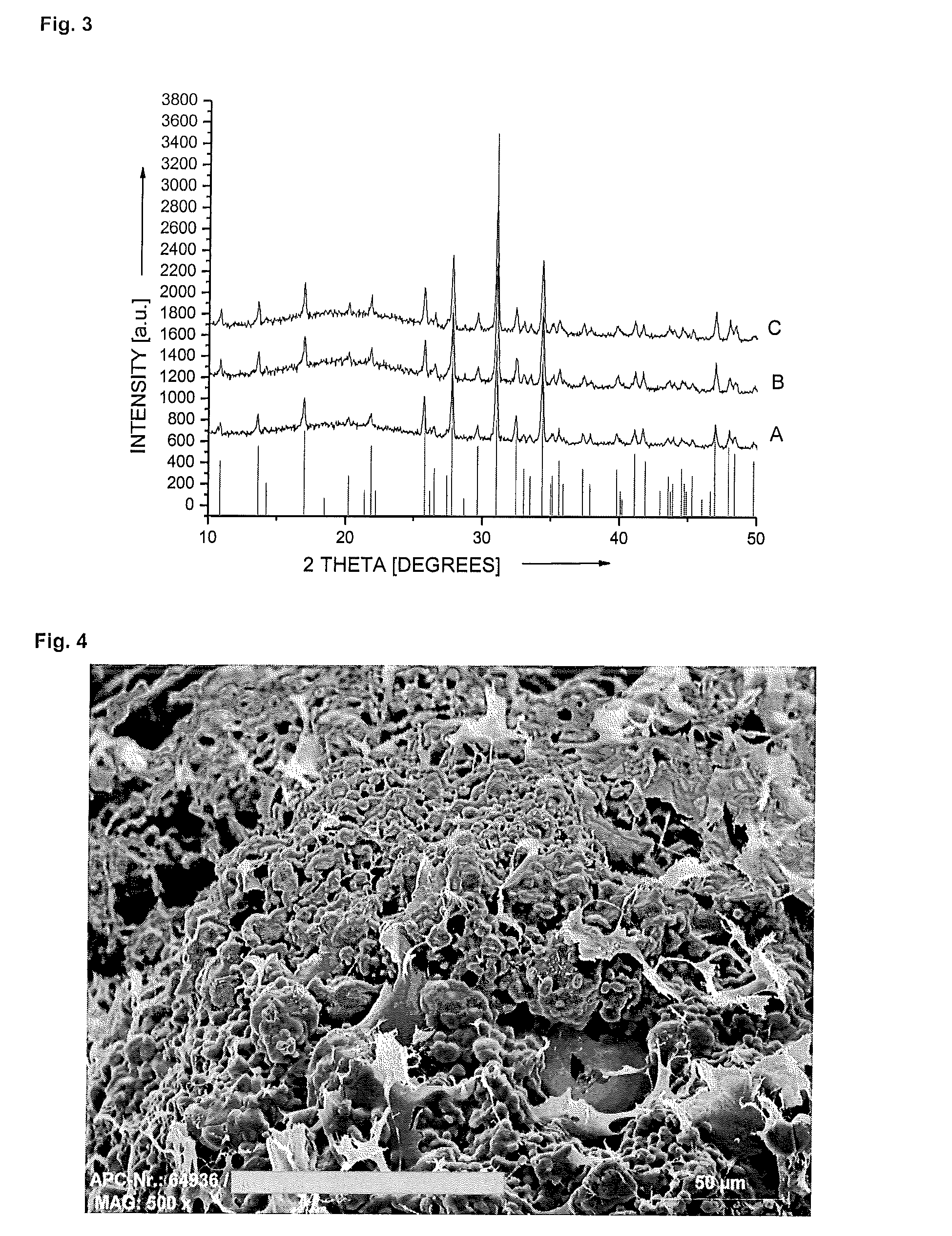

Biodegradable composite material

ActiveUS20140170202A1Improve propertiesBiocideInorganic phosphorous active ingredientsBone defectBiodegradable composites

The invention relates to a biologically degradable composite material and to a process for the preparation thereof. The biologically degradable composite material according to the invention is preferably a bone reconstruction material which can be used in the field of regenerative medicine, especially as a temporary bone defect filler for bone regeneration.

Owner:CURASAN

Starch-filled PLA/PBAT full-biodegradable composite material and preparation method thereof

The invention provides a starch-filled PLA / PBAT full-biodegradable composite material and a preparation method thereof, and belongs to the field of high polymer materials. A purpose of the invention is to solve the problems of poor toughness, brittleness and easy breaking of polylactic acid and the technical problems of difficult processing of starch, poor compatibility with PLA / PBAT resins and the like. The starch-filled PLA / PBAT full-biodegradable composite material comprises, by weight, 5-90 parts of polylactic acid, 10-90 parts of polyadipic acid / butylene terephthalate, 10-50 parts of starch, 2-15 parts of a plasticizer, 0.1-5 parts of a coupling agent, 0.1-0.5 part of a dispersing agent, 0.1-1 part of a compatibilizer and 0.1-0.5 part of an antioxidant. According to the invention, thepreparation method can be applied to preparation of starch-filled PLA / PBAT full-biodegradable composite materials.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

