Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

554results about How to "Good plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloy powder special for laser-remelted high hardness crackless iron-base alloy

InactiveCN101381869AHigh strengthHigh hardnessMetallic material coating processesThermal sprayingNiobium

The invention belongs to the technical field of alloy material, and relates to an improvement on the prior art, in particular to special alloy powder for laser cladding of high-hardness crack-free iron-based alloy. The formula of the alloy powder comprises the following compositions in weight percentage: 0.3 to 0.5 of C, 1.2 to 2.0 of Si, 0.4 to 1.0 of B, 1.5 to 2.5 of Ni, 1.0 to 1.5 of Cr, 1.0 to 1.5 of Mn, 1.5 to 2.5 of Mo, 0.15 to 0.7 of V, and 0.15 to 0.7 of Nb, the balance being Fe; and the total weight of the compositions is 100 percent. The special alloy powder can obtain the iron-based alloy with large area, large thickness and no crakes for laser cladding without preheating and subsequent heat treatment, has high strength, hardness and wear resistance and good plastic toughness of a cladding layer, and has lower cost compared with most of hot spraying self melting alloy powder and the prior laser cladding special iron-based alloy powder.

Owner:东莞市豪恩新材料技术有限公司

Medical high-strength titanium alloy wire and preparation method thereof

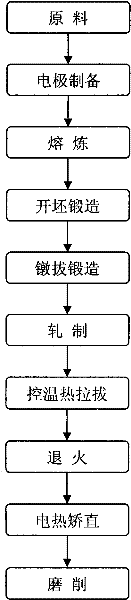

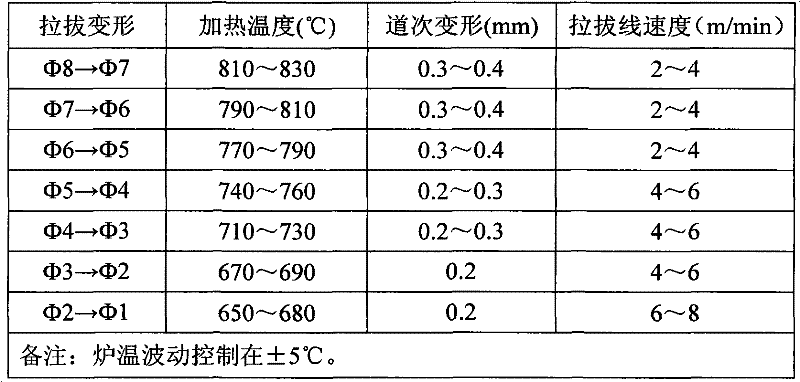

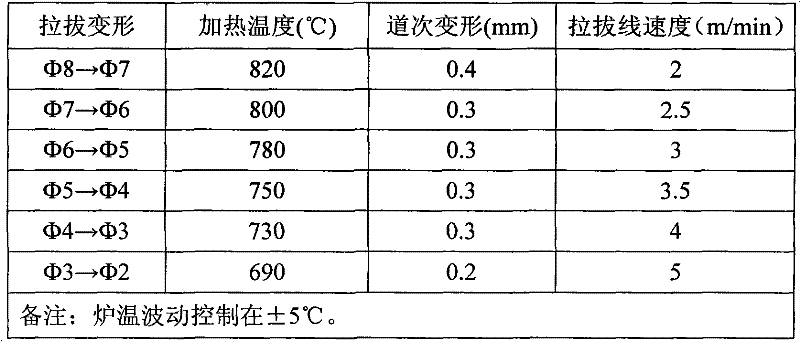

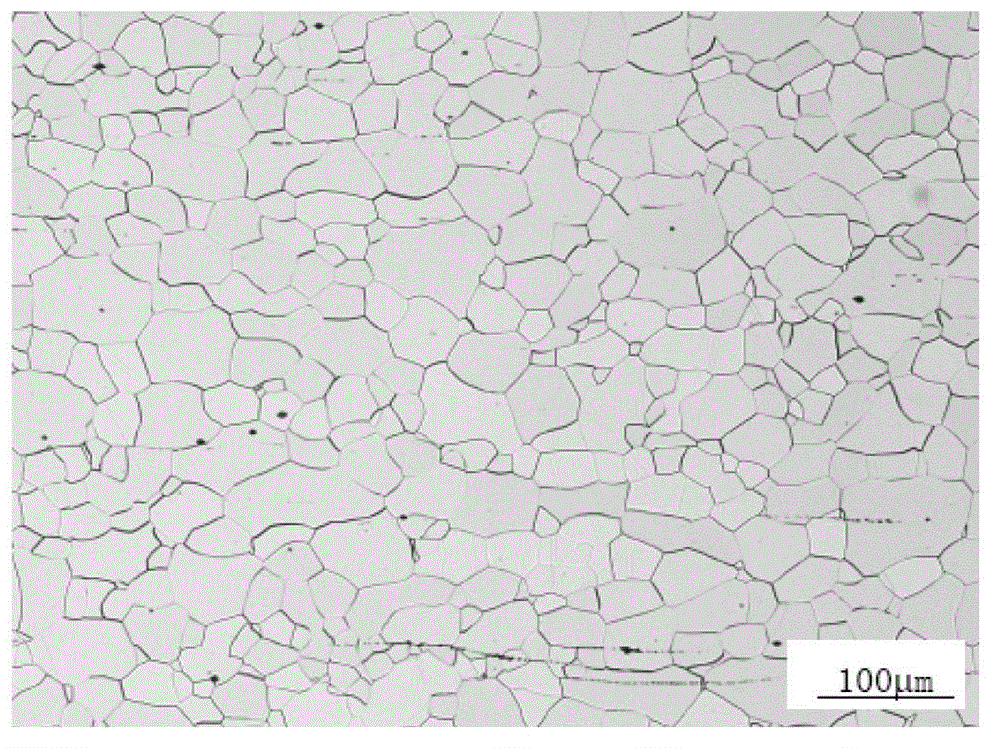

The invention provides a medical high-strength titanium alloy wire and a preparation method thereof and relates to component control of a Ti-6Al-4V titanium alloy wire having high strength and good cold molding characteristic and a preparation method thereof. The component control of the Ti-6Al-4V titanium alloy wire is as follows: based on weight percent, 6.0%-6.3% of main element Al, 4.2%-4.5% of V, 0.13-0.15% of interstitial element O and 0.08%-0.12% of Fe. The alloy obtained according to the component control is subjected to smelting, cogging and forging, multiple heating numbers of upsetting and forging, large-deformation rolling, temperature-control hot drawing, stress relief annealing, electric heating straightening and grinding processes so as to prepare the high-strength titanium alloy wire. The Ti-6Al-4V titanium alloy can obtain high strength (tensile strength of more than or equal to 1200Mpa and elongation A of more than or equal to 8%) and excellent plasticity, and can be applied to a medical Kirschner wire fixing system.

Owner:西安赛特金属材料开发有限公司

Steel for enamel and production method thereof

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Ti microalloyed ultra-fine grained cold rolling dual-phase steel of 1,000MPa level and preparation method thereof

InactiveCN101768695ALow priceInhibit growthTemperature control deviceFurnace typesChemical compositionMicrometer

