Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Good water vapor barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

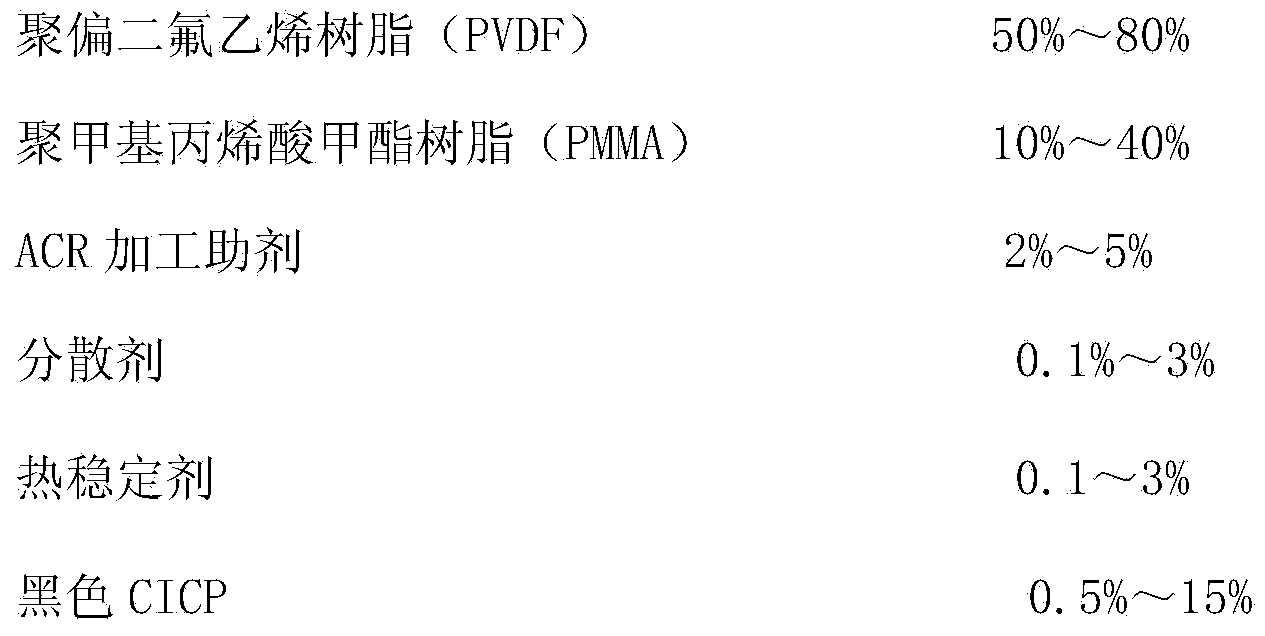

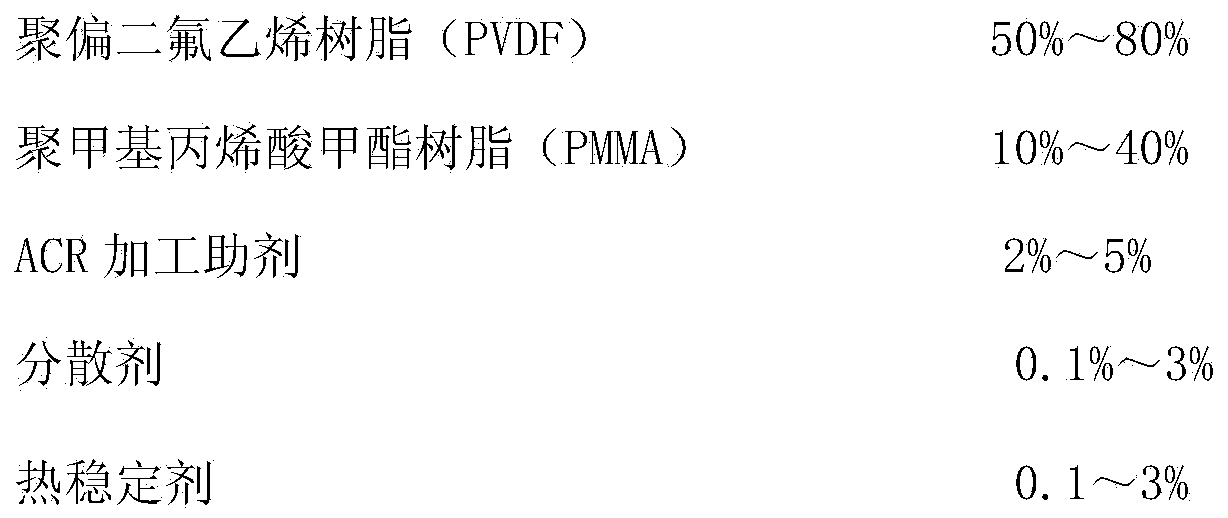

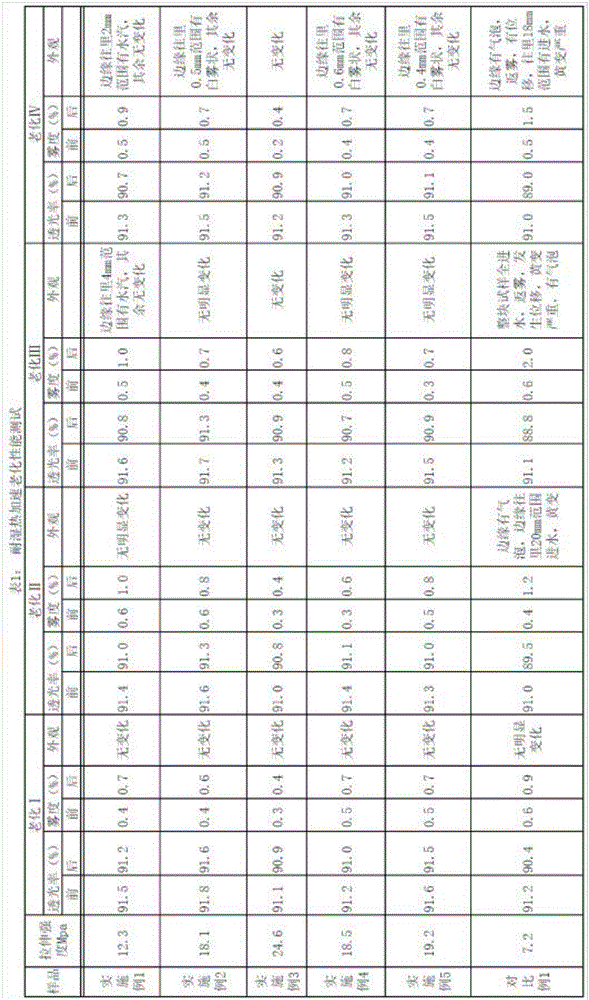

Black infrared reflection polyvinylidene fluoride (PVDF) solar cell rear panel composite film and manufacturing method thereof

ActiveCN103832038AHigh sun coverageHigh infrared reflective propertiesSynthetic resin layered productsPhotovoltaic energy generationComposite filmWater vapor

The invention discloses a black infrared reflection polyvinylidene fluoride (PVDF) solar cell rear panel composite film and a manufacturing method thereof. The composite film comprises a first layer facing air and a second layer under the first layer, wherein the material of the first layer is a complex A which is filled with black CICP based on PVDF / polymethyl methacrylate (PMMA) blended resin; the material of the second layer is a complex B which is filled with a mixture of non-composite inorganic pigments and black CICP based on the PVDF / PMMA blended resin; the complex A and the complex B are subjected to molten co-extrusion to prepare the composite film with the A / B structure. The preparation process is simple, convenient, safe and reliable and is easily controlled, the prepared film can meet the service requirements of solar rear panel films in aspects of shading property, weather resistance, water vapor barrier property, mechanical performance and the like, and the composite film with the thickness of 30 microns has over 90 percent of solar shading rate and high infrared reflection characteristics.

Owner:江苏昊华光伏科技有限公司

Preparation method of polyester chip for solar battery back film

InactiveCN105542138AImprove crystallization abilityReduce contentPhotovoltaic energy generationSemiconductor devicesSolid phasesChemistry

The present invention discloses a preparation method of a polyester chip for a solar battery back film. A polyester chip semi-finished product with intrinsic viscosity of 0.60-0.64 dl / g and terminal carboxyl group content of 12-18 mol / t is subjected to solid phase polycondensation to obtain the polyester chip for solar battery back film with intrinsic viscosity of 0.75-0.80 dl / g and terminal carboxyl group content of 5-10 mol / t. The preparation method has simple reaction conditions and low production costs; the obtained polyester chip can be separately produced into polyester film suitable for solar battery back without the addition of an anti-hydrolysis agent or an ultraviolet absorber, wherein the polyester film has good water vapor barrier property, resistance to wet heat aging and resistance to light aging. The method is not only friendly to the environment and human, but also avoids the problems of uneven dispersion and inconsistency of product performance of blend film production.

Owner:HEFEI LUCKY SCI & TECH IND

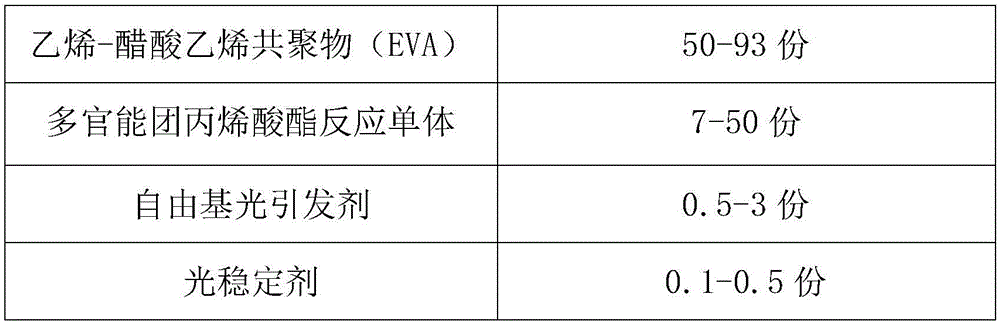

UV crosslinking and curing acrylic ester-modified EVA optical adhesive film and preparation method thereof

InactiveCN106147633ASimple processImprove Lamination Production EfficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesWeather resistanceWater vapor

The invention provides a UV crosslinking and curing acrylate modified EVA optical adhesive film and a preparation method thereof. The EVA optical adhesive film is prepared from the following raw materials in parts by weight: 50-93 parts of ethylene-vinyl acetate copolymer, 7-50 parts of multifunctional acrylate reactive monomer, 0.5-3 parts of free radical photoinitiator, photostable 0.1-0.5 part of anti-oxidant, 0.1-0.5 part of antioxidant, 2.5-10 part of coupling agent. The EVA optical adhesive film not only has the characteristics of simple lamination process, can be reworked, improves production efficiency, reduces defective rate and production cost, but also has excellent mechanical properties, water vapor barrier properties, heat resistance and stability, and other weather resistance.

