Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309results about How to "Reduce surface friction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC (polyvinyl chloride) decorative film surface treating agent, PVC decorative film treated with same and preparation method thereof

InactiveCN102702953AGood PVC adhesionImprove smoothnessOrnamental structuresSpecial ornamental structuresWater basedEmulsion

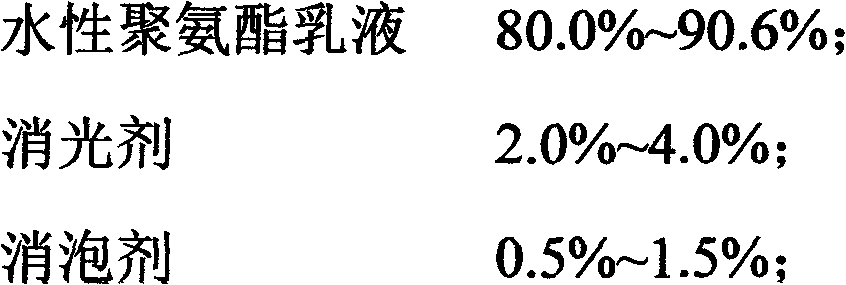

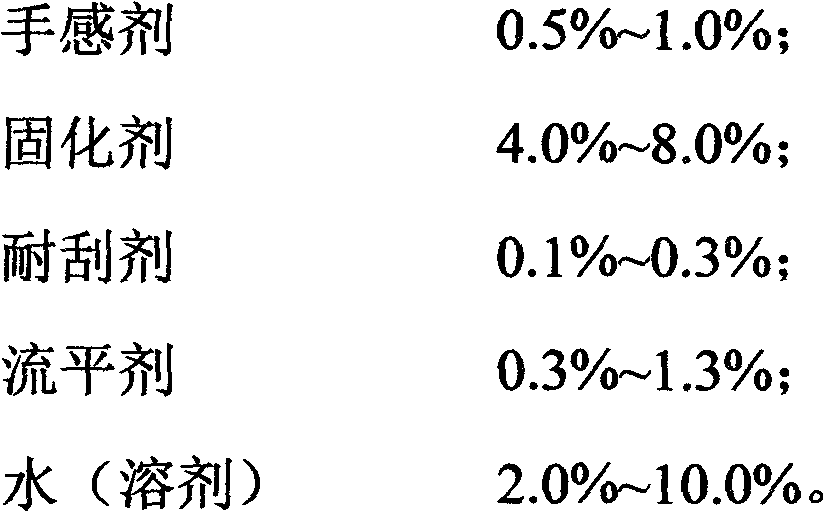

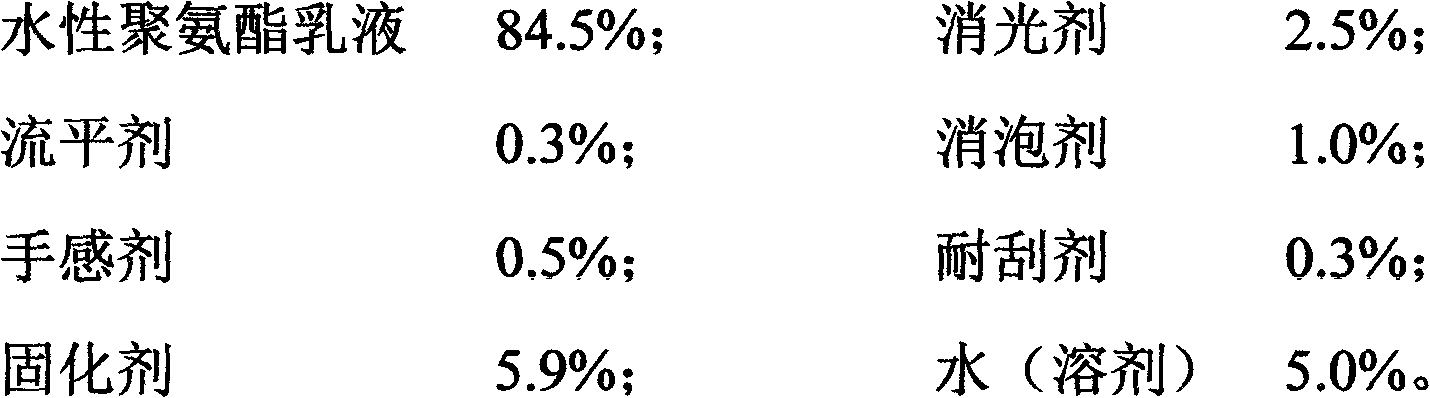

The invention discloses a PVC (polyvinyl chloride) decorative film surface treating agent and a PVC decorative film treated with the same. The surface treating agent comprises the following components in percentage by weight: 80.0-92.0% of water-based polyurethane emulsion, 2.0-4.0% of flatting agent, 0.5-1.5% of defoaming agent, 0.5-1.0% of hand feeling agent, 4.0-8.0% of curing agent, 0.1-0.3% of scraping inhibitor, 0.3-1.3% of leveling agent and 2.0-10.0% of water. The PVC decorative film treated with the surface treating agent has the advantages of excellent matte performance, scraping resistance, favorable compatibility with other decorating materials, and the like, and feels soft.

Owner:FOSHAN TIANJIN PLASTICS

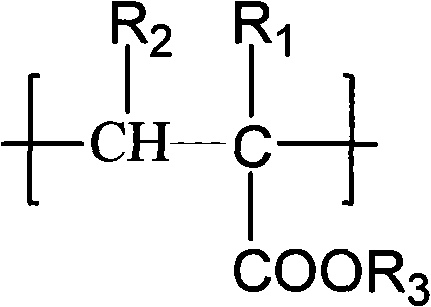

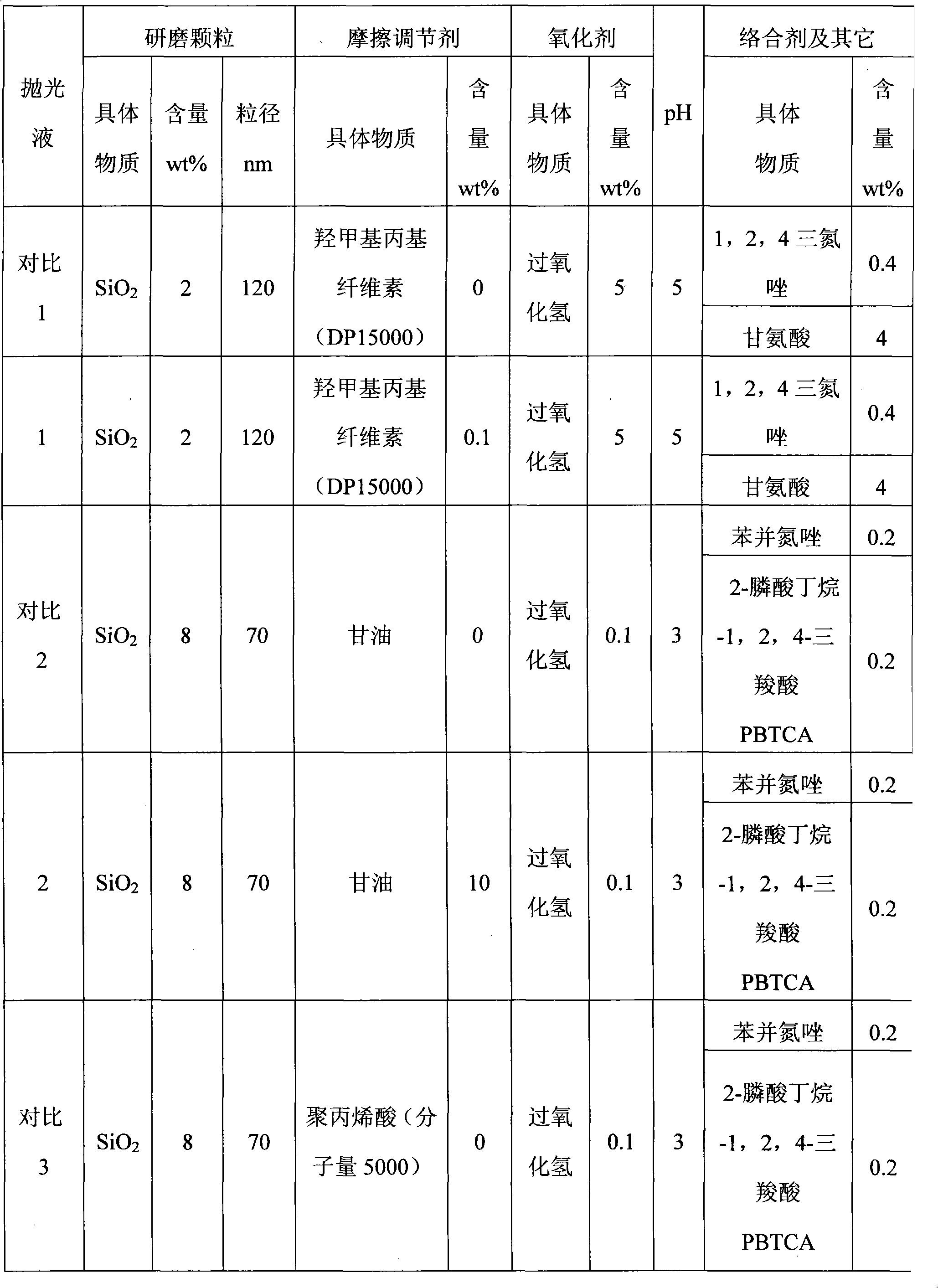

Chemical mechanical polishing solution

InactiveCN101550319AReduce surface friction coefficientReduce defectsOther chemical processesSemiconductor/solid-state device manufacturingFiberAlcohol

The invention discloses a chemical mechanical polishing solution containing polishing particles, oxidizer, water and one or more components in the following surface friction conditioning agents: water soluble poly-fatty chain polymers, water soluble alcohols, water soluble ethers and water soluble fibers. The polishing solution of the invention can lower the coefficient of surface friction and reduce the defects (scratch, corrosion, superficial particles, and the like) of the surface of a polished substrate.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

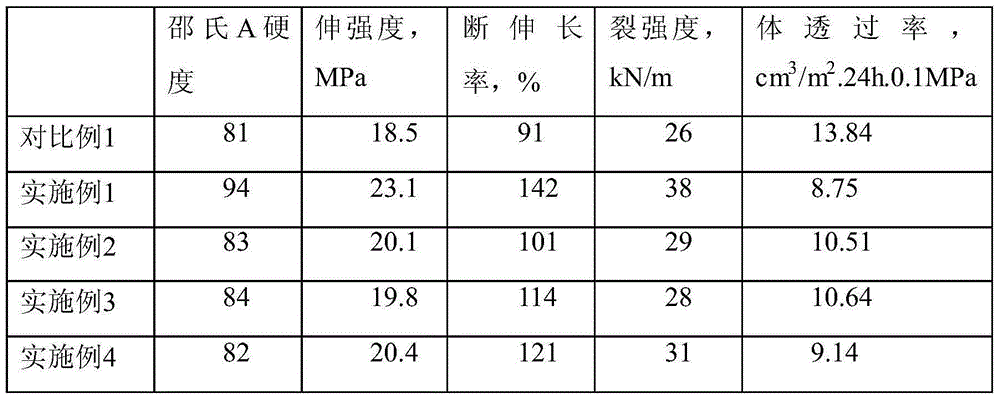

Graphene-containing fluororubber nanocomposite with low gas permeability and preparation method

The invention belongs to the field of rubber materials and relates to a graphene-containing fluororubber nanocomposite with low gas permeability and a preparation method, in particular to a nanocomposite formed by graphene and fluororubber. The graphene-containing fluororubber nanocomposite with low gas permeability comprises the fluororubber, the graphene, carbon black, graphite, an acid acceptor and a vulcanizing agent. The graphene is subjected to pre-dispersing treatment, and the dispersity of the graphene in the fluororubber is improved. The unique lamellar structure of the graphene can form a grid structure in the fluororubber to block gas effectively. The graphite has similar lamellar structure and is mixed with the graphene for combined action, so that gas grids in different sizes can be formed in the material, and the gas permeability of the material is reduced. A low-speed blender is adopted to perform pre-dispersing treatment on powder, and through mechanical agitation and interaction of the powder, the dispersity is improved while the lamellar structure of the graphene is guaranteed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

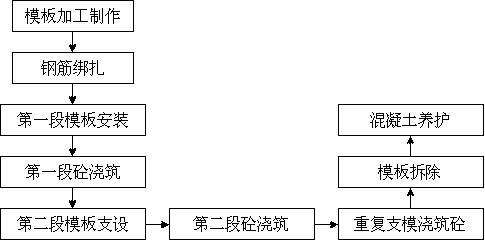

Construction process for coating faced concrete outside ultrahigh steel tube column after floor is closed

ActiveCN103015717AReduce surface friction coefficientReduce generationForms/shuttering/falseworksBuilding material handlingFloor slabPlastic film

The invention discloses a construction process for coating faced concrete outside an ultrahigh steel tube column after a floor is closed. The procedures of the construction process comprise template processing and manufacturing, steel bar binding, template installing, concrete pouring, template dismantling and concrete curing. A template uses stereotyped cylindrical wood plywood, and the inner side of the template adopts a 801 glue to stick an endurance plate with the thickness of 0.8 mm. The steel bar binding adopts non-embroidered binding silk, the head of the binding silk faces to the inner side of a steel bar, and the binding silk on the outer side is subjected to round hook pressing processing. Template reinforcing adopts a stereotyped flat steel bar hoop, the first segment of concrete is poured after the first segment of template is installed, and the self-compacting faced concrete is adopted. The second segment of template is installed before the initial setting of the first segment of concrete, then the second segment of concrete is poured, and the pouring of column concrete is sequentially completed. The template dismantling is as follows: the flat steel bar hoop of the reinforced template is dismantled firstly, the template is lightly knocked, so that the template is naturally separated from the concrete, and the segments of column templates are dismantled from top to bottom. After the template is dismantled, a plastic film and a blanket are adopted to package and cover the concrete for moistening maintenance 14d.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

