Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216results about How to "Low weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

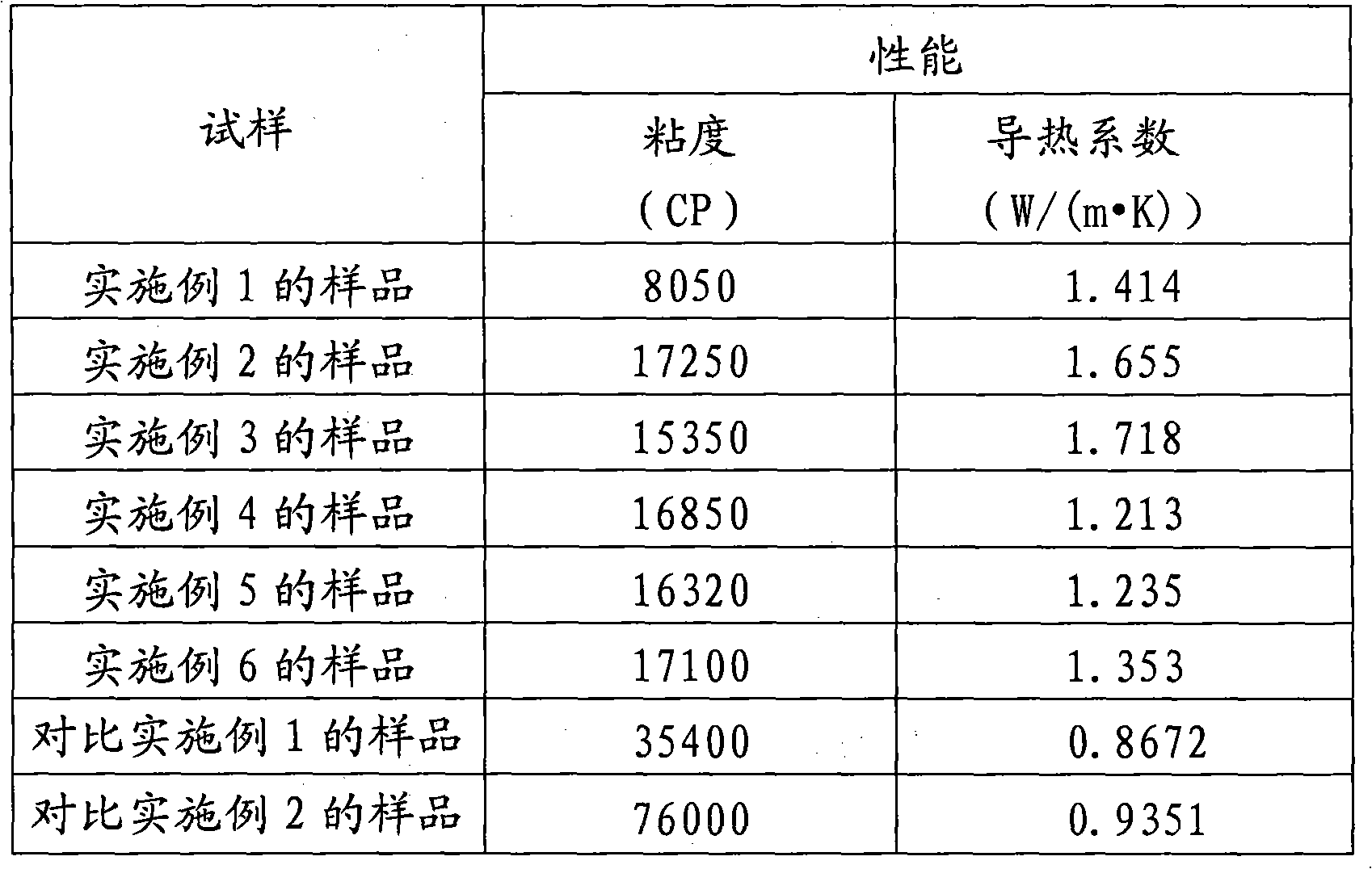

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

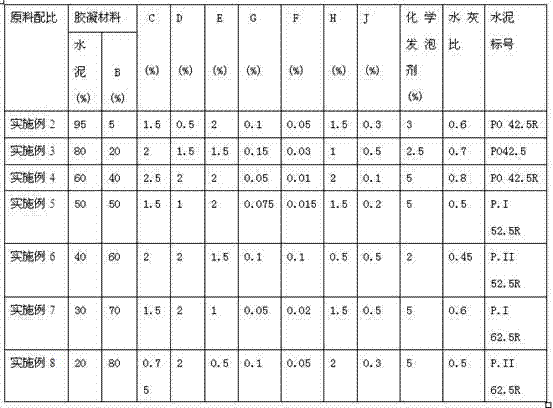

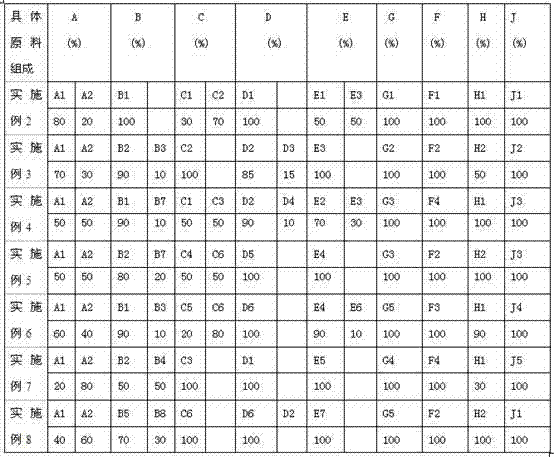

Inorganic foaming thermal-insulation mortar and preparation method thereof

The present invention provides an inorganic foaming thermal-insulation mortar and a preparation method thereof, and belongs to the technical field of building material preparation. The thermal-insulation mortar comprises a cementing material, expanded perlite particles, a macromolecule polymer, a coagulant, an early strength agent, a physical foaming agent, a chemical foaming agent hydrogen peroxide, a chemical foaming agent foaming catalyst, a hydrophobic agent, reinforced short fibers and water. According to the present invention, the inorganic foaming thermal-insulation mortar can be directly coated on the wall and the roof requiring the thermal-insulation treatment, the thickness of the inorganic thermal-insulation mortar layer can be adjusted within 10-100 mm, screeding finishing construction is performed before the cementing material is subjected to final setting, and hardening is performed to obtain the inorganic thermal-insulation mortar layer with characteristics of good durability, good water resistance and good heat insulation, wherein the inorganic thermal-insulation mortar layer never sheds, and has the same service life as the building being subjected to thermal-insulation by the inorganic thermal-insulation mortar layer; and the raw material cost is low, and significant economic benefits and environmental benefits are provided.

Owner:安徽融博科技有限公司

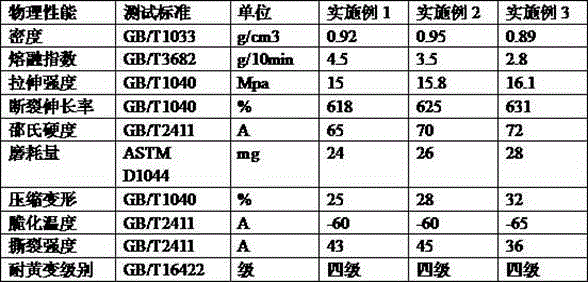

Highly wear-resistant elastomer sole material and preparation method thereof

The present invention discloses a highly wear-resistant elastomer sole material, which comprises the following raw materials: a SBS rubber elastomer, a softening plasticizer, a thermoplastic polyurethane elastomer, a polyolefin elastomer, ethylene propylene diene monomer, a polystyrene resin, a styrene-butadiene rubber, a filler, an antioxidant, a light stabilizer and a processing aid. The invention further discloses a preparation method of the highly wear-resistant elastomer sole material. According to the present invention, the formula of the highly wear-resistant elastomer sole material is reasonable, the thermoplastic elastomer SBS is adopted as the substrate, and the highly wear-resistant elastomer sole material has advantages of high elasticity, high wear resistance, low compression deformation, weather resistance, low temperature resistance, excellent mechanical property, extremely easy extrusion processing molding, and the like; and the preparation method has characteristics of simple process, easy achieving and high production efficiency, and can quickly produce the highly wear-resistant elastomer sole material product, and the product can be widely used in the fields of sports shoes and casual shoes.

Owner:DONGGUAN JISU PLASTIC TECH

Flame retardant high-heat-conductivity epoxy resin electronic adhesive glue

InactiveCN102533192AImprove thermal conductivityDisperse quicklyNon-macromolecular adhesive additivesEpoxynovolac adhesivesHalogenAdhesive glue

The invention relates to flame retardant high-heat-conductivity epoxy resin electronic adhesive glue, which is formed by mixing ingredients A with amine curing agents according to the weight ratio of 100:(5-12), wherein the ingredients A comprises the following ingredients in parts by weight: 50 to 60 parts of spherical alumina powder, 20 to 30 parts of flame retardant fillings, 10 to 20 parts of epoxy resin, 1.5 to 2.5 parts of reactive diluents, 2 to 3 parts of halogen-free liquid flame retardants, 2 to 3 parts of toughening agents, 0.2 to 0.8 parts of thixotropic agents and 0.1 to 0.5 parts of coupling agents. According to the adhesive glue provided by the invention, the adhesive glue filled by the spherical alumina has higher condensate heat conductivity when being compared with the adhesive glue filled by the non-spherical alumina, and the heat accumulation of heating devices can be fast dispersed.

