Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

294results about How to "Good matting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

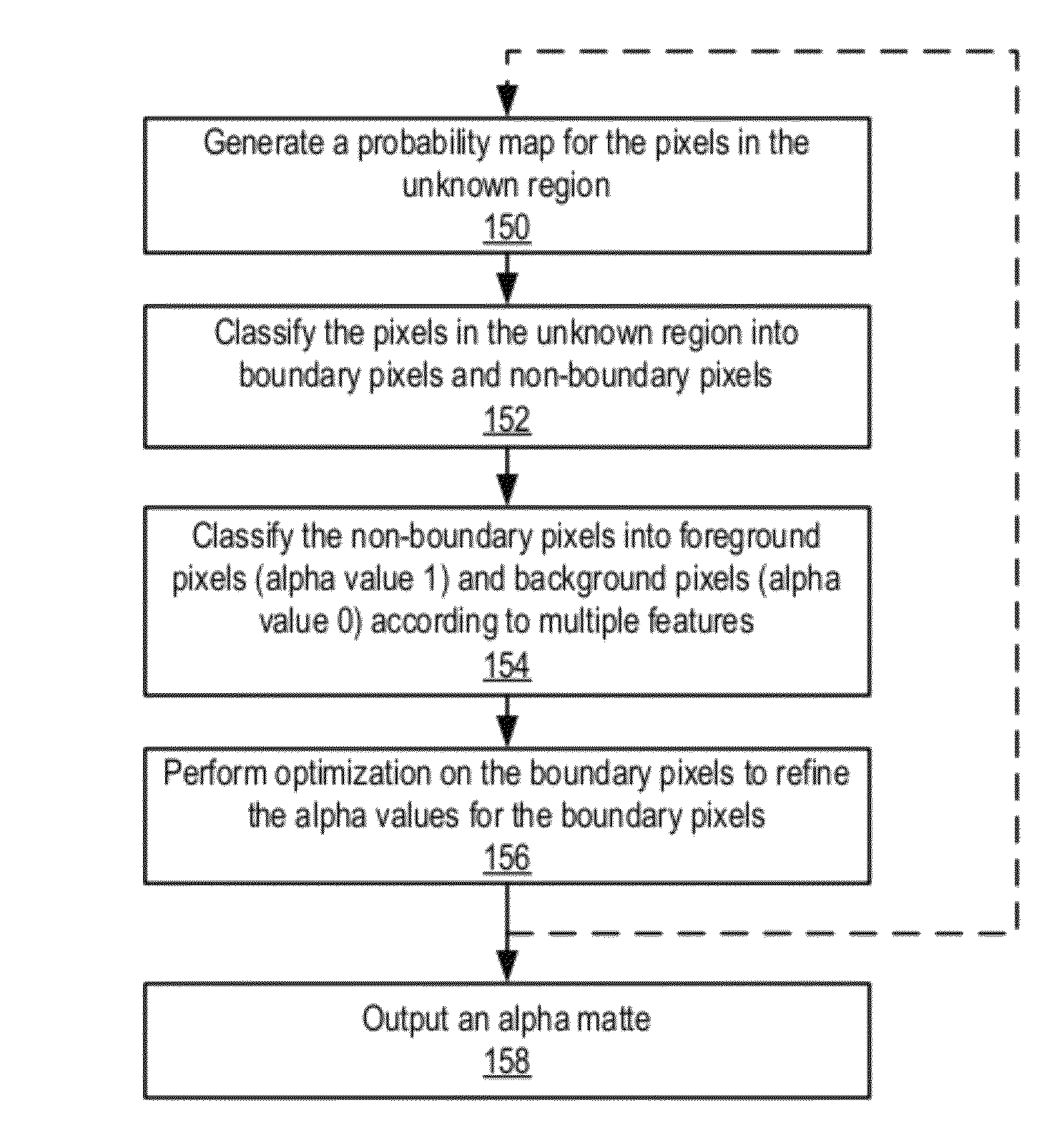

Method and apparatus for discriminative alpha matting

ActiveUS8175384B1Promote resultsThe result is accurateImage enhancementImage analysisBinary segmentationComputer vision

Method and apparatus for creating foreground masks, or mattes, in images including complex images. A discriminative matting technique may generate accurate alpha mattes for textured images or objects with spatial-varying color distributions. Given an input image and a trimap defining an unknown region, a discriminative color analysis is applied to the unknown region, yielding estimated alpha values, estimated binary segmentation values, and a mixture probability map for the region. The map may be adaptively smoothed. The pixels in the unknown region are classified into boundary pixels and non-boundary pixels according to the probability map. The non-boundary pixels are classified as either foreground or background pixels using a differencing technique that compares multiple pixel features. The estimated alpha values for the boundary pixels are refined. An alpha matte for the image is output. The process may be repeated until convergence of the alpha matte.

Owner:ADOBE INC

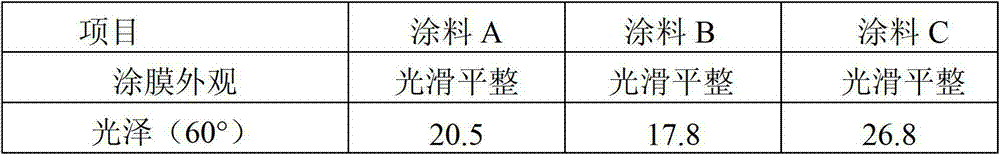

Mixed polyester resin for matte powder coatings and preparation thereof

InactiveCN101205293ALiquefiedSuitable glass transition temperaturePowdery paintsPolyester coatingsEpoxyPolyol

The invention discloses a mixed polyester resin for matte powder coating, which is obtained through the melting polycondensation by using the components with the following weight fraction: 23 percent to 50 percent of polyol, 35 percent to 65 percent of aromatic polybasic acid, 0 percent to 10 percent of fat polybasic acid, 0 percent to 2 percent of branching agent, 10 percent to 20 percent of acidulate agent and 0.01 percent to 0.15 percent of esterification catalyst. The invention also discloses a preparation method for a mixed polyester resin for matte powder coating. The polyester resin prepared through the method of the invention has the advantages of proper glass transition temperature,softening temperature, good storage stability, low cost, etc., and the matte powder coating with a gloss lower than 30 percent can be obtained by mixing the polyester resin with a certain proportion of the epoxy resin,stuffing, paint, flatting agent and matting agent and then melting, extruding, grinding and cribrating the mixtures and the obtained polyester resin has an outstanding mechanical performance and flatting effect.

