Preparation process of silicification-free rubber plug

A preparation process and technology for rubber stoppers, which are applied in the field of preparation of silicone-free rubber stoppers, can solve the problems of uniform coating on the surface of unfavorable rubber stoppers, the film is easy to fall off, and the adhesion of the film material is not strong. Good aging performance, excellent chemical corrosion resistance and temperature resistance, the effect of solving friction and bottle mouth jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

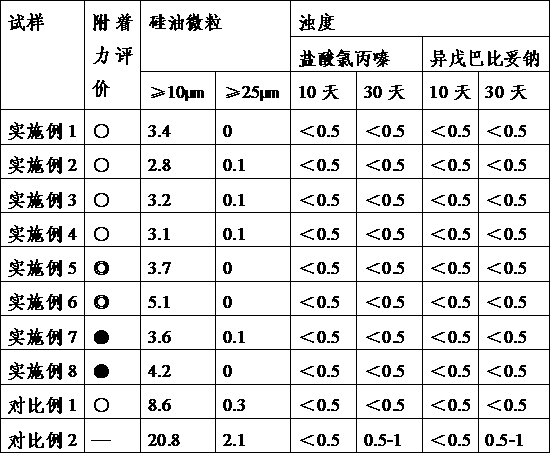

Examples

Embodiment 1

[0022] Example 1 The preparation process of silicon-free rubber stoppers, including rubber mixing, rubber sheeting, molding, vulcanization, slitting, cleaning and drying, and packaging steps, and also includes sequentially coating polydimethylformaldehyde on the surface of the cleaned and dried rubber stoppers. base siloxane prepolymer solution and polyvinylidene fluoride resin dispersion and coating drying and curing steps;

[0023] Wherein, the main components of polydimethylsiloxane prepolymer solution are end-blocked polydimethylsiloxane prepolymer, silane crosslinking agent and organic solvent;

[0024] The main components of the polyvinylidene fluoride resin dispersion are polyvinylidene fluoride resin emulsion with a solid content of 5-15% and a silicone rubber catalyst.

[0025] The polydimethylsiloxane prepolymer solution is composed of 100 parts of hydroxyl-terminated polydimethylsiloxane, 30 parts of coupling agent and 2500 parts of organic solvent A in the rubber s...

Embodiment 2

[0028] The difference between Example 2 and Example 1 is that it includes 1 part of end-blocked polydimethylsiloxane prepolymer, 0.5 part of silane crosslinking agent and 100 parts of organic solvent A in parts by weight, polyvinylidene fluoride resin dispersion The weight percentage of the silicone rubber catalyst in the liquid is 0.001%; the main composition of the polyvinylidene fluoride resin dispersion is the polyvinylidene fluoride resin emulsion and the silicone rubber catalyst with a solid content of 15%, and the silicone rubber in the polyvinylidene fluoride resin dispersion The weight percentage of the catalyst is 0.001%.

[0029] The drying temperature of the coating is 160°C. The curing of the coating includes two steps of room temperature curing and high temperature curing in sequence. The room temperature curing time is 36 hours, the high temperature curing temperature is 200°C, and the high temperature curing time is 5-10 minutes. Organic solvent A is acetone....

Embodiment 3

[0030] The difference between Example 3 and Example 1 is that it includes 5.5 parts of end-blocked polydimethylsiloxane prepolymer, 0.2 part of silane crosslinking agent and 100 parts of organic solvent A in parts by weight, polyvinylidene fluoride resin dispersion The weight percentage of the silicone rubber catalyst in the liquid is 0.005%; the main composition of the polyvinylidene fluoride resin dispersion is the polyvinylidene fluoride resin emulsion and the silicone rubber catalyst with a solid content of 5%, and the silicone rubber in the polyvinylidene fluoride resin dispersion The weight percent of the catalyst is 0.005%.

[0031] The drying temperature of the coating is 180°C. The curing of the coating includes two steps of room temperature curing and high temperature curing in sequence. The room temperature curing time is 12 hours, the high temperature curing temperature is 230°C, and the high temperature curing time is 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com