Water-base epoxy zinc-rich priming paint and preparation method thereof

A water-based epoxy zinc-rich and primer technology, applied in the field of coatings in the chemical industry, can solve problems such as potential safety hazards, environmental pollution, flammability, etc., and achieves the elimination of potential safety hazards, less human harm, and low odor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

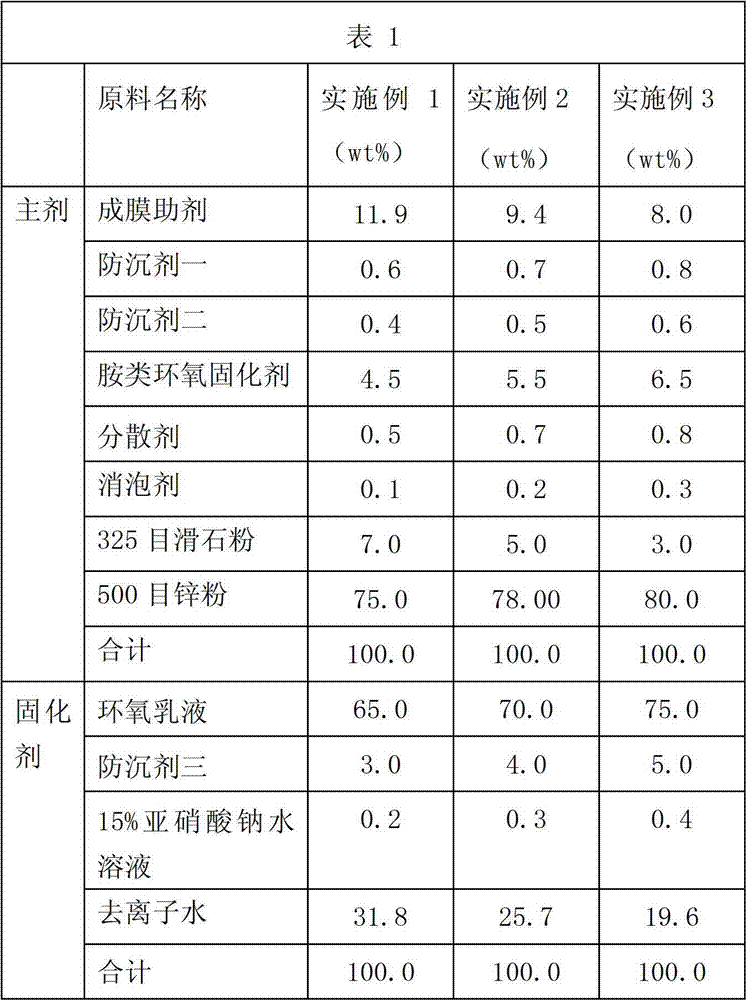

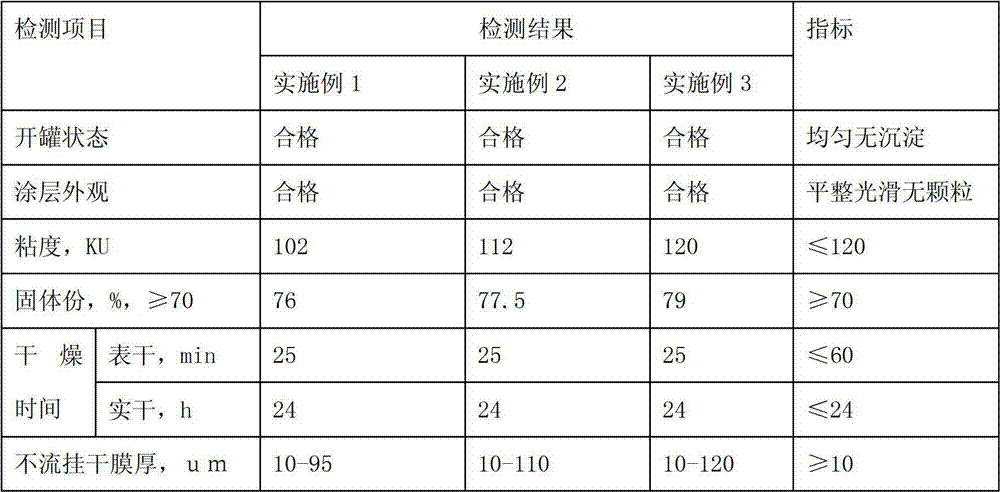

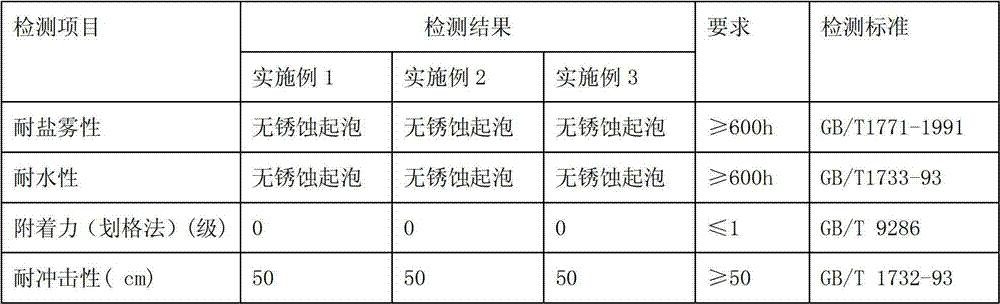

[0023] The main agent and curing agent formulations of the waterborne epoxy zinc-rich primer in Examples 1 to 3 are shown in Table 1.

[0024] In Table 1: the amine epoxy curing agent is Epikure 8538-Y-68 amine epoxy curing agent from Momentive Company of the United States. The dispersant is ADDITOL VXW6208 / 60 dispersant from Cytec Corporation of the United States. The defoaming agent is BYK-012 defoaming agent from BYK Company of Germany. Anti-sedimentation agent 1 is SD-2 anti-settling agent of Hemings Company in the United States, anti-settling agent 2 is R 812 S anti-settling agent of German Degusa Company, and anti-settling agent 3 is AQ600 anti-settling agent of Japan Kusumoto Chemical Co., Ltd. . The anti-flash rust agent is sodium nitrite anti-flash rust agent produced by domestic Yongfa Industry and Trade. Coalescing aid is the propylene glycol monomethyl ether coalescing aid of U.S. Dow Company. The epoxy emulsion is Epikote 6520-WH-53 epoxy emulsion from America...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com