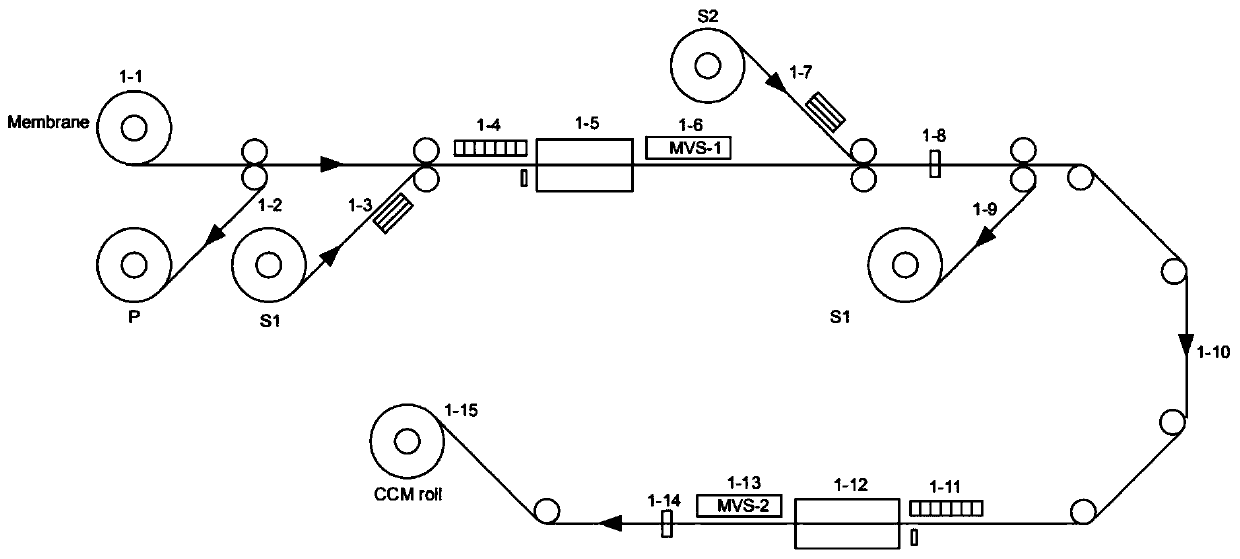

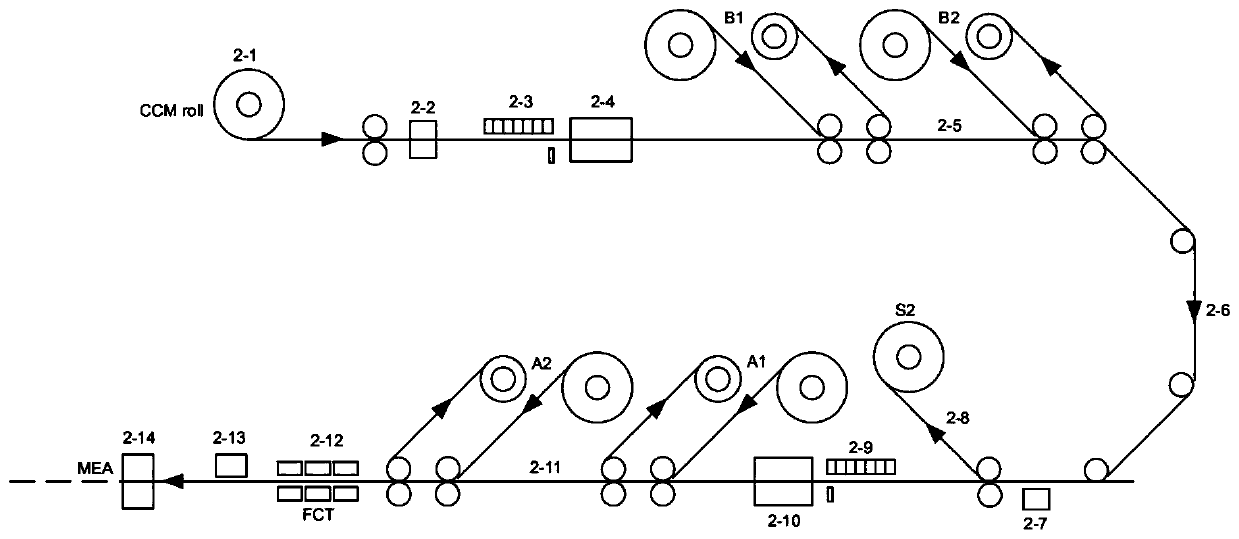

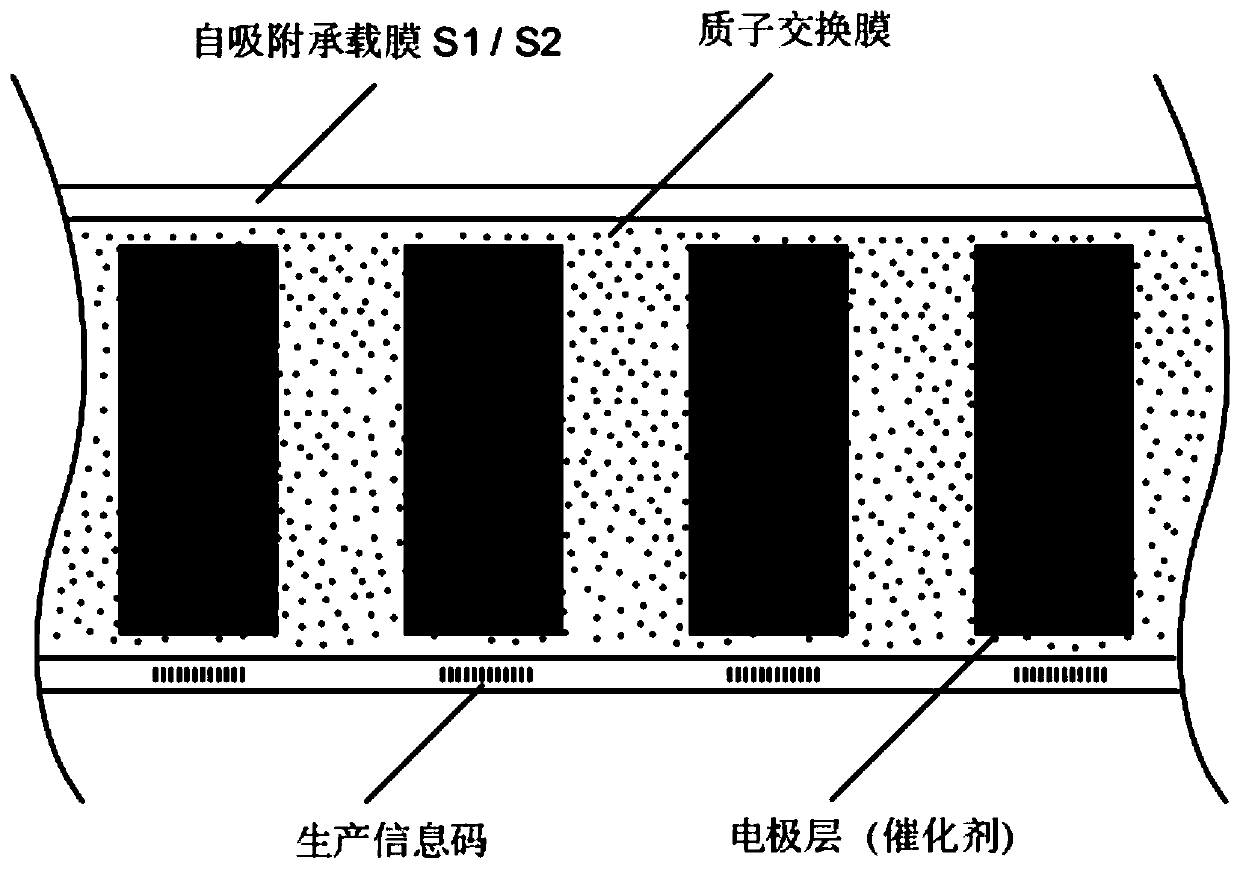

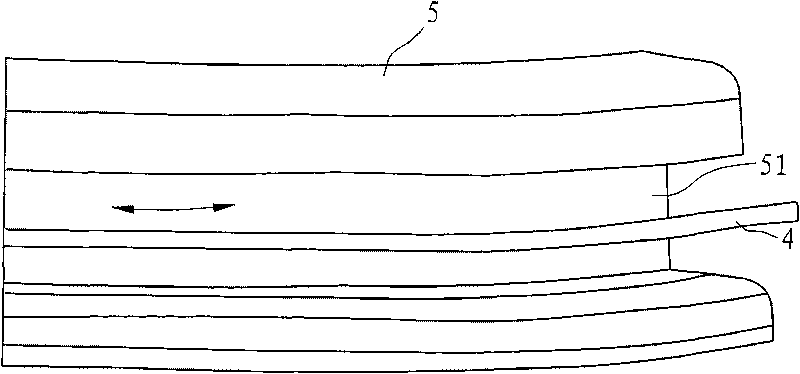

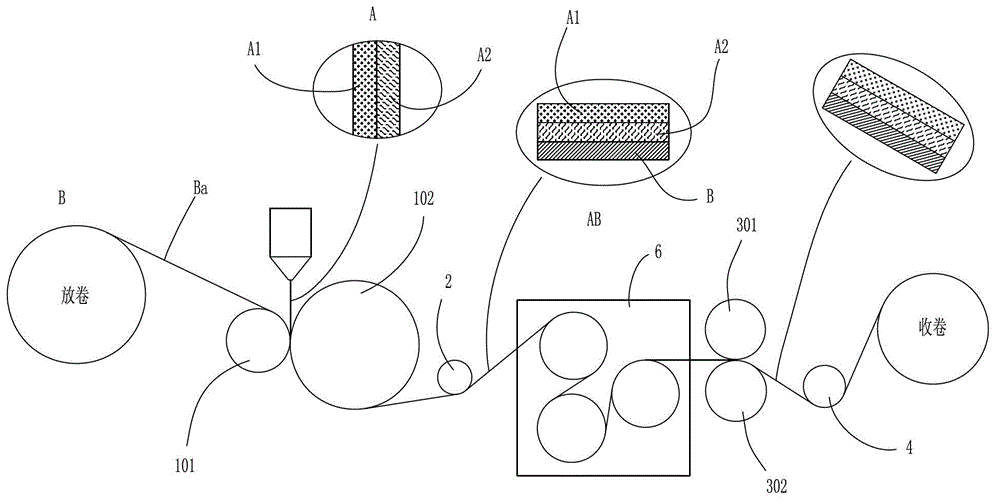

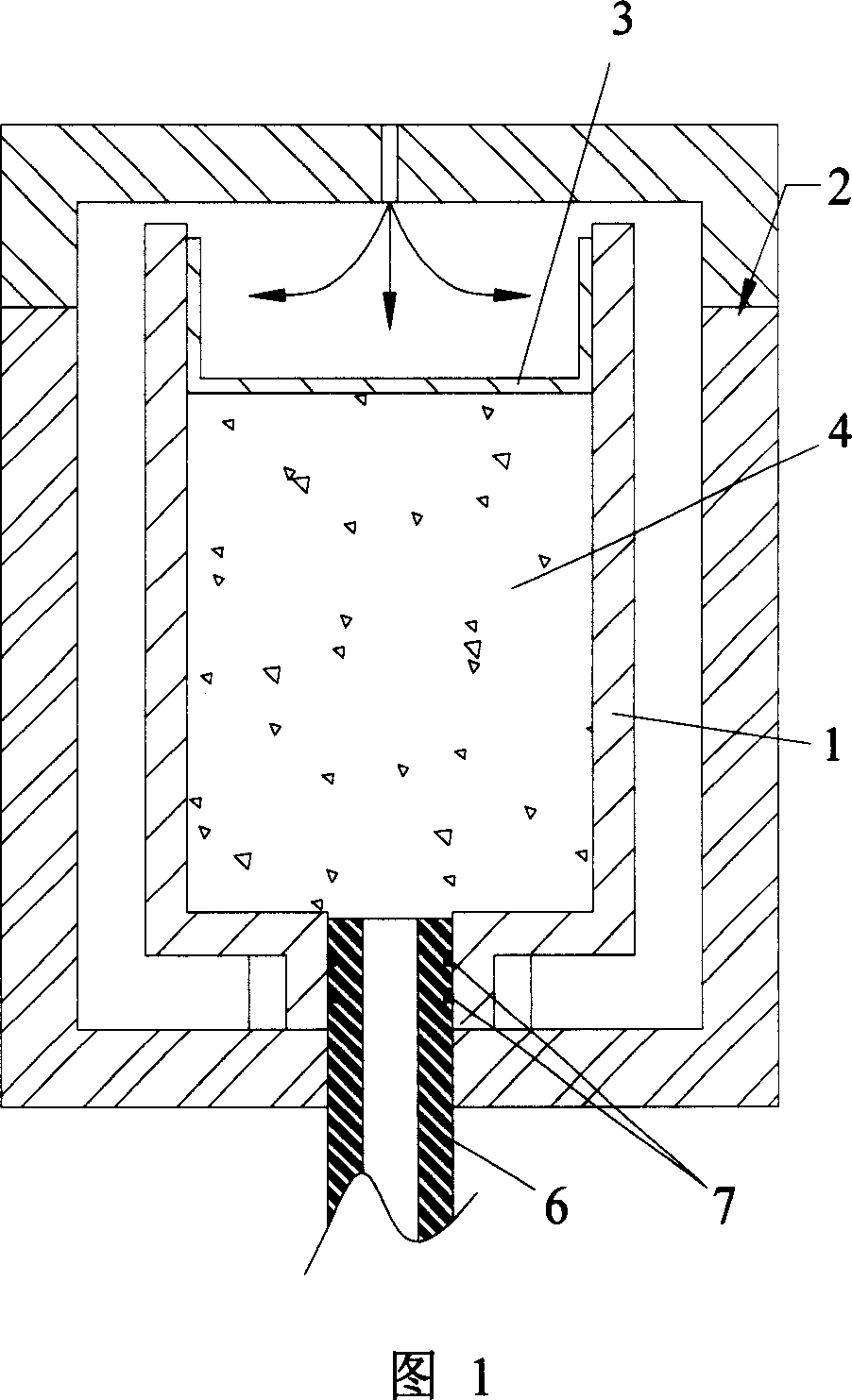

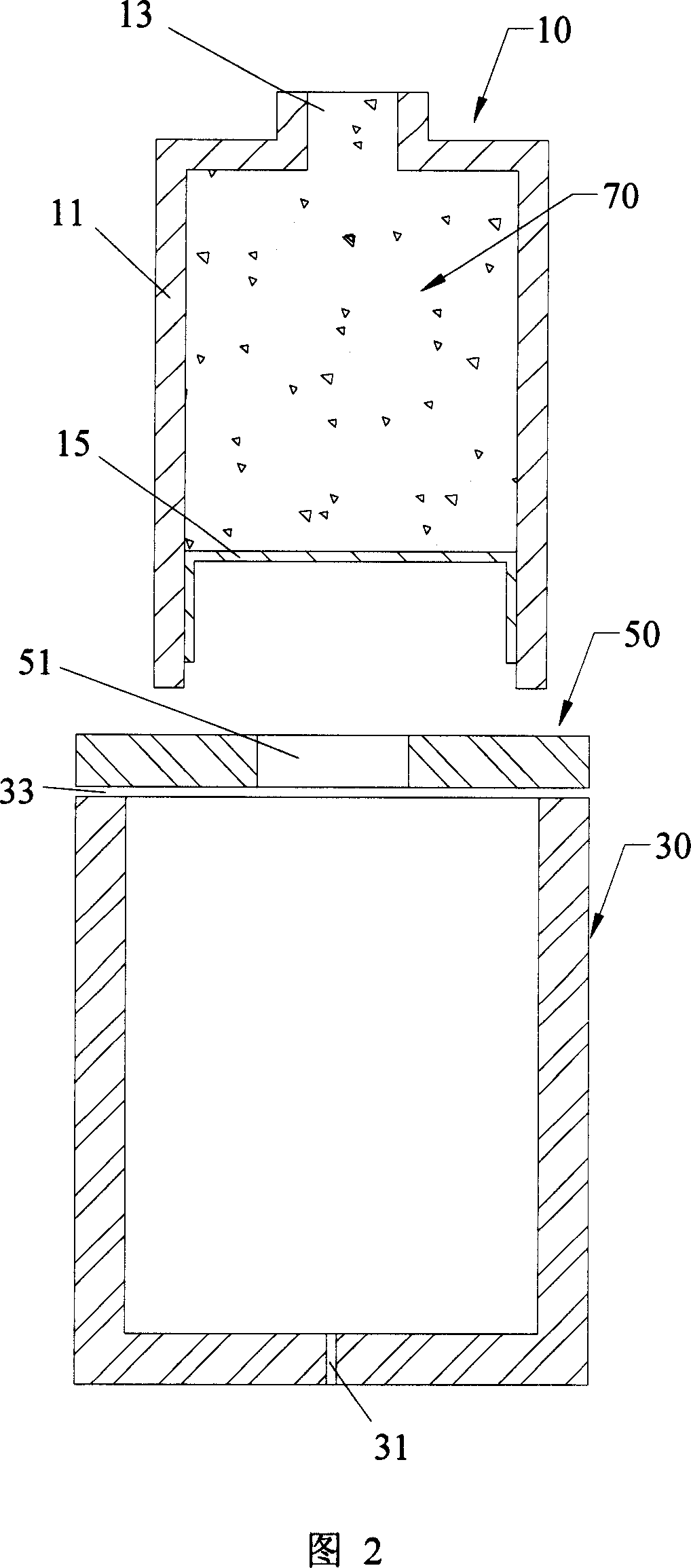

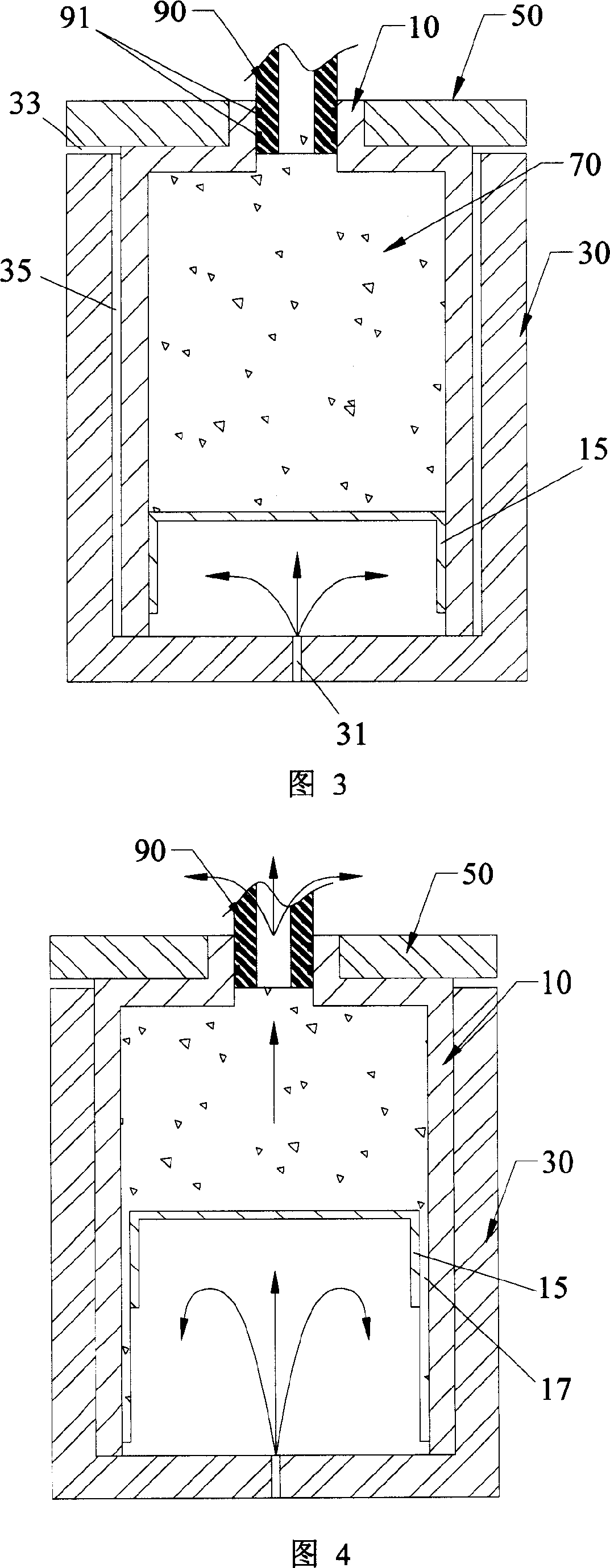

Continuous preparation device and method for fuel cell membrane electrode

ActiveCN110611113AReduce surface friction coefficientNo mechanical damageCell electrodesFinal product manufactureFuel cellsProton

The invention discloses a continuous preparation device and method for a fuel cell MEA membrane electrode. The device comprises a continuous preparation device for a roll fuel cell CCM membrane electrode and a continuous preparation device for a sheet fuel cell MEA membrane electrode. According to the device and method, which are provided by the invention, electrode layers are coated on both sidesof a proton exchange membrane; a self-adhesive carrier membrane capable of repeated simultaneous attachment and peeling is used as a carrier and a production information recorder to prepare a continuous CCM membrane electrode coil, wherein the surface of the self-adhesive carrier membrane is processed; the self-adhesive carrier membrane is further used as the carrier; relying on a precise conveying system, the processes of gas diffusion layer bonding and gas sealing layer bonding are carried out to prepare an MEA membrane electrode monomer; and synchronous cutting is carried out to acquire the MEA membrane electrode monomer meeting industrial standards. The high-efficiency, intelligent, integrated and fully-closed device disclosed by the invention can greatly improve the production capacity and greatly reduce the cost of the membrane electrode monomer.