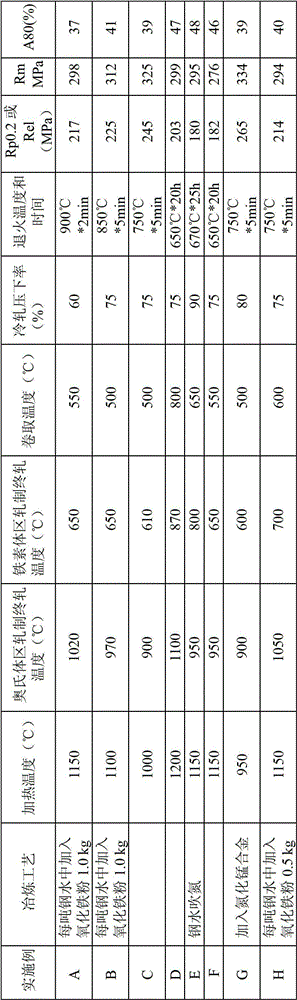

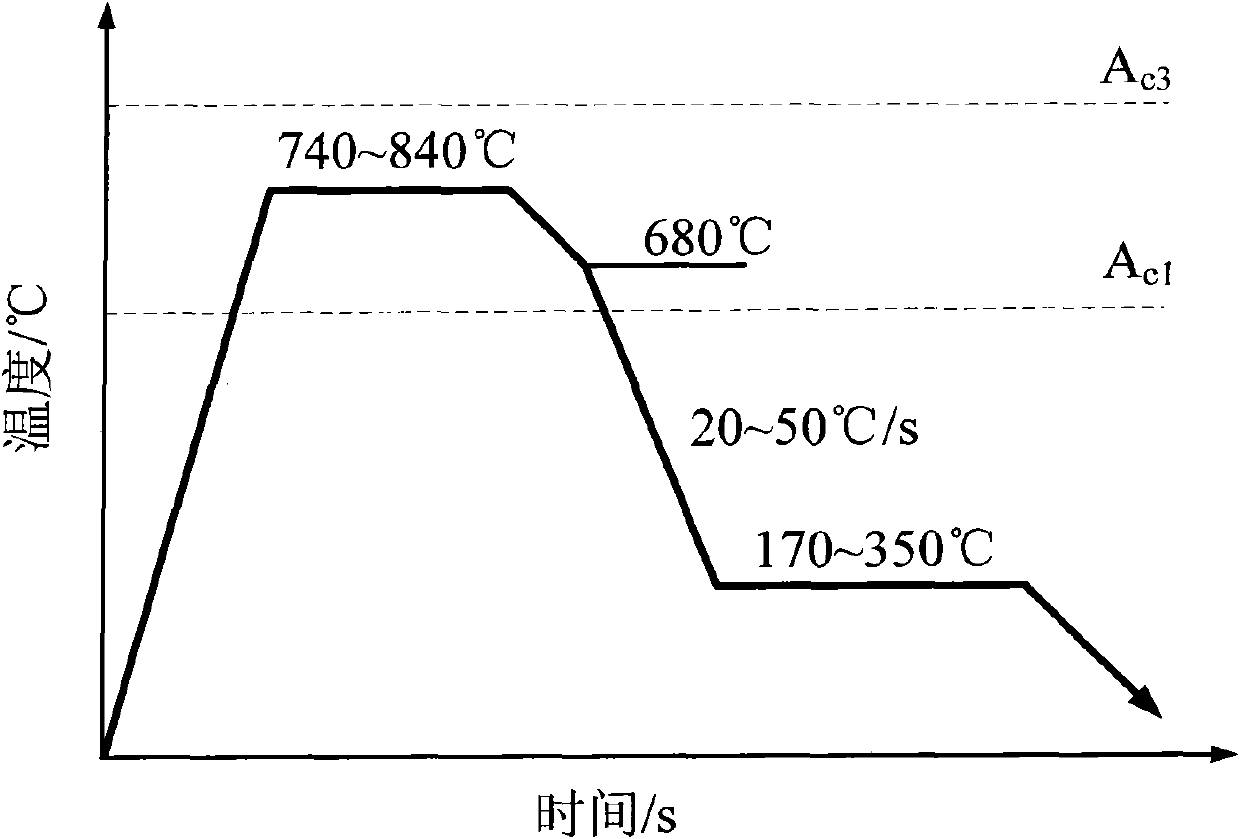

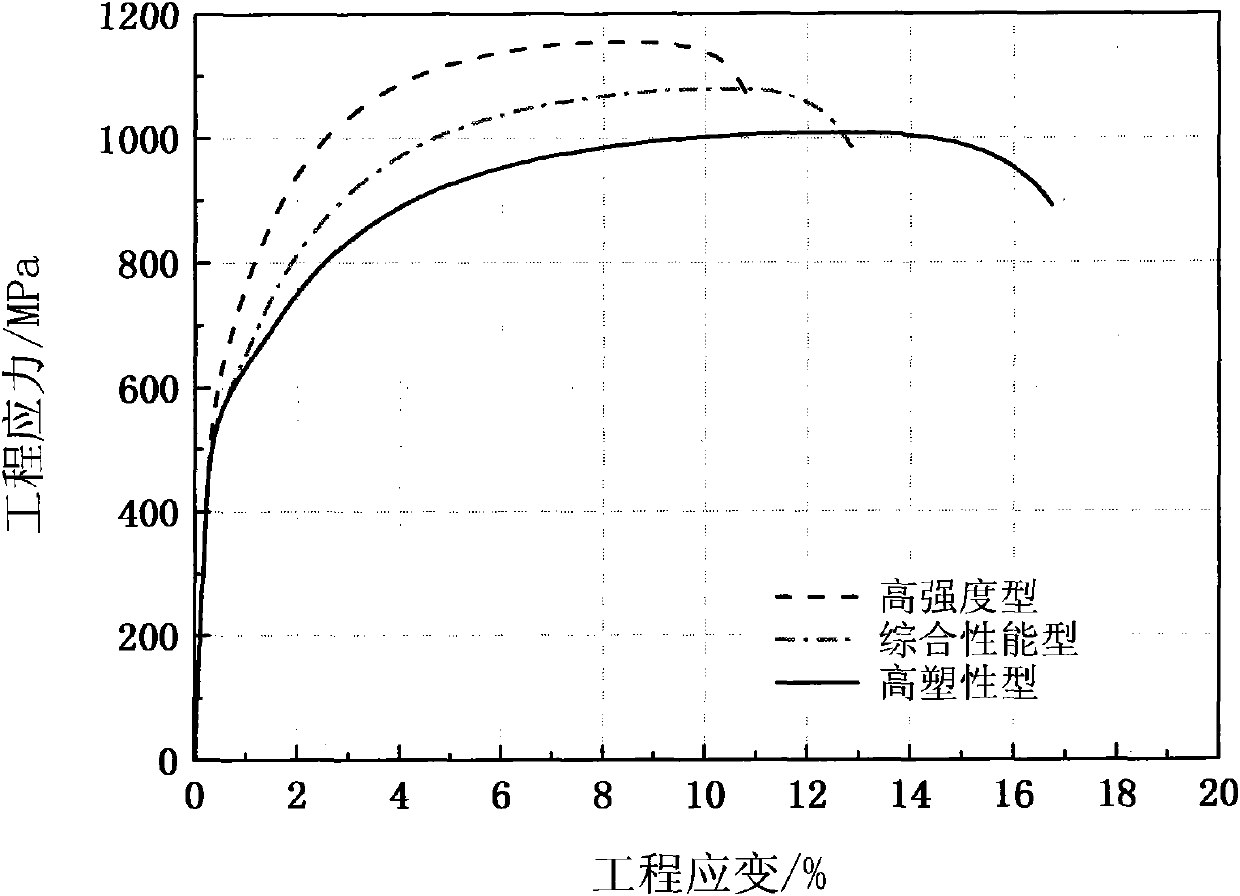

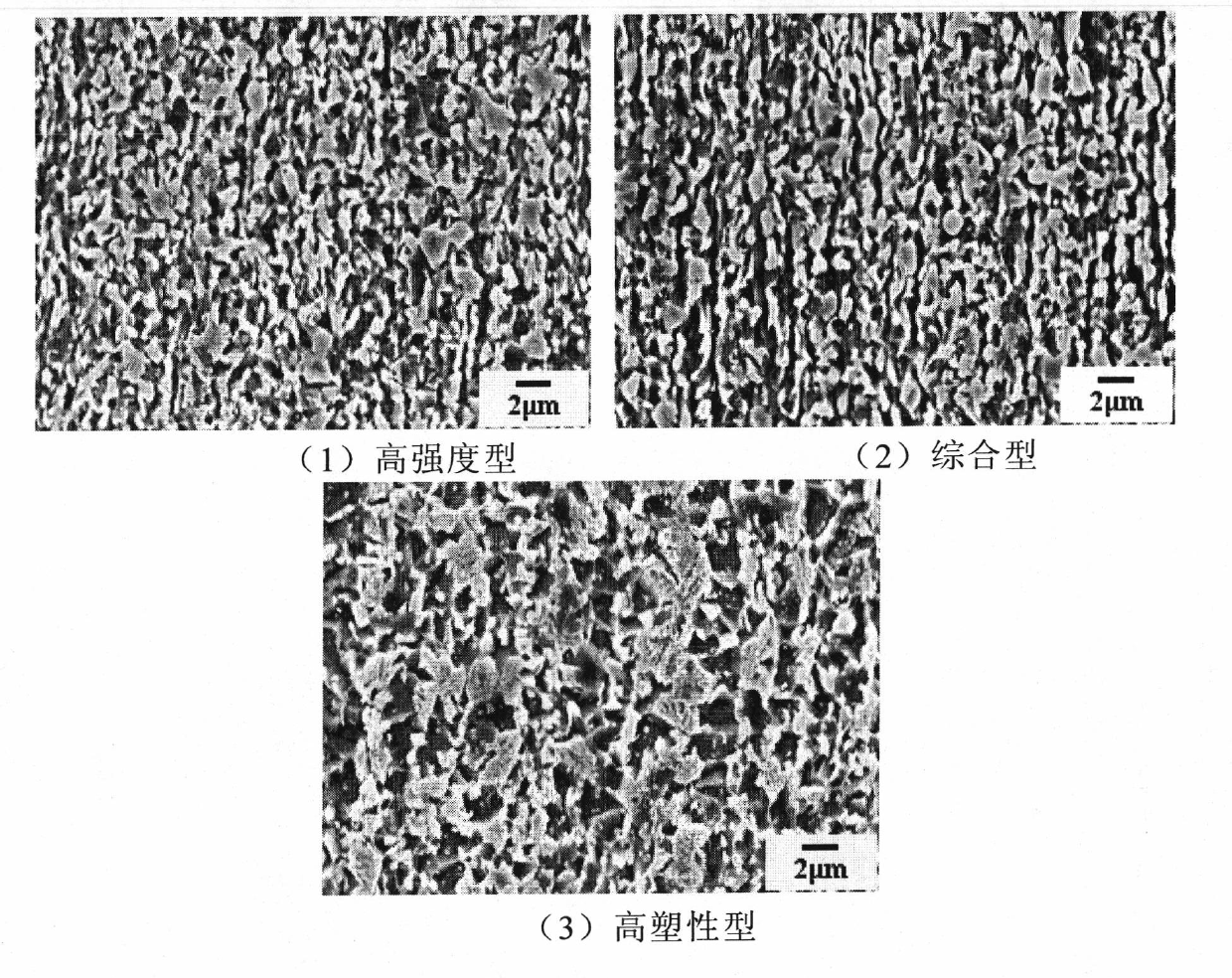

The invention relates to Ti microalloyed ultra-fine grained cold rolling dual-phase steel of a 1,000MPa level and a preparation method thereof, belonging to the technical field of cold rolling ultra-high strength steel for automobiles. The steel comprises the following chemical compositions in percentage by weight: 0.03-0.20 percent of C, 0.20-0.80 percent of Si, 1.2-2.0 percent of Mn, 0.03-0.15 percent of Ti, less than 0.15 percent of S, less than 0.020 percent of P, 0.02-0.15 percent of Als and the balance of Fe. In the invention, C-Si-Mn-Ti is used as a basic alloy system, low-price Ti is adopted, and alloy elements such as Cr, Mo, Nb, V, and the like are not added, thereby reducing the production cost; through a flexible continuous annealing process, the size of a martensite island can be controlled to be 1-2 micrometers or increased to about 5 micrometers under the condition that the quick cooling speed is lower than 50 DEG C / s in continuous annealing so as to obtain the following three different types of dual-phase steel: a high strength type (Rm is 980-1,200MPa, and A50 is 10-13 percent), a high plasticity type (Rm is 980-1,100MPa, and A50 is 14-18 percent) and a synthesizing type (Rm is 980-1,150MPa, and A50 is 12-15 percent); and the yield ratio is 0.47-0.65.

Owner:UNIV OF SCI & TECH BEIJING

High abrasion-proof laser cladding nickel-base alloy powder and preparation method thereof

InactiveCN102943267AHigh hardnessImprove wear resistanceMetallic material coating processesCarbideAlloy

The invention relates to a high abrasion-proof laser cladding nickel-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding nickel-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding the bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding nickel-base alloy powder not only is high in hardness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of alloy workpieces with high surface hardness and high wear resistance. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

Laser cladding nickel-based alloy powder and preparation method thereof

InactiveCN102912188AHigh hardnessNo crackMetallic material coating processesChemical compositionCrack free

The invention relates to laser cladding nickel-based alloy powder and a preparation method thereof. The laser cladding nickel-based alloy powder is characterized by comprising the following components by weight percent: 0.2-0.7% of C, 2-3.5% of Si, 1.5-3% of B, 1.0-1.5% of Mn, 3-10% of Cr, 2-5% of W, 3-5% of Mo, 0.5-1% of Nb, 0.5-2% of Co, less than 15% of Fe, 0.2-0.4% of Y, 0.2-0.5% of Ce and Ni and the balance of unavoidable impurity elements. A manufacturing process flow of the laser cladding nickel-based alloy powder is as follows: burdening, smelting, atomizing, drying and sieving. The alloy powder used for laser cladding provided by the invention is corrosion-resistant and also has higher hardness, and a treated laser cladding layer has the advantages of no crack, no pore, no impurity, compact structure and refined grain. A large-area thick crack-free laser cladding alloy layer can be obtained without preheating or follow-up heat treatment, and the cladding layer has the advantages of high strength, hardness and abrasion performance, good plasticity and toughness and low cost.

Owner:江苏新亚特钢锻造有限公司

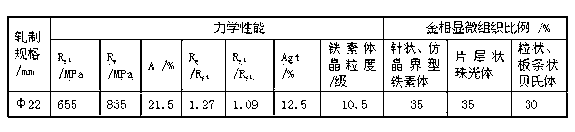

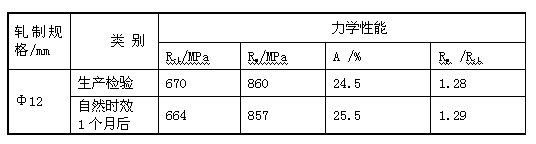

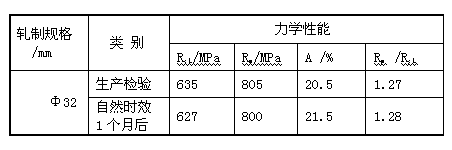

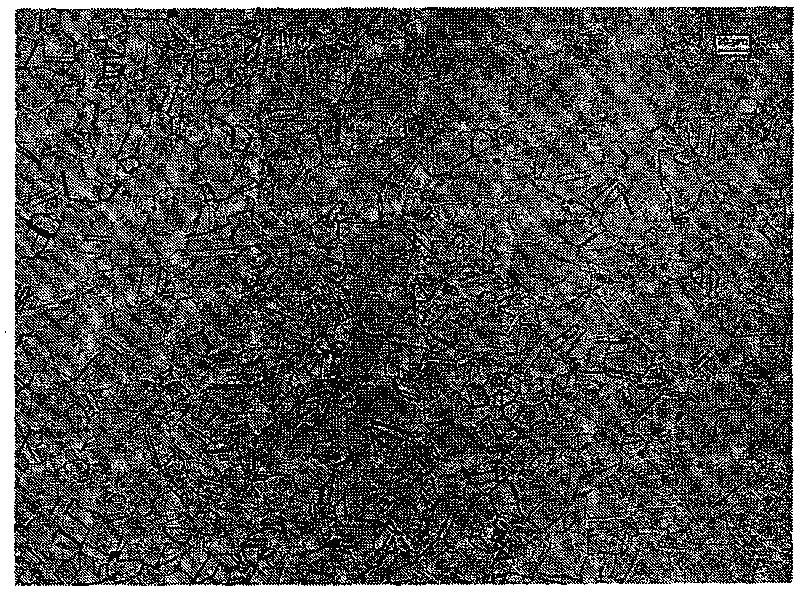

Niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production thereof

ActiveCN102796962ALow strain agingIncreased strain agingProcess efficiency improvementNiobiumTitanium

The invention provides a niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production of the niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar. Through molten steel smelting, molten steel casting, billet controlled rolling and controlled cooling, the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar is produced and comprises the following chemical constituents according to mass ratio: 0.14-0.18% of C, 0.30-0.50% of Si, 0.50-0.75% of Mn, 0.50-0.70% of Cr, 0.030-0.050% of Nb, 0.0015-0.0030% of B, 0.020-0.040% of Ti, no more than 0.045% of S, no more than 0.045% of P and the balance of Fe and unavoidable impurities. The niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar has the characteristics of low production cost, technological applicability, strong controllability and the like, the steel microstructure is uniformly distributed and has good form, the refining effect of ferrite is obvious, and the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcement has good low-strain timeliness, high strength, good toughness, good welding performance, excellent aseismic performance and excellent combination property.