Owner:GUANGZHOU QINGTIAN INDAL

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

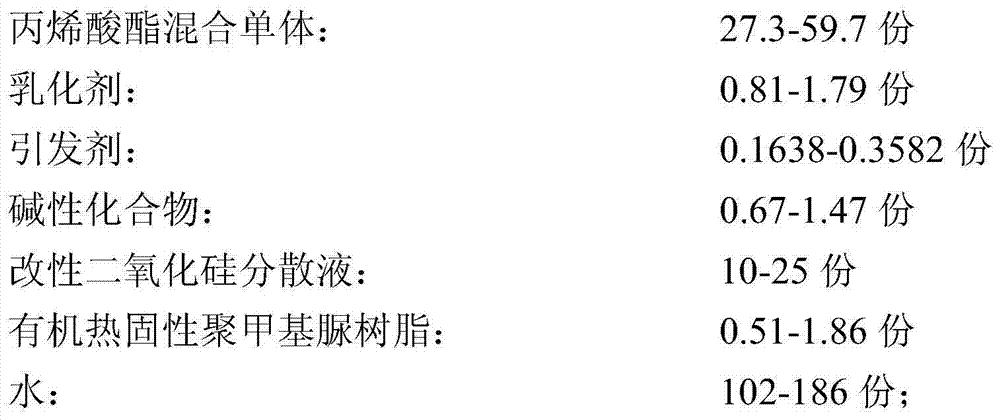

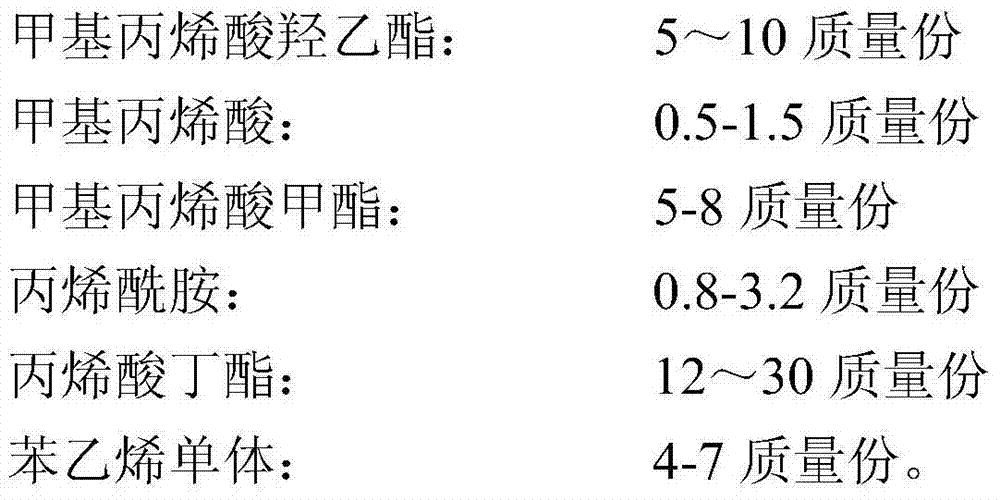

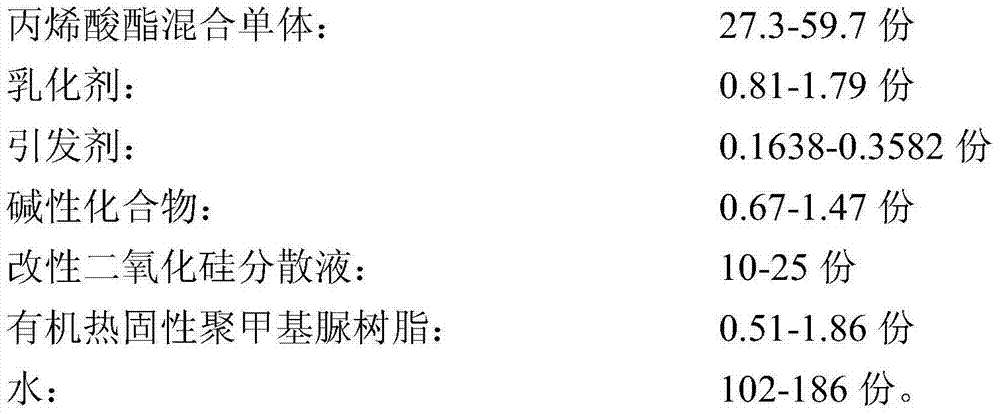

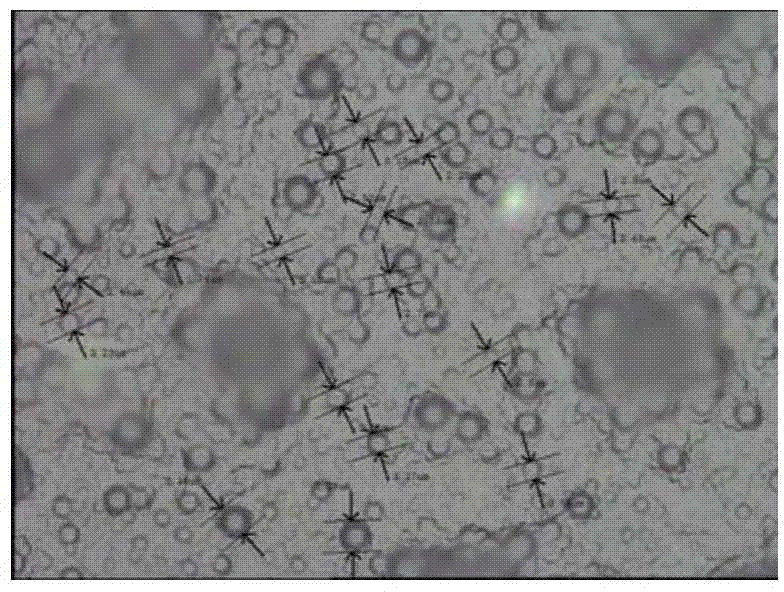

Aqueous multi-functional crylic acid extinction resin and preparation method thereof

The invention discloses an aqueous multi-functional crylic acid extinction resin and a preparation method thereof and belongs to the field of extinction type coatings. The preparation method of the aqueous multi-functional crylic acid extinction resin comprises the following steps: (1) preparing a crylic acid ester mixture monomer; (2) sufficiently mixing water, an emulsifier and a part of the crylic acid ester mixture monomer, heating to 70-90 DEG C, adding an initiator to react for 0.5-1 hour, dropwise adding the rest crylic acid ester mixture monomer within 3-5 hours, adding the rest initiator in different batches, performing heat preservation for 1-3 hours after the dropwise adding, cooling to 45 DEG C, sequentially adding modified silicon dioxide and an organic thermosetting polymethylurea resin with the particle size of 3.5mu m, uniformly stirring, cooling down and discharging so as to obtain the aqueous multi-functional crylic acid extinction resin. The aqueous multi-functional crylic acid extinction resin prepared by the preparation method disclosed by the invention is high in extinction efficiency, excellent in water resistance, acid resistance and alkali resistance, and good in abrasion resistance property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Environment-friendly thermoplastic polyolefin (TPO) auto interior material and preparation method thereof

InactiveCN103965800AImprove the decorative effectSmall smellLamination ancillary operationsFilm/foil adhesivesEnvironmental resistancePolyolefin

The invention provides an environment-friendly thermoplastic polyolefin (TPO) auto interior material comprising a TPO surface layer, and a polypropylene foam layer which is compounded with the TPO surface layer, wherein the TPO surface layer is formed by semi-crosslinked TPO, polypropylene, polyethylene, a light stabilizer, an antioxidant, a fire retardant, a filler, an extinction material, a scratch resistant agent and a pigment. The TPO auto interior material disclosed by the invention has the advantages of being good in decorative property, environment-friendly and recoverable, low in odor, low in haze, high and low temperature resistant, weather-resistant, free of separated bloom, good in machinability, high in qualification rate, low in cost, and high in bonding strength with a skeleton, and still can keep good matting property and scratch resistance after being scrubbed.

