Concrete protective agent and preparation method thereof

A protective agent and concrete technology, applied in coatings, climate change adaptation, reflective/signal coatings, etc., can solve problems such as reducing heat absorption, achieve the effects of reducing heat absorption, reducing heat island effect, and not easy to transfer heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

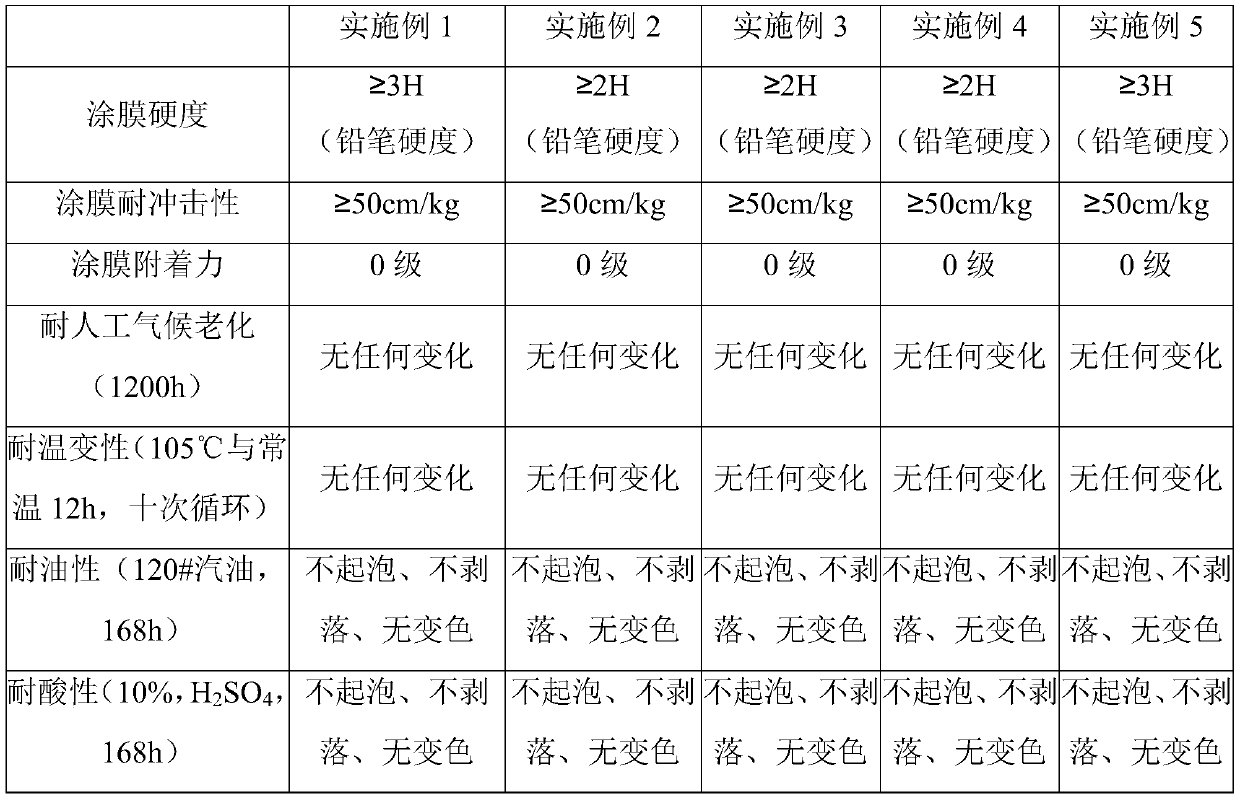

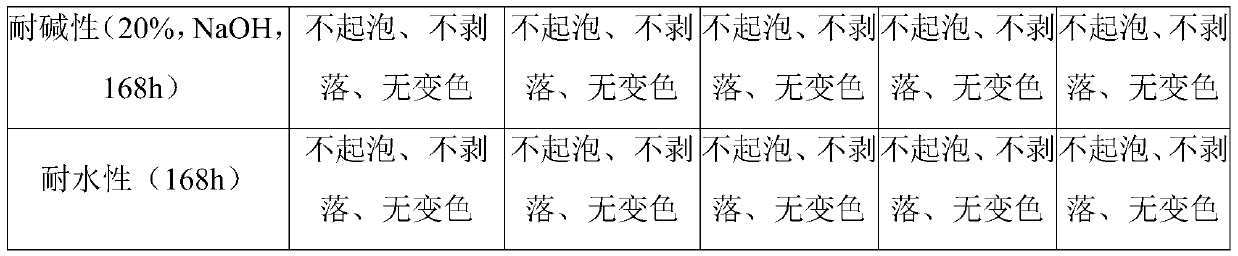

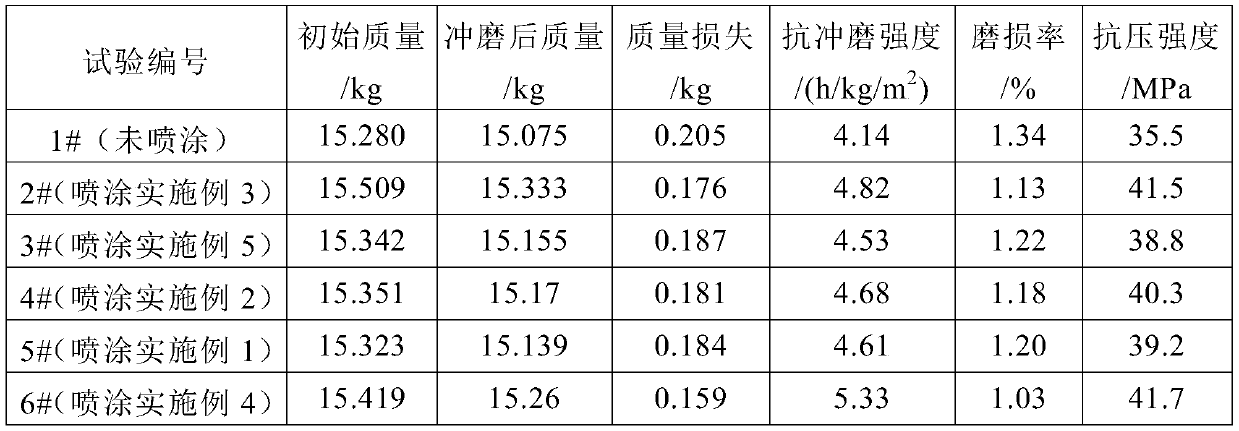

Examples

preparation example Construction

[0067] Further, an embodiment of the present invention provides a method for preparing a concrete protective agent, comprising the following steps:

[0068] 1) Stir the resin with a high-speed disperser, then add diluent, anti-corrosion agent and cooling agent, continue high-speed stirring to obtain a mixture, and grind the mixture through a sand mill until the particle size is less than or equal to 15 μm; add dispersant, Defoamer, obtains finished product A;

[0069] 2) Stir and disperse the curing agent, diluent, accelerator, dispersant and defoamer at high speed to make finished product B;

[0070] 3) The concrete protective agent is prepared by mixing finished product A and finished product B according to the weight ratio of resin to curing agent of 4.5:1-5.5:1.

[0071] In a preferred embodiment of the present invention, the mass fraction of the resin is 40-60 parts, and the resin is selected from epoxy (meth)acrylate epoxy resin.

[0072] In some embodiments, the mass ...

Embodiment 1

[0092] This embodiment provides a concrete protective agent, which comprises the following components in parts by mass: 50 parts of epoxy (meth)acrylate epoxy resin, 12 parts of silicon nitride, 8 parts of hollow glass microspheres, alkylene 9 parts of glycidyl ether, 0.2 part of solsperse, 0.2 part of polysiloxane, 20.55 parts of 651 low molecular weight polyamide, 0.05 part of DMP-30.