Owner:上海好世材料科技有限公司

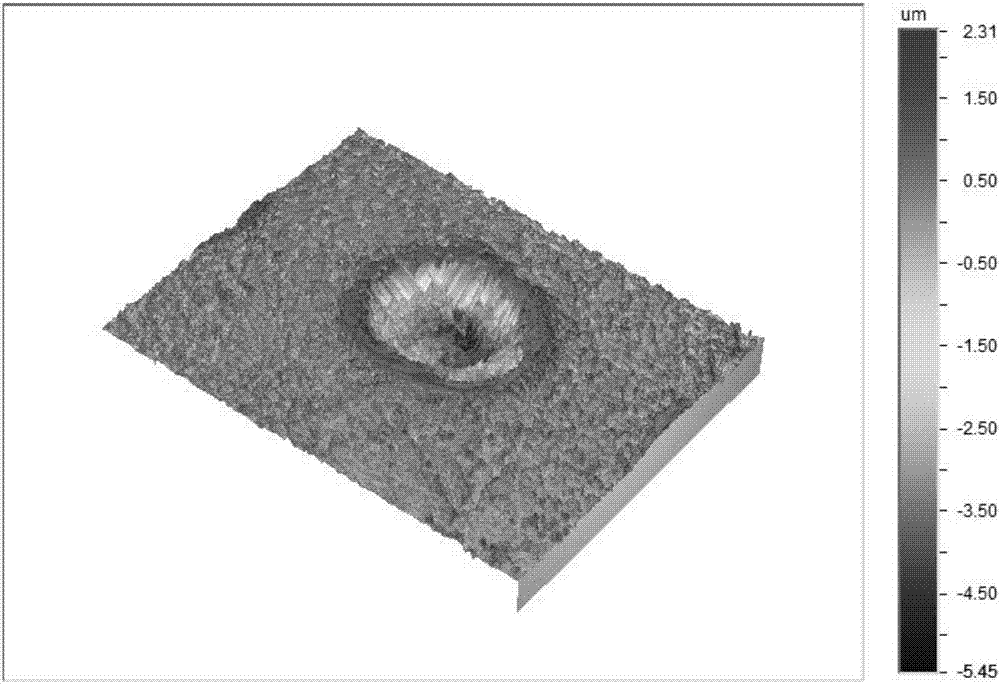

Modification method for improving surface nano indentation property of material

ActiveCN103422098AHigh fatigueImprove fatigue lifeSolid state diffusion coatingHigh densityDislocation

The invention discloses a modification method for improving the surface nano indentation property of a material. The modification method combines three technologies of mechanical shot blasting, surface alloying and laser shock peening effectively, parts realize the surface nanocrystallization and alloying modification through shot blasting and pack aluminization, and the surfaces of the parts are subjected to laser shock peening complex treatment. The sequence of the technologies improves the surface nano uniformity of the material greatly, and shortens the diffusion time; meanwhile, the high-ductility deformation of the material is caused, and high-amplitude residual compressive stress is applied on the surface of the material, and the surface of the material is subjected to high-density dislocation. The parts prepared by the peening method have a good nano indentation property, high abrasive resistance, high corrosion stability and high temperature oxidation resistance, and the fatigue lives of the parts at the normal temperature and high temperature are prolonged greatly.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

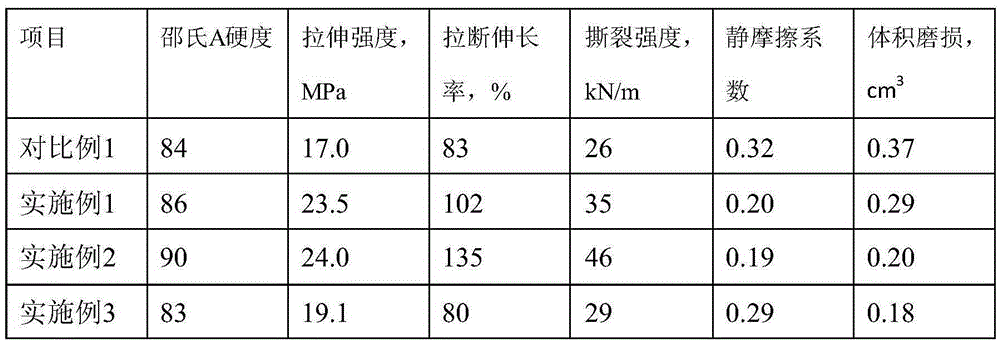

Graphene-containing wear-resisting fluororubber and preparation method thereof

ActiveCN105255073AReduce surface friction coefficientImprove wear resistanceRubber materialPolymer science

The invention relates to the field of rubber materials, and relates to graphene-containing wear-resisting fluororubber and a preparation method of the graphene-containing wear-resisting fluororubber, in particular to a composite material which is prepared from graphene, nano-diamond powder and fluororubber together. The graphene-containing wear-resisting fluororubber comprises the components of the fluororubber, the graphene, the nano-diamond powder and fillings and is prepared by adopting a machine blending method. According to the graphene-containing wear-resisting fluororubber disclosed by the invention, the mechanical property and the wear resistance of existing fluororubber are greatly increased, the surface friction coefficient of a material is reduced, and meanwhile, better gas barrier property and better heat conducting property are obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

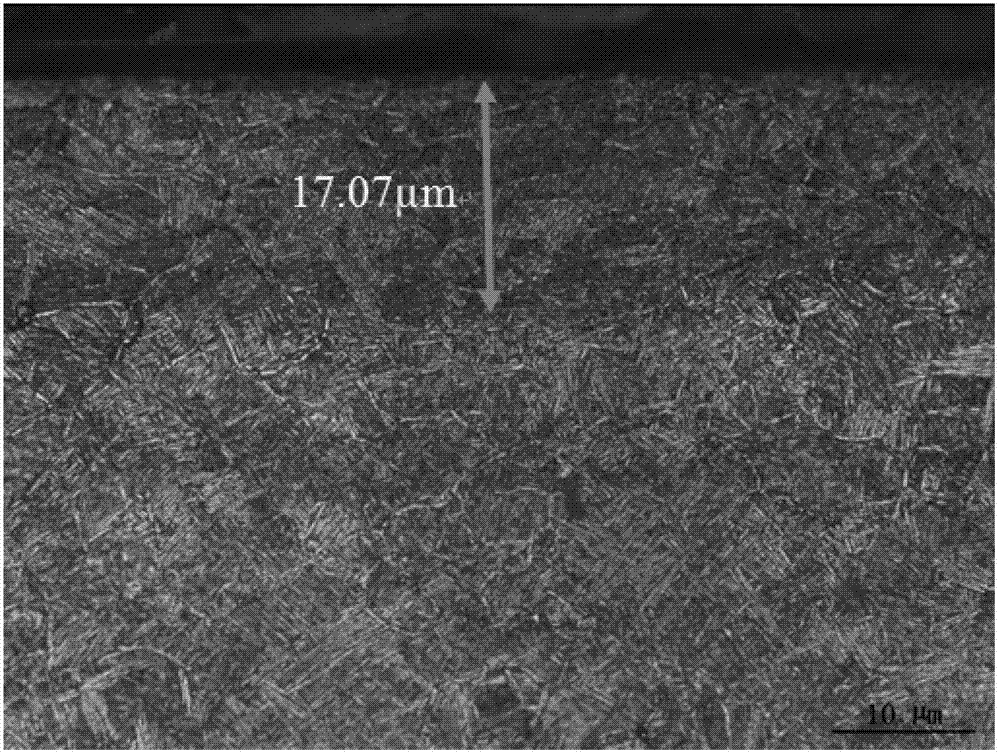

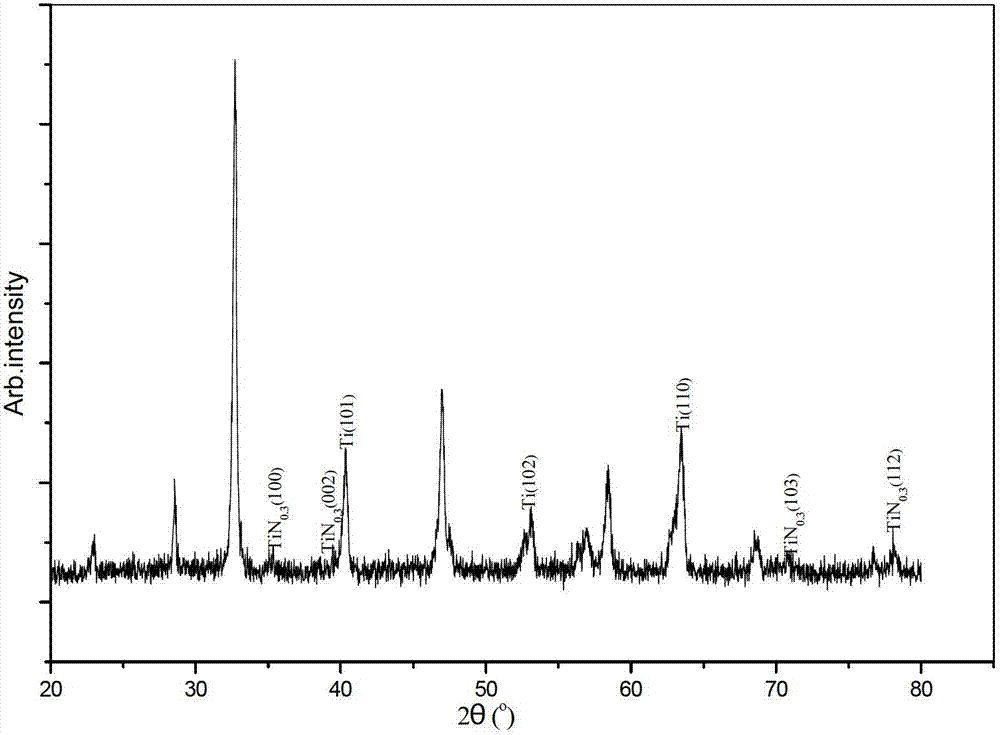

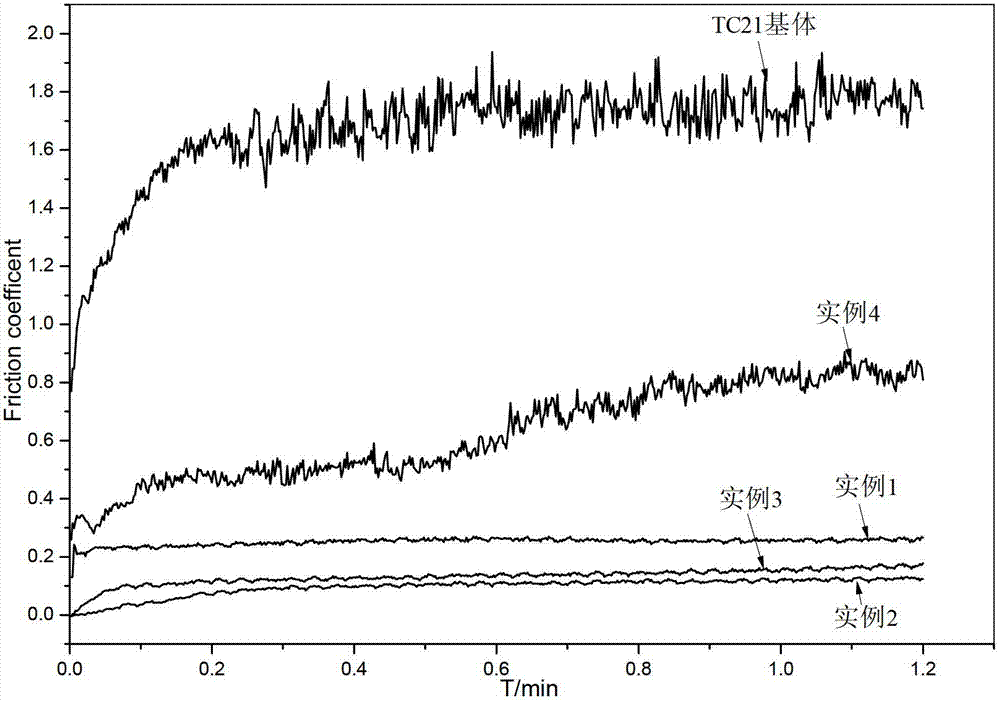

Low-temperature surface nitriding method of titanium alloy

ActiveCN102965613ASimple processImprove controllabilitySolid state diffusion coatingPtru catalystSand blasting

The invention discloses a low-temperature surface nitriding method of a titanium alloy, and belongs to the technical field of metal surface heat treatment and modification. The low-temperature surface nitriding method is characterized by comprising the following steps of: firstly, carrying out sand blasting cleaning on the surface of the titanium alloy, then carrying out chemical mechanical lapping and polishing, then mixing powder crystal sodium cyanate (NaCNO) and granular crystal potassium cyanate (KCNO) and rare earth CeO2 powder in a certain proportion so as to obtain a nitriding reagent, placing the nitriding reagent and the treated titanium alloy in a crucible for compacting and sealing, then drying, and placing the crucible in a high-temperature furnace for heating, wherein NaCNO and KCNO are used as nitriding sources, and rare earth CeO2 is used as a catalyst. According to the low-temperature surface nitriding method, a TiN 0.3-1 nitriding layer is formed on the surface of the titanium alloy TC21, the friction coefficient of the surface of the titanium alloy is remarkably reduced, the surface hardness is increased, and the surface property is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

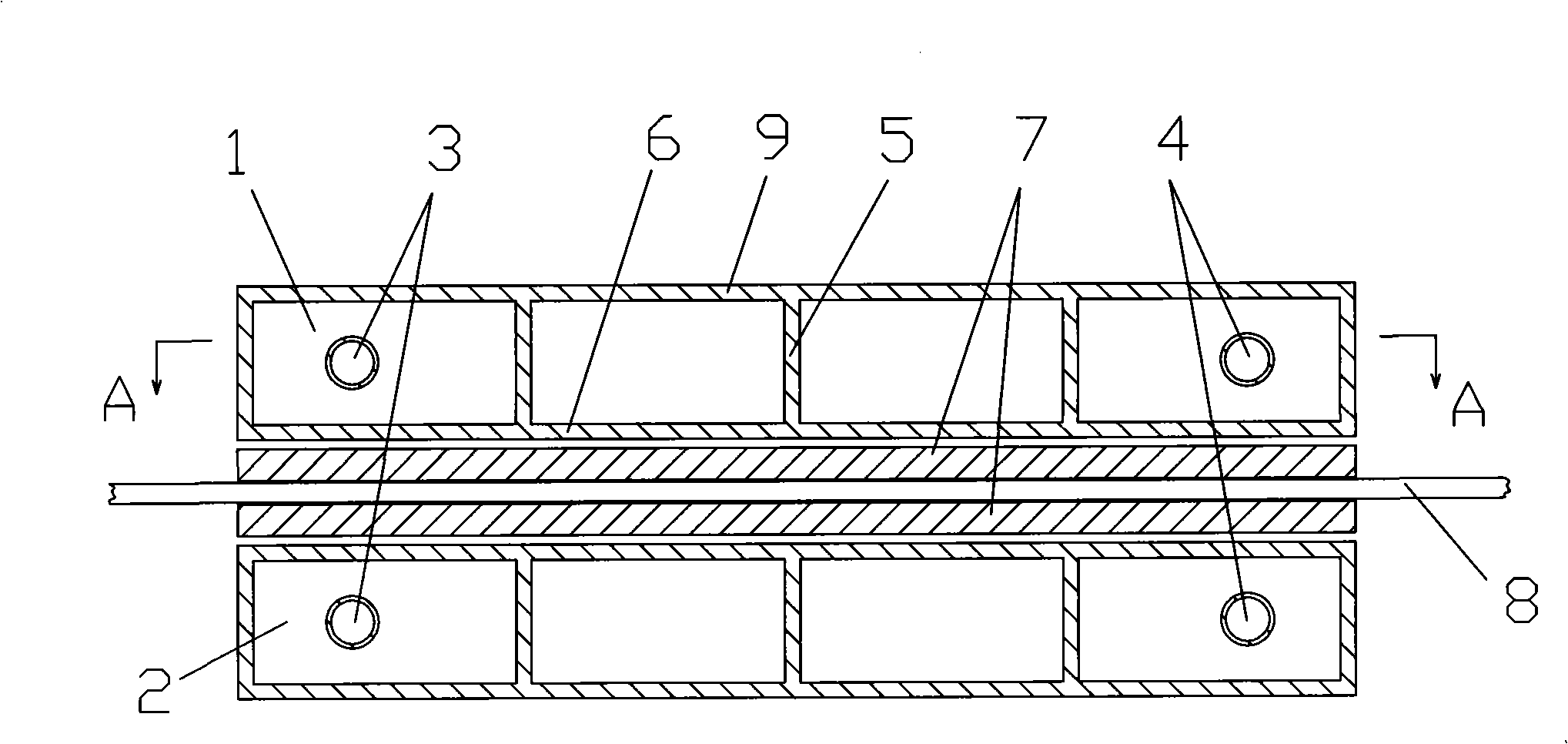

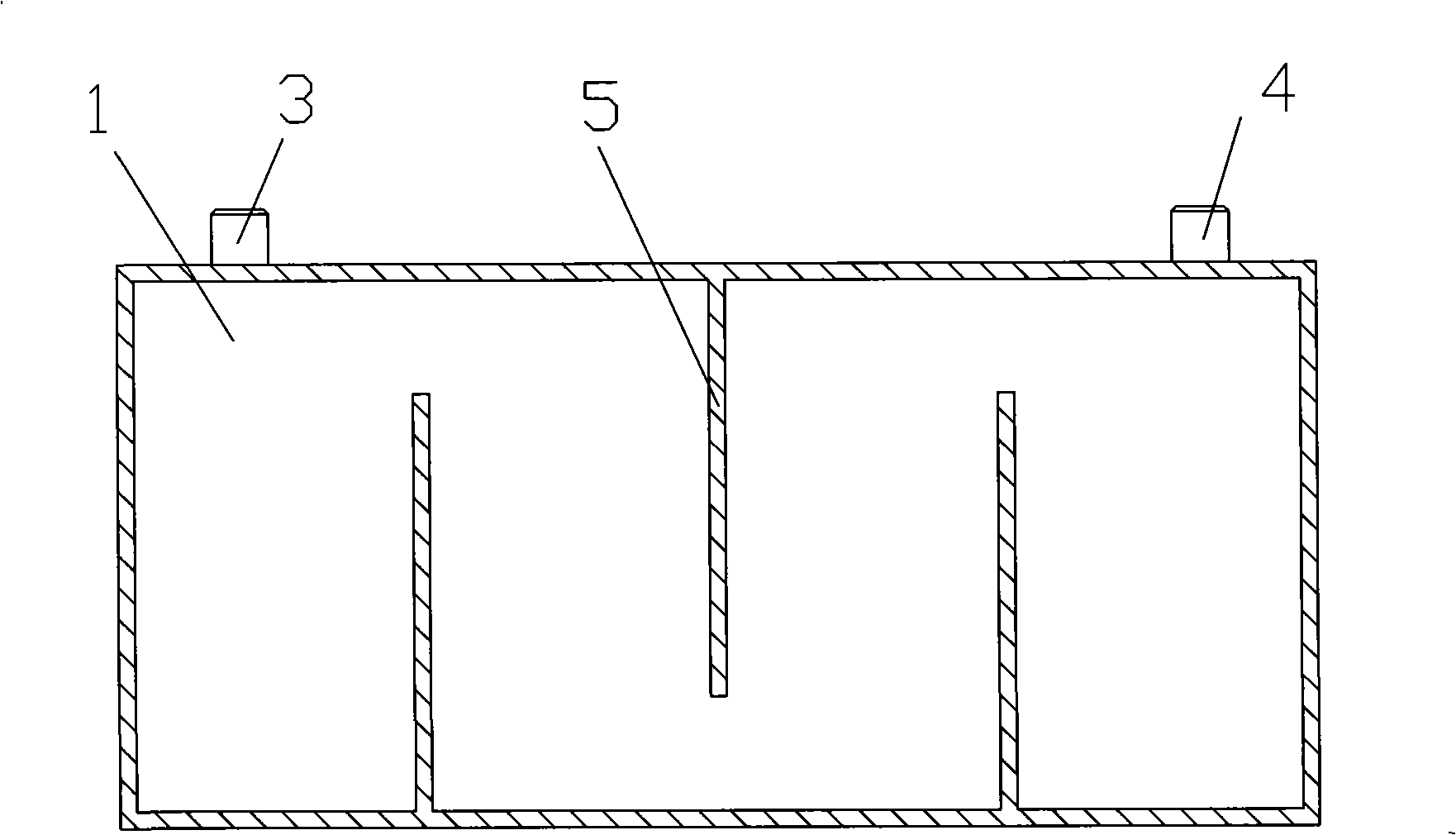

Non-hydraulic plate quenching device for steel belt continuous quenching and steel belt cooling method

InactiveCN101348858AClose contactImprove thermal conductivityFurnace typesHeat treatment furnacesSurface finishThermodynamics

The invention discloses a quenching device without a hydraulic plate with continuous quenching of a steel belt and a steel belt cooling method. The quenching device without the hydraulic plate comprises an upper water tank and a lower water tank, wherein a water inlet and a water outlet are arranged on each water tank; a plurality of water guide plates are arranged inside the water tanks; the steel belt passes through the two water tanks; one side of each water tank close to the steel belt is provided with a pressure plate; and a protective plate is arranged between the pressure plate and the steel belt. The quenching steel belt cooling method without the hydraulic plate transfers heat of the heated steel belt to flowing water by utilization of solid heat conduction and the temperature of the steel belt is quickly reduced to below the martensite transition temperature Ms without the necessity of direct cooling of liquid, thereby the steel belt texture is transformed from austenite to martensite. The quenching device without the hydraulic plate and the steel belt cooling method have the advantages of no necessity of any liquid quenching medium, no environmental pollution, simple equipment, high production efficiency, and good surface finish degree and flatness.

