Additive manufacturing method of surface high-entropy alloying gradient metallurgy layer

A high-entropy alloy and gradient technology, applied in the field of surface alloying, can solve the problems of crack plastic toughness in the metallurgical layer, poor metallurgical bonding between layers, and high production cost, achieve small deformation of the matrix, solve the problem of poor metallurgical bonding between layers, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

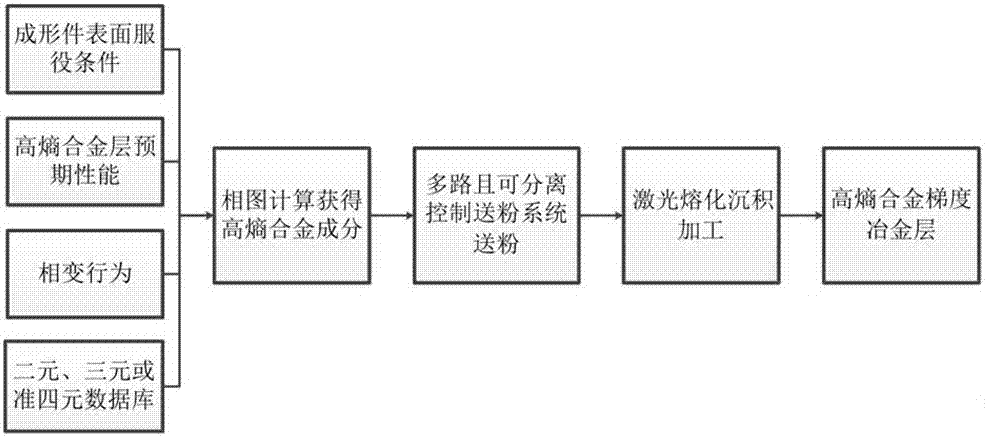

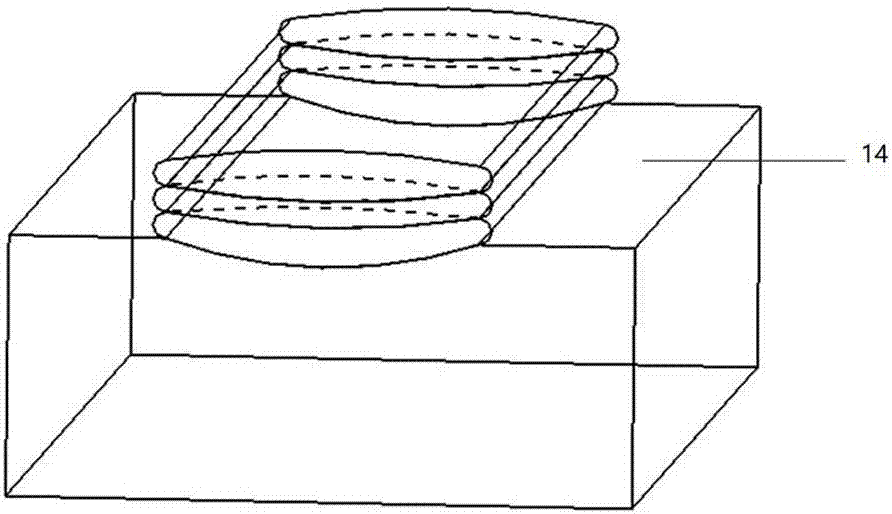

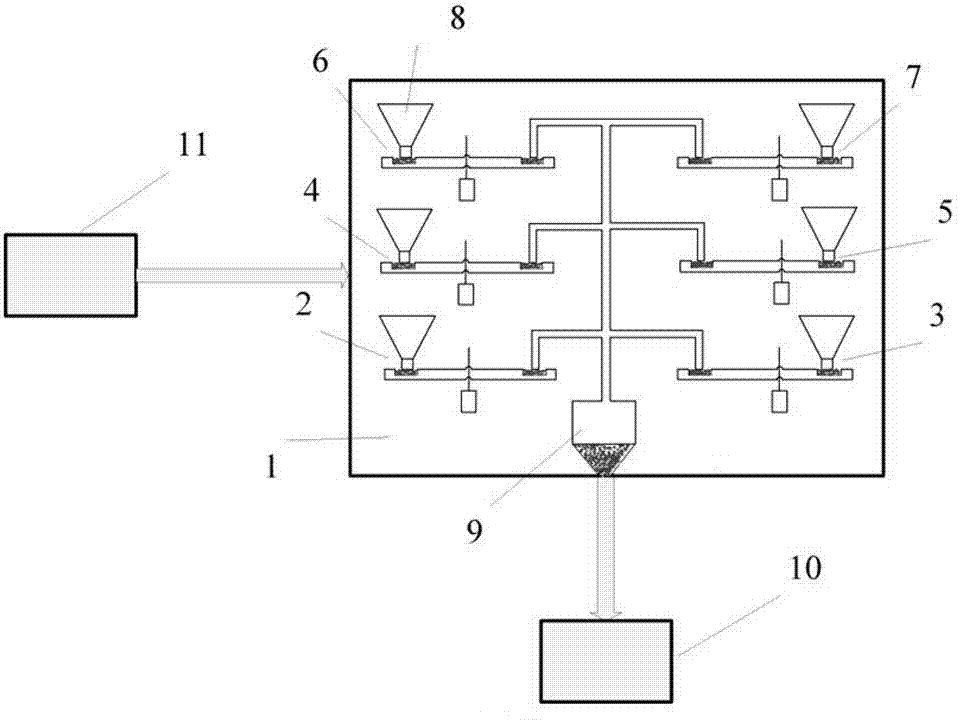

[0050] The invention provides a method for preparing a gradient metallurgical layer of a surface high-entropy alloy, aimed at the preparation of a gradient metallurgical layer of a high-entropy alloy on the surface of a TC4 titanium alloy. The specific steps are as follows figure 1 Shown: First, the components of the high-entropy alloy are selected according to the surface service conditions of the titanium alloy and the expected surface properties of the high-entropy alloy. Follow the following principles: select at least 5 or more components to obtain high mixing entropy; the maximum atomic radius difference is less than 12%; the alloy mixing enthalpy is in the range of -40 to 10KJ / mol; the content of each component is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com