[0093] The concrete protective agent of the present embodiment is prepared by the following method:

[0094]1) Stir the epoxy (meth)acrylate epoxy resin with a high-speed disperser, then add alkylene glycidyl ether, silicon nitride and glass microspheres, continue high-speed stirring to obtain a mixture, and pass the mixture through Grind with a sand mill until the particle size is less than or equal to 15 μm; add solsperse and polysiloxane to obtain finished product A;

[0095] 2) 2) Mix and disperse 651 low molecular weight polyamide, alkylene glycidyl ether, DMP-30, solsperse and polysilo...

Embodiment 2

[0098] This embodiment provides a concrete protective agent, comprising the following components in parts by mass: 60 parts of epoxy (meth)acrylate epoxy resin, 7 parts of silicon carbide, 12 parts of hollow glass microspheres, methyl glycidol 10 parts of ether, 0.2 parts of solsperse, 0.2 parts of polysiloxane, 10.5 parts of 304 low molecular weight polyamide, 0.1 part of DMP-30.

[0099] The concrete protective agent of the present embodiment is prepared by the following method:

[0100] 1) Stir the acrylic epoxy resin with a high-speed disperser, then add methyl glycidyl ether, silicon carbide and glass beads, continue high-speed stirring to obtain a mixture, and grind the mixture through a sand mill until the particle size is less than or equal to 15 μm ; Add solsperse and polysiloxane to obtain finished product A;

[0101] 2) 304 low molecular weight polyamide, methyl glycidyl ether, DMP-30, solsperse and polysiloxane are dispersed at high speed to make finished product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com