Packaging adhesive film and solar cell module using same

A solar cell and encapsulation adhesive film technology, which is applied to electrical components, film/sheet adhesives, circuits, etc., can solve problems such as battery surface passivation, high insulation, and component resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

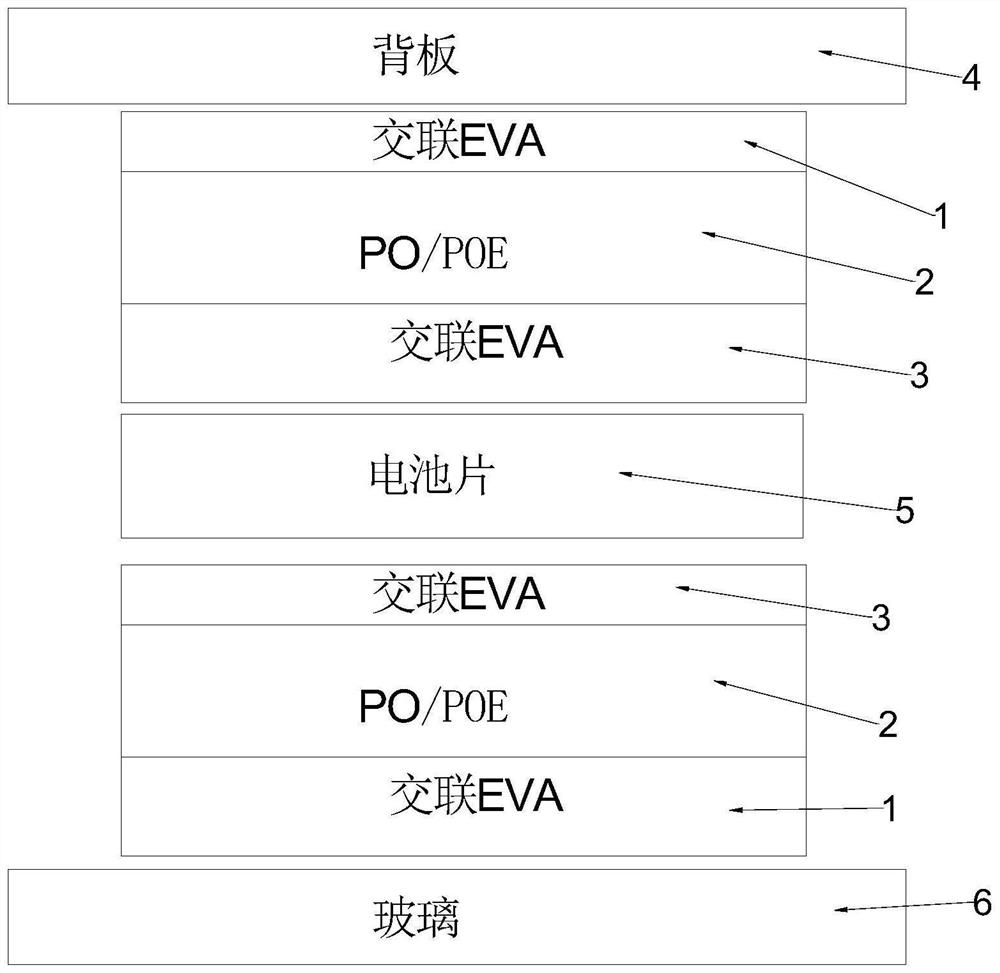

[0021] like figure 1 As shown, the packaging adhesive film includes an outer layer 1, a PO core layer 2, and an inner layer 3, the outer layer 1 is cross-linked EVA, and the PO core layer 2 is polyolefin (PO) and polyolefin elastomer modified A mixed material of material (POE), the inner layer 3 is cross-linked EVA. The encapsulant film is applied to a solar cell assembly, and the solar cell assembly includes a back plate 4, a battery sheet 5, and a glass 6. Between the back plate 4 and the battery sheet 5, and between the battery sheet 5 and the glass 6 are respectively An encapsulation film is provided, the outer layer 1 of the encapsulation film between the back plate 4 and the battery slice 5 is close to the back plate 4 , and the inner layer 3 is close to the battery slice 5 . The inner layer 3 of the encapsulant film between the battery sheet 5 and the glass 6 is close to the battery sheet 5 , and the outer layer 1 is close to the glass 6 . The thickness of the packagi...