Owner:YANTAI DARBOND TECH

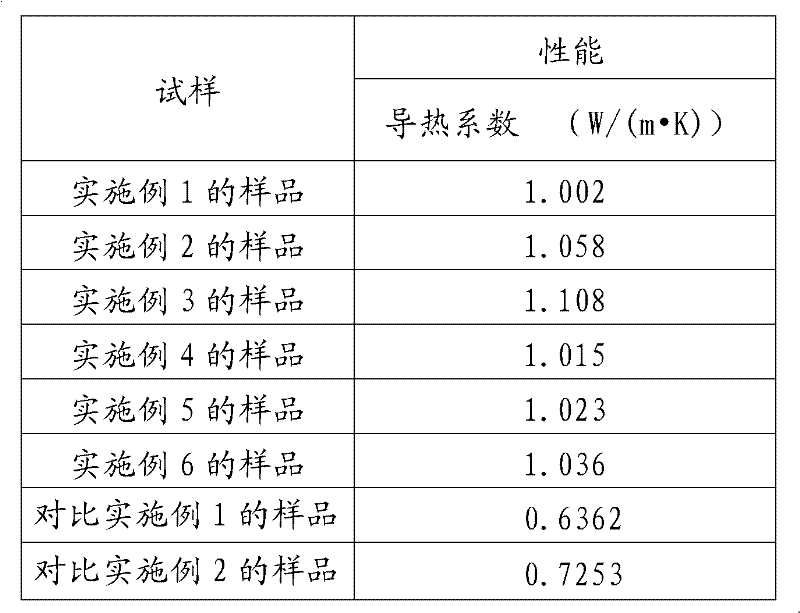

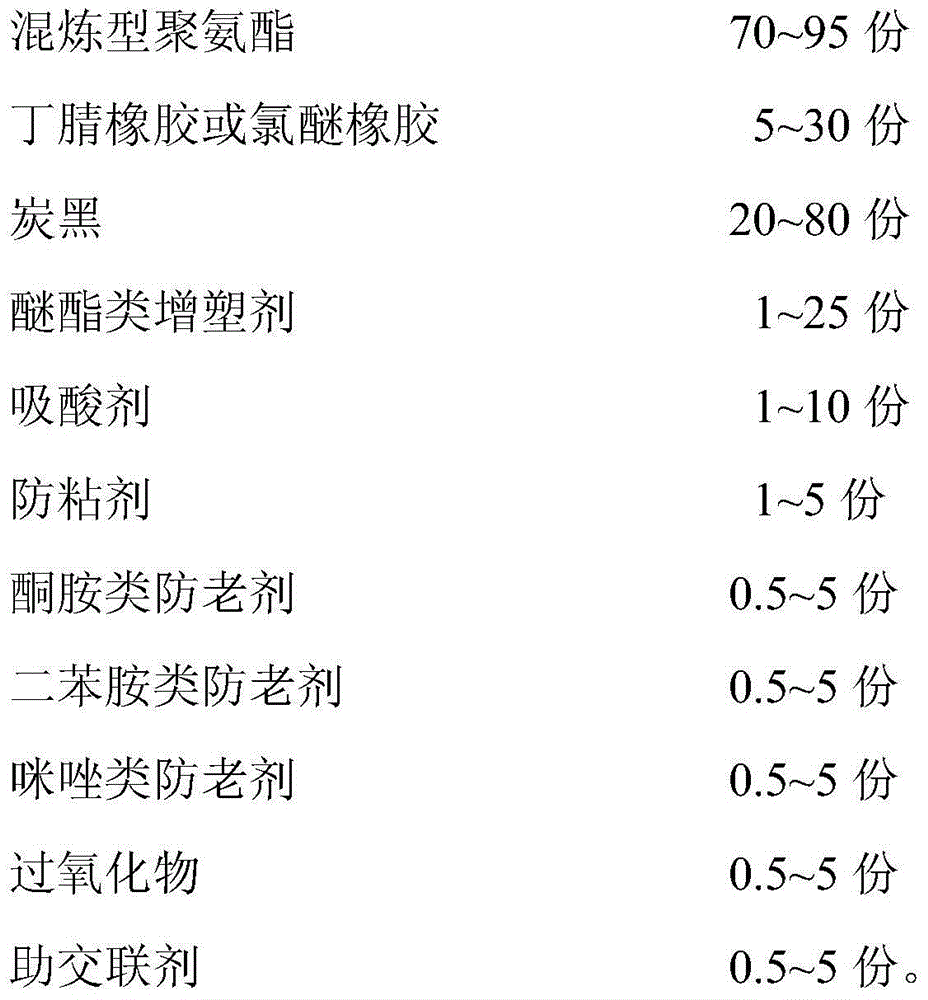

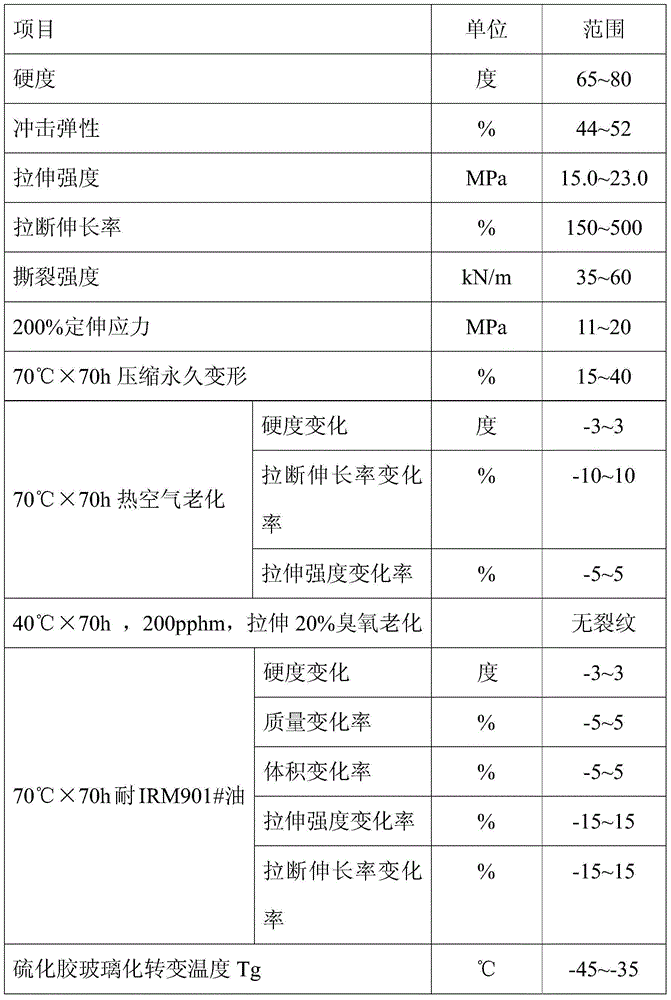

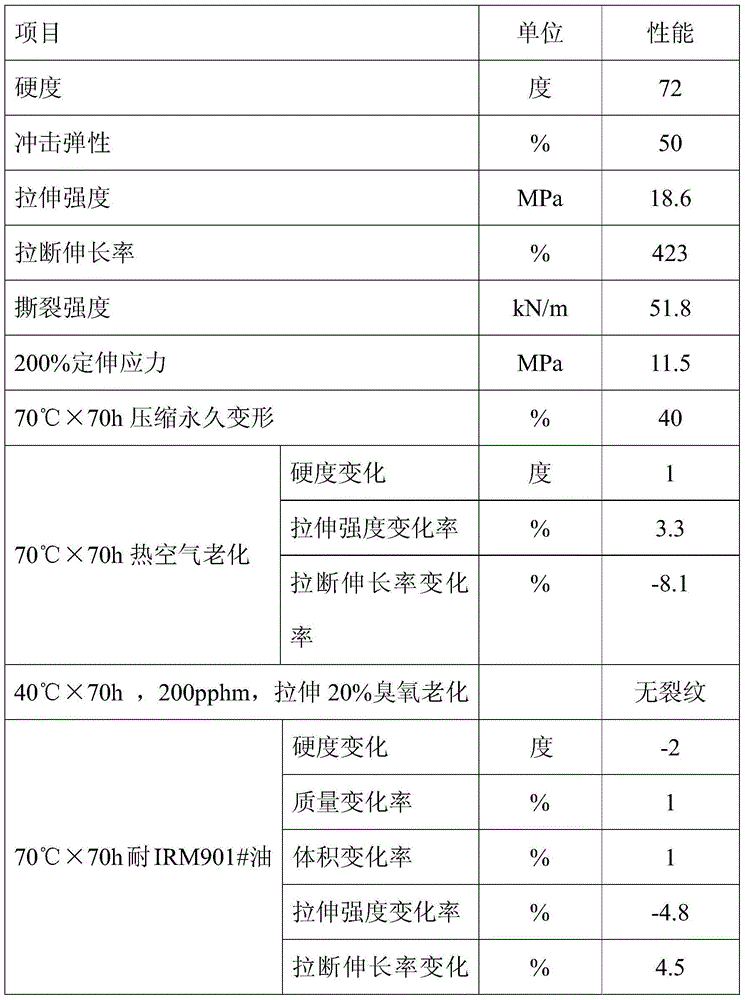

Oil-resistant low-temperature-resistant weather-proof rubber sealing material and preparation method and application thereof

ActiveCN104086980AGood oil resistanceImprove low temperature resistanceOther chemical processesPolymer scienceGlass transition

The invention belongs to the technical field of high molecular material, and discloses an oil-resistant low-temperature-resistant weather-proof rubber sealing material and a preparation method thereof. The rubber sealing material is prepared by taking millable polyurethane as a main material, adopting a small amount of nitrile rubber or epichloro-hydrin rubber, cooperatively adding a reinforcing agent, a plasticizer, an anti-sticking agent, a mold-release agent, an acid absorbing agent, a ketoamine anti-aging agent, a diphenylamine anti-aging agent, an imidazole anti-aging agent, a peroxide, an auxiliary cross-linking agent and other auxiliary materials, and mixing through an open mill or an internal mixer. A sealing product prepared by the rubber sealing material has better balance between low-temperature resistance and oil resistance, enables the glass transition temperature Tg to reach -40 DEG C or less, has excellent weather aging resistance performance, also has good comprehensive performance, and is long in service life.

Owner:GUANGZHOU MECHANICAL ENG RES INST

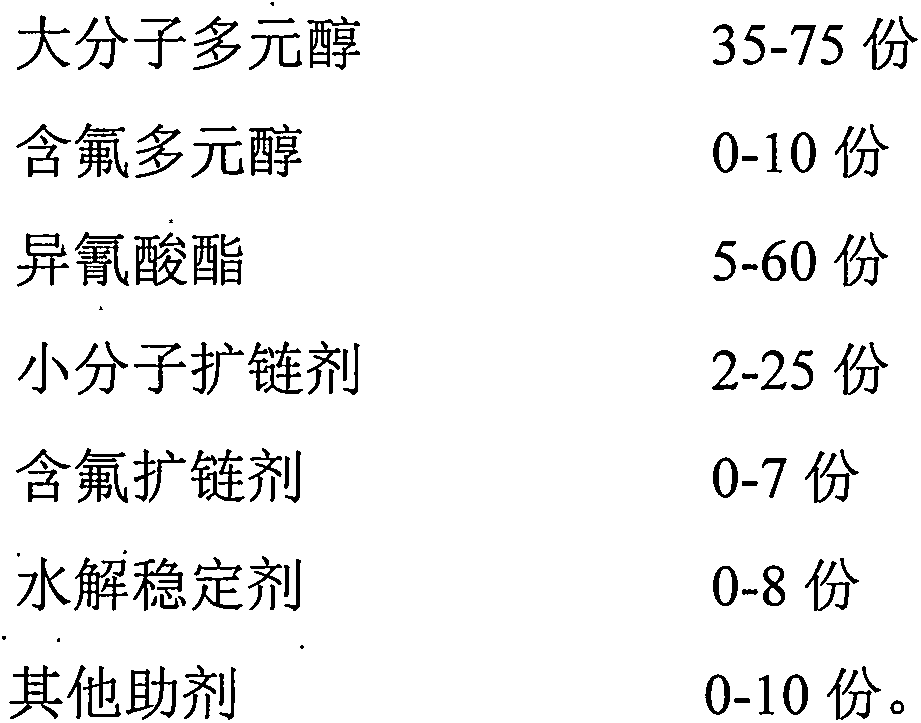

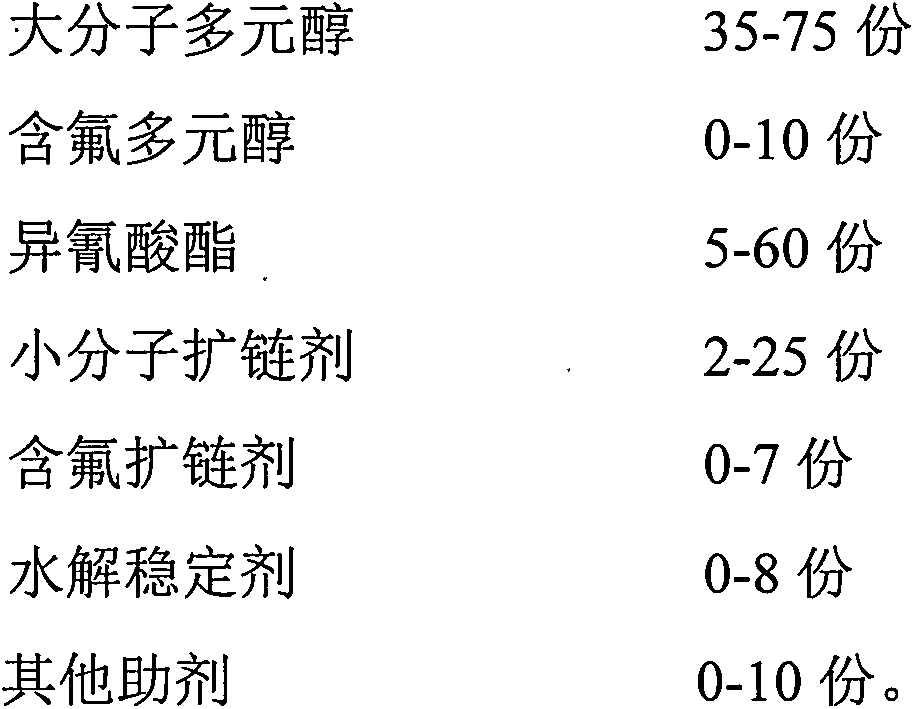

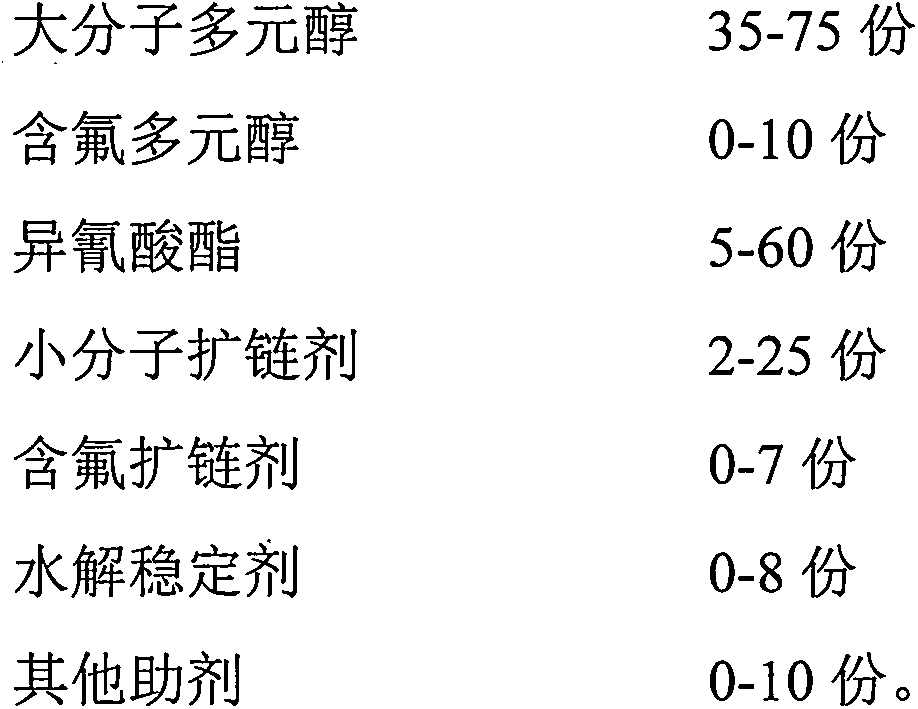

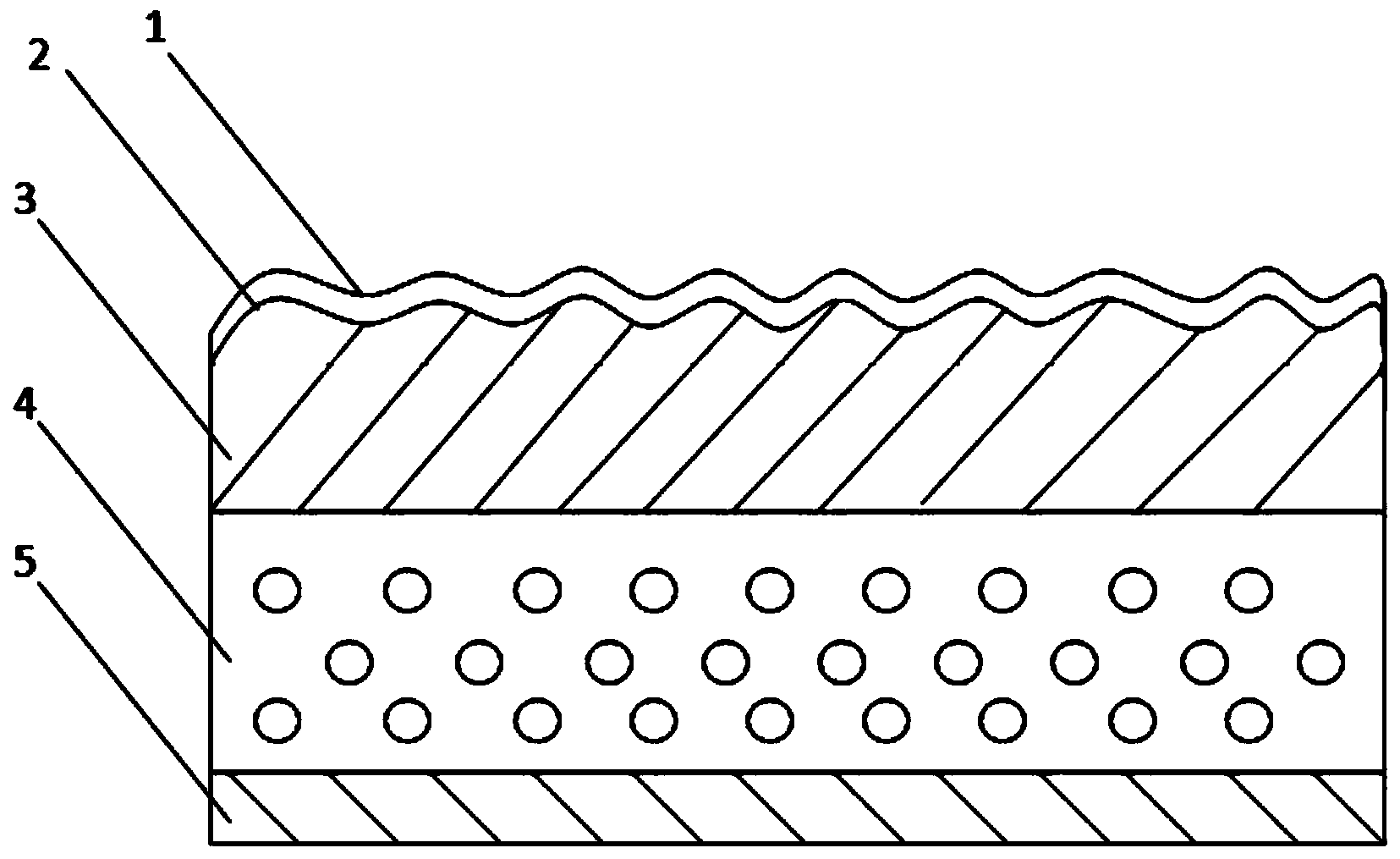

3D-printing thermoplastic polyurethane material and preparation method of same

The invention discloses a 3D-printing thermoplastic polyurethane material and a preparation method of same. The 3D-printing thermoplastic polyurethane material includes, by weight, 35-75 parts of a macro-molecular polyol, 0-10 parts of a fluorine-containing polyol, 2-25 parts of a small-molecular chain extender, 0-7 parts of a fluorine-containing chain extender, 5-60 parts of isocyanate, 0-8 parts of a hydrolysis stabilizing agent, and 0-10 parts of other additives. Compared with a method in the prior art, an in-situ polymerization one-step method is employed in the preparation method. By means of one or more of the fluorine-containing polyol and the fluorine-containing chain extender, fluorine is introduced into the thermoplastic polyurethane material to prepare the 3D-printing thermoplastic polyurethane material which has the advantages of both the fluorine-containing compound and the TPU. The material is excellent in thermal-stability, is low in shrinking rate, is high in mechanical performance and is low in water absorption. A 3D-printing product prepared from the material is excellent in performance.