Owner:WUKUN STEEL

Austenitic stainless steel medium-thick plate and manufacture method thereof

ActiveCN101724789AGood strengthGood corrosion resistance and ductilityMetal rolling arrangementsRare-earth elementAustenitic stainless steel

The invention relates to an austenitic stainless steel medium-thick plate which comprises the following components in percentage by weight: no more than 0.04 percent of C, 0.3-0.9 percent of Si, 1-2 percent of Mn, no more than 0.010 percent of S, no more than 0.04 percent of P, 16-22 percent of Cr, 8-14 percent of Ni, no more than 4 percent of Mo, 0.04-0.30 percent of N, 0.0010-0.0030 percent of B, smaller than 0.30 percent of one or more rare-earth elements, such as Ce, Dy, Y and Nd, 1-10 percent of high-temperature ferrite delta and the balance of ferrum and unavoidable impurities. The manufacture method of the austenitic stainless steel medium-thick plate comprises the following steps of: smelting; hot rolling; heating and preserving the temperature of the alloy and then carrying out 4-10 passes of rolling in a recrystallization area at 1,250-1,050 DEG C; water-cooling the recrystallization area by 20-40 DEG C / s to 700-950 DEG C, rolling 3-5 rounds in the temperature interval and water-cooling to room temperature; carrying out low-temperature annealing heat treatment at 900-1,050 DEG C; washing with acid and then obtaining the austenitic stainless steel medium-thick plate with excellent strength.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Casinghead gas corrosion resistant pumping rod steel and manufacturing method thereof

InactiveCN101440461AImproved corrosion cracking performanceGood plasticityTemperature control deviceFurnace typesNiobiumManganese

The invention provides steel for a pumping rod resisting casinghead gas corrosion and a manufacture method thereof. The steel comprises the following chemical compositions by mass percentage: 0.05 to 0.25 percent of carbon, 0.50 to 2.00 percent of silicon, 1.10 to 2.50 percent of manganese, 0.02 to 0.50 percent of molybdenum, 0.02 to 0.50 percent of nickel, 0.50 to 1.50 percent of chromium, 0.01 to 0.10 percent of vanadium, 0.005 to 0.050 percent of aluminum, 0.02 to 0.10 percent of niobium, 0.05 to 0.50 percent of copper, 0.01 to 0.10 percent of titanium, less than or equal to 0.015 percent of sulphur, less than or equal to 0.020 percent of phosphorus, and the balance being ferrum. The method is to manufacture a pumping rod wire through a design of adding the niobium and other trace alloy elements and corresponding compositions into steel, and controlled rolling and controlled cooling organization control technology. The pumping rod manufactured by the wire has excellent oilwell medium corrosion resistance, proper strength, excellent plastic tenacity and excellent welding performance, thereby improving the service life and reliability of the pumping rod, and improving the whole stability of pumping equipment, and further solving the problem that the prior pumping rod has repeated stress failure caused by endurance of complex casinghead gas corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD +1

High-strength steel for 750 to 880 MPa-level vehicles and production method thereof

The invention relates to high-strength steel for 750 to 880 MPa-level vehicles and a production method thereof. The high-strength steel comprises the following chemical ingredients in percentage by weight: 0.07 to 0.09 percent of C, 0.15 to 0.25 percent of Si, 1.4 to 1.9 percent of Mn, 0.04 to 0.06 percent of Nb, 0 to 0.15 percent of Mo, 0 to 0.04 percent of V, 0.07 to 0.14 percent of Ti, 0.01 to 0.06 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.008 percent of N and the balance of Fe and inevitable impurities. The production method comprises the following steps of: smelting; casting to form a casting blank; heating to the temperature of between 1,180 and 1,250 DEG C; performing final rolling at the temperature of between 820 and 850 DEG C; performing final cooling at the temperature of between 560 and 600 DEG C; and after a steel coil rolls off a production line, cooling slowly. By the production method, the strength of the material is between 750 and 880 MPa, and the steel has high low-temperature impact toughness and cold forming performance.

Owner:SHOUGANG CORPORATION

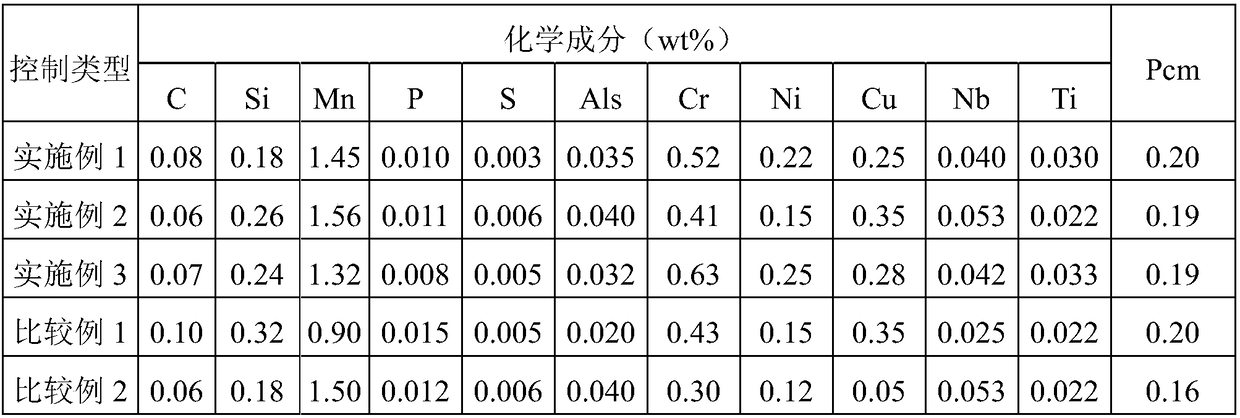

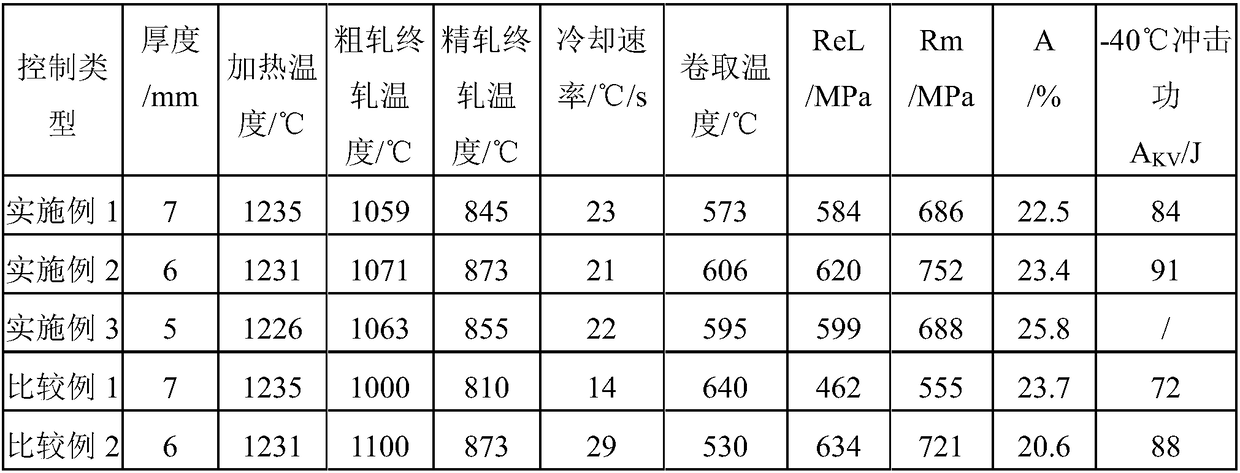

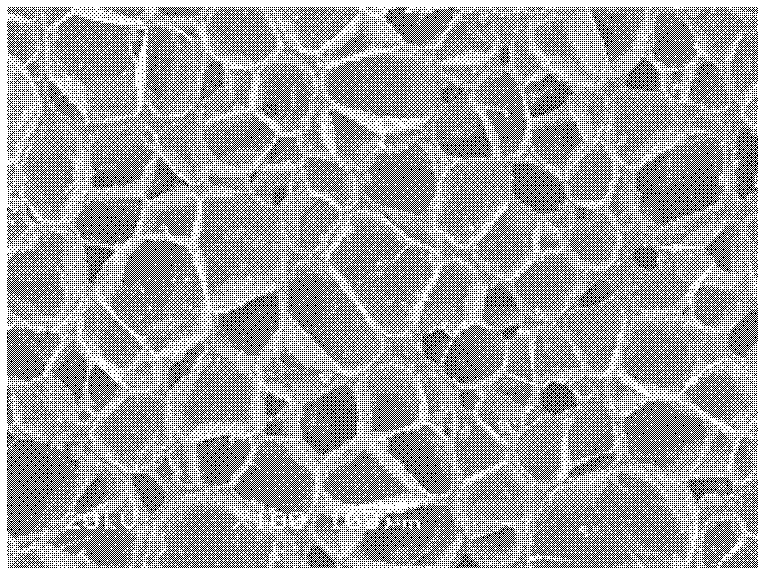

High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

ActiveCN108486466AGood welding performanceExcellent cold forming performanceToughnessAtmospheric corrosion

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

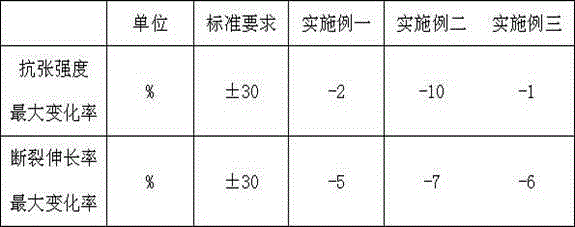

Elastic foamed material and preparation method of elastic foamed material

The invention discloses an elastic foamed material and a preparation method of the elastic foamed material, wherein the preparation method of the elastic foamed material comprises taking a thermoplastic elastomer material SEBS (styrene-ethylene-butylene-styrene) as a basic material and adding PP (polypropylene), EVA (ethylene-vinyl acetate) resin, an inorganic filler and a small amount of filling oil, a promoter, a cross-linking agent, a foaming agent and various auxiliary agents; the foamed material has uniform foamed holes, and the dosage of the cross-linking agent is small; and the foamed material is free from poison or odor, has good elasticity, is excellent anti-slipping property, low density which is as low as 0.040 grams per cubic centimeter.

