Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

605 results about "Kirschner wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

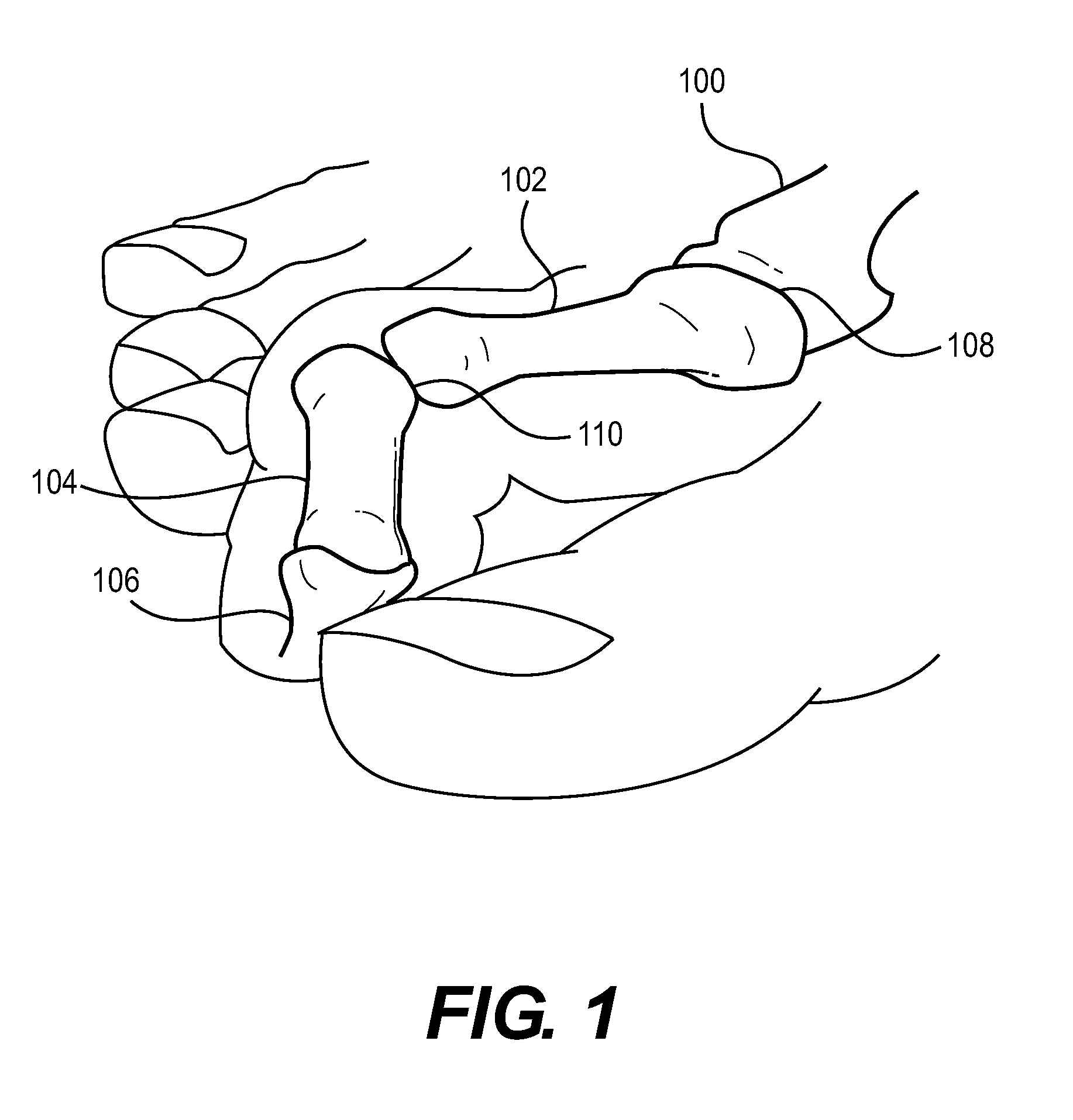

Kirschner wires or K-wires or pins are sterilized, sharpened, smooth stainless steel pins. Introduced in 1909 by Martin Kirschner, the wires are now widely used in orthopedics and other types of medical and veterinary surgery. They come in different sizes and are used to hold bone fragments together (pin fixation) or to provide an anchor for skeletal traction. The pins are often driven into the bone through the skin (percutaneous pin fixation) using a power or hand drill. They also form part of the Ilizarov apparatus.

