Cutting blade with improved coating structure and manufacturing method of cutting blade

A cutting insert and coating technology, applied in coating, turning equipment, tools for lathes, etc., can solve the problems of coating uniformity decline, performance decline, edge chipping, etc., to reduce cutting force and cutting heat, improve anti-oxidation performance, good effect of anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

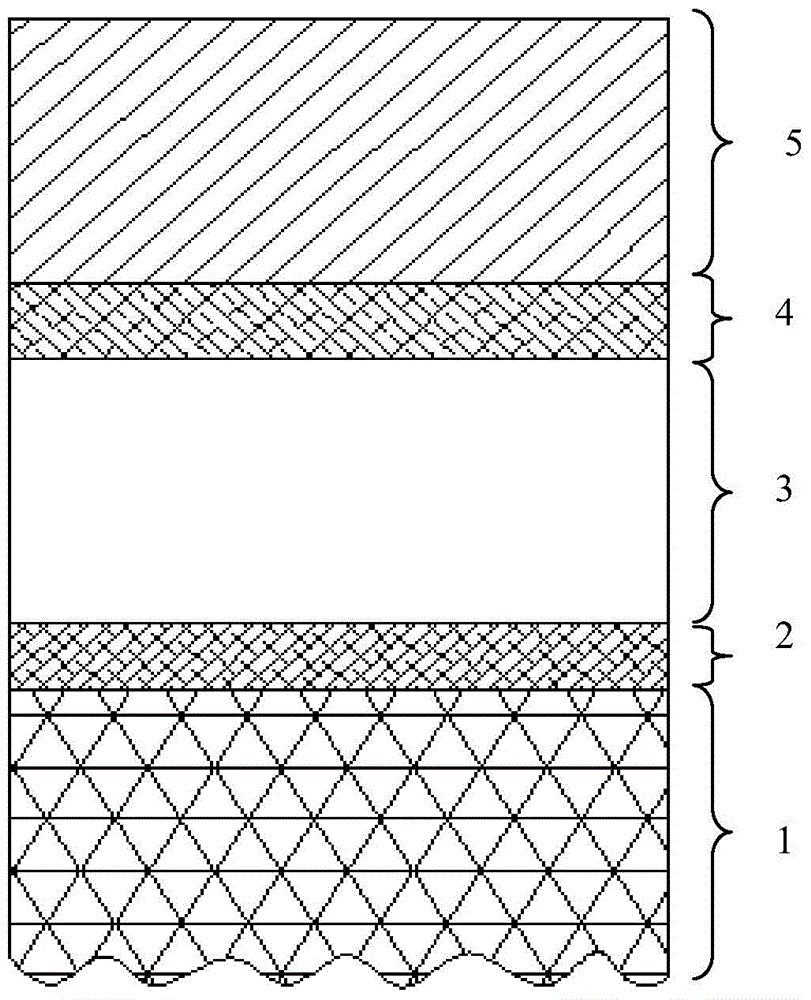

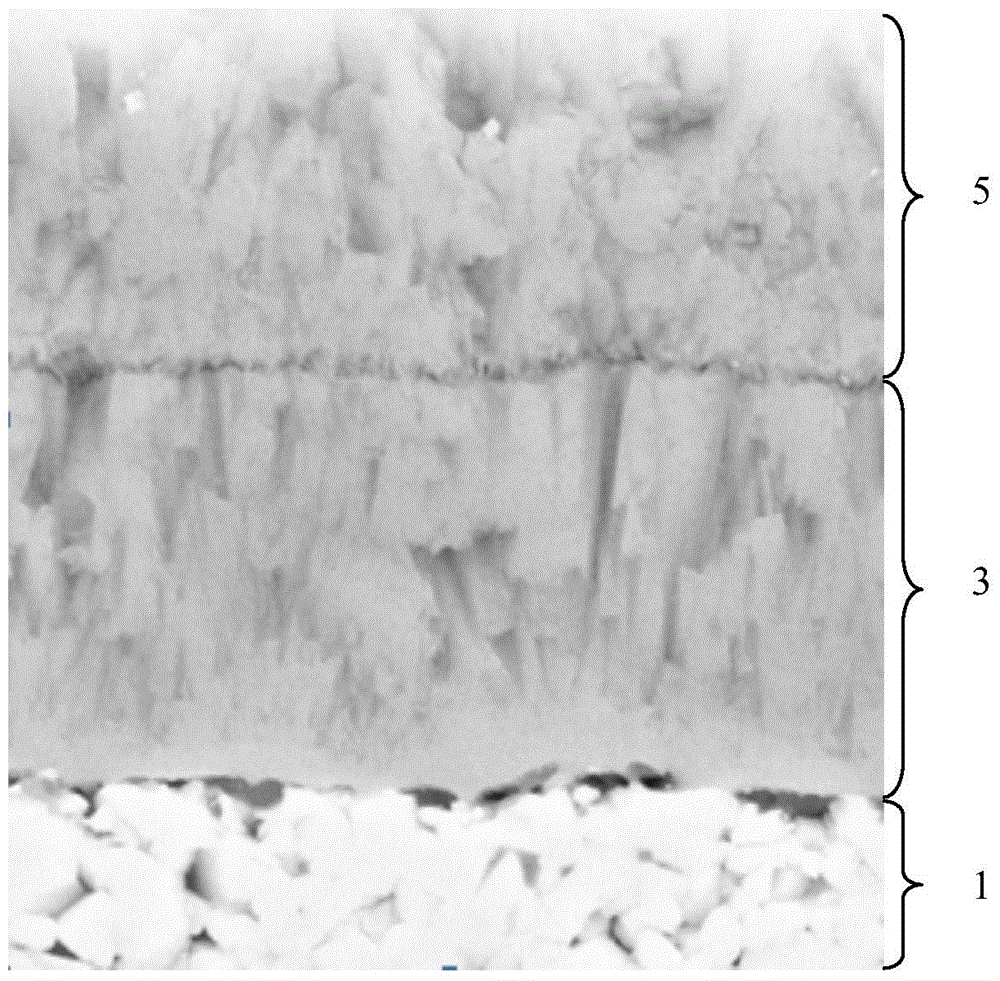

Embodiment 1

[0043] A cutting insert with improved coating structure of the present invention comprises a substrate A1 and a coating deposited on the substrate A1. The matrix A1 is cemented carbide, and its composition is 10wt% Co, 1wt% Ti and Ta cubic carbonitride, and the rest WC powder. Coating includes inner layer C3 as TiC x N y o z layer and the outer layer D5 is (Ti a Al b )(C i N j o k ) layer, in this embodiment, x=0.4, y=0.5, z=0.1, a=0.46, b=0.013, i=0.197, j=0.13, k=0.20, therefore, the inner layer C3 is TiC 0.4 N 0.5 o 0.1 layer, the outer layer D5 is (Ti 0.46 Al 0.013 )(C 0.197 N 0.13 o 0.20 )layer. The inner layer C3 has a thickness of 5 μm and has a face-centered cubic structure, and the outer layer D5 has a thickness of 5 μm and has a face-centered cubic structure. After the surface treatment of the outer layer D5, the surface residual stress δ is -1350MPa, and the surface roughness Ra on the length of 300μm is 0.18μm.

[0044] A method for preparing a cut...

