Heat-resistant completely biodegradable composite material for injection molded product and formula and preparation method of heat-resistant completely biodegradable composite material

A technology for biodegradable and injection-molded products, applied in the field of heat-resistant fully biodegradable composite materials for injection-molded products and their formulation and preparation, which can solve the problems of complex process, high relative cost, insufficient heat resistance, and insufficient mechanical properties of materials, etc. problem, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

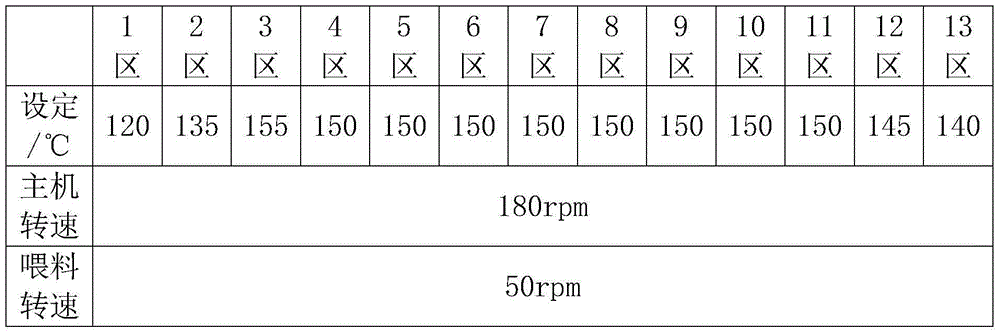

Embodiment 1

[0029] (1) Material mixing: Calculated by weight, first add 35 parts of fillers to a high-speed mixer, dehydrate at a temperature of 80°C for 25 minutes, wherein the filler is a mixture of heavy calcium carbonate and talcum powder, and heavy calcium carbonate and The parts of talcum powder are 20 parts and 15 parts respectively, then add 5 parts of silane coupling agent and stir for 2 minutes, then add 3 parts of synergist and stir for 2 minutes, wherein the synergist is a mixture of erucic acid and oleic acid, and erucic acid and oleic acid are 1 part and 2 parts respectively, and finally add 1 part of paraffin wax, 1 part of Hangzhou Ximao TMB-5000 and 50 parts of fully biodegradable resin, stir for 5 minutes, and discharge the material, wherein the fully biodegradable resin is polymer A mixture of butylene succinate-co-butylene terephthalate (PBST) and polybutylene succinate (PBS), and the number of parts of PBST and PBS is 20 parts and 30 parts respectively, the whole The ...

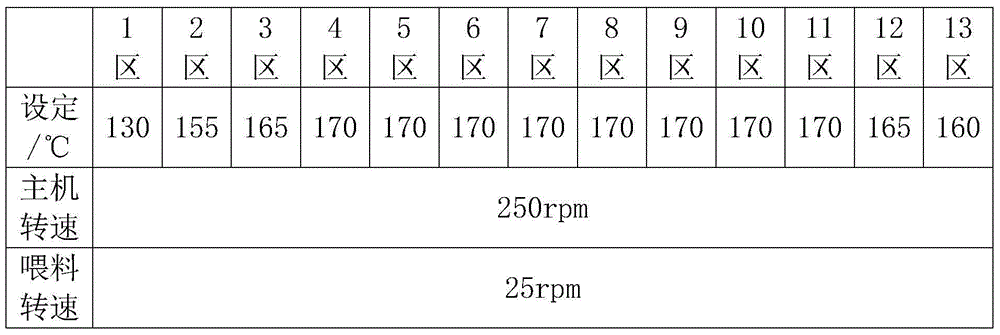

Embodiment 2

[0033] (1) Material mixing: Calculated by weight ratio, first add 20 parts of filler to a high-speed mixer, dehydrate at a temperature of 100°C for 15 minutes, wherein the filler is a mixture of talcum powder and calcium sulfate whiskers, and talcum powder, calcium sulfate whiskers The parts are 10 parts and 10 parts respectively, then add 3 parts of titanate coupling agent, stir for 3 minutes, then add 2 parts of synergist and stir for 3 minutes, wherein the synergist is a mixture of erucic acid and stearic acid, and erucic acid The parts of stearic acid and stearic acid are 1 part and 1 part respectively, and finally add 3 parts of dispersant, 2 parts of nucleating agent and 70 parts of complete biodegradable resin, stir for 4 minutes, and discharge, wherein the dispersant is calcium stearate , zinc stearate, and paraffin, and the parts of calcium stearate, zinc stearate, and paraffin are 1 part, 1 part, and 1 part respectively, and the nucleating agent is TMC-300, Shanxi Ins...

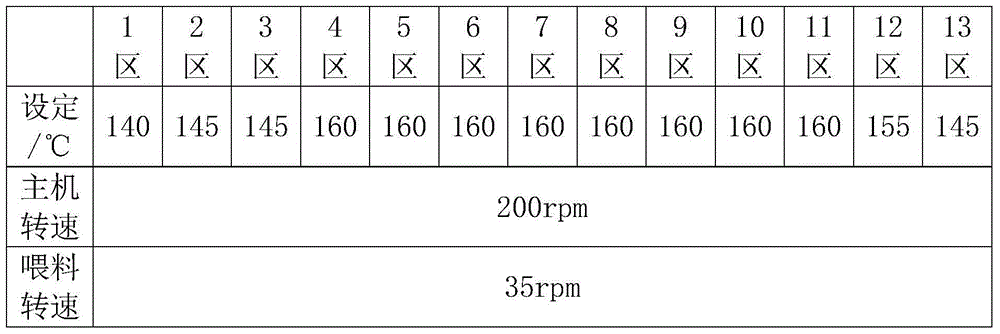

Embodiment 3

[0037](1) Material mixing: Calculated by weight ratio, first put 15 parts of filler into a high-speed mixer, dehydrate at a temperature of 120°C for 10 minutes, wherein the filler is a mixture of montmorillonite and glass fiber, and the mixture of montmorillonite and glass fiber The parts are 10 parts and 5 parts respectively, then add 1 part of aluminate coupling agent, stir for 5 minutes, add 1 part of oleic acid, stir for 5 minutes, finally add 5 parts of dispersant, 3 parts of nucleating agent and 75 parts of complete biological Degrade the resin, stir for 3 minutes, and discharge, wherein the dispersant is a mixture of calcium stearate, zinc stearate, paraffin, erucamide, N,N-bisstearamide, and calcium stearate, stearin The parts of zinc acid, paraffin, erucamide, and N,N-bisstearamide are 1 part, 1 part, 1 part, 1 part, 1 part respectively, and the nucleating agent is Hangzhou Ximao TMP-3000, TMC -300, a mixture of metal salts of hypophosphite compounds, and the parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com