Weather-resistant bridge steel with yield strength not less than 345 MPa and preparation method thereof

A technology of yield strength and bridge steel, which is applied in the field of iron and steel smelting, can solve the problems of high production cost, and achieve the effects of low cost, favorable promotion and application, and small electrode potential difference in micro-regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

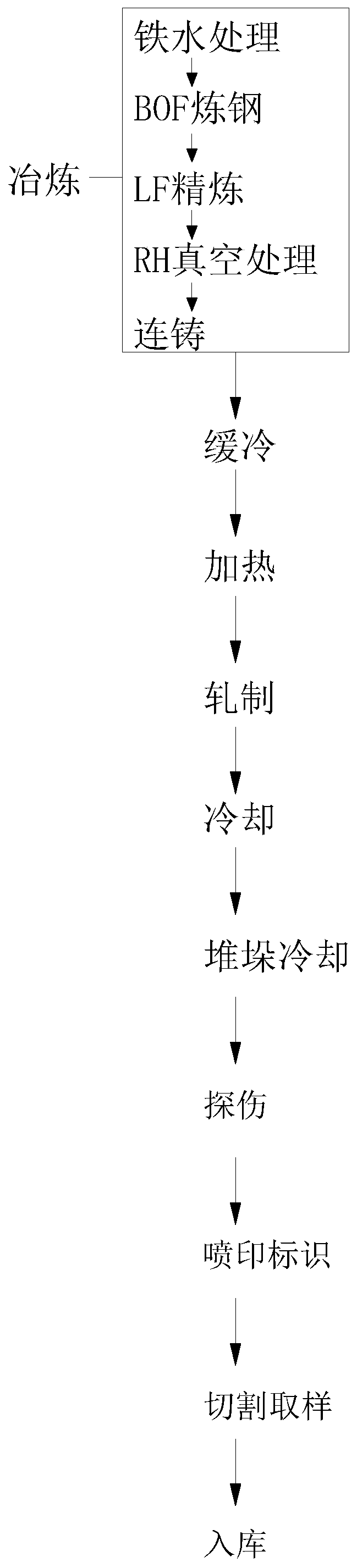

Method used

Image

Examples

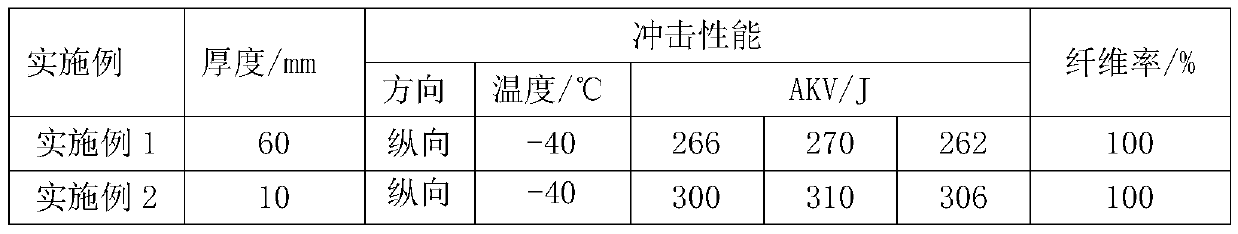

Embodiment 1

[0032] A weather-resistant bridge steel with a yield strength not less than 345MPa. The chemical composition of the 60mm weather-resistant bridge steel prepared in this example is as follows: C: 0.08%, Si: 0.23%, Mn: 1.0%, P: 0.012%, S: 0.003% , Al: 0.03%, Cr: 0.30%, Cu: 0.32%, Ni: 0.30%, Nb: 0.03%, Ti: 0.018%, and the rest are Fe and unavoidable impurities.

[0033] Its preparation method is as follows:

[0034] 1. Smelting: smelting by oxygen top blown converter steelmaking method, top and bottom double blowing, fully decarburization and dephosphorization; then through LF refining, RH vacuum treatment, reduce the content of harmful elements / impurities, and carry out microalloying; and then carry out continuous Casting, full protection casting, casting end, heavy billet adopts heavy reduction technology, the reduction ratio is 10%, and the cast billet is obtained;

[0035] 2. Slow cooling: After the slab is cut, put it into the slow cooling pit, and the slow cooling time is ...

Embodiment 2

[0042] A weather-resistant bridge steel with a yield strength not less than 345MPa. The chemical composition of the 10mm weather-resistant bridge steel prepared in this example is as follows: C: 0.09%, Si: 0.22%, Mn: 0.9%, P: 0.011%, S: 0.003% , Al: 0.028%, Cr: 0.25%, Cu: 0.30%, Ni: 0.28%, Nb: 0.04%, Ti: 0.019%, and the rest are Fe and unavoidable impurities.

[0043] Its preparation method is as follows:

[0044] 1. Smelting: smelting by oxygen top blown converter steelmaking method, top and bottom double blowing, fully decarburization and dephosphorization; then through LF refining, RH vacuum treatment, reduce the content of harmful elements / impurities, and carry out microalloying; and then carry out continuous Casting, full protection casting, casting end, heavy billet adopts heavy reduction technology, the reduction ratio is 9%, and the cast billet is obtained;

[0045] 2. Slow cooling: After the billet is cut, put it into the slow cooling pit, and the slow cooling time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com