Modified diaphragm for lithium-sulfur battery, preparation method thereof and lithium-sulfur battery with diaphragm

A lithium-sulfur battery and diaphragm technology, applied in the field of energy materials, can solve the problems of poor cycle stability, unsatisfactory improvement of battery electrochemical performance, poor conductivity, etc., to improve cycle life, facilitate large-scale implementation, and eliminate surface blunt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

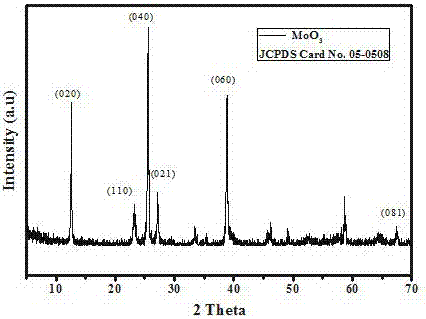

[0038] A molybdenum oxide (MoO 3 ) The preparation method of the modified separator and the example of the lithium-sulfur battery with the modified separator.

[0039] Molybdenum oxide (MoO 3 ) synthesis method

[0040] 0.4 mmol of (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 20 mL of deionized water and stirred continuously at room temperature for 30 min to obtain a precursor solution of molybdic acid, and then 10 mL of HNO was added to the solution 3 , followed by stirring for 30 min. Transfer the resulting mixed solution to a 50 mL polytetrafluoroethylene liner, then put it into a stainless steel autoclave, and put it into a 160-200 o React in an oven at C for 18-24 h, and cool naturally to room temperature. After filtering, wash thoroughly with ultrapure water and ethanol, collect samples, and place them in 60-100 o Dry in an oven at C for 12-24 h;

[0041] Molybdenum oxide (MoO 3 ) Modified separator: the hydrothermally synthesized molybdenum oxide (MoO 3 ) of ...

Embodiment 2

[0049] A molybdenum oxide (MoO 3 ) The preparation method of the modified separator and the example of the lithium-sulfur battery with the modified separator.

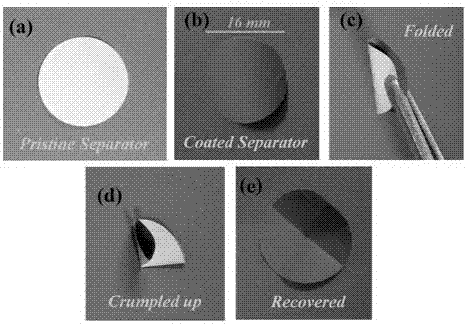

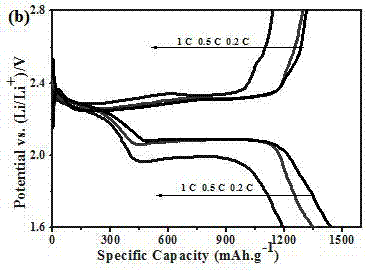

[0050] Preparation of modified separator: molybdenum oxide (MoO 3 ) nanoribbons, conductive carbon black (Super P) and binder according to the mass ratio of 7:2:1, placed in the sample tube, and mixed evenly under the condition of strong magnetic stirring for 90 min to form a slurry. The slurry was evenly coated on the battery separator (Celgard 2300) with a doctor blade coating method, the coating thickness was 50 μm, and the coated separator was placed in 60 o C in an oven for 24 h, and finally the dried membrane was cut into 16 mm diameter discs for later use.

[0051] Preparation of CNT / S composite: Weigh 50 mg of sulfur and add it to 220 mL of ethanol, sonicate in a 1500 W ultrasonic instrument for 10 min until the sulfur is completely dissolved in ethanol, add 117 mg of CNT to the solution, Continue to sonicat...

Embodiment 3

[0057] A molybdenum oxide (MoO 3 ) The preparation method of the modified separator and the example of the lithium-sulfur battery with the modified separator.

[0058] Preparation of modified separator: molybdenum oxide (MoO 3 ) nanoribbons, conductive carbon black (Super P) and binder according to the mass ratio of 6:3:1, placed in the sample tube, and mixed evenly under the condition of strong magnetic stirring for 90 min to form a slurry. The slurry was evenly coated on the battery separator (Celgard 2300) with a doctor blade coating method, the coating thickness was 50 μm, and the coated separator was placed in 60 o C in an oven for 24 h, and finally the dried membrane was cut into 16 mm diameter discs for later use.

[0059] Preparation of CNT / S composite: Weigh 50 mg of sulfur and add it to 220 mL of ethanol, sonicate in a 1500 W ultrasonic instrument for 10 min until the sulfur is completely dissolved in ethanol, add 117 mg of CNT to the solution, Continue to sonicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com