Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277results about How to "Meet packaging requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorescent glass sheet and preparation method thereof

ActiveCN103011614AImprove the quality of LED packagingAchieve color temperatureFluorescenceLed packaging

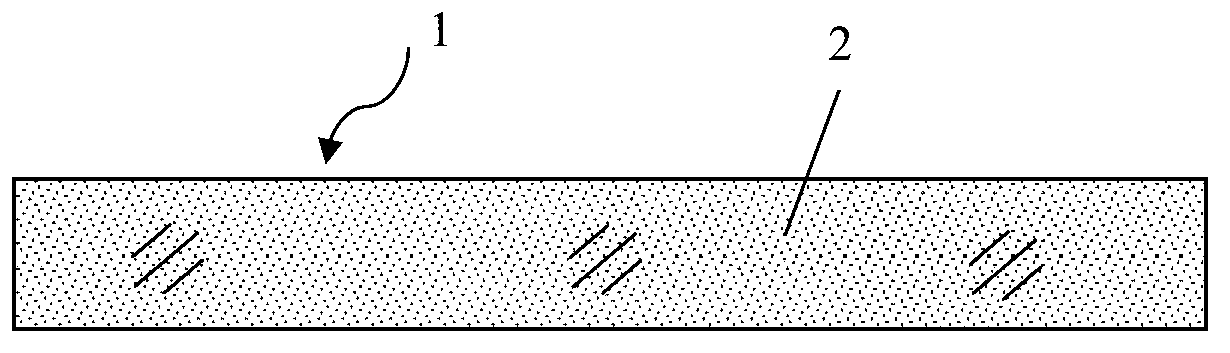

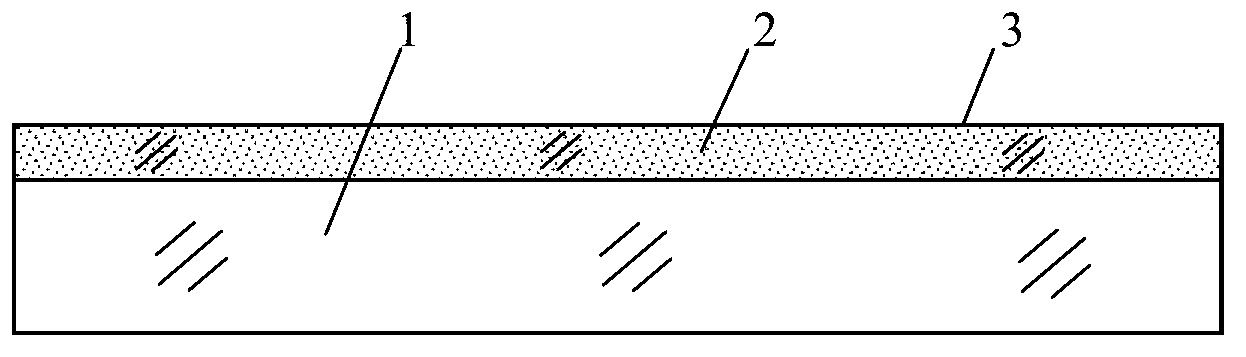

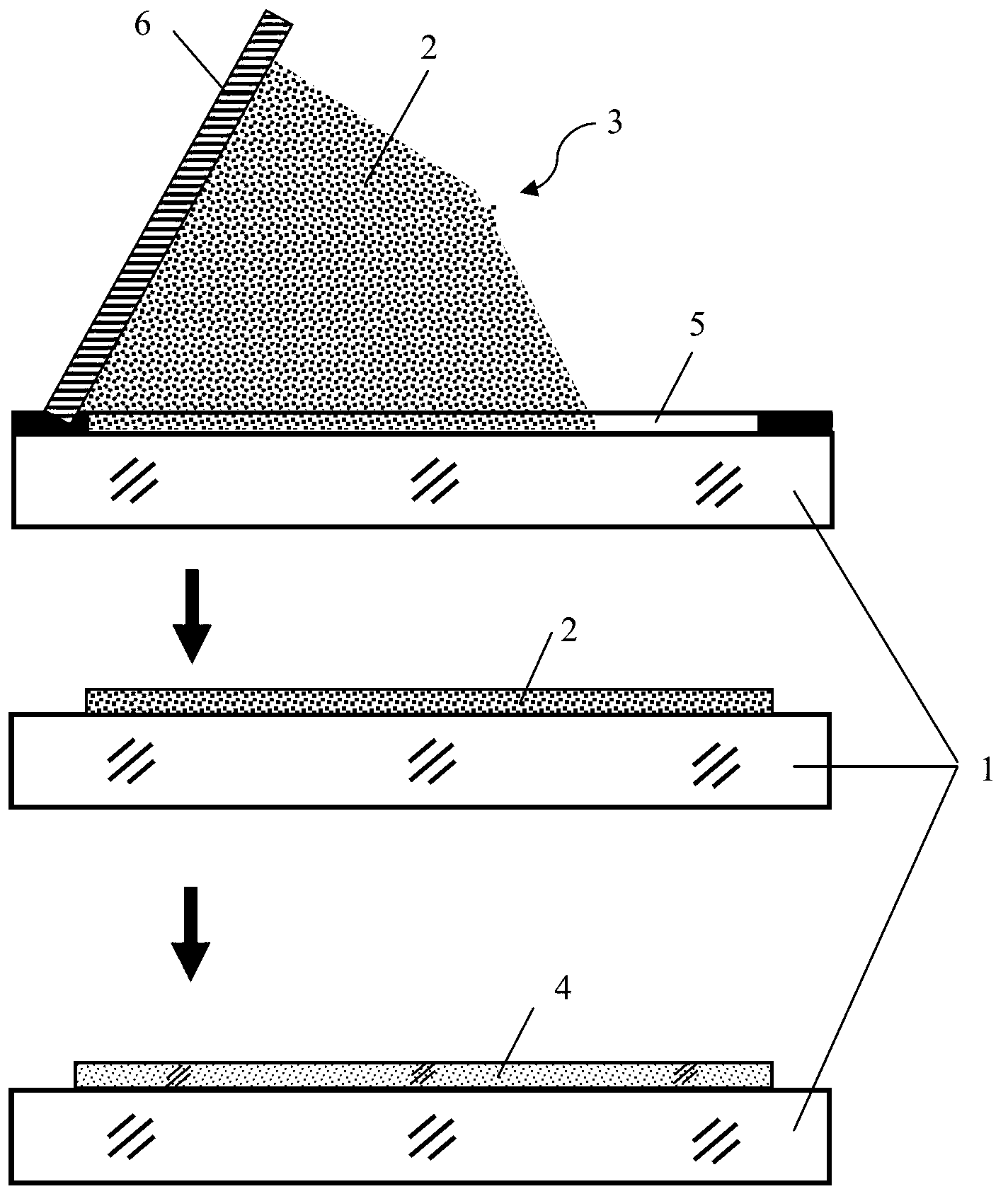

The invention discloses a fluorescent glass sheet and a preparation method thereof. A pulp layer with fluorescent powder is coated on the surface of a glass substrate sheet, wherein the main ingredients of the pulp consist of low-temperature glass powder, fluorescent powder, an intensifier, an adhesive, a dispersing agent and the like; the glass substrate sheet coated with the pulp layer is sintered; and the glass sheet with the fluorescent powder is obtained by controlling the sintering process. The fluorescent glass sheet is mainly applied to LED (Light Emitting Diode) packaging, the fluorescent powder preparation process can be reduced, and the packaging material and process cost are reduced; due to the high heat conductivity and the heat stability of the fluorescent glass sheet, the performance and the reliability of an LED module and a lamp can be remarkably improved; and at the same time, as the surface fluorescent powder layer is uniform in thickness and is far away from an LED chip, the LED packaging quality can be improved, and the effective control on color temperatures, chromaticity coordinates and color rendering indexes is realized. The fluorescent glass sheet can be used for packaging LED chips of various colors, can realize the single LED chip packaging and can also be used for multi-chip array LED module and LED lamp packaging, so that the method is simple and easy to carry out, and the fluorescent glass sheet is suitable for production in scale.

Owner:武汉利之达科技股份有限公司

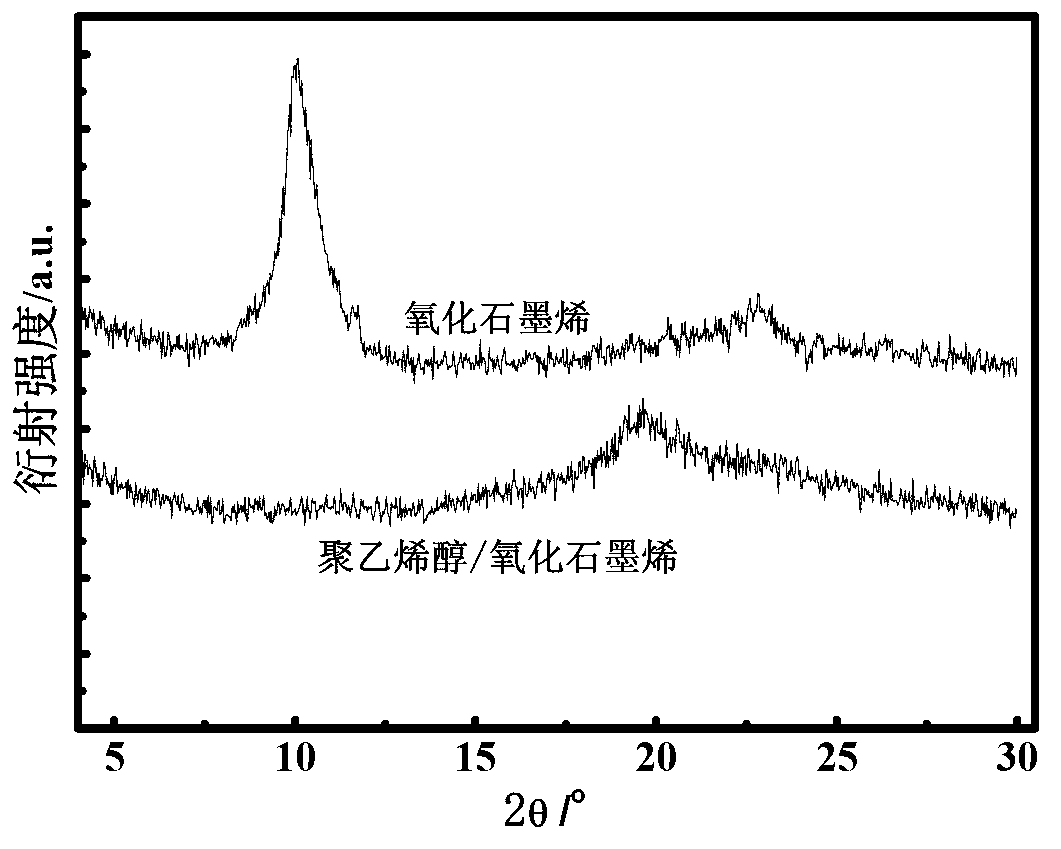

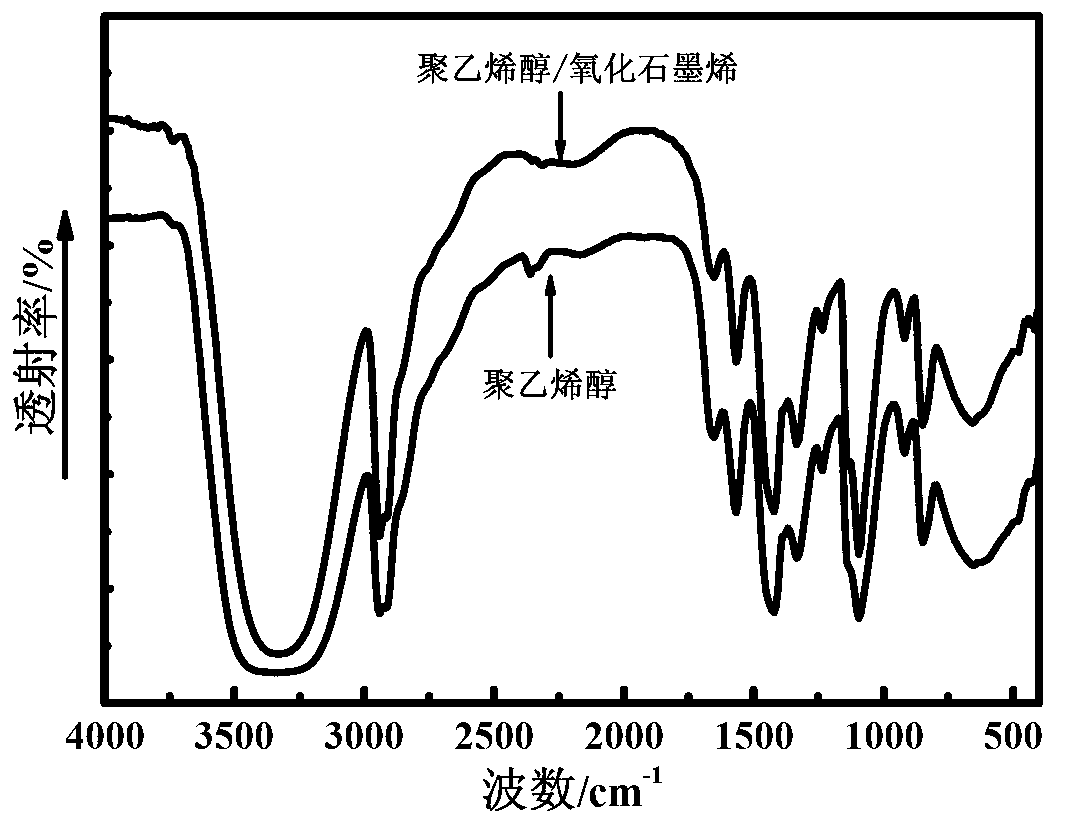

Polyvinyl alcohol/graphene oxide composite film preparation method

The invention discloses a polyvinyl alcohol / graphene oxide composite film preparation method. The method is carried out in the following steps: preparing a graphene oxide colloidal suspension liquid; preparing a polyvinyl alcohol and graphene oxide dispersion solution; coating a mould and non-isothermally drying; and demoulding so as to obtain a polyvinyl alcohol / graphene oxide composite film. A coating technology and a non-isothermally drying method are utilized to prepare the polyvinyl alcohol / graphene oxide composite film, the method has not only high safety but also good environment friendliness; moreover, the oxygen permeation coefficient of the composite film is reduced by 95.8 to the maximum extant, so that the composite film has ultrahigh oxygen barrier property and can satisfy the packaging requirements of various foods, pharmaceuticals and other products, and a problem that the polyvinyl alcohol / graphene oxide composite film prepared by the prior art has poor oxygen barrier property is solved; and the method is simple in technology and low in cost and has great application and popularization values.

Owner:唐炜程

Marine polysaccharide multilayer composite packaging film with antibacterial function

ActiveCN102120514AWide variety of sourcesGood film formingFlexible coversWrappersLow-density polyethylenePolyelectrolyte

The invention relates to a marine polysaccharide multilayer composite packaging film with an antibacterial function and a preparation method thereof, belonging to the fields of high polymer materials and food package. The marine polysaccharide multiplayer composite packaging film is prepared by forming a three-layer polyelectrolyte composite film by utilizing the static function of polycation electrolyte chitosan and polyanion electrolyte sodium alginate, and adding natural germicide, i.e. clove oil, to a middle film layer. The preparation method of the packaging film is simple; and the obtained packaging film has favorable mechanical performance, is superior to a low-density polyethylene film, can meet common requirements of food package, has favorable antibacterial controlled-release performance, can effectively prolong the shelf life of foods and can be used for fresh-keeping packaging of various foods, such as meat, cut fruits and vegetables, and the like.

