Method for extruding high viscosity content and extrusion device

A technology for extruding equipment and content, which is applied to the surface coating liquid device, liquid distribution, liquid injection device, etc., which can solve the problems of affecting the sealing effect, the resistance of the piston 3, the excessive wear of the sealing ring 7, etc., and achieve the reduction Effect of surface friction coefficient, guaranteed speed and quality, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

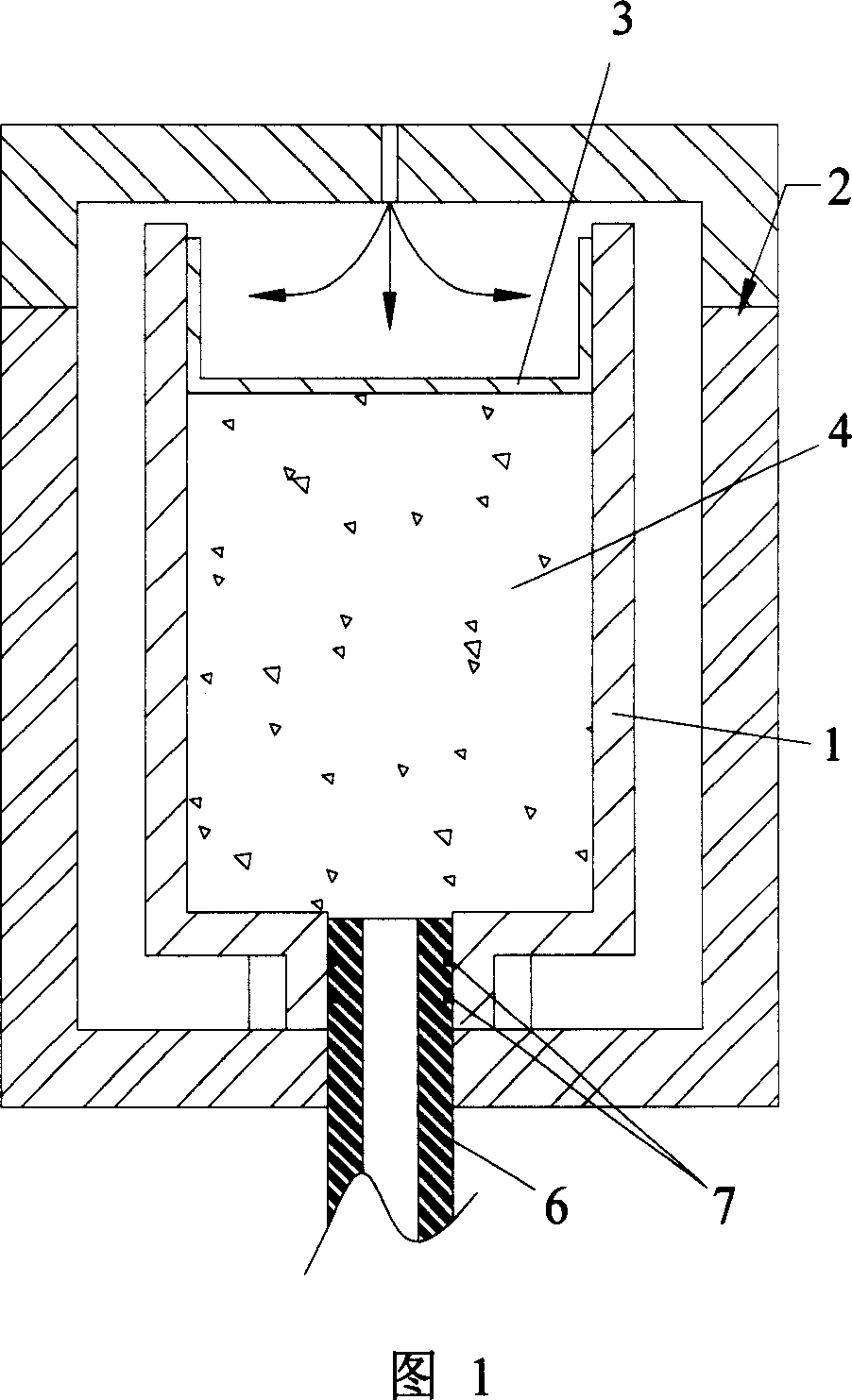

