Preparation method of water-based self-extinction spray resin

A self-dulling, resin-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as low gloss, high haze, and high cost, and achieve uniform and fine coating surface, simple and controllable process, and good extinction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

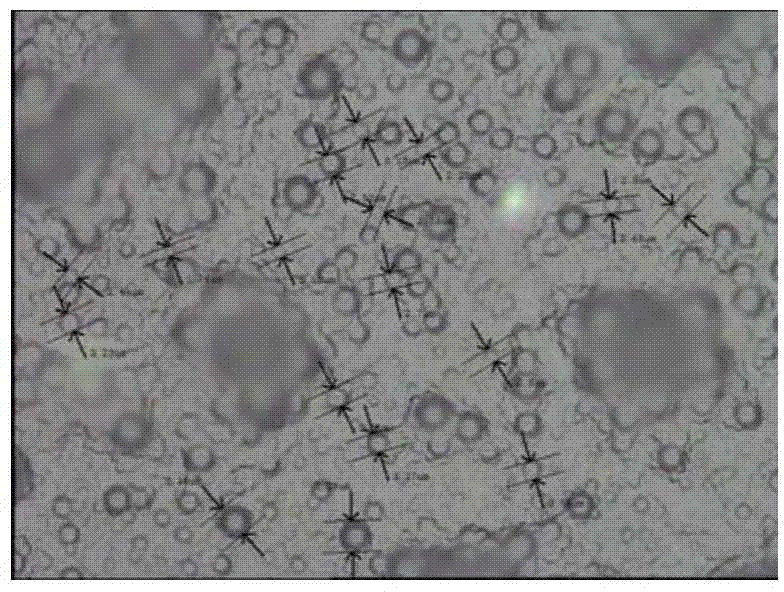

[0030] Such as figure 1 , figure 2 Shown, the present invention discloses a kind of preparation method of water-based self-dulling atomized resin, and it comprises the steps:

[0031] S1. Synthesizing polyurethane prepolymer; adding 90 to 120 parts of polyether diol and 2 to 20 parts of carboxylic acid type hydrophilic diol to the reactor in parts by weight, dehydrating and cooling under heating conditions; Continue to add 0.1-1.0 parts of catalyst and 100-250 parts of diisocyanate into the reactor for reaction until the isocyanate in the system reaches the theoretical value. Among them, the carboxylic acid type hydrophilic diol is preferably 4 to 10 parts.

[0032] S2. Pre-chain extension: In parts by weight, continue to add 7 to 20 parts of the first small molecule chain extender to the reactor for chain extension reaction.

[0033] S3. Post-chain extension: in parts by weight, add 800-1200 parts of an aqueous solution in which 5-35 wt % of an emulsifier is dissolved und...

Embodiment 1

[0048] 30g of polyethylene glycol with a molecular weight of 300 and 2g of bismethylolpropionic acid were vacuum dehydrated in a reactor at 120°C for 2 hours, and the temperature was lowered to 60°C.

[0049] Add 0.1g of di-n-butyltin dilaurate to the above reaction kettle, raise the temperature to 80°C, add 66.6g of isophorone diisocyanate dropwise into the above reaction kettle within 2 hours, continue the reaction for 1 hour, then cool down to 60°C ℃.

[0050] Add 4.14g of 1,4-butanediol and 4.14g of trimethylolpropane into the reactor, and react for 1h.

[0051] Under the state of stirring at 1500r / min, add an emulsifier formed by dissolving 10g of polypropylene alcohol and 5g of Span-80 in 300g of water into the reaction kettle, stir for 10min, and add 10g of water containing 1g of diethylenetriamine.

[0052] Reduce the stirring speed to 500r / min, add 1.51g of triethylamine into the stirred tank, continue to stir for 10min, cool down to room temperature, and filter out ...

Embodiment 2

[0054] 40 g of polyethylene glycol with a molecular weight of 400 and 2 g of bismethylolpropionic acid were vacuum dehydrated at 120°C for 2 hours in a reaction kettle, and the temperature was lowered to 60°C.

[0055] Add 0.1g of di-n-butyltin dilaurate to the above reaction kettle, raise the temperature to 80°C, add 54g of hexamethylene diisocyanate dropwise into the above reaction kettle within 2 hours, continue the reaction for 1 hour, then cool down to 60°C .

[0056] Add 4.81g of 1,4-butanediol and 4.81g of trimethylolpropane into the reactor, and react for 1h.

[0057] Under the state of stirring at 1500r / min, an emulsifier formed by dissolving 9g of polypropylene alcohol and 7g of Tween-80 in 310g of water was added to the reaction kettle, stirred for 15min, and 10g of water containing 1g of trimethylolpropane was added.

[0058] Reduce the stirring speed to 500r / min, add 1.51g of triethylamine into the stirred tank, continue to stir for 15min, cool down to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com