Owner:福建万弘海洋生物科技有限公司

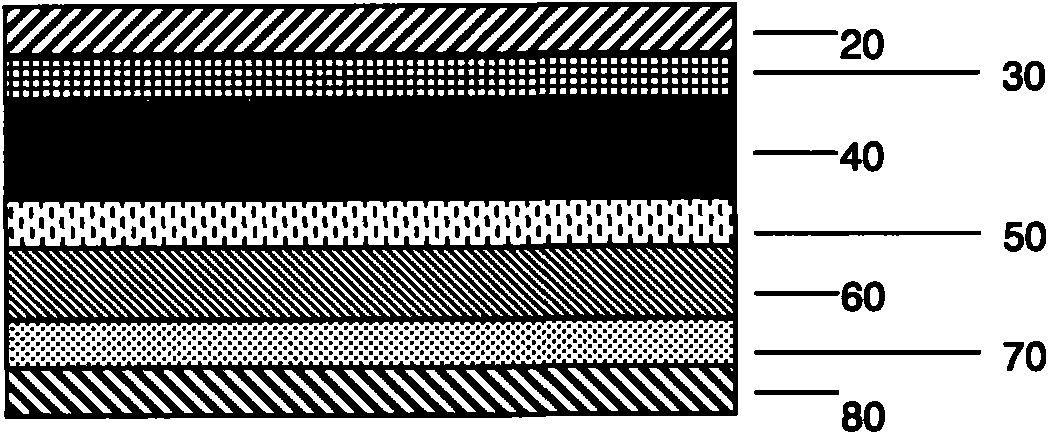

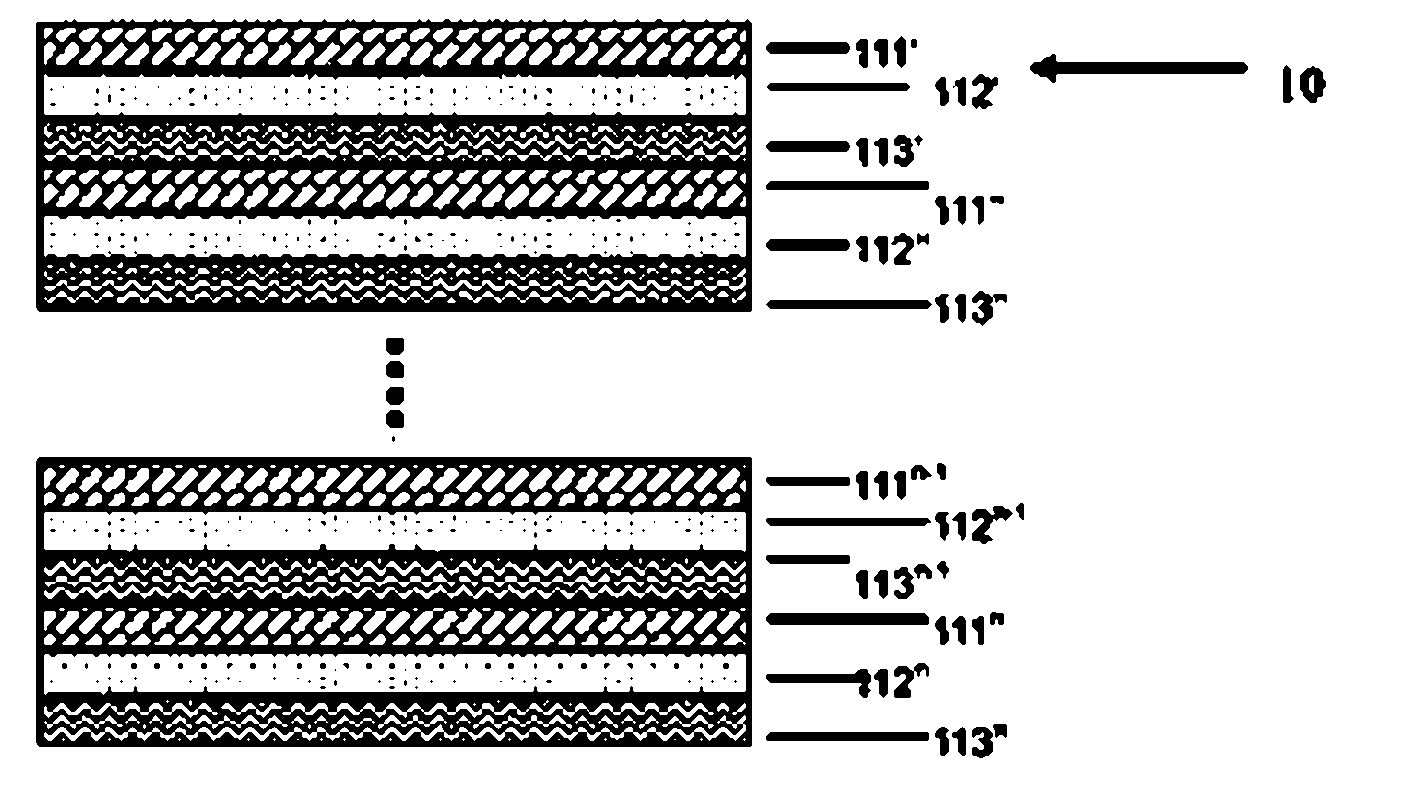

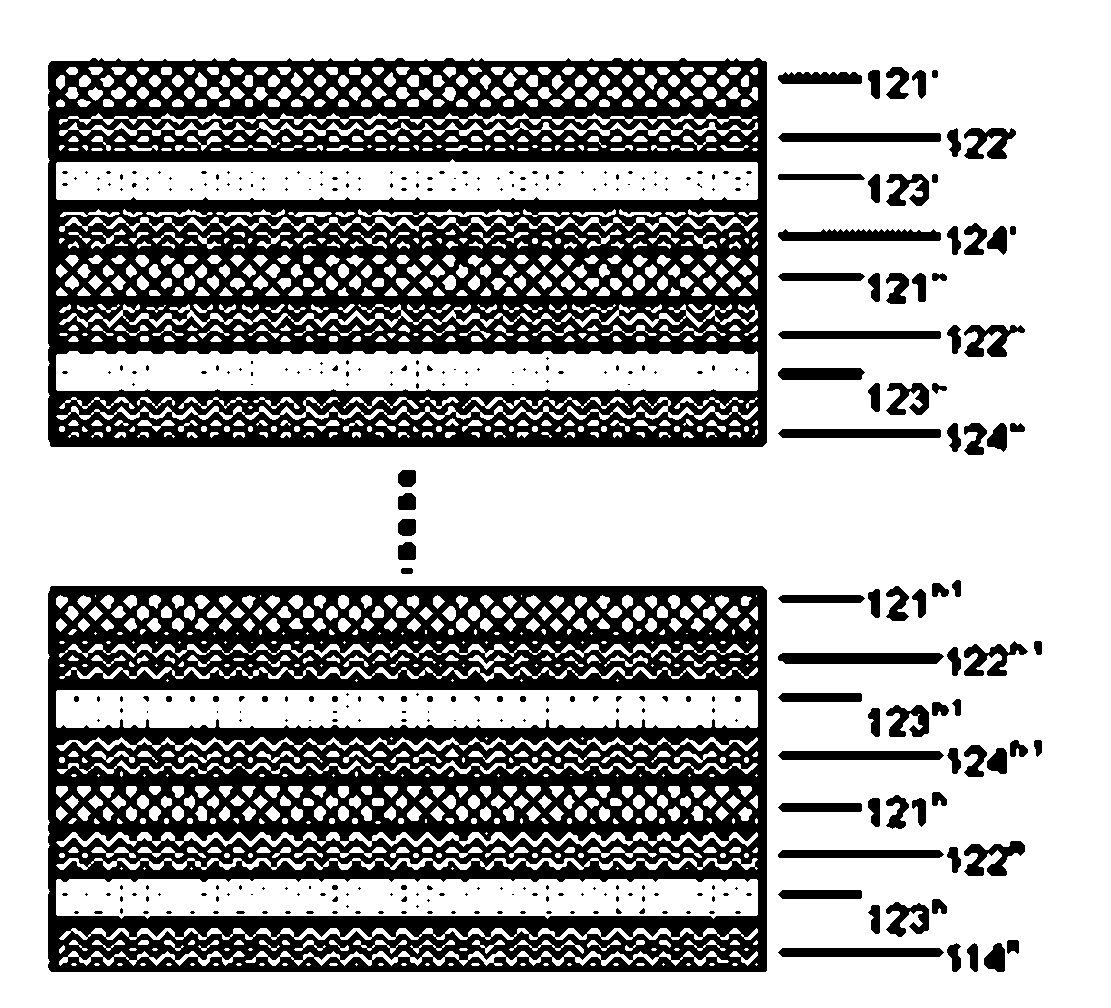

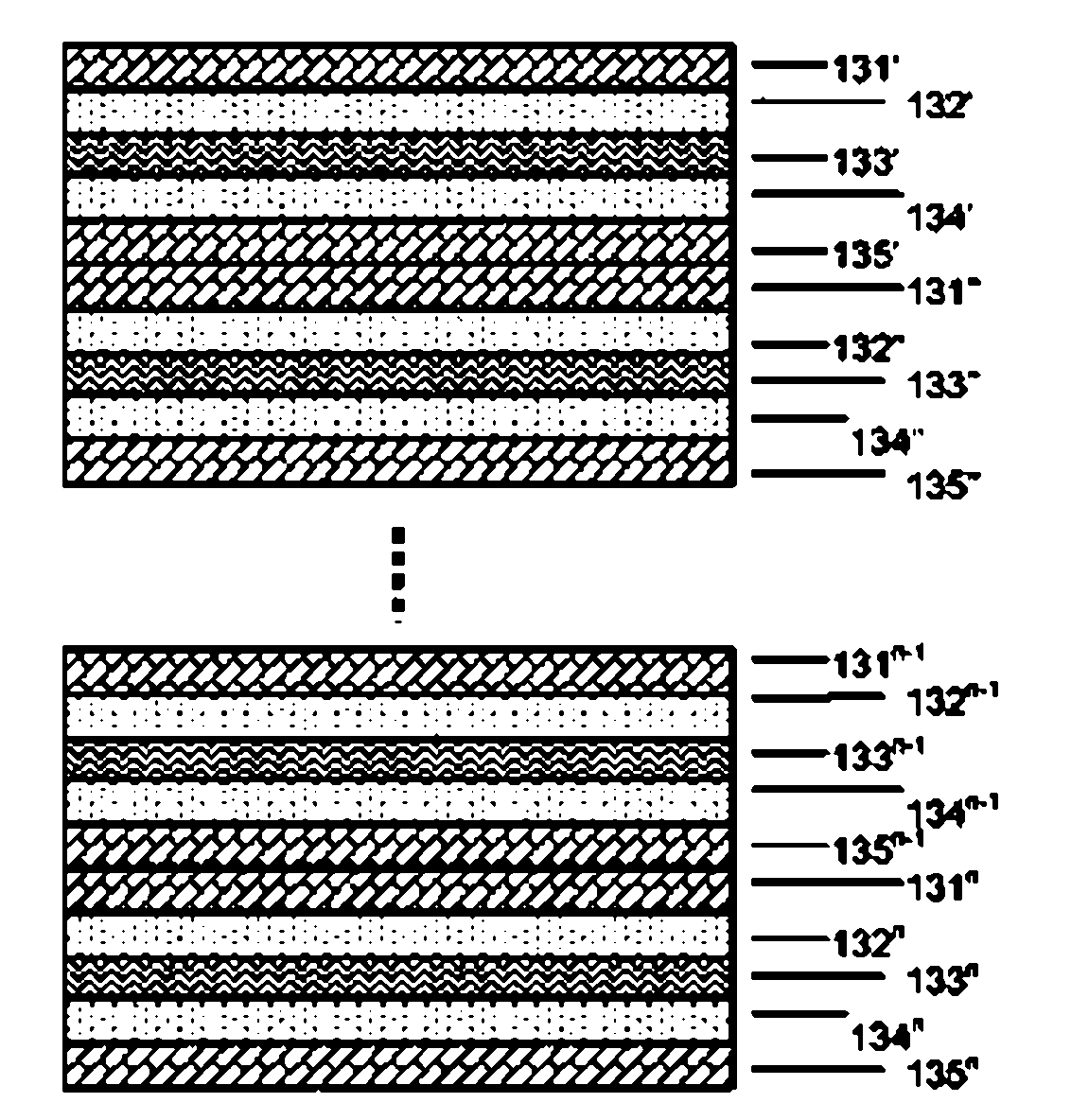

Isolation laminated packaging material

ActiveCN101875420AThe number of layers increasesLayer thickness reductionFlexible coversWrappersInter layerIsolation layer

The invention discloses an isolation laminated packaging material, which comprises a base material layer component, a compound isolation layer component, an outer layer component or an inner layer component or an middle layer component, and a bonding layer component, wherein the base material layer component conducts a supporting function and at least contains a paper or polymer base layer; the compound isolation layer component is laminated on the inner side of the base material layer component, the compound isolation layer component at least comprises a repetitive unit prepared by layer-redoubling and co-extrusion which are realized by repeated cutting, re-lamination and convergence and a compound isolation layer at least containing two individual layers, at least one of the compound layers only contains two polymer components, and at least one component contains at least one isolation polymer; and the bonding layer component is used for bonding the component layers and all layers in the components. In the invention, the structure, performance and price of the packaging material are selected and designed by the selection of the component and the selection and design of the structure of each component, particularly the layer-redoubled co-extruded compound layer component. Compared with other conventional aluminum foil-free laminated packaging material, the isolation laminated packaging material has obvious advantages.

Owner:厦门天策材料科技有限公司

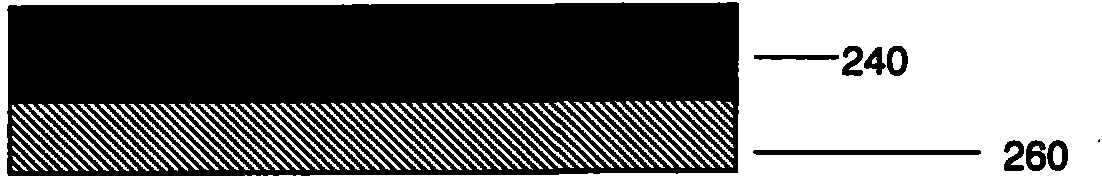

Laminated material without metal foil for blocking package

The invention discloses a laminated material without metal foil for a blocking package. The material at least comprises a substrate layer assembly and a composite blocking layer assembly, wherein the substrate layer assembly and the composite blocking layer assembly are laminated together; the substrate layer assembly has the effect of supporting; and the composite blocking layer assembly comprises at least one composite blocking layer which is prepared through a partition-laminated confluence layer multiplication and coextrusion method and comprises a plurality of repeated units. The material is characterized in that each repeated unit at least comprises three polymer constitutes, and each polymer constitute can form an individual layer or more than one individual layer; and only one of the polymer constitutes is a blocking polymer constitute which can block gas.

Owner:厦门天策材料科技有限公司

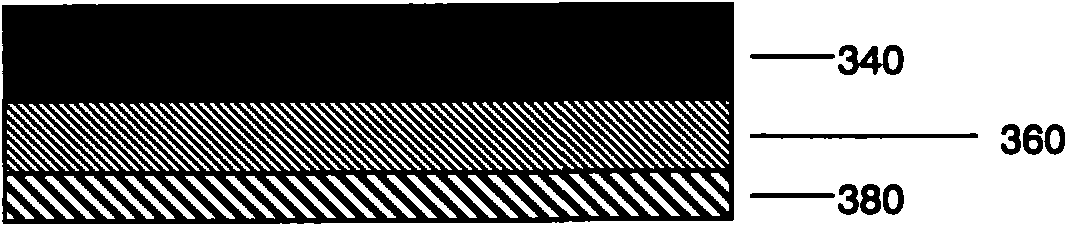

Barrier-property lapped polymer film packaging material

ActiveCN102001486AReduce dosageOne less contains at least dosageFlexible coversWrappersPolymer thin filmsEngineering

The invention discloses a barrier-property lapped polymer film packaging material comprising at least one layer-multiplied and coextruded lapped barrier compound layer. Each barrier compound layer comprises a plurality of repeating units which comprise at least two individual layers; each individual layer corresponds to one of two different polymers; at least one repeating unit of the lapped barrier compound layer at least comprises three individual layers; each of the individual layers corresponds to one of three different polymers; and at least one of the at least three polymers forms at least one barrier-property polymer part which can separate gas.