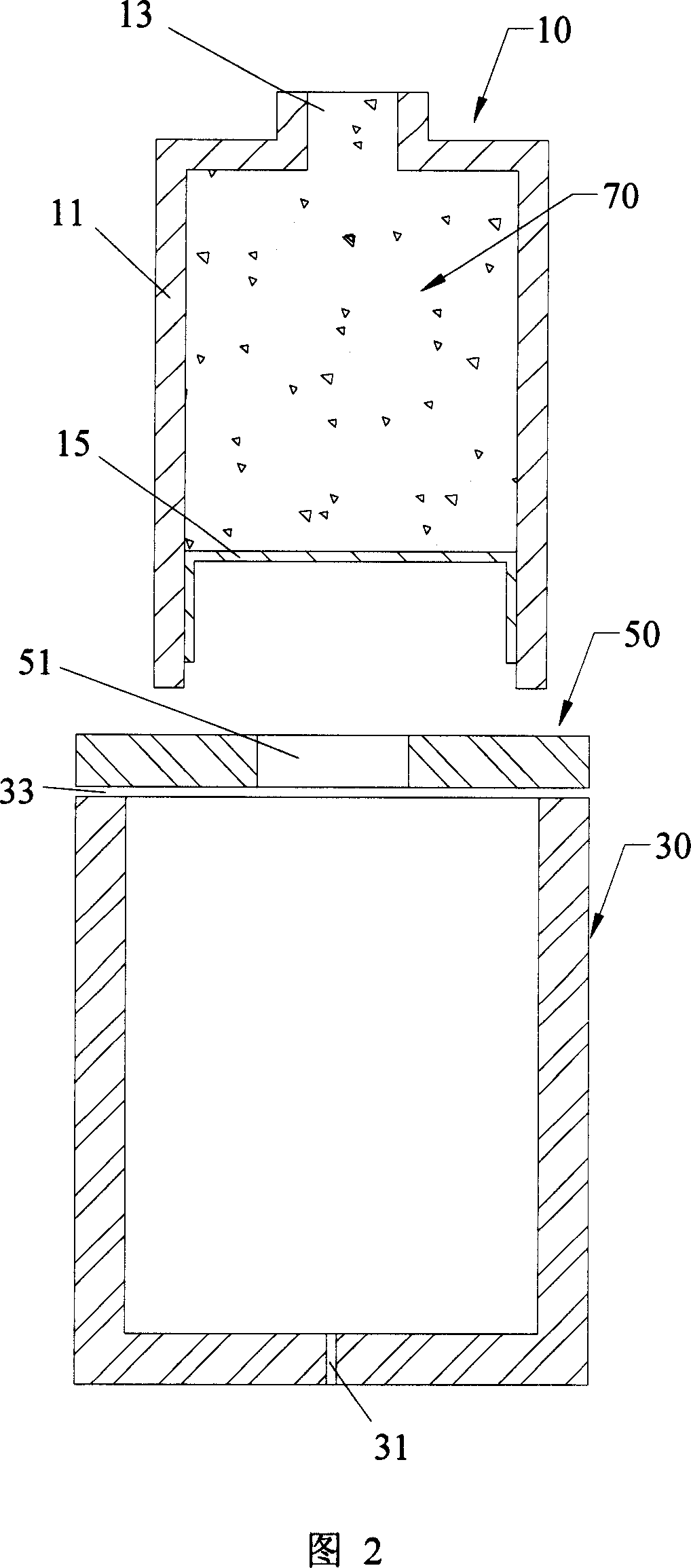

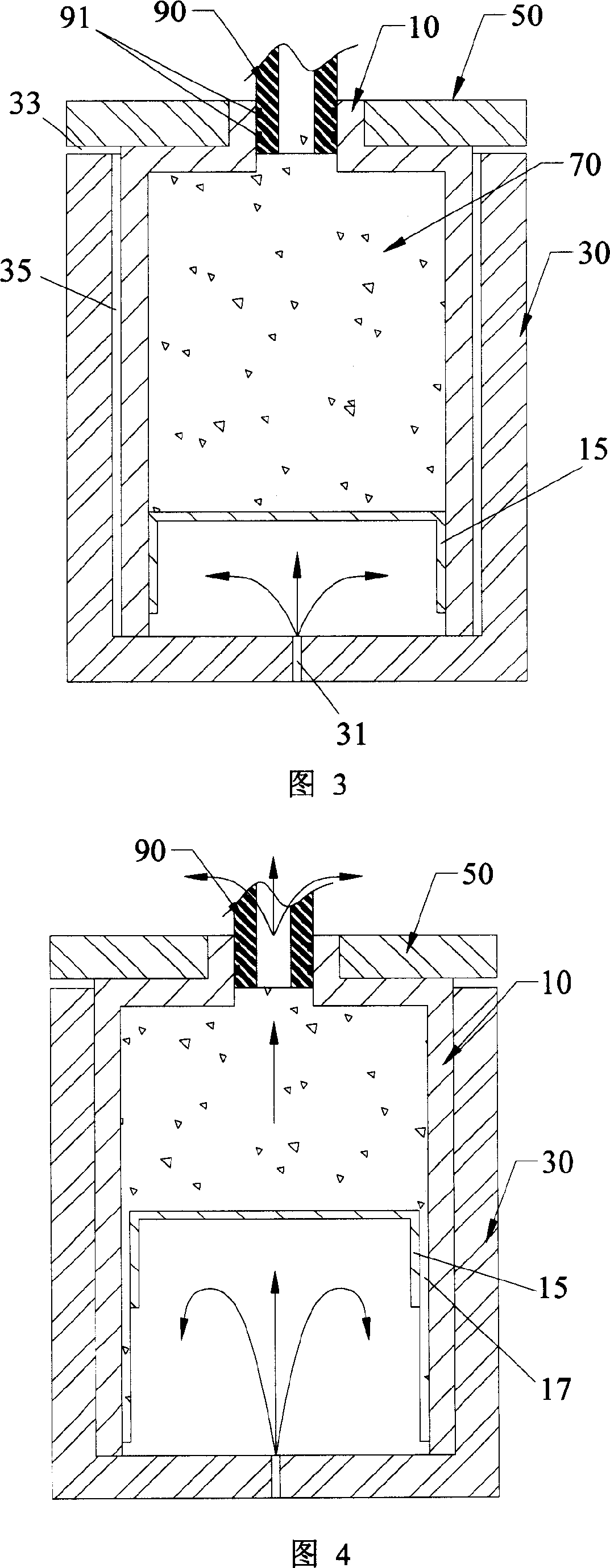

[0026] As shown in FIGS. 2 to 5 , the extrusion device for high-viscosity contents of the present invention includes an expandable container 10 , an outer cylinder 30 containing the expandable container 10 and a cover covering the open end of the outer cylinder 30 Body 50. In this embodiment, the expandable container 10 is a hollow cylinder, and correspondingly, the outer cylinder 30 and the cover 50 are also cylindrical; it can be understood that the shape can also be designed as an elliptical cylinder, Various shapes such as square barrels. The expandable container 10 may be a plastic cylinder or a cylinder made of other expandable materials.

[0027] The expandable container 10 is filled with a content 70 , and the content 70 is a high-viscosity fluid, such as room-temperature-curing glue, thermal paste, and other high-viscosity, poor-fluidity substances. The expandable container 10 includes a straight cylinder portion 11 , an outlet 13 disposed at one end of the straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com