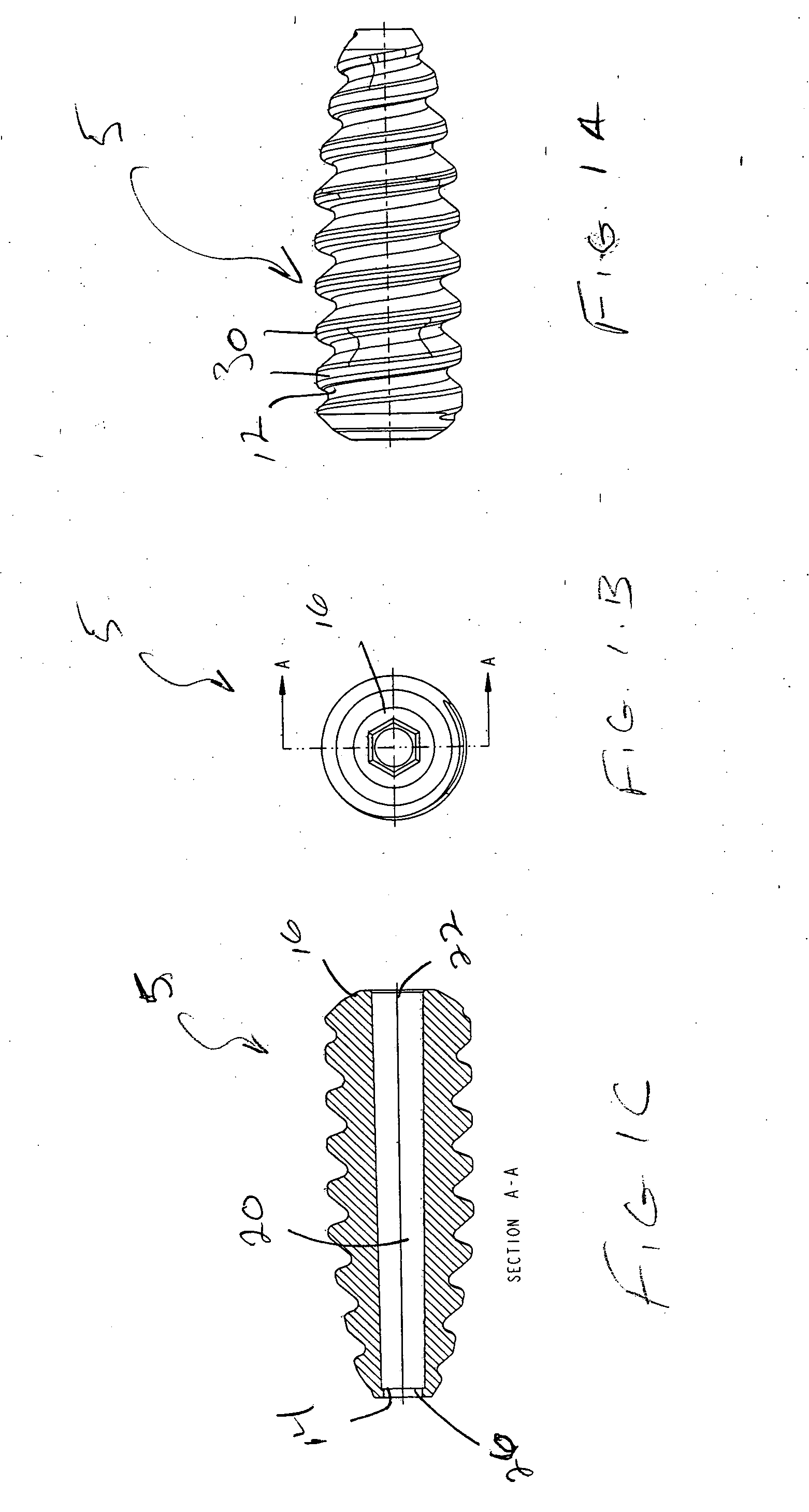

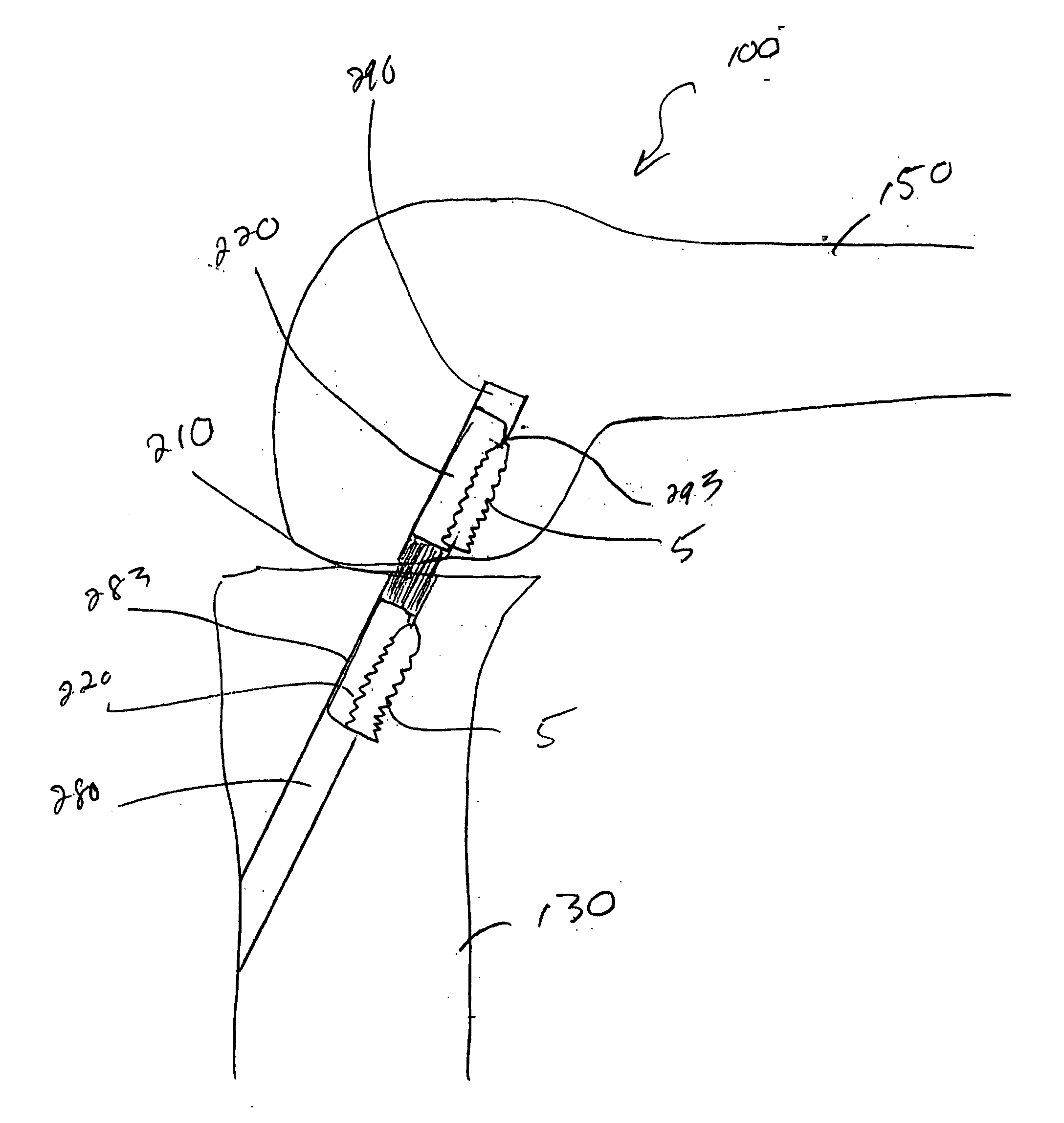

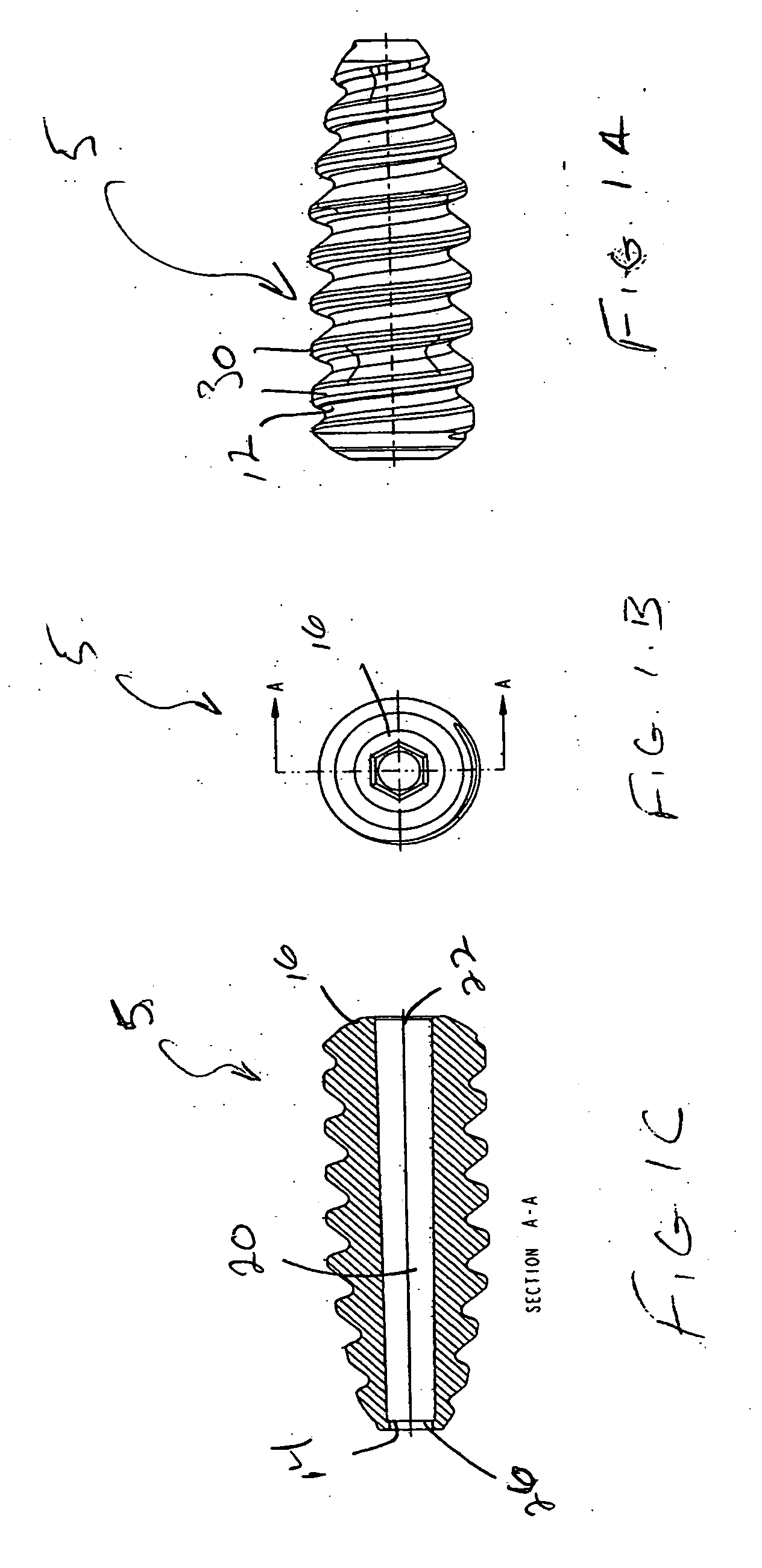

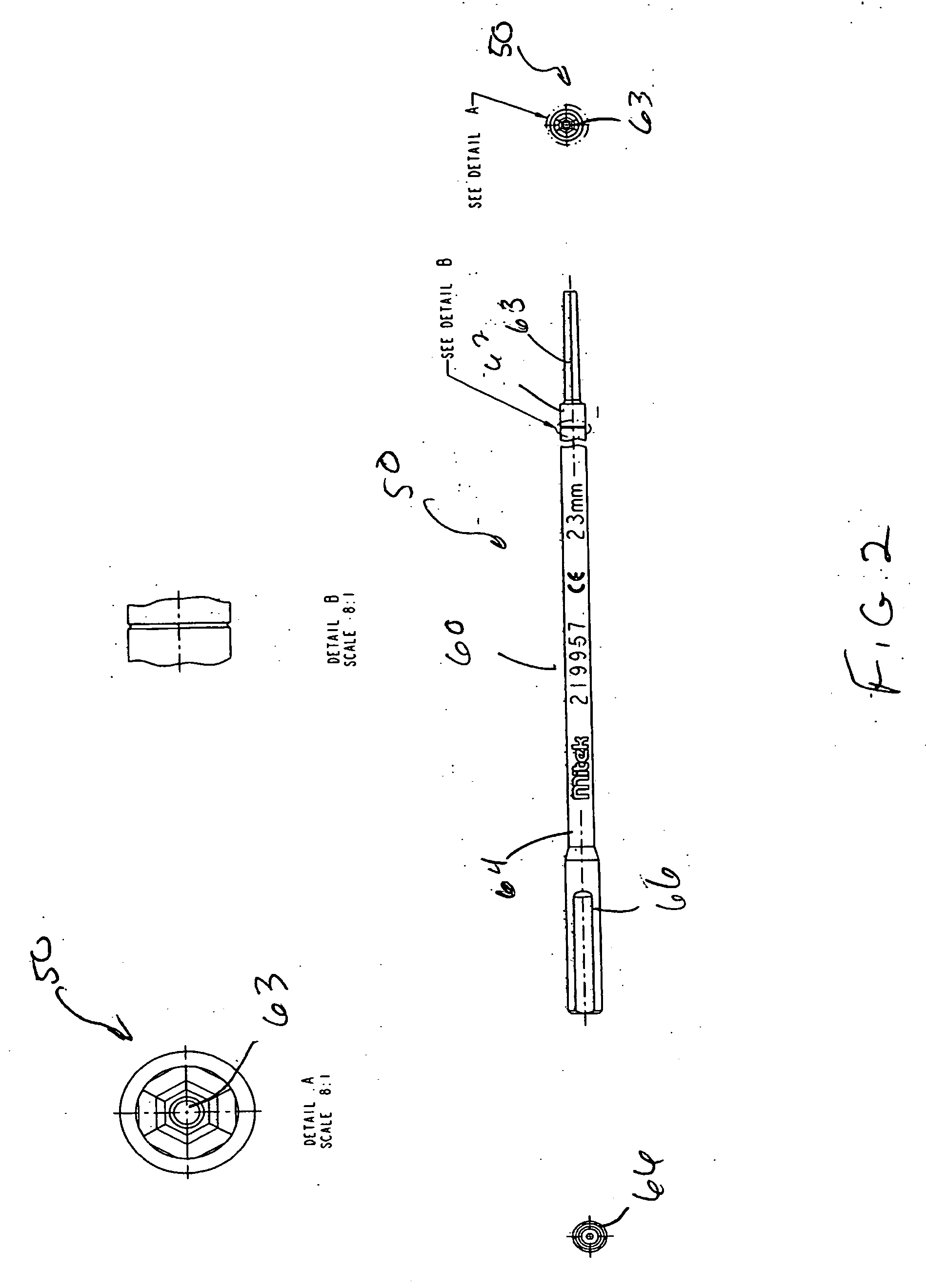

Method of performing anterior cruciate ligament reconstruction using biodegradable interference screw

A method of replacing an ACL with a graft. The method provides for the drilling bone tunnels in a femur and a tibia. A replacement graft is provided having first and second ends. A biodegradable composite screw is provided. The screw is made from a biodegradable polymer and a bioceramic or a bioglass. At least one end of the graft is secured in a bone tunnel using the biodegradable composite screw.

Owner:DEPUY SYNTHES PROD INC

Wood Adhesives Comprising Protein and Oxazoline Polymer or Resin

InactiveUS20100069533A1Improve curing speedEasy curingProtein adhesivesPaper coatingLignosulfonatesMedium density fiberboard

The present invention provides wood adhesive binder compositions comprising a naturally occurring protein component, e.g. soy flour, and an oxazoline-functional group containing polymer or resin component, the two components in a solids weight ratio of from 60:40 to 98:2. As formulated, the compositions may comprise from 40 to 98 wt. % of the naturally occurring protein component, preferably, 50 wt. % or more. Preferably, the wood adhesive binder further comprises lignins or lignosulfonate. Where the wood adhesive binder compositions comprise lignins or lignosulfonates, they remain more fluid and workable at a higher pH such as, for example, 4.5 or more. Any of the compositions may be formulated with one or more in situ acid generator compound to insure more rapid cure on heating or pressing. The binder enables the provision of mechanically sound, low cost and biodegradable composites, such as, medium density fiberboard (MDF).

Owner:BRADY JEAN M +4

Biodegradable composite wire for medical devices

A bioabsorbable wire material includes manganese (Mn) and iron (Fe). One or more additional constituent materials (X) are added to control corrosion in an in vivo environment and, in particular, to prevent and / or substantially reduce the potential for pitting corrosion. For example, the (X) element in the Fe—Mn—X system may include nitrogen (N), molybdenum (Mo) or chromium (Cr), or a combination of these. This promotes controlled degradation of the wire material, such that a high percentage loss of material the overall material mass and volume may occur without fracture of the wire material into multiple wire fragments. In some embodiments, the wire material may have retained cold work for enhanced strength, such as for medical applications. In some applications, the wire material may be a fine wire suitable for use in resorbable in vivo structures such as stents.

Owner:FORT WAYNE METALS RES PROD CORP

PLA/PBAT biodegradable composite material and product thereof

The invention relates to the technical field of high polymer materials, and particularly discloses a PLA / PBAT biodegradable composite material and a product thereof. The PLA / PBAT biodegradable composite material is prepared from 33 to 95.9 parts by mass of polylactic acid (PLA), 3 to 60 parts by mass of polybutylene adipate terephthalate (PBAT), 1 to 5 parts by mass of a compatilizer and 0.1 to 2parts by mass of a chain extender. The PLA / PBAT biodegradable composite material has the characteristics of PLA and PBAT, and is high in impact strength and good in toughness.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

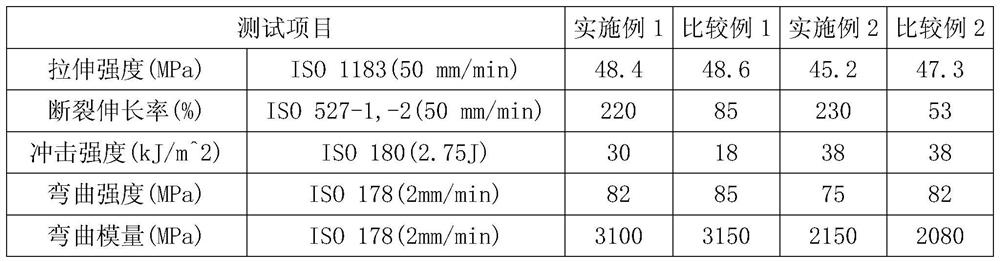

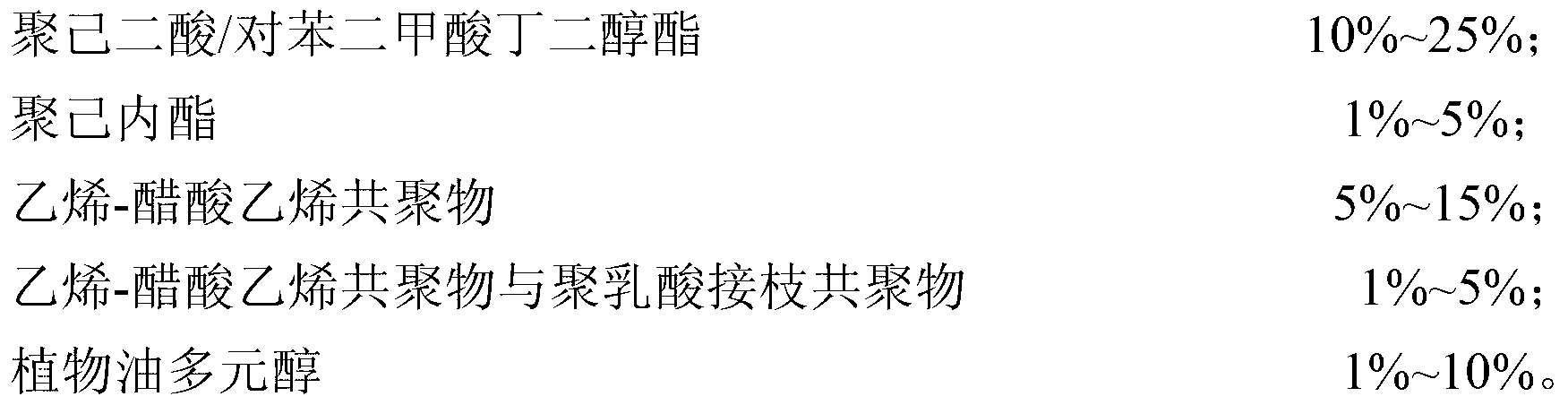

PLA/PBAT biodegradable composite material and preparation method thereof

The invention discloses a PLA / PBAT biodegradable composite material, which is prepared from the following components in percentage by weight: 60-75% of a polylactic acid, 60-75% of poly(adipic acid) / butylene terephthalate, 1-5% of poly (caprolactone), 5-15% of an ethylene-vinyl acetate copolymer, 1-5% of an ethylene-vinyl acetate copolymer and polylactic acid graft copolymer, and 1-10% of vegetable oil polyols. The PLA / PBAT biodegradable composite material disclosed by the invention is excellent in tensile strength and toughness, good in chemical stability, and easy to process, and in addition, the material is biodegradable. The invention also discloses a preparation method of the PLA / PBAT biodegradable composite material, which can be implemented through the existing equipment twin-screw extruder, therefore, the method is easy to implement, strong in maneuverability, and easy to realize industrialized mass production, and has good economic benefits and broad application prospects.