Owner:TIANJIN DALIN NEW MATERIAL TECH

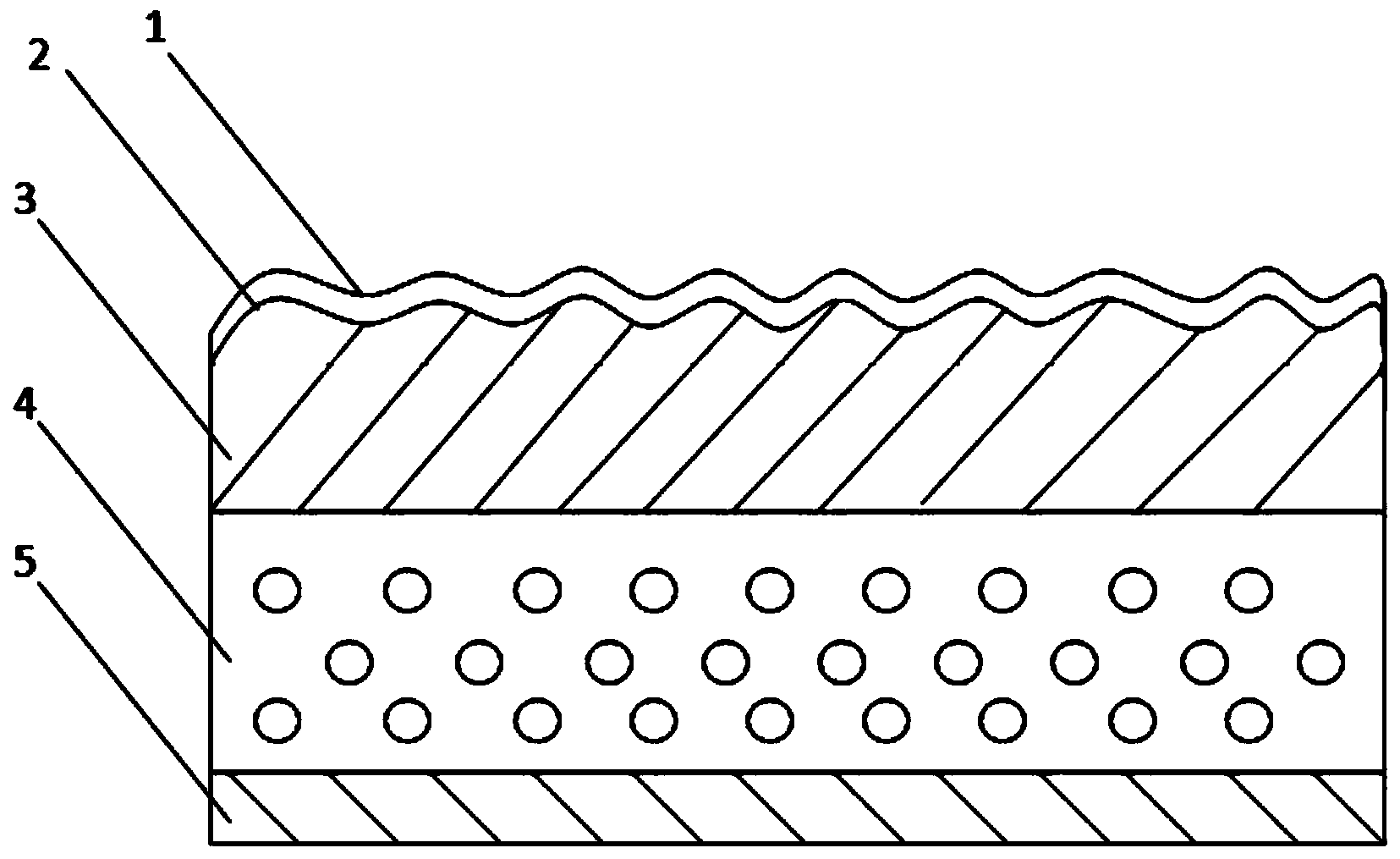

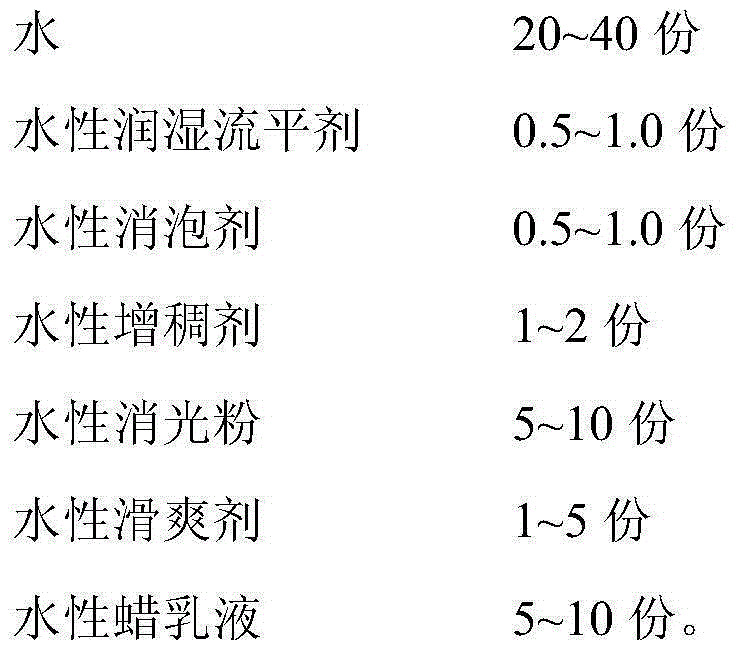

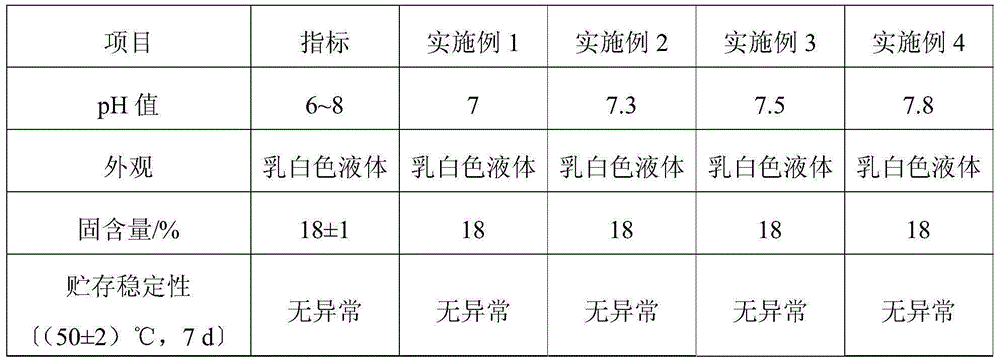

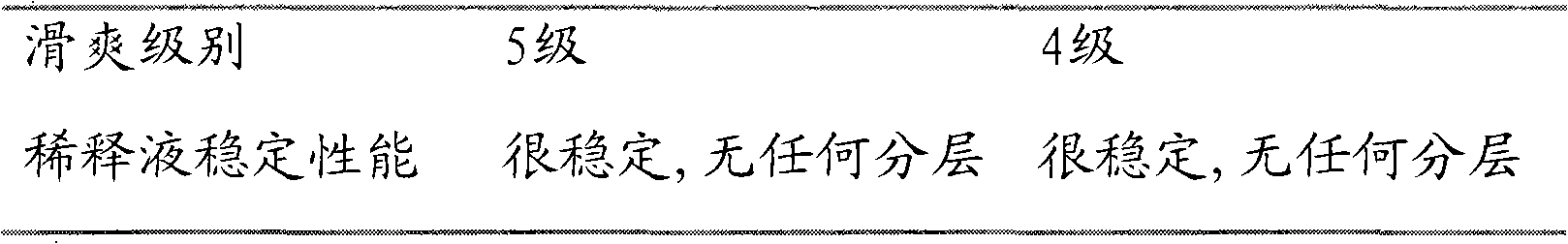

Synthetic leather surface conditioning agent

The invention provides a synthetic leather surface conditioning agent. The synthetic leather surface conditioning agent comprises, by weight, 60-80 parts of aqueous polyurethane resin, 20-40 parts of water, 0.5-1.0 part of an aqueous wetting leveling agent, 0.5-1.0 part of an aqueous antifoaming agent, 1-2 parts of an aqueous thickening agent, 5-10 parts of aqueous matting powder, 1-5 parts of an aqueous slip agent and 5-10 parts of an aqueous wax emulsion. The aqueous polyurethane surface conditioning agent has effects of dye fixation and wear resistance on the synthetic leather surface, makes synthetic leather surface fine and smooth, does not contain VOC, does not cause resource waste and environmental pollution, satisfies safety, environmental friendliness and energy saving requirements and is conducive to human health.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Preparation method of aqueous two-component super wear-resistant lusterless paint

InactiveCN105713496AImprove high temperature resistanceExcellent super wear resistancePolyurea/polyurethane coatingsMicrosphereWear resistant

The invention relates to a preparation method of aqueous two-component super wear-resistant lusterless paint. The lusterless paint comprises an ingredient A and an ingredient B and a mole ratio of OH to NCO in the ingredients A and B is 1: 1.0-1.5. The ingredient A comprises a hydroxyl-containing aqueous resin, SMA resin, PMMA microspheres, aqueous color paste, auxiliary agents and water. The ingredient B is an aqueous polyurethane curing agent. A film of the aqueous two-component super wear-resistant lusterless paint has excellent high temperature resistance, super wear resistance, water resistance, weatherability and chemical stability. The preparation method improves paint surface texture, fullness, flexibility, smoothness and delustring effects and does not influence paint film texture and a brilliant degree. The aqueous two-component super wear-resistant lusterless paint has low VOC, does not contain heavy metals, is environmentally friendly, can be widely used for surface coating and protection of a base material with high temperature resistance, wear and scratch resistance and lusterless effect requirements and can be used for aqueous floor paint, aqueous high-grade woodenware paint, aqueous plastic cement paint, aqueous mobile phone paint and aqueous industrial paint.