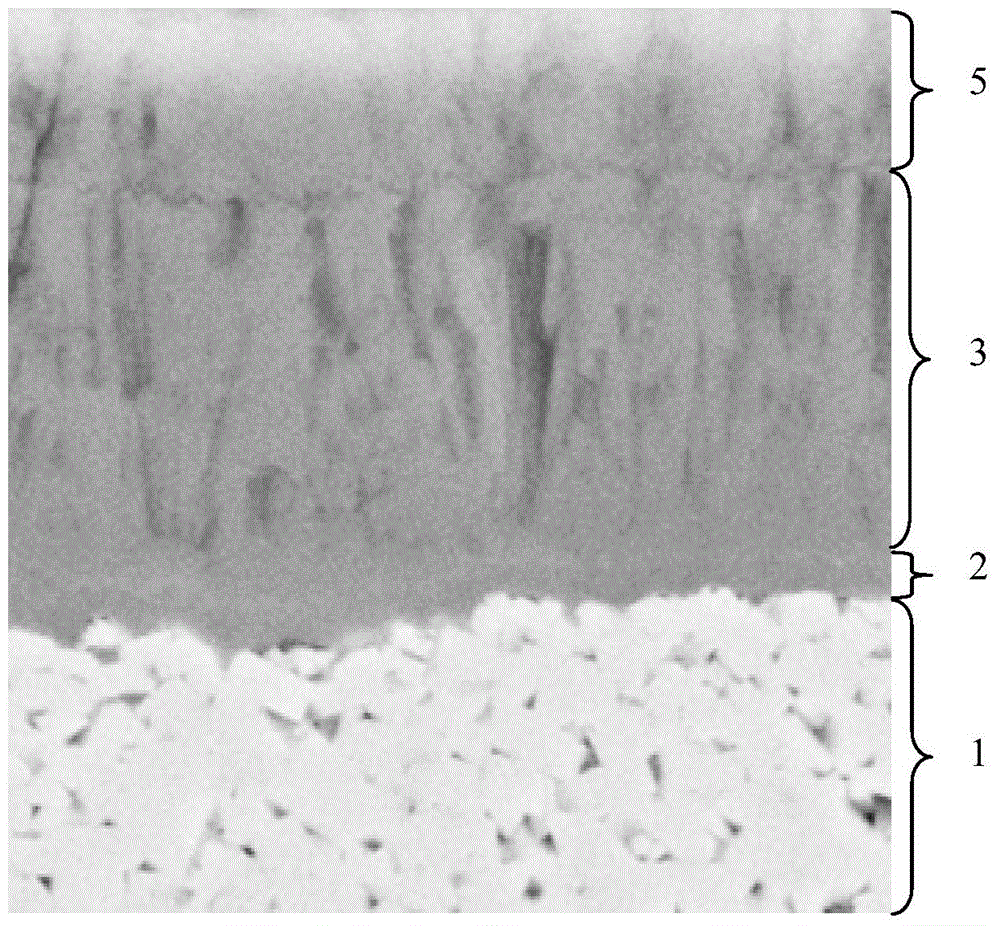

Embodiment 2

[0055] A cutting insert with improved coating structure of the present invention comprises a substrate A1 and a coating deposited on the substrate A1. The substrate A1 is cemented carbide, and its composition is the same as that of the substrate A1 in Example 1. The coating includes transition layer B2 as TiN layer and inner layer C3 as TiC x N y o z layer and the outer layer D5 is (Ti a al b )(C i N j o k ) layer, in this embodiment x=0.55, y=0.4, z=0.05, a=0.44, b=0.002, i=0.13, j=0.35, k=0.078, therefore, the inner layer C3 is TiC 0.55 N 0.4 o 0.05 layer, the outer layer D5 is (Ti 0.44 al 0.002 )(C 0.13 N 0.35 o 0.078 )layer. The inner layer C3 has a thickness of 5 μm and has a face-centered cubic structure; the outer layer D5 has a thickness of 2 μm and has a face-centered cubic structure. The transition layer B2 is TiN, which has a cubic crystal structure. The transition layer B2 mainly plays the role of optimizing the structure and improving the nucleation...

Embodiment 3

[0065] A cutting insert with improved coating structure of the present invention comprises a substrate A1 and a coating deposited on the substrate A1, the substrate A1 is cemented carbide, its composition is 8wt% Co, and the balance is WC powder. Coating includes inner layer C3 as TiC x N y o z layer, the outer layer D5 is (Ti a al b )(C i N j o k ) layer and the transition layer E4 between the inner layer C3 and the outer layer D5, in this embodiment, x=0.4, y=0.6, z=0, a=0.42, b=0.01, i=0.15, j=0.17, k=0.25, therefore, the inner layer C3 is TiC 0.4 N 0.6 layer, the outer layer D5 is (Ti 0.42 al 0.01 )(C 0.15 N 0.17 o 0.25 ) layer, and the transition layer E4 is TiCO coating. The inner layer C3 has a thickness of 6 μm and has a face-centered cubic structure; the outer layer D5 has a thickness of 1.8 μm and has a face-centered cubic structure. The transition layer E4 is a TiCO coating with a cubic crystal structure. The transition layer E4 mainly plays the role ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com