Owner:LINONGFENG TECH

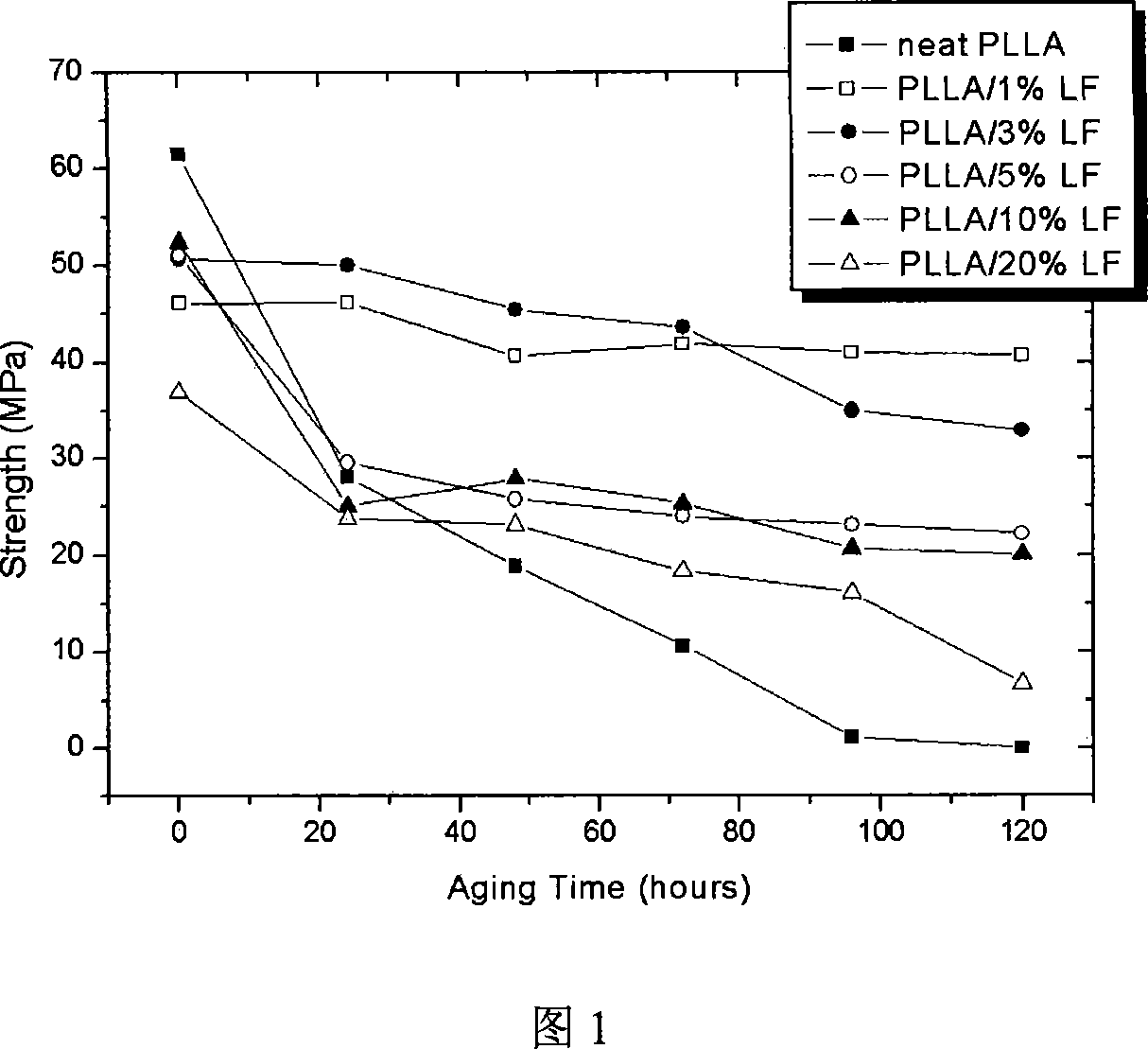

Polylactic acid/vegetable sponge fiber composite material and method for making same

The invention relates to a polylactic acid / vegetable sponge fiber composite material and the preparation method. The new fully biodegradable composite material can significantly improve the heat-resistant property of the polylactic acid, has good mechanical properties and can reduce the cost of raw material, which is favorable for the polylactic acid to obtain a wider range of applications. The composite material adopts polylactic acid as the main raw material and vegetable sponge short-fiber of organic modification, a small amount of lubricant and heat stabilizer are added. The invention has the advantages that: the fully biodegradable composite material which is prepared with the above raw material and the accessories has good mechanical property, excellent heat-resistant property, antisepsis, dampness-resistant and low cost, thus the composite material can be applied to the package-parcel, engineering construction, indoor decoration, automobile internal decoration and other fields, meanwhile the environmental problems brought by white pollution can also be resolved.

Owner:SHANGHAI UNIV

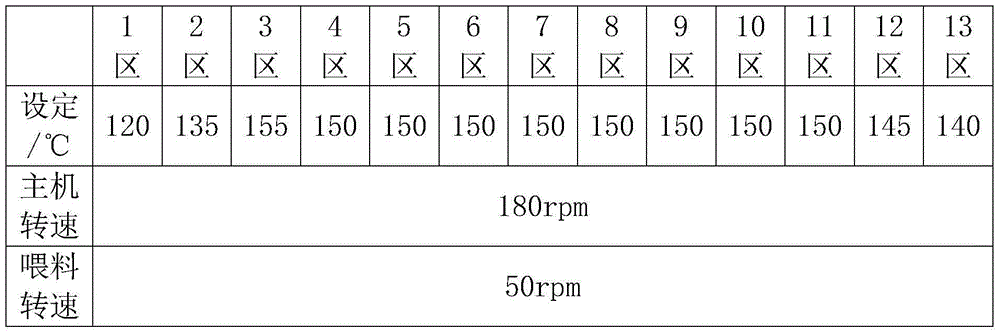

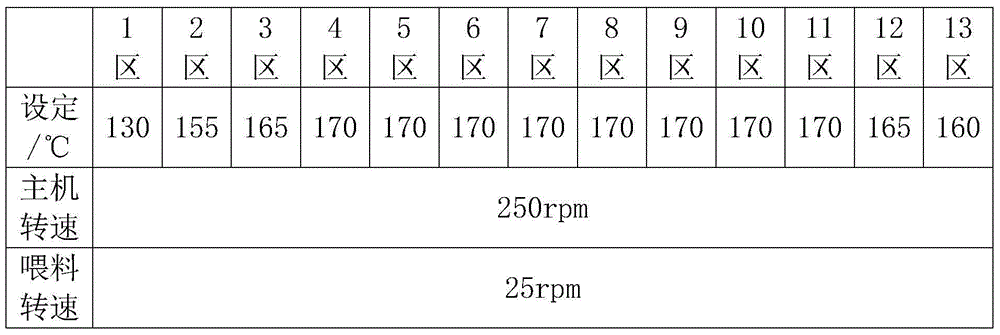

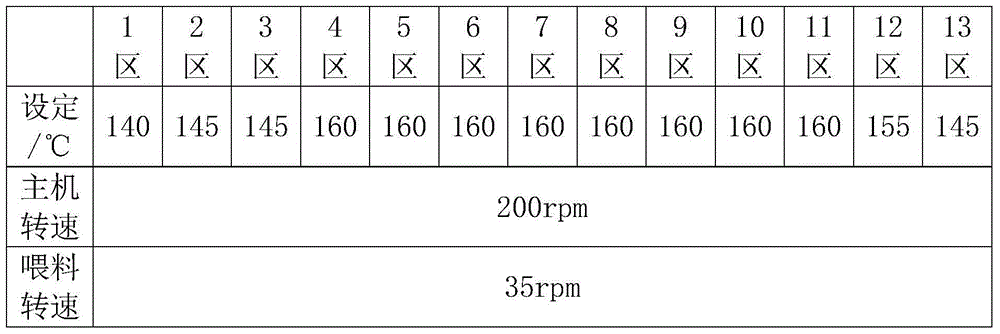

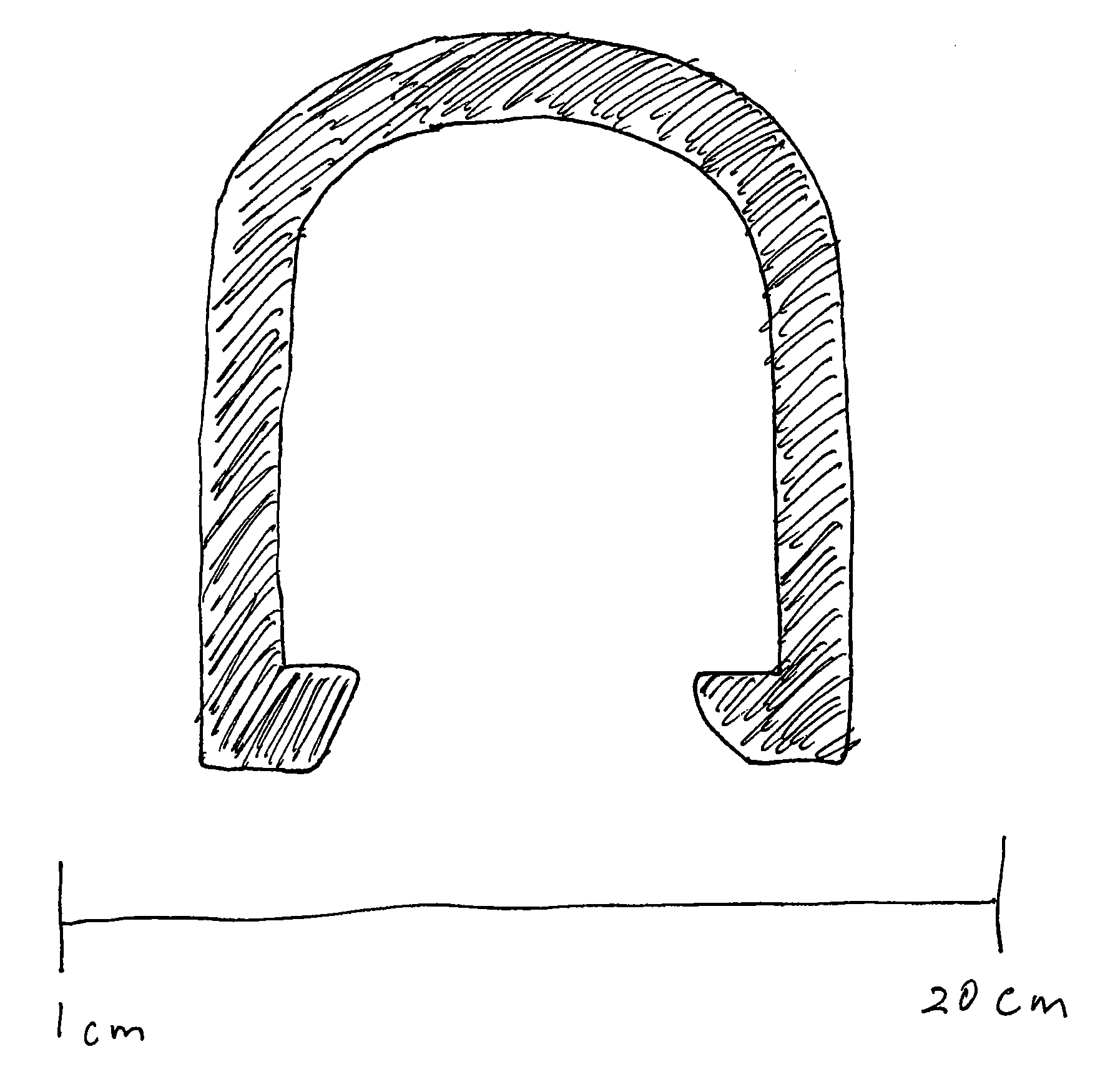

Heat-resistant completely biodegradable composite material for injection molded product and formula and preparation method of heat-resistant completely biodegradable composite material

The invention relates to a heat-resistant completely biodegradable composite material for an injection molded product and a formula and a preparation method of the heat-resistant completely biodegradable composite material. The invention aims at providing the heat-resistant completely biodegradable composite material for the injection molded product and the formula and the preparation method of the heat-resistant completely biodegradable composite material. The heat-resistant completely biodegradable composite material has the following physical properties: the Vicat temperature is 120-160 DEG C; the tensile strength is 60-110MPa; the elongation at break is 5-20%; the Shore D surface hardness is 80-90; and the melt mass-flow rate is 5-15g / 10min. The formula of the material comprises completely biodegradable resin, a filler, a coupling agent, a synergist, a nucleating agent component and a dispersant; the preparation method of the formula of the material comprises the steps of mixing the materials and performing spiral extrusion and discharge; and the heat-resistant completely biodegradable composite material provided by the invention has the advantages that a process for preparing the material is simple and the material is completely biodegradable.