Owner:UNION FOSHAN CHEM +1

Surface blackening treatment method for rolled copper foil

InactiveCN106191980AImprove acid resistanceGood alkali resistanceChromatisationSuperimposed coating processFolding enduranceSurface roughness

The invention discloses a surface blackening treatment method for a rolled copper foil. The surface blackening treatment method orderly comprises the following steps: (1) electrochemical oil removal, (2) coarsening treatment, (3) solidification treatment, (4) nickel-cobalt plating treatment, (5) zinc plating treatment, (6) passivation, (7) silicone coupling agent coating treatment, and (8) drying treatment, and obtaining the product. Current is applied in step (1) to step (6). The surface blackening treatment method for a rolled copper foil provided by the present invention has the advantage that the black appearance of the copper foil obtained after various electric plating steps meets FPC requirements. Through determination, the copper foil has a surface color blackness value of less than 30, surface roughness Ra of less than or equal to 1.0 micron and Rz of less than or equal to 2.0 microns, peel strength of more than 1.4 N / mm, and folding endurance MIT of more than 800; the copper foil has favorable acid resistance, alkali resistance, soldering resistance, and etching performance. With the blackness value RAL7016, a good extinction effect is achieved.

Owner:中铜(上海)铜业有限公司

High dilution ratio aqueous coating agent for PVC powder-free gloves and preparation method thereof

InactiveCN101591501ANo separationQuality assuranceGlovesPolyurea/polyurethane coatingsEmulsionFoaming agent

The invention discloses a high dilution ratio aqueous coating agent for PVC powder-free gloves; the coating agent is prepared by mixing the following materials by mass percentage: 40-80% of waterborne polyurethane, 10-40% of ylate emulsion, 0.1-1.5% of antifoaming agent, 0.05-5% of wetting flatting agent, 2-8% of anti-blocking slipping agent and 0.1-2% of water retention agent. Filling is not used in the coating agent, and high dilution ratio between 1:30-1:40 can be reached under the condition of moderate system viscosity, thus being more economical to use; the extinction effect is realized by applying compatibility limitation instead of filling so that when the coating agent is used to prepare the PVC powder-free gloves, diluted coating agent working solution can be kept stable for a long time without separation, thus being applicable to production.