Owner:SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

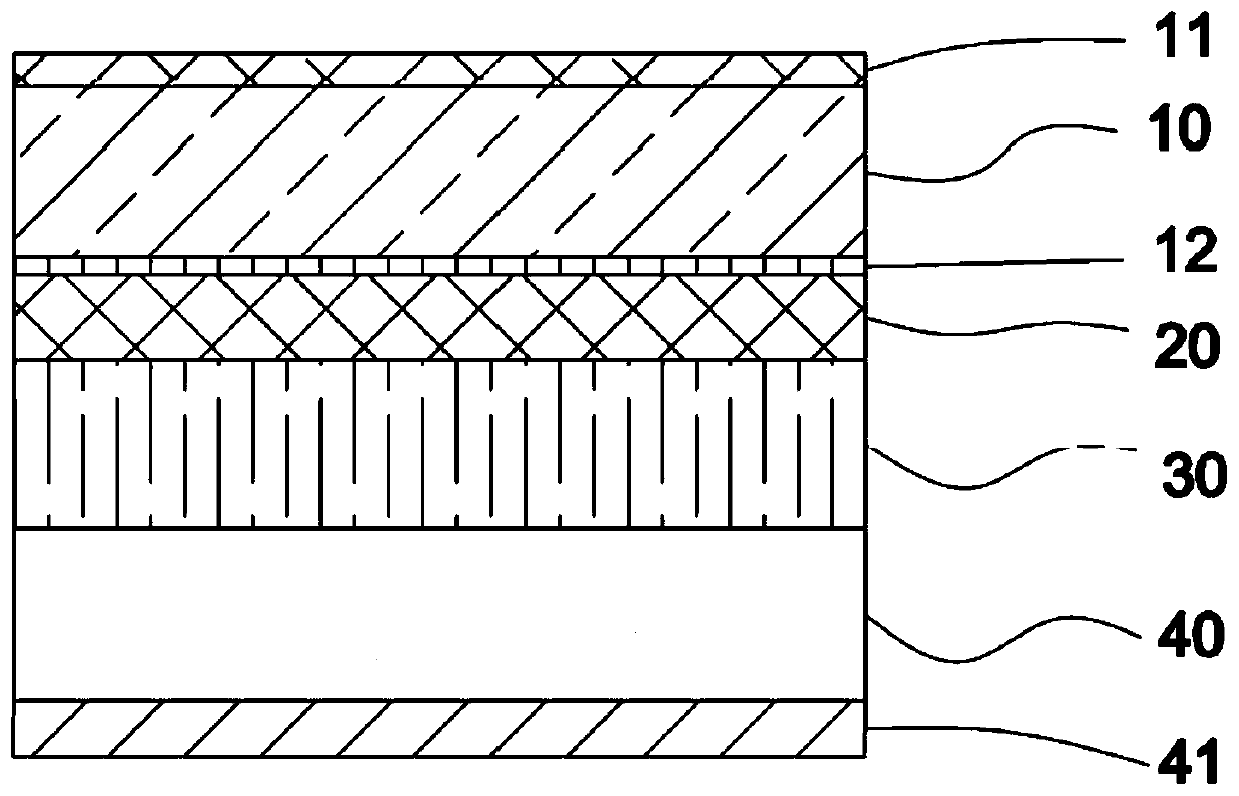

Backboard for high heat dissipation photovoltaic module and preparation method

ActiveCN104393084AProtection lifeGood resistance to water vapor transmissionFinal product manufacturePhotovoltaic energy generationPolyolefinUltraviolet lights

The invention relates to the technical field of solar cell backboard, and in particular relates to a backboard for high heat dissipation photovoltaic module and a preparation method, the backboard comprises a high thermal conductivity weather-proof layer, an aluminum foil layer, a bonding layer and a lower weather-proof layer orderly formed, the underside of the high thermal conductivity weather-proof layer is pasted to the aluminum foil layer, two sides of the bonding layer are respectively pasted to the aluminum foil layer and the lower weather-proof layer, the lower weather-proof layer is the fluorine resin modified polyolefin film provided with the concave-convex grid structure on the surface, wherein the high thermal conductivity weather-proof layer is prepared by the fluorocarbon coating, the raw material of the fluorocarbon coating comprises the fluorocarbon resin, isocyanate, inorganic filler, ultraviolet light absorber, light stabilizer and butyl acetate; the raw material of fluorine resin modified polyolefin film comprises the polypropylene resin, fluorinated ethylene-propylene resin, filler, anti-ultraviolet agent and antioxygen. The backboard for high heat dissipation photovoltaic module is good in heat dissipation effect, high in photoelectric conversion rate and simple in structure. The preparation method for the backboard for high heat dissipation photovoltaic module is simple in process, convenient in operation control, stable in quality and high in production efficiency.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

