Environment-friendly thermoplastic polyolefin (TPO) auto interior material and preparation method thereof

A technology for automotive interiors and interior materials, applied in the field of TPO automotive interior materials and its preparation, can solve the problems of poor decoration and poor touch of hard instrument panels, and achieve good decoration, high bonding strength and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

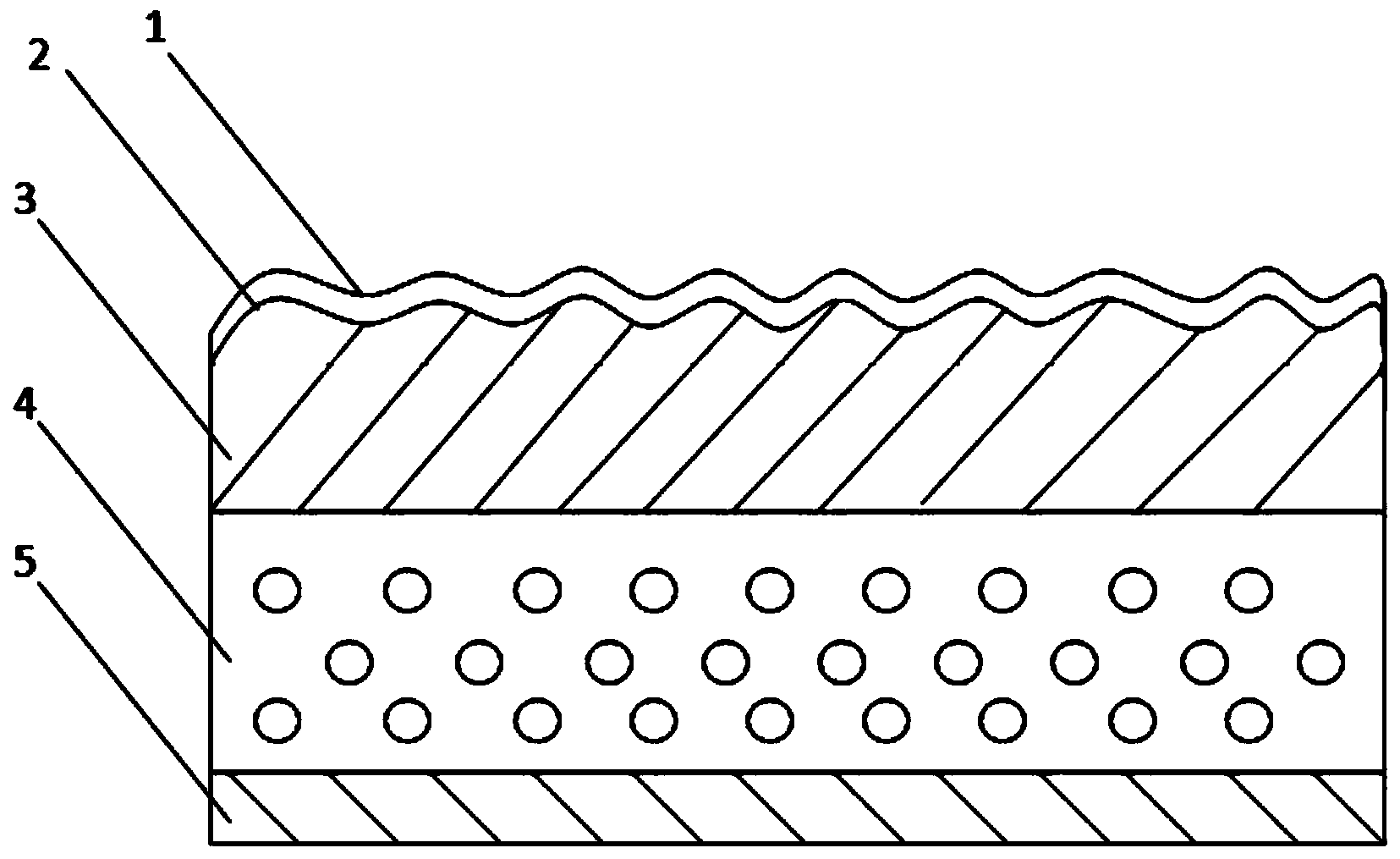

[0028] Such as figure 1 As shown, an environment-friendly TPO automotive interior material includes a TPO surface layer 3, a polypropylene foam layer 4 composited with the TPO surface layer, and the TPO surface layer 3 is also covered with a surface treatment agent layer 1 and a bottom surface treatment agent from top to bottom. Layer 2. Polypropylene foam layer 4 is coated with polyurethane adhesive 5 on the back. Among them, the surface treatment agent is water-based or solvent-based two-component polyurethane or polyurethane-polycarbonate; the bottom surface treatment agent is solvent-based or water-based two-component polyurethane or polyurethane-polycarbonate.

[0029] The thickness of the polypropylene foam layer of the present invention has four specifications of 1.0, 1.5, 2.0, 2.5, and 3.0 mm, the width is from 550 to 1350 mm, and the expansion ratio is 15 times or 20 times or 25 times or 30 times. It depends on different usage locations and usage requirements.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com