Owner:CHINA PETROCHEMICAL CORP

Laser-cladding high-toughness high-hardness nickel-base alloy powder and preparation method thereof

InactiveCN102719708AHigh hardnessNo crackMetallic material coating processesChemical compositionRare earth

The invention discloses laser-cladding high-toughness high-hardness nickel-base alloy powder and a preparation method thereof. The nickel-base alloy powder is characterized by comprising the following chemical components in percentage by mass: 0.4-0.8% of C, 2-3% of Si, 1-3% of B, 12-18% of Cr, 6-8% of Cu, 0.5-1% of Sn, 10-15% of Fe, 0.2-0.5% of rare earth and the balance of Ni and inevitable impurity elements. The preparation process flow sequentially comprises: dosing, smelting, atomizing, drying and screening. The laser-cladding alloy powder disclosed by the invention has corrosion resistance and relatively high hardness; and the processed laser-cladding layer has the advantages of no crack, no air hole, no impurity, dense tissue, grain refinement and the like. Through the invention, a large-area great-thickness laser-cladding alloy layer without cracks can be obtained without preheating or follow-up thermal treatment, and the laser-cladding alloy layer has the advantages of high strength, hardness and abrasion resistance, good plasticity and toughness, low cost and the like.

Owner:丹阳市协昌合金有限公司

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ultra supercritical heat-resistant steel welding rod and production method thereof

InactiveCN103737199AGood workmanshipGood mechanicalWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses an ultra supercritical heat-resistant steel welding rod which is composed of an H08A core wire and coating wrapping the surface of the core wire, wherein contents of sulfur, phosphorus, arsenic, aluminum and the like in the H08A core wire are low, and the coating comprises components of 30%-39% of marbles, 22%-30% of fluorites, 6%-9% of rutiles, 7.5%-8.6% of ferromolybdenum, 29%-31% of chromium metal, 5%-9% of silica powder, 2%-5% of ferrosilicon, 1%-1.8% of ferrovanadium, 0.4%-0.8% of ferroniobium, 1.8%-2.8% of nickel powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxyl methyl cellulose (CMC), 0.2%-0.6% of amorphous graphite, 0.6%-1.5% of nitrogen-bearing ferrochromium, 1.6%-3% of electrolytic manganese, 3%-3.8% of cobalt powder and 4%-5% of ferroboron.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:佛山市顺德区清大润彩涂料有限公司

Nickel-free high-toughness 80kg-grade high-strength steel and manufacturing method thereof

ActiveCN102719757ASimple welding processHigh strengthHeat treatment process controlNickel freeToughness

The invention relates to nickel-free high-toughness 80kg-grade high-strength steel and a manufacturing method thereof. A component system of ultralow C, ultralow Si, medium Mn and Ti, V and B microalloy steel is used as a basis; the acid-soluble Als content in steel is properly improved, the Als is not less than 10*[(%Ntotal)-0.292(%Ti)], Mn / C is not less than 12, (%C)*(%Si) is not more than 0.01, and [(%Cr)+1.3(%Mo)]*[(%V)+(%C)] is not less than 0.087; Ca treatment is carried out, the Ca / S ratio is 1.00-3.00, and (%Ca)*(%S)<0.18> is not more than 2.5*10<-3>; F*DI index number * zeta is not less than 2.0* finished steel plate thickness, wherein zeta is on-line DQ (direct quenching) hardenability contribution factor, and F is B element hardenability contribution factor; DQ (thermo mechanical control process: TMCP) and off-line tempering process (T) are optimized; the microscopic structure of the steel plate is fine low-carbon tempered martensite and tempered lower bainite; the steel has the average colony size below 20 mu m, has excellent strength and plasticity and strong toughness, and is particularly suitable for hydroelectric pressure water pipes, steel branch pipes, scrolls, ocean platforms, large-sized engineering machines and other large-sized steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

Oxide particle reinforced laser cladding high-wear resistance nickel-base alloy powder and preparation method thereof

InactiveCN103014475AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHigh surface

The invention provides oxide particle reinforced laser cladding high-wear resistance nickel-base alloy powder and a preparation method thereof. The powder is characterized by comprising basal body alloy powder, oxide hard particles and binding agent, and is proportioned as follows: 50-98 percent of basal body alloy powder, 1-45 percent of one of Al2O3, Cr3C2 and ZrO2 or combined mixture powder of more than two thereof, and 1-5 percent of binding agent are prepared to combined powder. The preparation method comprises the technique steps of preparation of basal body alloy powder, addition of oxide particles, addition of binding agent, stirring and ball milling, powder combination, drying, crushing and screening. The oxide particle reinforced laser cladding alloy powder has higher hardness and toughness, has excellent wear resistance and corrosion resistance, and is particularly suitable for laser cladding of alloy workpieces with higher surface hardness and high wear resistance; and the powder can effectively prevent segregation caused by great difference among specific gravities of all components in the process of storage, transportation and use.