Owner:BEIJING COMENS YANSHAN TECH +1

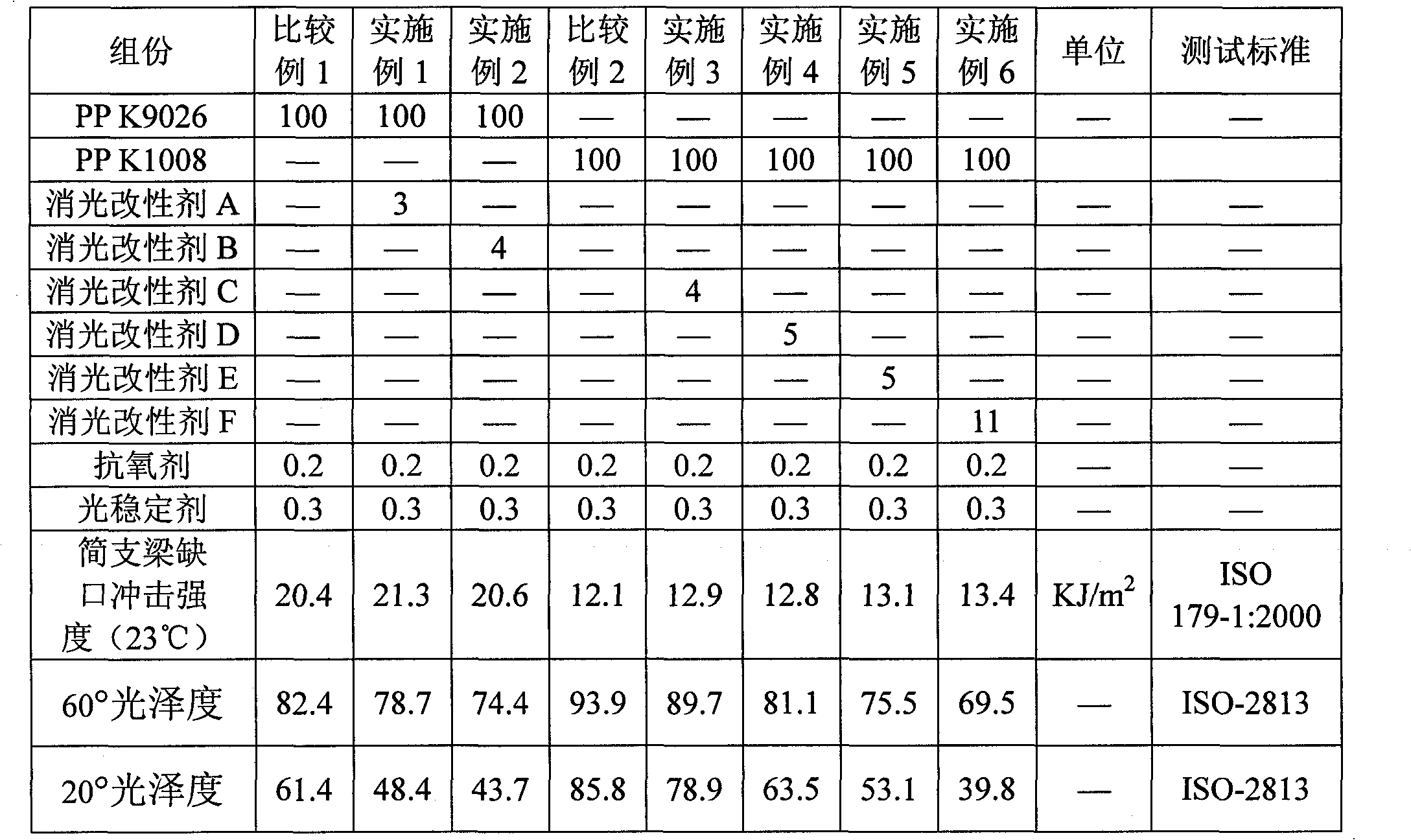

Low gloss polypropylene composition and preparation method thereof

The present invention relates to a low gloss polypropylene composition and a preparation method thereof. The low gloss polypropylene composition comprises the following blended components, by weight, 100 parts of polypropylene and 1-20 parts of an extinction modifier, wherein the extinction modifier comprises a powder rubber and grafted polypropylene, the powder rubber is a fully vulcanized powder rubber with an average particle size of 20-2000 nm and a cross-linked structure, gel content of the rubber is 60 wt% or higher, the grafted polypropylene is maleic anhydride grafted polypropylene, a maleic anhydride grafting ratio is 1-5%, and a weight ratio of the powder rubber to the grafted polypropylene is 1:(0.2-1). The low gloss polypropylene composition of the present invention has good toughness and low gloss. The preparation method of the present invention has characteristics of simple process, easy condition control, and strong applicability. In addition, the composition of the present invention can be used for automotive interior trims, household appliance shells and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

All-solid low-energy-curing matte UV coating for PVC plastic and preparation method for UV coating

The invention discloses an all-solid low-energy-curing matte UV (ultraviolet) coating for a PVC (polyvinyl chloride) plastic and a preparation method for the UV coating. The coating contains the following components: 25-30% of special modified acrylic resin, 5-10% of urethane acrylate, 20-25% of high-functionality active monomers, 20-25% of a reactive diluent, 2-5% of a photoinitiator 1, 1-4% of a photoinitiator 2, 3-6% of a photoinitiator 3, 0.3-1.0% of a dispersant, 5-10% of extinction powder, 0.5-1.0% of wax powder, 0.1-0.5% of a defoamer and 0.1-0.5% of a leveling agent. The UV coating does not contain a solvent and can be cured to form a low-luster, high-scratch-resistant and pollution-resistant paint film only by 150-200 mj / m<2> of UV energy; and the UV coating is applied to soft PVC and can enable a base material not to be thermally damaged in a curing process, so that the application range of the UV coating is greatly expanded.

Owner:HUNAN JINHAI SCI & TECH

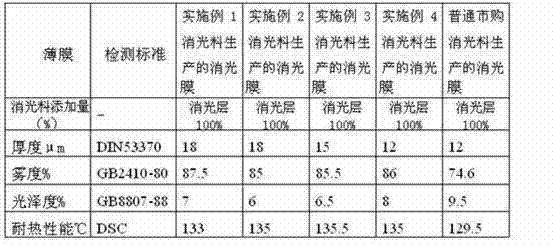

Extinction material for biaxially oriented polypropylene (BOPP) film and preparation method for extinction material

The invention relates to an extinction material for a biaxially oriented polypropylene (BOPP) film and a preparation method for the extinction material. The extinction material is characterized by comprising the following raw materials in part by weight: 30 to 60 parts of polypropylene (PP) resin, 30 to 60 parts of high density polyethylene, 2 to 15 parts of inorganic extinction powder, 2 to 10 parts of polybutylene terephathalate (PBT), 1 to 3 parts of dispersing agent and 0.1 to 1.0 part of antioxidant, wherein the total parts of the components are 100. By the extinction material for the BOPP film, a uniform extinction layer can be provided, high haze and high-temperature resistance are achieved, an extinction layer can be thinned for a BOPP film manufacturer, and the production speed and production efficiency of the extinction film are improved.