Owner:SHANGHAI HENGAN POLYURETHANE CO LTD

Environment-friendly thermoplastic polyolefin (TPO) auto interior material and preparation method thereof

InactiveCN103965800AImprove the decorative effectSmall smellLamination ancillary operationsFilm/foil adhesivesEnvironmental resistancePolyolefin

The invention provides an environment-friendly thermoplastic polyolefin (TPO) auto interior material comprising a TPO surface layer, and a polypropylene foam layer which is compounded with the TPO surface layer, wherein the TPO surface layer is formed by semi-crosslinked TPO, polypropylene, polyethylene, a light stabilizer, an antioxidant, a fire retardant, a filler, an extinction material, a scratch resistant agent and a pigment. The TPO auto interior material disclosed by the invention has the advantages of being good in decorative property, environment-friendly and recoverable, low in odor, low in haze, high and low temperature resistant, weather-resistant, free of separated bloom, good in machinability, high in qualification rate, low in cost, and high in bonding strength with a skeleton, and still can keep good matting property and scratch resistance after being scrubbed.

Owner:TIANJIN DALIN NEW MATERIAL TECH

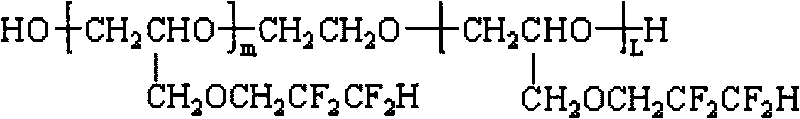

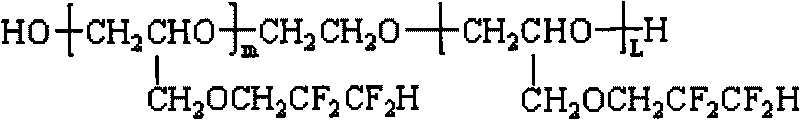

Method for preparing high-toughness thermoplastic fluorine-containing polyurethane elastomer

ActiveCN101717485AKeep the elastomer perfectly linearLower surface energyPolyurethane elastomerThermoplastic

The invention discloses a method for preparing a high-toughness thermoplastic fluorine-containing polyurethane elastomer, which is characterized in that a bulk polymerization two-step method is adopted to synthesize the fluorine-containing polyurethane elastomer, the isocyanate index is 0.98, and the hard segment content is between 20 and 40 weight percent. The method comprises the following steps of: weighing 6 to 40 parts of non-fluorine macromolecular polylol and / or 30 to 80 parts of fluorine-containing polyether diol in a reactor, performing vacuum dehydration on the mixture for 2h at thetemperature of 120 DEG C, cooling the mixture to be between 70 and 100 DEG C, adding 16 to 33 parts of polyisocyanate into the mixture, stirring the mixture to react for 3h, heating the mixture to bebetween 120 and 140 DEG C, adding 0.1 to 15 parts of low molecular (fluorine-containing) diol chain extender into the mixture, uniformly stirring the mixture, then dumping the mixture into a preheated container, and performing vacuum baking for 20 hours at the temperature of between 120 and 140 DEG C to obtain the high-toughness thermoplastic fluorine-containing polyurethane elastomer.

Owner:SICHUAN UNIV

High-heat-conductivity epoxy resin electronic binding glue

InactiveCN102127382AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesEpoxynovolac adhesivesReactive diluentThermal expansion

The invention relates to a high-heat-conductivity epoxy resin electronic binding glue. The invention is characterized in that the high-heat-conductivity epoxy resin electronic binding glue is prepared by mixing 100 parts by weight of a component A and 5-12 parts by weight of an amine curing agent; and the component A is prepared from the following raw materials in parts by weight: 70-85 parts of spherical aluminum oxide powder, 10-20 parts of epoxy resin, 2-3.5 parts of reactive diluent, 2.5-5 parts of toughener, 0.2-1 part of thixotropic agent and 0.1-0.5 part of coupling agent. The spherical aluminum oxide of the binding glue provided by the invention has higher filling volume than non-spherical aluminum oxide, and high heat conductivity for solids, and can quickly dissipate heat accumulated in the heating components; the filler with high filling volume can lower the thermal expansion coefficient and volume shrinkage, and thus, the binding glue is very suitable for binding electronic components; and the price of the spherical aluminum oxide is lower than that of boron nitride (BN) or aluminium nitride (ALN), and thus, the binding glue provided by the invention has the advantage of low cost.

Owner:YANTAI DARBOND TECH

Weather resistance steel argon-rich gas shielded welding wire for high-intensity railway vehicle

InactiveCN101357425AMeet the high requirements of weld seam resistance to atmospheric corrosionGood weather resistanceWelding/cutting media/materialsSoldering mediaChemical compositionWeather resistance

The invention discloses an argon-rich gas-shielded welding wire of high-strength weathering steel used in railway cars, which is prepared by the following chemical components according to mass percentage: 0.2-0.35 percent of Cu, 0.3-0.7 percent of Cr, 0.2-to 0.6 percent of Ni, 0.05-0.1 percent of C, 0.3-0.5 percent of Si, 1.2-1.45 percent of Mn, P which is less than or equal to 0.015 percent, S which is less than or equal to 0.015 percent, the rest of Fe and unavoidable impurities. The welding wire is characterized by high weatherability, high strength, good flexibility, good resistance to welding cold crack, and the like, and the tensile strength thereof is more than 600MPa and the low-temperature impact property Axv is equal to or more than 146J at minus 40 DEG C. The welding wire adopts argon-rich gas as shield gas and has stabilized arcs, little splash, no air hole and good welding appearance when in welding. Furthermore, weld joints have an excellent matching effect with the high-strength weathering wheel used in the railway cars.

Owner:HUBEI KMK WELDING MATERIALS

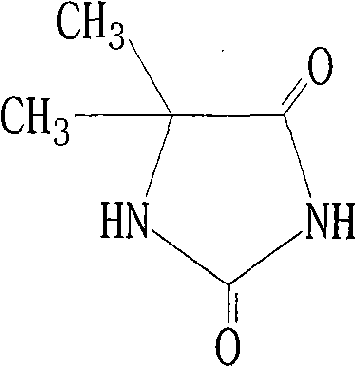

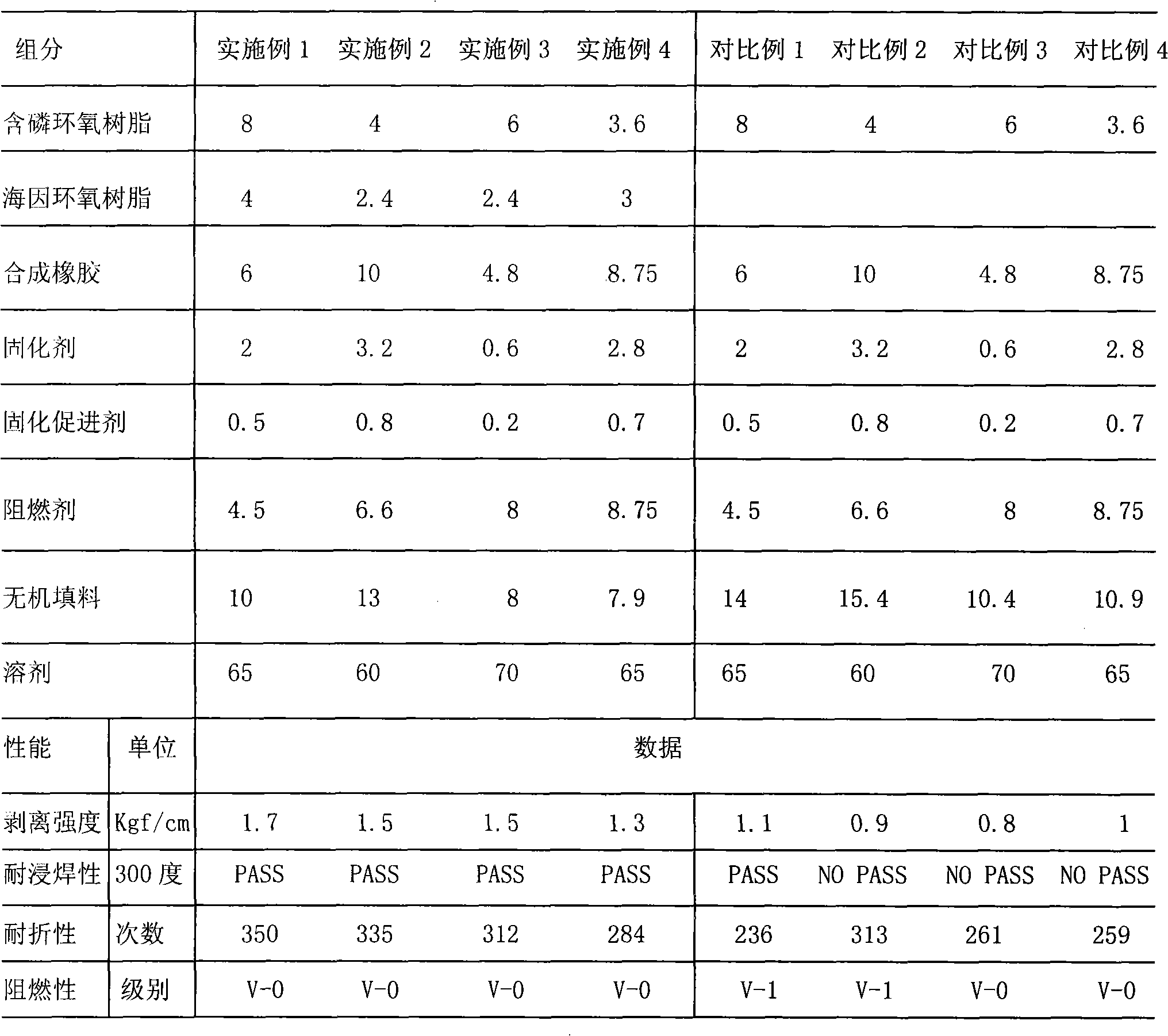

Halogen-free flame retardant epoxy resin composite and flexible copper clad laminate prepared with same

ActiveCN101633770ALow viscosityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentWeather resistanceChemistry

The invention discloses a halogen-free flame retardant epoxy resin composite and a flexible copper clad laminate prepared from same. The invention is characterized that hydantoin epoxy resin is added in the existing composite and the hydantoin epoxy resin has the advantage that the viscosity is low, the manufacturability is good; the thermal stability is good, the thermostability is high; the weather resistance is good, the hydantoin epoxy resin can be shined by sunlight and ultraviolet light without yellowing and chalking; the hydantoin epoxy resin can be is resistant to salt fog, the corrosion resistance is outstanding, the product has low toxicity and good flame retardant and the like. Therefore the hydantoin epoxy resin is very applicable to being used to prepare the halogen-free flame retardant epoxy resin composite. In addition, the invention also provides a polyimide copper clad laminate prepared by adopting the composite as adhesive, and the prepared copper clad laminate has the advantage of good flame retardant performance, high peel strength, good folding endurance and the like and can increase the electrical property of the copper clad laminate.

Owner:PANYU NANSHA YAN TIN CHEM

Powder coating composition having high weather resistance

InactiveUS6706794B1Excellent hiding effectDecrease color differenceSynthetic resin layered productsCellulosic plastic layered productsWeather resistancePolymer chemistry

A powder coating composition which comprises (A) a fluorine-containing copolymer having a crosslinkable reactive group and (B) a curing agent being capable of forming crosslinkage by reacting with the crosslinkable reactive group of the fluorine-containing copolymer in a weight ratio (A) / (B) of 40 / 60 to 98 / 2, and contains rutile titanium oxide and other pigment. The powder coating composition can form a coating film which can exhibit excellent weather resistance even under very strict environment specified in AAMA 2605 standard, etc., and is suitable particularly for an exterior member for building, for example, an aluminum sash.

Owner:DAIKIN IND LTD

Red schorl type titanium dioxide coating method and preparation of used reagent

InactiveCN101463195AHigh whitenessHigh glossPigment treatment with non-polymer organic compoundsAluminateWeather resistance

The invention relates to a rutile type titanium dioxide coating method and a preparation method of reagent used thereby. A layer of ZrO2 is firstly coated on a TiO2 particle, thus improving the white content, lustrousness and weather resistance of the product; four layers of pellumina are coated in batches to further improve the performances such as weather resistance, dispersivity (dry powder fluidness), hiding power, lustrousness and the like of the product; finally, the main function of organic coating is to improve the dry powder fluidness of the product and the dispersivity in the application media; meanwhile, the lustrousness of the product is improved, and the aggregation resistant performance of the product in storage and transportation can be enhanced. Sodium aluminate or aluminium sulphate is added at the different stages of the coating process, so that the pH value the sizing agent can be regulated by utilizing the different pH values of the two aluminates, and the complicated operation that the pH value the sizing agent is regulated after coating agent is added every time is omitted. The titanium dioxide which coated and finally obtained has the advantages of high lustrousness, dispersivity, dry powder fluidness and weather resistance.