Owner:SUZHOU HANFENG NEW MATERIAL

Absorbable/Biodegradable Composite Yarns and Property-Modulated Surgical Implants Therefrom

ActiveUS20090024151A1Improve propertiesMinimize tissue dragSuture equipmentsCoatingsYarnBiological property

The present invention is directed to absorbable / biodegradable composite yarns, each comprising at least two types of fibrous components having distinctly different absorption and strength retention profiles and the use of these composite yarns to construct surgical implants, such as sutures and meshes with integrated physicochemical and biological properties, modulated through varying the individual yarn content and controlling the geometry of these constructs.

Owner:POLY MED

Preparation method of biodegradable polyester composite material

A process for preparing the biodegradable composite polyester material includes the open-loop polymerization between nano-hydroxypatite and lactide in a sealed reactor in the heating and stirring condition under protection of N2 or argon gas to graft the lactide to the hydroxy on the surface of nano-hydroxyapatite and mixing it with the biodegradable polyester. Its advantages are high biodegradability and biocompatibility and excellent machinability.

Owner:CHANGCHUN SINOBIOMATERIALS

Biodegradable composite, product made therefrom, and method of manufacture thereof

Biodegradable composites and products, and methods of their manufacture are presented. The composites typically comprise 10 wt % to 80 wt % of a lignocellulosic material derived from an agricultural residue or obtained from a natural source, 20 wt % to 80 wt % of a polymer binder, 5 wt % to 20 wt % of a compatibilizer, and an effective amount of a processing aid. One method of manufacture of a product is by injection molding.

Owner:CITY UNIVERSITY OF HONG KONG

Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

The invention discloses a full-biodegradable composite as well as a preparation method and application of the full-biodegradable composite. The full-biodegradable composite comprises the following components: 5-40 parts of inorganic filler full-biodegradable masterbatches, 40-80 parts of biodegradable copolyester, 10-40 parts of starch and 5-20 parts of a plasticizer, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of biodegradable copolyester, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of a compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the matrix resin, so that the problem of relatively low tearing strength of a blend film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

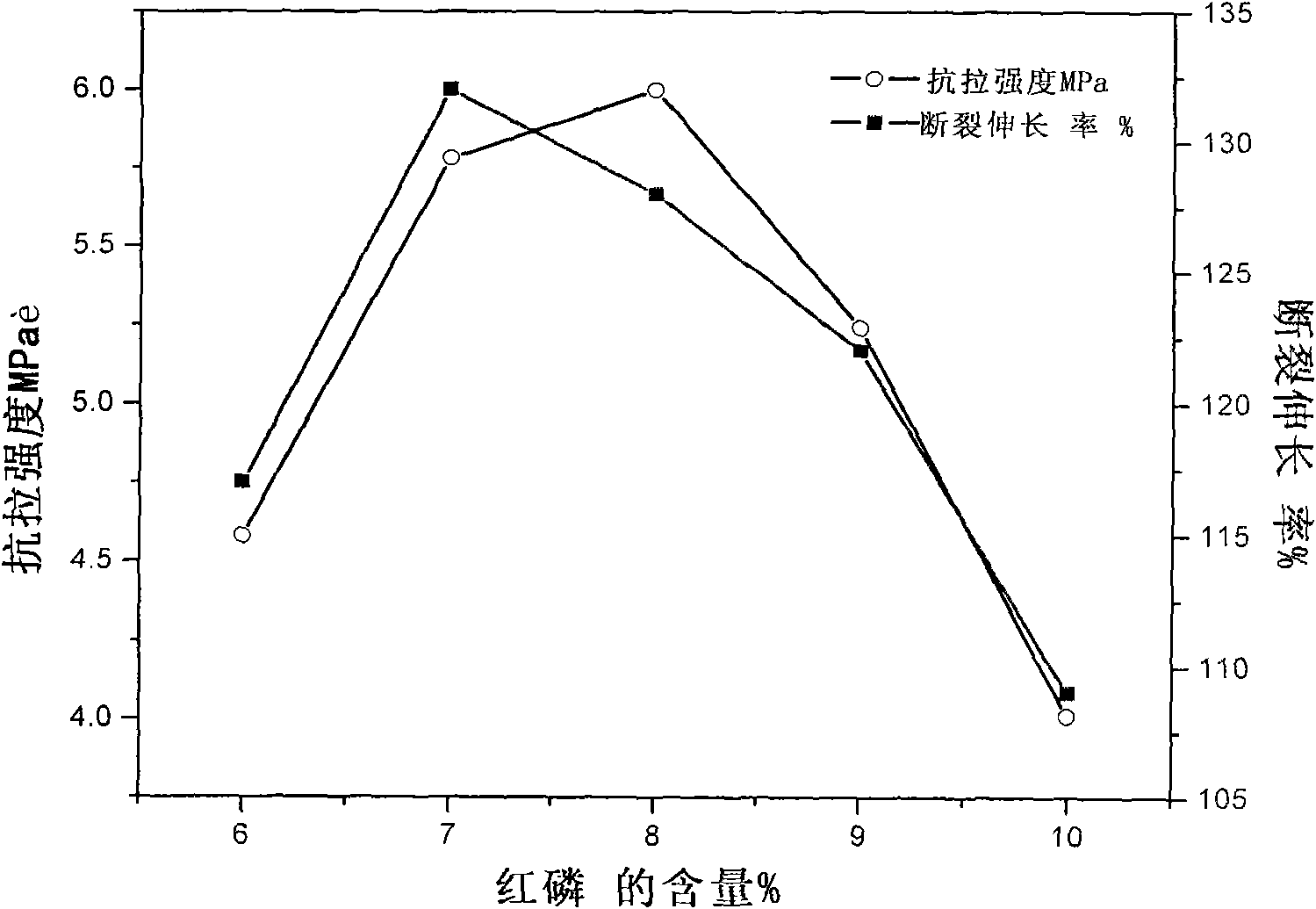

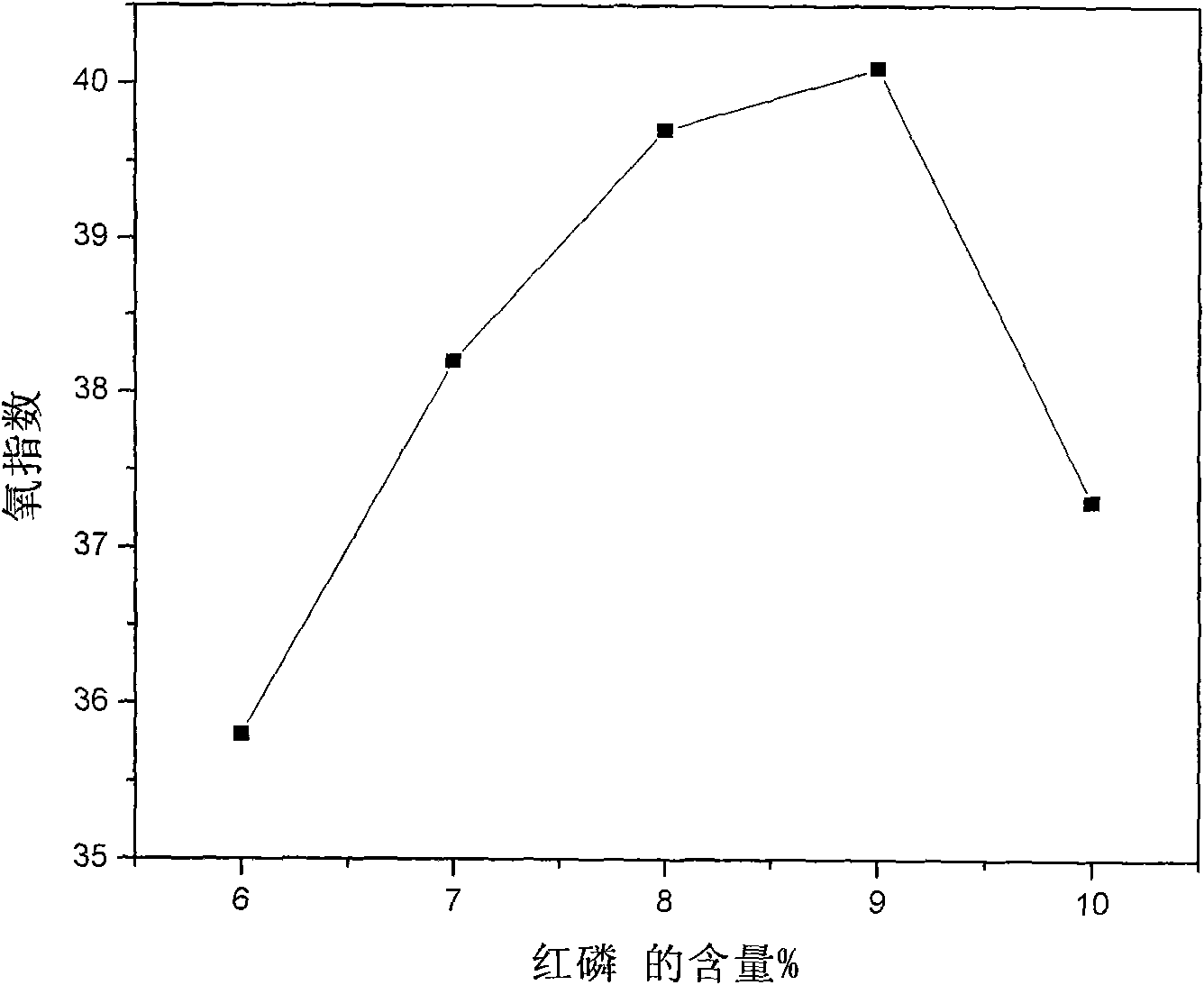

Biodegradable flame resistance material and preparation method thereof

InactiveCN101665588AImprove flame retardant performanceAvoid natural oxidationCoatingsAutoxidationPolymer science

The invention provides a biodegradable flame resistance material. The flame resistance material is characterized in that starch and chitosan are used as main components, red phosphorus is used as flame resistance additive, starch / chitosan can provides a great deal of carbon, chitosan contains nitrogen element, when acid source is added in red phosphorus, the flame resistance of the biodegradable material is effectively improved and the usable range of the biodegradable composite material is expanded so that the biodegradable composite material has wider application area; the preparation methodadopts solution method, ultrasonic dispersion and mechanical high-speed agitation so that red phosphorus used as fire retardant can be dispersed in solution on nano-scale and the autoxidation of thecomposite material can be effectively avoided, thus the composite material can have better mechanical performance.