Owner:ZHEJIANG BAINAI STEEL STRIP

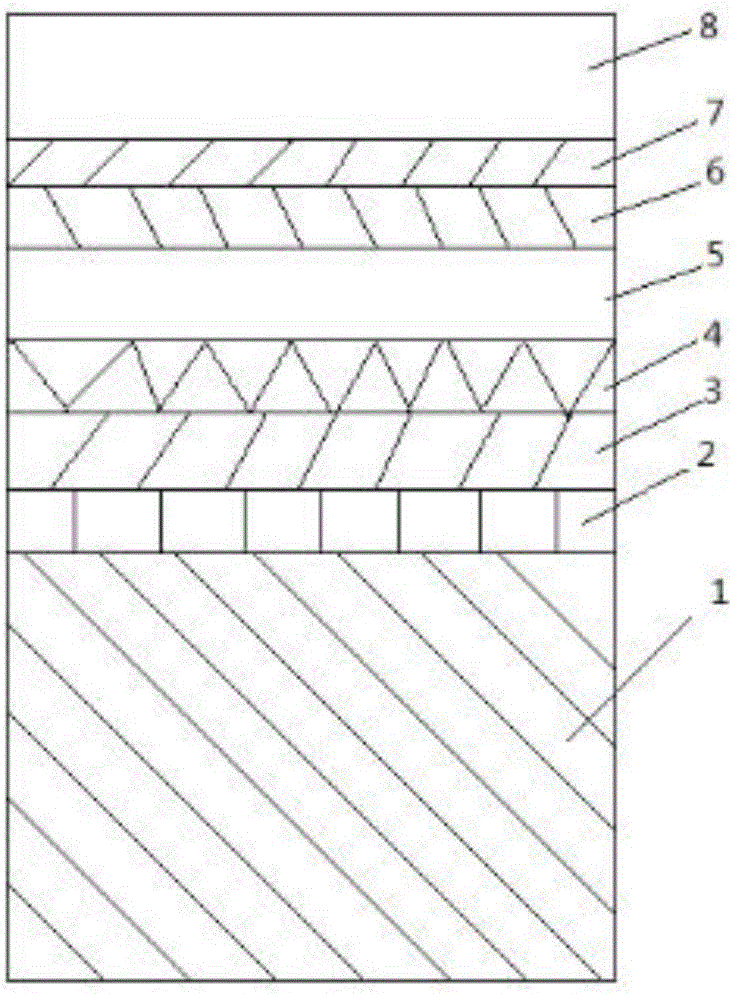

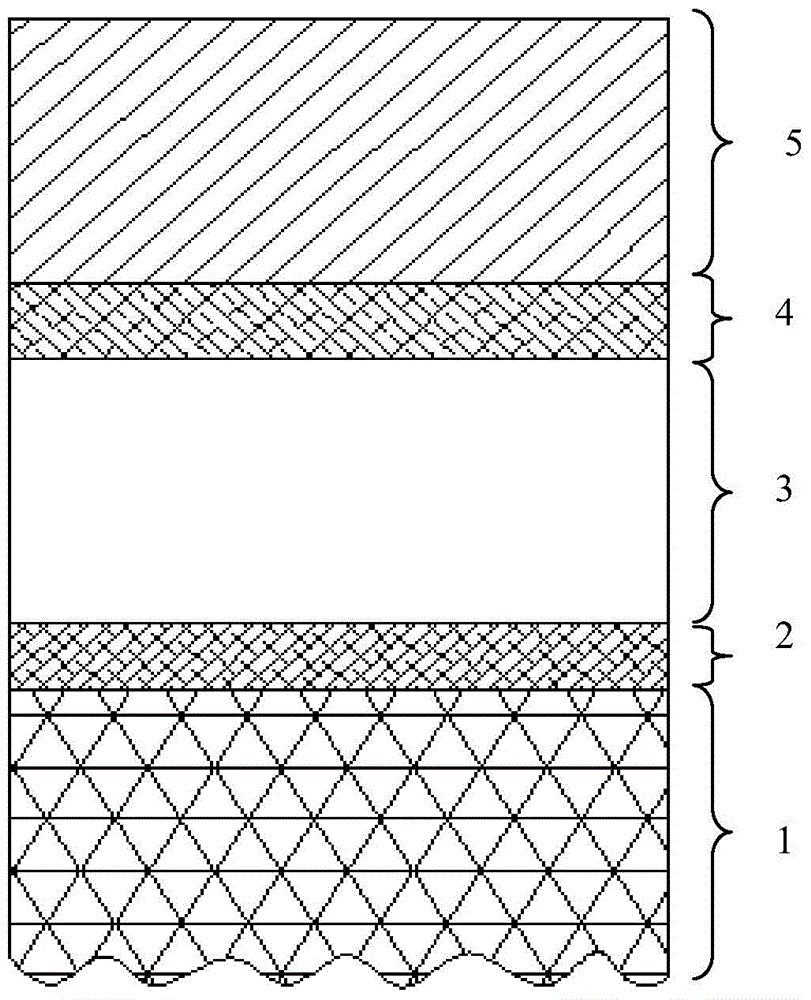

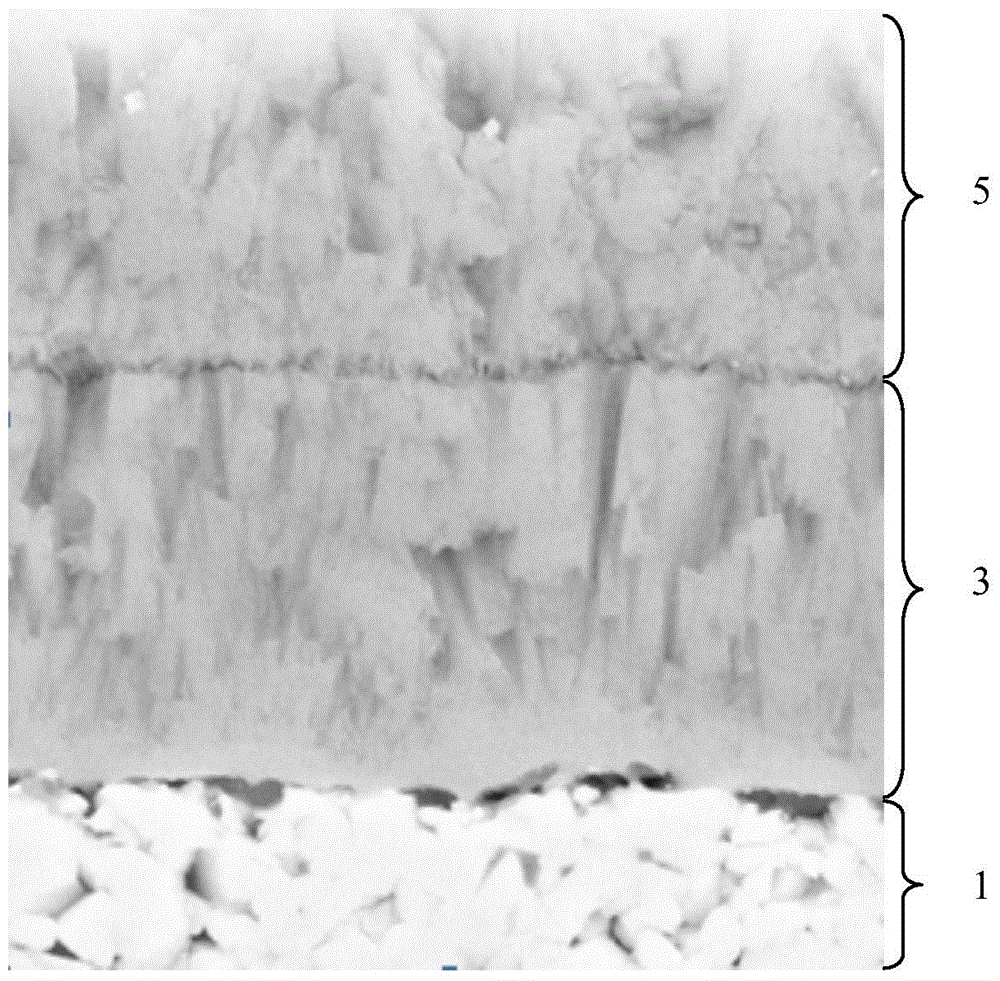

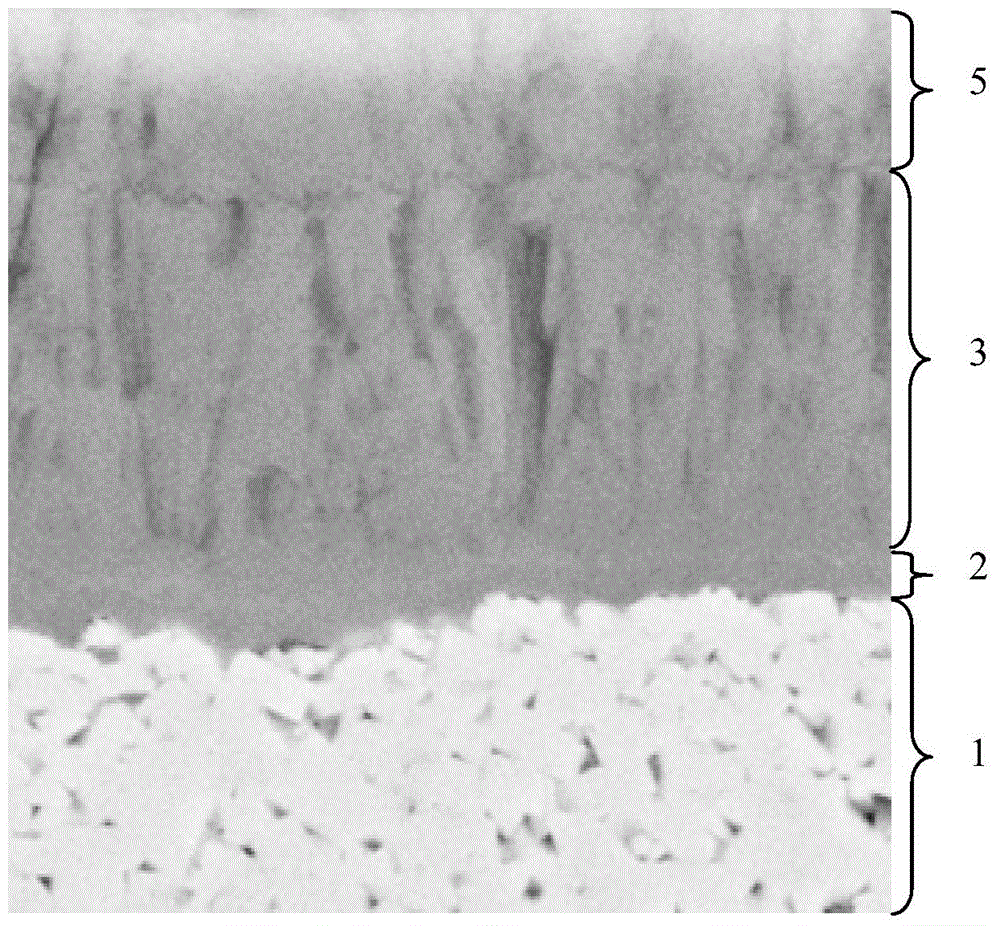

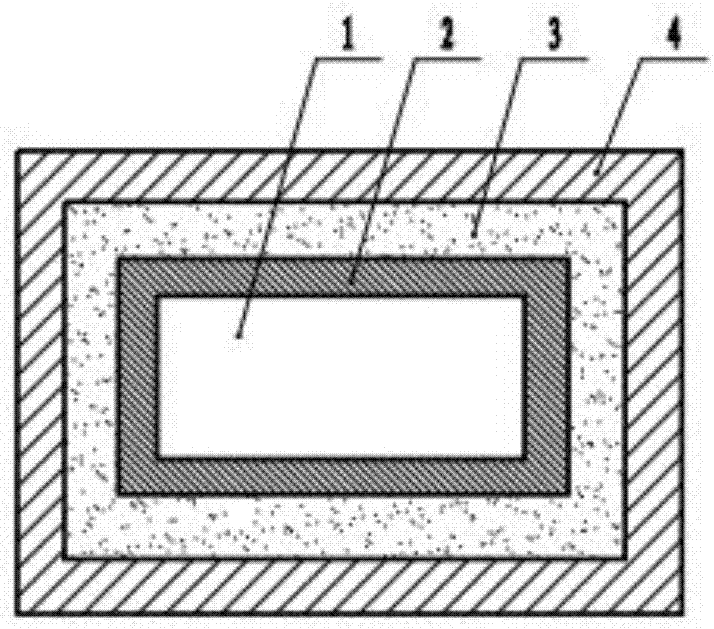

Diamond-like carbon film of gradient structure and preparation method thereof

ActiveCN106521493AImprove performanceImproved deformation coordinationSuperimposed coating processCarbon filmDiamond-like carbon

The invention relates to metal surface treatment, in particular to surface treatment of low-temperature iron-base alloy molds of sliding components, bearings and the like and provides a diamond-like carbon film of a gradient structure and a preparation method of the diamond-like carbon film of the gradient structure. The diamond-like carbon film of the gradient structure is provided with a coating structure comprising a pure metal layer, a first gradient transition layer, a metal nitride layer, a second gradient transition layer, a tungsten carbide, a third gradient transition layer and a surface layer. The surface layer is a diamond-like layer or a silicon-containing type diamond layer. According to the diamond-like carbon film of the gradient structure, gradient control over elasticity modulus and hardness is achieved through ingredient gradient control between all the layers, and therefore the film-substrate cohesion force and the delaminating resistance of the coating are greatly improved.

Owner:广州今泰科技股份有限公司 +1

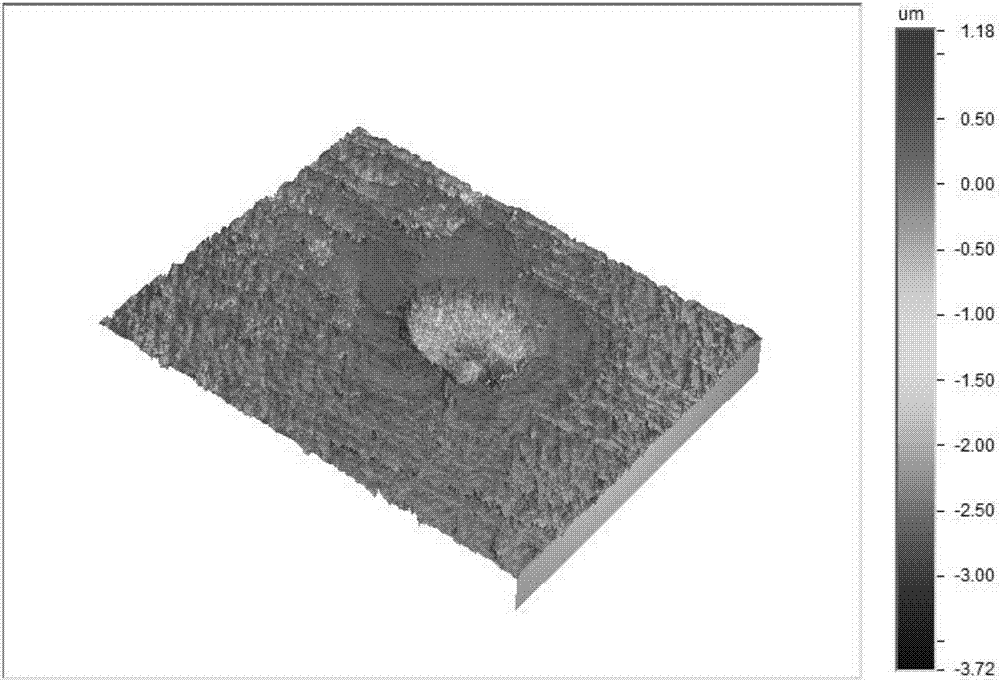

Self-lubricating treatment method for aero-engine bearing

InactiveCN107237821AImprove the overall performance of anti-friction and wear resistanceReduce surface friction coefficientVacuum evaporation coatingSputtering coatingSputteringCooperativity

The invention discloses a self-lubricating treatment method for an aero-engine bearing, and relates to the technical field of aero-engine bearing self-lubricating. The self-lubricating treatment method for the aero-engine bearing comprises the following steps: firstly, performing laser micro-modelling treatment on the surface of the aero-engine bearing, wherein the diameters of micro-pits are 60 to 120 mu m, the depths of the micro-pits are 4 to 10 mu m, the distances of the micro-pits are 150 to 220 mu m, and the area occupation ratio of the micro-pits is 12.5 to 19.6 percent; and secondly, performing magnetron sputtering to form a DLC-WS2 composite coating. By utilizing a composite treatment process and the complementarity and the cooperativity of diversified treatment, comprehensive performance of reducing friction and resisting friction of the aero-engine bearing is improved; wear is reduced; and the service life of the aero-engine bearing under complex working conditions that the rotating speed is 35,000 r / min, the temperature of 300 DEG C and the like is prolonged.

