Easy-cold-punch-molding soft packaging composite material, and preparation method and molding method thereof

A composite material and soft technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as improper molding, large drop, electrolyte pollution, etc., to improve depth and yield, The effect of reducing the coefficient of friction and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The flexible packaging composite material of this embodiment is configured according to the above-mentioned X shape.

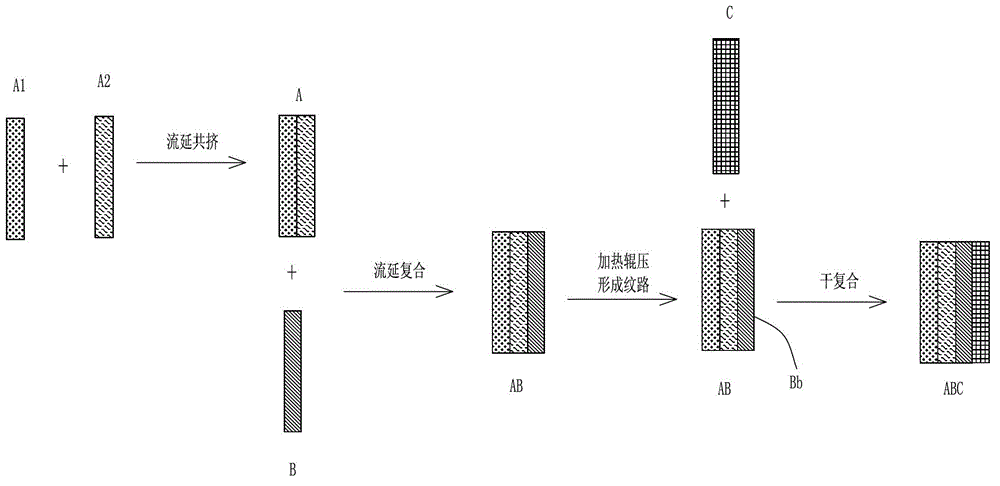

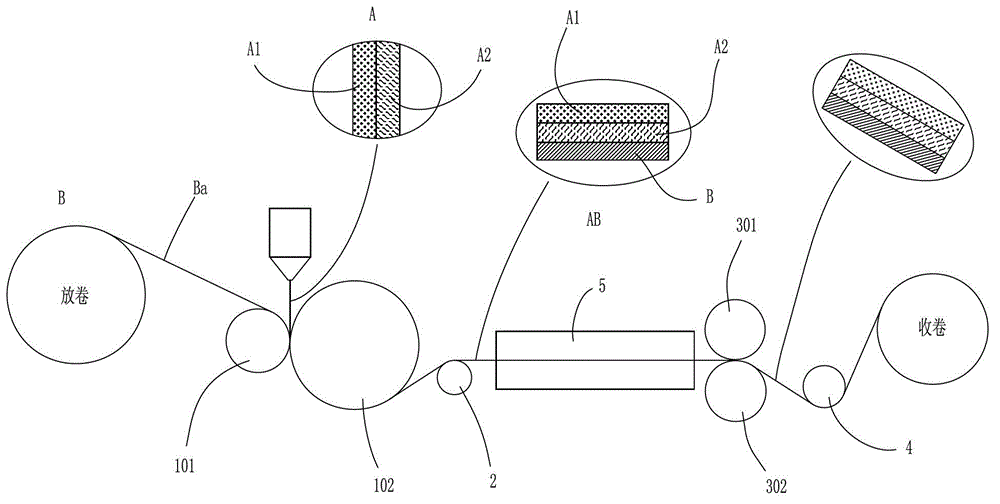

[0068] Its general process is as follows figure 1 As shown, first, while obtaining the thermoplastic resin film layer A of EVA (hot melt adhesive resin layer A2) and mPE (surface layer heat-sealing layer A1), thermocompression compounding obtains the laminated composite body AB of the thermoplastic resin film layer / aluminum foil layer ; Then, use the method of heating and rolling the AB film to form a fine convex-concave pattern on the surface of the heat-sealing layer A1 of the AB film; finally, combine the ON (heat-resistant or printed film layer C) with the dry composite method. The lower surface Bb of the aluminum foil layer B is bonded to form a multi-layer aluminum-plastic laminated composite that is easy to be formed by cold stamping.

[0069] Specifically, the above method includes the following steps:

Embodiment 2

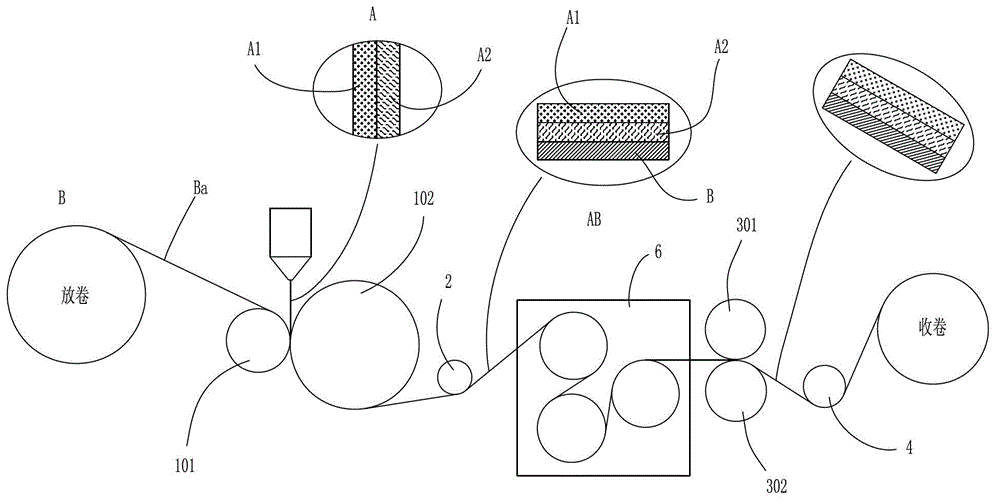

[0077] The difference between this embodiment and Embodiment 1 is: 1. The flexible packaging composite material is formed according to the above-mentioned Y shape; 2. When rolling to form convex and concave lines during the compounding process, the surface of the cooling roller 301 adopts diamond-shaped lines, and the lines are convex and concave. The depth is 2 μm; 3. In step C, use the heating guide roller group 6 to heat (such as image 3 shown).

[0078] Carry out the same experimental test as embodiment 1. The test results are shown in Table 1.

Embodiment 3

[0080] The difference between this embodiment and Embodiment 1 is: 1. The flexible packaging composite material is composed of the above-mentioned Z shape; 2. When rolling to form convex and concave lines in the compounding process, the surface of the cooling roller 301 adopts a grid pattern, and the lines are convex and concave. The depth is 10 μm.

[0081] Carry out the same experimental test as embodiment 1. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com