Owner:江苏新亚特钢锻造有限公司

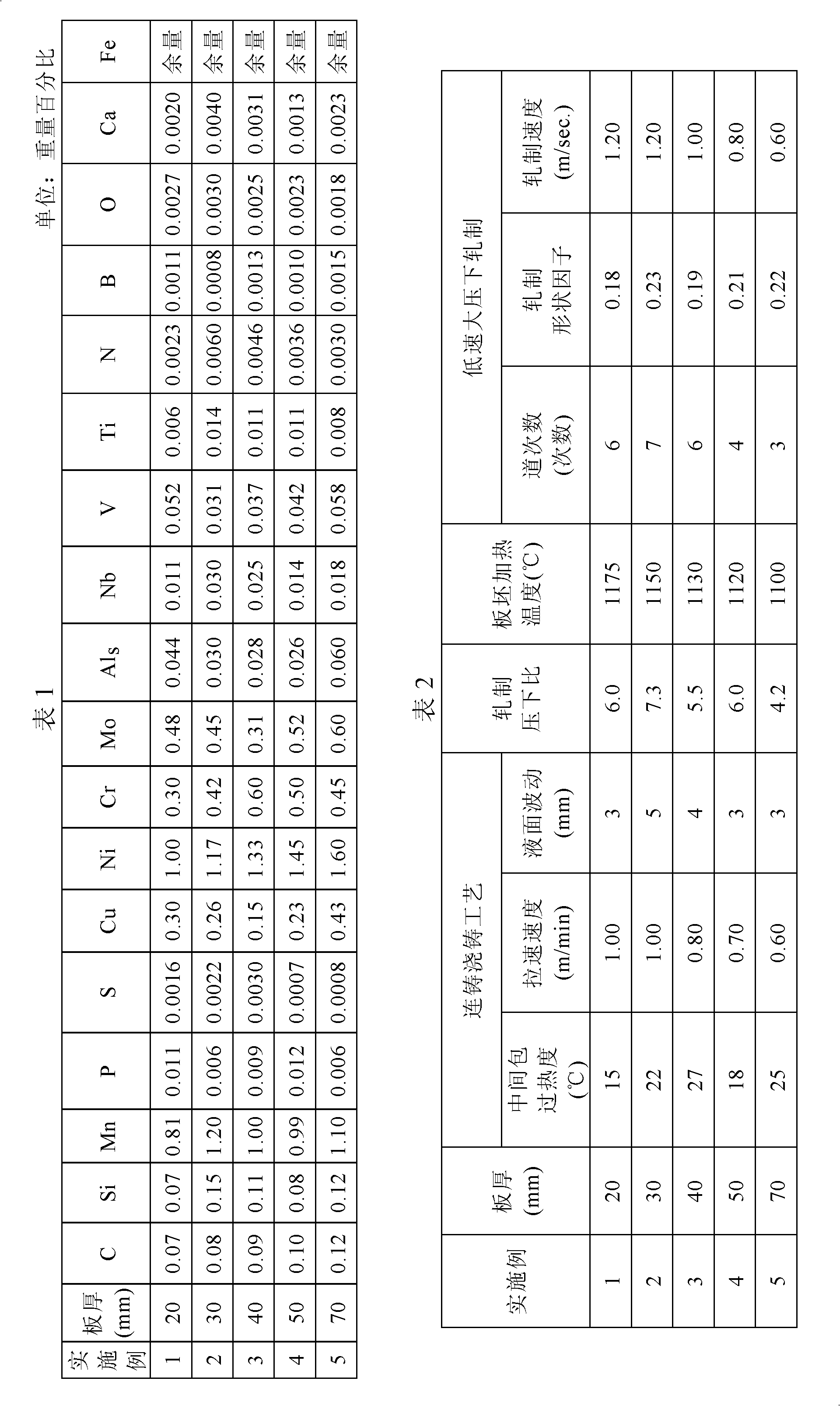

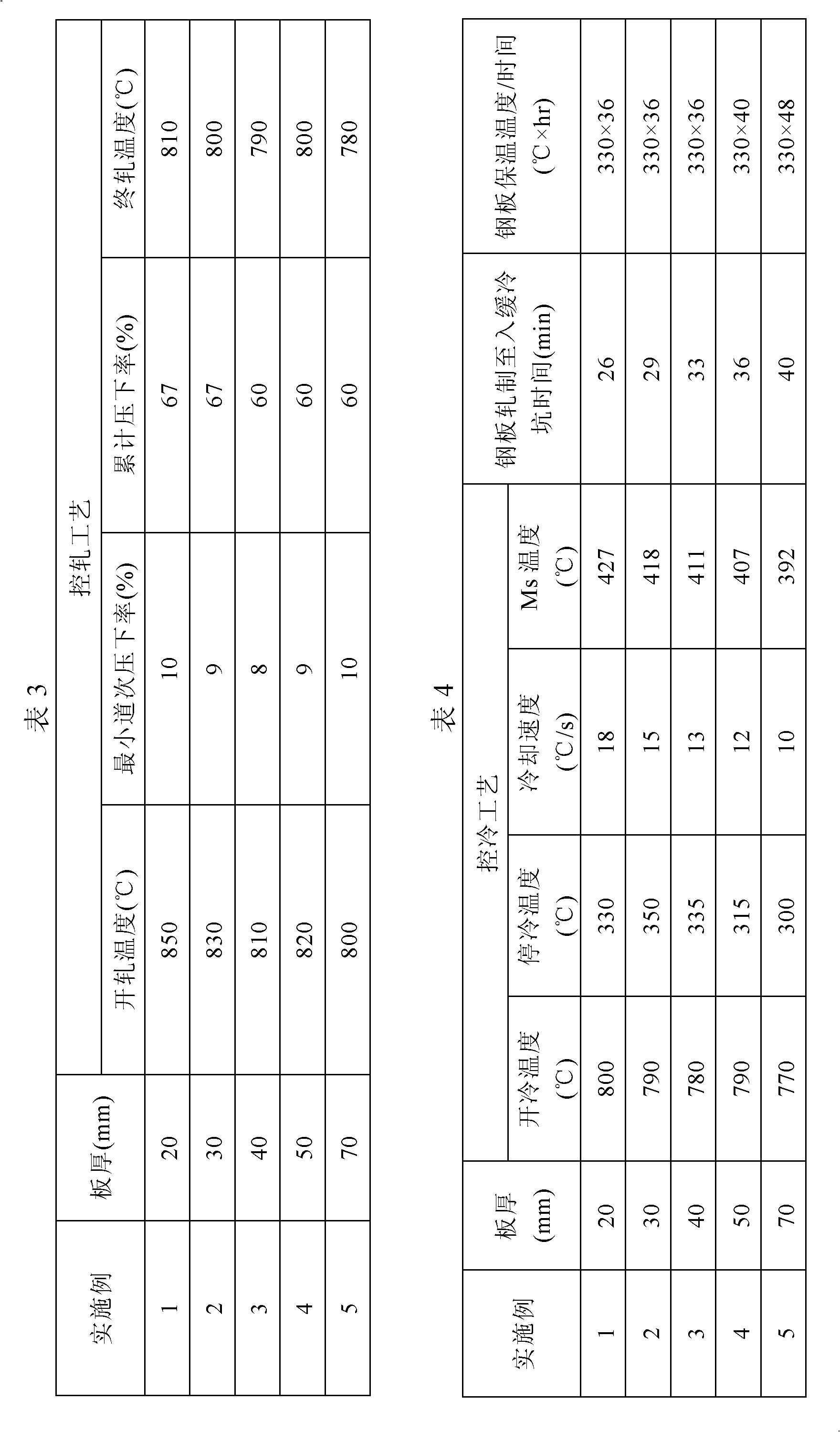

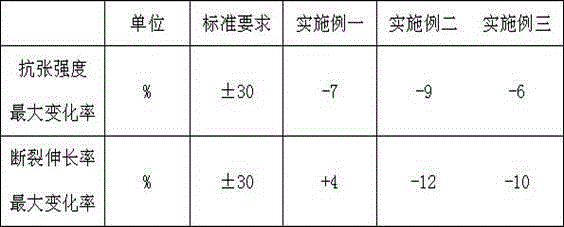

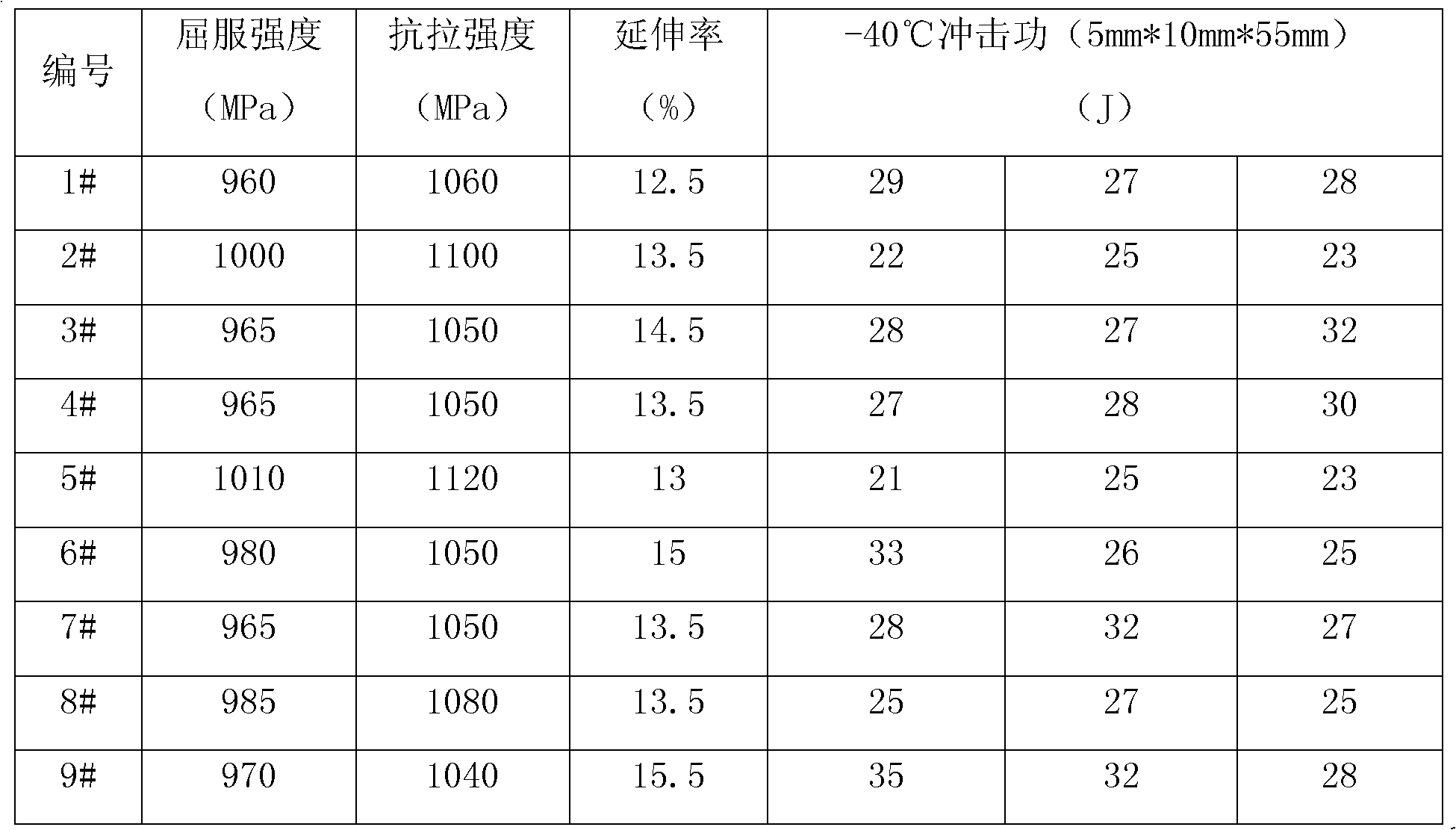

HT 960 steel plate with excellent plasticity and toughness and manufacture method thereof

ActiveCN102691010AIncrease added valueGood plasticityRoll mill control devicesFurnace typesThermal treatmentToughness

An HT 960 steel plate with excellent plasticity and toughness and a manufacture method thereof. The HT 960 steel plate comprises, by weight, 0.07%-0.12% of C, Si no mare than 0.15%, 0.80% -1.20% of Mn, P no mare than 0.012%, S no more than 0.0030%, 0.30%-0.60% of Cr, 0.30%-0.60% of Mo, 1.00%-1.60% of Ni, 0.15%-0.45% of Cu, 0.0008%-0.0016% of B, 0.006%-0.014% of Ti, 0.010%-0.030% of Nb, 0.025%-0.060% of Als, 0.030%-0.060% of V, N no more than 0.0060%, O no more than 0.0040%, 0.001%-0.004% of Ca, residual Fe and unavoidable inclusions. A TMCP + tempering thermal treatment process is employed to obtain super high strong steel plate with tensile strength no less than 960 MPa, yield strength no less than 900 MPa, Charpy transverse impact work (separate value) no less than 47J at -60 DEG C, fracture elongation percentage delta 5 no less than 15%, uniform elongation percentage Ag no less than 6% and excellent weldability.

Owner:BAOSHAN IRON & STEEL CO LTD

High abrasion-proof laser cladding cobalt-base alloy powder and preparation method thereof

InactiveCN102943266AImprove toughnessHigh hardnessMetallic material coating processesCarbideHardness

The invention relates to a high abrasion-proof laser cladding cobalt-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding cobalt-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding cobalt-base alloy powder not only is high in hardness and toughness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of parts with high impact resistance and high abrasion-proof property. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

InactiveCN102746587AGood plasticityHigh tensile strengthPlastic/resin/waxes insulatorsRaw rubberParaffin oils

The invention discloses an insulation rubber for longitudinal water-tight demagnetization cables used for ships and a manufacture method for the insulation rubber, belonging to the field of cables. The raw materials of the rubber are 15 parts of terpolymer EP rubber K21, 5 parts of terpolymer EP rubber 4045M; 0.5-0.6 parts of a vulcanizing agent DCP, 0.2-0.3 parts of a vulcanizing agent TAIC, 0.7-0.9 parts of an antioxidant MB, 0.2-0.3 parts of an antioxidant RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 parts of microcrystalline paraffin, 1.0-2.0 parts of zinc oxide, 0.3-0.5 parts of eleaostearic acid, 8-11 parts of powdered talcum, 1.0-1.5 parts of gas phase method silica, and 7-9 parts?of calcined pottery clay. First, mixing the raw rubbers of the terpolymer EP rubbers K21 and 4045 in an internal mixer; then adding the rest of the raw materials except the vulcanizing agents in sequence and mixing for 14-16 minutes, and after the obtained mixture being mixed uniformly, loading the obtained product on an open mill to make triangular bags eight times, followed by rubber sieving and sheets making. The insulation rubber has the advantages of good insulative and mechanical properties, aging resistance and oil resistance, which can satisfy the usage requirements of the longitudinal water-tight demagnetization cables used for ships.

Owner:嘉兴君宏光学有限公司

Manufacturing method of high-strength and high-plasticity continuous tube

The invention relates to a manufacturing method of a high-strength and high-plasticity continuous tube. The continuous tube comprises the following chemical components in mass percentage: 0.05-0.12% of C, 0.17-0.37% of Si, 0.60-1.75% of Mn, not more than 0.010% of P, not more than 0.005% of S, 0.20-1.0% of Cr, 0.15-0.45% of Mo, 0.10-0.35% of Ni, 0-0.05% of V, 0-0.03% of Ti, 0.10-0.25% of Cu, 0-0.07% of Nb, 0.02-0.04% of Al, 0.002-0.004% of Ca and the balance of Fe. The manufacturing method comprises the following steps: manufacturing hot-rolled steel coils; longitudinally shearing and butt-welding the steel coils; and producing a straight seam electric-resistance-welded steel tube by using steel bands and welding to obtain welding seams by normalization at the temperature of 930-960 DEG C. Yield strength of the continuous tube reaches 490-800MPa and elongation percentage thereof reaches 28-40%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