Owner:HENGYANG TIANYOU CHEM

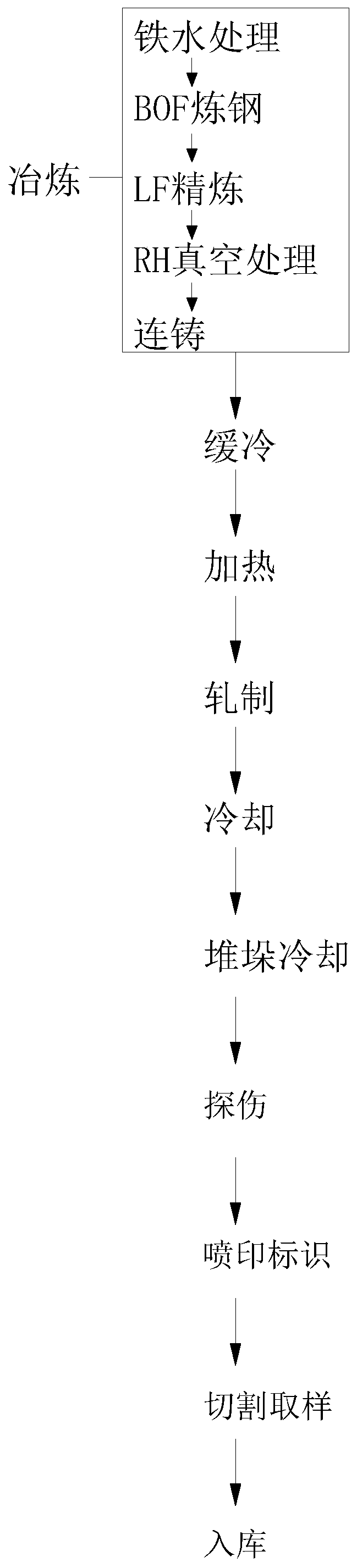

Weather-resistant bridge steel with yield strength not less than 345 MPa and preparation method thereof

The invention relates to weather-resistant bridge steel with yield strength not less than 345 MPa and a preparation method thereof. The weather-resistant bridge steel with the yield strength not lessthan 345 MPa comprises the following components of, in percentage by weight, 0.07%-0.11% of C, 0.15%-0.30% of Si, 0.80-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.01-0.04% of Al, 0.20-0.40% of Cr, 0.20-0.40% of Cu, 0.20-0.50% of Ni, 0.020-0.050% of Nb, 0.010-0.040% of Ti and the balance Fe and inevitable impurities; and the preparation method comprises thefollowing steps of smelting, slow cooling, heating, rolling, cooling and stacking and cooling. According to the weather-resistant bridge steel with the yield strength not less than 345 MPa and the preparation method thereof, the low-cost micro-alloying design is adopted, the production period is short, the cost is low, popularization and application are facilitated, the weather-resistant bridge steel has excellent welding performance, strong toughness and strong plasticity matching performance, low yield ratio, corrosion resistance, weather resistance, welding performance and anti-fatigue performance, compared with traditional weather-resistant steel, the weather resistance is improved by one time or above, the weather-resistant bridge steel can replace the traditional high-strength weathering steel, and can be applied to the fields of bridges, outdoor tower frames and the like without coating, so that the use cost and the maintenance cost are reduced.

Owner:SD STEEL RIZHAO CO LTD

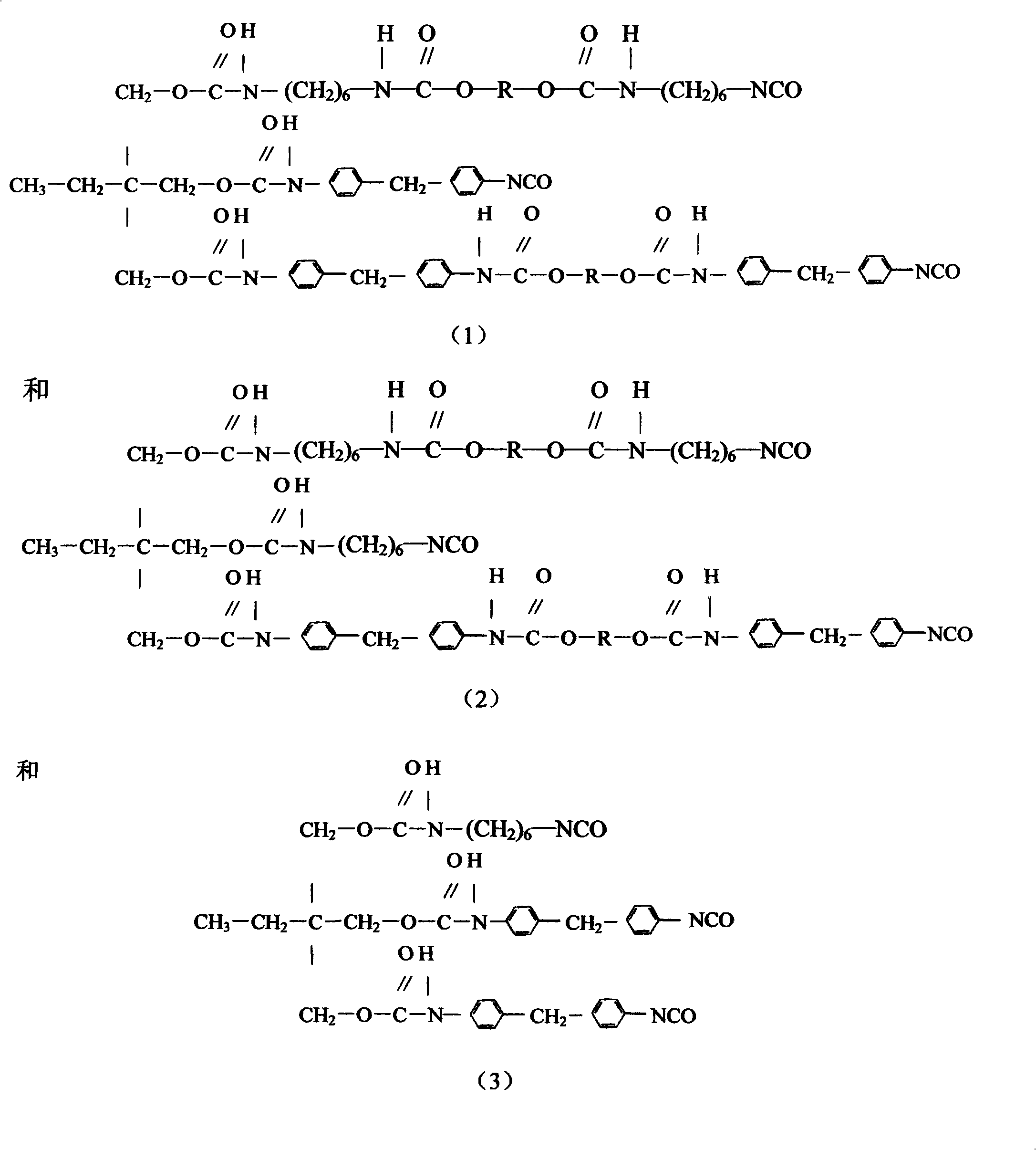

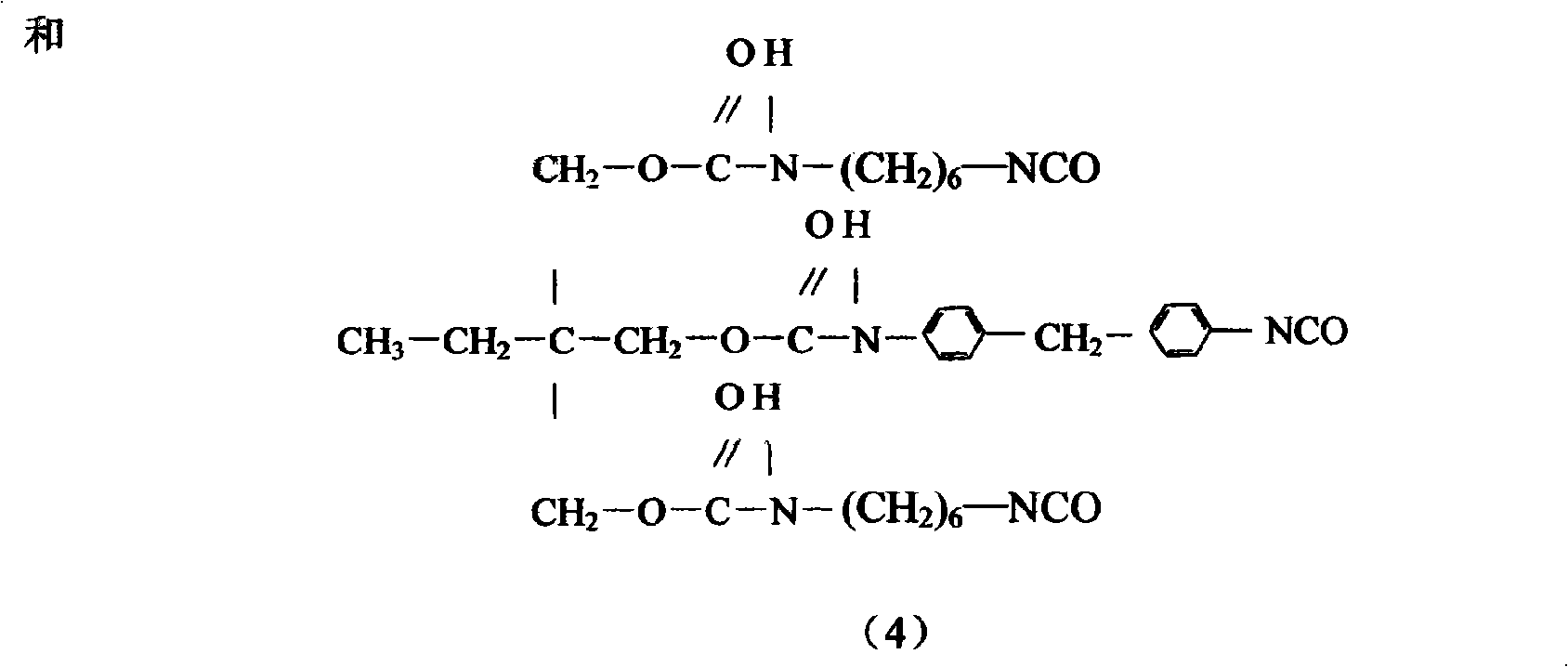

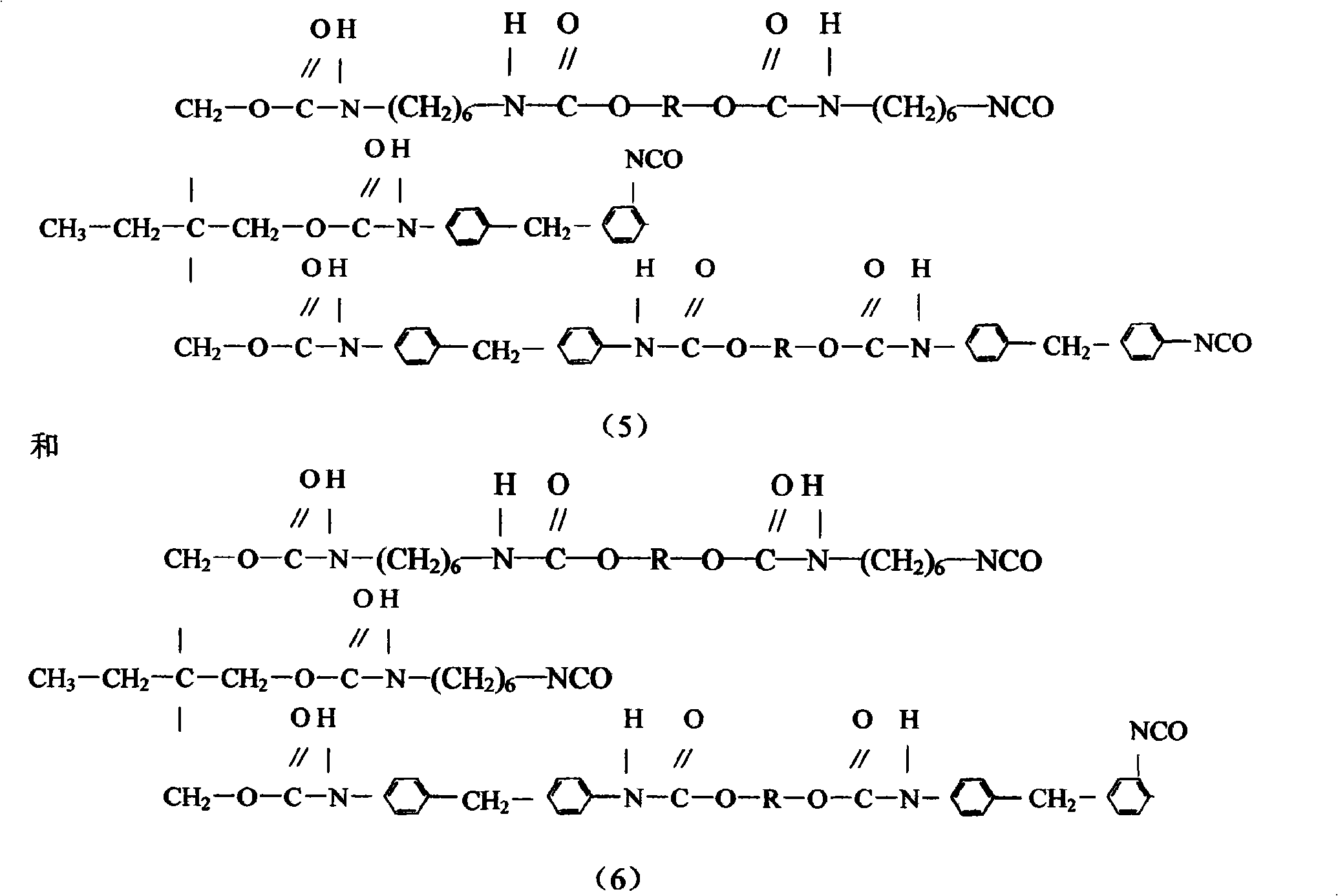

Mixed prepolymer of solidifying agent methyl diphenylene diisocyanate and 1,6-hexamethylene diisocyanate

The invention relates to a curing agent compound prepolymer composed of diphenylmenthane diisocyanate and 1, 6-hexamethylene diisocyanate and a preparation method thereof. The method comprises the following steps: MDI and an organic solvent are added and heated to 65 DEG C, polybasic alcohol is added and reacts with the mixture for 2 hours to 4 hours to obtain an MDI modifier; HID, an organic solvent and polybasic alcohol are added, heated and react for 2 hours to 5 hours, then the temperature is reduced below 70 DEG C, a TMP and organic solvent mixture is added, reaction at 70 DEG C lasts for 1 hour to 4 hours and 1 hour to 4 hours when the temperature is between 60 DEG C and 100 DEG C so as to obtain an HDI-MDI compound prepolymer curing agent. The method mixes and pre-polymerizes MDI and HDI, integrates the excellent performance of the two, produces a series of polyurethane curing agents with wide application range, high strength, good yellow-changing resistance, high curing speed, low toxicity, good storage stability and high solid content and has simple production technique.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