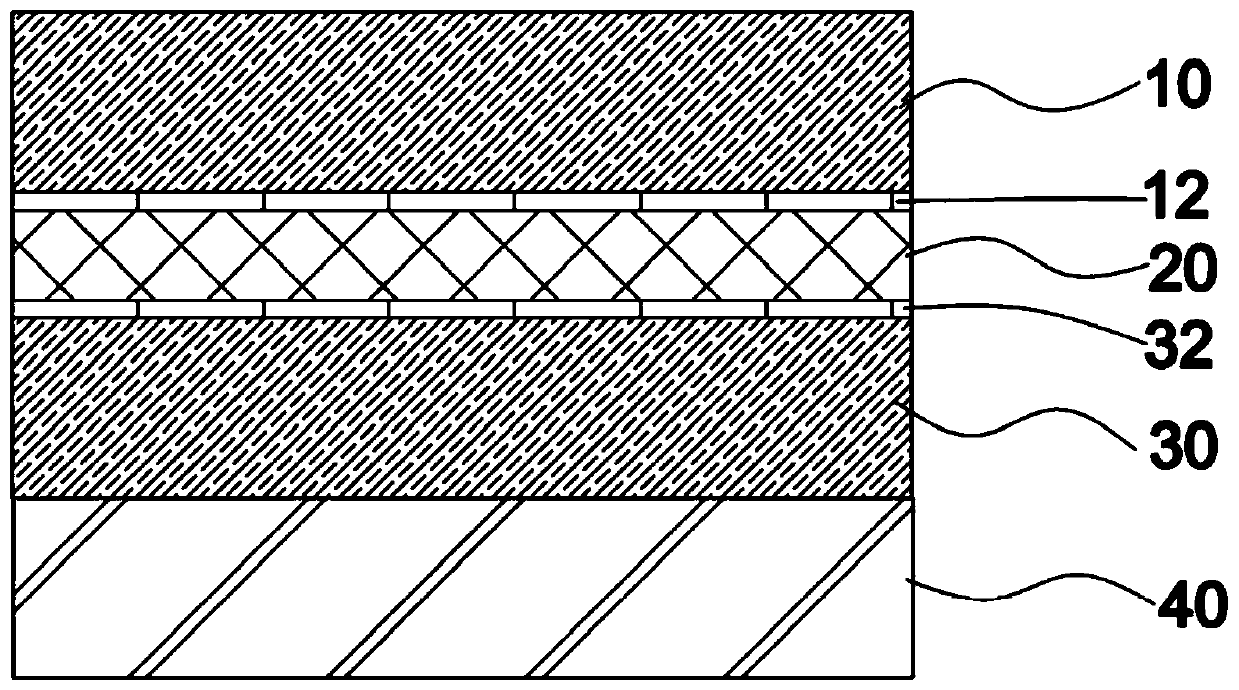

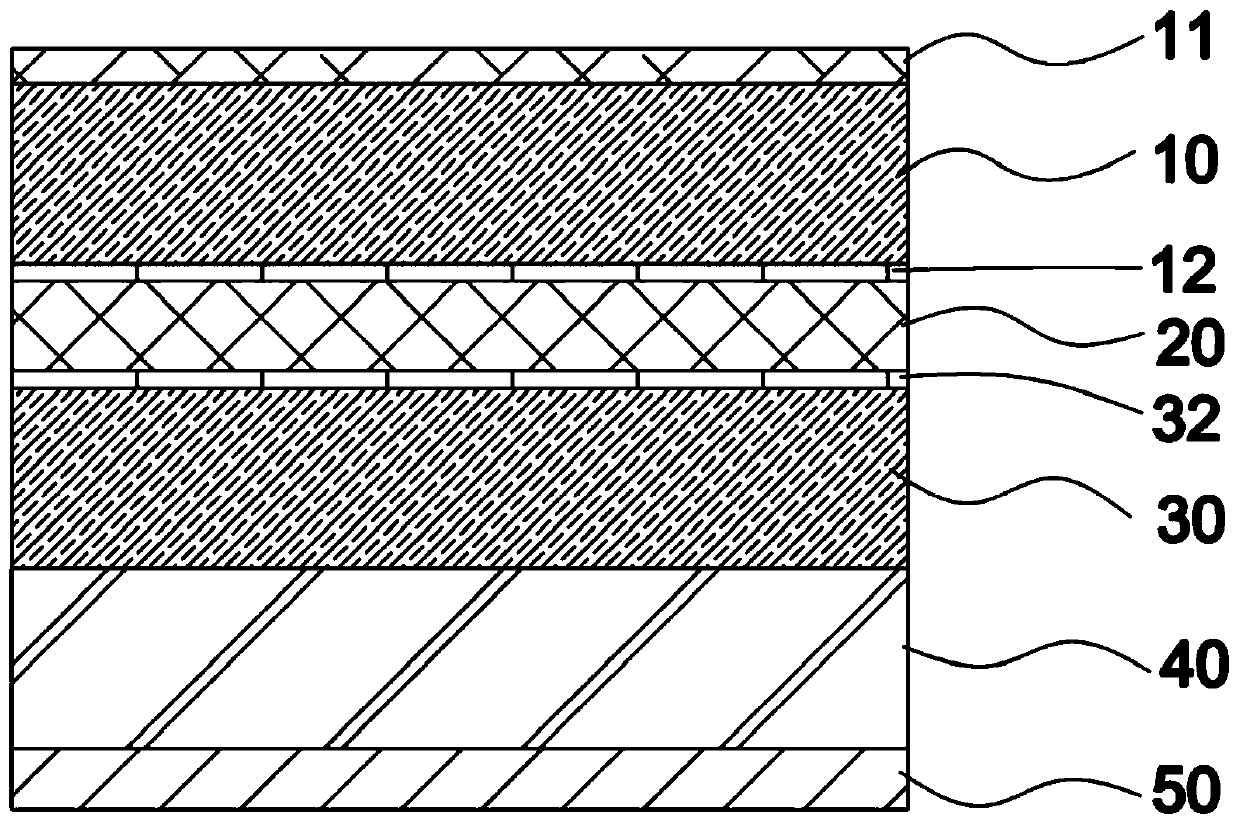

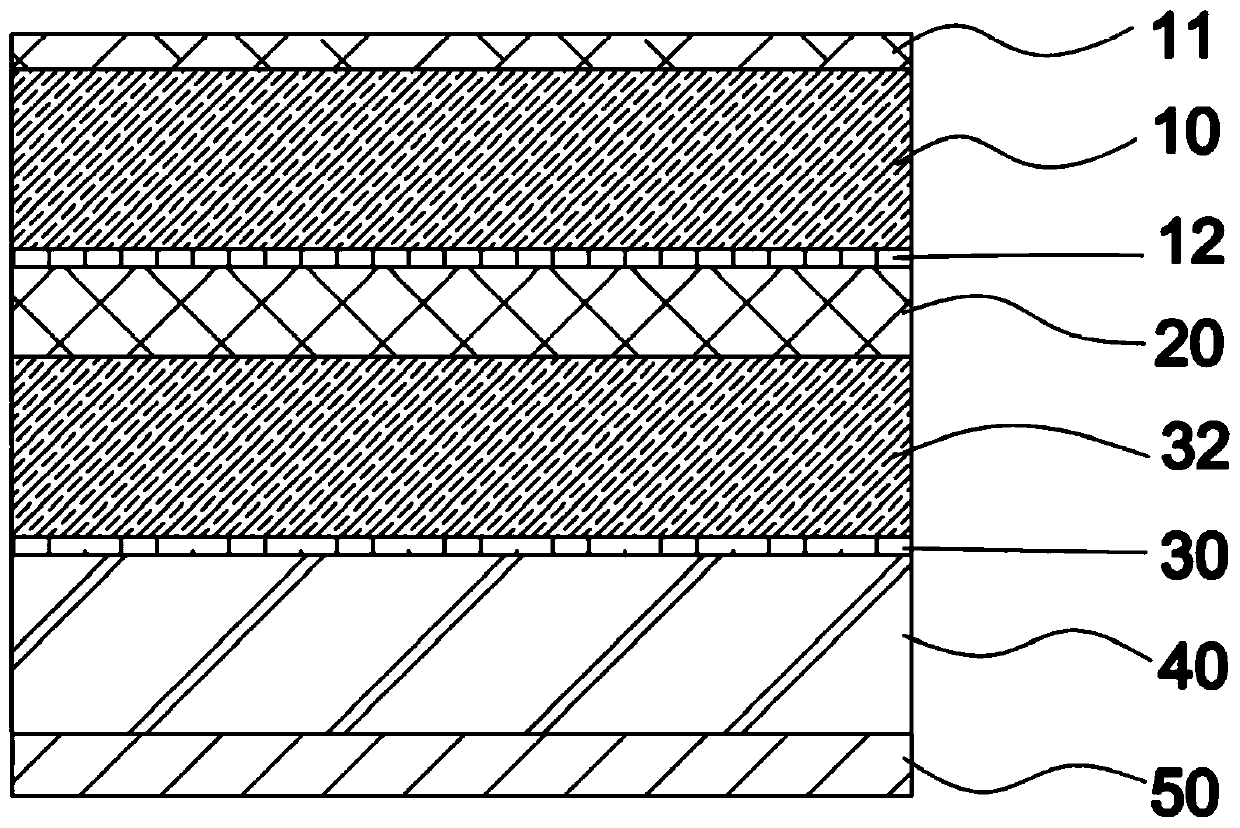

Photovoltaic solar cell composite backboard, preparation method and assembly thereof

ActiveCN104842616AReduce usageGood weather resistanceSynthetic resin layered productsLaminationPolyesterWater vapor

The invention relates to the field of solar cell backboards, and .provides a photovoltaic solar cell composite backboard, which is characterized by including an outer layer polyethylene glycol terephthalate and polyester co-extruded layer, an intermediate bonding layer, and an inner layer polyethylene and olefin polymer co-extruded layer. According to the invention, the melt coextrusion outer layer and inner layer respectively select PET and PE as the main body, select polymers with similar structure but different properties for complementation, melting coextrusion is conducted, polymer molecules interdiffuse, the bonding strength is large, and the melt coextruded layer enables endow the backboard with higher peel strength, excellent weatherability, water vapor barrier properties, insulativity and other performances. Thus, the photovoltaic solar cell composite backboard has good comprehensive properties.

Owner:JOLYWOOD SUZHOU SUNWATT

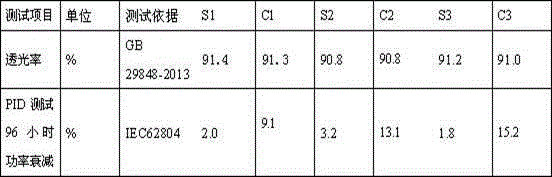

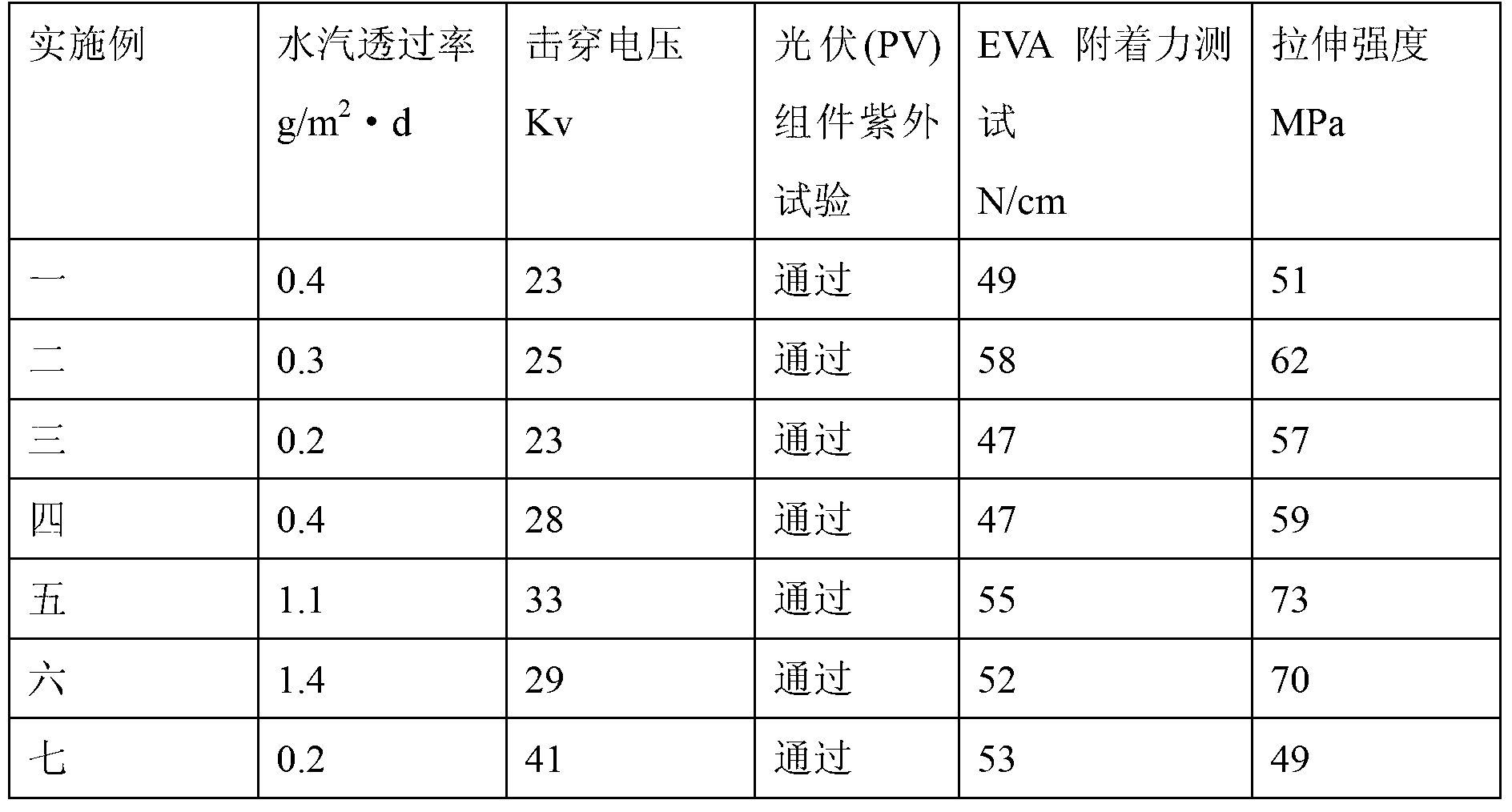

EVA adhesive film for encapsulating solar cell and preparing process of EVA adhesive film

ActiveCN104861886AGood water vapor barrierTransmittance is not affectedNon-macromolecular adhesive additivesFilm/foil adhesivesAcetic acidTransmittance

The invention discloses an EVA adhesive film for encapsulating a solar cell and a preparing process thereof. The EVA adhesive film is mainly characterized in that polyacrylamide is added into raw material components, the polyacrylamide is used as an acid-absorbing water repellent, and a small quantity of free acetic acid in EVA and acid micromolecular substances generated in the ageing process are effectively eliminated or neutralized, so that the encapsulating adhesive film has excellent vapor blocking performance. As the adopted polyacrylamide is nanoscale granules or powder and does not influence the light transmittance of the adhesive film basically, the PID resistance of the assembly is effectively improved.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

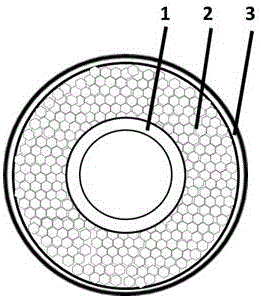

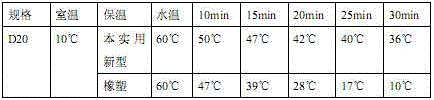

PPR insulating composite tube for home decoration and preparation method of composite tube

ActiveCN106641585ASolve the problem of scratch resistanceSolve insulation problemsThermal insulationPipe protection by thermal insulationManufacturing cost reductionProtection layer

The invention relates to a PPR insulating composite tube for home decoration and a preparation method of the composite tube. The composite tube is of a three-layer composite structure, the inner layer of a PPR or PPR aluminum-plastic composite tube is coated with an expanded polyethylene insulating layer through equipment, the expanded polyethylene insulating intermediate layer is coated with a weather-resistant and scratch-resistant outer protection layer through an extruding machine, closed-cell expanded materials are adopted by the expanded polyethylene insulating layer, the cell sizes range from 0.2 mm to 0.5 mm, and the weather-resistant and scratch-resistant layer is prepared from 60%-90% of LLDPE, 5%-15% of HDPE, 4%-20% of EVOH, 0.5%-2% of silane-modified nano-titanium dioxide and 0.5%-2% of compound additives. The expanded polyethylene insulating layer is obtained through a one-step method. The PPR insulating composite tube has the insulating and energy saving properties and the excellent weather-resistant and scratch-resistant properties, a synchronous coating molding process is adopted in the production process, the production efficiency is improved, the manufacturing cost is reduced, and the PPR insulating composite tube has a good market application prospect.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Resin composition for base material of photovoltaic backboard and preparation method of photovoltaic backboard

ActiveCN104212179AGood water vapor barrierLight in massSynthetic resin layered productsLaminationChemistryBackplane

The invention provides a resin composition for a base material of photovoltaic backboard and a preparation method of a photovoltaic backboard. The resin composition comprises the following components in parts by weight: 40-60 parts of polysilsesquioxane resin, 40-60 parts of epoxy resin, 5-10 parts of curing agent, and 0.01-1 part of accelerant. The photovoltaic backboard takes the resin composition which contains polysilsesquioxane resin, the epoxy resin, the curing agent and the accelerant as the base materials, and takes glass fiber cloth as a reinforcing material, has excellent characteristics of light weight, high strength and good light transmission, and can be used for substituting the existing photovoltaic backboard.

