Aqueous multi-functional crylic acid extinction resin and preparation method thereof

A technology of matting resin and polymeric acrylic acid, which is applied in the direction of coating, etc., can solve the problems of poor chemical resistance, harm to consumers, health of builders, general performance and other problems, and achieve low VOC content, excellent appearance effect and storage stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

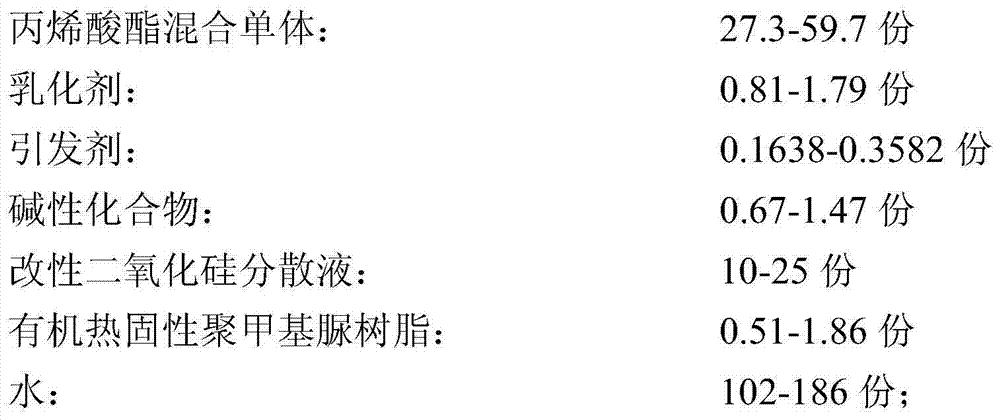

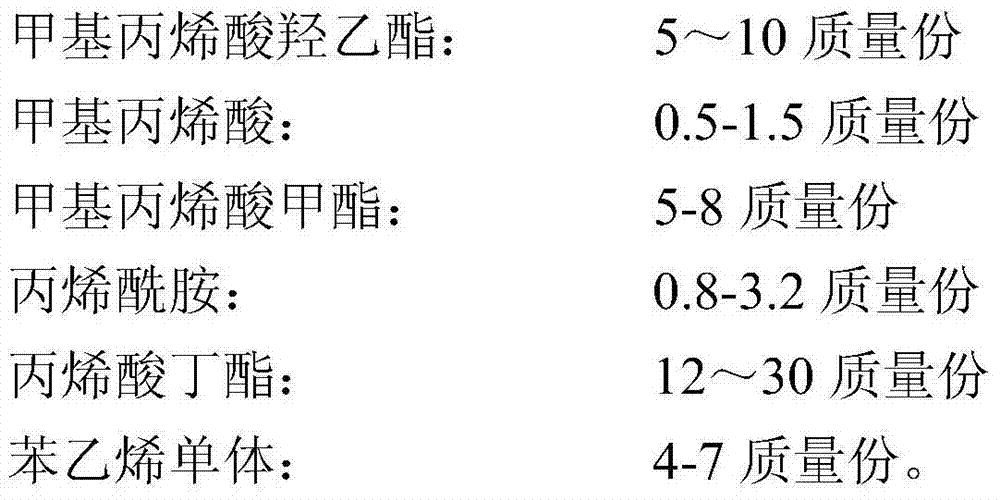

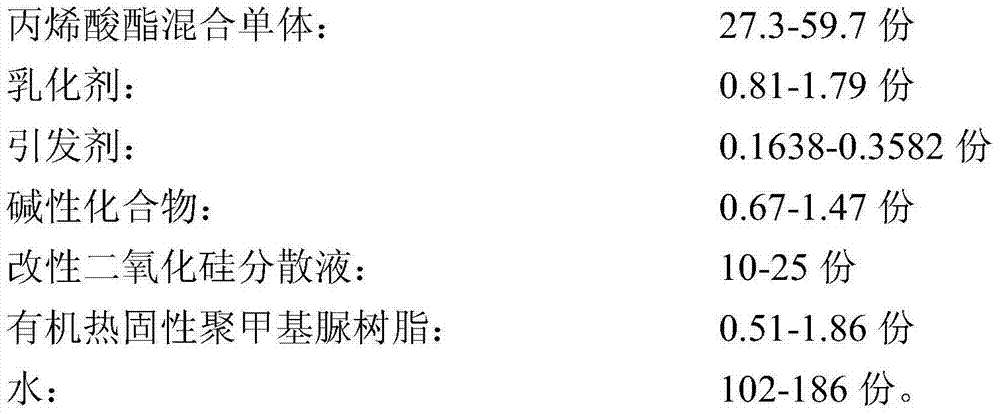

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of organosilicon-modified silica dispersion: mix ethyl orthosilicate, ethanol, and water in a molar ratio of 1:4:8, heat to 55°C, and adjust the system with 0.1mol / L hydrochloric acid pH to 3, under the condition of mechanical stirring, maintain the temperature and continue to react for 8h to obtain SiO 2 Alcohol sol, prepared in SiO 2 Add 4.06 parts of 3-(methacryloyloxy)propyltrimethoxysilane to the alcohol sol, condense and reflux for 2 hours under the condition of heating in a water bath at 75°C, and cool to obtain a silicone-modified silica dispersion.

[0043] (2) 5 parts by mass of hydroxyethyl methacrylate, 5 parts by mass of methyl methacrylate, 0.8 parts by mass of acrylamide, 0.5 parts by mass of methacrylic acid, 12 parts by mass of butyl acrylate, and 4 parts by mass of styrene monomer Mix evenly to prepare acrylate mixed monomer for future use.

[0044] (3) Under the protection of nitrogen, take 102 parts by mass of water, 1 / 4 of the acry...

Embodiment 2

[0047] (1) The preparation method of the organosilicon-modified silica dispersion is the same as step (1) of Example 1.