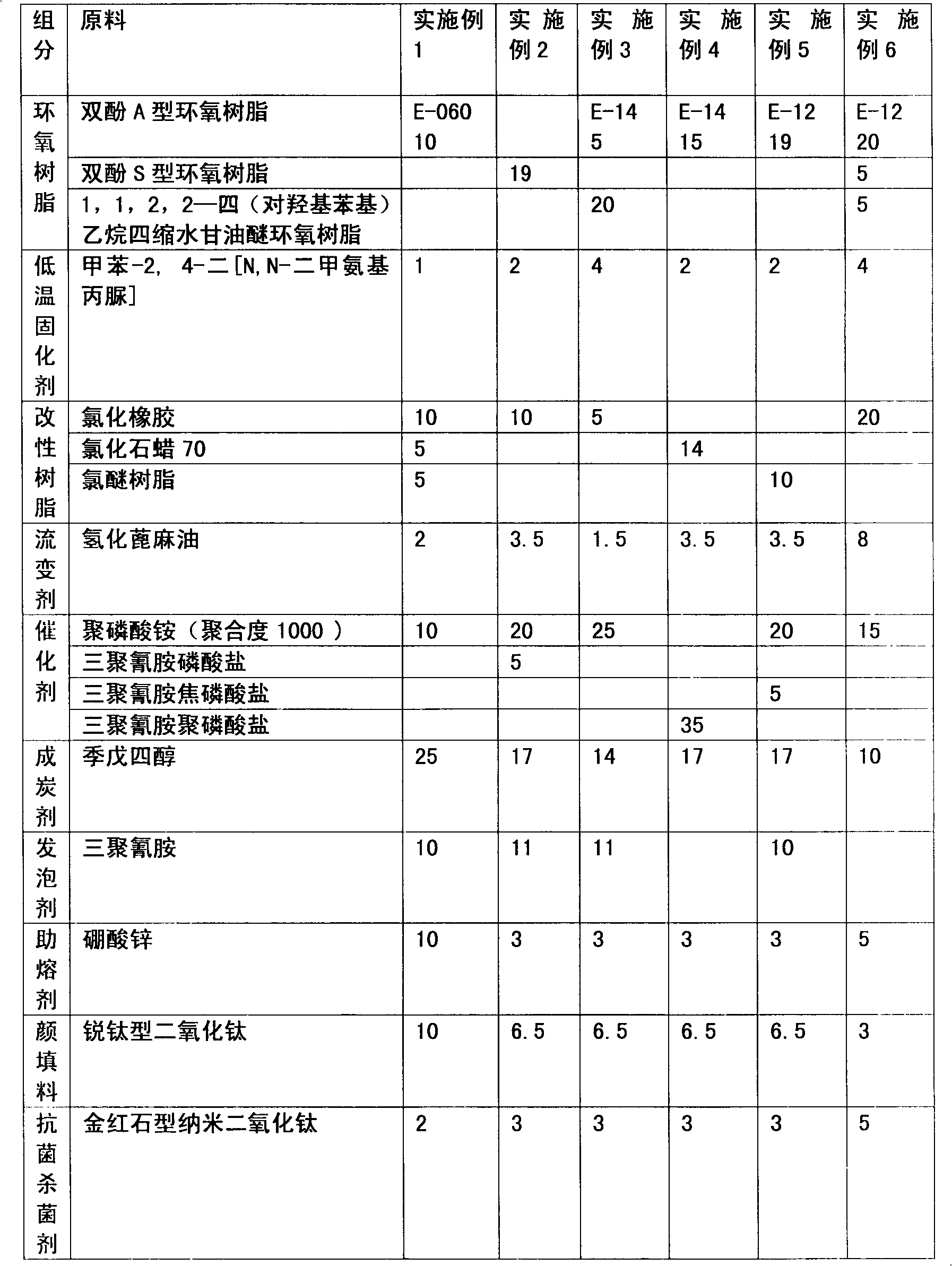

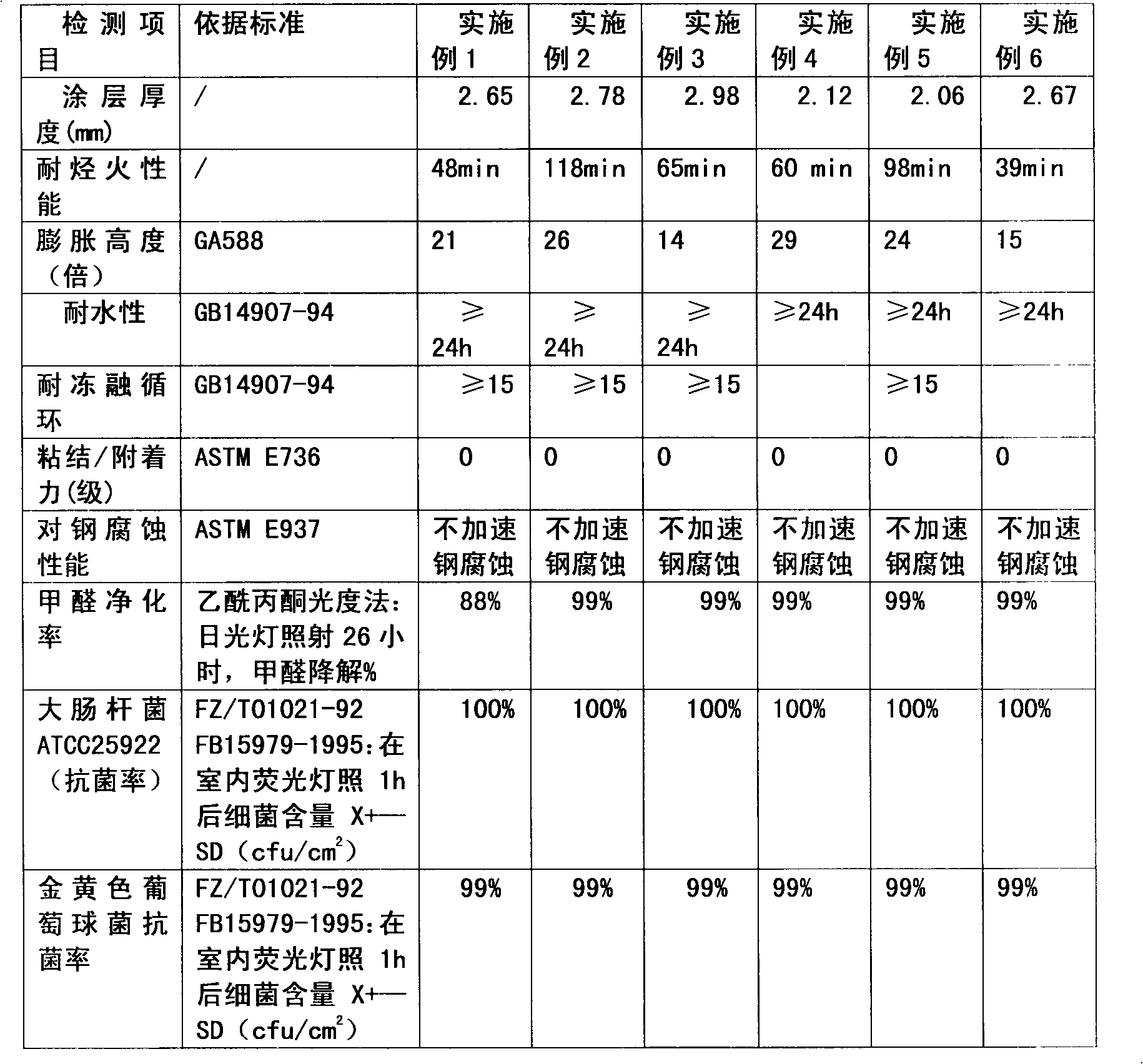

Hydrocarbon fire resistant ultrathin expanded fireproof coating and preparation method thereof

InactiveCN102020910ANot easy to fall offNo cross-linking reactionFireproof paintsRubber derivative coatingsEpoxyFire risk

The invention provides a hydrocarbon fire resistant ultrathin expanded fireproof coating and a preparation method thereof. The coating comprises the following components in part by weight: 10 to 30 parts of epoxy resin, 1 to 4 parts of modified curing agent, 5 to 20 parts of modified resin, 2 to 8 parts of rheological agent, 10 to 35 parts of catalyst, 10 to 25 parts of carbon forming agent, 0 to 11 parts of foaming agent, 5 to 10 parts of fluxing agent, 3 to 10 parts of pigment and filler, and 2 to 5 parts of antibacterial bactericide. The method comprises the following steps of: mixing the crushed resin and other components uniformly, extruding the mixture at the temperature of 95 DEG C at the rotational speed of 300 revolutions per minute, crushing the extruded product, and sieving the powder with a sieve of 40 meshes to obtain the coating. The coating has low curing temperature, high hydrocarbon fire resistant limit, good bonding force and high strength, can tolerate high and low-temperature circulating influence, has air purification and sterilization functions, and is convenient for construction; and the preparation method is simple, and has low energy consumption. The coating is particularly suitable for fire protection of steel, aluminum and other materials of the indoor and outdoor petrochemical industry with hydrocarbon fire risks.

Owner:应急管理部四川消防研究所

Highly-weather-resistant type ASA (acrylonitrile Styrene acrylate copolymer)-based color co-extrusion material with low heat absorption effect and preparation method thereof

ActiveCN104212107AReduced heat absorption capacityLow weather resistanceASA-polymerWeather resistance

The invention discloses a highly-weather-resistant type ASA (acrylonitrile Styrene acrylate copolymer)-based color co-extrusion material with low heat absorption effect and a preparation method thereof. The highly-weather-resistant type ASA-based color co-extrusion material is characterized by comprising the following components in parts by weight: 85-94 parts of ASA, 1-4 parts of a light stabilizer, 1-2 parts of an ultraviolet absorber, 1-3 parts of an antioxidant and 2-6 parts of pigments. The preparation method of the highly-weather-resistant type ASA-based color co-extrusion material comprises the following steps: (1) weighing base stock, the light stabilizer, the ultraviolet absorber, the antioxidant and the pigments in proportion; (2) firstly adding the light stabilizer, the ultraviolet absorber, the antioxidant and the pigments to uniformly mix, and then adding the base stock to uniformly mix; and (3) extruding and pelletizing the uniformly-mixed materials to prepare the highly-weather-resistant type ASA-based color co-extrusion material with low heat absorption effect. Compared with the prior art, the highly-weather-resistant type ASA-based color co-extrusion material has low heat absorption and more superior weather resistance.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

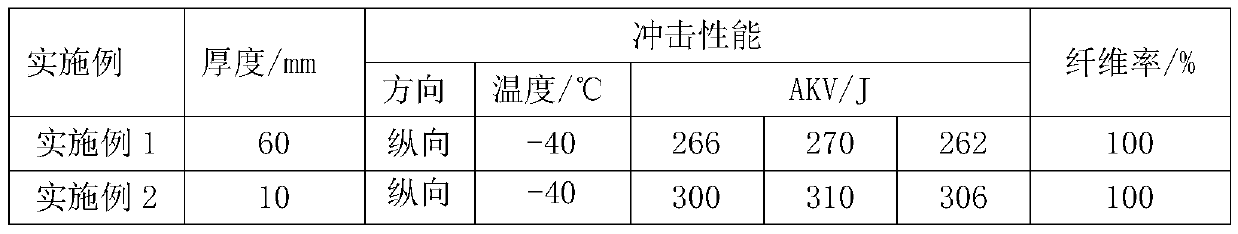

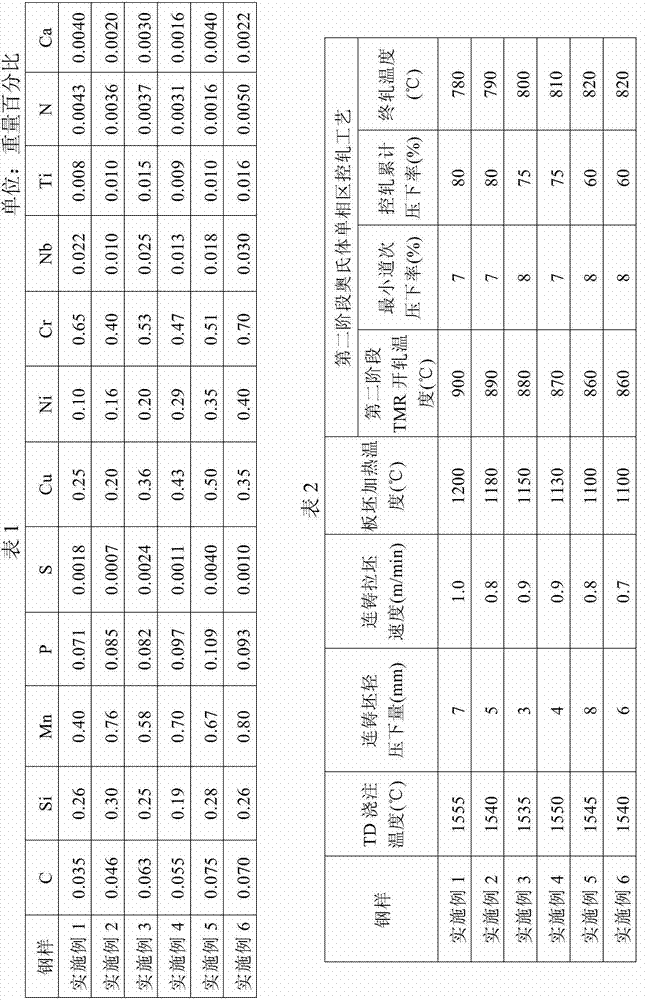

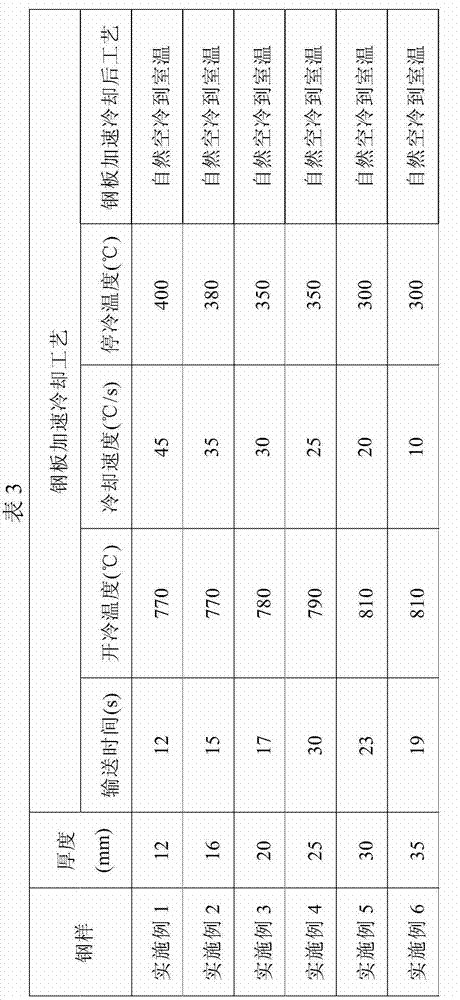

High-toughness and high-weather-resistance steel and manufacturing method thereof

The invention discloses high-toughness and high-weather-resistance steel and a manufacturing method thereof. The high-toughness and high-weather-resistance steel comprises the following components in percentage by weight: 0.035-0.075% of C, no more than 0.30% of Si, 0.40-0.80% of Mn, 0.07-0.11% of P, no more than 0.004% of S, 0.20-0.50% of Cu, 0.10-0.40% of Ni, 0.40-0.70% of Cr, 0.008-0.016% of Ti, 0.010-0.030% of Nb, no more than 0.0050% of N, 0.001%-0. 004% of Ca, and the balance of Fe and unavoidable impurities, wherein by taking a C-Mn-P component system with low C, low Mn and high P as a foundation and through the alloying of Cu, Ni and Cr, [%C] / [%P] is controlled to be not smaller than 0.49, [%Mn] / [%C] is controlled to be not smaller than 10, the weather resistance index DNH is controlled to be not smaller than 6.50%, [%C]*([%P]+2.5[%S]) is controlled to be not more than 0.0025, [%Ca] / [%S] is controlled to be equal to 1.0-3.0, ([%Cu]+0.36[%Ni]+0.27[%Cr])*[%P] is controlled to be not smaller than 0.030, [%Ca]*[%S]0.28 is controlled to be not more than 0.002, and a TMCP (ThermoMechanical Control Process) is adopted. Therefore, the high-toughness and high-weather-resistance steel has excellent low-temperature toughness, bending cold machining characteristic and high weather resistance, and is suitable to be used as a compartment body structure of a coating-free high-speed train.