Owner:厦门天策材料科技有限公司

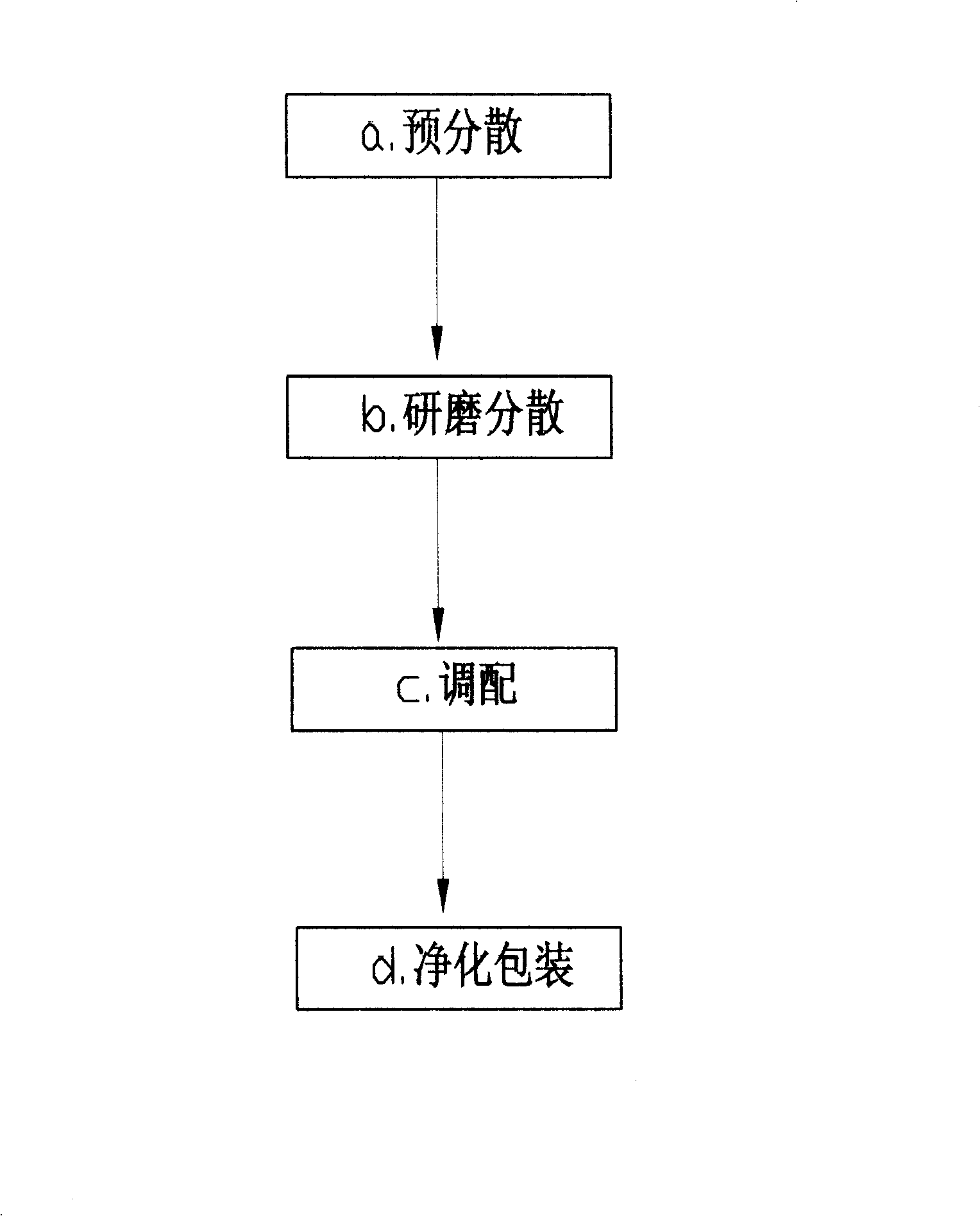

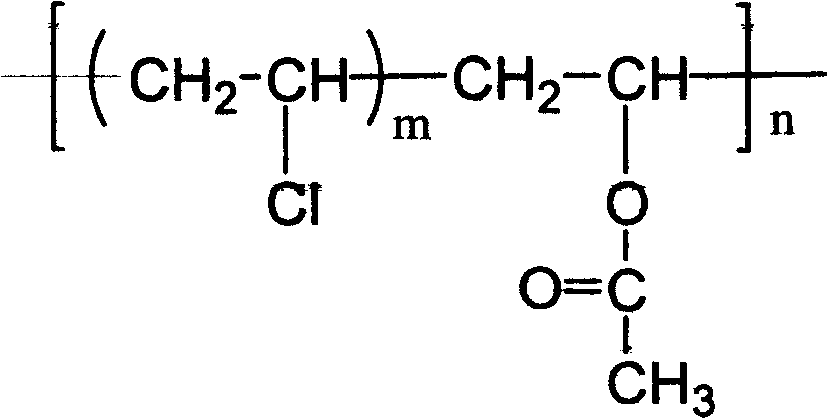

Polyurethane resin compound oil ink and method for manufacturing same

The invention discloses a polyurethane resin compound ink and preparation method thereof, comprising polyurethane resin, chloride-vinyl acetate resin, solvent, dye and dispersing auxiliary, wherein the solvent comprises methyl benzene, butanone, isopropyl alcohol. The composition of the polyurethane resin compound ink is: polyurethane resin liquor (30% solid content) 25-40%, chloride-vinyl acetate resin 0-4%, dye 5-25%, dispersing auxiliary 0.2-0.5%, methyl benzene 0-20%, butanone 25-35%, isopropyl alcohol 5-15%. The invention provides polyurethane resin compound ink with wide application range, good thermal stability, good adhesion and no aromatics solvent, in order to conquer the lacks such as not environment protection, narrow application range and bad thermal stability.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

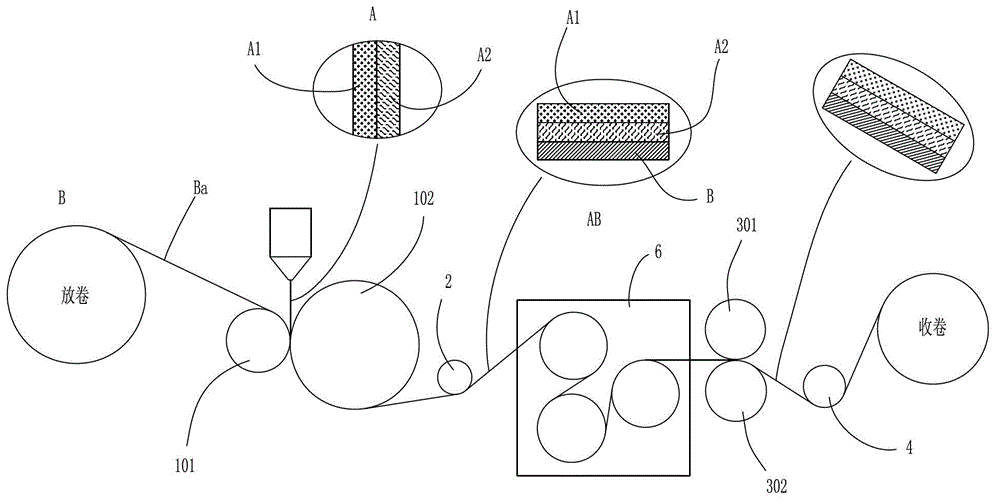

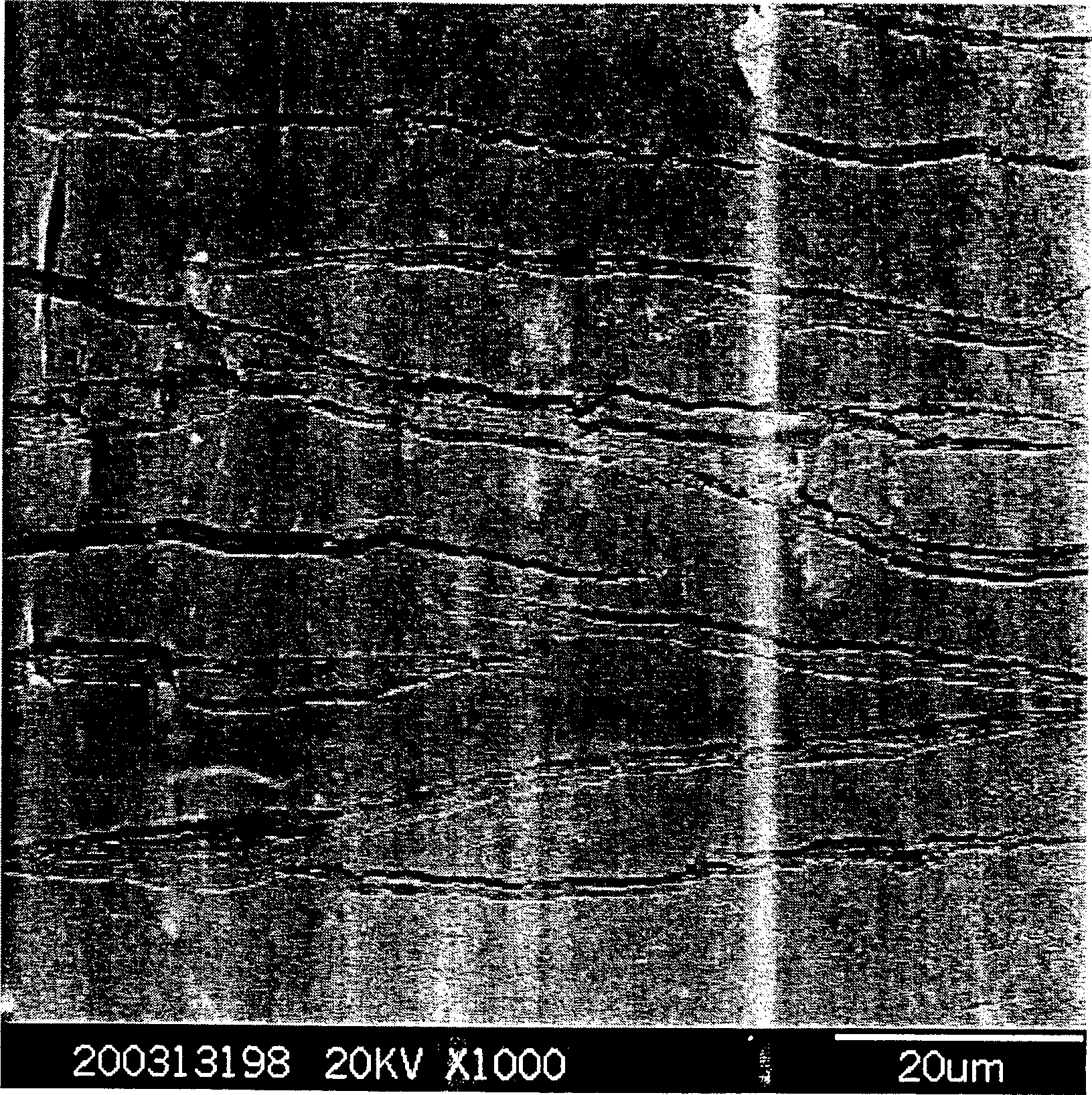

VMPET coated thin film, and production method

InactiveCN101092069AGood heat sealingImprove barrier propertiesFlexible coversWrappersPolyvinyl alcoholRaw material

The invention relates to a novel coated film and the producing method thereof. And it is a VMPET coated film, produced by coating PVDC, PVOH and AC as main raw materials on VMPET.

