Continuous preparation device and method for fuel cell membrane electrode

A technology for fuel cells and preparation devices, applied in fuel cells, electrochemical generators, sustainable manufacturing/processing, etc., can solve problems such as effective control of the operation and processing of proton exchange membranes, cost waste, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0132] The preparation method of the fuel cell CCM membrane electrode that the present invention proposes comprises the following steps:

[0133] It can adapt to the continuous roll-to-roll processing of proton exchange membranes of various materials, and its processing process covers double-sided pretreatment, coating, testing, laminating, quality control, cutting and other processes;

[0134] It can adapt to the continuous roll-to-roll processing of proton exchange membranes of various thicknesses, including the continuous roll-to-roll processing of proton exchange membranes with extremely thin thickness and close to the limit of mechanical properties. The processing process covers double-sided pretreatment, coating, Inspection, lamination, quality control, cutting and other processes;

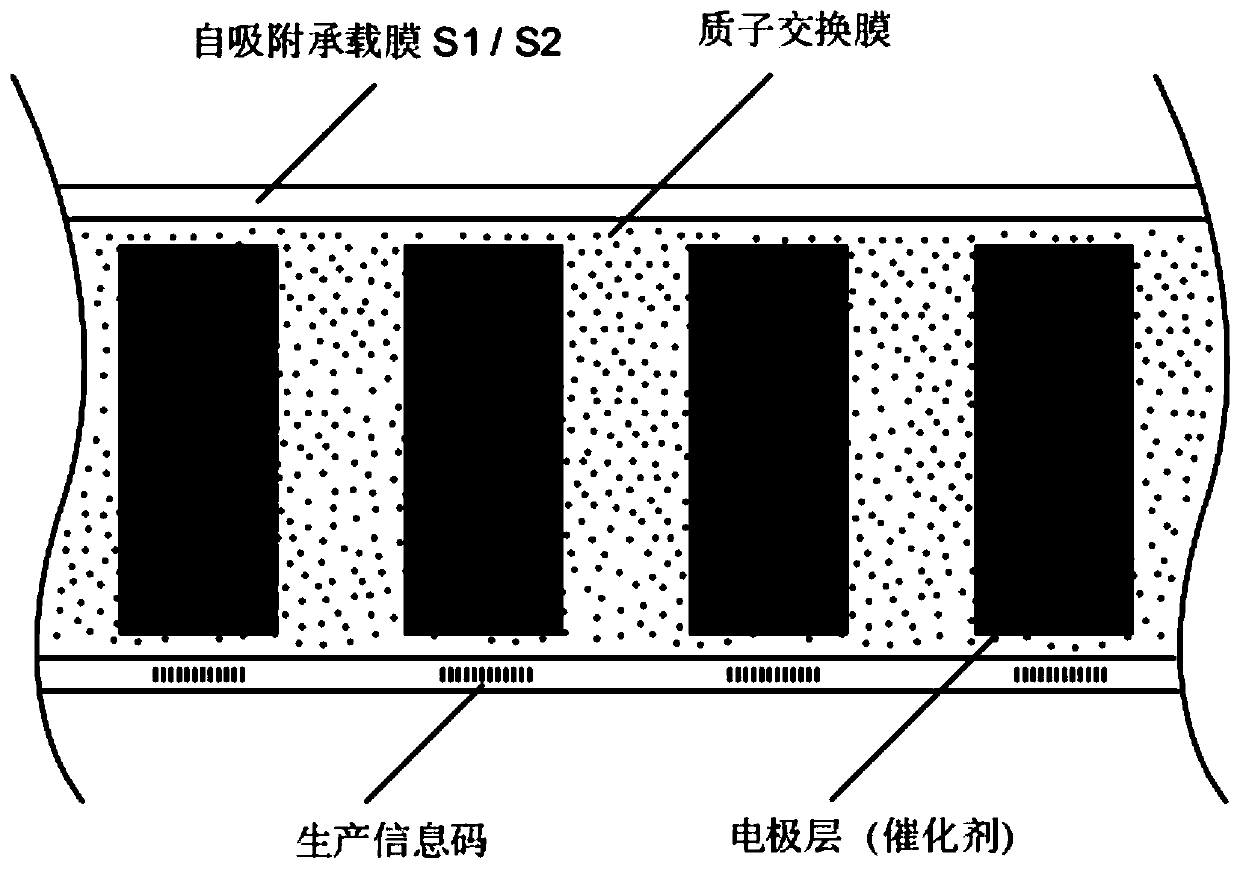

[0135] In the whole process of continuous roll-to-roll processing, a self-absorbing carrier film is used as the carrier conveying system and production data recording medium to achieve preci...

