Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

An insulating rubber and degaussing cable technology, which is used in the manufacture of longitudinal watertight degaussing cable insulation rubber for ships and the field of longitudinal watertight degaussing cable insulation rubber for ships, can solve the problem of poor flame retardancy and poor flame retardancy of ethylene-propylene rubber. Good and other problems, to achieve the effect of promoting activity, excellent insulation properties and mechanical properties, soft mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

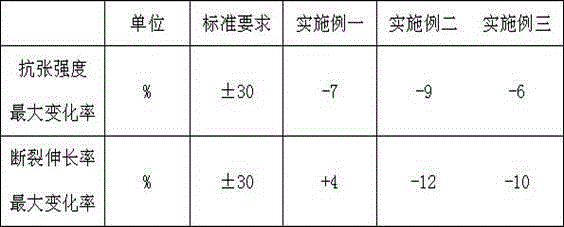

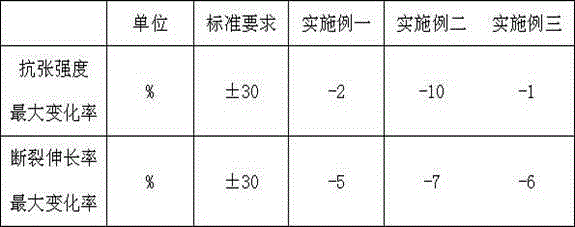

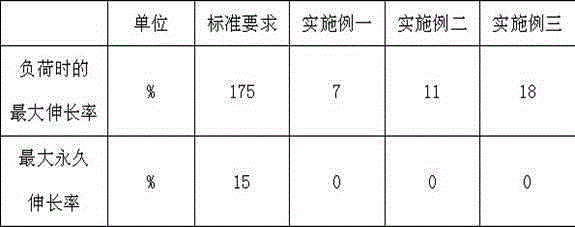

Embodiment 1

[0019] The preparation steps of insulating rubber are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; EPDM rubber 4045M: 5 parts; vulcanizing agent dicumyl peroxide: 0.5 part; vulcanization accelerator triallyl isocyanurate: 0.2 part; antiaging agent 2-mercaptobenzimidazole: 0.7 part; antiaging agent 2,2,4-trimethyl-1,2-di Hydroquinoline polymer: 0.2 parts; plasticizer paraffin oil: 1.0 parts; plasticizer chlorinated paraffin-52: 1 part; plasticizer microcrystalline paraffin: 0.5 parts; active agent zinc oxide: 1.0 parts; active agent Stearic acid: 0.3 parts; filler superfine talcum powder: 8 parts; reinforcing filler fumed silica: 1.0 parts; reinforcing filler calcined clay: 7 parts; K21 and EPDM 4045M raw rubber were kneaded on an internal mixer at a temperature of 65°C until they were uniform, and then the antioxidant 2-mercaptobenzimidazole and the antioxidant 2,2,4-trimethyl- 1,2-dihydroquinoline ...

Embodiment 2

[0022] The preparation steps of insulating rubber are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; EPDM rubber 4045M: 5 parts; vulcanizing agent dicumyl peroxide: 0.55 parts; vulcanization accelerator triallyl isocyanurate: 0.25 parts; anti-aging agent 2-mercaptobenzimidazole: 0.8 parts; anti-aging agent 2,2,4-trimethyl-1,2-di Hydroquinoline polymer: 0.25 parts; plasticizer paraffin oil: 1.5 parts; plasticizer chlorinated paraffin-52: 1.5 parts; plasticizer microcrystalline paraffin: 0.8 parts; active agent zinc oxide: 1.5 parts; active agent Stearic acid: 0.4 parts; filler superfine talcum powder: 9 parts; reinforcing filler fumed silica: 1.2 parts; reinforcing filler calcined clay: 8 parts; K21 and EPDM 4045M raw rubber were kneaded on an internal mixer at a temperature of 70°C until they were uniform, and then the antioxidant 2-mercaptobenzimidazole and the antioxidant 2,2,4-trimethyl- 1,2-dihydr...

Embodiment 3

[0025] The preparation steps of insulating rubber are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; EPDM rubber 4045M: 5 parts; vulcanizing agent dicumyl peroxide: 0.6 part; vulcanization accelerator triallyl isocyanurate: 0.3 part; antiaging agent 2-mercaptobenzimidazole: 0.9 part; antiaging agent 2,2,4-trimethyl-1,2-di Hydroquinoline polymer: 0.3 parts; plasticizer paraffin oil: 2.0 parts; plasticizer chlorinated paraffin-52: 2 parts; plasticizer microcrystalline paraffin: 1.0 parts; active agent zinc oxide: 2.0 parts; active agent Stearic acid: 0.5 parts; filler superfine talcum powder: 11 parts; reinforcing filler fumed silica: 1.5 parts; reinforcing filler calcined clay: 9 parts; K21 and EPDM 4045M raw rubber were kneaded on an internal mixer at a temperature of 75°C until uniform, and then the antioxidant 2-mercaptobenzimidazole and the antioxidant 2,2,4-trimethyl- 1,2-dihydroquinoline polymer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com