Owner:海南现代高科实业有限公司

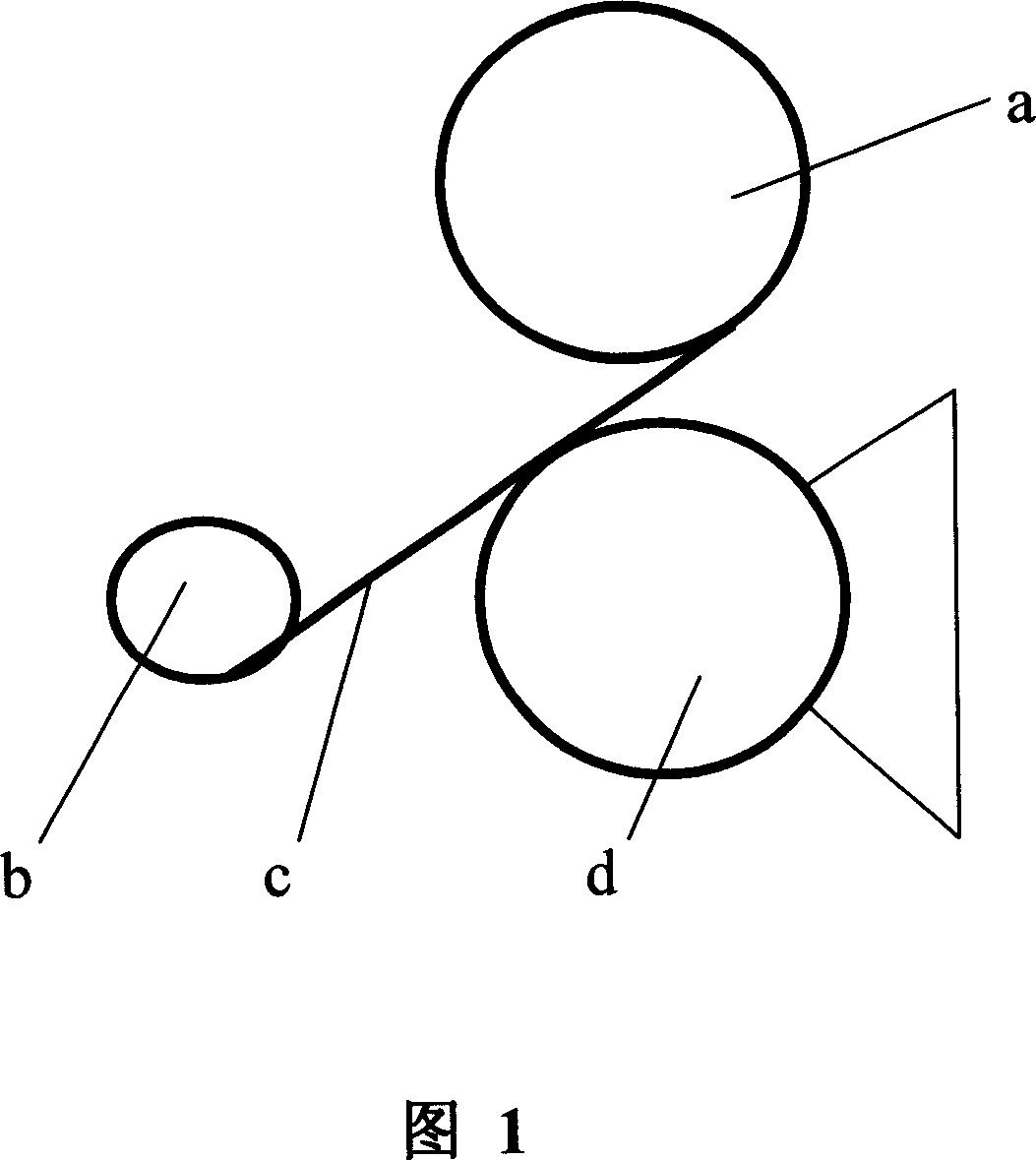

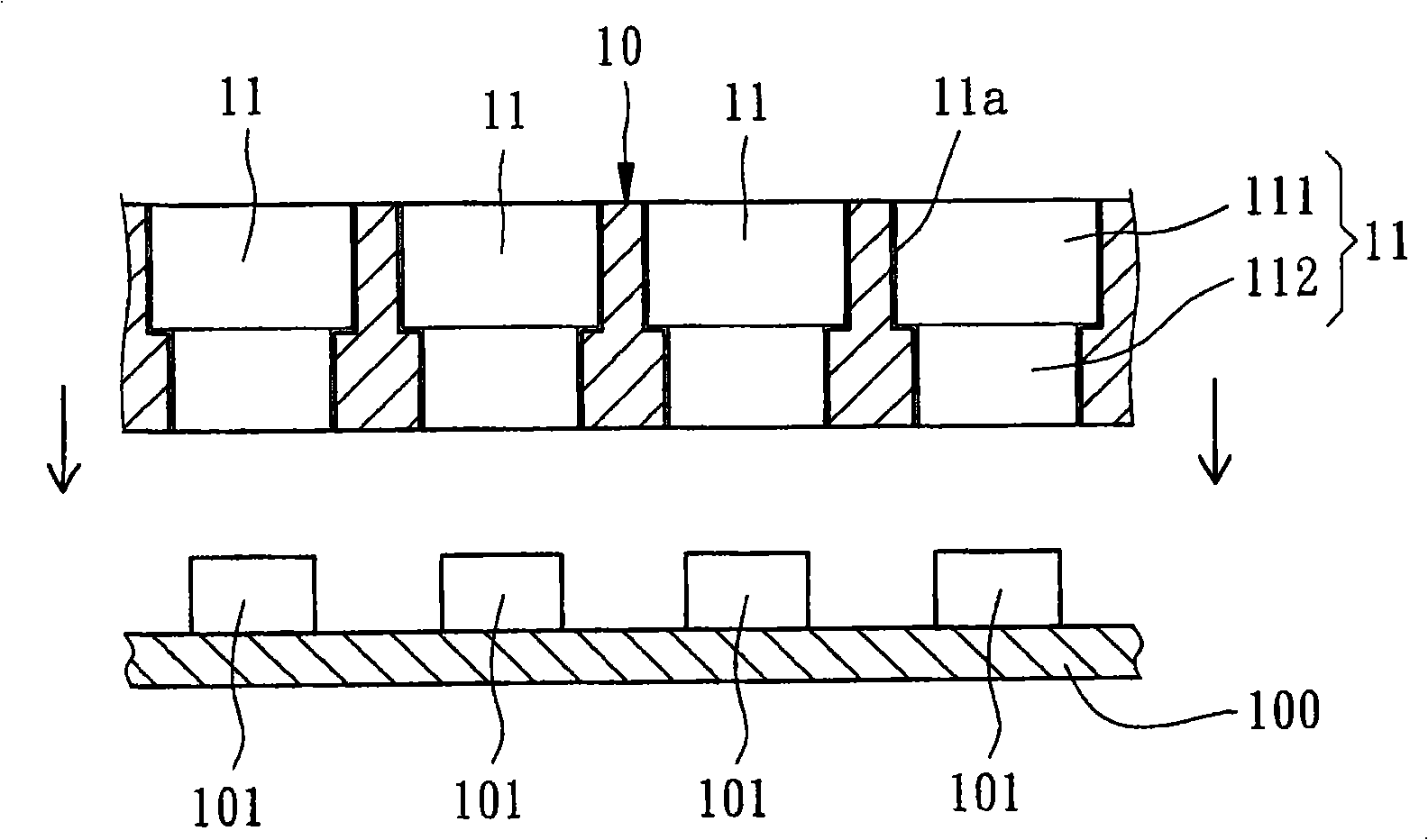

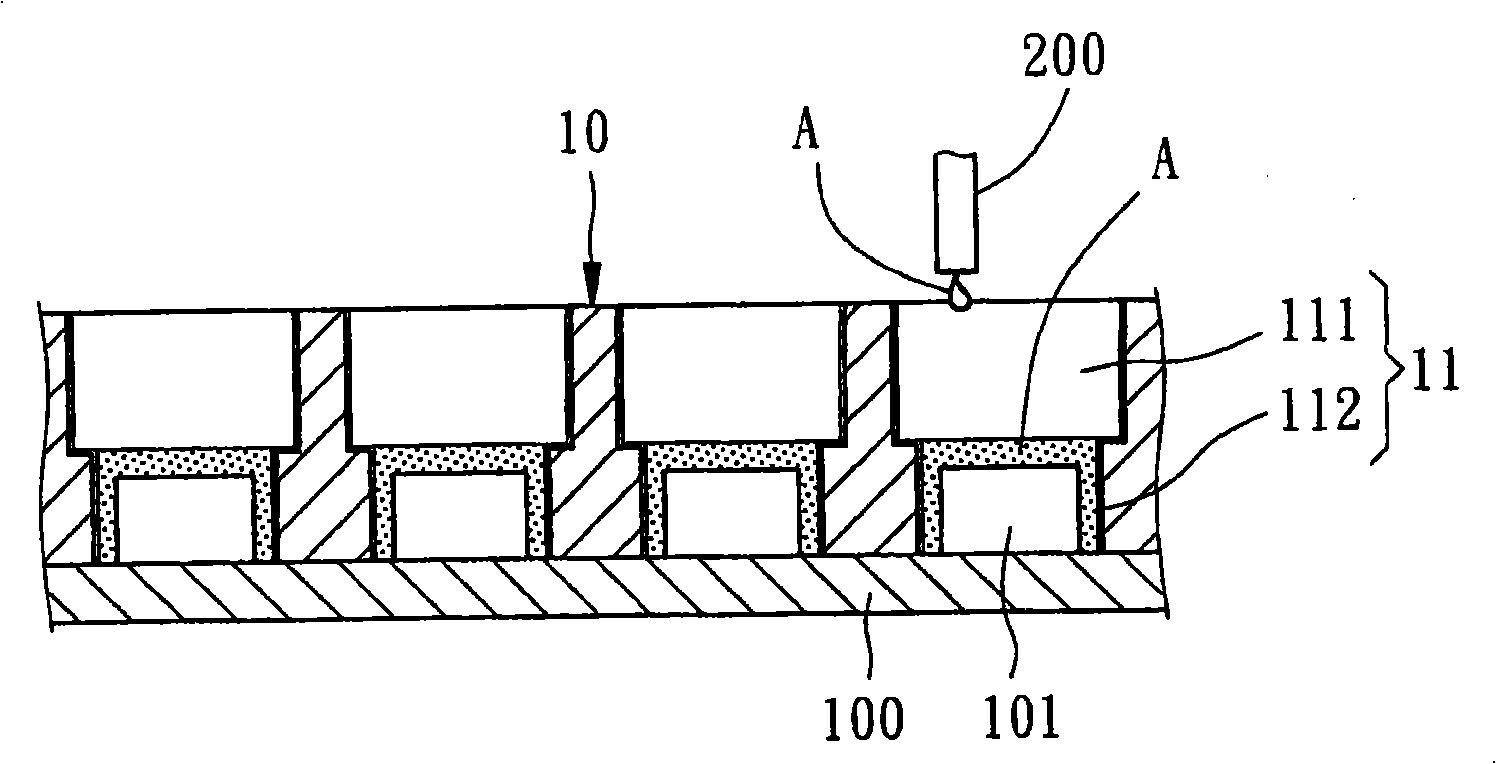

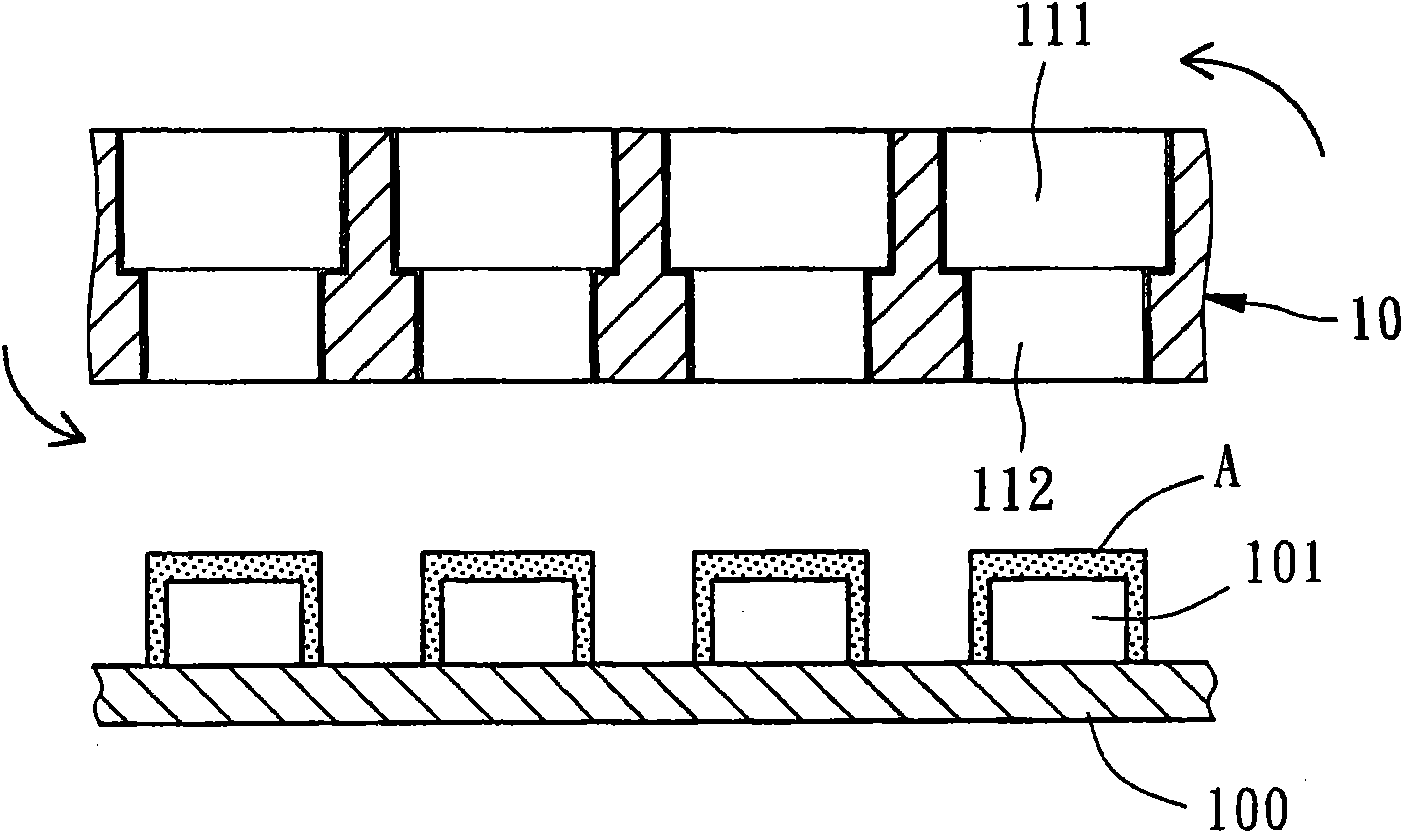

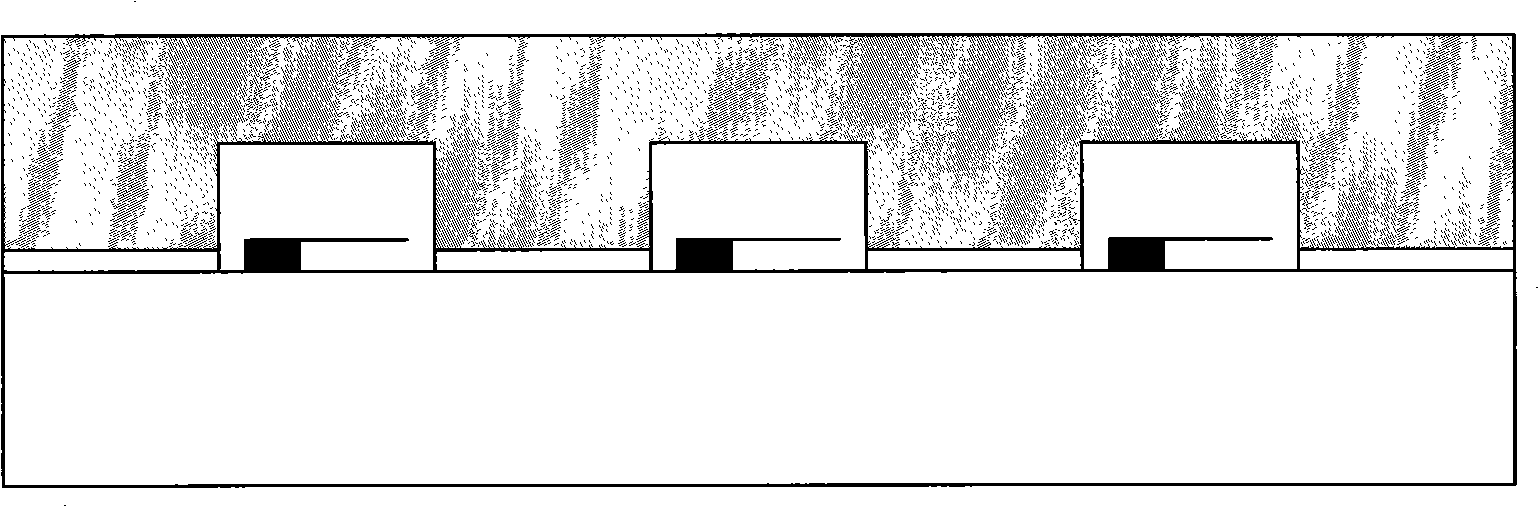

Method for using screen plate for packaging and molding light emitting diode (LED)

InactiveCN101587923AMeet packaging requirementsSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLed packaging

The invention relates to a method for using a screen plate for packaging and molding a light emitting diode (LED).The screen plate with a plurality of class holes is put on a substrate carrying a plurality of LED chips, wherein the class holes are provided with a large aperture part and a small aperture part, and the small aperture part and the large aperture part are sequentially utilized to respectively coat a first packaging glue material and a second packaging glue material onto the LED chips. The method can repeatedly use the same screen plate for coating a glue layer onto the LED chips so as to simplify the process, improve the production efficiency, reduce the equipment cost and meet the packaging requirement of diversified LED packaging structures.

Owner:GENIUS ELECTRONICS OPTICAL CO LTD

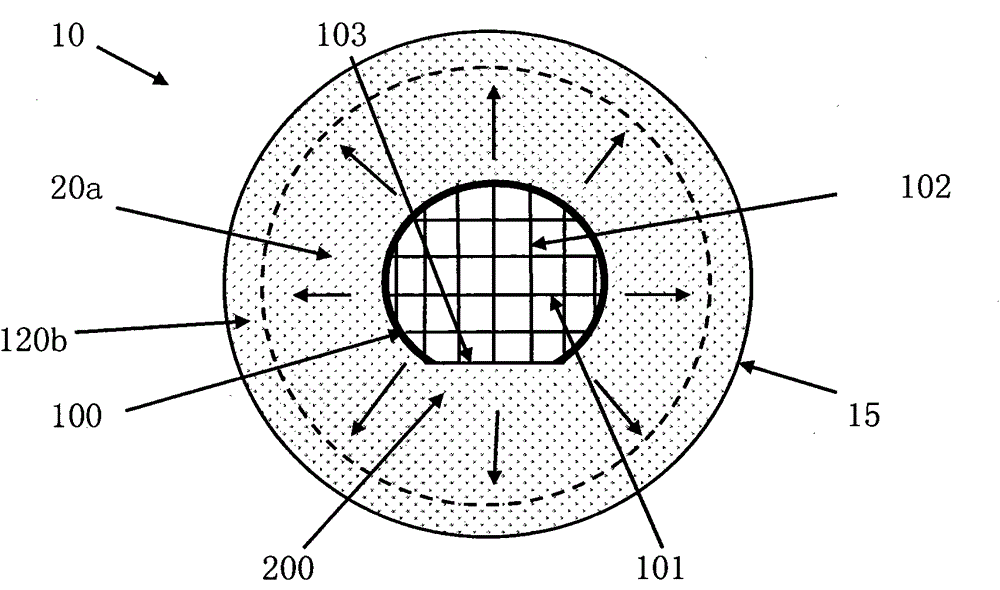

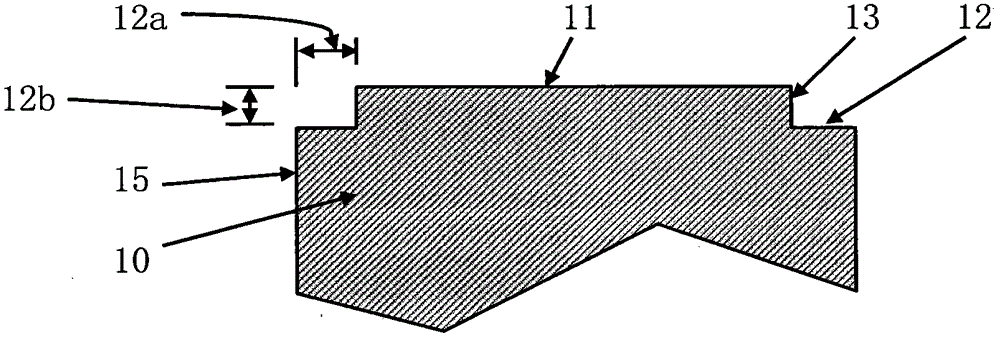

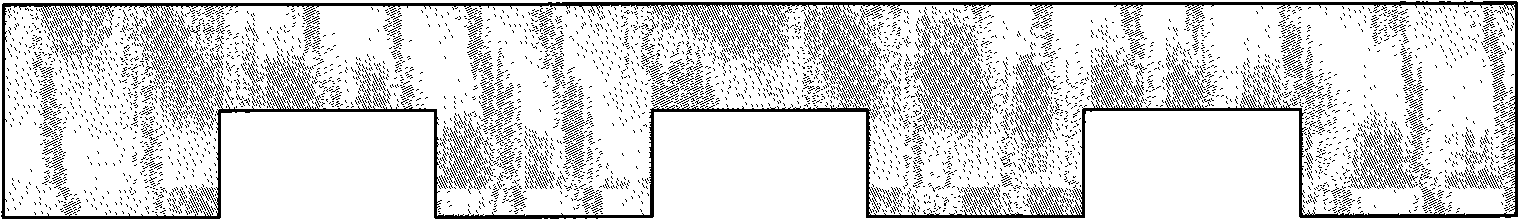

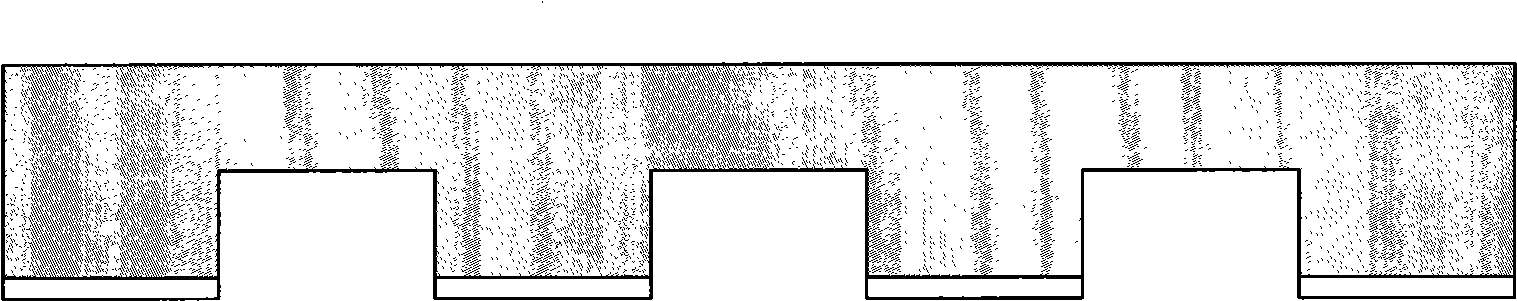

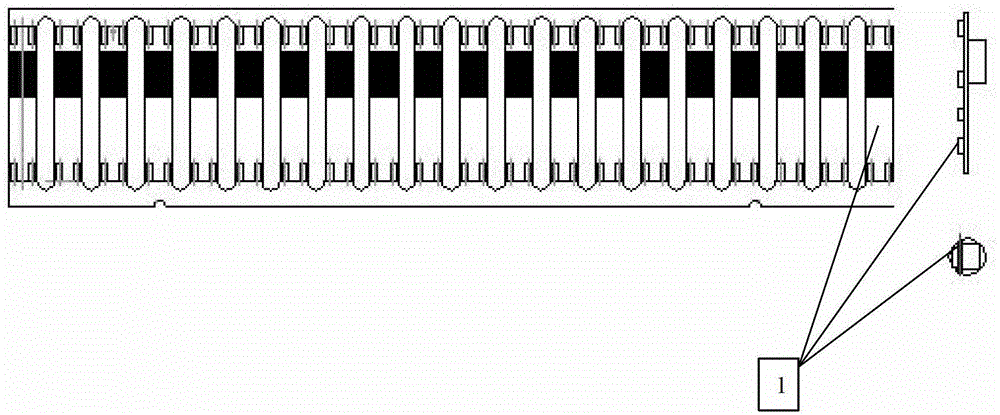

Wafer expander with high expansion uniformity

InactiveCN104008986AReduce occupancyMeet packaging requirementsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a wafer expander used in the semiconductor industry and the LED industry. A cross blue film is expanded in the direction of two mutually perpendicular chip cutting ways so that the cut wafers stuck to the cross blue film are evenly expanded and chips can be separated. The distances between the adjacent chips are the same, the subsequent measurement and sorting processes occupy less machine identification and positioning time, the requirements of chip-level packaging or wafer-level packaging are met, and the subsequent processes are facilitated.