Owner:余姚市环华电器有限公司

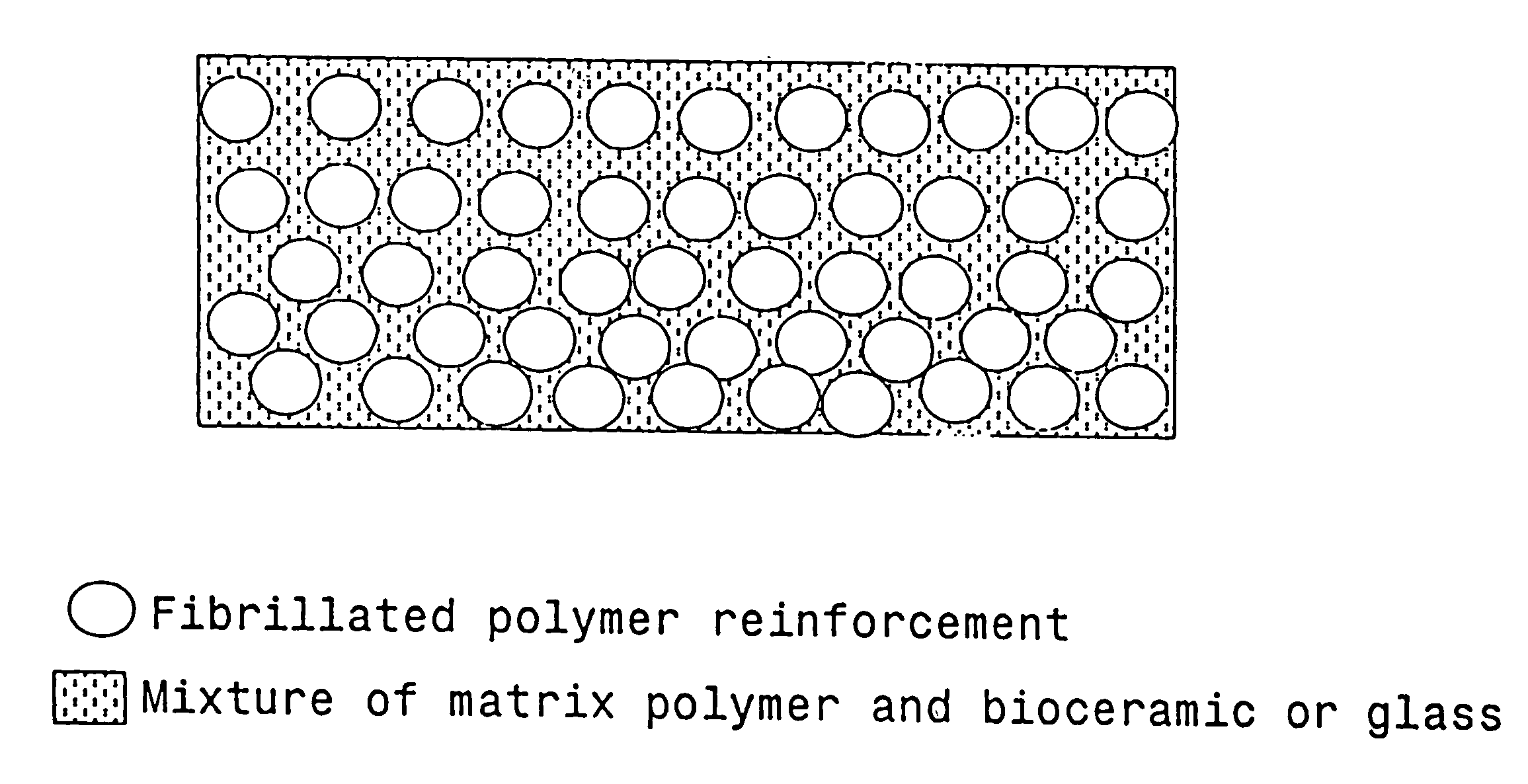

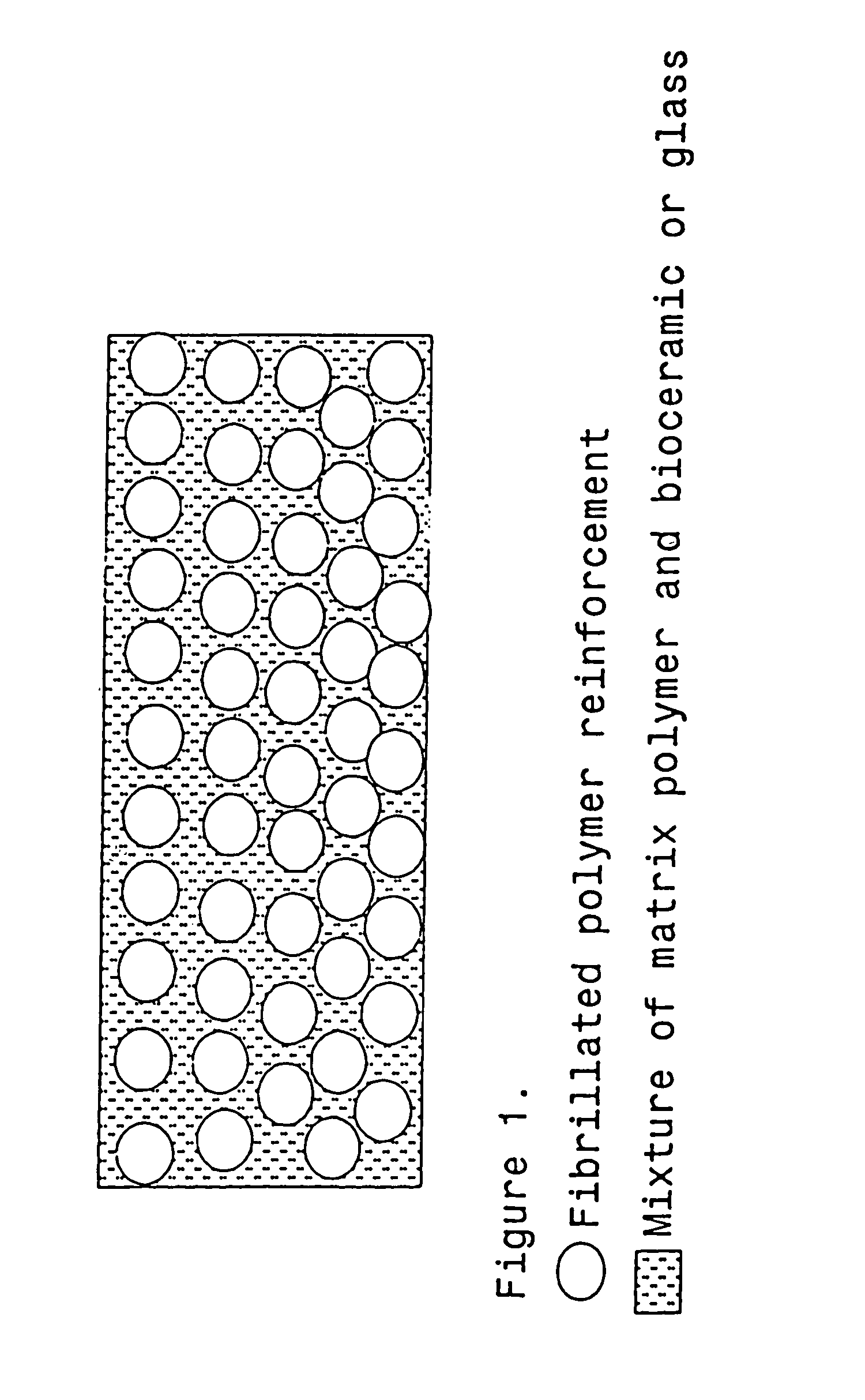

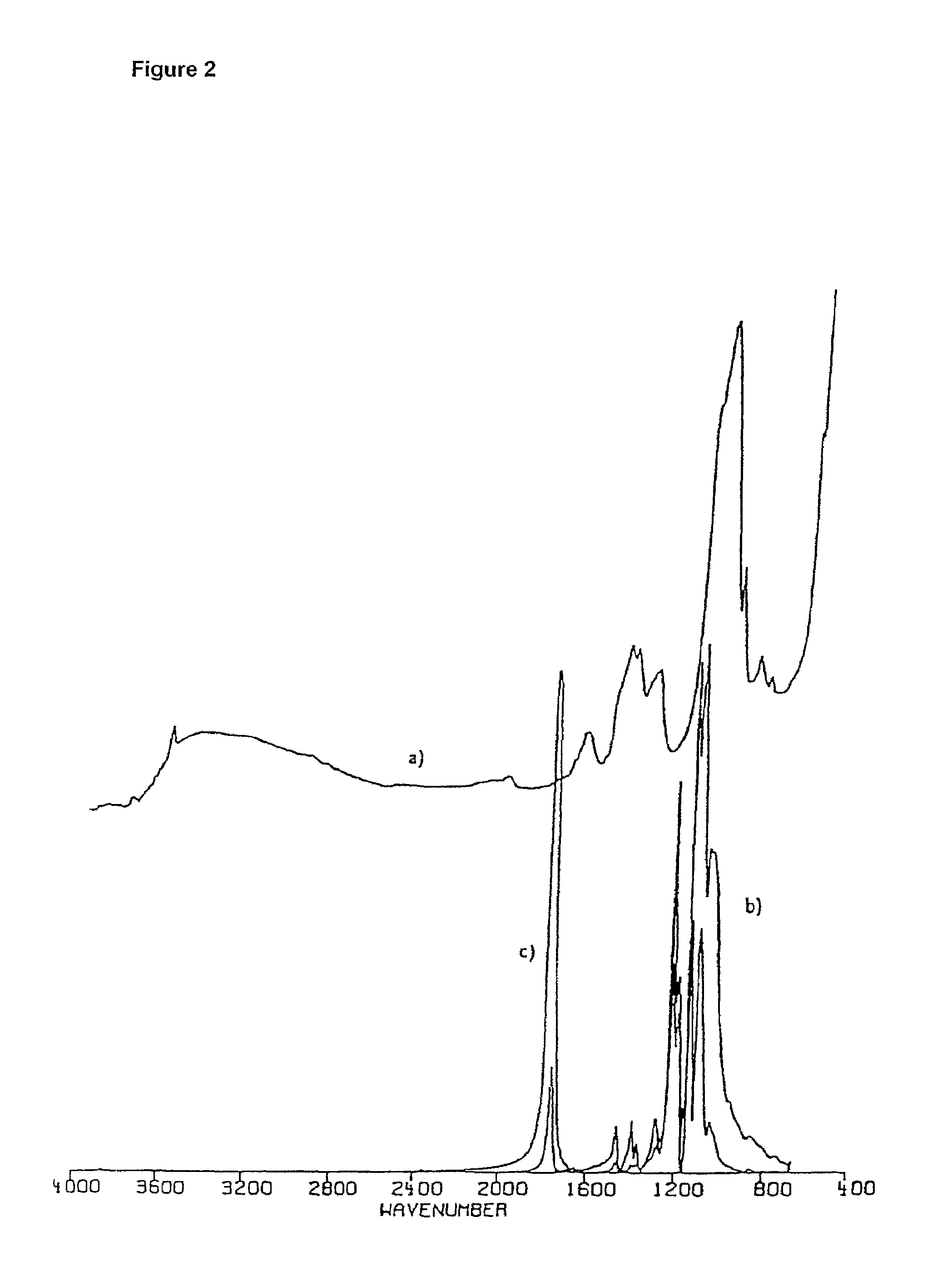

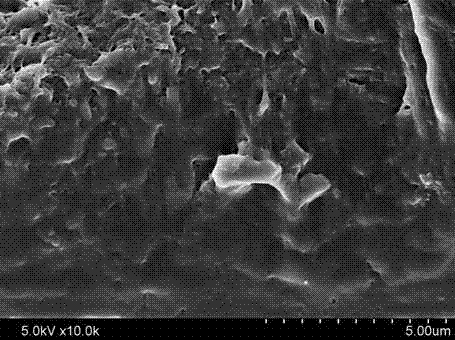

Bioactive and biodegradable composites of polymers and ceramics or glasses and method to manufacture such composites

Surgical osteosynthesis composite material which has three components: biodegradable polymer reinforcement, bioceramic or bioglass filler reinforcement and biodegradable polymer matrix. This invention relates to biodegradable materials used for bone fracture fixation devices and methods of their manufacture. Unlike other known materials used prior to this application, the composites of this invention have two different reinforcing phases and one matrix phase. One reinforcing element is referred as the polymeric reinforcing element and the other as the ceramic reinforcing element.

Owner:LINVATEC BIOMATERIALS

Method of performing anterior cruciate ligament reconstruction using biodegradable interference screw

A method of replacing an ACL with a graft. The method provides for the drilling bone tunnels in a femur and a tibia. A replacement graft is provided having first and second ends. A biodegradable composite screw is provided. The screw is made from a biodegradable polymer and a bioceramic or a bioglass. At least one end of the graft is secured in a bone tunnel using the biodegradable composite screw.

Owner:DONNELLY LISA +4

Fully-biodegradable composite membrane filled with nano silver/cellulose nanocrystal composite particles, and preparation method thereof

InactiveCN103483786AImprove mechanical propertiesGood thermal propertiesGlass sheetBiodegradable polymer

The invention relates to a preparation method of a fully-biodegradable composite membrane filled with nano silver / cellulose nanocrystal composite particles. The fully-biodegradable composite membrane comprises a biodegradable polymer, and the nano silver / cellulose nanocrystal composite particles, and the mass ratio of the biodegradable polymer to the nano silver / cellulose nanocrystal composite particles is 4-99:1. The preparation method comprises following steps: cellulose is added into a formic acid / hydrochloric acid mixed acid solution, and aldehyde group modified cellulose nanocrystals are obtained after reaction; the aldehyde group modified cellulose nanocrystals are added into silver nitrate solution so as to obtain the nano silver / cellulose nanocrystal composite particles; the nano silver / cellulose nanocrystal composite particles are added into a solution of the biodegradable polymer so as to obtain a mixed solution; and the mixed solution is subjected to direct coating on a glass plates, and products are dried so as to obtain the fully-biodegradable composite membrane filled with the nano silver / cellulose nanocrystal composite particles. The preparation method is simple and convenient, is low in cost and high in efficiency, and is suitable for industrialized batch production; the multi-functional membrane is degradable, and is excellent in mechanical and thermal properties; antibacterial effect is excellent and lasts long; and application prospect is promising.