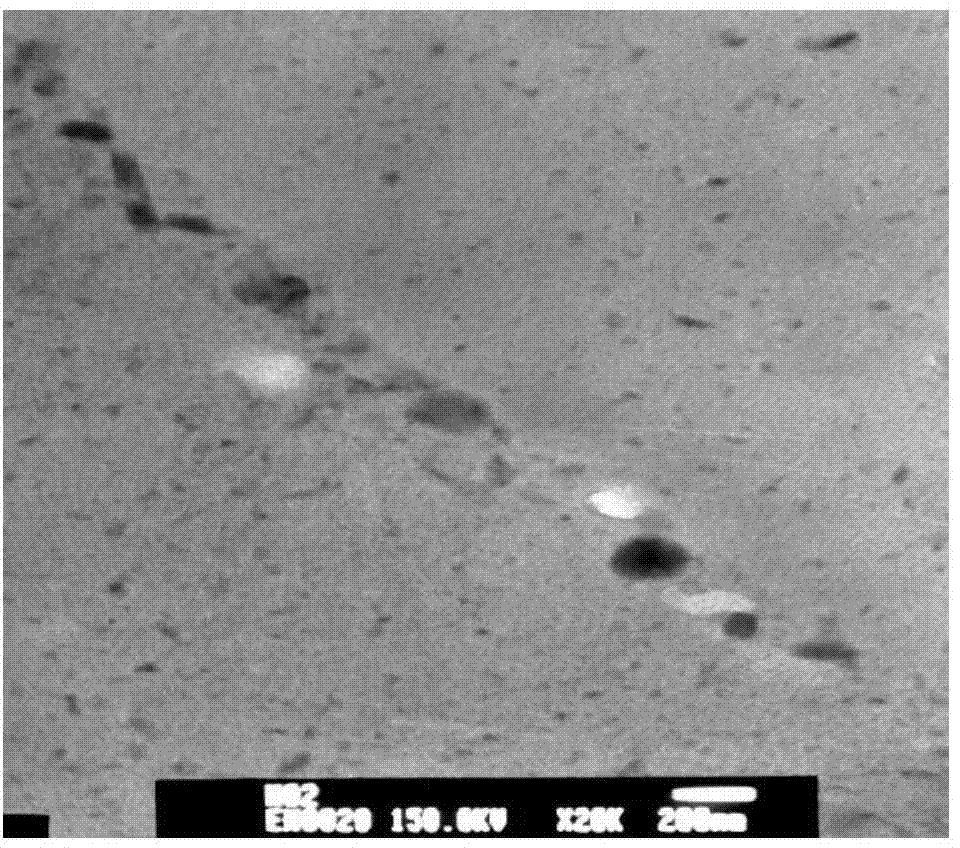

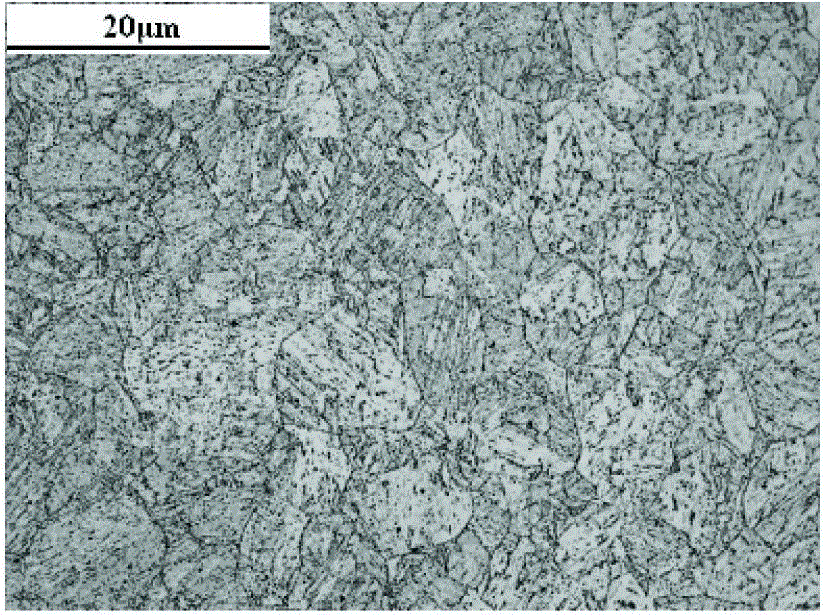

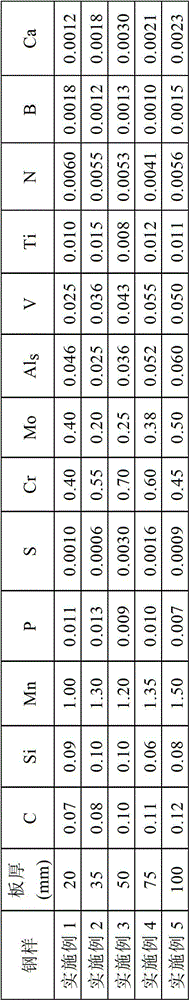

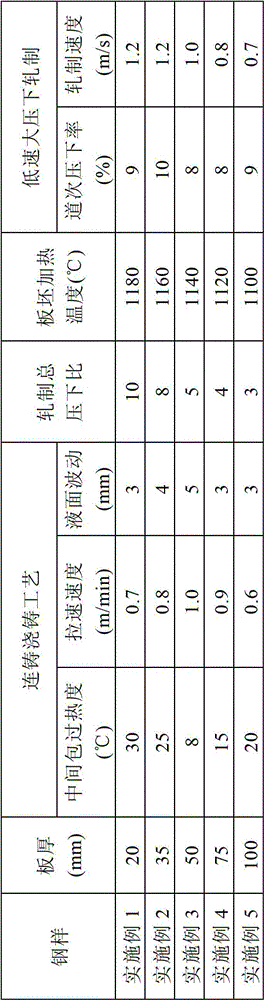

Method for medium sized or thin plate blank continuous casting and continuous rolling for producing superfine crystal grain steel plate and the steel plate

InactiveCN1995431ASimple chemical compositionImprove plastic toughnessTemperature control deviceFurnace typesSheet steelChemical composition

The invention discloses a manufacturing method of hyperfine crystal steel board through continuous rolling thin board, which comprises the following steps: allocating raw material with 0.12-0.18% C, 0.15- 0.35% Si, 0.65-1. 20% Mn, not more than 0.02% P, not more than 0.015% S and Fe; casting in the 100-200mm*1000-2000mm blank; setting the loading temperature over 800 deg. c; heating to 1100-1280 deg. c; reducing rough rolling of blank to 30-60 mm; setting refining rolling temperature between 920 and 1050 deg. c; exerting multi-channel and large-deforming strain accumulation with even deforming velocity at 1-10 / s; setting the refining rolling outlet temperature at 750-900 deg. c; setting cooling speed of laminar flow at 10-45 deg. c / s; coiling at 400-620 deg. c; setting the norm of continuous heat rolling steel at 2-18mm with even crystal size at 3-7um and yielding strength over 400Mpa; making the extending proof strength between 510 and 580 Mpa and extending rate over 26%.

Owner:ANGANG STEEL CO LTD

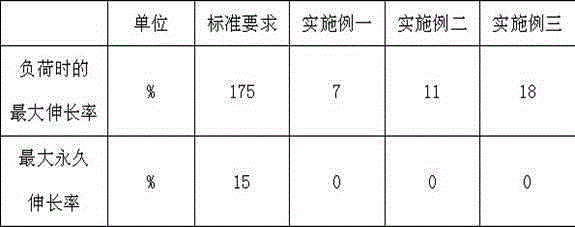

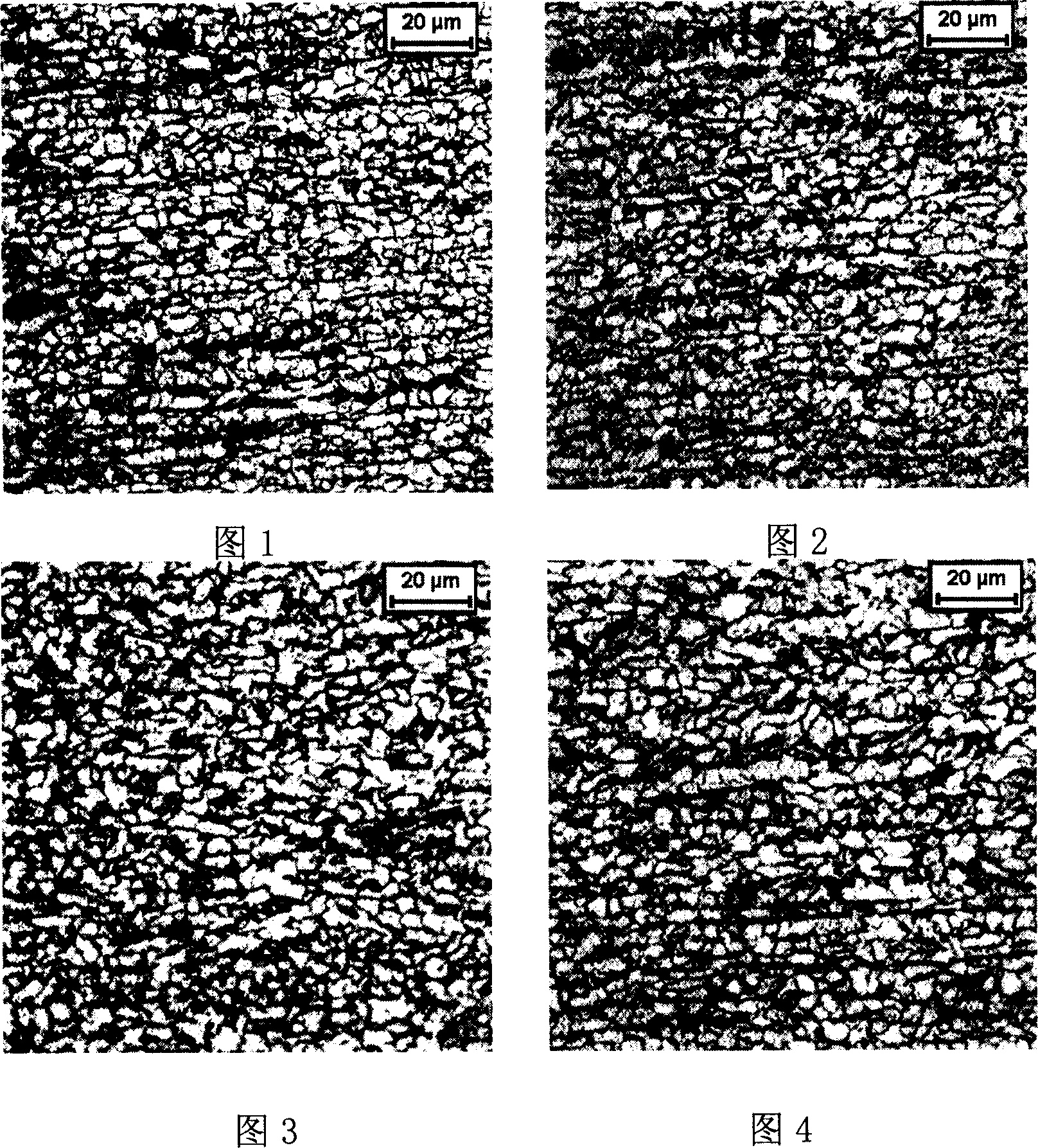

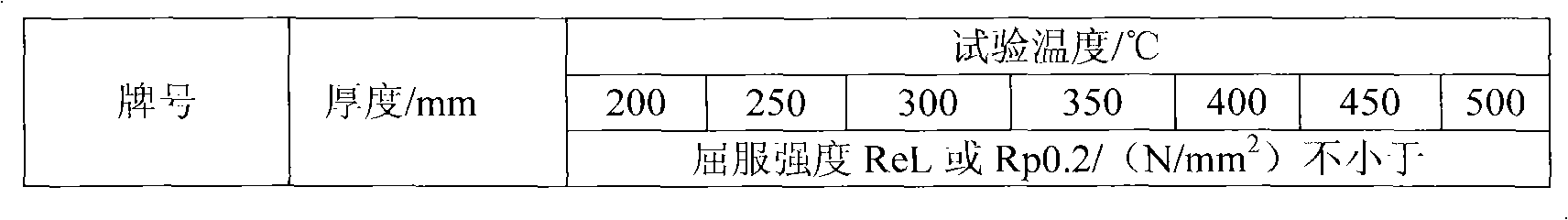

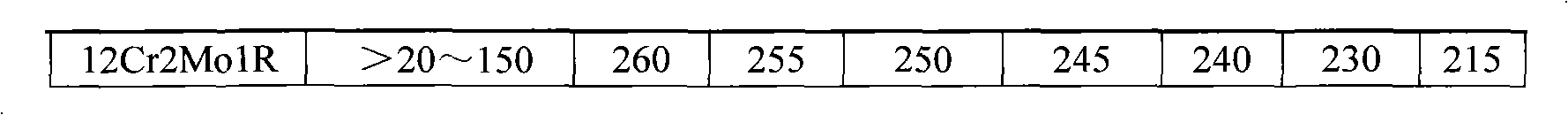

Large-thickness Cr-Mo system 12Cr2Mo1R container steel and production method thereof

ActiveCN102080187AMeet ideal needsGood plasticityRoll force/gap control deviceTemperature control deviceDie castingToughness

The invention discloses large-thickness Cr-Mo system 12Cr2Mo1R container steel and a production method thereof. Under the process sequences of high quality molten iron and KR molten iron pretreatment, 100 ton top and bottom combined blown converter, argon-blowing treatment, low frequency (LF) furnace refinement, die casting pouring, walking beak reheating furnace, 3800-meter rolling mill, activated calcium carbonate (ACC) laminar flow cooling, 11 roller hot strainghtener, stack cooling, tempering, finishing, outer detecting, fault detecting and warehousing, various property indexes of the container steel are ensured through tempering, thereby meeting the idea demands of users. In the production method, fine grain elements such as Nb, V, Ti and the like are not added; and the large-thickness container steel is produced by virtue of a low carbon equivalent design, a controlled rolling and controlled cooling process and a tempering production process, is a 12Cr2Mo1R steel plate with the thickness of 120-150 millimeters, maintains Maddox position direction of sorbite steel, and has the advantages of good ductility and toughness and favorable high-temperature tensile property.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