Owner:江苏生益特种材料有限公司

Thermal conductivity filler composition as well as high thermal conductivity insulating composite material and preparation method thereof

ActiveCN108192136AHigh thermal conductivityImprove thermal conductivityWater vaporThermal insulation

The invention discloses a thermal conductivity filler composition. The thermal conductivity filler composition is characterized by being prepared from the following components in parts by weight: 90 to 95 percent of component A and 5 to 10 percent of component B, wherein the component A is prepared from thermal conductivity filler and a silane coupling agent, and the silane coupling agent accountsfor 1 to 3 percent of the total weight of the component A; the component B is prepared from graphene oxide and isocyanate, and the isocyanate accounts for 70 to 80 percent of the total weight of thecomponent B. The invention also discloses a high thermal conductivity insulating composite material and a high thermal conductivity insulation base film and preparation methods of the high conductivity thermal insulating composite material and the high thermal insulation base film. The high thermal conductivity insulating composite material has high thermal conductivity, good insulation and mechanical properties, good dielectric properties and high water vapor barrier property.

Owner:GUANGDONG SHENGYI SCI TECH

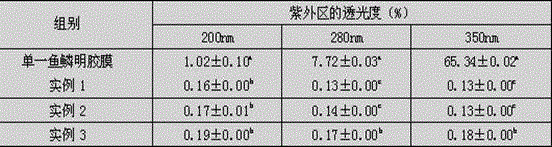

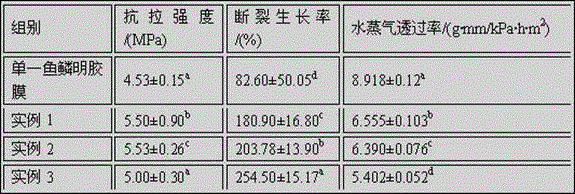

Method for preparing bamboo leaf flavonoid fish scale gelatin edible fresh-keeping film

The invention discloses a method for preparing a bamboo leaf flavonoid fish scale gelatin edible fresh-keeping film. The method is characterized by comprising the following steps: dissolving tilapia mossambica scale gelatin in water to absorb water and swell for 18-22 minutes, and dissolving in a water bath kettle at 45-55 DEG C for 20 minutes; then adding glycerinum which is 3 percent of mass of the tilapia mossambica scale gelatin, magnetically stirring and uniformly mixing, adding bamboo leaf flavonoid which is 0.4-0.8 percent of mass of the mixed liquid, and magnetically stirring and uniformly mixing to obtain film forming liquid; centrifugally degassing the film forming liquid at a speed of 3500-4500 revolutions / minute for 1-2 minutes, pouring into a glass sheet for tape casting; putting the glass sheet in an air dry oven, controlling the temperature to be 22-28 DEG C, drying with air blast for 2-4 hours, and peeling the film. The bamboo leaf flavonoid fish scale gelatin edible fresh-keeping film has the advantages of excellent ultraviolet blockage, excellent ductility, excellent water vapor barrier property and good heat stability.

Owner:NINGBO UNIV

Transparent high-barrier food packaging composite film and preparation method thereof

The invention belongs to the technical field of food packaging material preparation, and particularly relates to a transparent high-barrier food packaging composite film and a preparation method thereof. The transparent high-barrier food packaging composite film comprises a first film layer, a coating layer, an adhesive layer, a second film layer, a coating layer, an adhesive layer and a third film layer which are arranged in sequence, and the coating layer is a waterborne polyurethane-nano silicon mixed coating layer. The transparent high-barrier food packaging composite film prepared by theinvention still has excellent barrier property after being cooked and sterilized at the high temperature of 121 DEG C for 30 minutes, so that the shelf life of food is greatly prolonged, and the safety and sanitation of the food are guaranteed.

Owner:RAOPING ZHIXIN COLOR PRINTING

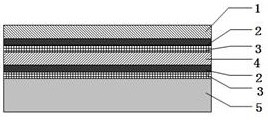

Barrier composite film and preparation method thereof

PendingCN110387195AGood water vapor barrierHigh peel strengthFilm/foil adhesivesComposite filmWater vapor

The invention relates to the field of barrier films for blocking water vapor, and provides a barrier composite film with a good barrier effect and a simple process and a preparation method thereof. The defects that in the prior art, the oxygen barrier effect of water vapor is not ideal and the process is complicated are overcome. The barrier composite film sequentially comprises a polymer layer with a thickness of 5-100 [mu]m, a first adhesive layer with a thickness of 5-50 [mu]m, a metal layer with a thickness of 10-100 [mu]m and a second adhesive layer with a thickness of 10-200 [mu]m. Compared with the prior art, the barrier composite film and the preparation method thereof are simple in process, the barrier performance of the barrier film is good, the barrier water permeability is lessthan 10<-4>g / m<2> / day, and the peel strength and the filling performance are good.

Owner:ZHONGSHAN DONGYI HIGH TECH MATERIAL

Material used for solar cell rear panels and preparation method of material

ActiveCN103311344AHigh mechanical strengthImprove adhesionFinal product manufacturePhotovoltaic energy generationPolymer scienceSolar cell

The invention provides a hybrid polymer material used for solar cell rear panels and a preparation method of the material. Single-layer solar cell rear panels can be produced by utilizing the material, the hybrid polymer material is composed of a polymer obtained by copolymerizing functional powder (i) composed of europium carbonate and graphene oxide at a specific mass ratio of 0.3-0.65:1 and several monomers including 1,4-cyclohexane dicarboxylic acid, 2,6-naphthalic acid, 3-fluorine-1,2-propylene glycol and 1,4 butanediol, and the functional powder is added in the process of polymer synthesis. By utilizing the material to manufacture the single-layer solar cell rear panels, process complexity in production of the solar cell rear panels is lowered, adhesive consumption is avoided, and excellent blocking resistance and mechanical performance are provided.

Owner:NANJING UNIV OF SCI & TECH

High-performance polylactic acid nano composite material and preparation method thereof

ActiveCN112239590AStrong UV shielding effectGood antibacterial effectBio-packagingCytotoxicityPack material

The invention discloses a high-performance polylactic acid nano composite material and a preparation method thereof, and the high-performance polylactic acid nano composite material is composed of thefollowing components in parts by weight: 93-99 parts of polylactic acid and 1-7 parts of zinc complex modified cellulose nanocrystalline. According to the invention, the cellulose nanocrystal modified by the zinc complex is used as a modifier, so that the performance of polylactic acid can be effectively improved. The polylactic acid nano composite material prepared by the invention has excellentultraviolet shielding property, antibacterial property, mechanical property, water vapor barrier property and fluorescence property, low hygroscopicity, low cytotoxicity and low hydrophilicity, and is simple in preparation process, easy in chemical component control, good in repeatability, and higher in yield; the polylactic acid composite material has potential application value in the fields ofpackaging materials, biomedical materials and the like, is suitable for large-scale production, and expands the application field of the polylactic acid composite material.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Novel solar cell back panel and preparation method thereof

InactiveCN103311341AAvoid pollutionImprove defects with poor mechanical propertiesSynthetic resin layered productsPhotovoltaic energy generationPolyesterAdhesive

The invention relates to the technical field of solar cell back panels, in particular to a novel solar cell back panel and a preparation method thereof. The solar cell back panel is prepared by a fluorine-containing polymer, a polyacrylate polymer layer and a two-way stretch polyester film through multilayer co-extrusion coating technology. According to the novel solar cell back panel and the preparation method thereof, the technique is simple, the production cycle is short, the continuous industrial production is facilitated, the harm to the health of operating staff and the pollution to environment, caused by organic solvent type adhesive, is effectively avoided, the defect of poorer mechanical property of the solar cell back panel prepared by the multilayer co-extrusion technology is improved, and the polyacrylate polymer layer with hydrolysis resistance and ageing-resistant property is adopted, has good weather resistance ability, moisture barrier property, mechanical property and interlaminar peel strength, and can effectively guarantee the long-term operation of a solar component.