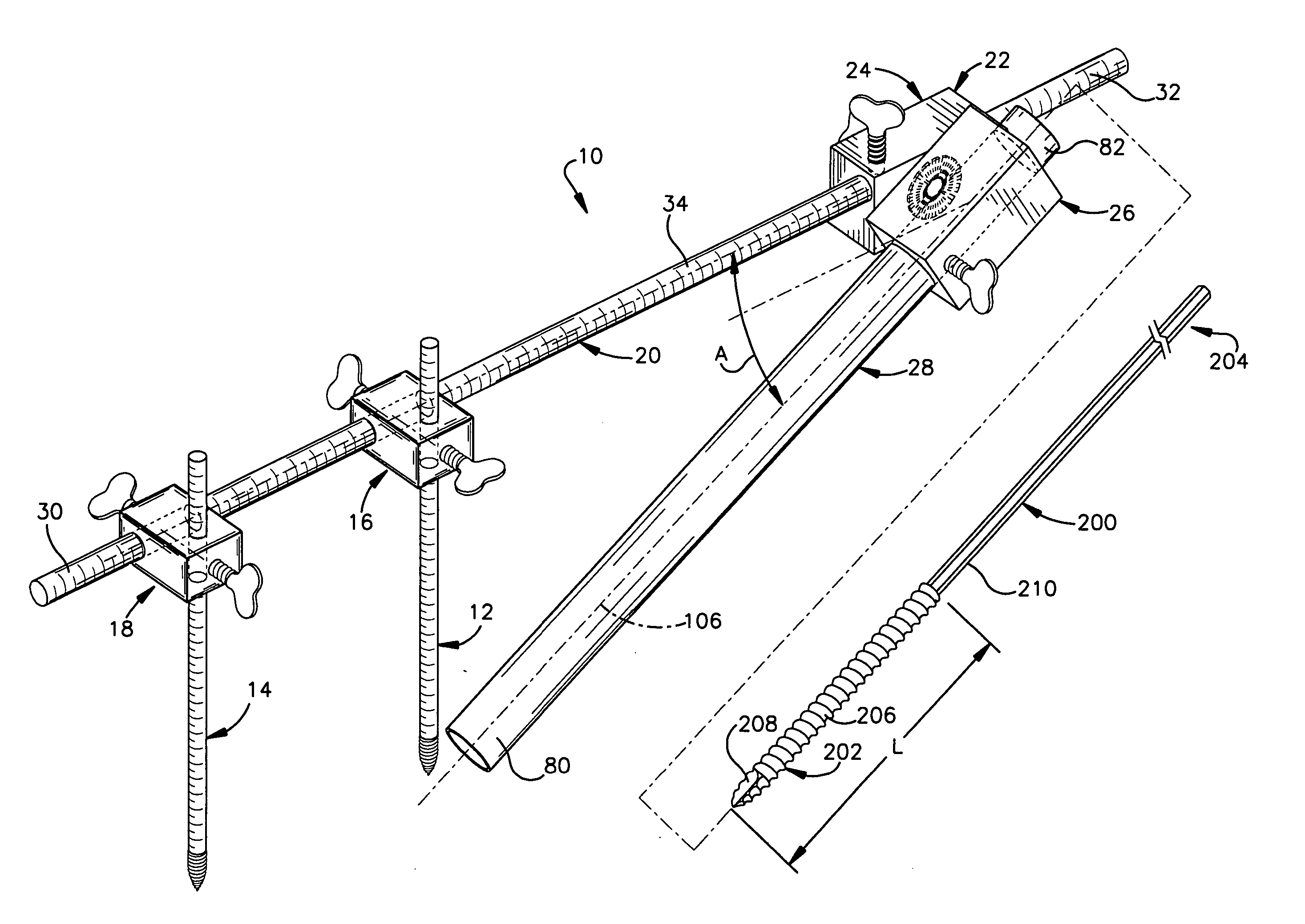

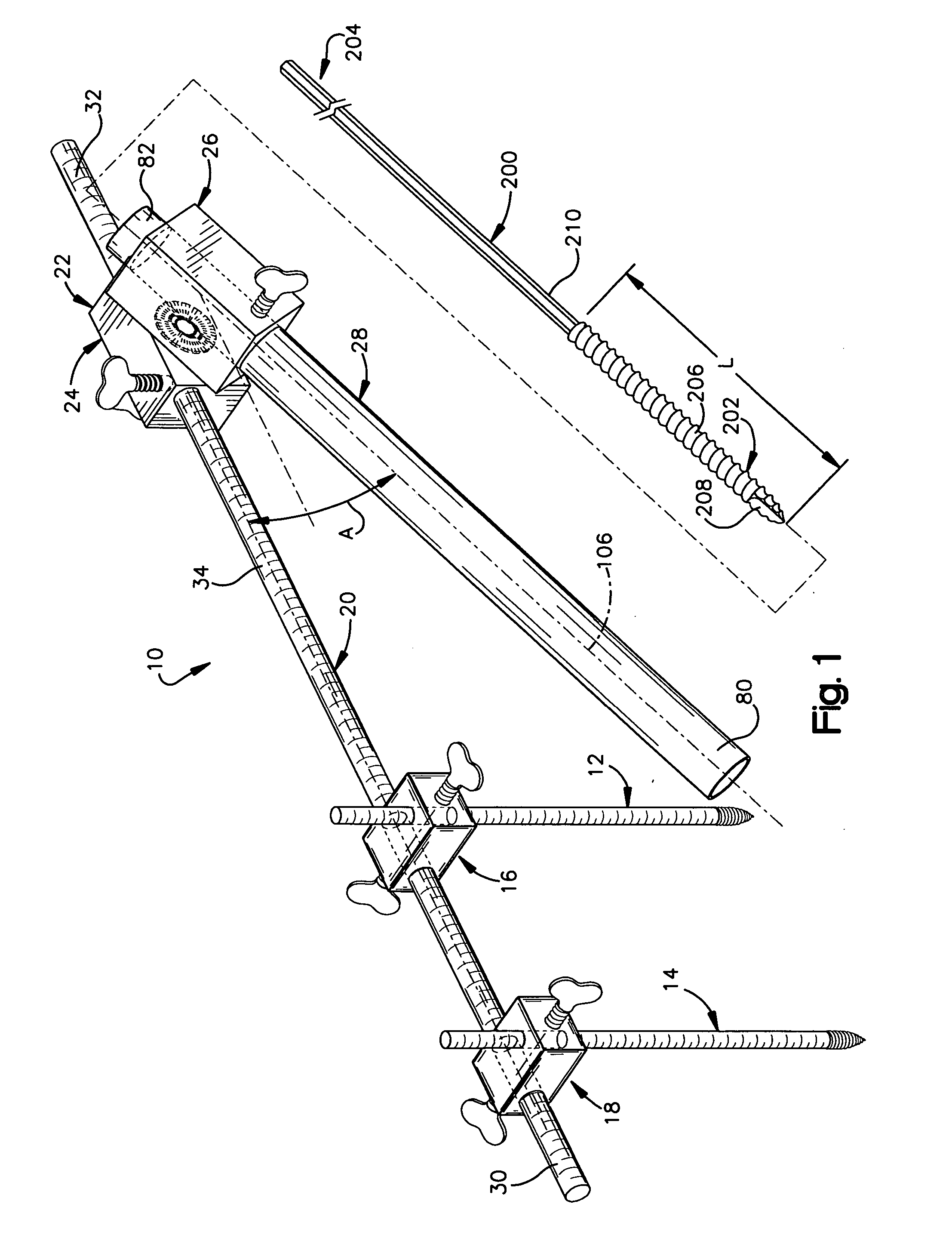

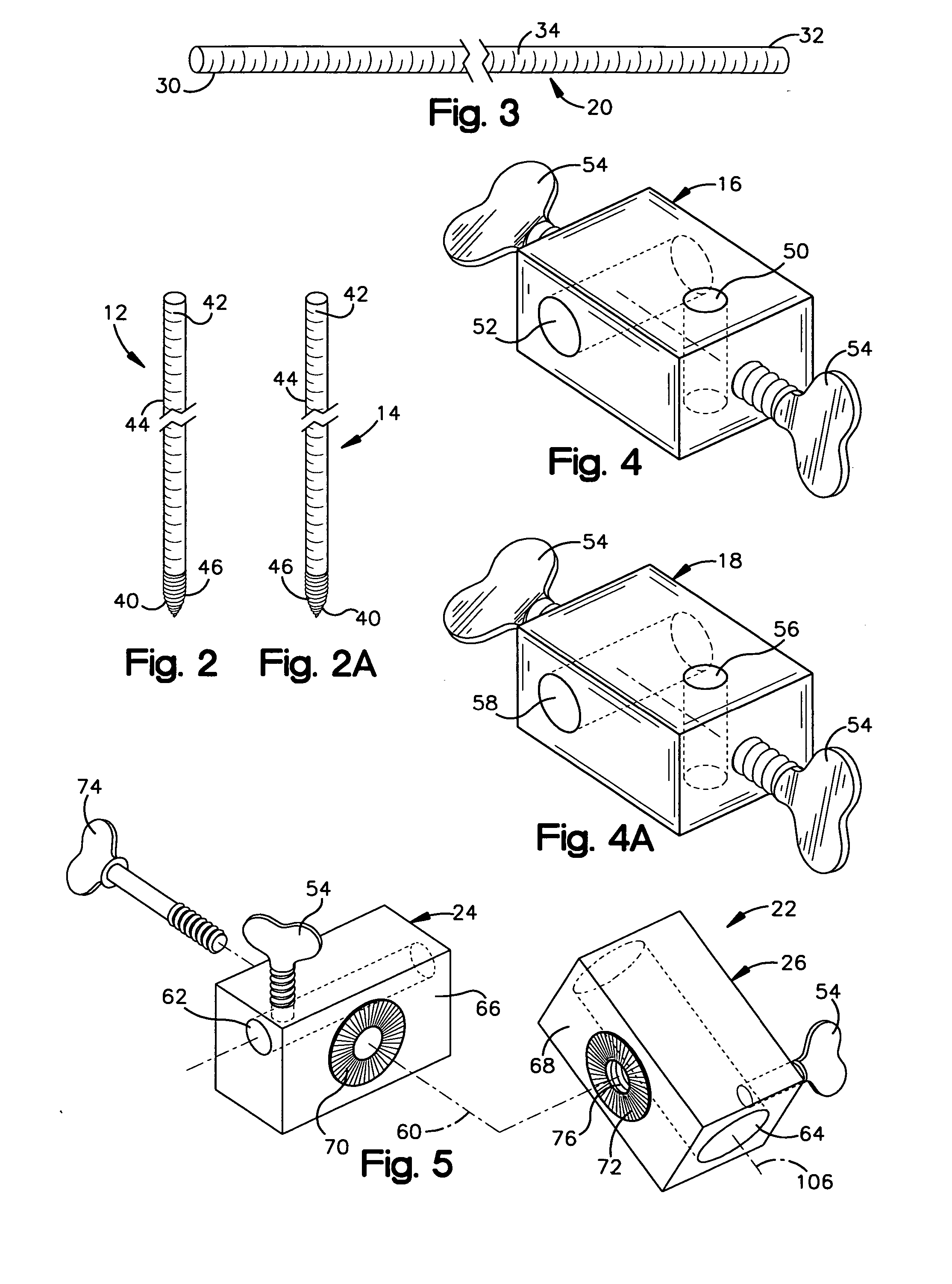

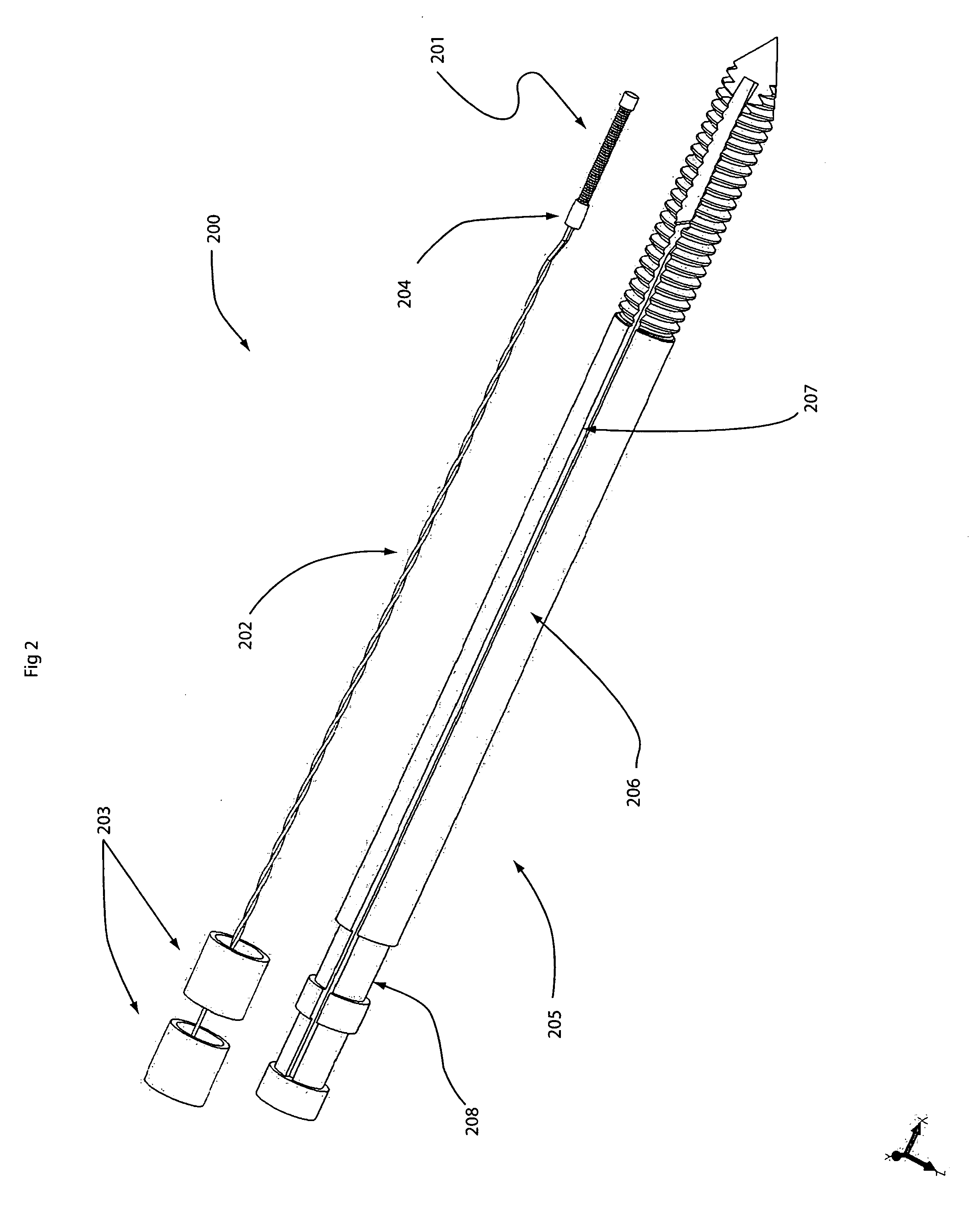

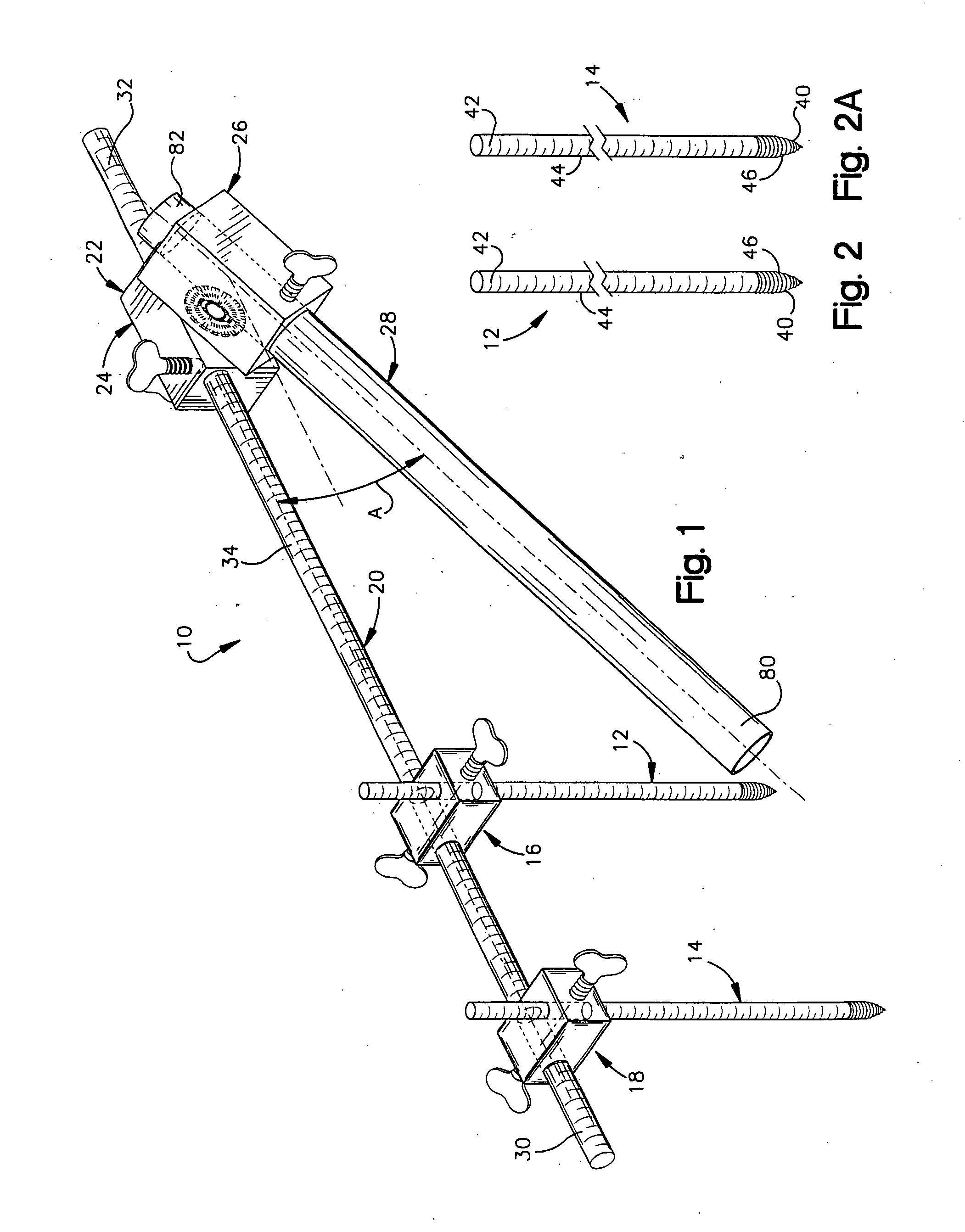

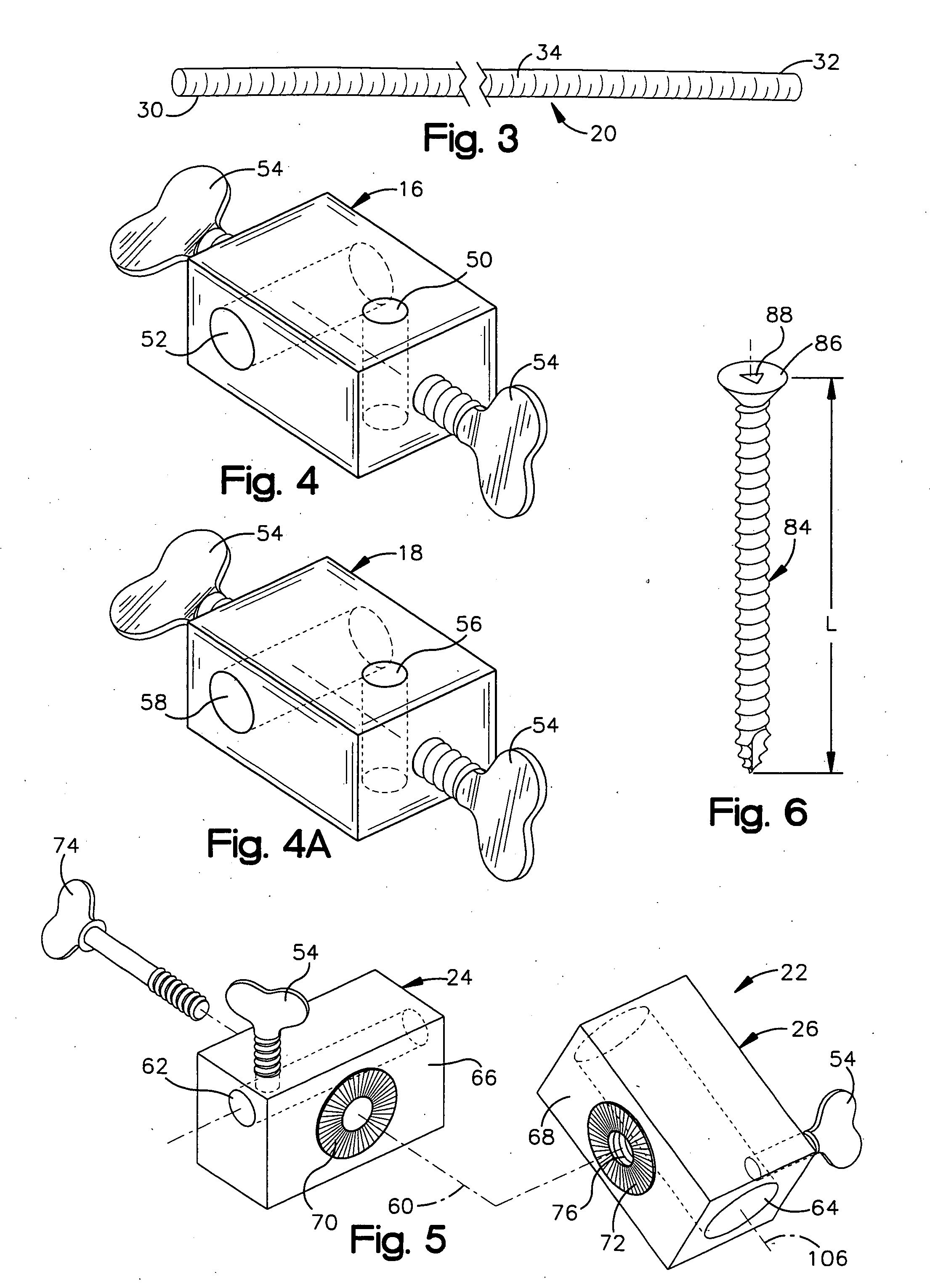

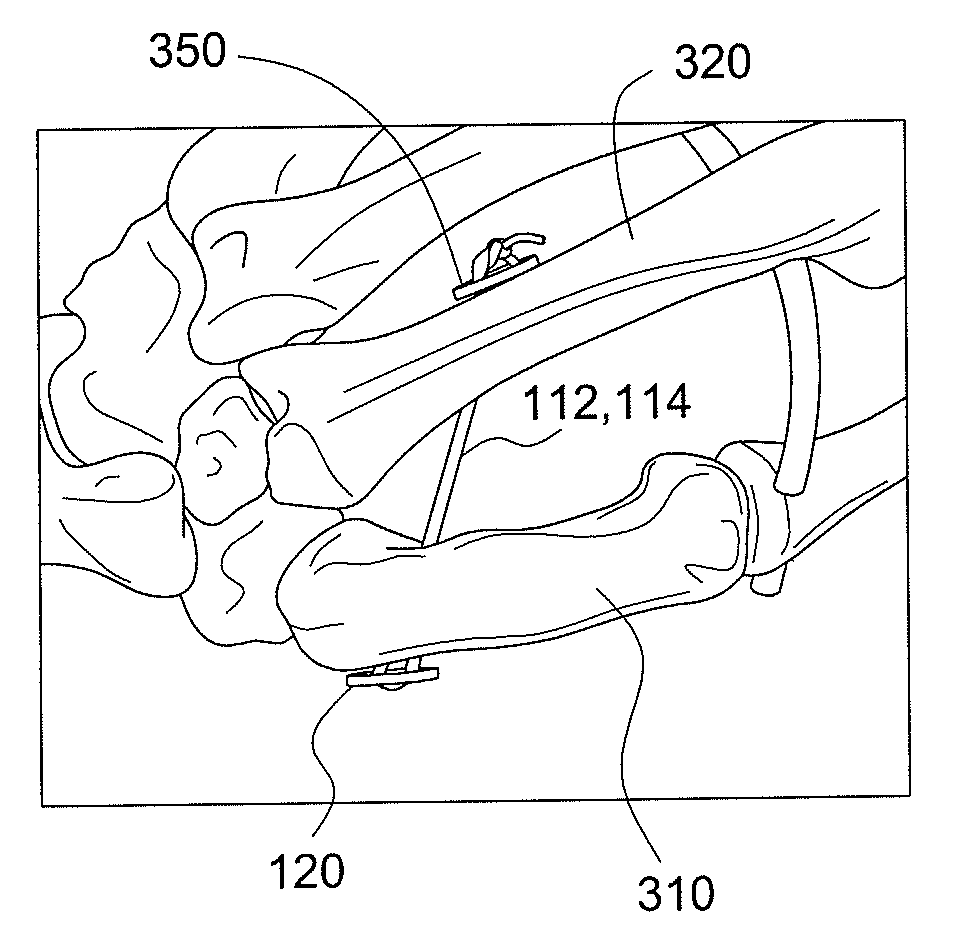

Minimally invasive method and apparatus for fusing adjacent vertebrae

The present invention is a minimally invasive surgical method for fusing adjacent vertebrae. A first K-wire is inserted into the spinous process of an upper vertebrae. A second K-wire is inserted into a transverse process of a lower vertebrae. A first fixation block is secured to the first K-wire and a second fixation block is secured to the second K-wire. A rod member extends across the K-wires. A swivel block assembly is secured to achieve a desired angle for a first axis along which a first screw will be implanted into a facet joint. The swivel block assembly is secured at a desired axial position on the rod member. Percutaneous access to the upper vertebrae along the first axis is then obtained via a cannula. A removable screw having a threaded section for implantation across the facet joint and an elongated shank section that is shearable subcutaneously is inserted through the cannula. The threaded section is implanted along the first axis across the facet joint to attach the upper and lower vertebrae. A shearing tool is inserted percutaneously over the shank section and the shank section is sheared off immediately above the lamina.