Owner:BAOSHAN IRON & STEEL CO LTD

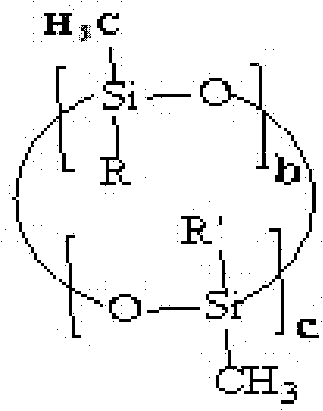

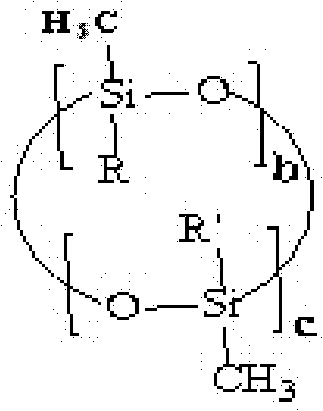

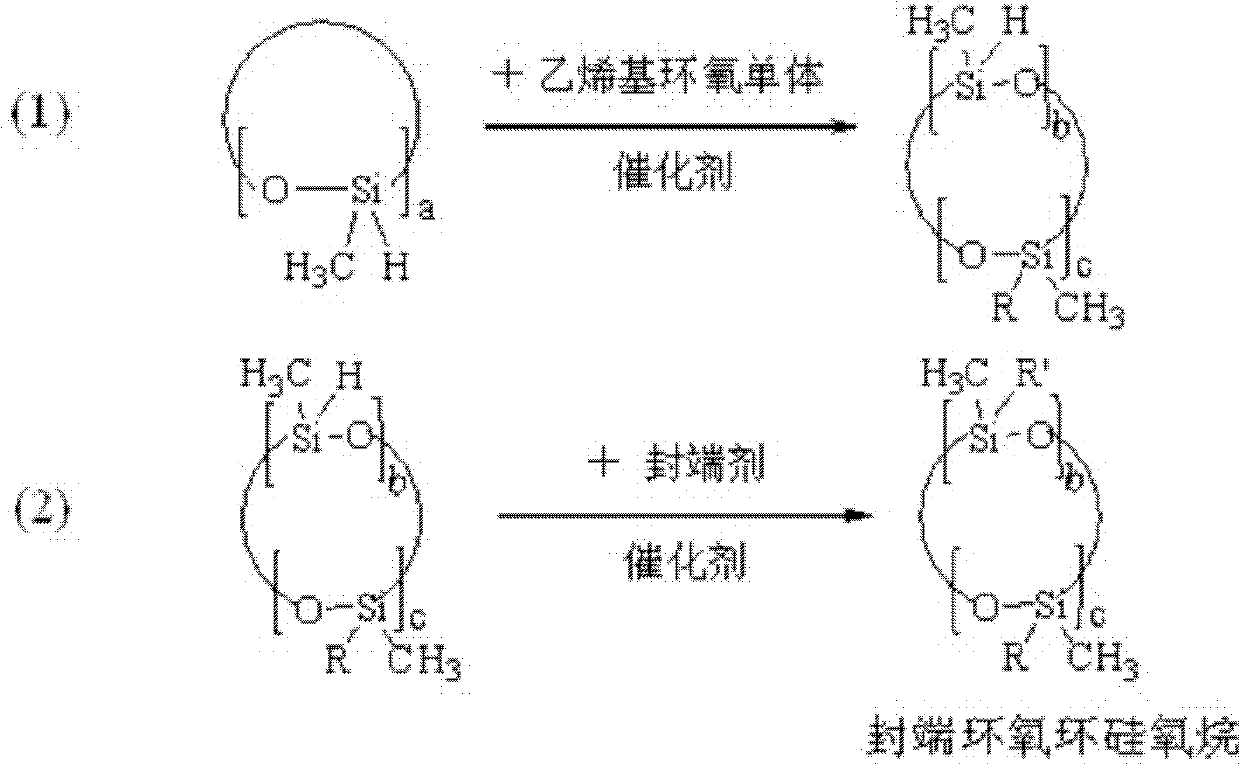

High performance organosilicon epoxy material, preparation method and applications thereof

InactiveCN103319692AHigh light transmittanceGood adhesionSilicon organic compoundsPlastic/resin/waxes insulatorsEpoxyAdhesive

The invention belongs to the field of light emitting semiconductor packaging, and discloses a high performance organosilicon epoxy material, a preparation method and applications thereof. According to the present invention, a vinyl epoxy monomer and methylhydrosiloxane are subjected to a catalysis reaction for 2-24 h, an end capping agent and a catalyst are added to continuously carry out the reaction to obtain end capped epoxy cyclosiloxane, 0.1-5.0 parts of a cyclosiloxane ring opening agent, 0.01-80 parts of an epoxy curing agent and 0.01-5.0 parts of a curing catalyst are added to 100 parts of the end capped epoxy cyclosiloxane in batches, stirring is performed for 0.5-12.0 h under a nitrogen condition during the addition, an auxiliary agent is added, stirring is continuously performed for 0.5-3.0 h, and curing is performed to obtain the organosilicon epoxy material; and the material has characteristics of the epoxy resin and the organosilicon material, further has characteristics of excellent light transmittance, excellent adhesion, excellent mechanical strength, excellent heat resistance and excellent UV performance, and can be adopted as a LED packaging material, an optical lens material, a photoelectric conversion material, an integrated circuit packaging material, an insulation material, a coating material and an adhesive.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Polyurethane-compounded cement-based expanded-perlite heat preservation plate and preparing method thereof

InactiveCN106116328AIncrease productivityGood dimensional stabilityCeramicwarePolyurethane adhesiveWeather resistance

The invention discloses a polyurethane-compounded cement-based expanded-perlite heat preservation plate and a preparing method thereof. The polyurethane composite cement-based expanded-perlite heat preservation plate is prepared from 50-100 parts of expanded perlite, 40-90 parts of cement, 5-10 parts of two-component polyurethane adhesive, 0.1-0.5 part of coupling agent, 0.1-0.25 part of fiber, 0.1-0.5 part of reusable dispersion emulsion powder, 40-90 parts of water, 0.5-2 parts of early strength agent and 0.1-0.5 part of water reducing agent. According to the polyurethane-compounded cement-based expanded-perlite heat preservation plate and the preparing method thereof, cement mortar is modified through polyurethane, polyurethane resin and the cement are evenly dispersed into the expanded perlite, hydration of the cement and solidification of polyurethane are carried out at the same time, and the mutually-filled whole structure is formed; the expanded perlite and the polyurethane cement-based composite are combined, and the polyurethane composite cement-based expanded-perlite heat preservation plate is prepared in a compression-molding mode; the defects of the expanded perlite are effectively overcome, and meanwhile the advantages and the like of the water resistance and heat preservation performance of the polyurethane material, the low heat conductivity of the expanded perlite, the high weather resistance of concrete and the liker are used.

Owner:ANHUI MINGYUAN NEW BUILDING MATERIAL TECH CO LTD

Optical fiber filling paste for polypropylene tube optical cable and preparation method thereof

ActiveCN102902026AEnsure performance transferGood for controlling excess lengthFibre mechanical structuresWeight gainingEngineering

The invention relates to a novel optical fiber filling paste for a polypropylene tube optical cable. The novel optical fiber filling paste is composed of synthetic oil A, high-viscosity synthetic oil B, anchoring agents, viscosity index improvers, gelling agents, thickening agents and antioxidant. The invention further provides a preparation method of the novel optical fiber filling paste. The novel optical fiber filling paste is applicable to an optical fiber loose tube made of the polypropylene material, and has the main features of fine compatibility with the polypropylene material (under the temperature of 80 DEG C for 672 hours, the weight gain ratio is less than or equals to 15%; and under the same experimental condition, the weight gain ratio of a common optical fiber filling paste is larger than 30%), colloid stability and oxidation stability, heat resistance, weather resistance, no system oil separation and low acid value. And the novel optical fiber filling paste is high in water resistance, is not emulsified, fine in high-temperature dripping, high-and-low temperature resistance, and is favorable for the control of the residual length of an optical fiber in the loose tube. Therefore, the optical fiber and a cable core can always be in a most free and unstressed state respectively in the polypropylene loose tube and the cable, and performance transmission of the optical cable is guaranteed.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

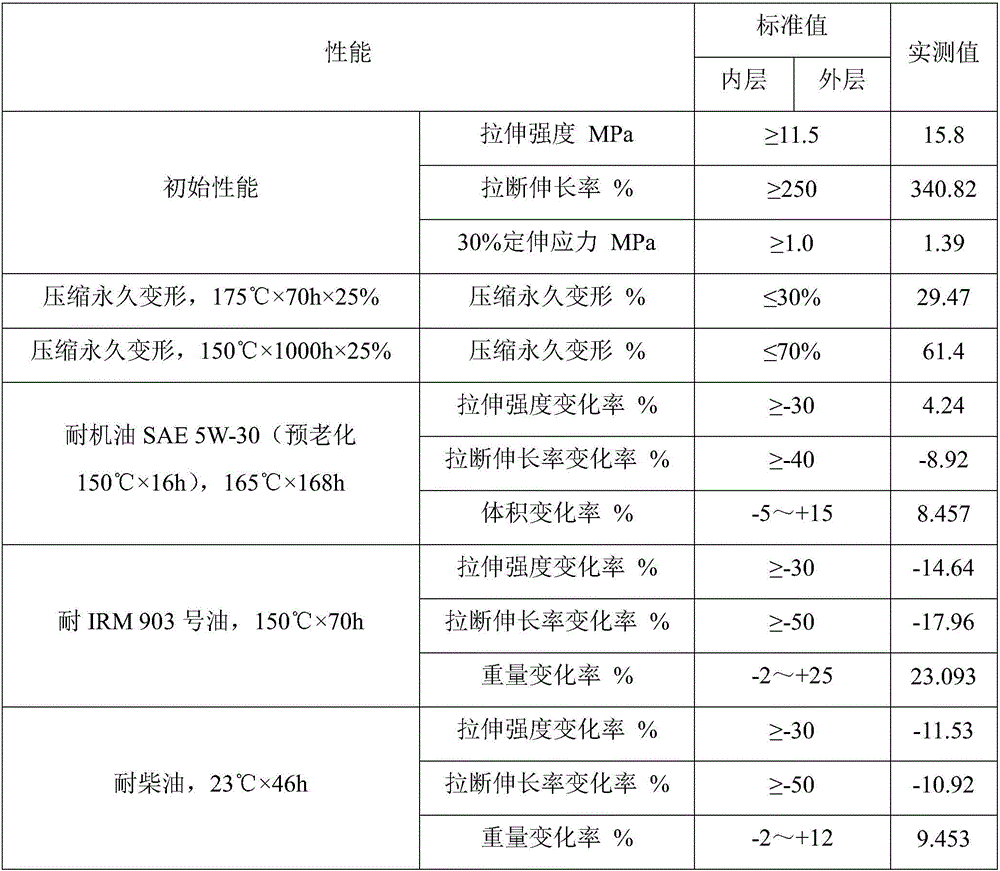

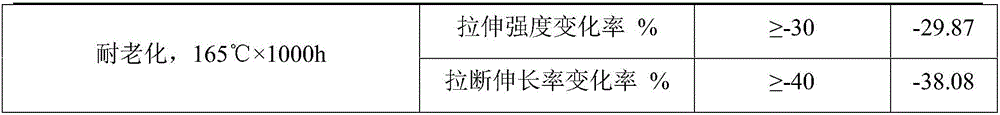

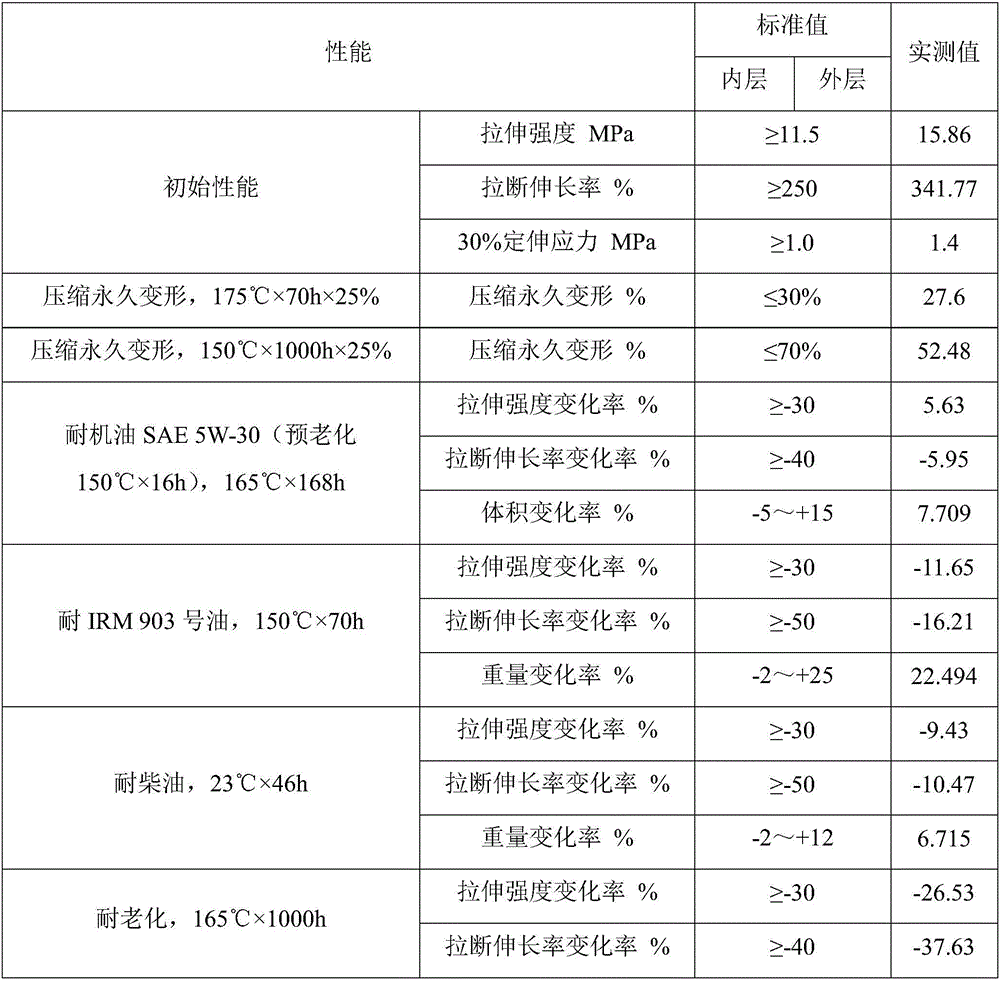

Rubber composition for preparing external and internal layers of automotive turbocharged hose and production method thereof

The invention relates to a rubber composition for preparing external and internal layers of an automotive turbocharged hose. The rubber composition comprises 100 parts of ethylene acrylate rubber, 1.0-3.0 parts of anti-aging agent, 1.0-3.0 parts of processing agent, 10.0-20.0 parts of plasticiser, 50.0-70.0 parts of carbon black, 0.5-1.5 parts of internal releasing agent, 2.0-3.0 parts of vulcanization activator and accelerator and 1.0-2.0 parts of vulcanizing agent. The invention further provides a preparation method for the rubber composition. The rubber composition improves high temperature resistance and oil resistance, reduce compression permanent sets, and is not prone to scorching, good in processing characteristics, and can serve as the external layer and the internal layer of the automotive turbocharged hose.

