Steel for 690MPa grade hot rolled thick low-yield-ratio automobile spoke and preparation method thereof

An automotive wheel, thick gauge technology, applied in the field of automotive steel, can solve the problems of affecting production rhythm, prone to cracking, waste of resources, etc., and achieve the effects of low yield ratio, high fatigue life, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

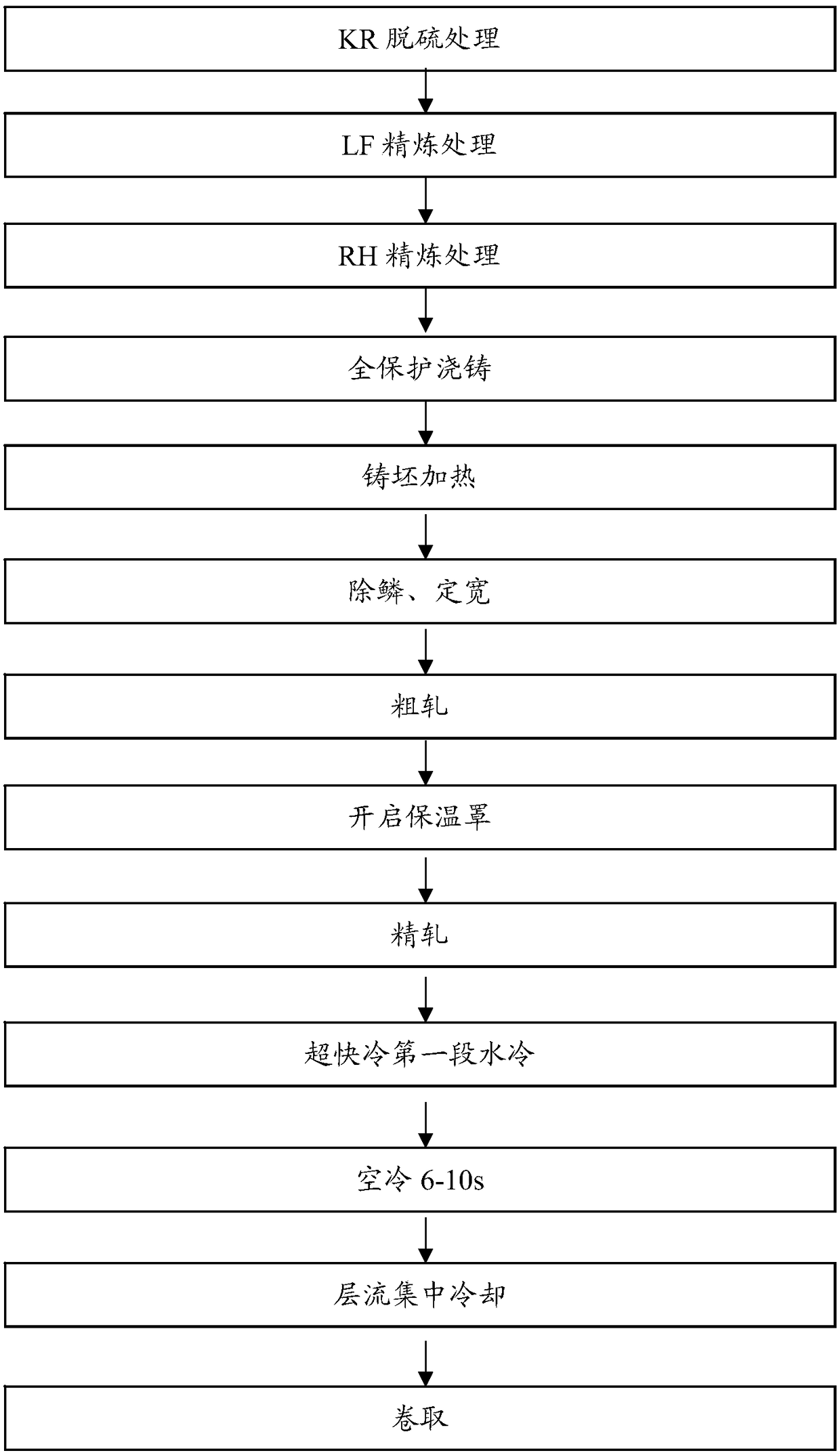

Method used

Image

Examples

Embodiment 1

[0049] After the molten iron is subjected to KR desulfurization treatment, the double refining treatment of LF refining + RH refining is carried out, and then fed to the pure Ca line for Ca treatment; after soft blowing, it enters the tundish, and then uses the continuous casting crystallizer for full protection casting; after casting, it goes off the production line Slow cooling in the slow cooling pit, the obtained slab composition