Owner:JIANGYIN FINE PLASTICS

Odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and preparation method thereof

The invention belongs to the field of coatings and particularly relates to an odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and a preparation method thereof. The odorless and wear-resisting smooth UV matt finish paint coating comprises components in percentage by weight as follows: 25%-50% of hexa-functional polyurethane acrylate prepolymers, 15%-50% of trifunctional modified polyurethane acrylate prepolymers, 15%-50% of acrylate monomers, 1%-10% of a photoinitiator, 0.2%-2% of a wetting dispersant, 0.2%-1% of a leveling agent, 0.2%-0.5% of a defoaming agent and 1%-15% of a matting agent. According to the odorless and wear-resisting smooth UV matt finish paint coating, the technical problems that a pungent smell is left, wetting of the matting agent is difficult, matting is difficult, a paint film is prone to floating and the like after curing of a conventional UV matt finish paint coating are solved, and meanwhile, the defect of crispness of the paint film caused by improvement of the wear resistance of the conventional UV matt finish paint coating is overcome.

Owner:AODA KOALA PAINT HUIZHOU

Pinhole-proof aqueous coating agent for powder-free PVC gloves and preparation method thereof

InactiveCN101735721AObvious anti-adhesion effectGood anti-pinhole effectGlovesPolyurea/polyurethane coatingsDefoaming AgentsRaw material

The invention discloses a pinhole-proof aqueous coating agent for powder-free PVC gloves, which belongs to the field of chemical raw materials. The coating agent consists of the following components in percentage by weight: 10 to 40 percent of aqueous polyacrylic resin, 40 to 80 percent of aqueous polyurethane resin, 0.1 to 0.5 percent of defoaming agent, 0.05 to 3 percent of wetting flatting agent, 5 to 15 percent of anti-sticking slipping agent, 0.3 to 1.2 percent of pH adjustor and 0.1 to 2 percent of thickening agent. When the coating agent is used for producing the PVC gloves, the aqueous polyacrylic resin in the coating agent can be densified to form a film after the coating agent is coated on a base material of the PVC gloves so as to form a thicker and more compact film layer compared with the traditional coating agent, endow the coating with obvious anti-sticking effect and good water resistance and further provide better pinhole-proof effect; therefore, the pinhole rate of the produced PVC gloves meets the requirement of less than 4 percent.

Owner:BEIJING COMENS NEW MATERIALS

Thermal-isolating coating

ActiveCN1962768AImprove mechanical propertiesFast heat conductionFireproof paintsSolventResin adhesive

The invention discloses a heat-proof paint, which comprises the following parts: 40-50wt% resin adhesive, 3-8wt% solvent and 30-50wt% organic inorganic composite filler, wherein the heat-proof resin contains at least one macromolecule; the organic inorganic composite filler possesses nanometer micro-hole structure to connect resin adhesive effectively to reduce the quantity of resin adhesive, which is compatible with insulating and mechanic property for heat-proof paint.

Owner:IND TECH RES INST

Preparation method of extinction polyvinyl chloride resin

The invention provides a preparation method of extinction polyvinyl chloride resin. The preparation method comprises the following steps: acquiring vinyl chloride monomer, deionized water, an initiator, a buffering agent, a dispersant and a matting agent which serve as reaction raw materials; performing pre-emulsification treatment on the matting agent by use of part of the dispersant; adding the vinyl chloride monomer, the deionized water, the initiator, the buffering agent and the rest dispersant into a polymerization kettle, performing polyreaction, and adding the matting agent subjected to pre-emulsification treatment during the reaction process so as to prepare the extinction polyvinyl chloride resin, wherein the matting agent is a monomer or polymer containing two or more reaction active functional groups, the dosage of the deionized water accounts for 105-200% of the weight of the vinyl chloride monomer, the dosage of the initiator accounts of 0.04-0.18% of the weight of the vinyl chloride monomer, the total dosage of the dispersant accounts for 0.04-0.15% of the weight of the vinyl chloride monomer, the dosage of the buffering agent accounts for 0.06-0.18% of the weight of the vinyl chloride monomer, and the dosage of the matting agent accounts for 0.01-8.0% of the weight of the vinyl chloride monomer. The prepared extinction polyvinyl chloride resin is fewer in crystal spot and good in extinction effect.

Owner:HANGZHOU ELECTROCHEM GROUP

Water-soluble anionic acrylic resin composition for extinction and preparation method thereof

The invention discloses a water-soluble anionic acrylic resin composition for extinction and a preparation method thereof. The eater-soluble anionic acrylic resin composition for extinction is composed of 140-316 parts by mass of water-dispersible ethylene copolymer resin and 30-65 parts by mass of organosilicon-modified silicon dioxide dispersion solution, wherein the water-dispersible acrylate copolymer is prepared by carrying out emulsion polymerization on hydroxy acrylate unsaturated monomer, carboxyl acrylate unsaturated monomer and other free-radical polymerizable unsaturated acrylate monomers; and the organosilicon-modified silicon dioxide dispersion solution is prepared by the following steps: carrying out acid-catalyzed hydrolysis reaction on ethyl orthosilicate in an ethanol-water solution to obtain silicon dioxide low polymer, and reacting with a silane coupling agent. By regulating the preparation process and consumption of the organosilicon-modified silicon dioxide dispersion solution, the invention can effectively control the luster of the water-soluble anionic acrylic resin, and enhances the compatibility between the anionic acrylic resin and the silicon dioxide dispersion solution.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method of indoor flatting powder paint

InactiveCN102850913AEasy material selectionSuperior performancePowdery paintsEpoxy resin coatingsChemistryOrganic acid

The invention relates to a preparation method of indoor flatting powder paint, which is characterized by comprising the following steps: adding polybasic acid or acid anhydride, polyalcohol, catalyst and antioxidant into a reaction kettle, mixing, introducing nitrogen, heating to carry out esterification reaction or ester exchange reaction until the reaction liquid is completely clear, carrying out vacuum polycondensation until the acid value is 40-200mg KOH / g and the viscosity is 10-50 poise, cooling, and discharging to obtain the light yellow transparent or semitransparent solid component A polyester resin; adding polybasic acid or acid anhydride, polyalcohol, catalyst and antioxidant into a reaction kettle, mixing, introducing nitrogen, heating to carry out esterification reaction or ester exchange reaction until the reaction liquid is completely clear, carrying out vacuum polycondensation until the acid value is 10-50mg KOH / g and the viscosity is 30-100 poise, cooling, and discharging to obtain the light yellow transparent or semitransparent solid component B polyester resin, wherein the molecular weight of the component A polyester resin and the component B polyester resin are respectively controlled at 1000-10000 dalton; evenly mixing the component A polyester resin, component B polyester resin and polybasic organic acid to obtain a component C polyester resin; and mixing the component C polyester resin, epoxy resin E-12, barium sulfate, titanium white, leveling agent, brightener, physical flatting agent and benzoin to obtain the indoor flatting powder paint. The synthesis method has the advantages of diversity and the like, and can easily implement industrialized mass production.