Owner:THE CLEVELAND CLINIC FOUND

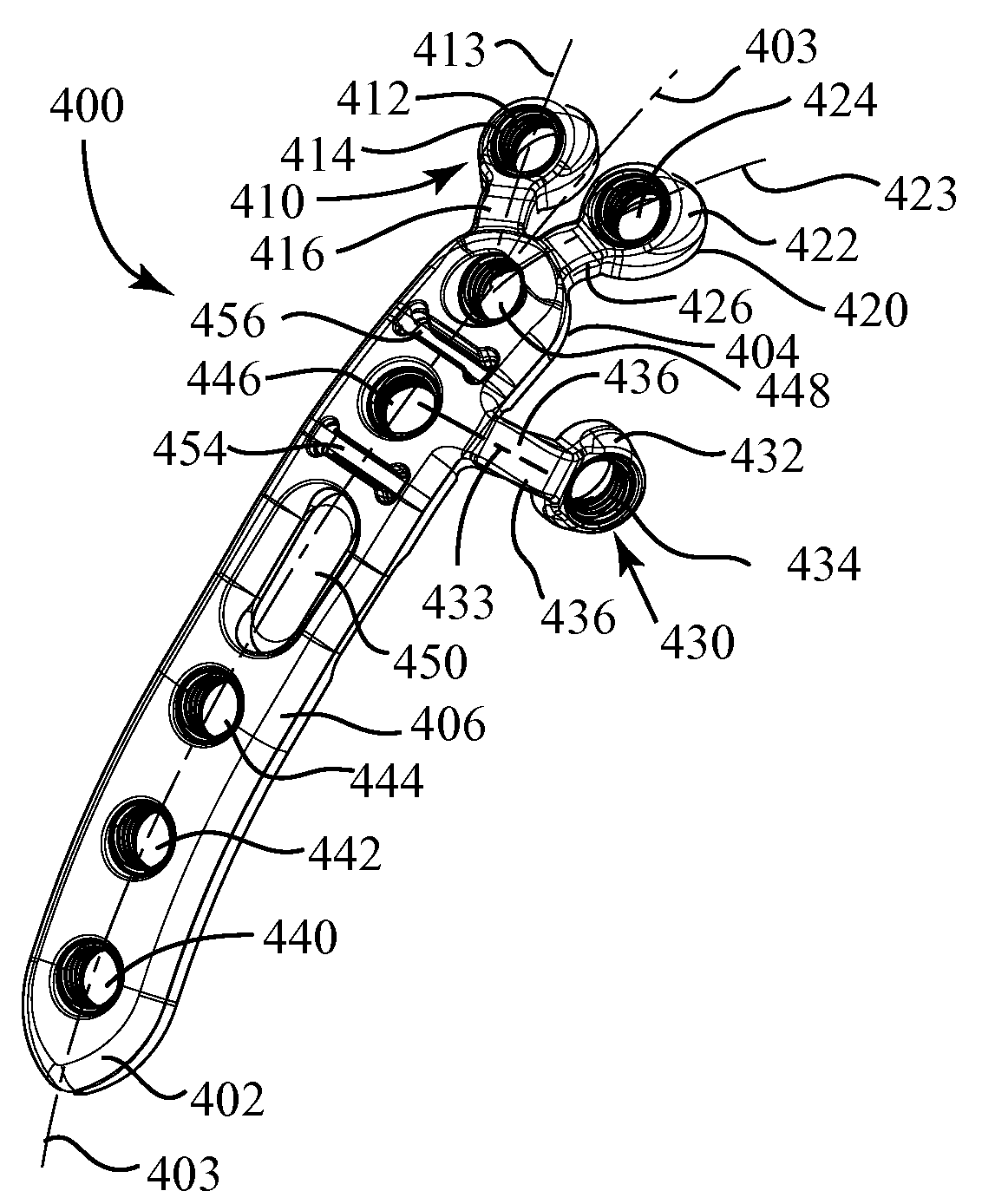