Owner:JIANGSU UNIV

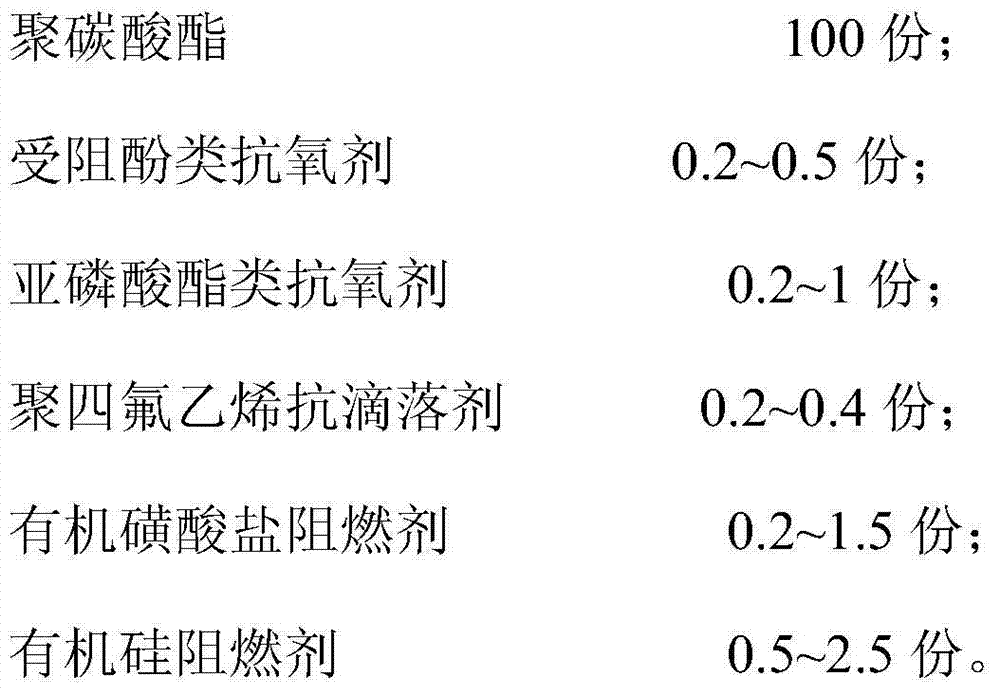

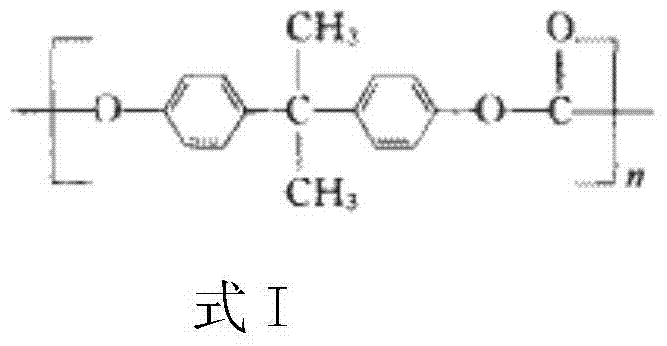

Flame-retardant polycarbonate composition and preparation method thereof

ActiveCN104497536AImprove flame retardant performanceMaintain mechanical propertiesHeat resistancePhenolic antioxidant

The invention discloses a flame-retardant polycarbonate composition. The flame-retardant polycarbonate composition comprises the following components in part by mass: 100 parts of polycarbonate, 0.2-0.5 part of a hindered phenolic antioxidant, 0.2-1 part of a phosphite-type antioxidant, 0.2-0.4 part of polytetrafluoroethylene anti-dripping agent, 0.2-1.5 parts of an organic sulphonate flame retardant and 0.5-2.5 parts of an organosilicone flame retardant. By the synergistic flame-retardant effect of the organic sulphonate flame retardant and the organosilicone flame retardant which are compounded at a mass ratio of 2-3: 5 for use and optimizing the content of each component, the flame retardancy of polycarbonate is increased and the original mechanical property and heat resistance of polycarbonate are kept.

Owner:SHENZHEN HALCYON NEW MATERIALS

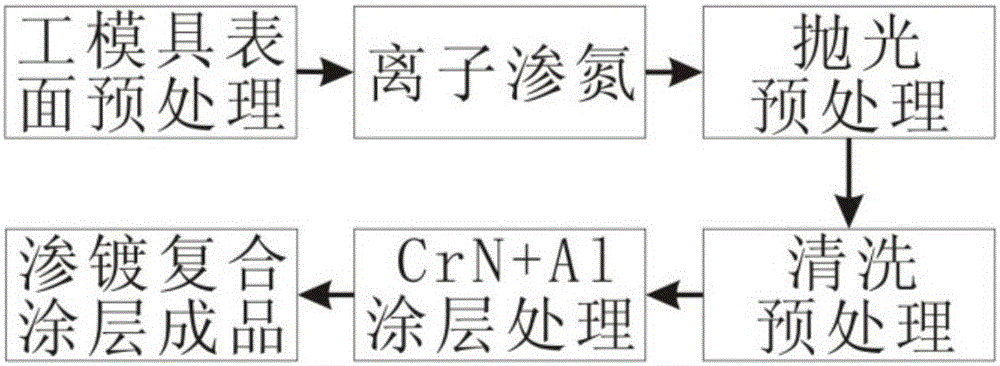

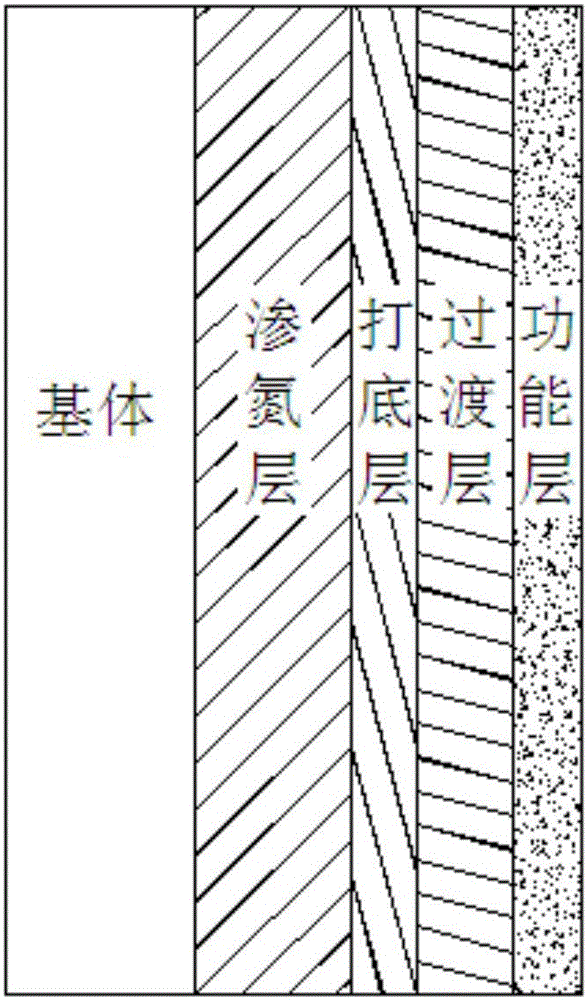

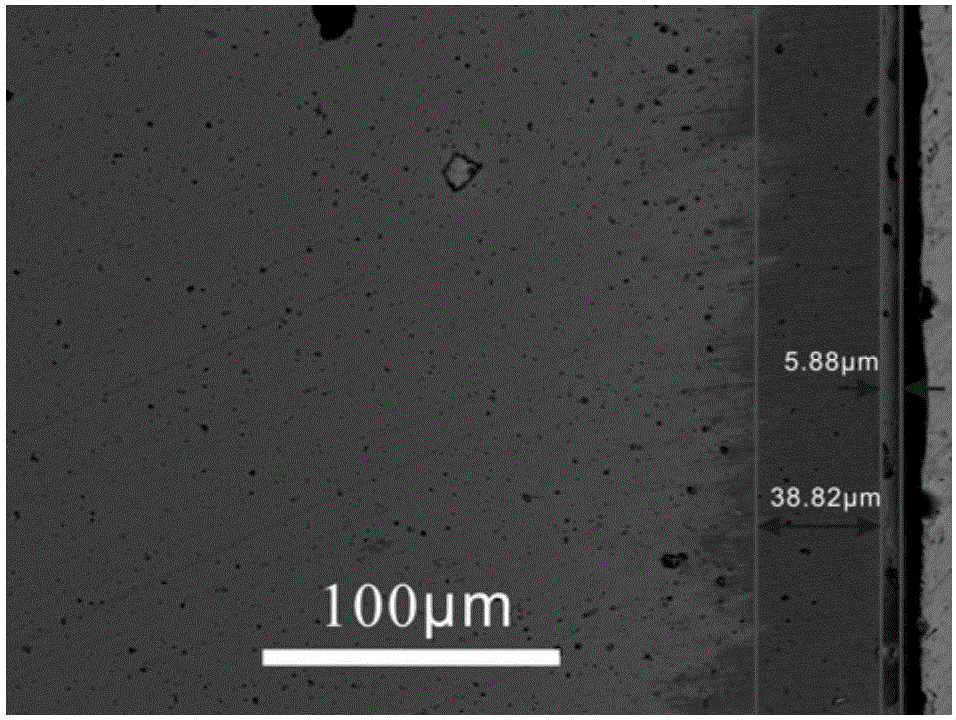

Surface plating composite coating process for die

ActiveCN106011738AEasy to useHigh performance, high hardnessVacuum evaporation coatingSputtering coatingPunchingHardness

The invention relates to a surface plating composite coating process for a die. The process comprises the steps that the die which is treated through the plasma nitriding process is polished and cleaned, and then is clamped; the die is placed into multi-arc ion coating equipment for coating process treating; and plasma nitriding and CrN+Al coating are combined, and meanwhile the effects of two treatment processes are optimized. The surface plating composite coating process has the characteristics of being low in process temperature, high in processing efficiency, small in die deformation and low in energy consumption. An obtained die composite coating has the characteristics of being high in usability, high in hardness, toughness and abrasive resistance, and excellent in high-temperature oxidation resistance. The surface friction coefficient of the die can be effectively lowered, the service life of the die is prolonged, production cost is reduced and product competitiveness is improved. The process is suitable for cold-work die steel with high abrasive resistance requirements and capable of bearing large impact loads, particularly suitable for treatment of the dies like a punching die, stamping die, cold heading die and cold extruding die in the field of automobiles and also suitable for further application and popularization.

Owner:PVT COATING CHANGZHOU

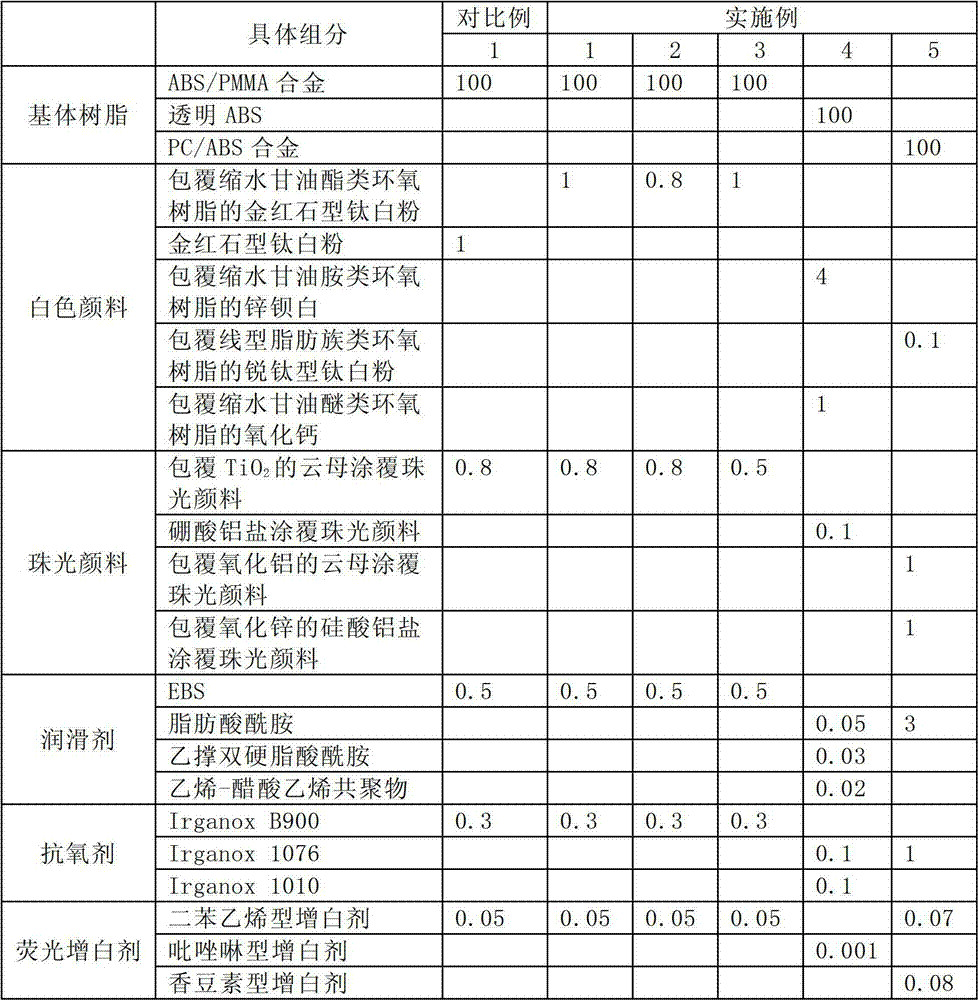

Aesthetic resin for improving whiteness and scintillation effect and preparation method thereof

InactiveCN102888071AReduce surface hardnessReduce surface friction coefficientFluorescenceAntioxidant

The invention relates to an aesthetic resin for improving whiteness and scintillation effect and a preparation method thereof. The resin comprises the following components in parts by weight: 100 parts of base resin, 0.1-5 parts of white pigment, 0.1-2.0 parts of pearlescent pigment, 0.1-3.0 parts of lubricant, 0.2-1.0 part of antioxidant and 0.001-0.15 part of fluorescent whitening agent. The preparation method of the resin comprises the following steps: stirring and mixing the components in a high-speed mixer, and then transferring into a double screw extruder; under the transferring, shearing and mixing effects of double screws, melting and compounding the materials; and then extruding, performing bar drawing, cooling, and pelleting to obtain the product. The invention overcomes the disadvantage that the existing white aesthetic resin can not simultaneously realize high whiteness and high scintillation effect, and ensures that the apparent effect of the white aesthetic resin is greatly enhanced, thereby ensuring that the white aesthetic resin meets the higher appearance application requirements in the fields of household appliances, automobiles, consumable electronics and the like and greatly widening the application range of the white aesthetic resin product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Modified thermoplastic polyurethane and preparation method and application thereof

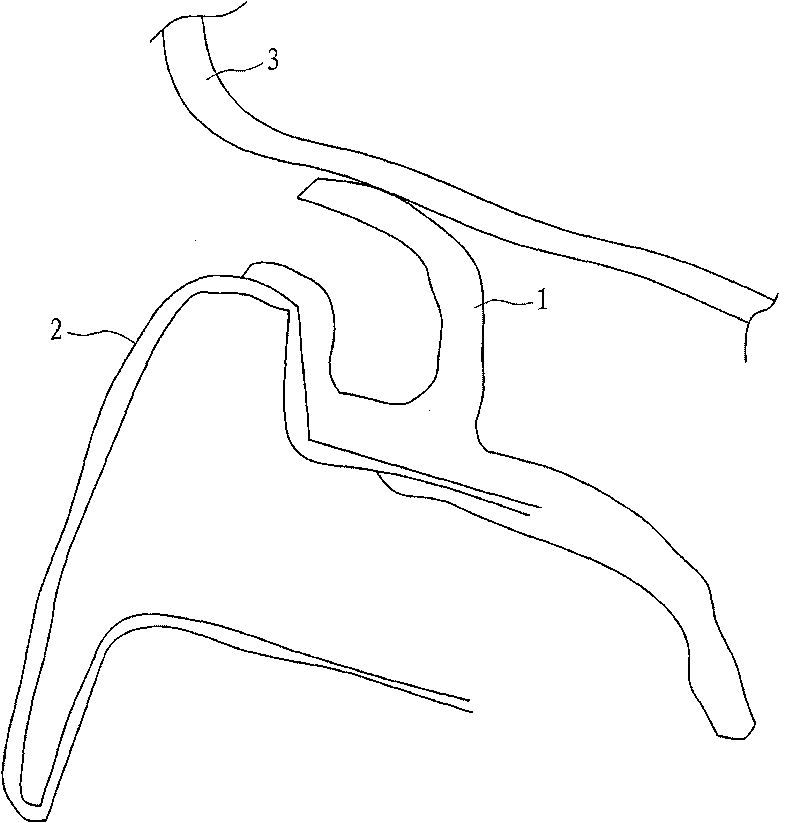

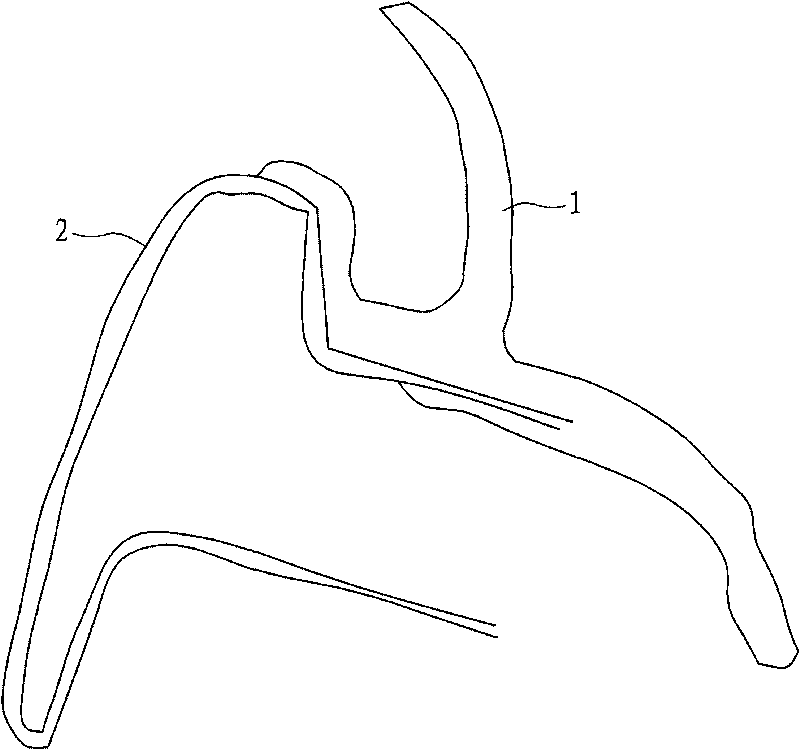

ActiveCN101724253AReduce surface friction coefficientImpact resistantEngine sealsVehicle sealing arrangementsState of artThermoplastic polyurethane

The invention relates to modified thermoplastic polyurethane which is prepared by blending the components in weight ratio: 62-76 parts of thermoplastic polyurethane, 7.6-37 parts of ultra high molecular weight polyethylene, 3.8-9.3 parts of surface lubricant, 1.5-6 parts of compatibilizer and 0.2-0.4 part of stabilizer. Compared with the prior art, the modified thermoplastic polyurethane has the advantages that the ultra high molecular weight polyethylene (UHMWPE) material is taken as a modifier with low friction coefficient; as a synergistic assistant, the modified thermoplastic polyurethane is simultaneously added with the surface lubricant so that the surface friction coefficient of thermoplastic polyurethane (TPU) is lowered simultaneously and the processability is also improved; by the suitable formula and the blending modification of the materials, the friction coefficient of the TPU is lowered.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Cutting blade with improved coating structure and manufacturing method of cutting blade

ActiveCN105269010AImprove toughnessGood wear resistanceTurning toolsChemical vapor deposition coatingSurface finishingOxide