Owner:ZHEJIANG SCI-TECH UNIV

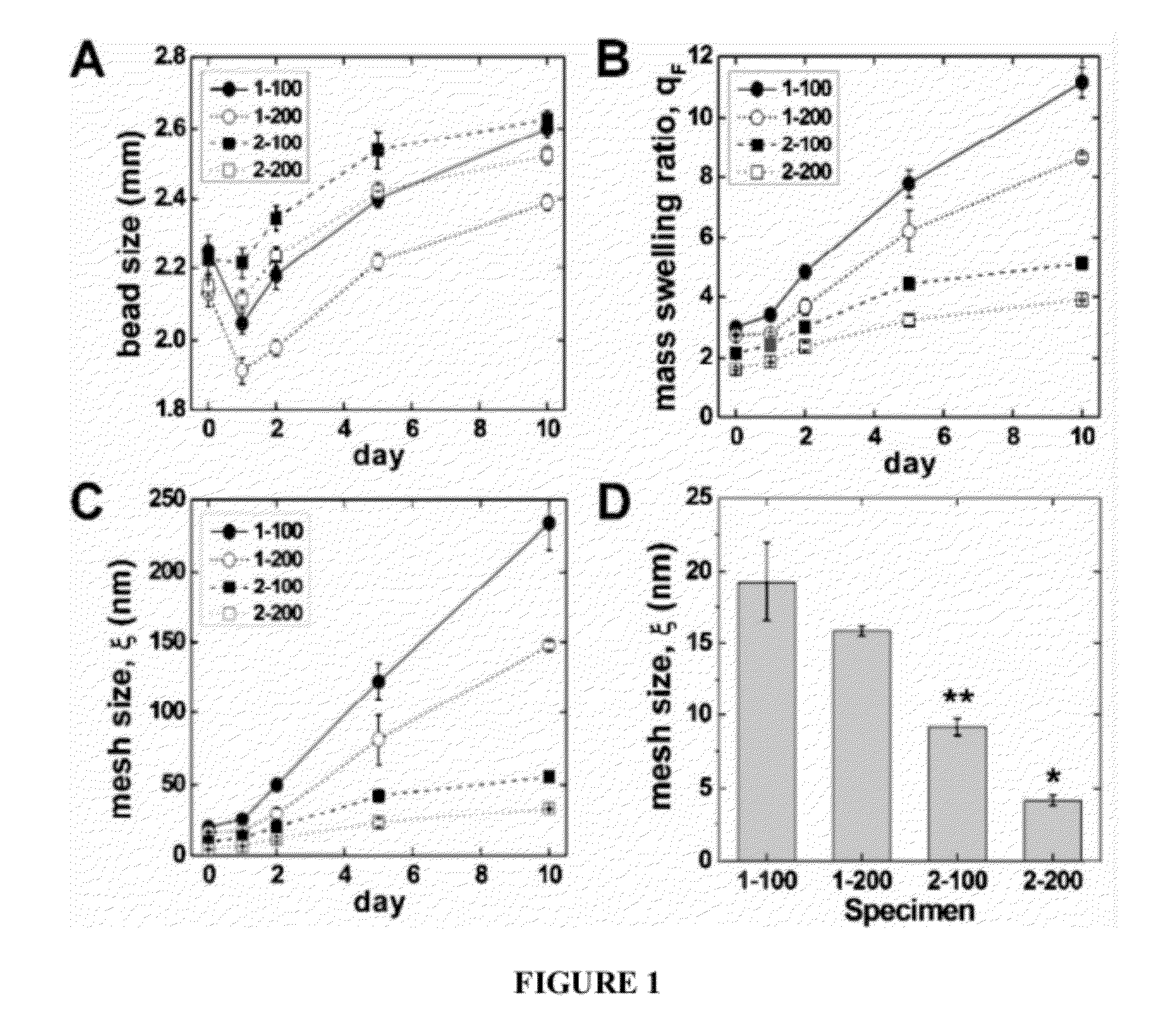

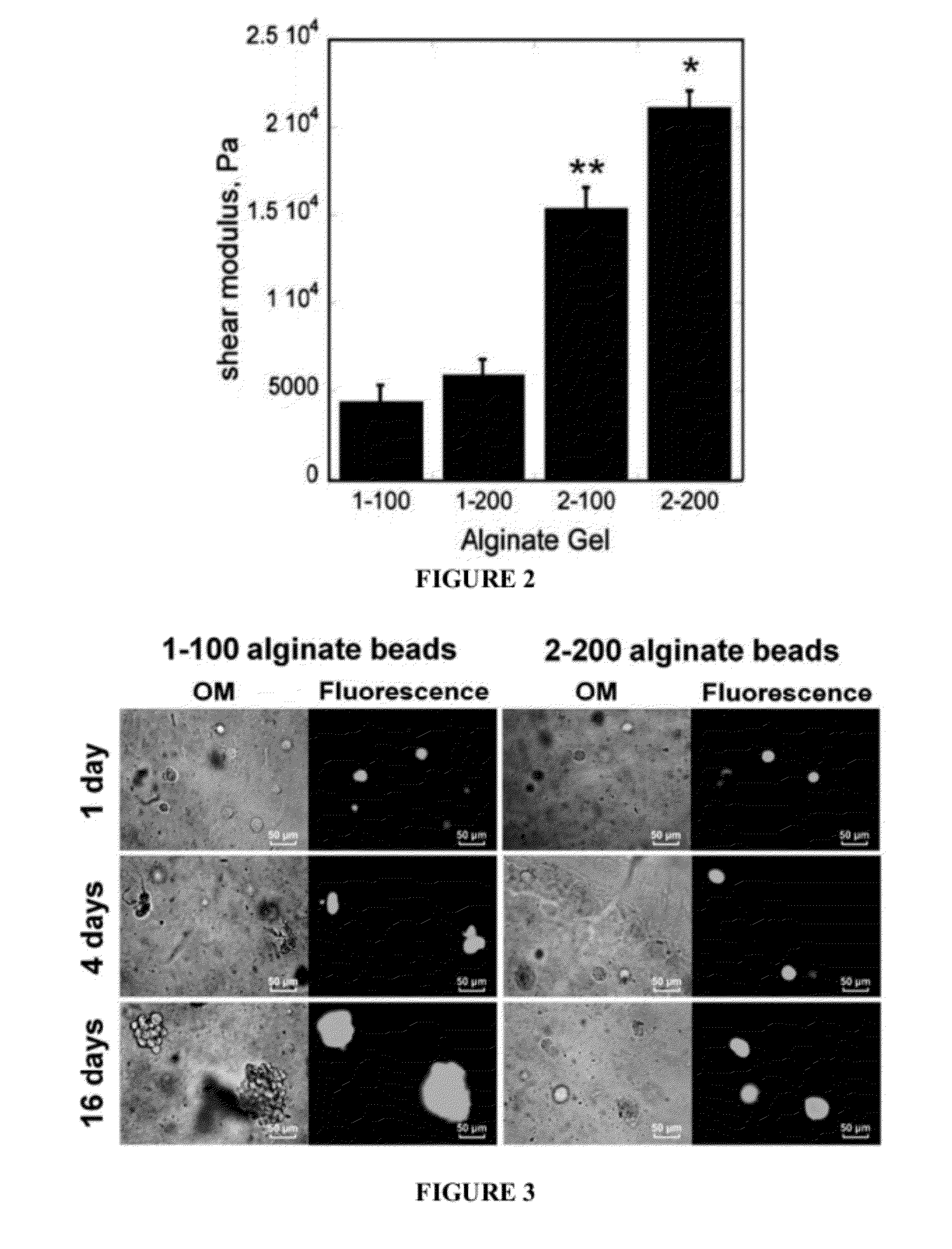

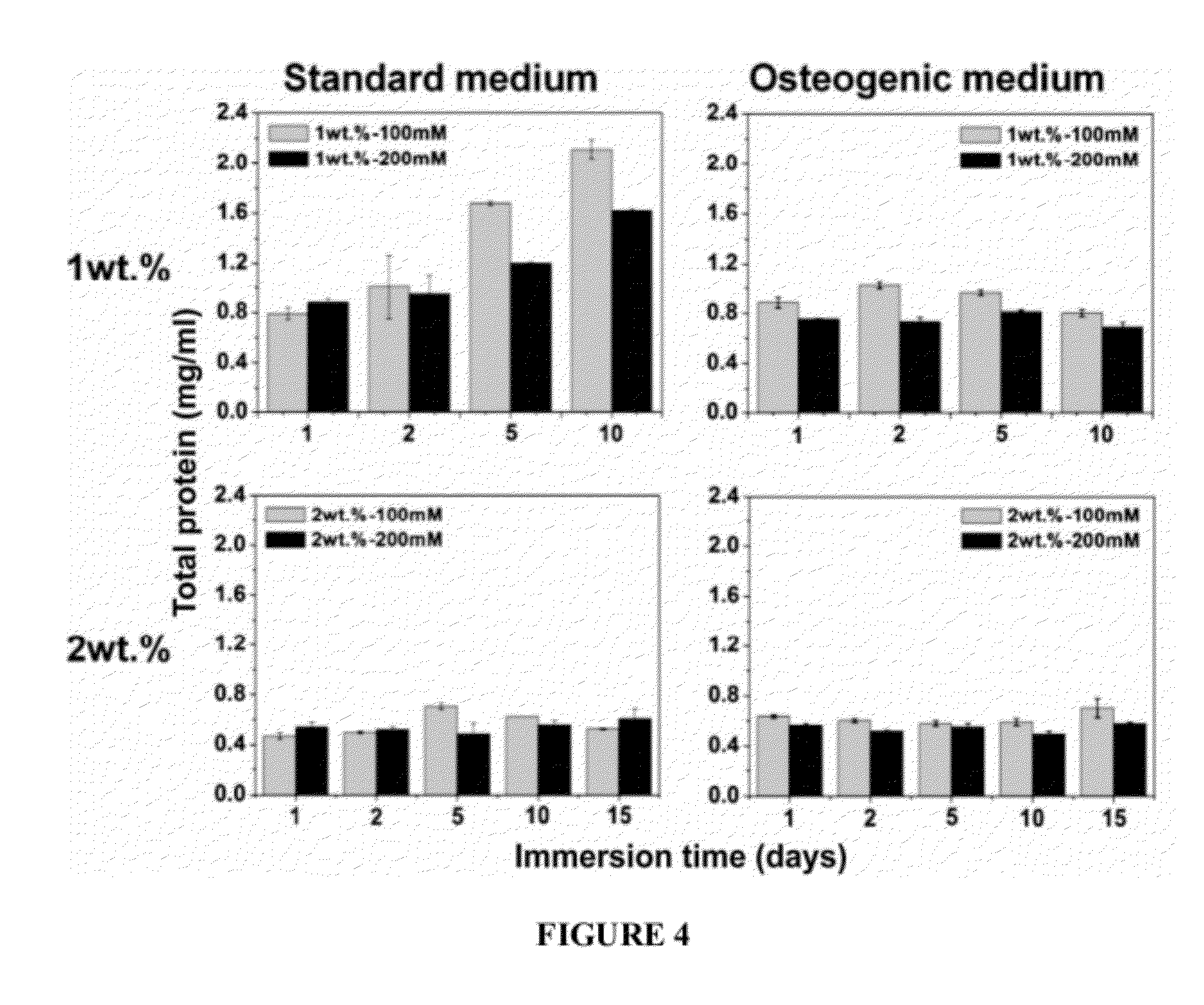

Encapsulated cells and composites thereof

InactiveUS20120183622A1Improve usabilityEnhance cell viabilityBiocideMammal material medical ingredientsBiodegradable compositesImplantation Site

Owner:VANDERBILT UNIV

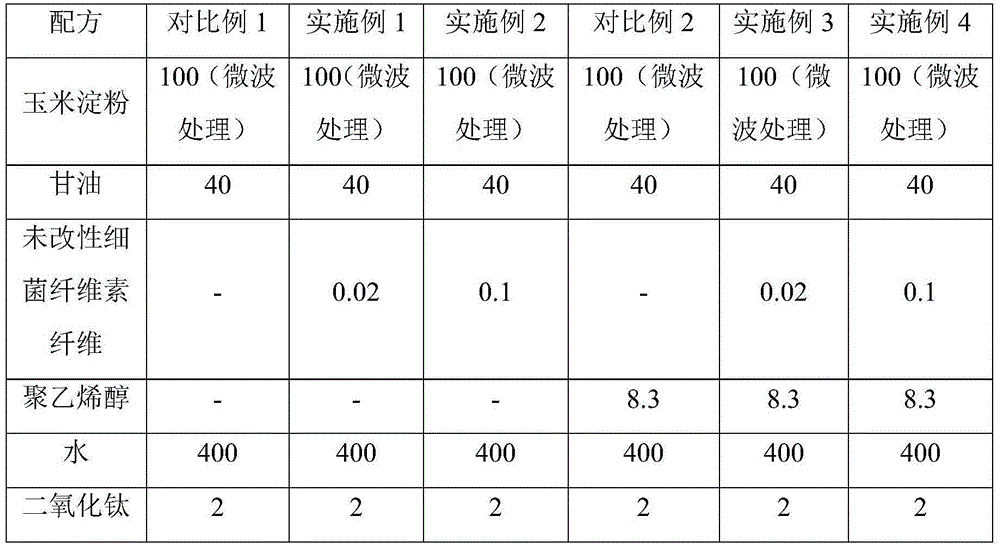

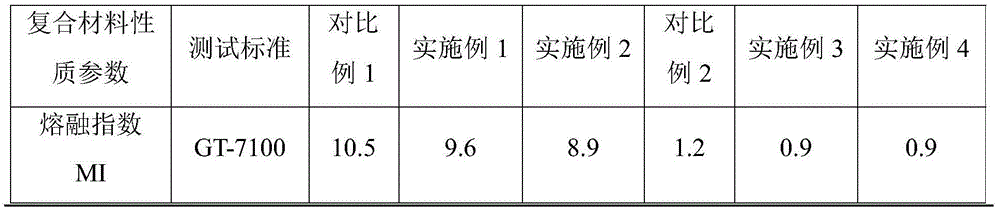

Starch-based biodegradable composite material and preparation method thereof

The invention discloses a starch-based biodegradable composite material and a preparation method thereof. The preparation method comprises the following steps: treating starch with microwave; mixing the starch treated with microwave with a plasticizer and a pre-plasticizing dispersant in a mass ratio of 1: (0.1-0.5): (2-6), and performing mechanical dispersion to obtain a mixture A; mixing a blending material containing an enhancer and a pre-plasticizing dispersant in a mass ratio of (0.01-1): (5-30) with the mixture A to obtain a mixture B, wherein the enhancer is unmodified bacterial cellulose fiber and / or modified bacterial cellulose fiber, and the mass ratio of the enhancer to the starch is (0.01: 100)-(0.2: 100); and heating and stirring the mixture B, drying to remove water, extruding and granulating, thus obtaining the composite material. The starch-based biodegradable composite material has relatively high mechanical strength and good water resistance.