contains C 0.06%, Si 0.15%, Mn 1.65%, P 0.010%, S0.002%, Alt 0.035%, Cr 0.20%, Nb 0.035% Ti 0.02 %, the balance is Fe and unavoidable impurities; the slab is heated to 1200°C for 3.5 hours, soaked for 35 minutes, and the furnace temperature is 1230°C, after descaling and width setting, and then 1+5 passes of rough Rolling and finishing rolling, the finish rolling exit speed is 3.8m / s; the rough rolling exit temperature is 1025°C, and the finishing rolling temperature is 859°C; the steel plate after finish rolling is cooled by laminar flow, using wa...

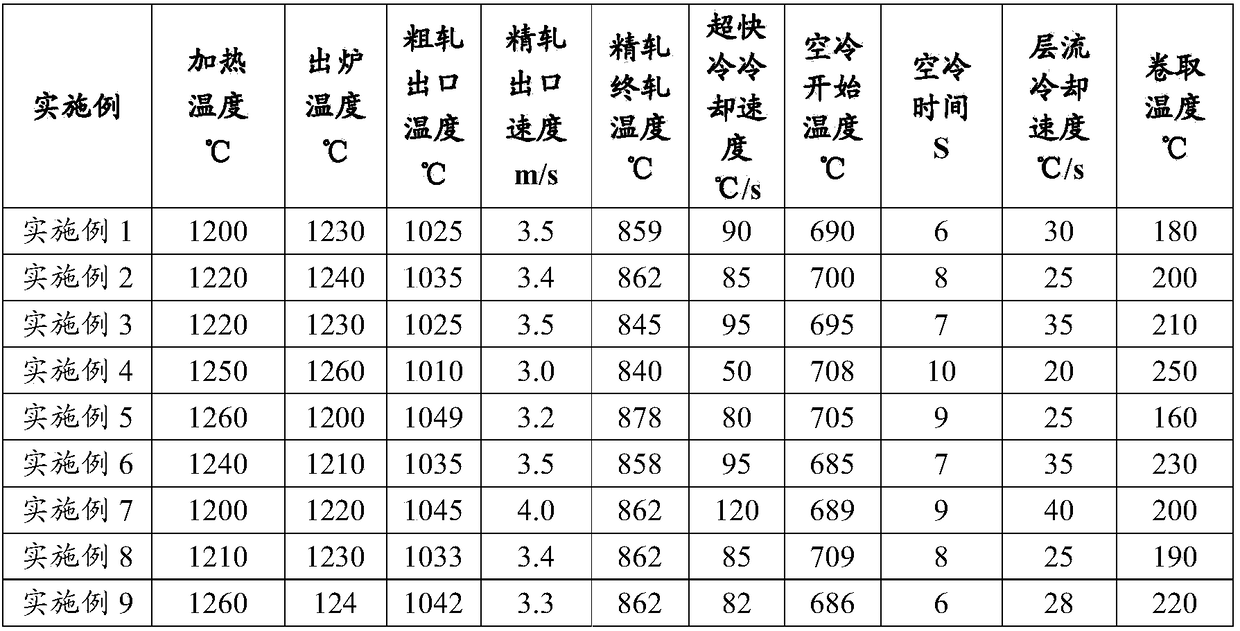

Embodiment 1-9

[0054] Table 2 embodiment 1-9 prepares the process parameter control of steel for automobile wheel spoke

[0055]

[0056] Characterization of finished steel

[0057] The mechanical property of the steel for automobile wheel spoke of table 3 embodiment 1-9

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com