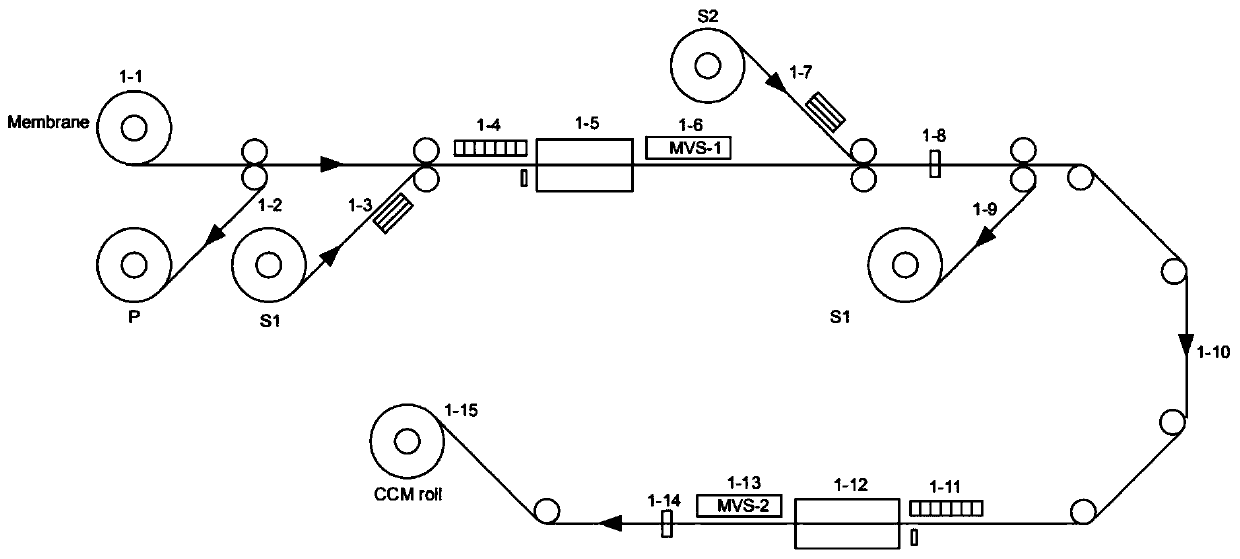

Embodiment 1

[0217] In this embodiment, the original state of the proton exchange membrane is a roll. Before the electrode layer A is coated, the original roll-shaped proton exchange membrane is linearly conveyed by the raw material unwinding device. The front side of the proton exchange membrane released in the original roll shape is defined as the A side, and the other side has the original protective film P. In this embodiment, the side with the original protective film P is defined as the B side of the proton exchange membrane.

[0218] This embodiment provides a continuous CCM membrane electrode preparation method, which is implemented through the following technical solutions:

[0219] 1) peeling off the original protective film P of the proton exchange membrane;

[0220] 2) Attaching the self-adsorption supporting membrane S1 on the B side of the proton exchange membrane;

[0221] 3) Coating and drying the electrode layer A on the A side of the proton exchange membrane;

[0222] 4...

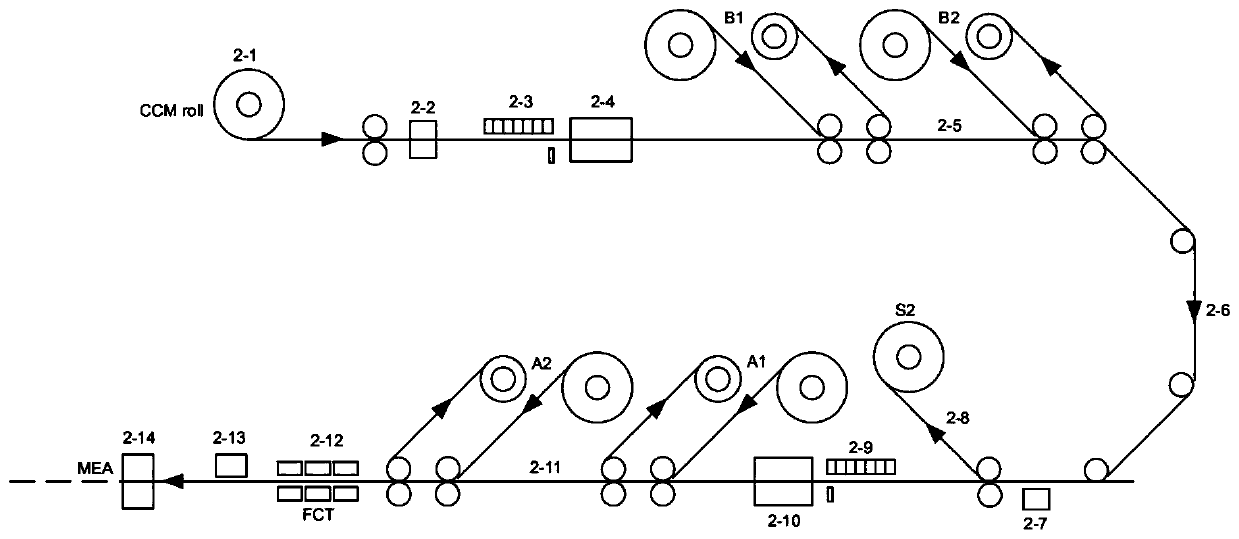

Embodiment 2

[0237] The preparation method of the continuous CCM membrane electrode of this embodiment comprises the following steps:

[0238] 1) Peel off the original bottom membrane P on the B side of the proton exchange membrane, and attach the self-absorbing carrier film S1. When bonding, apply a voltage and current intensity of 20KV / 500mA to 50KV / 1000mA on the self-adsorbing carrier film S1, and the polarity of the electric field It is the positive electrode or the negative electrode, and after lamination, it forms an easy-to-transport whole with the proton exchange membrane;

[0239] Wherein, the self-absorbing carrier film S1 undergoes at least one of surface activation treatment, physical processing treatment, and chemical method treatment to make it surface purified and kept transparent / close to transparent, and does not contain any adhesives and other substances that cause adhesion. , polluting substances;

[0240] Among them, the release action of the self-absorbing carrier fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com