Owner:CHANGZHOU HUITIAN NEW MATERIALS

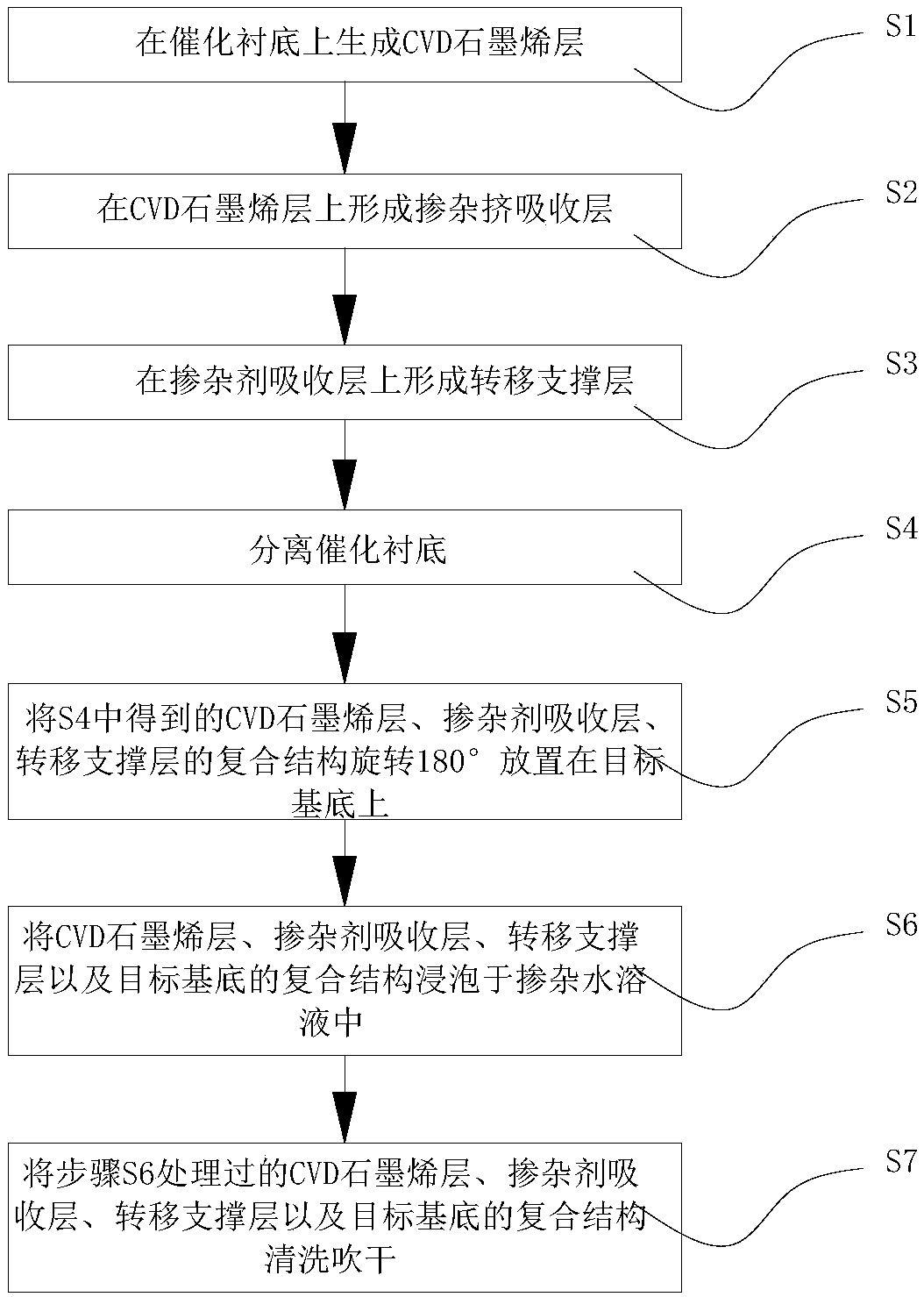

Large-area CVD graphene doping and transferring method

ActiveCN108101027AEfficient and uniform and stable dopingGood mechanical propertiesGrapheneCvd grapheneGraphene membrane

The invention discloses a large-area CVD graphene doping and transferring method which can ensure the stable doping effect of CVD graphene and can avoid the transferring damage. The method comprises the following steps: S1, growing a CVD graphene layer on a catalytic substrate; S2, forming a dopant absorption layer on the CVD graphene layer; S3, forming a transferring supporting layer on the dopant absorption layer; S4, separating the catalytic substrate; S5, rotating a composite structure of the CVD graphene layer, the dopant absorption layer and the transferring supporting layer obtained inS4 for 180 degrees, and then placing on a target substrate; S6, soaking the composite structure obtained in S5 in a doping aqueous solution; and S7, cleaning and drying the composite structure soakedin S6. By adopting the large-area CVD graphene doping transferring method, the graphene layer can be efficiently, uniformly and stably doped; and the effective supporting protection can be provided inthe transferring process, the damage of a graphene membrane is avoided, and the transferring completeness of the large-area CVD graphene layer is ensured.

Owner:CHONGQING GRAPHENE TECH

Multilayer coextruded anti-polarization composite adhesive film and preparation method thereof

InactiveCN110041835AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveVapor barrierOptical transmittance

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a multilayer coextruded anti-polarization composite adhesive film. The composite adhesivefilm comprises a POE layer, an anti-polarization layer and an EVA layer arranged from top to bottom sequentially. After adoption of the structure, the composite adhesive film has the benefits as follows: 1, the EVA layer making contact with a battery surface has better compatibility with a polarity aid, and bubble, non-melting and piece combining problems during module lamination can be solved; 2, ethylene segments contained in copolymer resin in the anti-polarization layer have better compatibility with POE and EVA, and higher surface bonding can be formed; besides, acrylate has higher polarization performance, and negative voltage values produced by modules through outer frames can be reduced, so that the anti-PID performance of modules is improved; 3, the POE layer making contact witha back plate and glass has better vapor barrier performance, the light transmittance and volume resistivity of the adhesive film can be increased, thus, electric potential on battery pieces can be increased, the power generation efficiency of the modules can be improved, and the service life of the modules can be prolonged.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Degradable low-water-vapor-transmittance heat-sealable two-way stretching polylactic acid smoke film and preparation method thereof

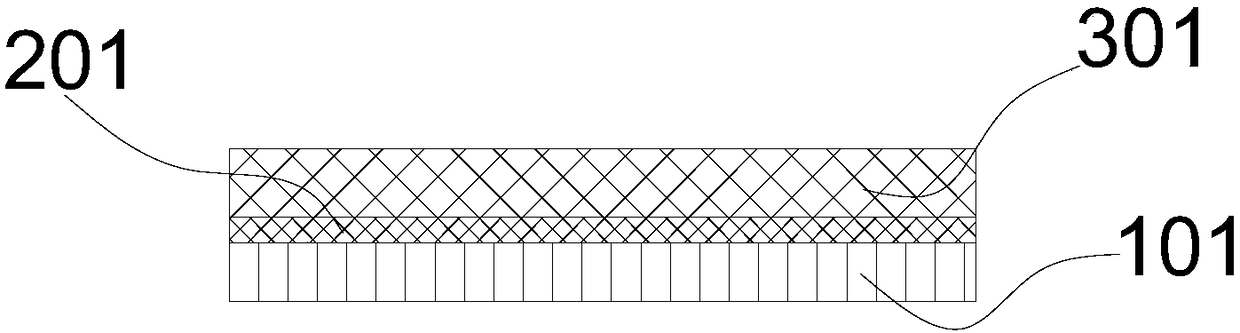

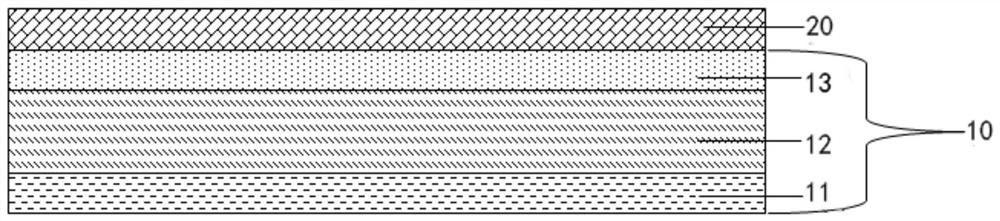

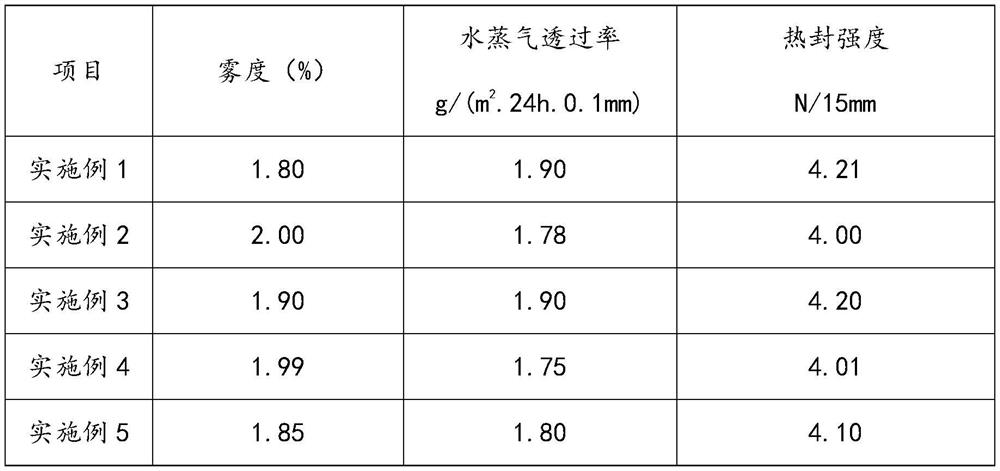

ActiveCN114193890ALow water vapor transmission rateGood water vapor barrierBio-packagingSynthetic resin layered productsPolymer scienceBoPET

The invention relates to the technical field of flexible packaging, in particular to a degradable low-water-vapor-transmittance heat-sealable two-way stretching polylactic acid cigarette film and a preparation method thereof. The film layer structure of the biaxially oriented polylactic acid smoke film comprises a BOPLA film layer and a water vapor barrier layer, the water vapor barrier layer comprises the following raw material components: a polyurethane polymer coating, inorganic powder, a suspending agent, a cross-linking agent and water; the mass ratio of the polyurethane polymer coating to the inorganic powder to the suspending agent to the cross-linking agent to the water is (65.5 to 85.0) to (5.89 to 8.50) to (0.50 to 1.25) to (1.00 to 2.50) to (33.7 to 43.5). The two-way stretching emulsion polymer film is low in water vapor transmission rate, has excellent water vapor barrier property, has excellent properties such as low haze and high heat sealing strength, has degradability and good heat sealing property, and has a very good application prospect in product packaging with high requirements on the water vapor barrier property.

