Biodegradable composite with barrier property and preparation method and applications thereof

A technology of biodegradation and biodegradation of polyester, applied in the field of biodegradable composition and its preparation, can solve the problems of inability to recycle, low recycling value, difficult to separate, etc., and achieve good water vapor barrier and good biodegradation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12 and comparative example 1-6

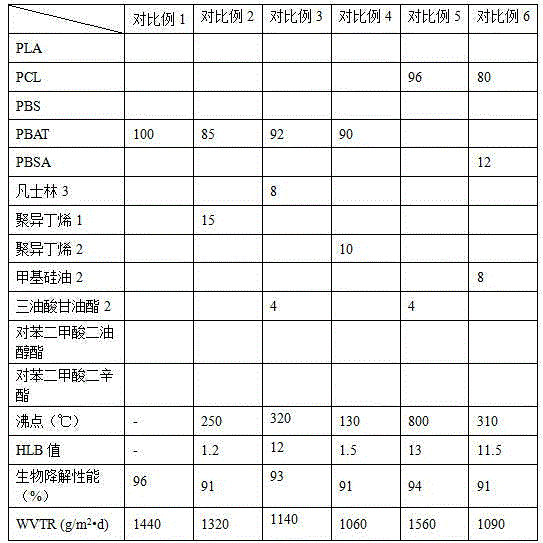

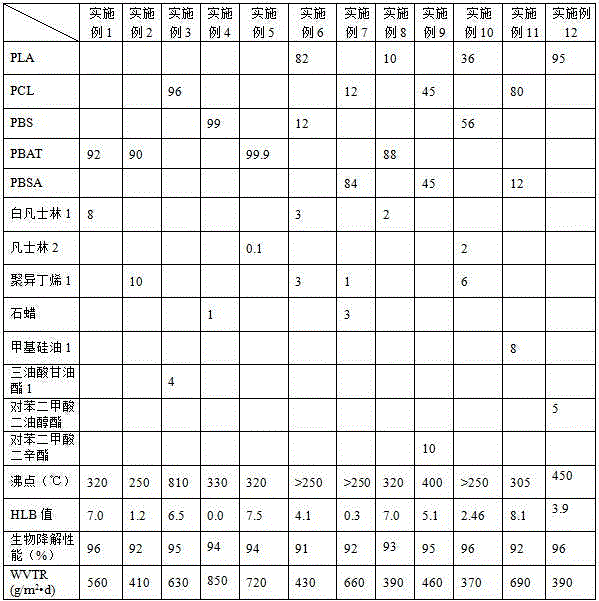

[0064] Examples 1-12 and Comparative Examples 1-6: Preparation of biodegradable compositions with barrier properties

[0065] Dry the weighed raw materials in an oven at 80°C for 5 hours in advance according to the formula ratio in Table 1, then stir in a high-speed mixer for 5 minutes to 10 minutes at a low speed, and then leave after stirring at a high speed for 3 minutes to 5 minutes, and mix well The material is fed into a twin-screw extruder, extruded and granulated at a temperature of 60°C-240°C to obtain a biodegradable composition with barrier properties; wherein, the diameter of the extruder is 40mm, and the aspect ratio is 36: 1. There are 9 heating zones and a vacuum exhaust device. The following operating conditions are selected for the extrusion process:

[0066] Temperature setting: 80°C / 150°C / 190°C / 190°C / 190°C / 190°C / 190°C / 190°C / 170°C;

[0067] Feeding speed: 100kg / h;

[0068] Screw speed: 300rpm;

[0069] Vacuum pressure: 0.4 atmospheres.

[0070] The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com