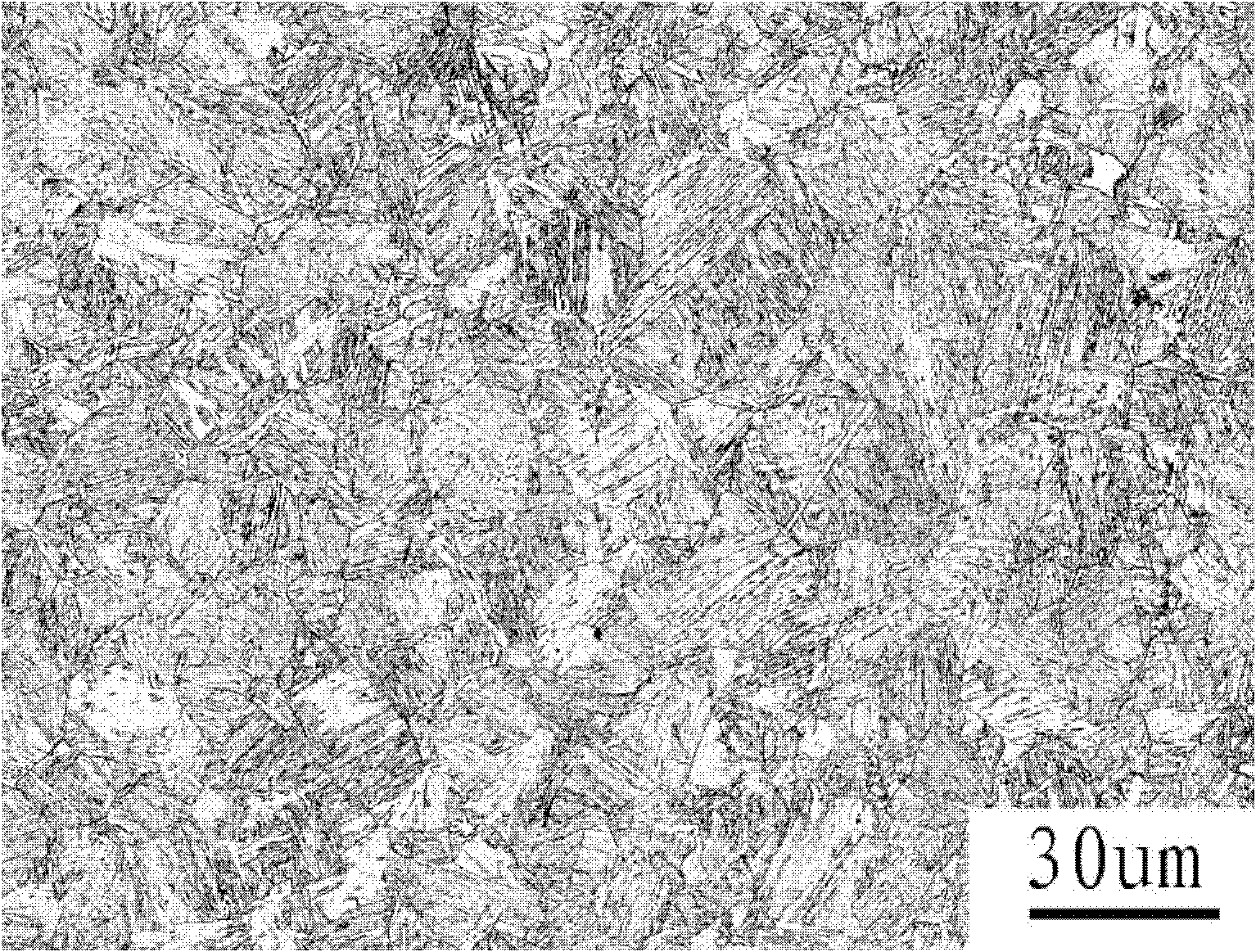

Ultrahigh strength steel with 960MPa of yield strength and production method thereof

The invention provides ultrahigh strength steel with 960MPa of yield strength and a production method thereof. The steel comprises the following chemical components by weight percent: 0.07-0.09% of C, 0.15-0.25% of Si, 1.00-1.20% of Mn, 1.05-1.15% of Cr, 0.15-0.20% of Mo, 0.01-0.06% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.008% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and casting are performed to obtain a casting blank, and the casting blank is heated to 1150-1250 DEG C; the finish rolling temperature is 840-900 DEG C; the finish cooling temperature is 640-700 DEG C; and quenching and tempering are performed, the quenching heating temperature is 880-920 DEG C, the heating preservation time is 20-60 minutes, the tempering heating temperature is 150-450 DEG C, and the heating preservation time is 90-180 minutes. The obtained material meets the performance requirement of the 960MPa grade ultrahigh strength steel and has good elongation rate and impact toughness.

Owner:SHOUGANG CORPORATION

HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and production method thereof

The invention discloses an HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and a production method thereof. The reinforced bar comprises the following chemical components in percentage by weight: 0.23-0.30% of C, 0.5-0.8% of Si, 1.20-1.60% of Mn, 0.15-0.20% of V, no more than 0.035% of P, no more than 0.030% of S, 0.015-0.025% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: performing converter or electric furnace smelting, performing external refining, performing continuous casting, heating a casting blank, rolling and performing air cooling on a cooling bed. According to the invention, the V and N contents in steel are controlled, thereby promoting formation and precipitation of V (C, N) fine particles; steel making and steel rolling process parameters are strictly controlled, thereby obviously enhancing the strength of the reinforced bar and having certain hydrogen corrosion resistance; indicators of the reinforced bar meets the requirements of an earthquake-resistant reinforced bar; and the reinforced bar has the practical meanings of energy saving, emission reduction, high safety and environment friendliness.

Owner:HEBEI IRON AND STEEL

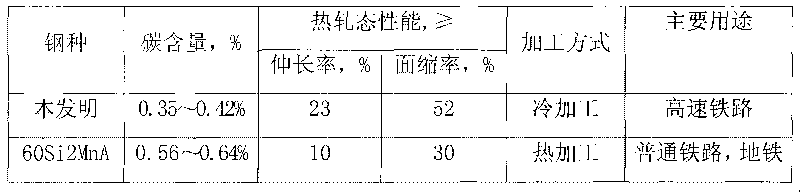

Manufacturing process of spring steel wire rod

InactiveCN101716721AReduce carbon contentLow physical qualityTemperature control deviceProcess efficiency improvementWire rodElectric arc furnace

The invention belongs to the field of metallurgy and discloses a manufacturing process of a spring steel wire rod, which comprises the following steps: preparing raw materials, smelting the raw materials in an EAF eccentric bottom tapping electric arc furnace, refining the raw materials outside an LF furnace, performing vacuum degassing (VD) treatment, performing CCM continuous casting, performing shot blasting on a continuous casting billet, performing flaw detection, polishing, heating and rolling to manufacture the steel wire rod by a high-speed wire-rod rolling mill. The manufacturing process of the invention has the advantages of simple process, low energy consumption, less investment equipment and high production efficiency; and compared with the spring steel wire rod used by the traditional domestic railway spring strip, the spring steel wire rod of the invention has the advantages of low carbon content, good plasticity and toughness, delivery in the form of the steel wire rod, high size precision and yield, and good quality of a real object, capacity of being machined into the steel wire rod, and low manufacturing cost.

Owner:NANJING IRON & STEEL CO LTD

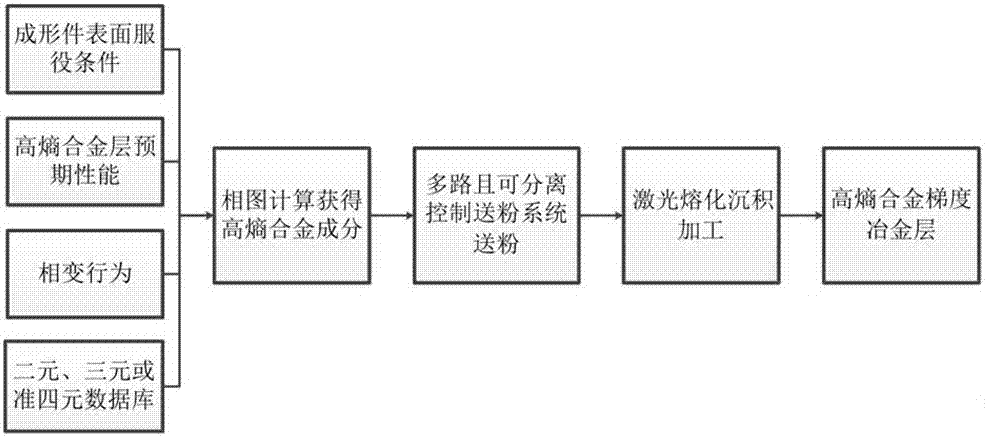

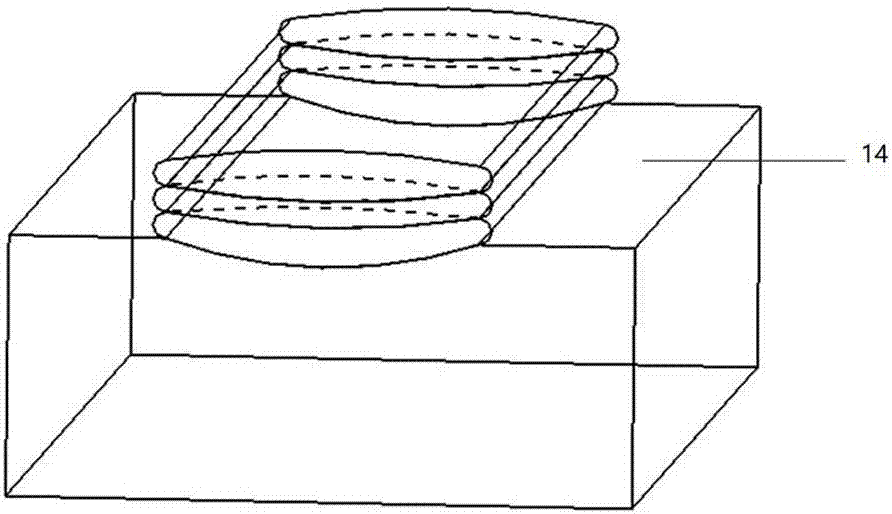

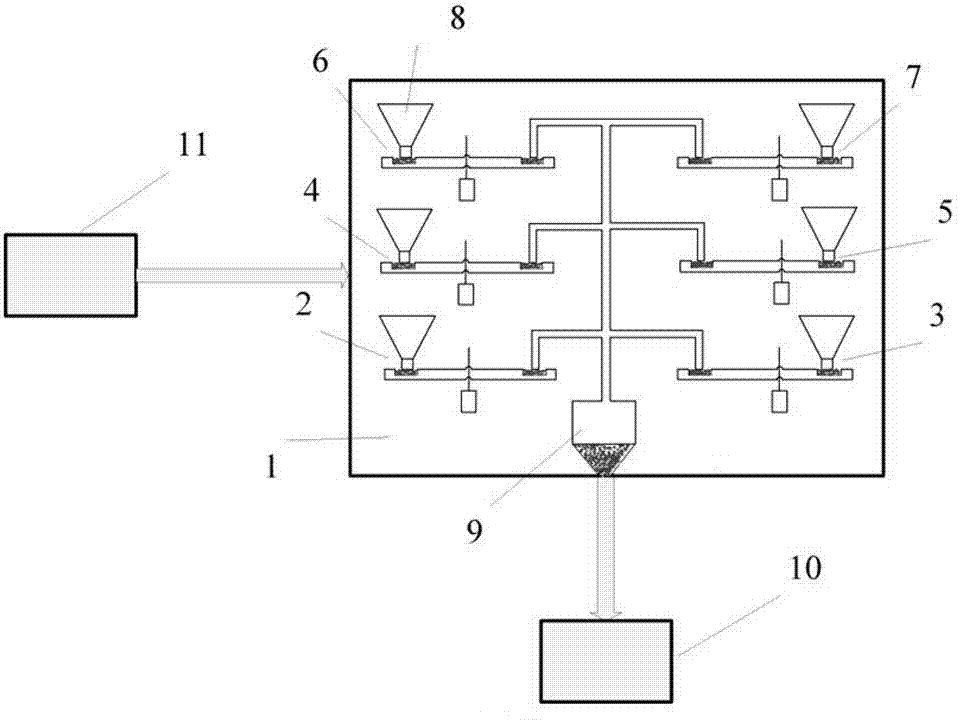

Additive manufacturing method of surface high-entropy alloying gradient metallurgy layer

InactiveCN107971490AReduce distortionImprove work efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysUltimate tensile strength