Owner:QINGDAO SUNSONG CO LTD

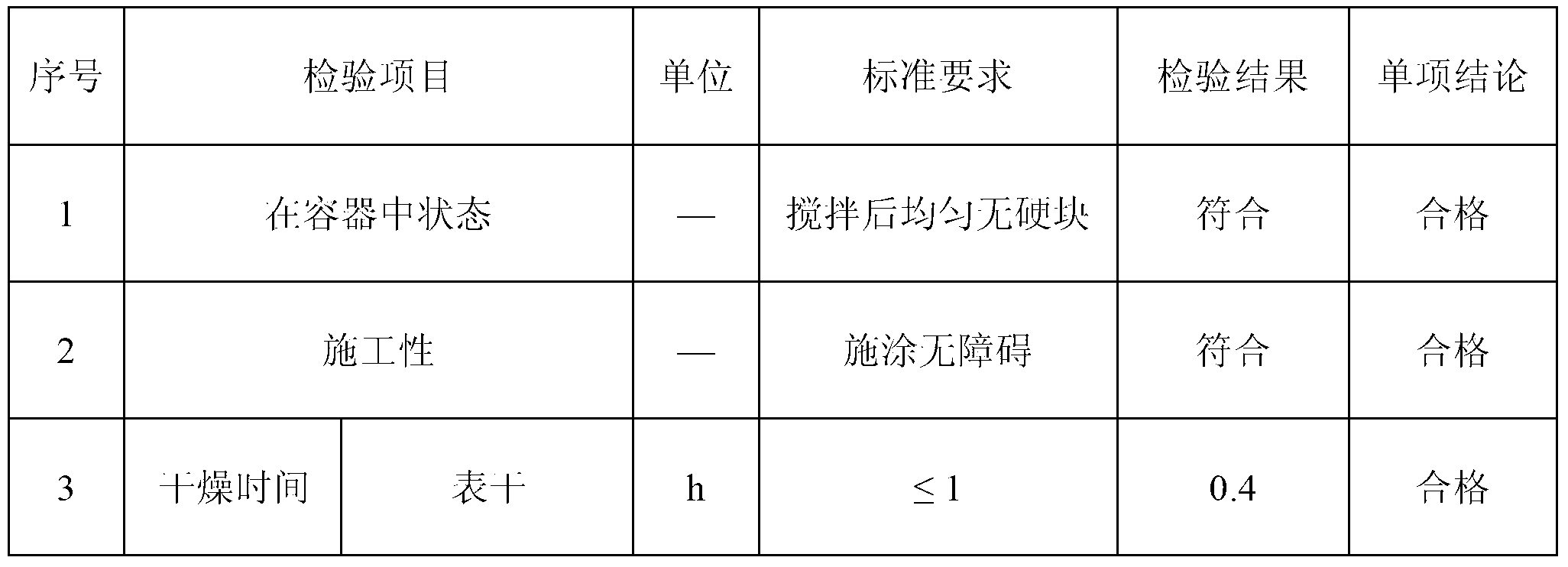

Transparent intumescent-type aqueous flame-retardant paint, and preparation method and applications thereof

ActiveCN108912939ACompact structureIrregular structureFireproof paintsHalogenMelamine formaldehyde resin

The invention discloses an environment-protection transparent intumescent-type aqueous flame-retardant paint, and a preparation method and applications thereof, and belongs to the field of paint. Thepreparation method is used for solving problems in the prior art, that in using process of conventional flame retardant paint, halogen containing toxic organic volatile matters are released, flame retardant effect is poor because of the high dehydration catalyst temperature, and nontransparent paint using range is limited. The environment-protection transparent intumescent-type aqueous flame-retardant paint is composed of a component A, a component B, and a paint auxiliary agent. The preparation method comprises following steps: the component A is prepared; the component B is prepared from melamine formaldehyde resin and / or melamine modified urea-formaldehyde resin; the component A and the component B are mixed, the paint auxiliary agent is added, and an obtained mixture is stirred to be uniform so as to obtain the environment-protection transparent intumescent-type aqueous flame-retardant paint. The environment-protection transparent intumescent-type aqueous flame-retardant paint usedfor flame retardant protection of indoor timber structure materials, wood plastic composite materials, steel structure materials, or concrete structures.

Owner:广州诺一新材料有限公司

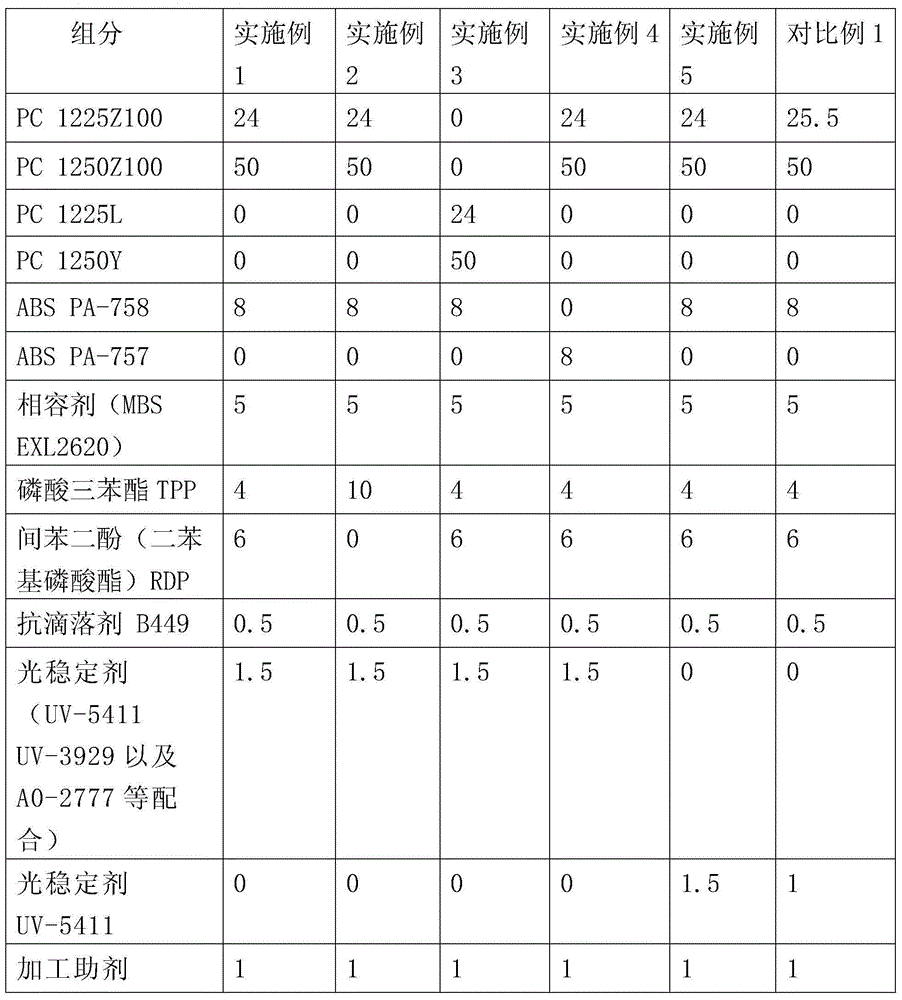

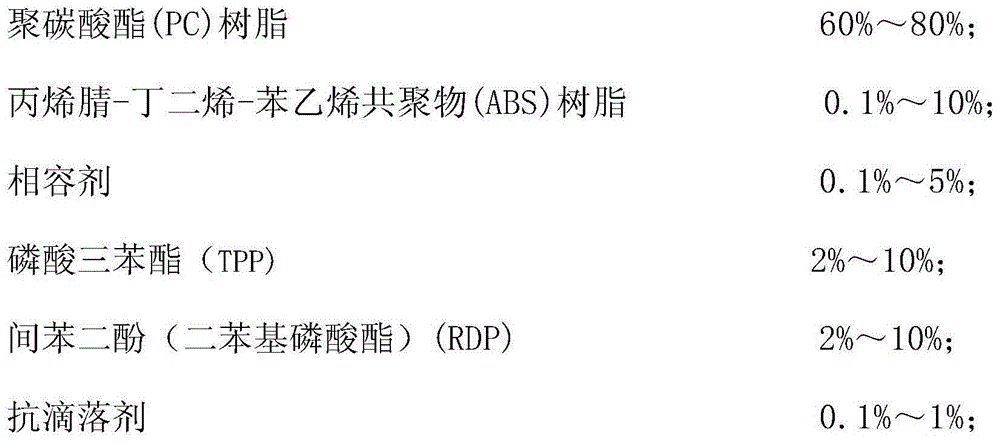

High weather resistant, halogen-free and flame retardant PC/ABS alloy material special for outdoor telecommunication box and preparation method thereof

The invention discloses a high weather resistant, halogen-free and flame retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material special for an outdoor telecommunication box and a preparation method thereof. The PC / ABS alloy material is prepared from the following raw materials by weight percentage: 60%-80% of polycarbonate resin; 0.1%-10% of acrylonitrile-butadiene-styrene resin; 0.1%-5% of a compatibilizer; 2%-10% of triphenyl phosphate; 2%-10% of resorcinol (diphenyl phosphate); 0.1%-1% of an anti-dripping agent; 0.1%-2% of a light stabilizer; and 0.1%-2% of assistants. According to the invention, the PC and ABS resin with good weather resistance are adopted as the matrix, and through synergy of the compatilizer, the halogen-free flame retardants and the light stabilizer, the halogen-free and flame retardant PC / ABS alloy material with high heat resistance and high performance can be obtained, and can be widely used in the communications industry, the automobile industry, building materials, decoration materials, cables and the electrical industry. The preparation method of the alloy material adopts existing equipment, is simple to operate, and is suitable for industrialized production.

Owner:SHANGHAI AUSELL CHEM TECH

Anti-sinking PU extra-clear primer and preparation method thereof

ActiveCN103305113AGood anti-sag performanceHigh transparencyPolyurea/polyurethane coatingsMethyl carbonateSlurry

The invention provides an anti-sinking PU extra-clear primer which is prepared by mixing an anti-sinking PU polyurethane primer, a PU anti-sinking curing agent and a PU anti-sinking diluent, wherein the anti-sinking PU polyurethane primer is prepared from soybean oil alkyd resin, a dispersant, an antifoaming agent, anti-settling slurry, pigment and filler, nitrocotton liquid, a leveling agent, a dryer and the like in addition with an environment-friendly solvent; the PU anti-sinking curing agent is prepared from n-butyl acetate, isocyanate tripolymer and isocyanate heteropolymer; and the PU anti-sinking diluent is prepared from the solvents such as n-butyl acetate, propylene glycol monomethyl ether acetate, dimethyl carbonate and the like. The anti-sinking PU polyurethane primer, the PU anti-sinking curing agent and the PU anti-sinking diluent are sufficiently and uniformly mixed to prepare the anti-sinking PU extra-clear primer which has excellent anti-sinking property and extra high transparency and is easy to polish; and the shortcomings of slow drying, poor anti-sinking property, common adhesion, low transparency, common polishing property and the like of the commercially available products are overcome.

Owner:广东花王涂料有限公司

Seawater corrosion resistant submerged arc welding wire

InactiveCN101664863AImprove matchCorrosion resistantWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

A seawater corrosion resistant submerged arc welding wire is characterized in that the welding wire is made by the following chemical components according to mass percentage: 0.20-0.35 percent of Cu, 0.65-1.15 percent of Cr, 0.35-0.55 percent of Ni, 0.15-0.25 percent of Mo, 0.07-0.11 percent of C, 0.07-0.22 percent of Si, 1.0-1.38 percent of Mn, 0.05-0.1 percent of Nd, not more than 0.012 percentof P, not more than 0.012 percent of S, and the balance of iron and inevitable impurities. By reasonable design to the chemical components, the seawater corrosion resistant submerged arc welding wireis characterized by corrosion resistance, high strength, good toughness, strong anti-welding cold cracking ability and the like, with the tensile strength of greater than 600MPa and the minus 40 DEG C low temperature impact property of Axv of not less then 65J. After welding, the forming is beautiful, harmful defects such as crack, welding beading and undercut and the like do not exist, and the welding seam has good matching effect with the ocean engineering steel, thereby meeting the high requirements of seawater corrosion resistance, high strength, and high toughness of the welding seam.