The invention discloses a cutting blade with an improved coating structure and a manufacturing method of the cutting blade. The cutting blade comprises a matrix A and a coating deposited on the matrix A. The coating is a multi-layer coating and at least comprises an inner layer C and an outer layer D. The inner layer C is composed of carbon-nitrogen oxide of transition elements of the IV B group or carbonitride of transition elements of the IV B group. The outer layer D is a (TiaAlb)(CiNjOk) layer, the thickness of the outer layer D is 1-20 [mu]m. Both the inner layer C and the outer layer D are of face-centered cubic structures. The manufacturing method comprises the steps of manufacturing the matrix A, selectively depositing a transition layer B, depositing the inner layer C, selectively depositing a transition layer E, depositing the outer layer D, and conducting surface treatment. The cutting blade is good in tenacity, abrasion resistance and oxidation resistance, the cutting blade has excellent cutting performance in machining of materials such as steel and stainless steel, and the manufacturing method is simple, convenient to implement, and easy to operate and control.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

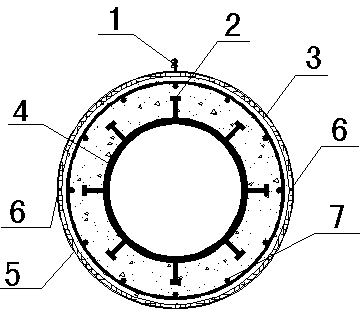

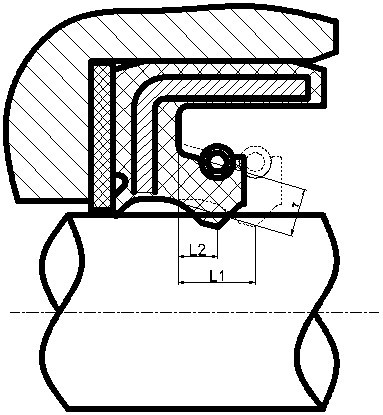

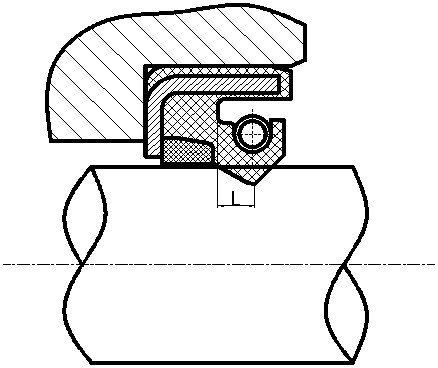

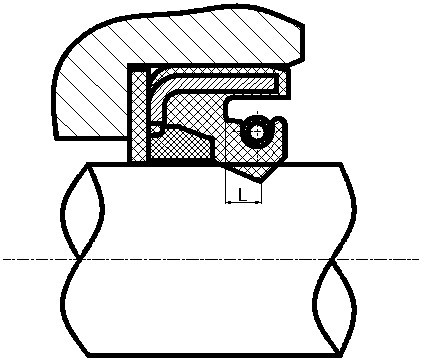

Assembled half-exposed framework high-pressure seal ring

ActiveCN102537360AImprove carrying capacityIncrease stiffnessEngine sealsVulcanizationMetal framework

The invention discloses an assembled half-exposed framework high-pressure seal ring, which not only can seal in a rotating way, but also can seal in a reciprocating way. The seal ring includes a rubber body with a sealing lip, a metal framework vulcanized in the rubber, and a half-exposed framework, a pressure bearing ring taking a metal or non-metal composite material and a spring that are assembled on the rubber body. The half-exposed framework, the composite material pressure bearing ring and the rubber body of the seal ring are designed in an assembling way; and the composite material pressure bearing ring is arranged between the half-exposed framework and the sealing lip, and the pressure bearing ring bears a large amount of working pressure. The assembled half-exposed framework high-pressure seal ring has extremely high high-pressure resistance, outstanding and stable extrusion resistance, excellent heat dissipation and friction lubricating property, good eccentricity adaptability, extremely long service life, simple process, and efficient and stable machining.

Owner:重庆杜马斯克科技有限公司 +2

AlNbCN multielement gradient composite coating tool and preparing method thereof

ActiveCN107338411AHigh hardnessHigh strengthVacuum evaporation coatingSputtering coatingHeat stabilityCutting force

The invention belongs to the field of machining cutting tools, and relates to an AlNbCN multielement gradient composite coating tool and a preparing method thereof. The coating tool sequentially comprises a tool base body, a Ti transition layer, an AlNbC transition layer and an AlNbCN multielement gradient composite coating with the nitrogen content gradually changing in a gradient manner from interior to exterior, and the coating tool is prepared in a middle-frequency magnetron sputtering and arc plating composite coating method. According to the AlNbCN ultrahard carbohydrates and nitrogenous compound coating, due to the fact that the Al element and the Nb element are added in the coating at the same time, and the content of the nitrogen which is the structure component of the coating gradually changes in a gradient manner, thecutting machining performance of the tool can be improved. The AlNbCN multielement gradient composite coating tool has very high hardness and strength, low surface friction coefficient, good high-temperature oxidization preventing performance and excellent friction abrasion characters. In the cutting process, tool surface friction and cuttings bonding can be reduced through the tool, the cutting force and the cutting temperature can be reduced by 45% or above, the heat stability of the coating tool is improved by 65% or above, the service life of the tool is prolonged by 60% or above, and durability of the tool is improved by 60% or above.

Owner:JINING UNIV

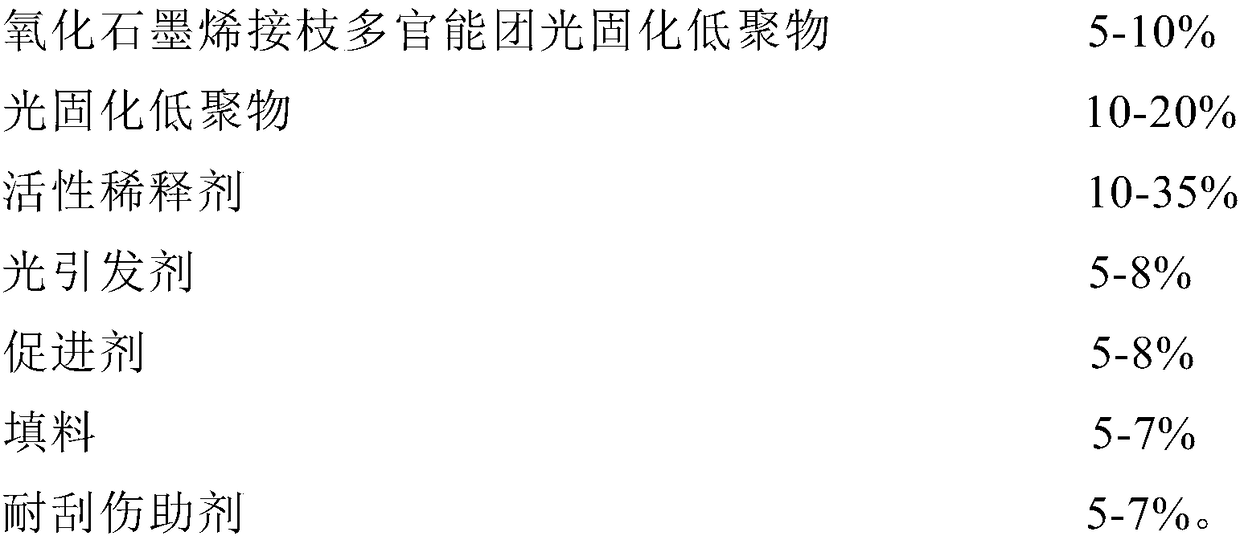

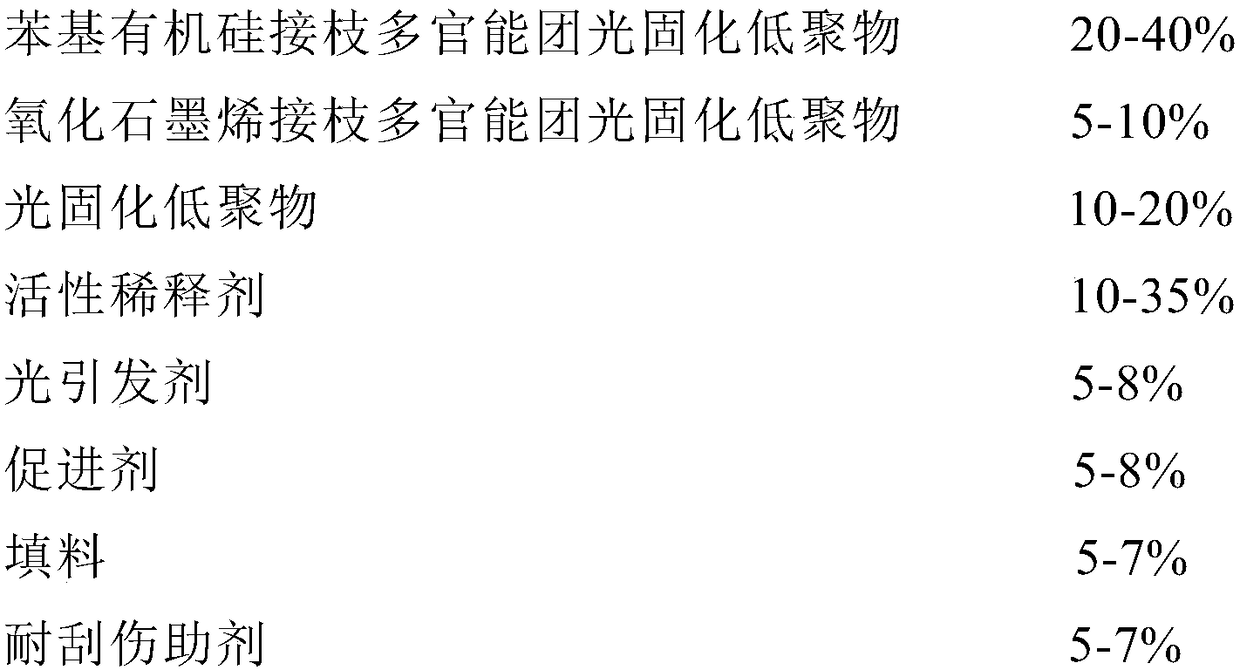

Super durable ultraviolet ray curing coating

ActiveCN108977056AGuaranteed flexibilityGuaranteed wear resistanceAntifouling/underwater paintsPaints with biocidesUltravioletReactive diluent

The invention provides a super durable ultraviolet ray curing coating which comprises the following raw materials by weight percent: 20-40% of phenyl organosilicone grafted polyfunctional group photo-cured oligomer, 5-10% of graphene oxide grafted polyfunctional group photo-cured oligomer, 10-20% of photo-cured oligomer, 10-35% of a reactive diluent, 5-8% of a photoinitiator, 5-8% of an accelerant, 5-7% of padding and 5-7% of an anti-scratching agent. The super durable ultraviolet ray curing coating provided by the invention has super abrasive resistance, high scratch resistance, sufficient toughness, excellent pollution tolerance, capability of preventing steel wool scratching and capability of preventing the problems of insufficient adhesive force with substrate and easiness in falling of the present ultraviolet ray curing coating.