Owner:广东大盈新材料科技有限公司 +1

Matting resin modified polyvinyl chloride (PVC) matt film

The invention relates to a matting resin modified polyvinyl chloride (PVC) matt film, belonging to the technical field of PVC matt films. The matting resin modified PVC matt film comprises the following components: 60 to 90 weight parts of polyvinyl chloride resin, 10 to 40 weight parts of matting resin (VinnolitC 100V), 20 to 50PHR of dioctyl phthalate, 2 to 10PHR of epoxy soybean oil, 2 to 5PHR of a thermal stabilizer, 0.3 to 0.5PHR of an antioxidant, and 0.1 to 1.0PHR of an ultraviolet absorbent. The modified matt film can achieve surface effects of anti-sticking, matting, grain forming and the like, has a good surface matting effect, has high adaptability to processing conditions, and has the advantages of good matting effect and the like in a broad plasticizing temperature range.

Owner:TIANJIN TIANSU SCI & TECH GROUP

Preparation method of water-based self-extinction spray resin

ActiveCN103936959AThe process is simple and easy to controlEasy to operatePolyurea/polyurethane coatingsWater basedWax

The invention discloses a preparation method of a water-based self-extinction spray resin, which comprises the following steps: S1. synthesis of polyurethane prepolymer; adding polyether dibasic alcohol and carboxylic-acid hydrophilic dibasic alcohol into a reactor according to parts by weight, heating to dehydrate, and cooling; adding a catalyst and diisocyanate into the reactor to react; S2. primary chain extension: continuing adding a first micromolecule chain extender into the reactor according to parts by weight to perform chain extension reaction; S3. secondary chain extension: adding an emulsifier-containing water solution according to parts by weight while stirring, and adding a second micromolecule chain extender while continuing stirring; and S4. neutralization: adding tertiary amine into the reactor, stirring and discharging. The preparation method is simple and controllable in technique and easy to operate, can obtain favorable extinction effect without adding any extinction powder or extinction wax; and the surface of the coated film is uniform, fine and smooth.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Polyester resin and synthesis method thereof

InactiveCN103467714AHigh hydroxyl valueGood matting effectPowdery paintsPolyester coatingsChemistryDiol

The invention relates to polyester resin and a synthesis method thereof. The polyester resin comprises the following raw material components in parts by mass: 45-53 parts of aromatic binary acid, 40-50 parts of a branching agent, 0-10 parts of dihydric alcohol and 0-0.01 part of an esterification catalyst; the polyester resin is synthesized by melt phase polycondensation. The polyester resin has an ultrahigh hydroxyl value, has acceptable glass-transition temperature, can be used for preparing an AB dry-blending extinction powder coating and has a favorable extinction effect.

Owner:ANHUI SHENJIAN NEW MATERIALS

Matte, high-elasticity and low-temperature-resistant PVC hose and preparation method thereof

InactiveCN105924846AGood compatibilityImprove impact resistanceFlexible pipesTubular articlesEnvironmental resistanceWear resistant

The invention provides a matte, high-elasticity and low-temperature-resistant PVC hose. The matte, high-elasticity and low-temperature-resistant PVC hose comprises an inner tube and an outer tube, and the inner tube or the outer tube comprises the following components in parts by mass: 100 parts of PVC, 2-3 parts of a heat stabilizer, 20-30 parts of an environmentally friendly plasticizer, 5-15 parts of a low-temperature-resistant modifier, 5-10 parts of an anti-impact modifier, 2-3 parts of an ultraviolet screening agent, 2-3 parts of pigment, 4-6 parts of a wear-resistant modifier and 1-3 parts of an antioxidant. Outer tube PVC consists of conventional PVC and 25-40 parts by mass of extinction PVC. Correspondingly, the invention further provides a preparation method of the PVC hose. The PVC hose which is low in production cost and simple in production technology, is matte, and has high strength, good impact toughness, good stretching strength and good low temperature resistance is obtained.

Owner:PROSPER IND

Matting Agent and Method for Obtaining the Same

ActiveUS20170121551A1Excellent matting propertiesReadily prepared and handled and applicablePigmenting treatmentCoatingsChemistryPigment particle

The invention relates to a matting agent comprising agglomerates of pigment particles, to a method for the preparation of such matting agents, and to coating formulations containing the matting agents disclosed herein. The present invention further relates to pigmented mat surfaces, and to the use of agglomerates of pigment particles for matting pigmented coatings.