Owner:FOSHAN CITY NANHAI DISTRICT LIANHE GUANGODNG XINGUANGYUAN IND INNOVATION CENT +1

Low-temperature glass solder bonding and encapsulating method based on disc level glass micro-chamber

InactiveCN101497422AGuaranteed reliabilityLower packaging costsTelevision system detailsPrecision positioning equipmentCMOSFritted glass

The invention discloses a low-temperature glass solder bonding and packaging method based on wafer-level glass microcavities, which comprises the following steps: firstly, utilizing a silk-screen printing process to coat low-temperature glass solder on a packaging contact part of a Pyrex7740 glass substrate provided with a microcavity structure, preliminarily drying the low-temperature glass solder, and making the low-temperature glass solder be cured and cling to the Pyrex7740 glass substrate provided with the microcavity structure; secondly, aligning a Pyrex7740 glass packaging wafer which is cured with the low-temperature glass solder and a silicon substrate wafer comprising an MEMS device or a CMOS circuit, and making the microcavity structure on the Pyrex7740 glass substrate correspond to the position of the MEMS device or the CMOS circuit to be packaged of a silicon substrate; and thirdly, using a clamper to firmly clamp the two aligned wafers, applying the pressure, sintering the glass solder in a specified packaging atmosphere, and cooling the glass solder. The whole process is based on integral processing of the silicon wafer and the Pyrex7740 glass wafer, belongs to a process for manufacturing and packaging a wafer-level MEMS, and has the characteristics of simple method, adjustable packaging space and low cost.

Owner:SOUTHEAST UNIV

Binding agent for solvent-free two-component polyurethane composite film, and preparation method for binding agent

ActiveCN105111999AHigh peel strengthMeet food packaging requirementsPolyureas/polyurethane adhesivesPolyesterPolyol

The invention discloses a binding agent for a solvent-free two-component polyurethane composite film, and a preparation method for the binding agent. The binding agent comprises an isocyanate-terminated component A and a hydroxy-terminated component B, wherein the component A is synthesized by enabling isocyanate to react with polyether polyol and polyester polyol, the component B is synthesized by enabling polyether polyol to react with isocyanate, and the functional group molar ratio of the component A to the component B is (1.2-2.0) : 1. The method comprises the following steps: firstly, mixing polyisocyanate with polyether glycol, polyether polyol and polyester polyol, adding an appropriate amount of phosphoric acid, and heating to realize reaction to generate the component A; secondly, mixing polyether polyol and isocyanate, and heating to generate the component B; finally, compounding the component A and the component B to obtain the binding agent for the solvent-free two-component polyurethane composite film. During use, the binding agent consumption is low, the wettability of a base material is good, and the bonding strength is high. The binding agent is wide in applicable range, safe, environmental-friendly, and free of solvent discharge, and can adapt to cooking for 30 min at 121 DEG C.

Owner:BEIJING COMENS NEW MATERIALS

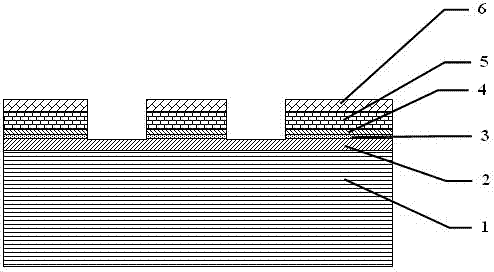

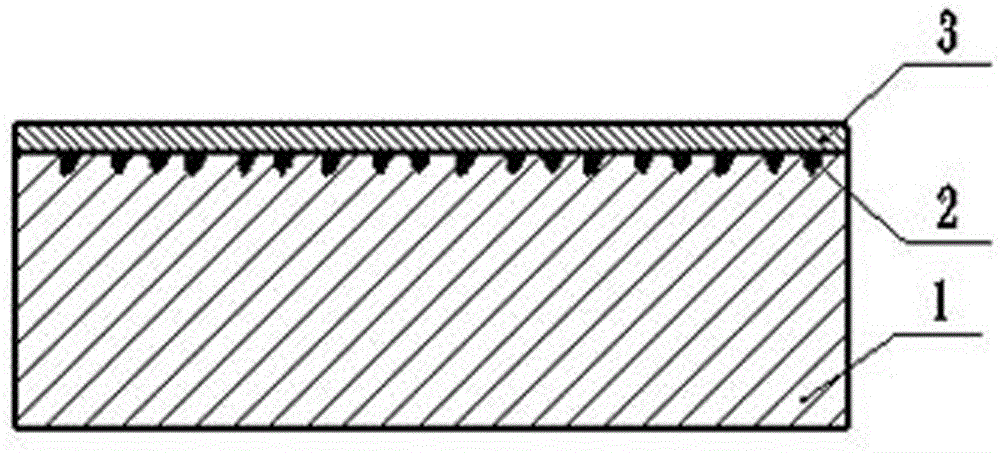

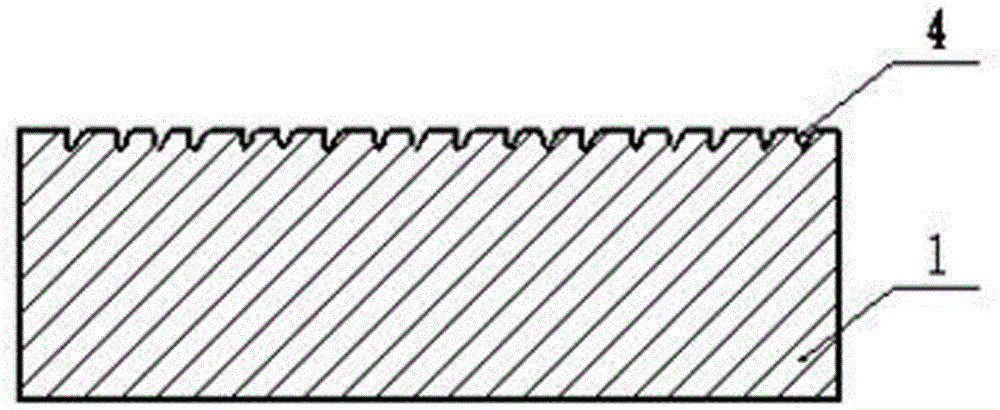

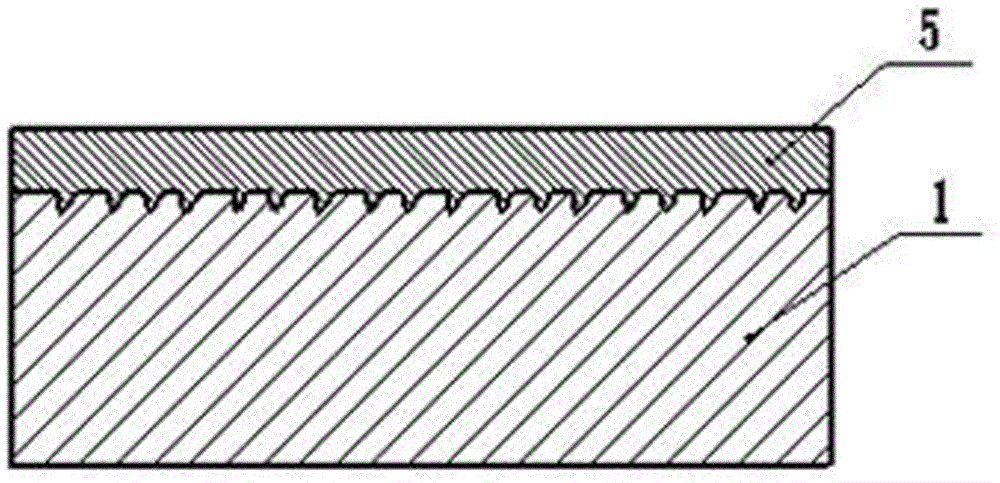

Metal substrate of heat conducting aluminium-based core and preparation method thereof

InactiveCN102256441ARaw materials are easy to obtainStable production processCircuit susbtrate materialsMetal core circuit manufactureMetallic aluminumHeat conducting

The invention discloses a metal substrate of a heat conducting aluminium-based core and a preparation method thereof. The metal substrate is composed of a metal aluminium substrate, an alumina insulating layer, a buffer layer, a first conducting layer, a second conducting layer and a weldable layer, wherein the metal aluminium substrate, the alumina insulating layer, the buffer layer, the first conducting layer, the second conducting layer and the weldable layer are superposed successively. According to the preparation method, a surface of the aluminium substrate is processed by using an anodization solution to generate the alumina insulating layer; the buffer layer and the first conducting layer are coated on the alumina insulating layer by a physical deposition method and then the second conducting layer is coated by an electrochemical deposition method; pad pasting and etching processes are carried out on the surface of the second conducting layer to obtain a needed circuit; at last, the weldable layer metal is coated on the second conducting layer by the electrochemical deposition method. According to the invention, the metal substrate has advantages of light weight, high heat radiation efficiency, long service life, and high reliability of performance; moreover, the metal substrate completely meets packaging requirements of various components and has low production cost; therefore, the metal substrate provided in the invention satisfies a condition of large-scale industrial application.

Owner:SUN YAT SEN UNIV

Diamond single crystal surface metallization treatment method

ActiveCN106835054AImprove the efficiency of graphitization transformationPromote the graphitization processVacuum evaporation coatingSputtering coatingEtchingIron group

The invention discloses a diamond single crystal surface metallization treatment method. The method comprises steps as follows: the surface of a diamond single crystal is bombarded and sputtered with Fe, Co or Ni as a source electrode target material with a double-glow plasma diffusion metallizing technique; the single crystal is soaked in an acid solution, so that remaining metal and graphite are removed; a metal diffusion coating is prepared on the surface of the diamond single crystal with strong carbide metal as a target material with a double-glow plasma diffusion metallizing technique. Uniformly distributed micro pits are formed in the surface of the single crystal under the bombardment and sputtering functions of the double-glow plasma and the graphitized catalytic function of Fe, Co, Ni and other iron group metals, surface roughening and activation are realized, strong carbide metallic elements react with a part of carbon atoms on the surface of the diamond so that chemical bond combination is realized, and the bonding strength of the surface metallization coating and the single-crystal diamond is improved. Bombardment etching and metallization treatment are realized with one device, the process is simple, the cost is low, and the method is suitable for industrial production.

Owner:山西国脉金晶碳基半导体材料产业研究院有限公司

Preparation method and application of polyhedral oligomeric silsesquioxane skeleton containing vinyl silicone oil

ActiveCN103289096AEasy to prepareMeet packaging requirementsSemiconductor devicesMethyl phenyl polysiloxaneMechanical property

The invention relates to an organic silicon rubber for LED packaging. In order to solve the problems that during direct physical blending of POSS (polyhedral oligomeric silsesquioxane) with vinyl silicone oil and hydrogen containing silicone oil, POSS has poor compatibility with vinyl silicone oil and hydrogen containing silicone oil and is very easy to precipitate, so that the light transmittance and mechanical properties of the product can be affected, the invention provides a preparation method of a POSS skeleton containing vinyl silicone oil. The method includes: mixing POSS with one or two of dimethyl polysiloxane and methylphenyl polysiloxane at any proportion to obtain a mixture, in the presence of a catalyst, carrying out end-capping with a vinyl end-capping reagent, and performing a polymerization reaction to obtain the POSS skeleton containing vinyl silicone oil. The preparation method is simple. The invention also provides application of the POSS skeleton containing vinyl silicone oil in LED packaging materials.

Owner:HANGZHOU NORMAL UNIVERSITY

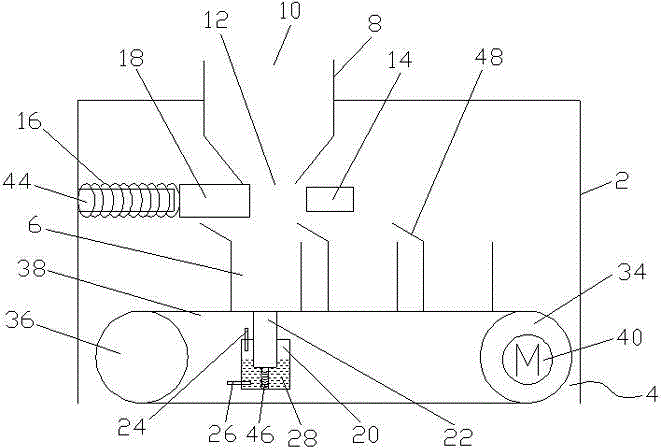

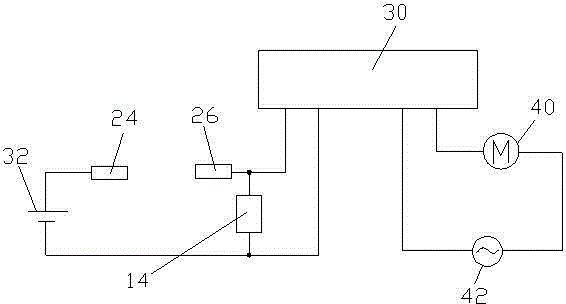

Equal-weight packaging automatic control device for material

The invention relates to an equal-weight packaging automatic control device for a material. The equal-weight packaging automatic control device for the material comprises a bracket, a conveying mechanism, a plurality of packaging boxes and a feed hopper located above the box, wherein the packaging boxes are arranged on the conveying mechanism; the upper ends of the packaging boxes are open; an opening-closing mechanism and a control mechanism are fixedly arranged on the bracket; the opening -closing mechanism comprises an electromagnet, a first spring and a metal stop block which is fixed with the first spring; the control mechanism comprises a conducting solution storage tank, a floating block, and a first conducting post and a second conducting post, which are at least partially arranged in the conducting solution storage tank; one end of the first conducting post or the second conducting post is connected with an electromagnetic relay; the electromagnetic relay is connected in parallel with the electromagnet; the conveying mechanism comprises a driving wheel, a driven wheel, a conveying belt which is used for connecting the driving wheel with the driven wheel, and a motor used for driving the driving wheel; the motor is connected with the electromagnetic relay. By using the equal-weight packaging automatic control device for the material, the accurate control of the packaged weight of the material is ensured; a packaging requirement is met; the first conducting post can be regulated vertically, so as to be conveniently suitable for materials of different types.