The invention discloses an additive manufacturing method of a surface high-entropy alloying gradient metallurgy layer, and belongs to the field of surface alloying. The additive manufacturing method comprises the following steps that step one, high-entropy alloying components are obtained through calculation based on a phase diagram; step two, an LMD technological strategy is designed, wherein anLMD technology is designed to carry out laser multilayer melting and sedimentation and increase the content of alloy powder in mixed powder layer by layer from the bottom up, and powder delivering schemes of different gradient coatings are formulated to design a multichannel and separable control powder delivering system; and step three, laser melting and sedimentation machining is carried out, thus the high-entropy alloying gradient metallurgy layer is obtained. The additive manufacturing method achieves the effects that the high-entropy alloying gradient layer excellent in properties is prepared on the surface of a cheap base material, the requirement that the surface properties of a formed part are outstanding is met, the production cost is lowered substantially, the bonding strength between the material surface metallurgy layer and a base is improved, and cracking of the metallurgy layer is inhibited effectively.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

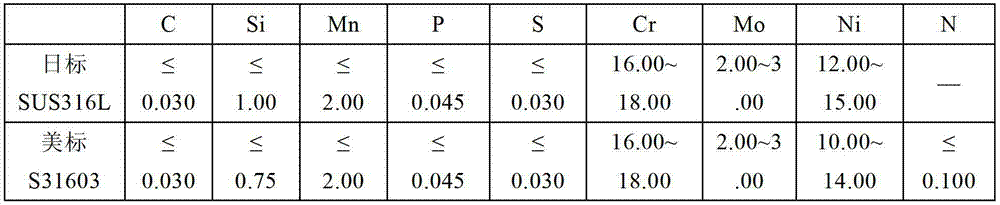

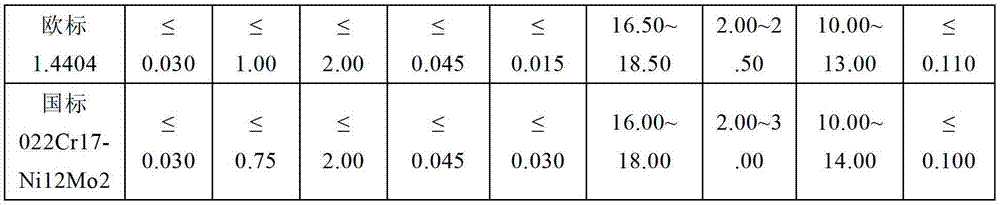

Sn-containing austenitic stainless steel and manufacturing method thereof

The invention discloses Sn-containing austenitic stainless steel and a manufacturing method thereof. The Sn-containing austenitic stainless steel is chemically composed of, by weight, < / =0.030% of C, < / =1.00% of Si, < / =2.00% of Mn, < / =0.045% of P, < / =0.030% of S, 10.00-15.00% of Ni, 16.00-18.50% of Cr, 2.00-3.00% of Mo, < / =0.10% of N, 0.01-1.00% of Sn, < / =1.2% of Cu, and the balance Fe and unavoidable impurities. On the basis of existing 316L stainless steel, resistance to reducing sulfuric acid corrosion is improved through Sn micro-alloying, and better effect is obtained by compositely adding a small amount of Cu. On the basis of maintaining original low cost and mechanical performance, resistance to sulfuric acid corrosion is remarkably improved, and the Sn-containing austenitic stainless steel is suitable for SOx-containing corrosive environments more demanding in corrosion resistance.

Owner:BAOSTEEL STAINLESS STEEL

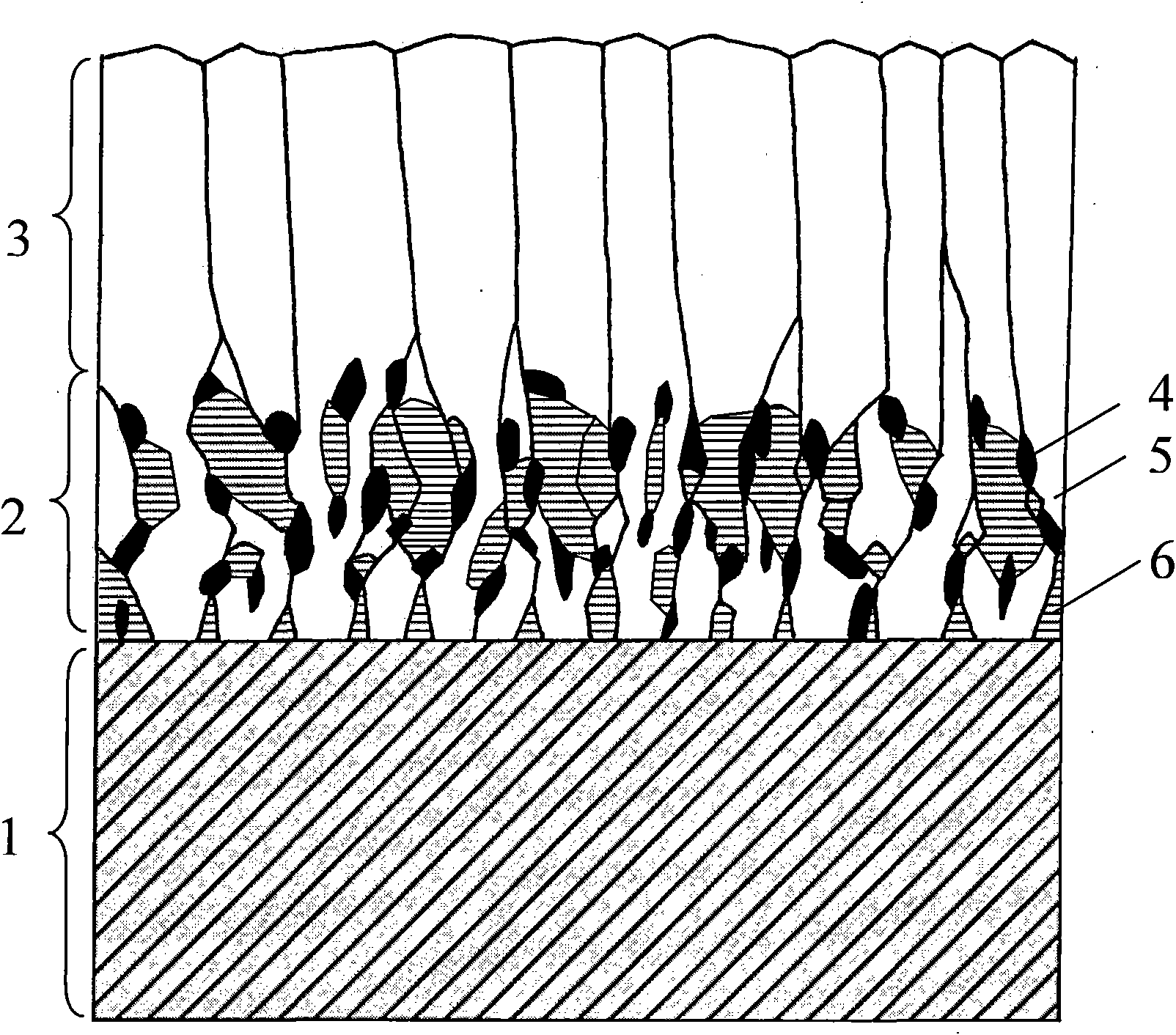

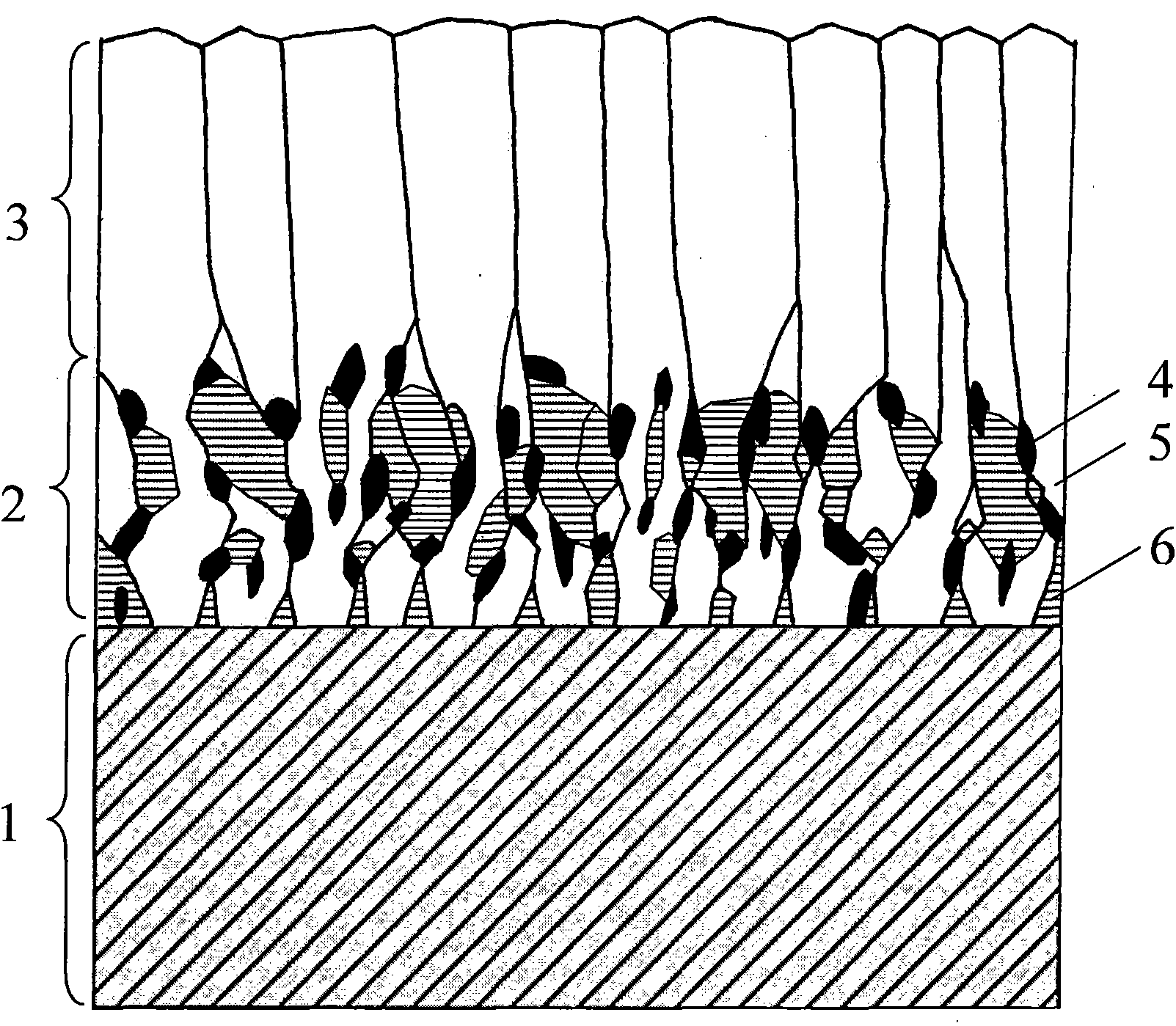

Method for preparing diamond-silicon carbide-cobalt disilicide composite interlayer of diamond coating on hard alloy

ActiveCN101880866ALow elastic modulusGood plasticityChemical vapor deposition coatingCemented carbideAlloy substrate

The invention discloses a method for preparing a diamond-silicon carbide-cobalt disilicide composite interlayer of a diamond coating on a hard alloy and belongs to the technical field of diamond coatings. The method is characterized in that: direct current plasma-assisted hot filament chemical vapor deposition (CVD) technology is adopted, hydrogen, methane and tetramethylsilane are used as reactant gases, the diamond-silicon carbide-cobalt disilicide composite interlayer is deposited on the hard alloy of which the surface is etched for removing cobalt, the composite interlayer is subjected to isothermal treatment in an atmosphere of methane and hydrogen in a volume ratio of 1 percent, and a diamond thin film is deposited on the composite interlayer. The method has the advantages that: the cobalt disilicide generated in the composite interlayer improves the adhesive force between a CVD diamond coating and a hard alloy substrate and the toughness of the CVD diamond coating obviously. The process of the invention is easy to control, can be applied to hard alloy CVD diamond coating tools and parts and large-area CVD diamond coatings and has a promising industrial prospect.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com