Owner:上海耐特复合材料制品有限公司 +1

Composite material for packaging full-biological degradation medicament

The invention relates to a full-biodegradable composite material for packaging medicine, which is prepared by mixing 20 percent to 80 percent of polylactic acid (PLA) and 20 percent to 80 percent of poly propylene carbonate (PPC), and the percentage is weight percentage. The invention has good mechanical property, biodegradability, good thermal stability, simple processing and moulding, excellent brightness and transparency, and meets the various performance requirements of medicine packaging sheets. The invention can be completely degraded by microorganisms in soil, and after being used, no pollution is produced, thus being a desirable full-biodegradable composite material for packaging medicine.

Owner:威海赛绿特科技发展有限公司

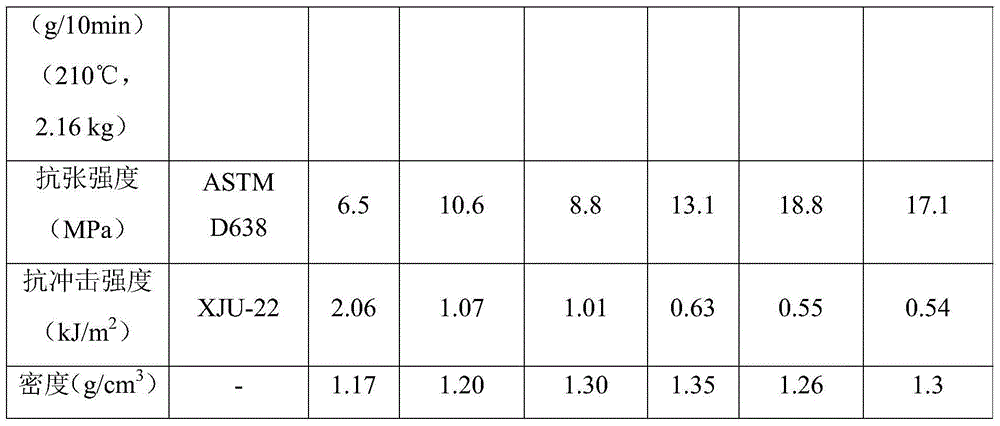

Biodegradable composite and preparation method thereof

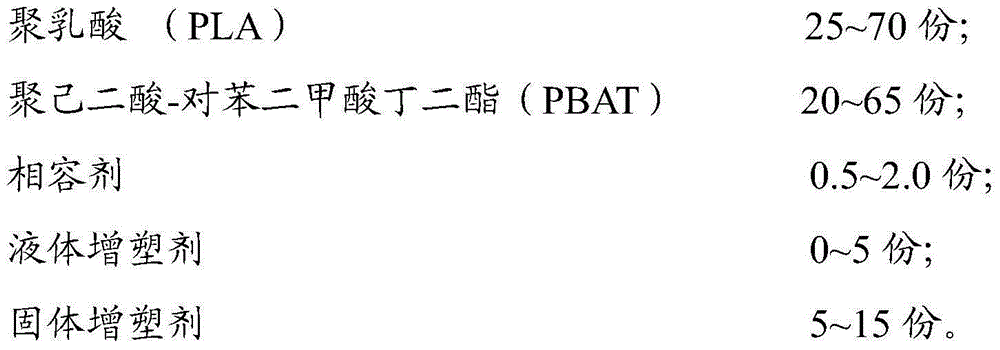

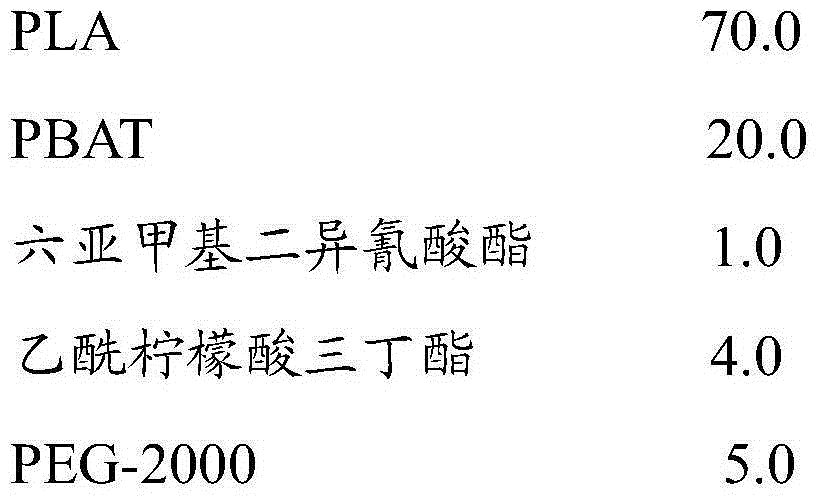

The invention relates to biodegradable composite and a preparation method thereof. The biodegradable composite comprises components in parts by mass as follows: 25-70 parts of polylactic acid, 20-65 parts of poly(butylene adipate-butylene terephthalate), 0.5-2.0 parts of a compatilizer, 0-5 parts of a liquid plasticizer and 5-15 parts of a solid plasticizer, wherein the liquid plasticizer is at least one of tributyl citrate, acetyl tributyl citrate, epoxidized soybean oil, polyethylene glycol-200, polyethylene glycol-300, polyethylene glycol-400 and polyethylene glycol-500; the solid plasticizer is at least one of polyethylene glycol-1500, polyethylene glycol-2000, polyethylene glycol-3000, polyethylene glycol-4000, polyethylene glycol-6000, polyethylene glycol-8000, polyethylene glycol-10000 and polyethylene glycol-20000. The biodegradable composite has higher elongation at break and is easier to prepare.

Owner:深圳新诺包装制品有限公司

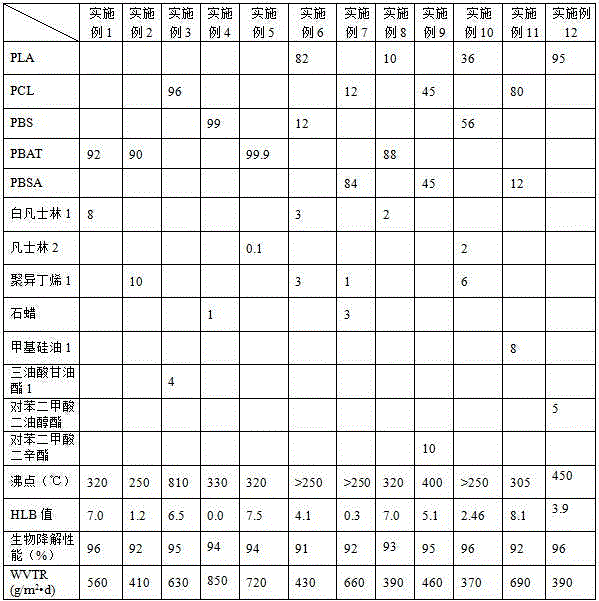

Biodegradable composite with barrier property and preparation method and applications thereof

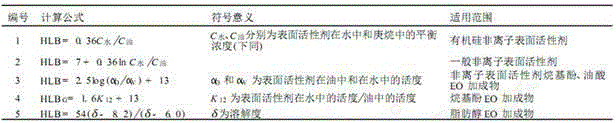

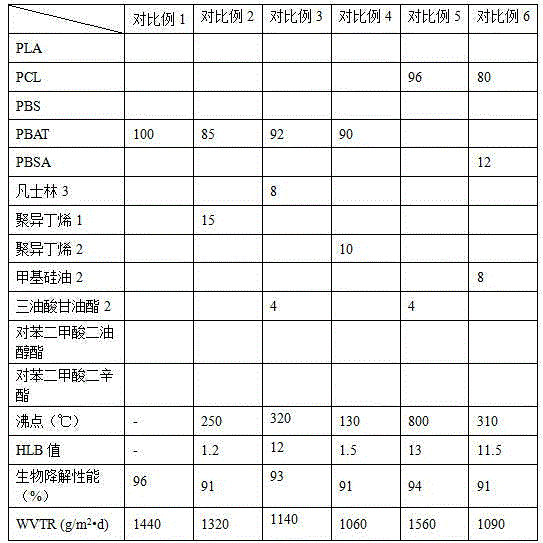

The invention discloses a biodegradable composite with a barrier property, which comprises the following components in percentage by weight: 0.1-10 % (preferably 1-8 %) of a waterproofing agent, and 90-99.9 % (preferably 92-99 %) of biodegradable polyester, wherein the boiling point of the waterproofing agent is greater than or equal to 160 DEG C, and the HLB value is less than or equal to 10. According to the invention, the biodegradable composite prepared by adding a specific amount of the waterproofing agent with a boiling point of greater than or equal to 160 DEG C and an HLB value of less than or equal to 10 into the biodegradable polyester not only has good biodegradability, but also has a good water-vapor barrier property, therefore, the biodegradable composite can be widely applied to the fields of packaging and agricultural plastic mulching films.

