PVC artificial leather and preparation method thereof as well as car seat containing PVC artificial leather

An artificial leather and temperature control technology, applied in the field of automotive interior materials, can solve the problems of wear resistance, poor air permeability, easy wear and tear, and achieve the effect of high strength residual, environmental protection, and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The PVC artificial leather of the present embodiment comprises a base cloth layer 1, a PVC adhesive layer 2, a PVC foam layer 3, a PVC dense layer 4, and a surface layer 5 arranged sequentially from bottom to top. The preparation method of the above-mentioned PVC artificial leather includes The following steps:

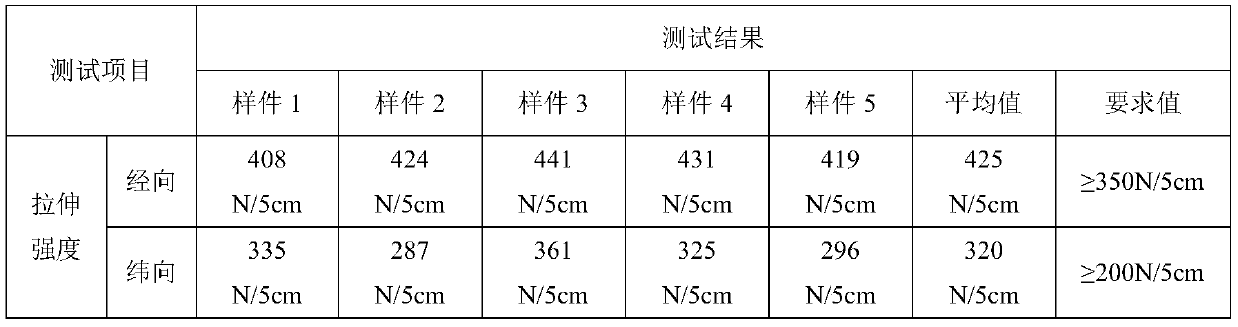

[0040] 1) Material preparation: configure PVC adhesive layer slurry, PVC foam layer slurry, PVC dense layer slurry, adhesive layer slurry, and surface coating slurry according to the formula, and select base cloth and release paper according to product needs. 3D high-density base fabric with an area density of 280g / m 2 , two-way breaking strength ≥ 900N / 5cm, elongation at break ≥ 120%;

[0041] The preparation method of the PVC adhesive layer slurry is as follows: weigh 100 parts of polyvinyl chloride (K value is 55), 55 parts of plasticizer (plasticizer 911), and 1 part of calcium zinc stabilizer in parts by weight. 1 part of AC foaming agent, mix and stir f...

Embodiment 2

[0067] The PVC artificial leather of the present embodiment comprises a base cloth layer 1, a PVC adhesive layer 2, a PVC foam layer 3, a PVC dense layer 4, and a surface layer 5 arranged sequentially from bottom to top. The preparation method of the above-mentioned PVC artificial leather includes The following steps:

[0068] 1) Material preparation: configure PVC adhesive layer slurry, PVC foam layer slurry, PVC dense layer slurry, adhesive layer slurry, and surface coating slurry according to the formula, and select base cloth and release paper according to product needs. 3D high-density base fabric with an area density of 340g / m 2 , two-way breaking strength ≥ 900N / 5cm, elongation at break ≥ 120%;

[0069] The preparation method of the PVC adhesive layer slurry is as follows: weigh 100 parts of polyvinyl chloride (K value is 65), 75 parts of plasticizer (plasticizer 911), and 2.5 parts of calcium zinc stabilizer in parts by weight. , 2 parts of AC foaming agent, mixed an...

Embodiment 3

[0096] The PVC artificial leather of the present embodiment comprises a base cloth layer 1, a PVC adhesive layer 2, a PVC foam layer 3, a PVC dense layer 4, and a surface layer 5 arranged sequentially from bottom to top. The preparation method of the above-mentioned PVC artificial leather includes The following steps:

[0097] 1) Material preparation: configure PVC adhesive layer slurry, PVC foam layer slurry, PVC dense layer slurry, adhesive layer slurry, and surface coating slurry according to the formula, and select base cloth and release paper according to product needs. 3D high-density base fabric with an area density of 400g / m 2 , two-way breaking strength ≥ 900N / 5cm, elongation at break ≥ 120%;

[0098]The preparation method of the PVC adhesive layer slurry is specifically: weigh 100 parts of polyvinyl chloride (K value is 75), 90 parts of plasticizer (plasticizer DPHP), 5 parts of calcium zinc stabilizer by weight , 3 parts of AC foaming agent, mixed and stirred for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com