Owner:SUZHOU INST OF INDAL TECH

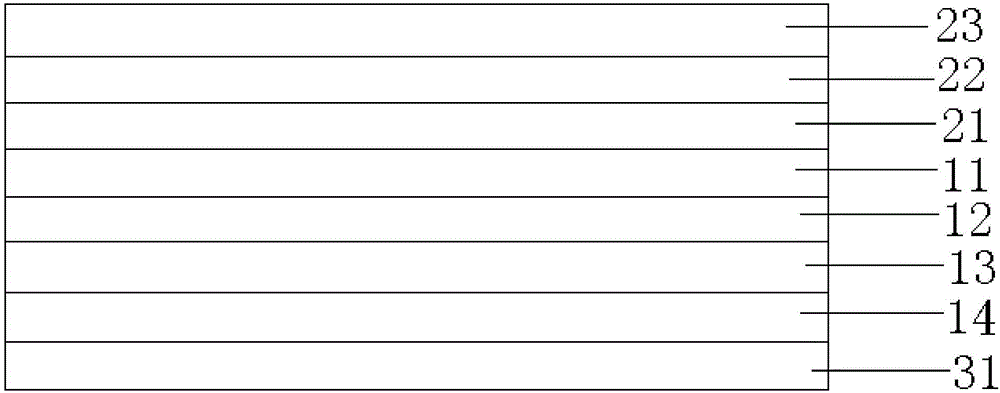

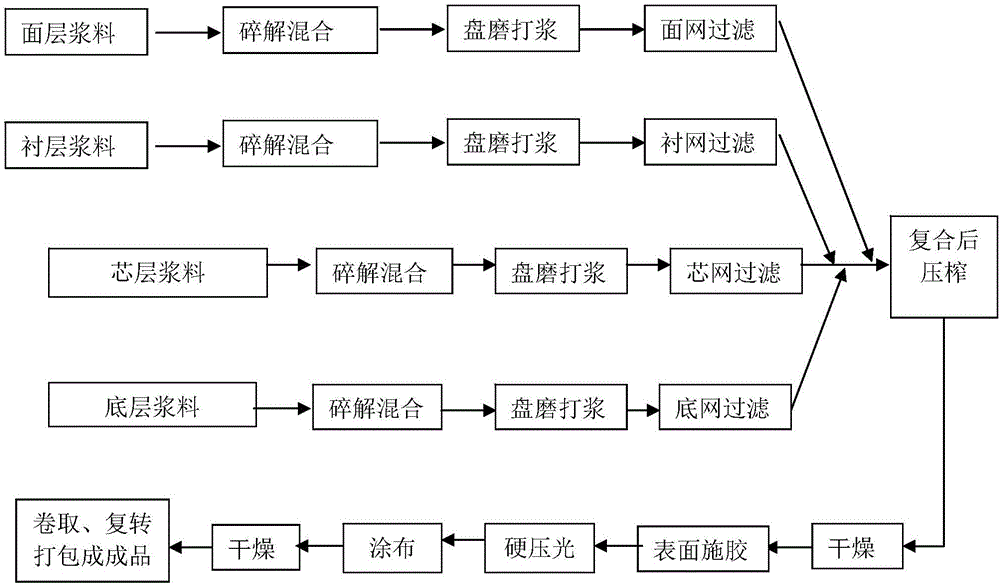

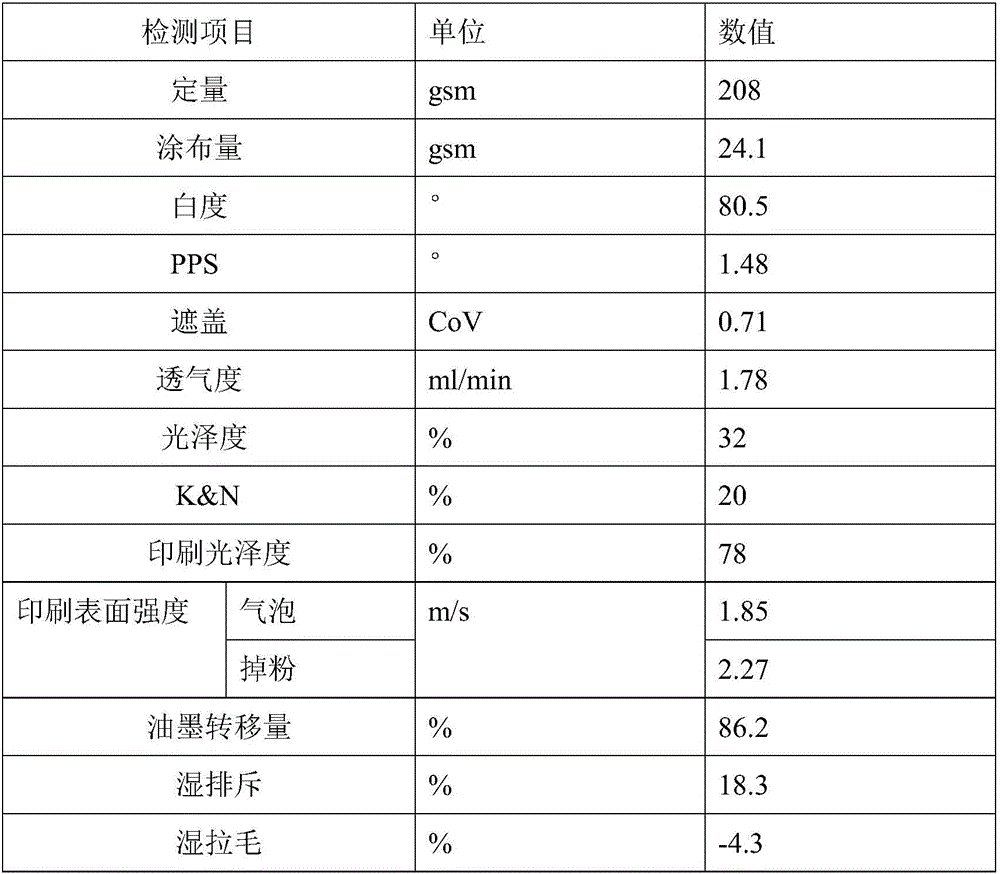

Natural-color liquid packaging paper and production process thereof

InactiveCN106245459ALose weightImprove uniformityFlexible coversCoatings with pigmentsPulp and paper industrySizing

The invention discloses natural-color liquid packaging paper, comprising a body paper layer, and a coating layer and a back-coating layer respectively coating the upper surface and the bottom surface of the body paper layer, wherein the body paper layer comprises a surface paper layer, a lining paper layer, a core paper layer and a bottom paper layer which are stacked in sequence from top to bottom. The natural-color liquid packaging paper is produced by the following steps: respectively draining pulp of the surface paper layer, the lining paper layer, the core paper layer and the bottom paper layer, compounding, squeezing, drying, and performing surface sizing to obtain the body paper layer; performing hard calendaring on the body paper layer, then coating the upper surface and the bottom surface of the body paper layer, and drying. The liquid packaging paper adopts a four-layer structure, thus reducing forming and dewatering requirements, effectively improving evenness of surface pulp, and improving the surface covering property of the paper. Besides, a mode of combining measuring stick pre-coating, ceramic scraper core-coating and soft-blade scraper surface-coating is adopted, thus effectively improving the covering property of the paper, and meeting the packaging requirements of various printing patterns in a later period.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER +1

Medicinal neutral borosilicate glass tube and preparing method thereof

InactiveCN105036553AGood visible light transmittanceImprove UV transmittanceLithium oxideUltraviolet lights

The invention discloses a medicinal neutral borosilicate glass tube and a preparing method thereof. Manganese dioxide ingredients, titanium oxide ingredients and ferric oxide ingredients are added into preparing raw materials of the glass tube. One hundred parts of the raw materials comprise, by mass, 65 parts to 75 parts of silicon dioxide, 5.0 parts to 7.0 parts of aluminum oxide, 8.2 parts to 11.6 parts of diboron trioxide, 0.5 part to 2.4 parts of calcium oxide, 0.3 part to 3.4 parts of potassium oxide, 4.5 parts to 7.6 parts of sodium oxide, 0.2 part to 1.0 part of lithium oxide, 0.5 part to 7.0 parts of manganese dioxide, 0.4 part to 5.0 parts of titanium oxide and 0.2 part to 2.5 parts of ferric oxide. By means of the medicinal neutral borosilicate glass tube and the preparing method, the performance indexes such as the visible light transmittance, the ultraviolet light transmittance and the chrominance of an existing neutral borosilicate glass tube are improved, and the requirement for visible-light and ultraviolet-light sensitive medicine packages is met.

Owner:沧州四星玻璃股份有限公司

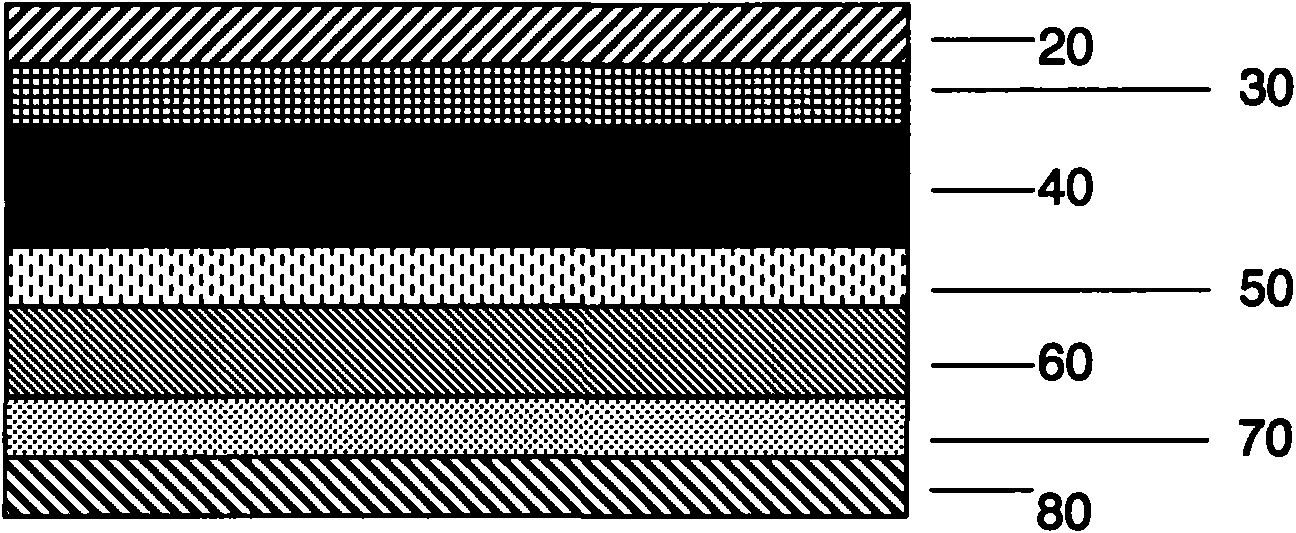

Organic electroluminescent device and method for producing same

InactiveCN103811668AHigh bonding strengthStop erosionSolid-state devicesSemiconductor/solid-state device manufacturingFlat glassOrganic electroluminescence

The invention provides an organic electroluminescent device comprising an anode conductive substrate, a functional layer, a luminescent layer, a cathode layer, a protective layer, and an encapsulating layer. The encapsulating layer comprises an insulating layer, metallic layers, and plate glass. The insulating layer is arranged in a surrounding manner along the edge of the top surface of the anode conductive substrate. A groove is surrounded by the insulating layer surrounding structure. The functional layer, the luminescent layer, the cathode layer, and the protective layer are successively extended from the top surface of the anode conductive substrate to the groove. The metallic layers are disposed on the top surface of the insulating layer and a gap is arranged between the metallic layers and the functional layer, the luminescent layer, the cathode layer, and the protective layer. The sum of heights of the insulating layer and the metallic layers is more than that of the functional layer, the luminescent layer, the cathode layer, and the protective layer. The plate glass is disposed on the top surfaces of the metallic layers. The invention also provides a method for producing the organic electroluminescent device. The method effectively reduces erosion, caused by moisture and oxygen, on the device, and substantially prolongs the service life of the device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

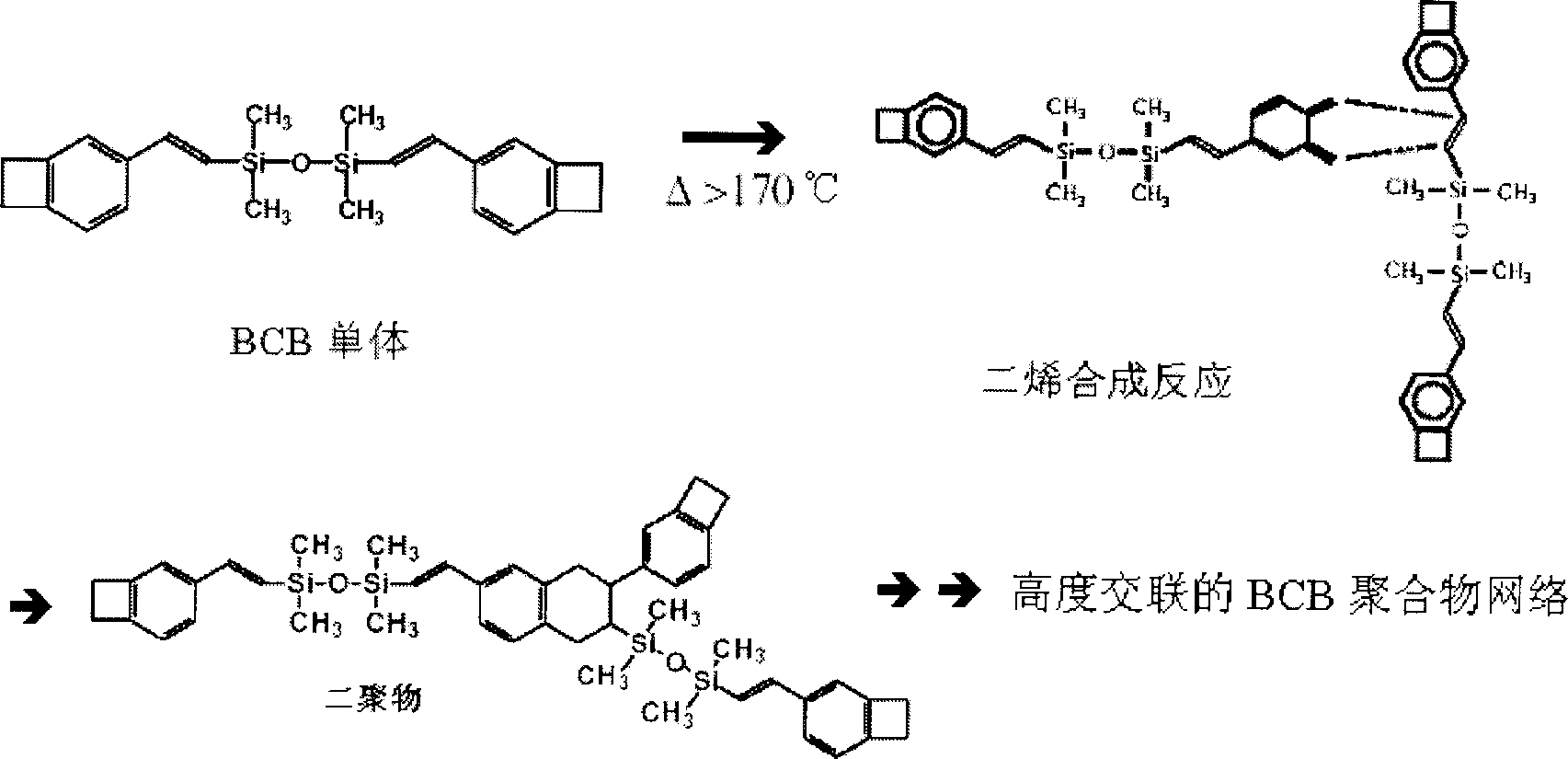

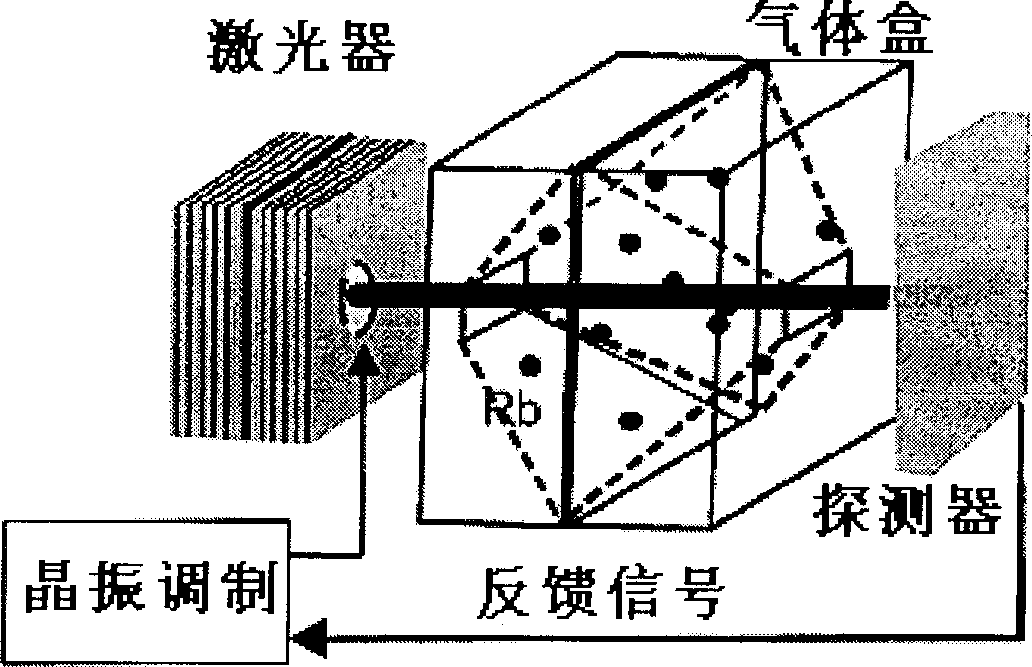

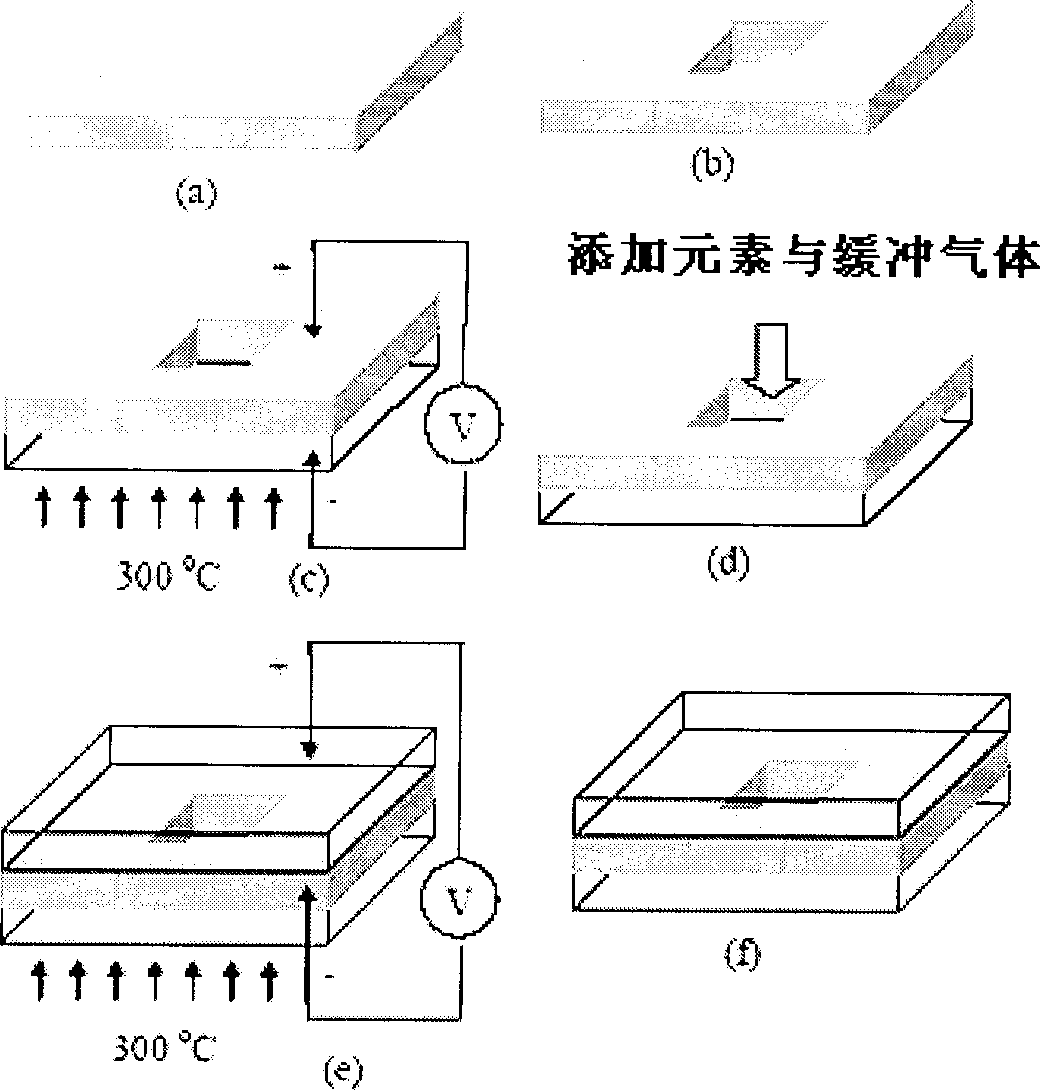

Process for preparing low-temperature wafer-level mini-sized gas container

InactiveCN1827522AMeet packaging requirementsAvoid lostNanostructure manufactureSemiconductor materialsAir tightness