Owner:夏世勇

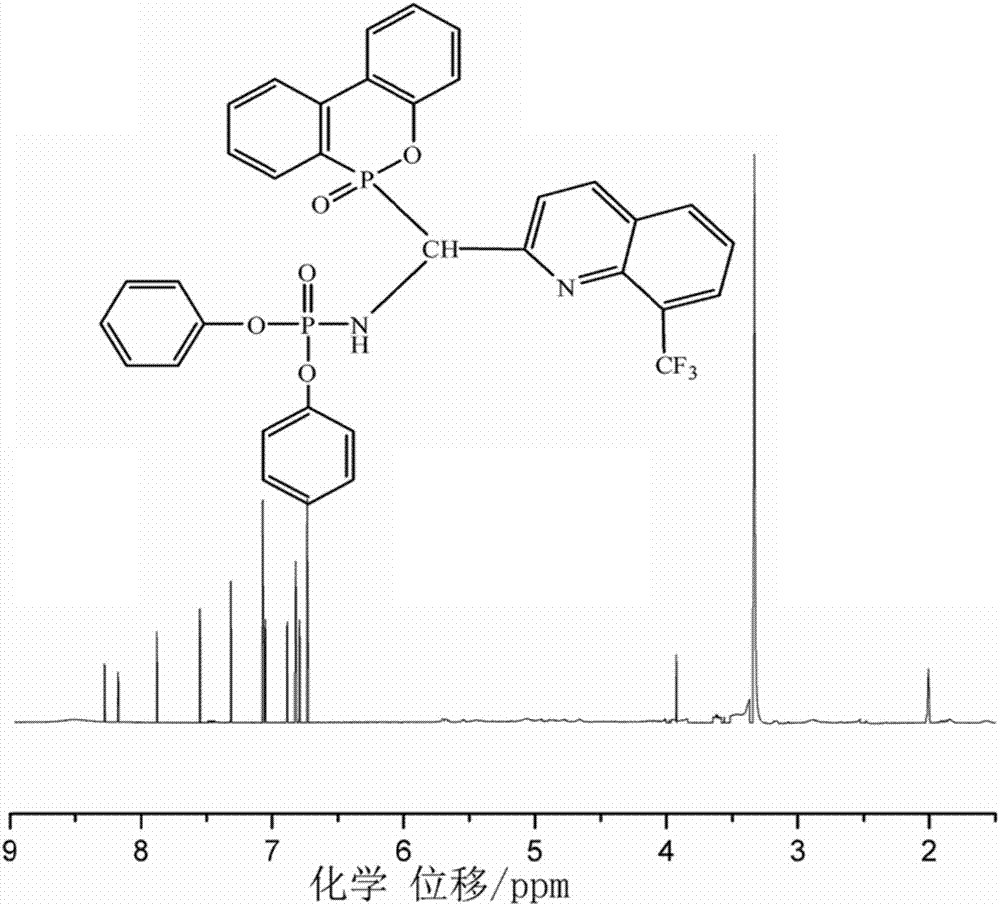

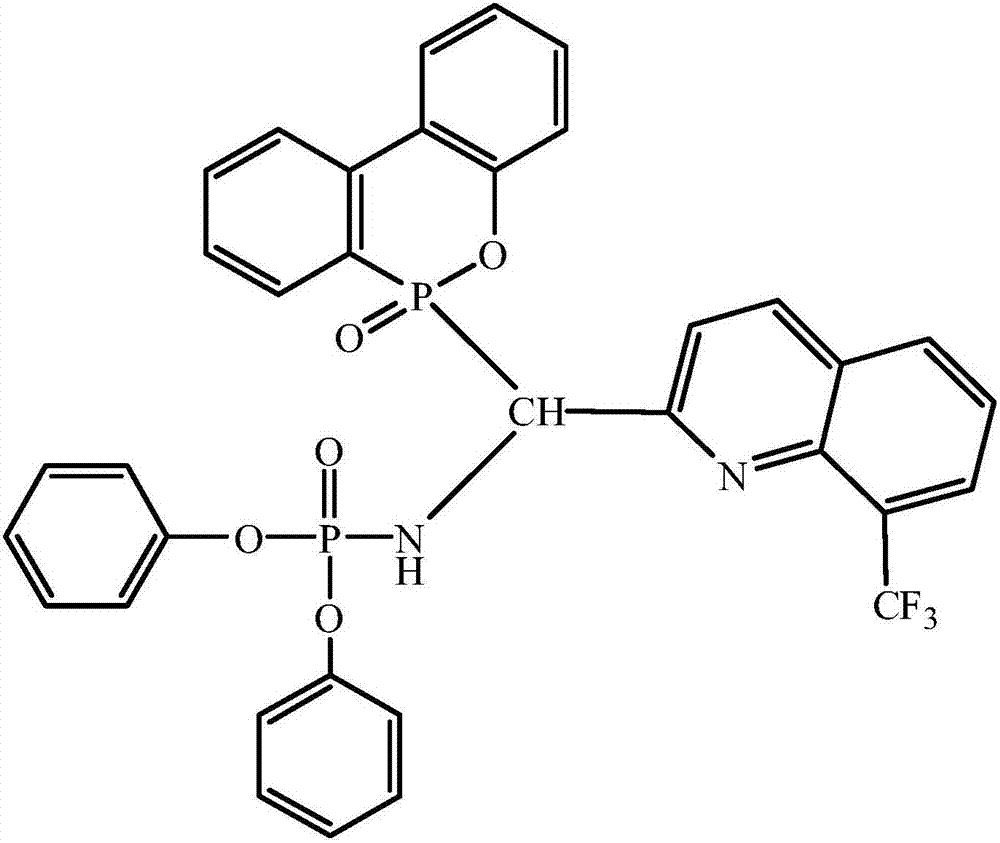

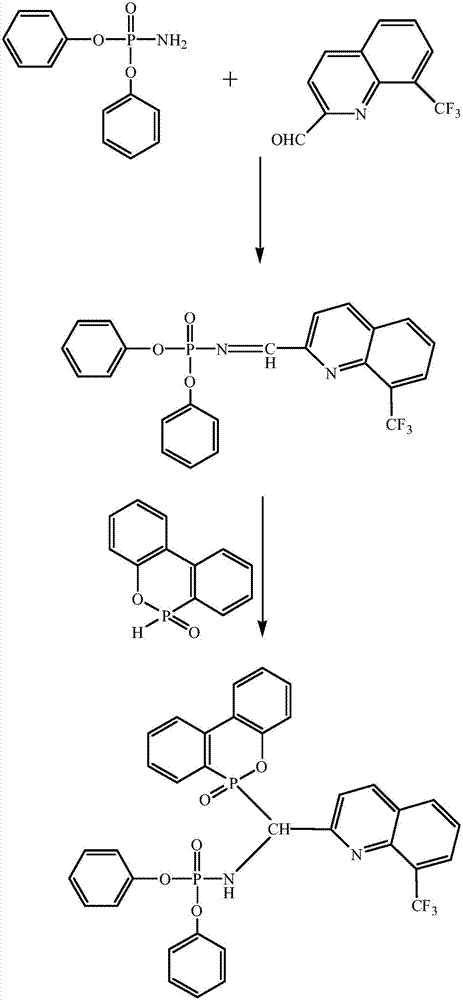

Flame-retardant and antibacterial PLA (polylactic acid) biodegradable composite for 3D (three dimensional) printing

ActiveCN107151430AGood surface mobilityNothing producedAdditive manufacturing apparatusGroup 5/15 element organic compoundsAntioxidantFire retardant

The invention relates to the field of polymer materials, in particular to a flame-retardant and antibacterial PLA (polylactic acid) biodegradable composite for 3D (three dimensional) printing. The composite is prepared from the following raw materials in parts by weight: 100 parts of PLA, 2-10 parts of a nucleating agent, 5-10 parts of a natural macromolecule antibacterial agent, 1-5 parts of a toughening agent, 0.3-0.8 part of an antioxidant, 0.5-1 part of a compatibilizer, 0.5-1.5 parts of a lubricant and 5-10 parts of a DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) derivative flame retardant. According to the flame-retardant and antibacterial PLA biodegradable composite for 3D printing, the DOPO derivative flame retardant and the natural macromolecule antibacterial agent are added to a PLA composite system, so that on the one hand, the PLA composite is endowed with a lasting and broad antibacterial property by the natural macromolecule antibacterial agent, bactericidal power is high, performance is stable, biodegradation is facilitated, and secondary pollution can be prevented; on the other hand, when content of the flame retardant reaches 5%-10%, a cured product can reach the level of UL94, V-0.

Owner:义乌市筑真电子科技有限公司

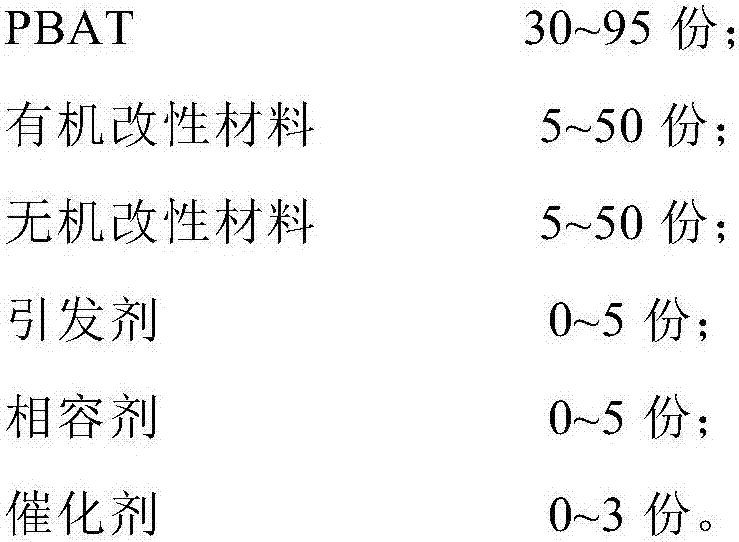

PBAT-based biodegradable composite material with high vapor barrier property

The invention provides a PBAT-based biodegradable composite material with high vapor barrier property. The composite material comprises the following components: PBAT, organic modification material, inorganic modification material, an initiator, a compatilizer and a catalyst. Compared with the prior art, the PBAT-based biodegradable composite material has the following beneficial effects: the compatibility and dispersity of the inorganic material in PBAT can be greatly improved by bridging PBAT with the inorganic material; the bridging action, generated due to combination of the compatilizer and the initiator, of the inorganic material is partially directionally distributed by layers in a blending system, the pass route of water molecules can be prolonged, and the motion time of the water molecules in the material can be prolonged, so that the water retention property of the material can be remarkably improved, the water vapor permeability of the composite material 10mum thin film material is reduced to 320g / m<2>.24h from 280g / m<2>.24h of the original-specification thin film, which is obviously superior to the similar materials.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

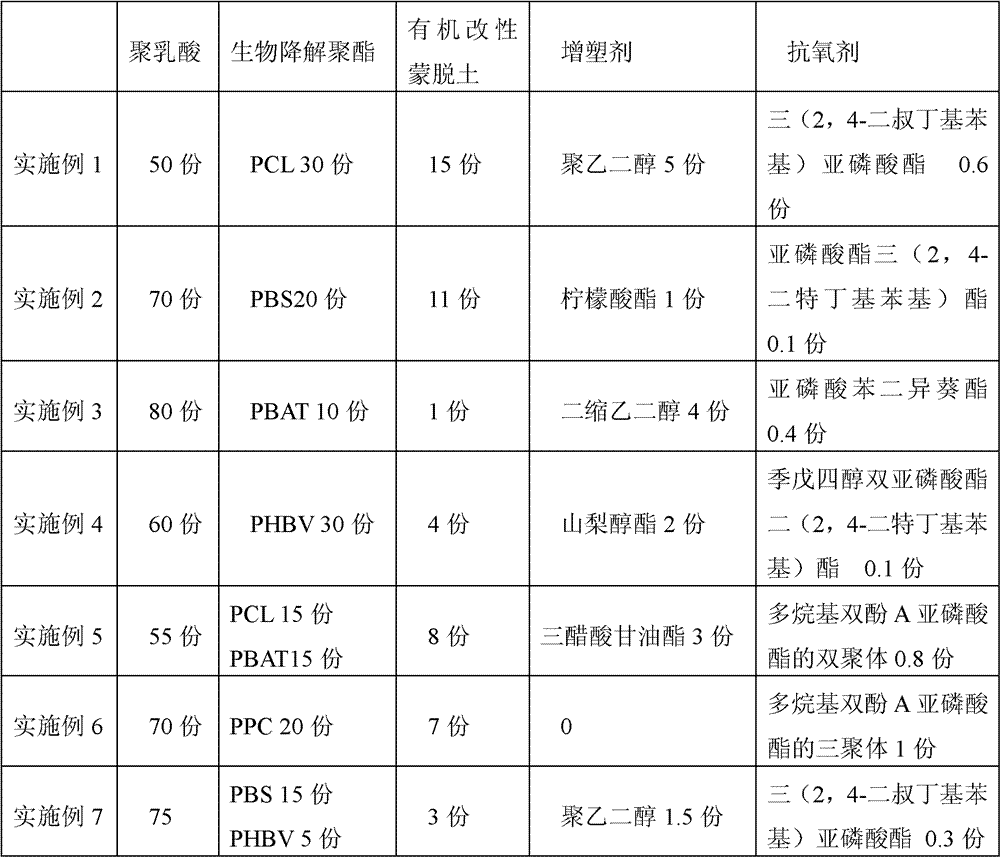

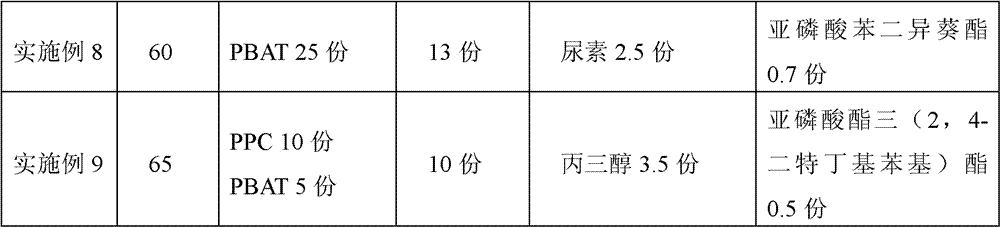

Biodegradable composite material and preparation method thereof

InactiveCN103242631AImprove heat resistanceImprove mechanical propertiesAntioxidantBiodegradable polyester

The invention belongs to the technical field of high polymer materials, and discloses a biodegradable composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 50-80 parts of polylactic acid, 10-30 parts of biodegradable polyester, 1-15 parts of organic modified montmorillonite, 0-5 parts of plasticizer and 0.1-1 part of antioxidant. The preparation method comprises the following steps: weighing 50-80 parts of dried polylactic acid, 10-30 parts of dried biodegradable polyester, 1-15 parts of dried organic modified montmorillonite, 0-5 parts of plasticizer and 0.1-1 part of antioxidant; adding into a high-speed mixer, and blending for 5-10 minutes; and feeding the mixture into a double-screw extruder, performing melt blending and extrusion, performing bar drawing, cooling in water, granulating, and drying to obtain the degradable composite material. The invention can improve the heat resistance of the material, overcome the defects of pure polylactic acid such as low material strength and low toughness, improve the mechanical properties and widen the application area of the material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com