[0048] (2) 6 parts by mass of hydroxyethyl methacrylate, 7 parts by mass of methyl methacrylate, 2.6 parts by mass of acrylamide, 1.0 parts by mass of methacrylic acid, 18 parts by mass of butyl acrylate, and 5 parts by mass of styrene monomer;

[0049] (3) Under the protection of nitrogen, take 121 parts by mass of water, 1 / 4 of the acrylate mixed monomer prepared in step (1), 0.05940 parts by mass of initiator, 0.891 parts by mass of sodium lauryl sulfate and 0.297 parts by mass of polystyrene Oxyethylene-8-octylphenyl ether compound emulsifier, mix well, react at 75-85°C for 0.5-1h to prepare seed emulsion; then add the remaining 3 / 4 acrylate mixed monomer and 0.1782 mass part initiator, the dropping time is controlled at 4h, after the dropwise addition is completed, the temperature is kept for 2h, after cooling to room temperature, a basic compound is a...

Embodiment 3

[0052] (1) Preparation of organosilicon-modified silica dispersion: mix ethyl orthosilicate, ethanol, and water in a molar ratio of 1:4:8, heat to 70°C, and adjust the system with 0.1mol / L hydrochloric acid pH to 4, under the condition of mechanical stirring, maintain the temperature and continue to react for 12h to obtain SiO 2 Alcohol sol, prepared in SiO 2 Add 4.69 parts of 3-(methacryloyloxy)propyltrimethoxysilane to the alcohol sol, condense and reflux for 3 hours under the condition of heating in a water bath at 80°C, and cool to obtain a silicone-modified silica dispersion.

[0053] (2) 10 parts by mass of hydroxyethyl methacrylate, 8 parts by mass of methyl methacrylate, 3.2 parts by mass of acrylamide, 1.5 parts by mass of methacrylic acid, 30 parts by mass of butyl acrylate, and 7 parts by mass of styrene monomer;

[0054] (3) Under the protection of nitrogen, take 186 parts by mass of water, 1 / 4 of the acrylate mixed monomer prepared in step (2), 0.090 parts by mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com