The invention relates to a method for producing low-temperature circle sheet micro gas box, which is characterized in that: the benzocyclobutene is used to process material linkage with humid etching or dry etching technique of semi-conductor in 250Deg. C, to realize the circle sheet air-tightness sealing linkage of chip-level gas box. The invention comprises a atom gas box containing a chip-level atom clock gas box, a high-precision magnetic field sensor gas box, a atom feedback glimmer frequency stabilizer; a atom gas box containing a atom light filter, with glimmer Fabry-Perot chamber. The linked BCB glue is in 0.2ª–m thickness, the air-tightness of sealed He gas can reach 2.1-5.9X10-4Pa cm3 / s, and the linkage strength is higher than 4.65MPa, while the thermal cycle reliability can fully reach the packing standard of micro electric device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Formula of organic silicon rubber for light-emitting diode (LED) chip packaging

InactiveCN102391651AMeet packaging requirementsRich sourcesSemiconductor devicesVulcanizationHazardous substance

The invention discloses a formula of organic silicon rubber for light-emitting diode (LED) chip packaging. According to the formula, the organic silicon rubber mainly comprises 45 to 85 percent of vinyl silicon oil, 35 to 65 percent of methyl hydrogen-containing silicon oil, 0.3 to 0.7 percent of platinum catalyst, 0.2 to 0.45 percent of catalysis inhibitor, and 1.2 to 1.8 percent of functional filler. The invention discloses the formula of the organic silicon rubber for LED packaging; the components in the formula are reasonable, the sources of the raw materials are rich, and the prepared organic silicon rubber can fully meet the packaging requirements of LED chips with different power, and has high hardness, light transmission, cold and heat resistance, and toughness; meanwhile, a vulcanization process in the process for preparing the organic silicon rubber is smooth, gelling time is easy to control, harmful substances are not breeded, and the organic silicon rubber is a more environment-friendly organic material.

Owner:常熟市广大电器有限公司

Integrally gummed electronic circuit module for electronic detonator and process method thereof

The invention relates to an integrally gummed electronic circuit module for an electronic detonator and a process method thereof. The process method specifically comprises the steps of: welding electronic circuit modules for electronic detonators of one to twenty connectors with one to twenty electric ignition charge heads once, placing the electronic circuit modules welded with the charge heads after the assay is approved in a curing and sealing mould filled with thermosetting silicon gel or epoxy resin glue, and ejecting the gummed electronic circuit module out of the mould by using a punch after the electronic circuit module and curing and sealing glue are cured together so as to be used by subsequently welding a leg wire and assembling the electronic detonator. Through curing and gumming an electronic circuit and a charge head module, the properties of resisting static impaction, mechanical impaction, direct current impaction and alternating current impaction of the electronic detonator can be effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

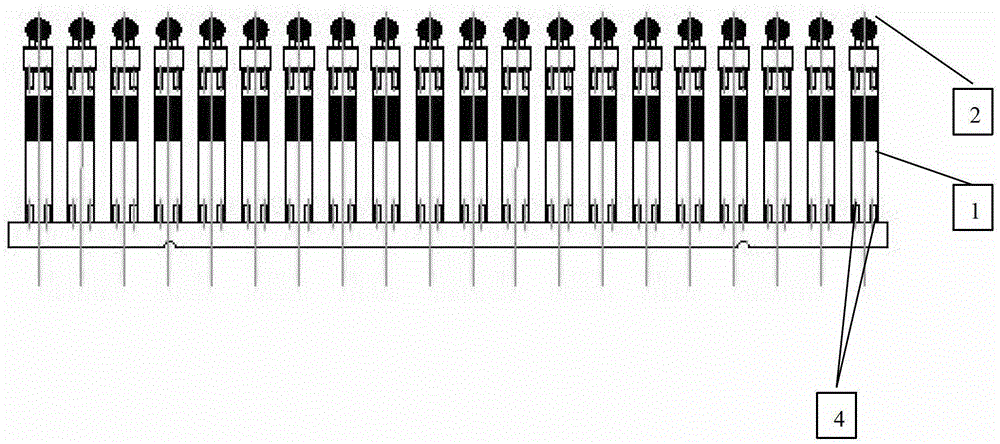

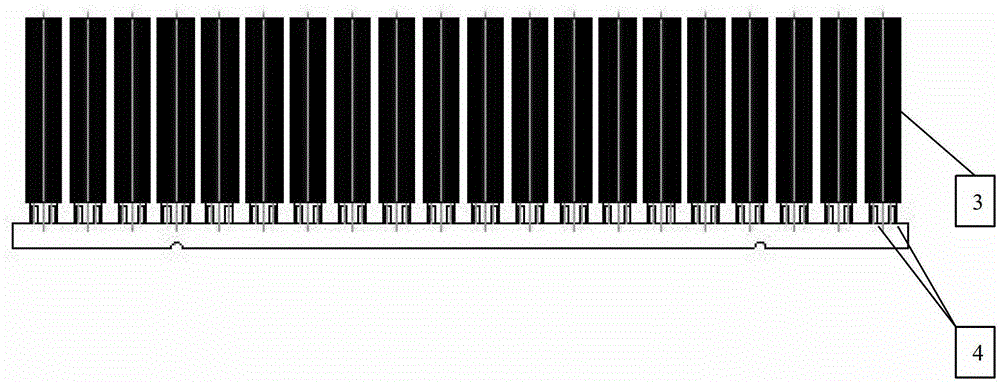

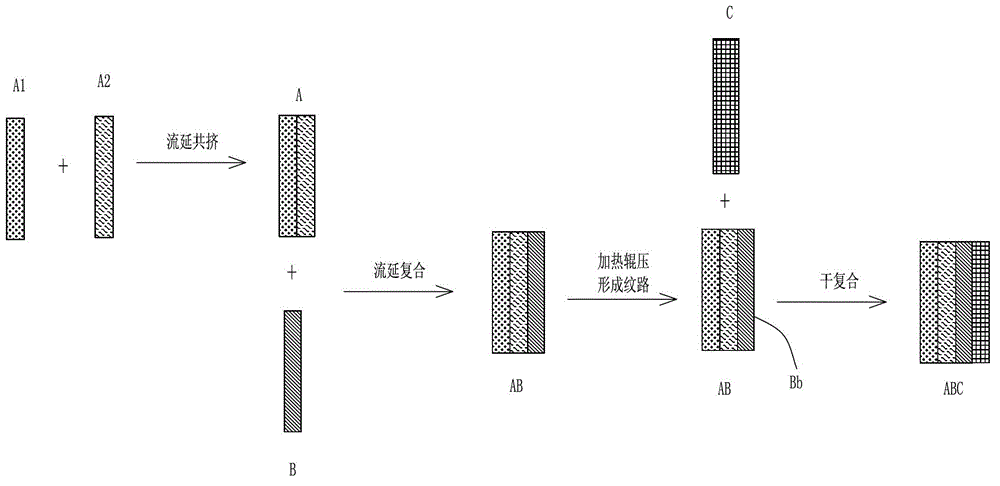

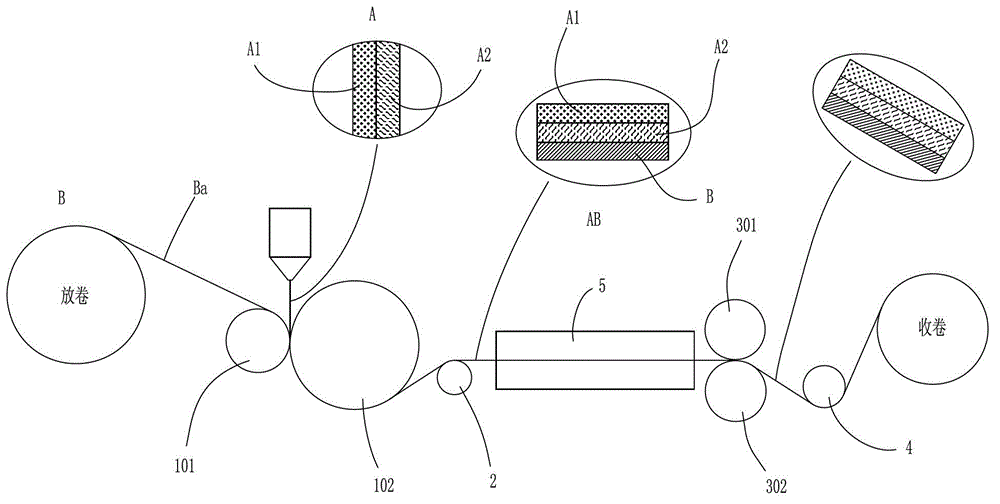

Easy-cold-punch-molding soft packaging composite material, and preparation method and molding method thereof

ActiveCN103331957AAvoid "sticking" problemsThe surface coefficient of friction value is reducedMetal layered productsAluminum foilBonding problems

The invention provides an easy-cold-punch-molding soft packaging composite material. The composite material comprises a thermoplastic resin film layer, an aluminum foil metal core layer, and a heatproof or printing film layer; the aluminum foil metal core layer is positioned between the thermoplastic resin film layer and the heatproof or printing film layer; the thermoplastic resin film layer comprises a surface heat-sealing layer and a hot melt adhesive resin layer compounded with the aluminum foil metal core layer; and the surface of the heat-sealing layer has fine slight convex-concave lines formed through heating roll molding in the compounding process, and the convex-concave depth of the fine slight convex-concave lines is 0.5-25mum. By utilizing the fine convex-concave characteristics of the fine slight convex-concave lines, a bonding problem formed by the clinging of the surface of the composite material and a die can be avoided during stamping, and air can be residual in a slit between the die and the convex-concave lines on the surface of the composite material during the stamping, so the surface friction coefficient value of the composite material is greatly reduced, and it is in favor of demolding the composite material in the cold punch molding process. The invention also provides a preparation method of the composite material, and a molding method when used.

Owner:FSPG HI TECH

Method for preparing high-plasticity welding wire by use of brittle Sn-Bi alloy

ActiveCN102528336AFine Alloy GrainWell-organized ingredientsWelding/cutting media/materialsSoldering mediaCrystalliteTemperature control

The invention discloses a method for preparing high-plasticity welding wire by use of brittle Sn-Bi alloy. The method is characterized in that the method comprises processing a Sn-Bi alloy ingot into an equal channel angular extrusion billet, preheating and keeping the temperature; subjecting the equal channel angular extrusion billet to isothermal extrusion in an equal channel angular extrusion mold to prepare an extrusion blank; extruding to obtain a drawing blank meeting the requirement for drawing formation; conducting isothermal drawing by use of a water-cooled temperature-control wire drawing machine to obtain the Sn-Bi welding wire; and coiling and packaging. The method can prepare all specifications of high-strength and high-plasticity continuous welding wires having a diameter less than 1.5mm from the high-brittleness Sn-Bi alloy that is difficult to deform and process. The prepared wire has fine grains, uniform components and, excellent welding performance, and can meet the various requirements for packaging and welding packaging. The method has the advantages of simple process and high operability, and is an ideal method for preparing Sn-Bi alloy welding wire.

Owner:浙江亚通新材料股份有限公司

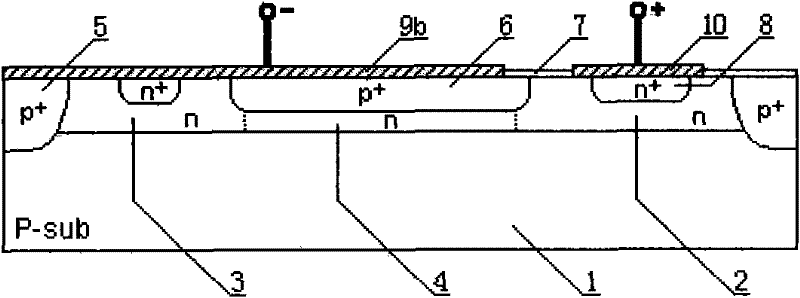

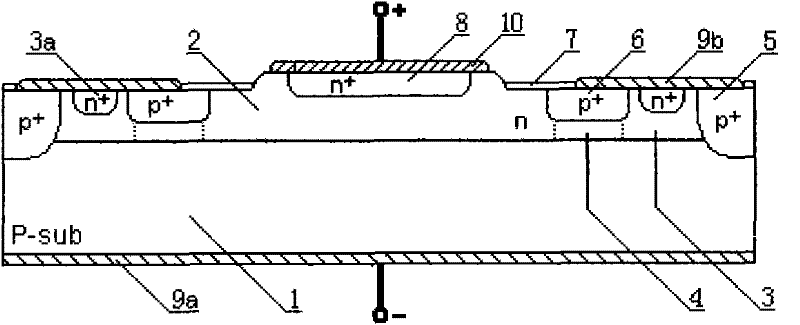

Current regulation diode chip and manufacturing method thereof

ActiveCN102130182AMeet packaging requirementsEasy to packSemiconductor/solid-state device detailsSolid-state devicesOhmic contactDiffusion layer

The invention discloses a current regulation diode chip, which comprises a substrate layer and an epitaxial layer covered on the substrate layer, wherein a drain region is formed on a central area of the epitaxial layer, and a first ohmic contact diffusion layer and a first metal layer covered on the first ohmic contact diffusion layer are arranged on the surface of the drain region further; an annular P-type grid region and a channel positioned below the P-type grid region are respectively formed on the outer edge of the drain region; an annular source region is arranged on the outer edge of the channel, and a second ohmic contact diffusion layer is arranged on the surface of the source region further; a through diffusion layer 5 is arranged on the outer edge of the source region; a second metal layer is arranged on the outer side of the grid region, the source region and the inner side of the through diffusion layer; and a third metal layer covered on the reverse side is arranged at the bottom of the substrate layer. The current regulation diode chip can meet packaging requirements, and has the advantages of low cost of a metalizing process and a packaging process and the like.

Owner:ZHEJIANG MINGDE MICROELECTRONICS CO LTD

Red and green composite fluorescence glass for white-light LED (light-emitting diode) and preparation method of fluorescence glass

The invention discloses red and green composite fluorescence glass for a white-light LED (light-emitting diode). The fluorescence glass comprises host glass, red fluorescent powder and green fluorescent powder. The preparation method of the glass includes the steps: preparing glass substrates; grinding the glass substrates into glass powder; mixing the glass powder and the fluorescent powder; performing sintering and annealing to obtain the red and green composite fluorescence glass. The composite fluorescence glass and blue-light chips are packaged to prepare the LED, and the LED is high in light effect and color development, low in light attenuation and less in color shift and color tolerance.