Owner:KRONOS INTERNATIONAL INC

Thermoplastic polyurethane composition and preparation method thereof

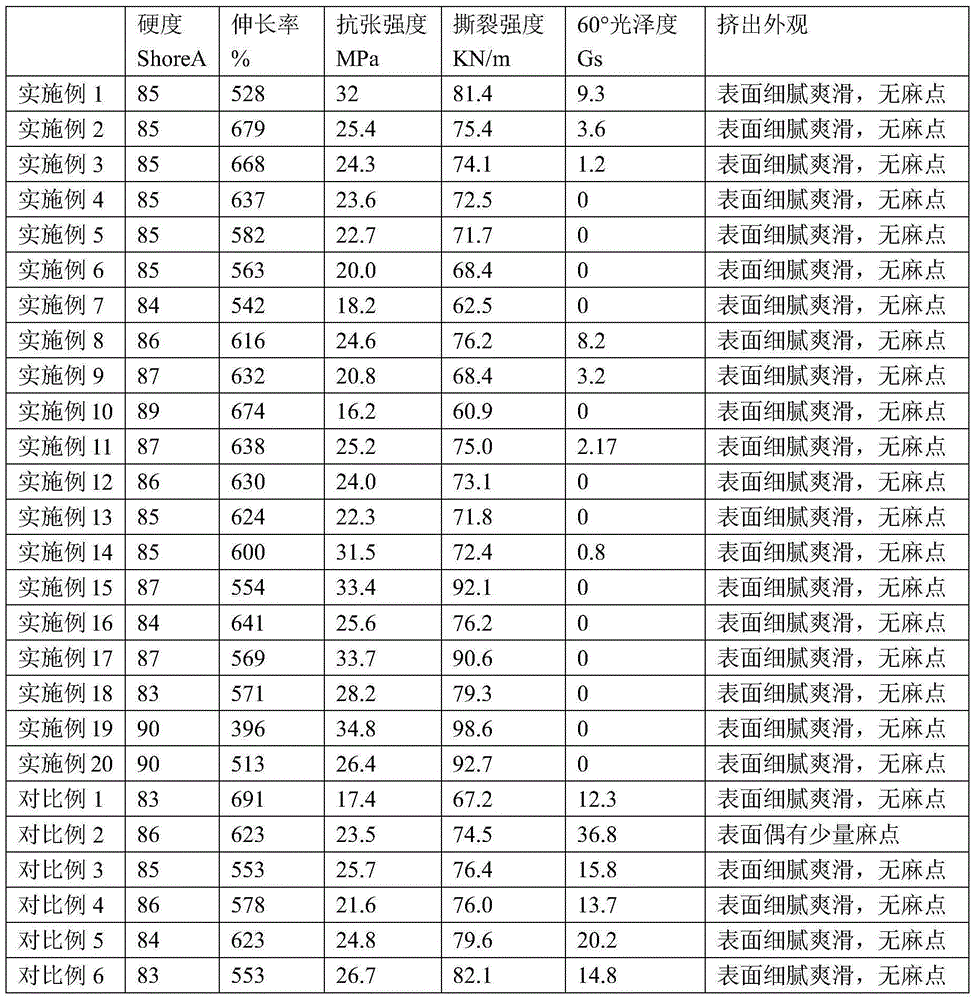

The invention relates to a thermoplastic polyurethane composition and a preparation method thereof. The composition comprises the following substances by the mass percentage: (a) 55-90% of a thermoplastic polyurethane elastomer, (b) 7-40% of a copolymer, and (c) 2-8% of a compatilizer. The copolymer is selected from one or more of the following polymers: SBS, SEBS, SIS and SEPS with the number-average molecular weight of 50 thousand-100 thousand. In addition, EPDM with the weight-average molecular weight of 100 thousand-400 thousand can be added and can cooperate with the copolymer, and in the premise of relatively low copolymer amount, better extinction effect is achieved. According to the ASTM D523 standard, the surface glossiness of the angle of 60 degrees is tested to be less than 10 Gs, and the lowest reaches 0; and the material has good mechanical properties and processing performance, and is suitable for preparation of wire cables, pipes, belts and thin film products.

Owner:WANHUA CHEM GRP CO LTD

Technique of fluidized instant calcinations of kaolin in coal series

InactiveCN1915814AGood dispersionLarge gas-solid heat transfer areaPigmenting treatmentAluminium silicatesFlue gasEngineering

This invention relates to a fluid-state instantaneous calcining technique for calcining kaolin. The technique comprises a flue gas generating system, a loading system, a fluid-state calcining system, a gas-solid separating system and a post-calcining system. The material is loaded into the fluid-state calcining system by the loading system, where it is mixed with high-temperate flue gas flow generated by the flue gas generating system for instantaneous calcining. The calcined material is introduced into the gas-solid separating system, and the collected solid is then introduced to the post-calcining system for whitening treatment. The instantaneous calcining time is adjusted by the valve. The method can realize large-scale and continuous industrial manufacture, and can effectively reduce the time and energy consumption of post-calcining whitening treatment. The calcined kaolin product has improved oil-absorbency, hiding contrast rate and light extinction performance.

Owner:内蒙古蒙西高岭粉体股份有限公司

Preparation method of extinction powder special for elastic paint

InactiveCN108557828AHigh oil absorption valueGood matting effectSilicaPigment treatment with macromolecular organic compoundsChemistryAmmonium hydroxide

The invention relates to a preparation method of extinction powder special for elastic paint. In a reaction kettle, sodium silicate and water are added, the temperature is increased to 45 DEG C, in the stirring state, sulfuric acid with the concentration being 30% is added, the PH value is regulated to 6-6.5, ammonium hydroxide is added to regulate the PH value to 8.5-9.0, aging is performed for 50 min, then, the temperature is increased to 90 DEG C, meanwhile, sodium silicate and sulfuric acid of the certain concentration are added, aging is performed for 50 min, acid is added till the PH value is 4-5, and filtering, washing, drying and smashing and classification are performed to obtain finished extinction powder. The extinction powder has the advantages of being high in oil absorption value, good in dispersibility, fine in touch, high in transparency and the like, and is reasonable in technology and high in production efficiency.

Owner:山西天一纳米科技股份有限公司

Graft copolymer and thermoplastic resin composition

InactiveCN1486347AGood mattingGood lookingDispersed particle separationDisinfectionFunctional monomerMeth-

A thermoplastic resin composition comprising 10 to 98 parts by weight of a graft polymer (1A) containing a rubber-like polymer (1G) having a diene unit content of 50% by weight or less, 2 to 50 parts by weight of a hydroxyl group-containing acrylic copolymer (1B) and 0 to 80 parts by weight of other thermoplastic resin (1F), wherein the rubber-like polymer (1G) is at least one selected from the group consisting of a diene-based rubber, a polyorganosiloxane-based rubber and an olefin-based rubber; and, a graft copolymer (2A) obtained by grafting a vinyl-based polymer to a (meth)acrylate-based rubber-like polymer (2G) expansion-treated with an acid group-containing copolymer latex (2K) wherein the (meth)acrylate-based rubber-like polymer contains two or more poly-functional monomer units.

Owner:MITSUBISHI CHEM CORP

Space filtering based light shield of star sensor

ActiveCN106383427ARealize the spectral filtering functionReduce stray light interferenceCamera filtersExit pupilLens hood

The invention discloses a space filtering based light shield of a star sensor. The light shield comprises a cover casing and first to sixth shading rings, and the first to sixth shading rings are arranged from an entrance pupil position to the exit pupil position sequentially and mounted in the cover casing; the first shading ring and the sixth shading ring are arranged at the two ends of the cover casing opposite to each other, and a connecting line between cutting edges of the first shading ring and the sixth shading ring and a center line of the cover casing form an included angle of 16 degree; and the middle portions of the fourth, fifth and sixth shading rings are provided with optical filters in a rotational installation manner respectively. The light shield has the advantages that the cover casing, the shading rings and the optical filters form an optical-mechanical assembly of the light shield, and it is ensured that the star sensor can output effective attitude data when a sun shielding angle is greater than 20 degree; a non-imaging spectrum of the sun shielding angle greater than 20 degree can reach the entrance pupil position of an optical system via at least twice absorptive scattering; and the light shield has a high light shielding performance, and is capable of spectrum filtering.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Ultraviolet-curable extinction resin and preparation method thereof

ActiveCN103113554AGood matting effectGood anti-fouling performancePolyurea/polyurethane coatingsThioetherIsocyanate

The invention provides an ultraviolet-curable extinction resin which is obtained by reacting poly-1,4-butanediol esterdiol, trimethylolpropane, hydroxyl silicone oil, phenol thioether, diisocyanate and hydroxyl-terminated acrylate under the action of a catalyst and an inhibitor. The ultraviolet-curable extinction resin has a good extinction effect without adding extinction powders as phenyl sulfide and siloxane structures are introduced to the main chain structure of the ultraviolet-curable extinction resin provided by the invention and the group refraction coefficients of the phenyl sulfide and siloxane structures make a great difference. At the same time, the ultraviolet-curable extinction resin has good pollution resistant property as the siloxane structure is introduced into the main chain structure. The experimental results show that the vancometer adopted by the ultraviolet-curable coating prepared by the ultraviolet-curable extinction resin provided by the invention enters at 60 degrees with the glossiness of 8GU, and no imprinting is left by wiping 10 minutes later after a 3M marking pen writs on the ultraviolet-curable coating.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com