Embodiment 2

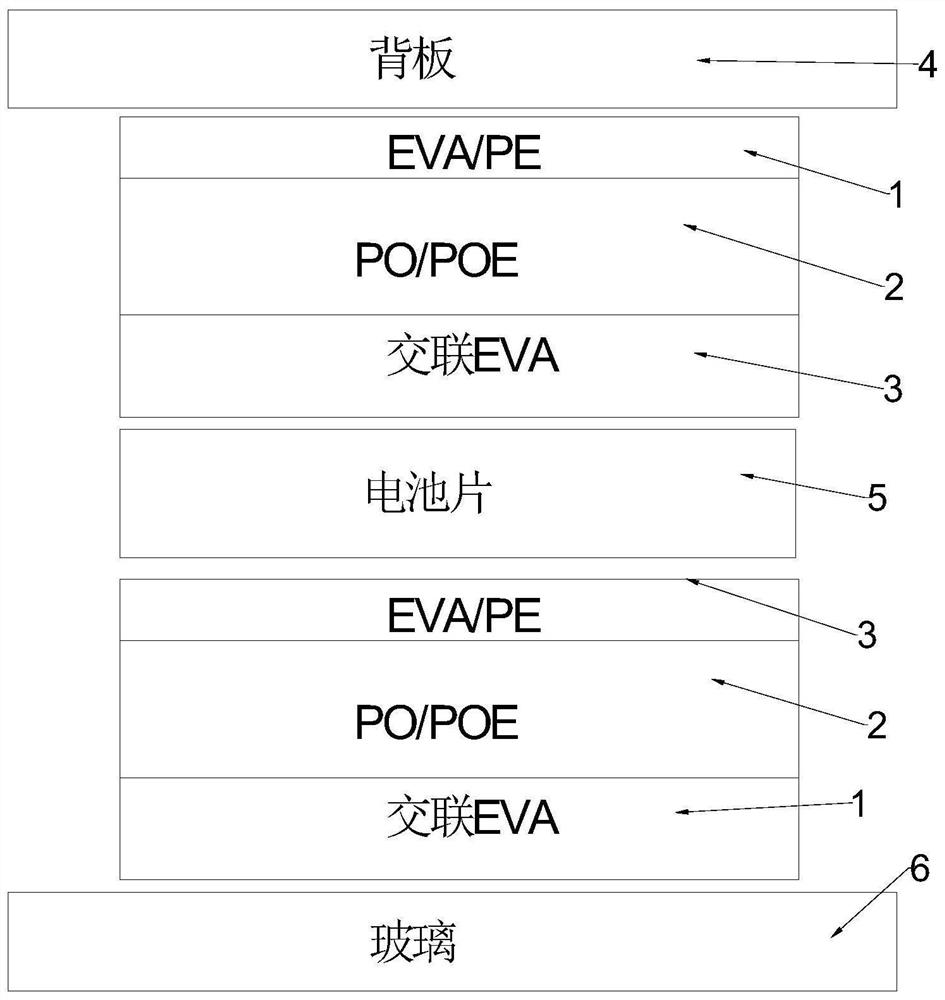

[0023] like figure 2 As shown, the packaging adhesive film includes an outer layer 1, a PO core layer 2, and an inner layer 3, the outer layer 1 is EVA / PE, and the PO core layer 2 is polyolefin (PO) and polyolefin elastomer modified The mixed material of the material (POE), the mixing ratio of polyolefin (PO) and polyolefin elastomer modified material (POE) is 4:1. The inner layer 3 is cross-linked EVA. The encapsulant film is applied to a solar cell assembly, and the solar cell assembly includes a back plate 4, a battery sheet 5, and a glass 6. Between the back plate 4 and the battery sheet 5, and between the battery sheet 5 and the glass 6 are respectively An encapsulation film is provided, the outer layer 1 of the encapsulation film between the backplane 4 and the cell 5 is close to the backplane 4, the inner layer 3 is close to the cell 5, and the inner layer of the encapsulation film between the cell 5 and the glass 6 Layer 3 is close to cell sheet 5 and outer layer 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com