Owner:NANXIONG RISING CHEM IND

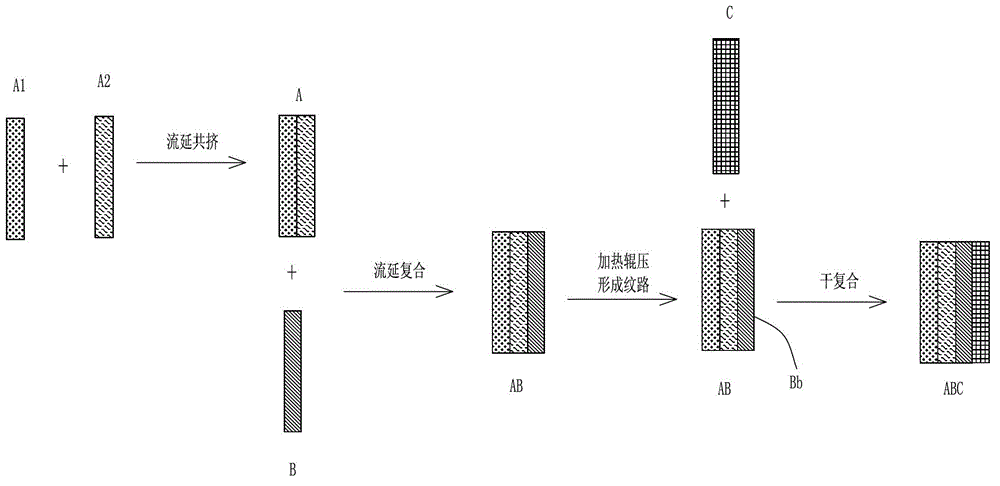

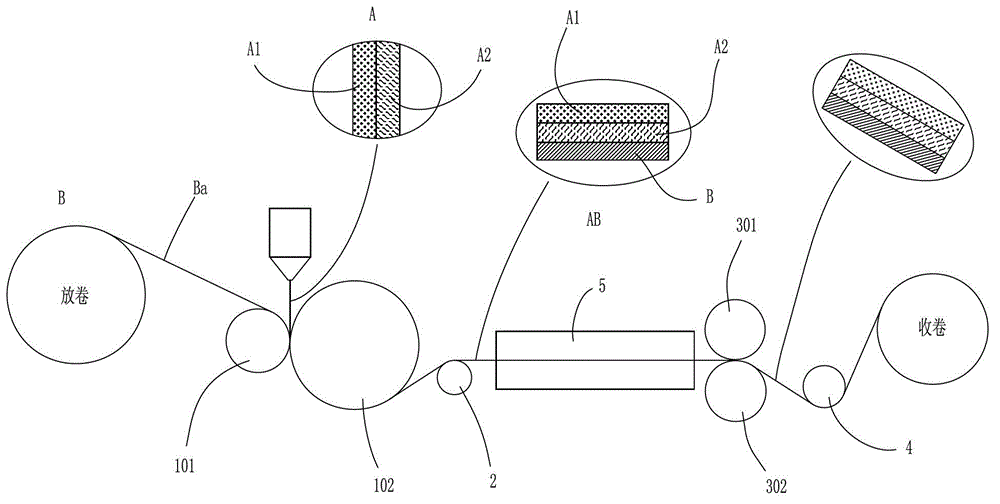

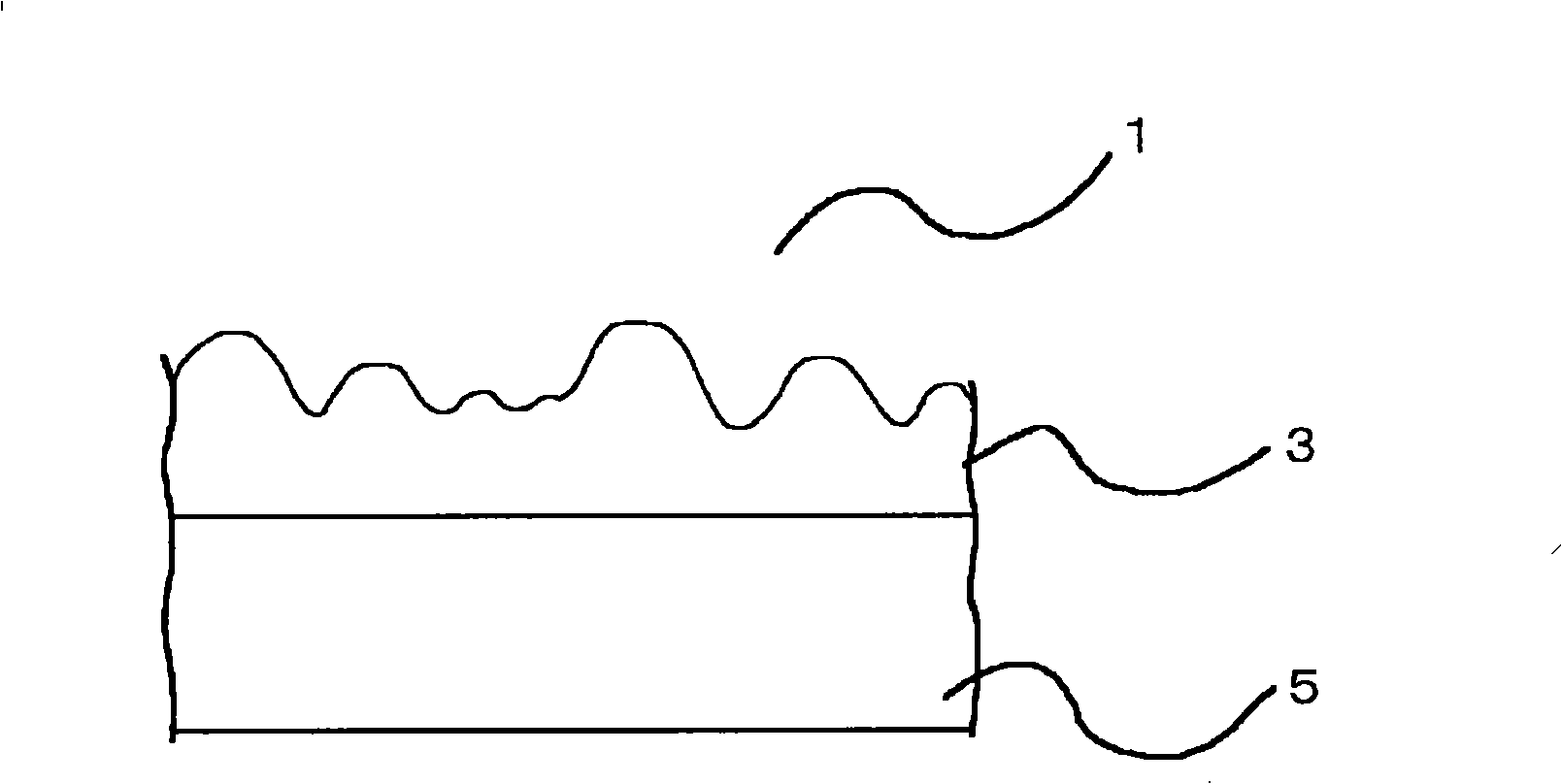

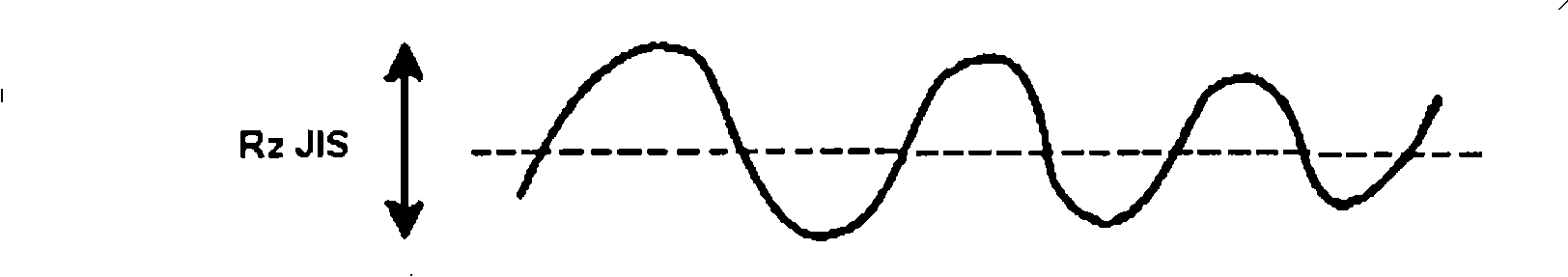

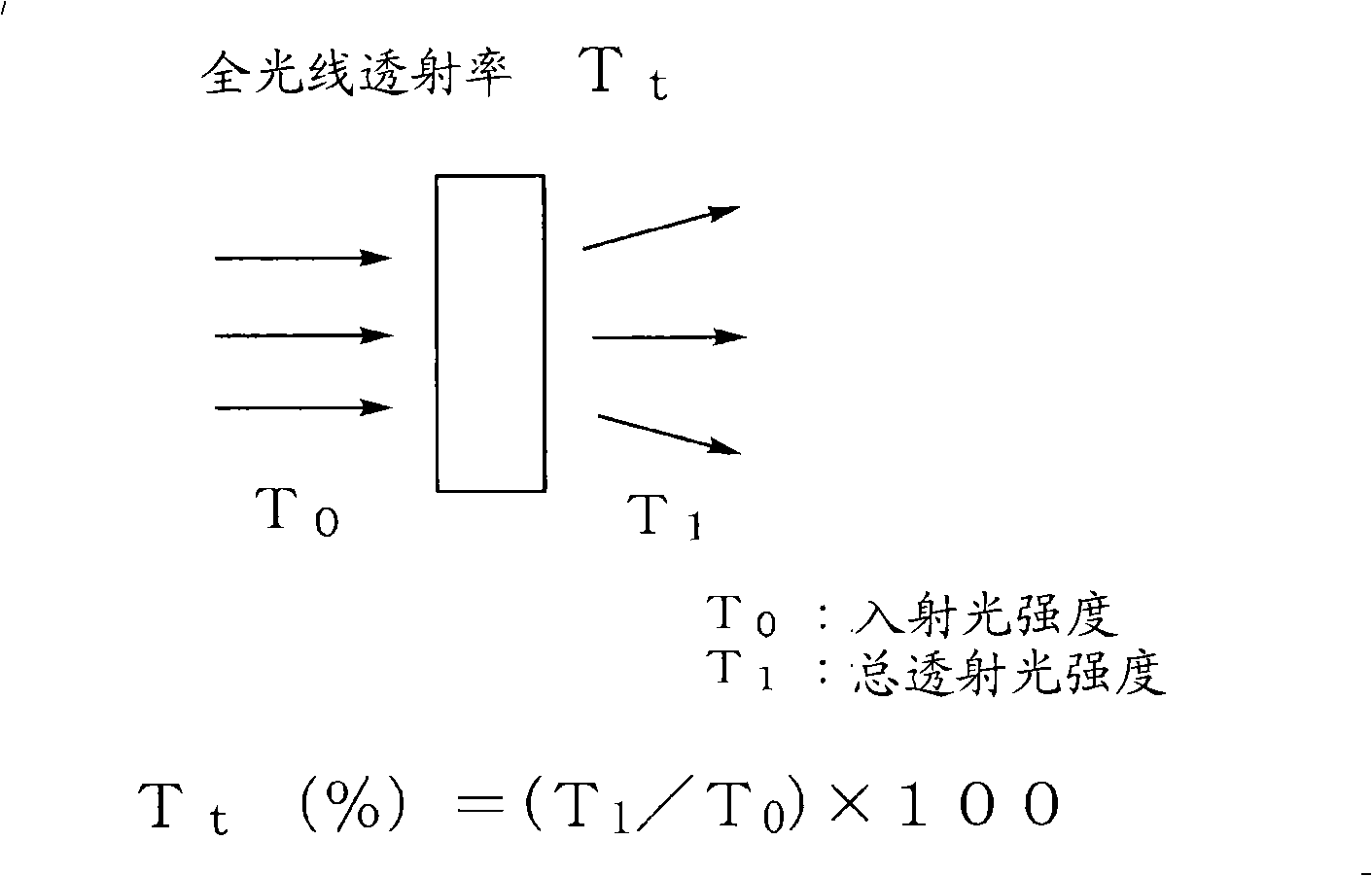

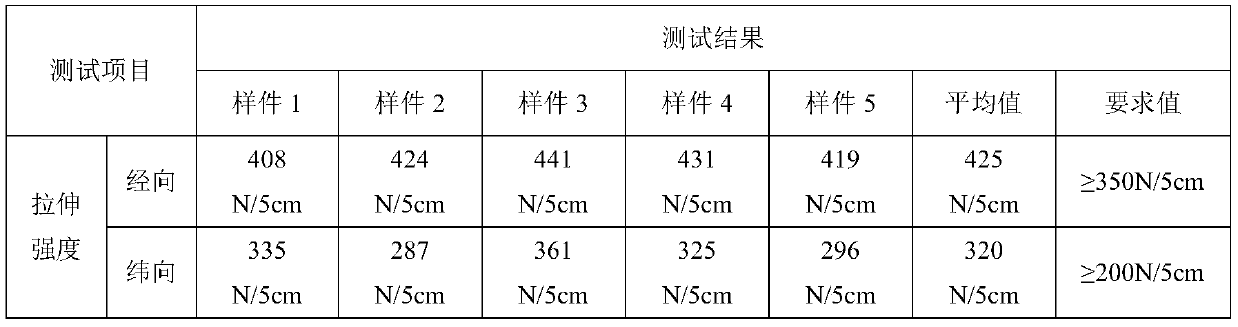

Easy-cold-punch-molding soft packaging composite material, and preparation method and molding method thereof

ActiveCN103331957AAvoid "sticking" problemsThe surface coefficient of friction value is reducedMetal layered productsAluminum foilBonding problems

The invention provides an easy-cold-punch-molding soft packaging composite material. The composite material comprises a thermoplastic resin film layer, an aluminum foil metal core layer, and a heatproof or printing film layer; the aluminum foil metal core layer is positioned between the thermoplastic resin film layer and the heatproof or printing film layer; the thermoplastic resin film layer comprises a surface heat-sealing layer and a hot melt adhesive resin layer compounded with the aluminum foil metal core layer; and the surface of the heat-sealing layer has fine slight convex-concave lines formed through heating roll molding in the compounding process, and the convex-concave depth of the fine slight convex-concave lines is 0.5-25mum. By utilizing the fine convex-concave characteristics of the fine slight convex-concave lines, a bonding problem formed by the clinging of the surface of the composite material and a die can be avoided during stamping, and air can be residual in a slit between the die and the convex-concave lines on the surface of the composite material during the stamping, so the surface friction coefficient value of the composite material is greatly reduced, and it is in favor of demolding the composite material in the cold punch molding process. The invention also provides a preparation method of the composite material, and a molding method when used.

Owner:FSPG HI TECH

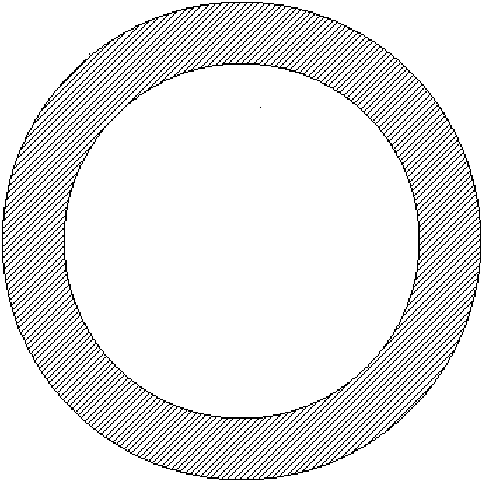

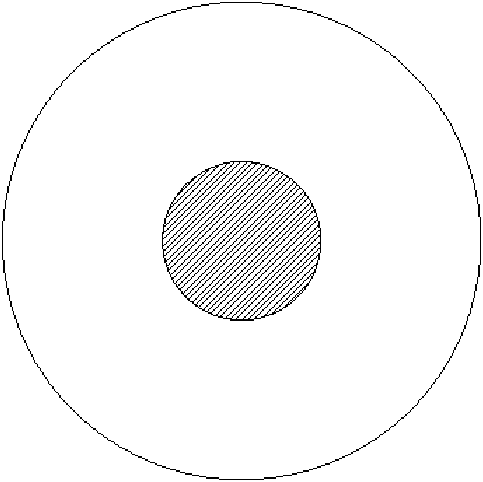

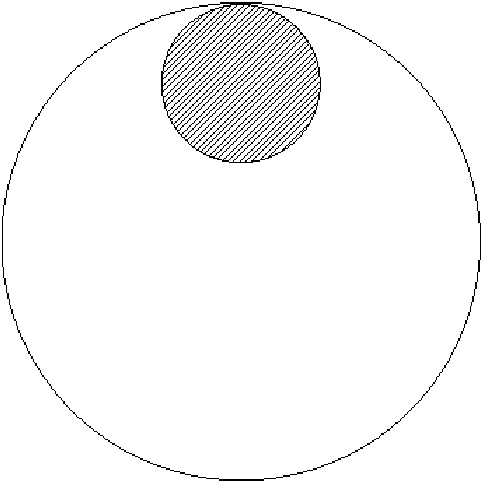

Durable carbon black conductive fiber and preparation method thereof

ActiveCN102031588AImprove conductivityNot easy to peel offElectroconductive/antistatic filament manufactureFilament/thread formingFiberSpecial design

The invention provides durable carbon black conductive complex fiber and a manufacturing method thereof. The complex fiber comprises a functional layer and a protective layer, wherein in a circle O2 of the cross section of the complex fiber, the functional layer comprises a part surrounded by three equilong circular arcs L1, L2 and L3 and the periphery of the circle O2; the three equilong circular arcs respectively pass through three equidistant points on a concentric circle O1 of which the radius is smaller than that of the circle O2; and the three equilong circular arcs are non-intersected mutually. The preparation method of the conductive fiber comprises the following steps: evenly mixing conductive carbon black and an additive; then adding fiber-forming high polymer to prepare conductive master batch; and after drying the master batch, preparing the conductive complex fiber from the master batch and the fiber-forming high polymer by a spinning and drafting one step method. Due to the cross-section structure with the special design of the conductive complex fiber, the carbon black in the fiber can not peel off easily, so that the durability is improved. Simultaneously, the mechanical properties of the fiber are improved, and the surface friction coefficient of the fiber is reduced, thereby improving the post processing performance and being more favorable for use for customers.

Owner:CTA HIGH TECH FIBER

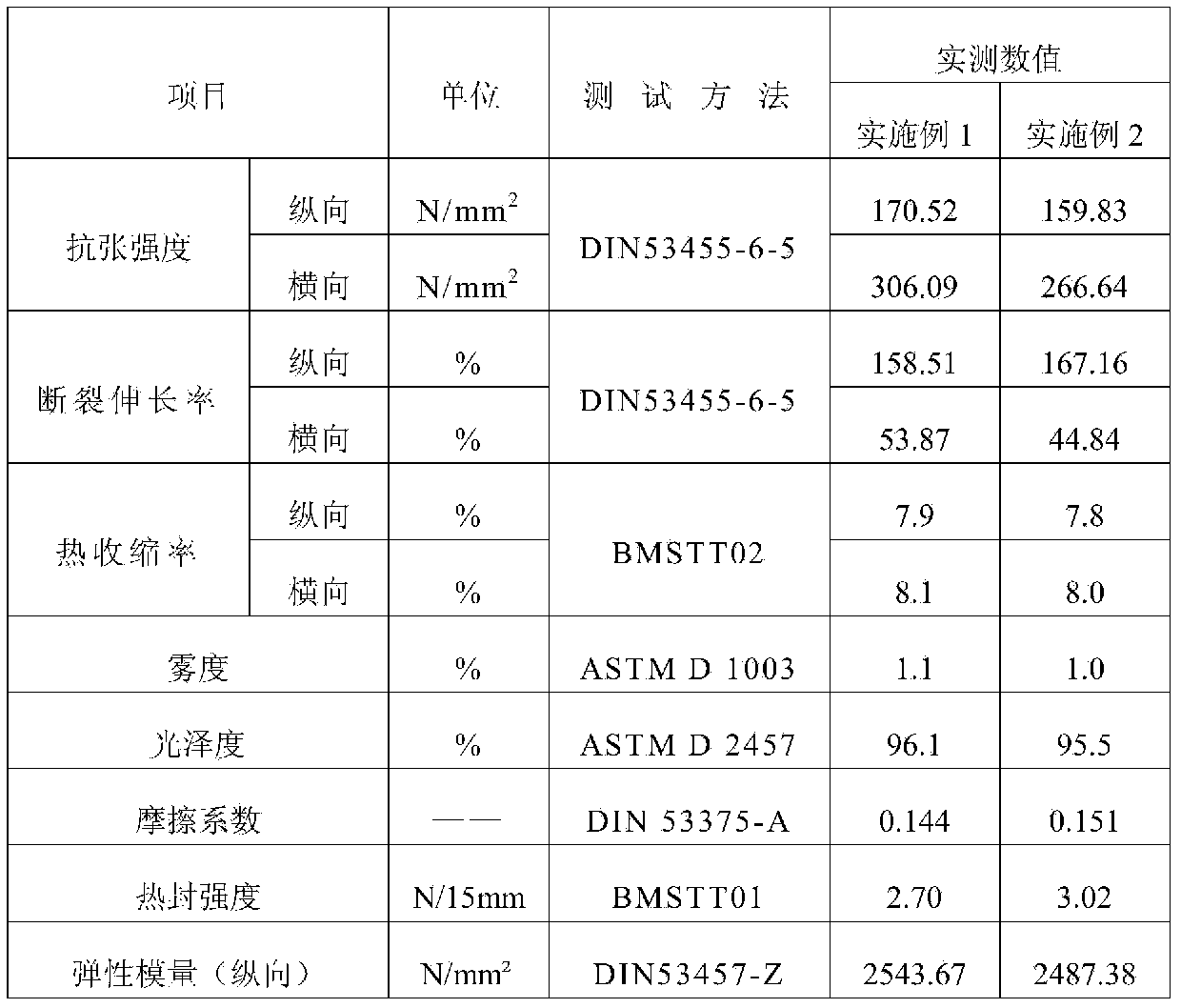

Special BOPP film for cold transfer cigarette label paper and preparation method of BOPP film

InactiveCN104210205ASmooth packaging processBroad machine applicabilitySynthetic resin layered productsMasterbatchAntistatic agent

The invention discloses a special BOPP film for a cold transfer cigarette label paper and a preparation method of the BOPP film. A direct co-extrusion composite way of a three-layer structure is adopted, and according to the formula, each layer of raw material comprises the following components in parts by weight: 85-99 parts of upper surface copolymer polypropylene, 1-15 parts of slipping anti-sticking agent master batch, 55-80 parts of core layer homopolymer polypropylene, 15-30 parts of stiffening agent maser batch, 5-15 parts of slip-antistatic agent master batch, 65-89 parts of lower surface copolymer polypropylene, 10-20 parts of slipping agent master batch and 1-15 parts of anti-sticking agent master batch. The produced BOPP film has relatively wide operation applicability, good stiffness and high elasticity modulus by optimal raw materials and process, and is capable of reducing the contact surface of the BOPP film and the cold transfer cigarette label as a special package film for the cold transfer cigarette label paper, and therefore, the film is effectively prevented from being fitted with the cigarette label to avoid generating the 'watermark' phenomenon during packaging, and compared with an existing BOPP film, the BOPP film has the advantages that the packaging efficiency and the packaging quality are obviously improved.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

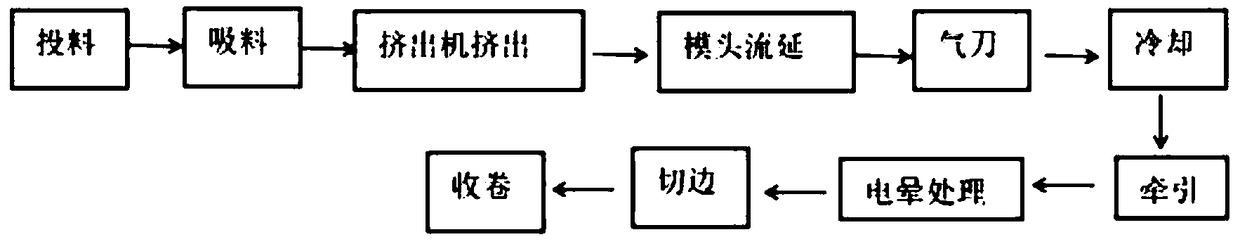

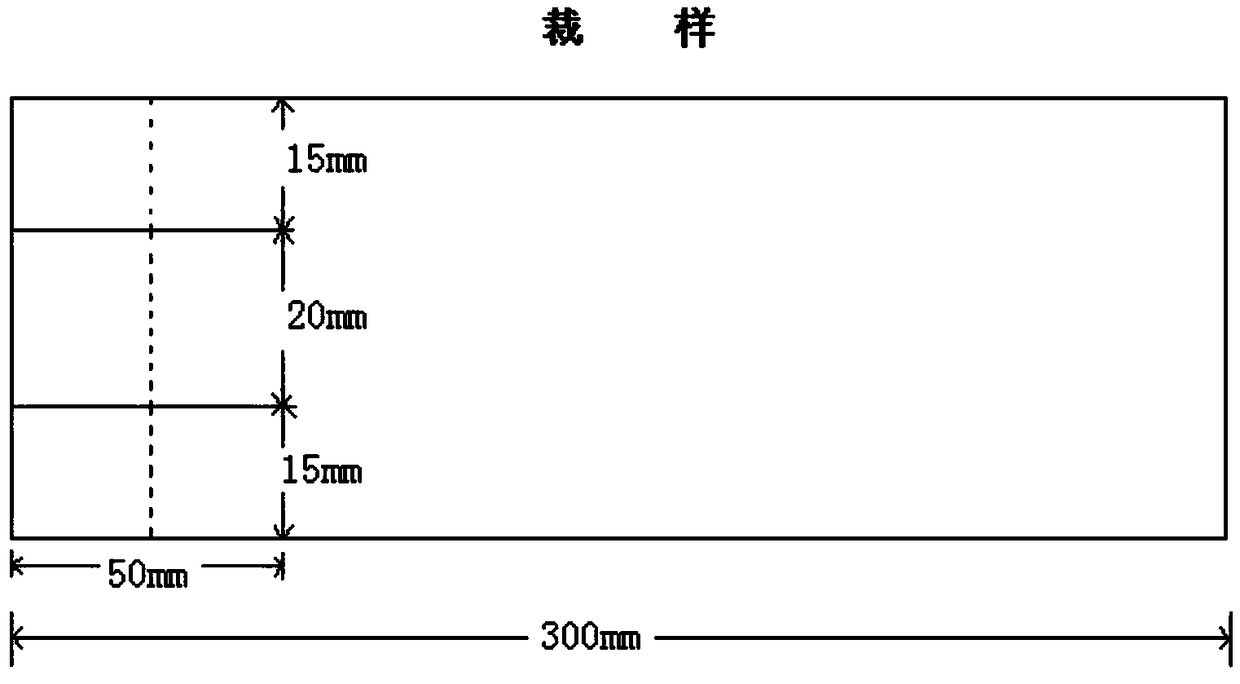

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

High-hardness and anti-impact PMMA/ABS (Polymethyl Methacrylate/Acrylonitrile Butadiene Styrene) composite sheet material

The invention discloses a high-hardness and anti-impact PMMA / ABS (Polymethyl Methacrylate / Acrylonitrile Butadiene Styrene) composite sheet material. The high-hardness and anti-impact PMMA / ABS composite sheet material is prepared from the following components in parts by weight: 10 to 50 parts of PMMA resin, 20 to 70 parts of ABS resin, 1 to 15 parts of MBS (Methacrylate-Butadiene-Styrene) resin, 0.5 to 3 parts of polyester grafted modified silicone auxiliary agent, 0.2 to 0.8 part of compatilizer, 0 to 0.5 part of dispersant, 0 to 1 part of antioxidant and 0 to 0.3 part of ultraviolet absorbent UV-531. The high-hardness and anti-impact PMMA / ABS composite sheet material disclosed by the invention combines advantages of two types of plastic and makes up the respective disadvantages; the PMMA and the ABS are commixed and other additives are added; compared with common PMMA resin, the surface hardness of the obtained PMMA / ABS material is improved by 20 percent to 30 percent; meanwhile, the PMMA has a more excellent anti-impact performance; the polyester grafted modified silicone auxiliary agent is added into to the PMMA raw material so that the surface scraping resistance, abrasion resistance, smoothness and hydrophobic property of the PMMA are improved and surface friction coefficients are reduced; an anti-scratching protection layer does not need to be arranged on the surface of a PMMA plate, so that the process can be effectively simplified, the production efficiency is improved and the production cost of enterprises is reduced; meanwhile, the high-hardness and anti-impact PMMA / ABS composite sheet material has a good ultraviolet-proof performance and the service life of the sheet material is prolonged.