Owner:厦门长塑实业有限公司

Modified polypropylene membrane, and preparation method thereof

The invention provides a modified polypropylene membrane, and a preparation method thereof. The preparation method comprises following steps: vinyl acetate, allyl glycidyl ether, and an initiator aresubjected to primary polymerization so as to obtain a vinyl acetate-allyl glycidyl ether copolymer; at least a part of the vinyl acetate-allyl glycidyl ether copolymer is used for modification of silicon dioxide so as to obtain a silicon dioxide modifying agent; a first polypropylene resin and the silicon dioxide modifying agent are subjected to melt blending and bidirectional stretching treatmentsuccessively so as to obtain the modified polypropylene membrane. According to the preparation method, polypropylene is injected among net-shaped fiber bundles, on one hand, it is beneficial for improving of the mechanical strength of the modified polypropylene membrane, and reducing the number and the length of cracks on the surface of the modified polypropylene membrane, and on the other hand,it is beneficial for formation of a compact structure of the surface of the modified polypropylene membrane, the compact structure is beneficial for reducing of diffusion rate of organic solvents, oxygen, and water vapor from the outside into the modified polypropylene membrane, and is beneficial for improving of the barrier properties of the modified polypropylene membrane.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Cellulose acetate nano composite material with ultraviolet shielding and bacteriostatic properties and preparation method thereof

PendingCN112175244AExcellent UV shielding propertiesLow hygroscopicityMaterial nanotechnologyCellulose acetateUltraviolet protection

The invention discloses a cellulose acetate nano composite material with ultraviolet shielding and bacteriostatic properties and a preparation method thereof. The cellulose acetate nano composite material is composed of the following components by weight: 96-99.5 parts of cellulose acetate and 0.5-4 parts of copper complex modified halloysite. The copper complex modified halloysite is used as a modifier, so that the performance of the cellulose acetate can be effectively improved. The cellulose acetate nano composite material prepared by the invention has excellent ultraviolet shielding performance, bacteriostatic performance, thermal stability, water vapor barrier property, low hygroscopicity and low cytotoxicity, can keep high optical transparency, and is simple in preparation process, environment-friendly, low in cost, suitable for large-scale production, and has good application prospects in the fields of packaging, ultraviolet protection and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Composition for forming sealant, application thereof in photovoltaic field, and photovoltaic module

InactiveCN110499124AReduce the chance of air bubblesImprove thermal stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceWater vapor

The invention provides a composition for forming a sealant, an application thereof in the photovoltaic field, and a photovoltaic module. The composition includes an olefin polymer, a silane-modified olefin polymer, and a thixotropic agent. The thixotropic agent is added into the olefin polymer and silane modified olefin polymer system, so that the composition has a good thixotropic performance inthe sealant preparation process and the subsequent coating process of the sealant. The good thixotropic property can greatly reduce the probability of bubbles existing in the sealant in the laminatingprocess. The sealant formed by the composition has the advantages of high thermal stability, good degradation resistance under high-intensity ultraviolet rays, low cost and the like. The sealant formed by the composition also has the advantages of excellent water vapor barrier property, excellent thermal stability, excellent degradation resistance under ultraviolet rays, low cost and the like, and can meet the requirement of the photovoltaic field for the long-term stability of the product in the outdoor environment.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

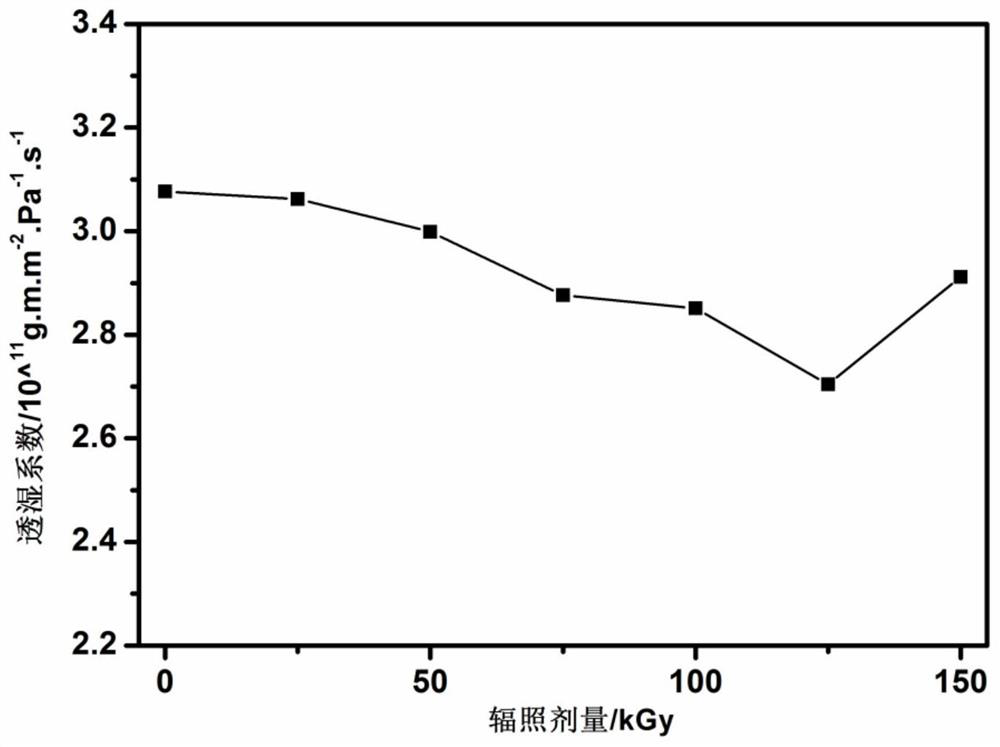

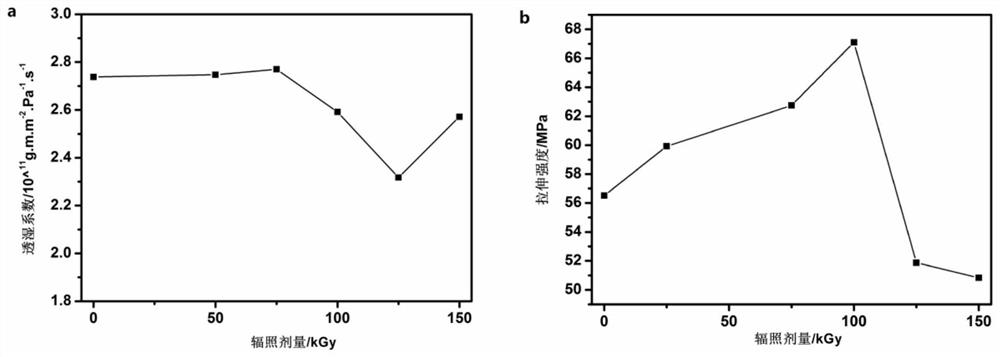

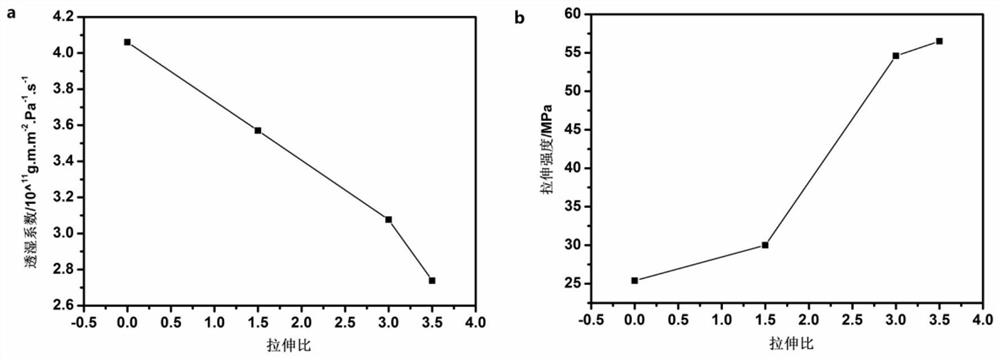

Water vapor barrier biodegradable polymer film as well as preparation and application thereof

ActiveCN111234279AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersPolymer sciencePlastic mulch

The invention belongs to the field of biodegradable materials. The invention discloses a water vapor barrier biodegradable polymer film as well as preparation and application thereof. The preparationmethod comprises the following steps: blending the biodegradable polymer and the cross-linking agent to obtain a special material, molding the special material to form a thick film, carrying out bidirectional stretching on the thick film, and carrying out electron beam irradiation to obtain the water vapor barrier biodegradable polymer film, thereby improving the water vapor barrier property of the biodegradable polymer film. According to the invention, the overall flow process design of the preparation method is improved, wherein the biodegradable polymer film is modified by using a two-way stretching process and an electron beam irradiation technology, so that the problem of poor water vapor barrier property of the biodegradable polymer film can be effectively solved, and the biodegradable polymer film can be widely applied to the fields of agricultural mulching films, food and daily necessity packaging, electronic product packaging and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

A photovoltaic solar cell composite back sheet and preparation method and components thereof

ActiveCN104842616BReduce usageGood weather resistanceSynthetic resin layered productsLaminationPolyesterWater vapor

The invention relates to the field of solar cell backboards. A composite backsheet for photovoltaic solar cells, characterized in that it includes an outer polyethylene terephthalate and polyester coextrusion layer, an intermediate adhesive layer, and an inner polyethylene and olefin polymer coextrusion layer . In the present invention, the outer layer and the inner layer of the melt coextrusion are respectively selected PET and PE as the main body, and polymers similar in structure but different in performance are selected to complement each other, melt coextrusion, the polymer molecules diffuse each other, the bonding strength is large, and the melting The co-extruded layer makes the back sheet have higher peel strength, excellent weather resistance, water vapor barrier, insulation and other properties, and is a photovoltaic solar cell composite back sheet with good comprehensive performance.