Owner:HUBEI KMK WELDING MATERIALS

Self-cleaning ceramic tile and preparation method thereof

The invention relates to the field of a ceramic tile and particularly provides a self-cleaning ceramic tile and a preparation method thereof. The self-cleaning ceramic tile mainly comprises an unglazed tile, a bottom-layer immobilizing membrane and a surface-layer immobilizing membrane; the surface of the unglazed tile is coated with the bottom-layer immobilizing membrane and the surface-layer immobilizing membrane sequentially; each of the bottom-layer immobilizing membrane and the surface-layer immobilizing membrane consists of specific components with specific content; tiny pores exist on the surface of the unglazed tile, so that attachment of the bottom-layer immobilizing membrane is facilitated; the bottom-layer immobilizing membrane has strong adhesive force, is not liable to remove,has high extensibility, elastoplasticity, anti-cracking property, anti-permeability and weather resistance, and has high bondability with the unglazed tile and the surface-layer immobilizing membrane; the surface-layer immobilizing membrane can significantly improve the self-cleaning ability of the surface of the ceramic tile, and has high bondability with the bottom-layer immobilizing membrane and high weather resistance. In the self-cleaning ceramic tile, the unglazed tile, the bottom-layer immobilizing membrane and the surface-layer immobilizing membrane cooperate with one another to forma whole body, and the advantages of high self-cleaning ability, high chemical corrosion resistance, weather resistance, high stability and low cost are achieved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +1

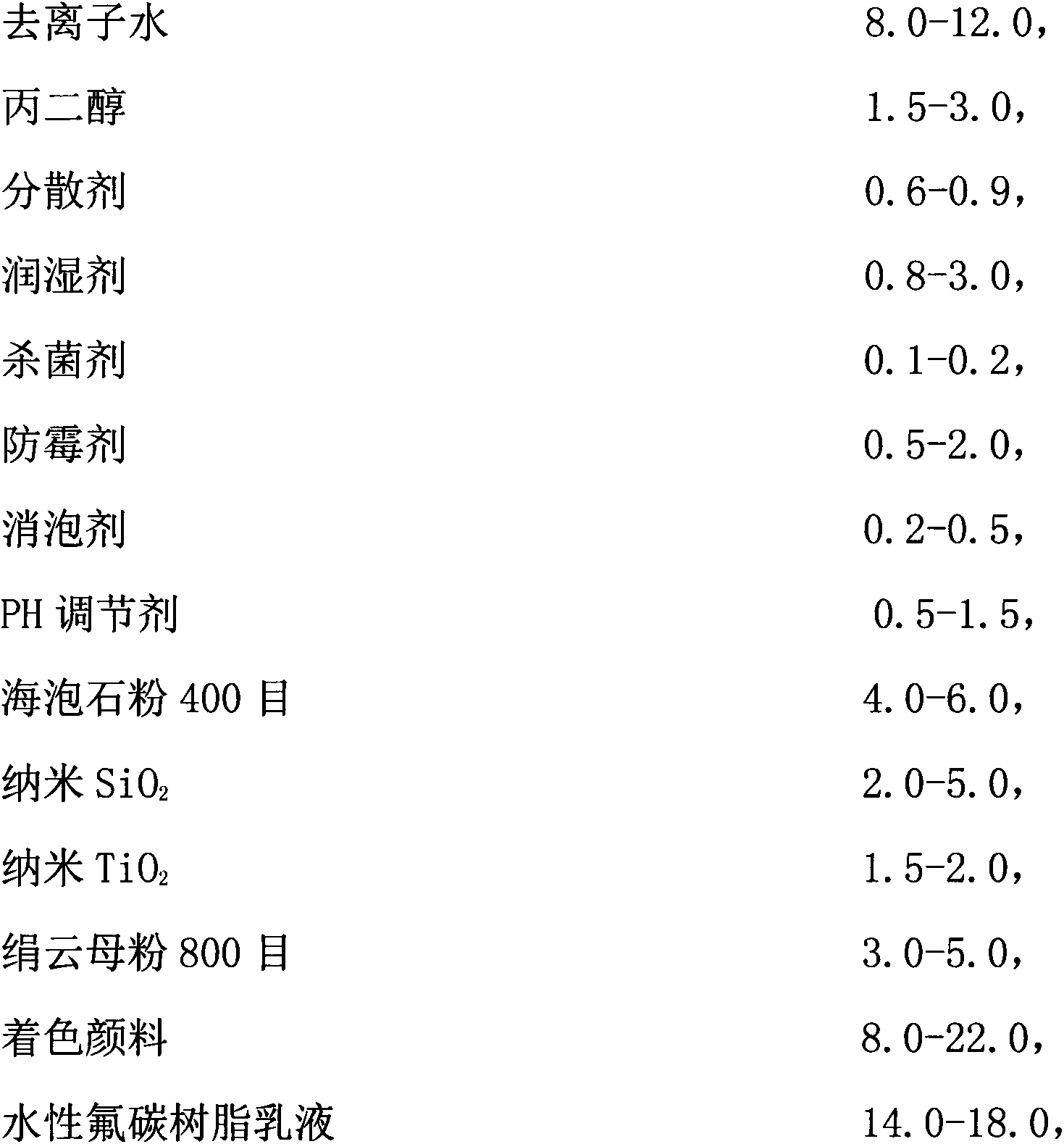

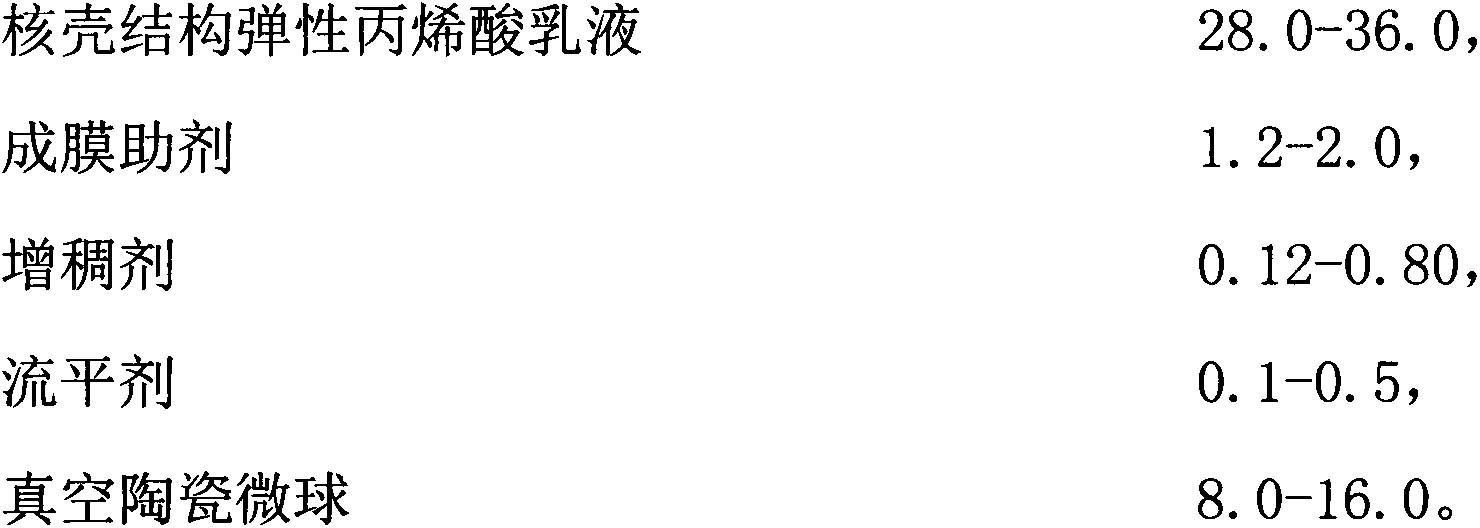

Multifunctional ecological optimizing energy-saving coating and preparation method thereof

InactiveCN103865343AImprove immunityHarm reductionAntifouling/underwater paintsPaints with biocidesWater basedEcological environment

The invention provides a multifunctional ecological optimizing energy-saving coating and a preparation method thereof, belonging to the field of functional materials for wall bodies of buildings. The coating comprises deionized water, water-based fluorocarbon resin emulsion, core-shell structure elastic acrylic emulsion, various additives, 400-mesh sepiolite powder, nanometer materials, 800-mesh sericite powder, tinting pigment, and vacuum ceramic microspheres. The preparation method comprises steps of (1) adding additives like deionized water and propylene glycol into a reaction kettle, mixing uniformly, then adding various powdery materials, dispersing and grinding into particles with fineness less than 50mu m; and (2) mixing water-based fluorocarbon resin emulsion and core-shell structure elastic acrylic emulsion with ground pigment paste, then adding other additives and vacuum ceramic microspheres, mixing uniformly so as to obtain the coating. The coating is used for painting outer wall surfaces of buildings, and has functions of decoration, sound insulation, water proofing, pollution prevention, ecological environment optimizing, thermal insulation and the like.

Owner:王文贵

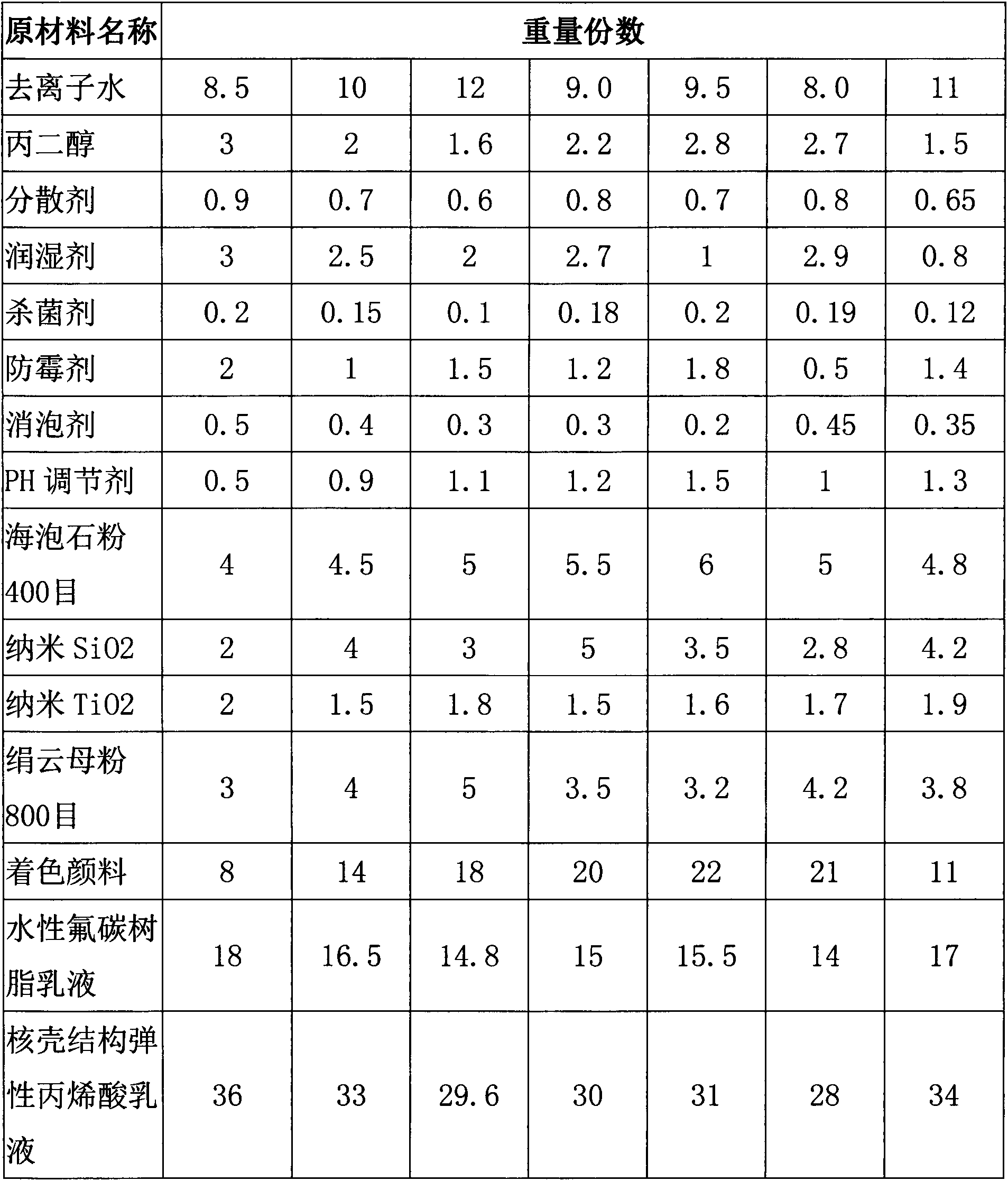

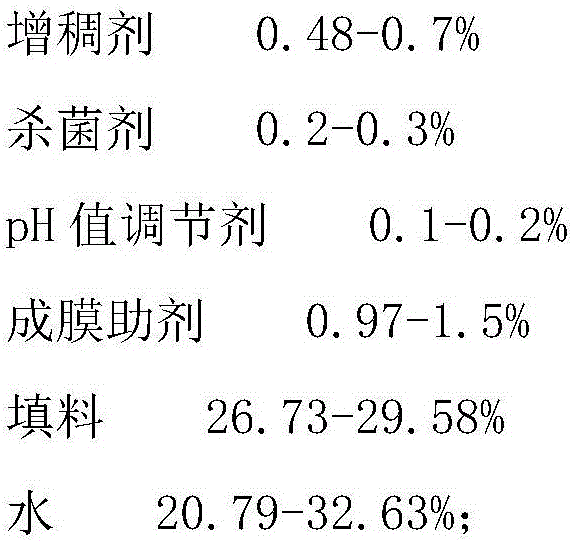

Reflective insulation coating and preparing method thereof

InactiveCN106554685AHigh hiding powerLow weather resistanceFireproof paintsAntifouling/underwater paintsTitanium dioxideDefoamer

The invention discloses a reflective insulation coating. The reflective insulation coating comprises raw materials including, by mass, 1%-5% of near-infrared reflection material IR-1000, 10%-20% of titanium dioxide, 22.89%-24.79% of film forming matter, 0.8%-1.1% of a dispersing agent, 0.18%-0.26% of a defoamer, 0.5%-0.7% of a wetting agent, 0.22%-0.25% of hydroxyethyl celluloses, 0.48%-0.7% of a thickener, 0.2%-0.3% of a sterilizing agent, 0.1%-0.2% of a pH value conditioning agent, 0.97%-1.5% of a coalescing agent, 26.73%-29.58% of fillers and 20.79%-32.63% of water. Meanwhile, the invention discloses a preparing method of the reflective insulation coating. The reflective insulation coating has the beneficial effects that the reflective insulation coating can strongly reflect near-infrared rays, and the temperature of the surface of a coated object can be greatly reduced.

Owner:JIANGSU TOP FINE NEW RAW MATERIAL CO LTD

Waterborne highlight environment-friendly toughened glass ink and preparation method thereof

The invention belongs to waterborne highlight environment-friendly toughened glass ink and a preparation method thereof. The toughened glass ink is prepared from, by weight, 8-30 parts of inorganic pigments, 30-78 parts of a low-melting-point frit, 10-55 parts of ink abrasive oil, 0-2 parts of a wetting dispersant, 0-1 part of a defoamer, 0-2 parts of a flatting agent and a 0-2 parts of a solid additive. The glass ink is low in melting point, good in weather fastness, good in brightness and high in artistic appreciation; the low-melting-point frit is low in melting temperature and power saving, service life of the device can be effectively prolonged, and oxide is less volatile; the low-melting-pint frit does not contain Pb, Cr<6+>, Cd and Bi, cost of the ink can be effectively reduced, and harmful Pb, Cd and Cr<6+> are not contained; a Te element is introduced in the low-melting-point frit which can reduce the melting temperature, low-temperature viscosity of the frit is effectively reduced, and high covering power and anti-ultraviolet linear capacity of the glass are achieved.

Owner:郑州市亚美凯新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com