Owner:GETTEL GRP TONGCHENG PLASTIC IND

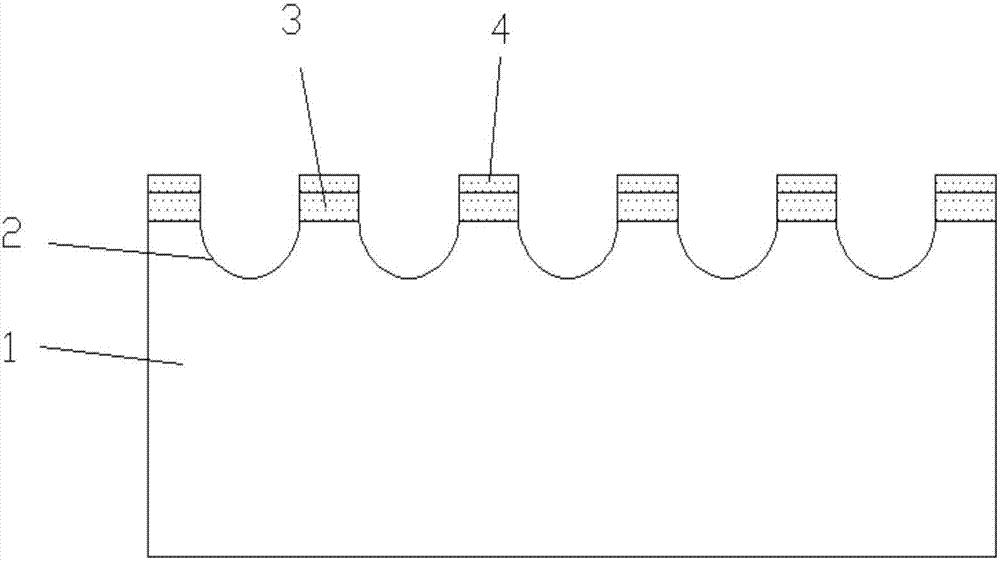

Antiblocking photocurable resin composition, antiblocking structure coating the same on substrate and production method thereof

InactiveCN101343342ANo adhesion phenomenonReduce surface friction coefficientLayered productsCoatingsOligomerPolyresin

The invention relates to a lability antiblocking light-settability resin composition, a solidified antiblocking structure coated on basis materials and a preparation method. The invention provides a film which prevents adhension between laminas of thermoplastic films, namely blocking, and a sandwich, a technology for improving glidability. The lability antiblocking light-settability resin composition of the invention comprises a first component, a second component and silicone compound, wherein the first component includes at least one resin, the second component includes more than one selected from more than one monomer or oligomer, after coating the composition, the resin of the first component is separated due to separation, and minute sagging is formed on the surface.

Owner:NIPPON PAINT CO LTD

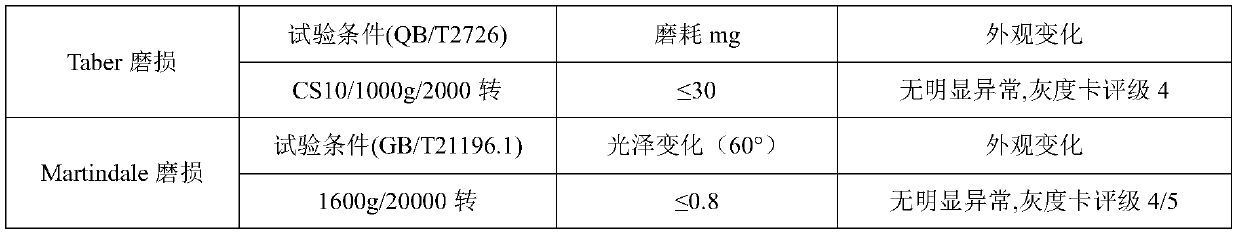

PVC artificial leather and preparation method thereof as well as car seat containing PVC artificial leather

InactiveCN110373912AGuaranteed abrasion resistanceImprove wear resistanceRoad vehiclesTextiles and paperPlasticizerCar seat

The invention discloses PVC artificial leather and a preparation method thereof as well as a car seat containing the PVC artificial leather. The PVC artificial leather comprises a base fabric layer, aPVC adhesive layer, a PVC foaming layer, a PVC dense layer and a surface layer which are arranged in order from bottom to top; the PVC adhesive layer is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 55-90 parts of a plasticizer, 1-5 parts of a calcium-zinc stabilizer and 1-3 parts of an AC foaming agent. The PVC artificial leather provided by the invention not only meets the technical standards of ordinary PVC leather, but also has the advantages of high wear resistance, environmental protection, and relatively high residual strength after punching, and meets the increasingly stringent requirements of the industry environmental protection regulations.

Owner:DONGFENG MOTOR CORP HUBEI

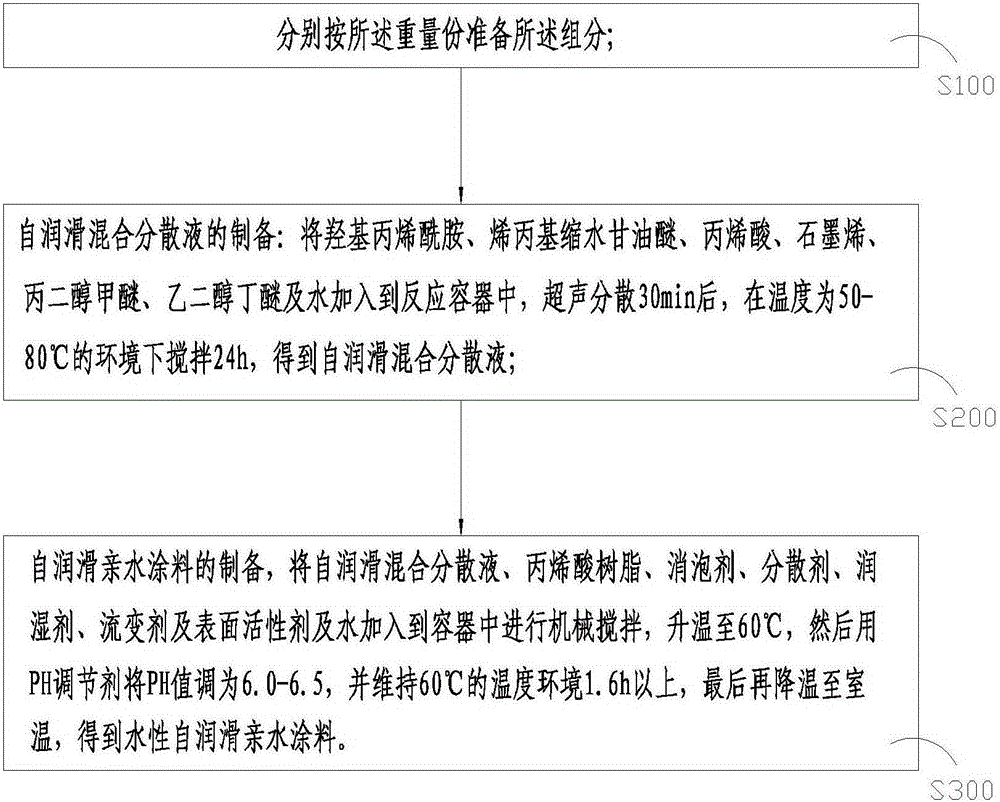

Self-lubricating hydrophilic coating and preparation method thereof

ActiveCN105219135AImprove thermal conductivityImprove cooling effectCoatingsAcrylic resinFood science

The invention provides a self-lubricating hydrophilic coating which comprises, by weight, 30-50 parts of self-lubricating mixed dispersion liquid, 60-85 parts of acrylic resin, 20-90 parts of water, 1-2 parts of antifoaming agents, 4-8 parts of dispersing agents, 0.5-1.2 parts of wetting agents, 0.5-1.8 parts of PH modifiers, 0.5-0.8 part of rheological agents and 0.5-2.5 parts of surfactants, wherein the self-lubricating mixed dispersion liquid comprises, by weight, 20-50 parts of hydroxyl acrylamide, 30-45 parts of allyl glycidyl ether, 25-50 parts of acrylic acid, 40-80 parts of graphene, 80-120 parts of water, 20-50 parts of propylene glycol monomethyl ether and 50-80 parts of ethylene glycol monobutyl ether. Compared with related technology, the self-lubricating hydrophilic coating has the advantages that heat conduction efficiency, hydrophilia and self-lubricating performance are all high.

Owner:湖南天氟新材料有限公司

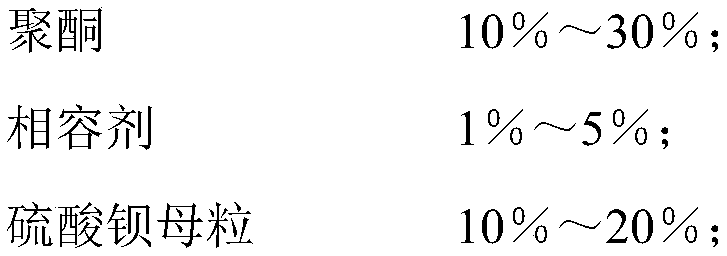

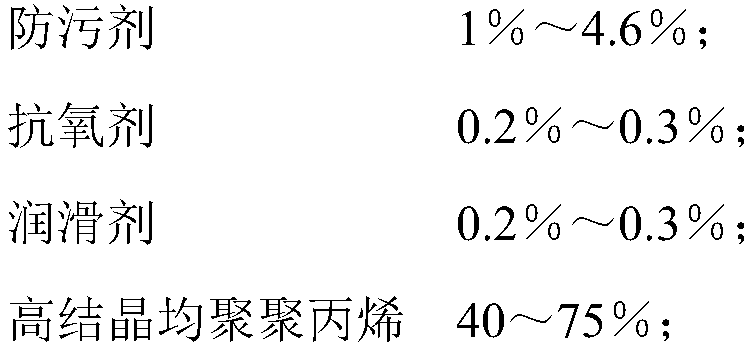

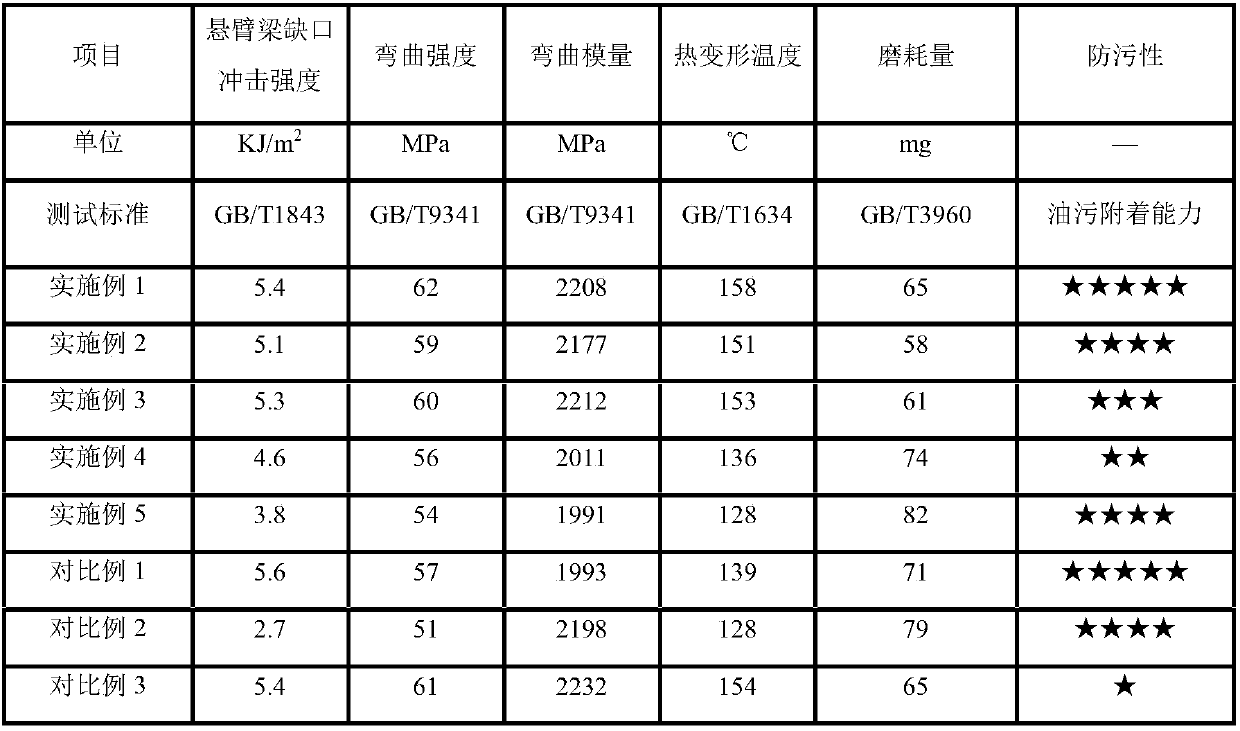

Pollution-resistance high-temperature-resistance polypropylene material and preparation method thereof

The invention belongs to the technical field of polymer composite material modification, and particularly relates to a pollution-resistance high-temperature-resistance polypropylene material and a preparation method thereof. The polypropylene material is characterized in that high-crystallization homopolymer polypropylene is taken as a basic component, polyketone resin is added to improve the wearresistance and mechanical performance of the material, barium sulfate masterbatch is taken as a filling agent to reduce dust pollution, a compatibilizer is added to improve the bonding force betweenraw materials to improve the mechanical performance of the material, organic group modified ultrahigh molecular weight polyorganosiloxane is taken as an antifouling agent to improve the water and oilresistance and the wear resistance of the material, and the anti-ageing performance of the material is improved by adopting an antioxidant. The material has the advantages of easy processing, high glossiness, high wearing resistance, pollution resistance, easy dyeing, excellent physical mechanical performance and the like, the demands by household electrical appliance products and kitchen electrical appliances on housing materials thereof in severe environments can be completely met, and the material can be widely applied to the production of plastic spare parts which need to slide or rotate in the fields of machinery, building materials, sports and the like.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

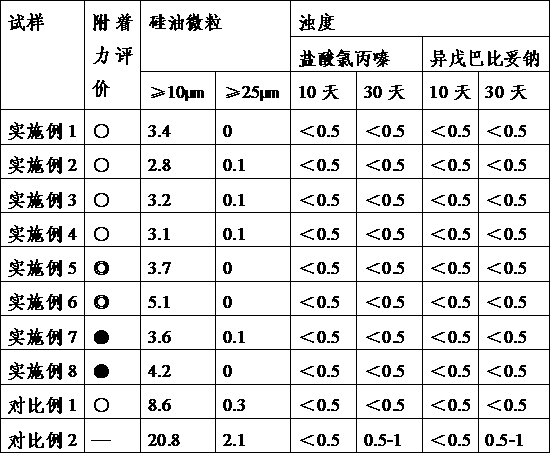

Preparation process of silicification-free rubber plug

ActiveCN107629240ALower requirementReduce surface friction coefficientCoatingsPrepolymerPolyvinylidene fluoride

The invention discloses a preparation process of a silicification-free rubber plug. The preparation method comprises the steps of compounding rubber, flaking rubber, molding, volcanizing and molding,cutting, washing and drying, and packaging, and further comprises the steps of sequentially coating a dimethylsiloxane prepolymer solution and a polyvinylidene fluoride resin dispersion on the surfaceof washed and dried rubber plug, and drying and curing coating layers, wherein the dimethylsiloxane prepolymer solution is mainly prepared from the following components in parts by weight: 1-5.5 parts of dimethylsiloxane prepolymer, 0.2-0.5 part of silane crosslinking agent, 100 parts of organic solvent A, and the polyvinylidene fluoride resin dispersion is mainly prepared from polyvinylidene fluoride resin emulsion containing 5-15% of solid and silicon rubber catalyst. The cured rubber plug has a compound coating layer, low surface friction coefficient, good anti-ultraviolet performance, chemical resistance and anti-aging performance, and the silicification process in preparation of the rubber plug is prevented.

Owner:江阴市海华橡塑有限公司

Method for extruding high viscosity content and extrusion device

InactiveCN101099957AReduce surface friction coefficientGuaranteed speed and qualityLiquid surface applicatorsLiquid spraying apparatusPistonEngineering

The present invention relates to high viscosity material extruding apparatus and process. The apparatus includes one expandable container, one outer cylinder and one cylinder cover. The container includes one straight barrel, one outlet and one piston set inside the straight barrel, and has its bottom connected airtightly to the bottom plate of the outer cylinder to avoid extrusion of compressed gas to the straight barrel. Under the action of both compressed air and the piston, the high viscosity material and the compressed gas push the side wall of the container outwards for expanding to increase the gap between the piston and the inner wall of the container for the high viscosity material to be filled in, so as to form a lubricant interface, decrease the friction between the piston and the inner wall of the container and raise the extruding speed and quality. Filling the gap with the high viscosity material can avoid compressed gas to enter the straight barrel and ensure the extrusion safety.

Owner:陈宜健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com