Owner:JOLYWOOD SUZHOU SUNWATT

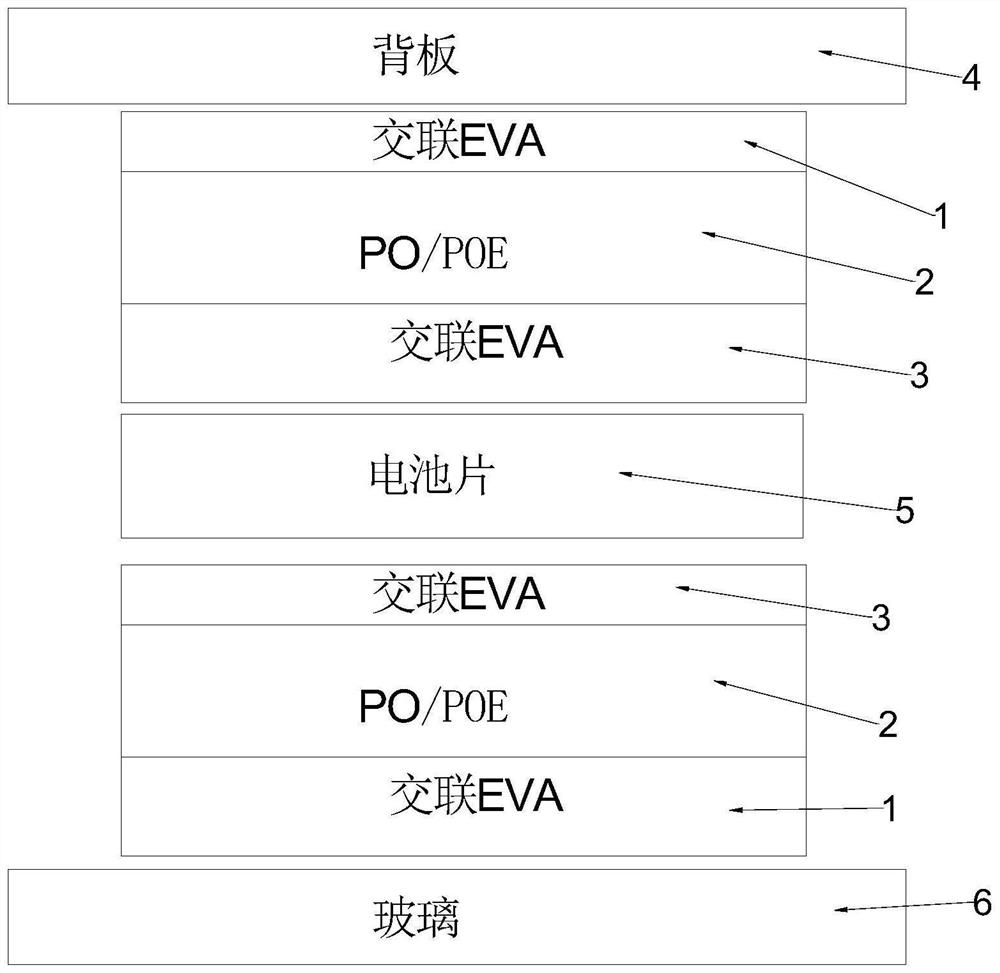

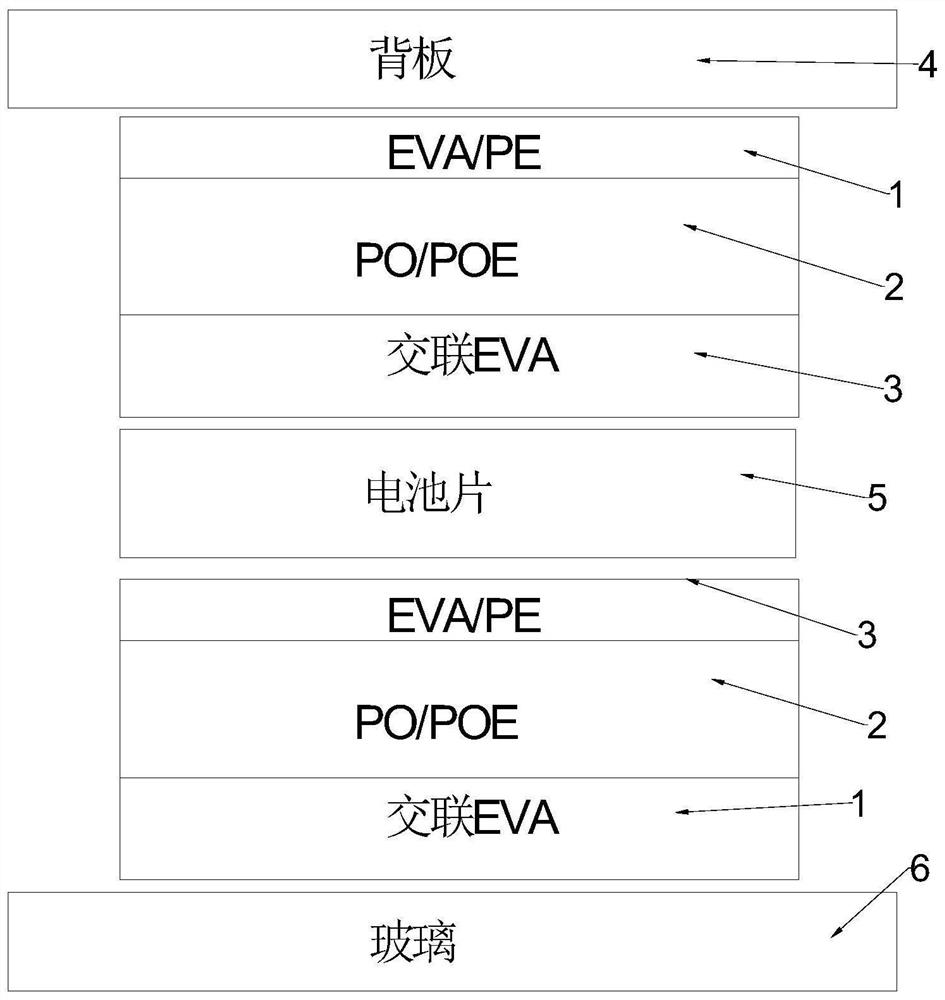

Packaging adhesive film and solar cell module using same

PendingCN111808538AGood water vapor barrierLow PID riskNon-macromolecular adhesive additivesFilm/foil adhesives without carriersAcetic acidPolymer science

The invention discloses a packaging adhesive film and a solar cell module using the packaging adhesive film, the packaging adhesive film comprises an outer layer, a PO core layer and an inner layer, the outer layer is EVA or EVA / PE, the PO core layer is a polyolefin and / or polyolefin elastomer modified material, and the inner layer is crosslinked EVA. The solar cell module comprises a back plate and a cell piece, the packaging adhesive film is arranged between the back plate and the cell piece, the outer layer of the packaging adhesive film is close to the back plate, and the inner layer of the packaging adhesive film is close to the cell piece. The packaging adhesive film has good binding force with the backboard or the glass, the phenomenon of delaminating of the adhesive film and the glass is avoided, acetic acid is not generated after long-term use, and the PID risk of the assembly is reduced.

Owner:浙江中聚材料有限公司

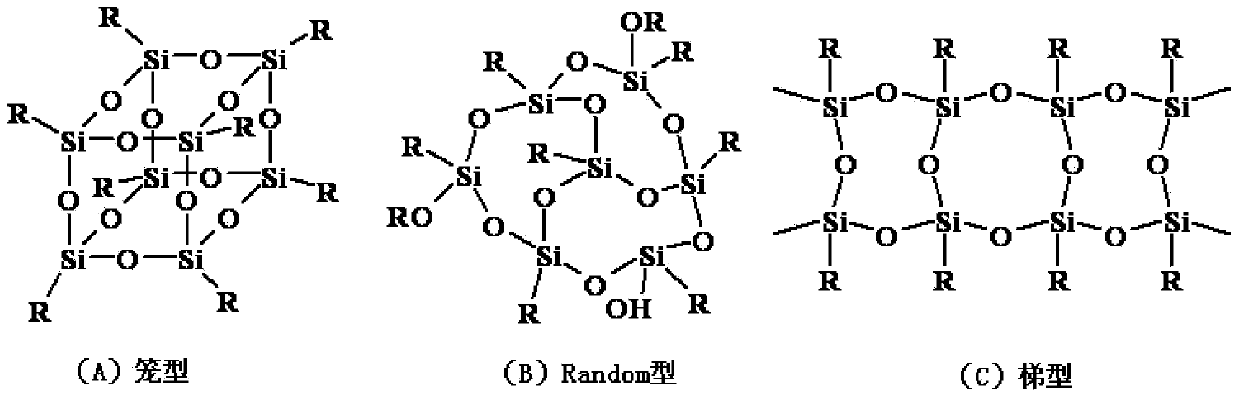

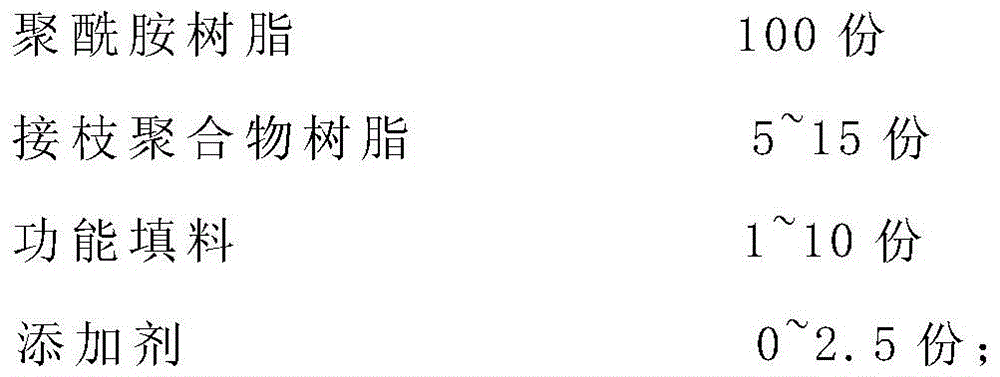

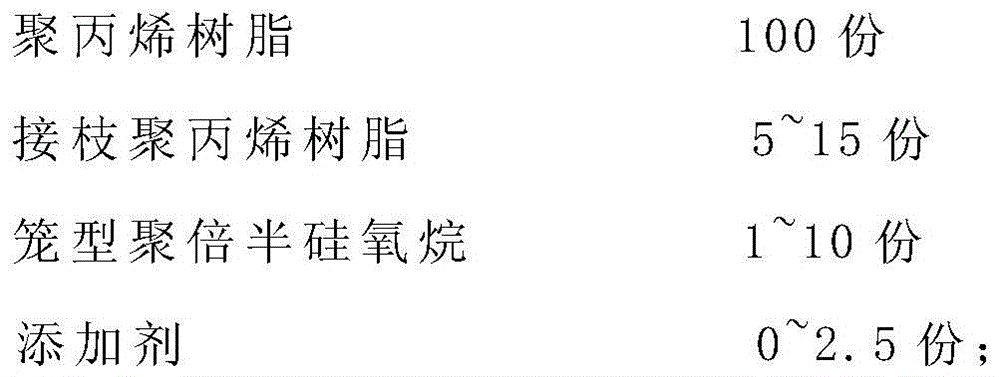

A kind of backplane for photovoltaic cells and preparation method thereof

ActiveCN104538474BImprove low temperature brittlenessImprove adhesionFinal product manufactureSemiconductor devicesPolymer resinSurface layer

The invention discloses a back plate for a photovoltaic cell, which comprises an inner surface layer, an intermediate layer and an outer surface layer from the inside to the outside, the outer surface layer is made of a modified polyamide resin composition, and the modified polyamide resin composition It includes the following components, polyamide resin, graft polymer resin, functional filler, additive; the functional filler is a layered silicate clay modified by isobutylamine polyhedral oligomerization silsesquioxane; the intermediate The layer is made of a modified polypropylene resin composition; the modified polypropylene resin composition includes the following components: polypropylene resin, grafted polyethylene resin, cage polysilsesquioxane, and additives. The bonding performance between the back sheet and EVA, the aging resistance performance and the water vapor barrier performance of the present invention are all very excellent, can fully meet the service life requirements of the solar battery module, obtain remarkable effects, and have positive practical significance.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Preparation method of ultraviolet-resistant and damp-heat aging-resistant copolyester

ActiveCN113583221AImproves UV resistanceImprove water vapor barrier performanceBio-packagingPhotovoltaic energy generationPolycyclic aromatic hydrocarbonCopolyester

A preparation method of ultraviolet-resistant and damp-heat-aging-resistant copolyester is characterized in that the copolyester is prepared by controlling the charging ratio of polycyclic aromatic hydrocarbon derivative monomers to dibasic acid to dihydric alcohol to perform esterification and polycondensation and then performing end capping through monofunctional epoxy substances, and the end capping step is performed at the end of the polycondensation reaction. Compared with the prior art, the preparation method has the advantages of ultraviolet resistance, damp-heat aging resistance, water vapor barrier property and dimensional stability.

