Two-way linear easy-to-tear polyethylene film and production process thereof

A polyethylene film and production process technology, applied in the field of packaging film materials, can solve the problems of general linear tearability, low tensile strength, poor mechanical properties, etc., and achieve excellent linear tearability, high tensile strength, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0037] Raw material source:

[0038] Low-density polyethylene: LDPE, produced by Sinopec, brand 4533H, melting finger melting finger 4.0g / 10min, density 0.932g / cm 3 ;

[0039] Low-density polyethylene: LDPE, produced by Exxon, brand 100AC, melt index 2.0g / 10min, density 0.923g / cm 3 ;

[0040] Polybutene: produced by Basel, brand PB0110, melt index 12.0g / 10min, density 0.914g / cm 3 ;

[0041] High-density polyethylene: HDPE, produced by Exxon Company, the brand is HMA025, the melt index is 8.0g / 10min, and the density is 0.964g / cm 3 ;

[0042] Processing aid: produced by Beijing Yalun, the brand is DS-A1058LD;

[0043] Open-ended masterbatch: produced by Beijing Yalun, the brand is AB-20LD;

[0044] Slippery agent: produced by Ann Color, the brand is 10090-k.

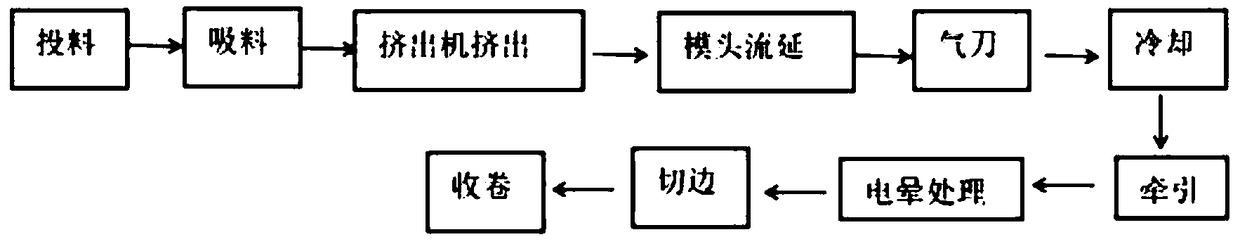

[0045] The production process of the two-way linear easy-tear polyethylene film of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com