Owner:SHANGHAI INST OF TECH +1

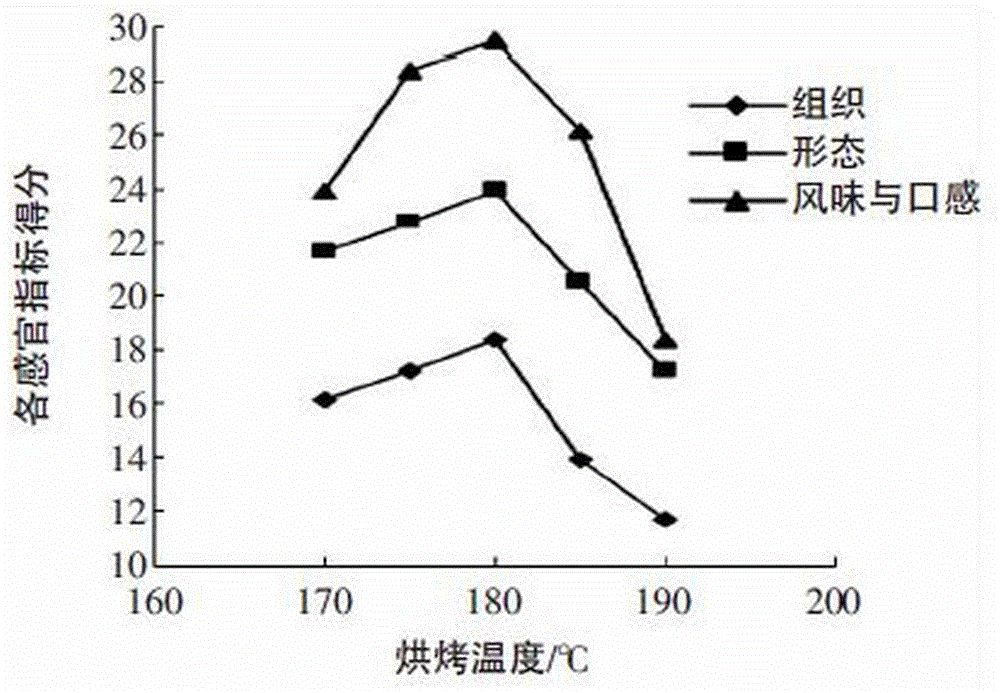

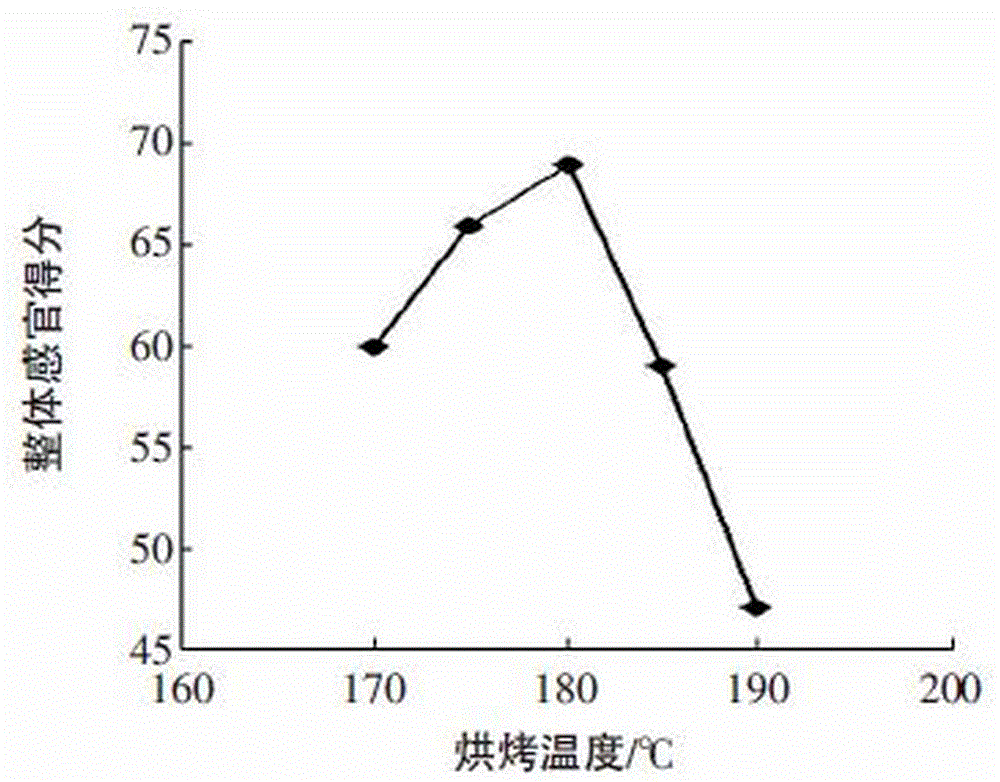

Mooncakes with white lotus paste and nuts and preparation method thereof

InactiveCN106259802APromote absorptionGood edible effectDough treatmentBakery productsWaxPumpkin seed

The invention relates to the food field and discloses mooncakes with white lotus paste and nuts and a preparation method thereof. The mooncakes are prepared from the following components in parts by weight: cake wrappers: 22-28 parts of refined flour, 14-18 parts of syrup, 0.10-0.40 part of drinking water, 6-8 parts of vegetable oil and 1-3 parts of lard, wherein the syrup is prepared by mixing honey with maltose in a mass ratio of 5 to 5; the stuffing formula: 8-12 parts of white lotus paste stuffing, 1-3 parts of steamed flour, 1-3 parts of peanut kernels, 1-3 parts of black sesame, 1-2 parts of pumpkin seed kernels, 0.8-1.2 parts of walnut kernels, 1-3 parts of shelled melon seeds, 0.4-0.6 part of diced cumquats, 0.8-1.2 parts of diced wax gourds and 0.8-1.2 parts of olive oil. The preparation method comprises the following steps: cake wrapper and stuffing preparation; stuffing filling and forming; baking; cooking; packaging. The prepared mooncakes have the advantages of good appearances and colors, crisp taste and moderate fragrance and sweetness and also have the effects of maintaining beauty and keeping young, losing weight and reducing lipid and being beneficial to cardiac vessels.

Owner:湄潭县宏发食品有限公司

Waterproof packing cardboard and producing method thereof

InactiveCN101037854AHigh strengthImprove toughnessFlexible coversMechanical working/deformationEpoxyCardboard

The present invention relates to a waterproof and antirust packaging paperboard and a manufacturing method thereof. Said method comprises coating one side of a waterproof paperboard with a layer of surface water-resistance agent, wherein said waterproof paperboard is made of a paper board containing a composite water-resistance agent prepared by mixing alkyl ketene dimmer and polyamide epoxy resin with a proportion of 4-6:1 by weight. The beneficial effects in accordance with the present invention are as follows: 1, the waterproof paperboard manufactured by a multi-layer recombination not only exhibit better intensity, tenacity and impact resistance, but also has excellent waterproof and damp proof insulation performances, and further exhibits better antirust performance after being coated with a vapor phase inhibitor, then said paperboard has excellent packaging performances which is stable, and the packaging requests and outdoor storage requests can be satisfied by packaging steel (coil) sheet materials with the waterproof paperboard in accordance with the present invention; 2, the manufacturing cost is low ans the source of the raw material is extensive; 3, said waterproof paperboard can be recovered and recycled easily, and is naturally degradable, and then is environment-friendly.

Owner:武汉市江夏区江南实业有限公司 +1

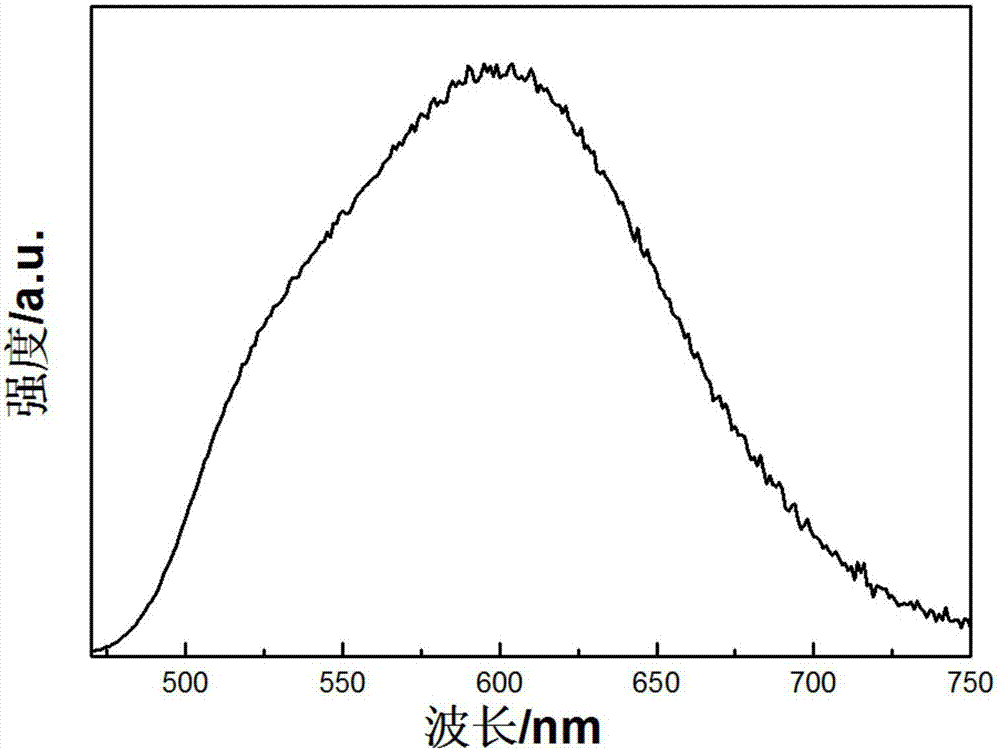

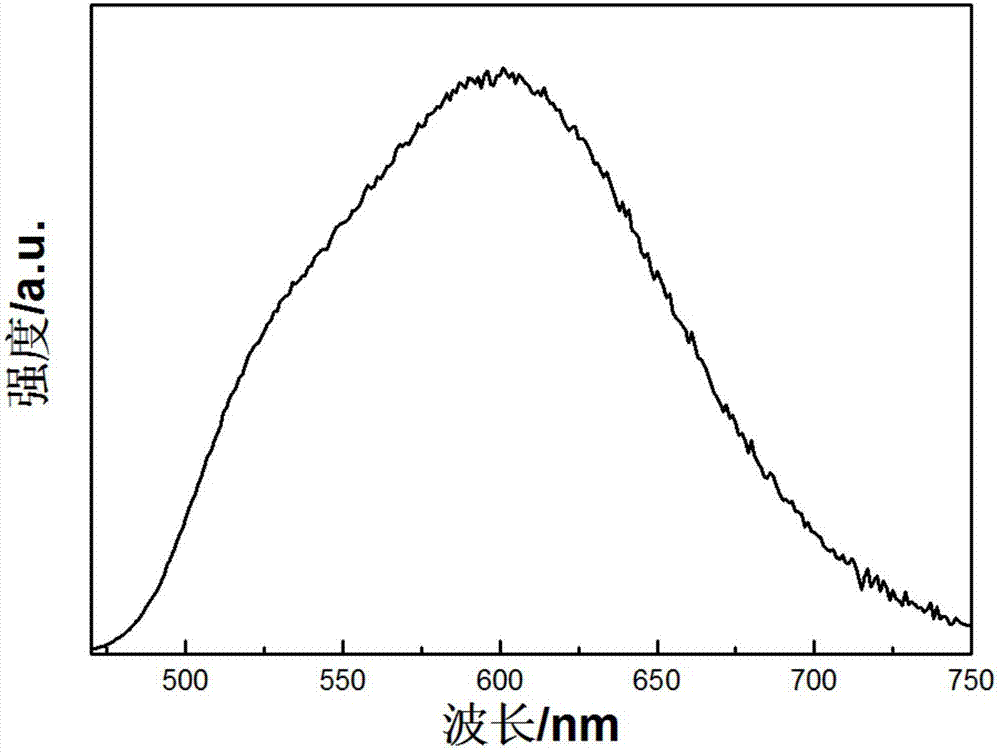

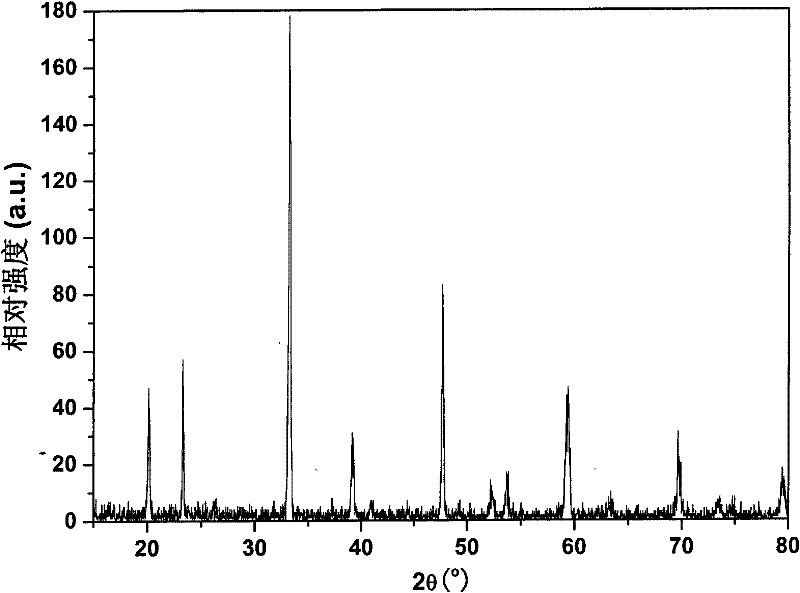

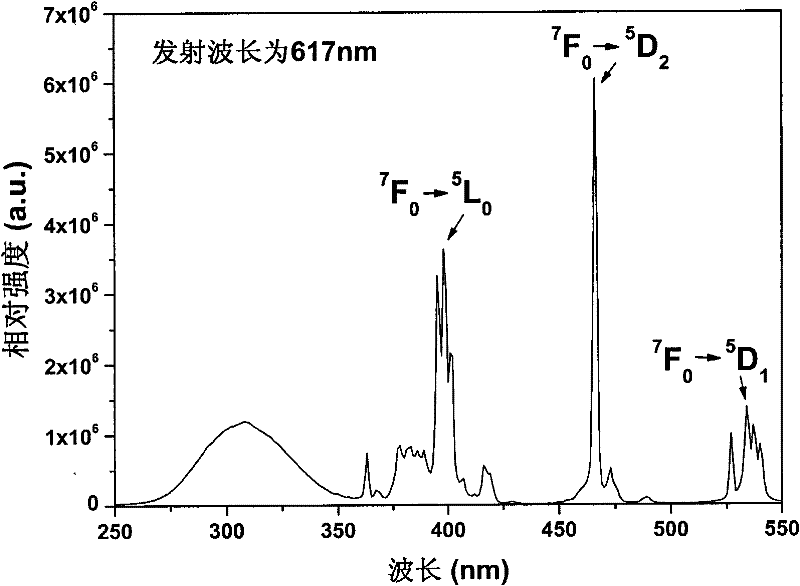

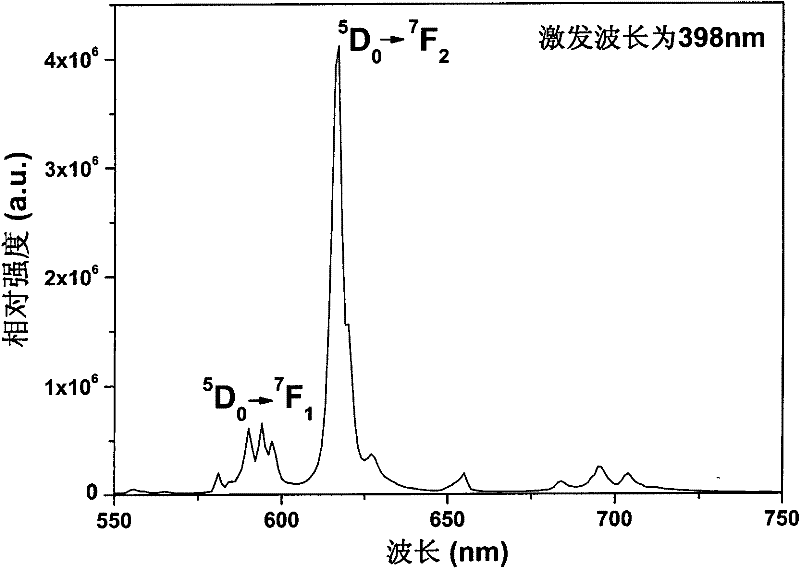

Red phosphor for Eu-activated light emitting diode and preparation method thereof

InactiveCN102191048ASimple methodEasy handling and industrial productionLuminescent compositionsColor rendering indexChemistry

A Eu-activated light emitting diode and a method for preparing the red phosphor are disclosed in the invention. The general chemical formula of the phosphor is that: the molecular formula for the phosphor containing ions without charge compensation is (EuxCa1-x)2AlNbO6+x; the molecular formula for the phosphor containing ions with charge compensation is (EuxRxCa1-2x)2AlNbO6, R represents an alkali metal ion such as Li+, Na+ or K+. The dopant concentration x of Eu3+ ranges from 0.01 percents by weight to 0.10 percents by weight. The emission peak wavelength of the red phosphor is 617nm, and the excitation spectrum of the phosphor consists mainly of an excitation peak of 308nm, an excitation peak of 398nm and an excitation peak of 466nm. The red phosphor prepared in the invention is capableof emitting strong red light at a wavelength of 610-630nm upon excited by ultraviolet light, purple light or blue light, Thereby that the packaging requirements for white light LED can be satisfied favorably, the color rendering index can be increased, and the color temperature can be decreased. The method for preparing the phosphor is simple and easy to perform, and is easy to apply in industry.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Overall plastic microcosmic laminar composite and its preparation method

InactiveCN1733829ATear resistantPrevent leakageLinear low-density polyethyleneLow-density polyethylene

The invention relates to overall-plastic microcosmic layered composite material with the weight proportion of material as: 75~85% polyvinyl resin composed of HDPE, LDPE, and LLDPE, 5~16% aromatic nylon selected one between nylon 6, nylon 66 and nylon 1010, 3~8% montmorillonite selected one between NB901 and NB908, and 5~13% grafts selected one between ethylene-vinyl acetate copolymer, polyvinyl maleic anhydride grafts, and glyceryl methacrylate. Wherein, the preparation method comprises: using material to mix and granulate, using extrusion calendar to tablet and form for one time. The product can not only fit to package request for grease, organic solvent, etc, but also needs no special device, and is photodegradated.

Owner:于志文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com