Owner:浙江凯普奇新材料科技有限公司

A kind of water vapor barrier biodegradable polymer film and its preparation and application

ActiveCN111234279BImprove barrier propertiesImprove mechanical propertiesFlexible coversWrappersPolymer scienceWater vapor

The invention belongs to the field of biodegradable materials, and discloses a water vapor barrier biodegradable polymer film and its preparation and application. The preparation method is to firstly blend a biodegradable polymer and a crosslinking agent to obtain a special The material is formed into a thick film, and then the thick film is biaxially stretched, and finally electron beam irradiation is performed to obtain a water vapor barrier biodegradable polymer film, which improves the water vapor barrier properties of the biodegradable polymer film. The present invention improves the overall flow process design of the preparation method and modifies the biodegradable polymer film by using the biaxial stretching process and electron beam irradiation technology, which can effectively solve the problem of poor water vapor barrier properties of the biodegradable polymer film. It can be widely used in many fields such as agricultural mulching film, food and daily necessities packaging, and electronic product packaging.

Owner:HUAZHONG UNIV OF SCI & TECH

Food-grade rust-proof biaxially-oriented polypropylene film and preparation method thereof

InactiveCN109232938AMeet packaging requirementsGood water vapor barrierAnti-corrosive paintsFlat articlesPolymer sciencePolyvinyl alcohol

The invention relates to a food-grade rust-proof biaxially-oriented polypropylene film. The food-grade rust-proof biaxially-oriented polypropylene film comprises a substrate and a coating layer on thesubstrate surface, wherein a primer layer is arranged between the coating layer and the substrate; the coating layer is a modified polypropylene coating formed by applying modified barrier polypropylene latex to the surface of the primer layer and drying the latex; the ultrahigh vapor-barrier polypropylene latex is prepared from raw materials in parts by weight as follows: 52-95 parts of deionized water, 0.9-1.9 parts of sodium percarbonate, 0.5-2.3 parts of vinyl chloride, 37-40.9 parts of polypropylene, 2.9-3.9 parts of polyvinyl alcohol, 6-8 parts of propionamide and 1-2 parts of polytetrafluoroethylene propyl ester. The traditional food-grade rust-proof biaxially-oriented polypropylene film is modified, so that the food-grade rust-proof biaxially-oriented polypropylene film is endowedwith ultrahigh vapor barrier performance while keeping original characteristics.

Owner:SICHUAN GAOSHENG PACKAGING PROD

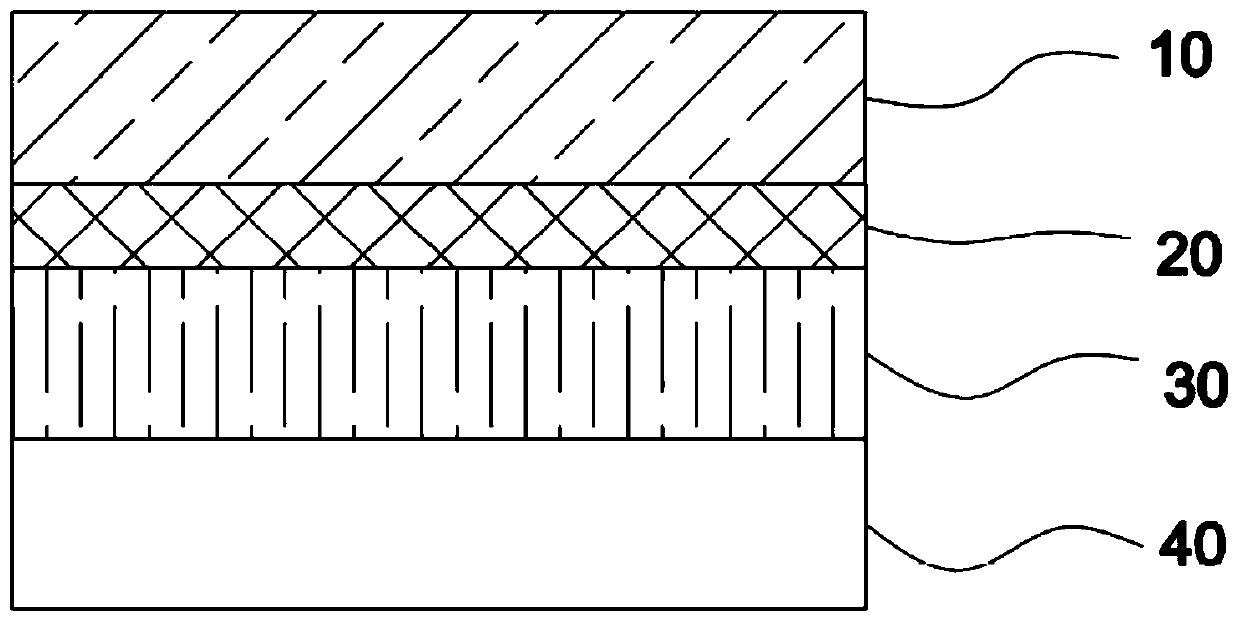

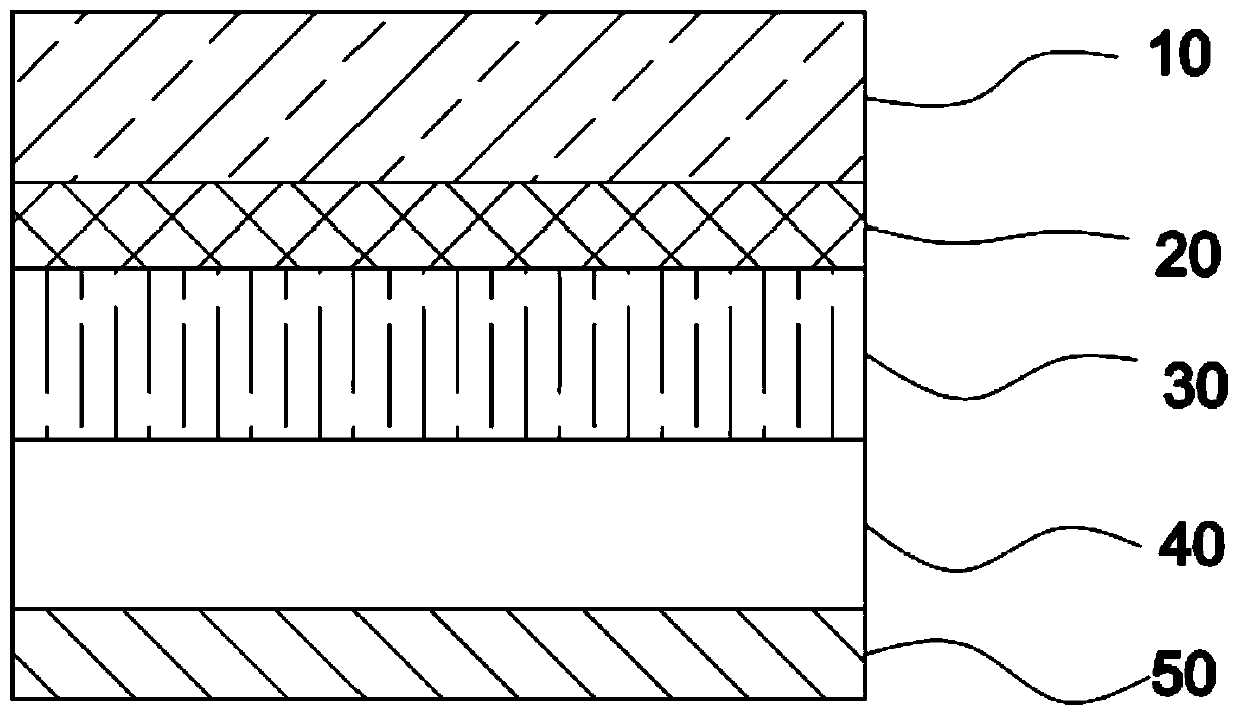

Light-transmitting barrier composite film and preparation method thereof

ActiveCN110776837AGood water vapor barrierHigh peel strengthFilm/foil adhesivesCoatingsPolymer scienceComposite film

The invention belongs to the field of barrier films for blocking water vapor. Based on disadvantages of poor water vapor barrier effect and complex process in the prior art, the invention provides a light-transmitting barrier composite film with characteristics of good barrier effect and simple process and a preparation method thereof. The light-transmitting barrier composite film sequentially comprises a first macromolecule polymer layer, a first adhesive layer, a second macromolecule polymer layer and a second adhesive layer, wherein the first macromolecule polymer layer is subjected to inorganic treatment and has a thickness of 25-150 [mu]m, the first adhesive layer has a thickness of 5-50 [mu]m, the second macromolecule polymer layer is subjected to inorganic treatment and has a thickness of 25-150 [mu]m, and the second adhesive layer has a thickness of 10-250 [mu]m. Compared with the light-transmitting barrier composite film in the prior art, the light-transmitting barrier composite film is simple in preparation process and good in barrier performance, has the water vapor transmission rate of less than 10<-4> g / m<2> / day, and further has good peel strength and good filling performance.

Owner:ZHONGSHAN DONGYI HIGH TECH MATERIAL

Barrier type CIGS solar cell and preparation method thereof

ActiveCN110112228AImprove job stabilityImprove protectionFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a barrier type CIGS solar cell and a preparation method thereof, which belong to the technical field of CIGS solar cell film materials. The problem of CIGS failure caused by poor water vapor barrier performance of ITO in the prior art is solved. The barrier type CIGS solar cell provided by the invention comprises a substrate, a back electrode layer, a first absorption layer, a buffer layer and a transparent surface electrode layer, wherein the back electrode layer, the first absorption layer, the buffer layer and the transparent surface electrode layer are sequentiallylaminated on the substrate. The transparent surface electrode layer is made of IZTO. The preparation method provided by the invention comprises the steps that the back electrode layer, the first absorption layer and the buffer layer are sequentially formed on the substrate; and a first surface electrode layer and a second surface electrode layer are formed on the surface of the buffer layer. The barrier type CIGS solar cell and the preparation method thereof can be used for solar power generation.

Owner:SUNFLARE NANJING ENERGY TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com