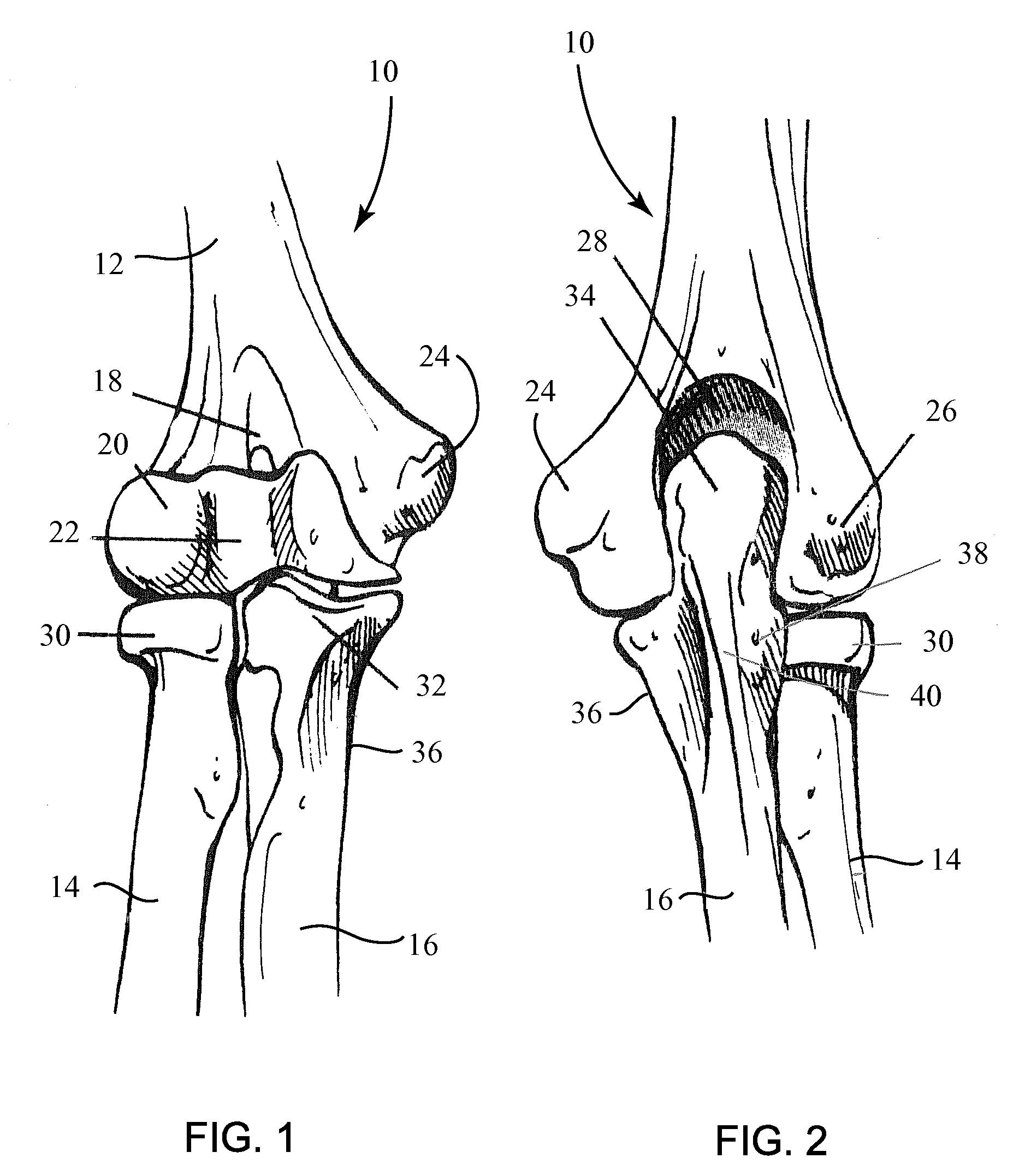

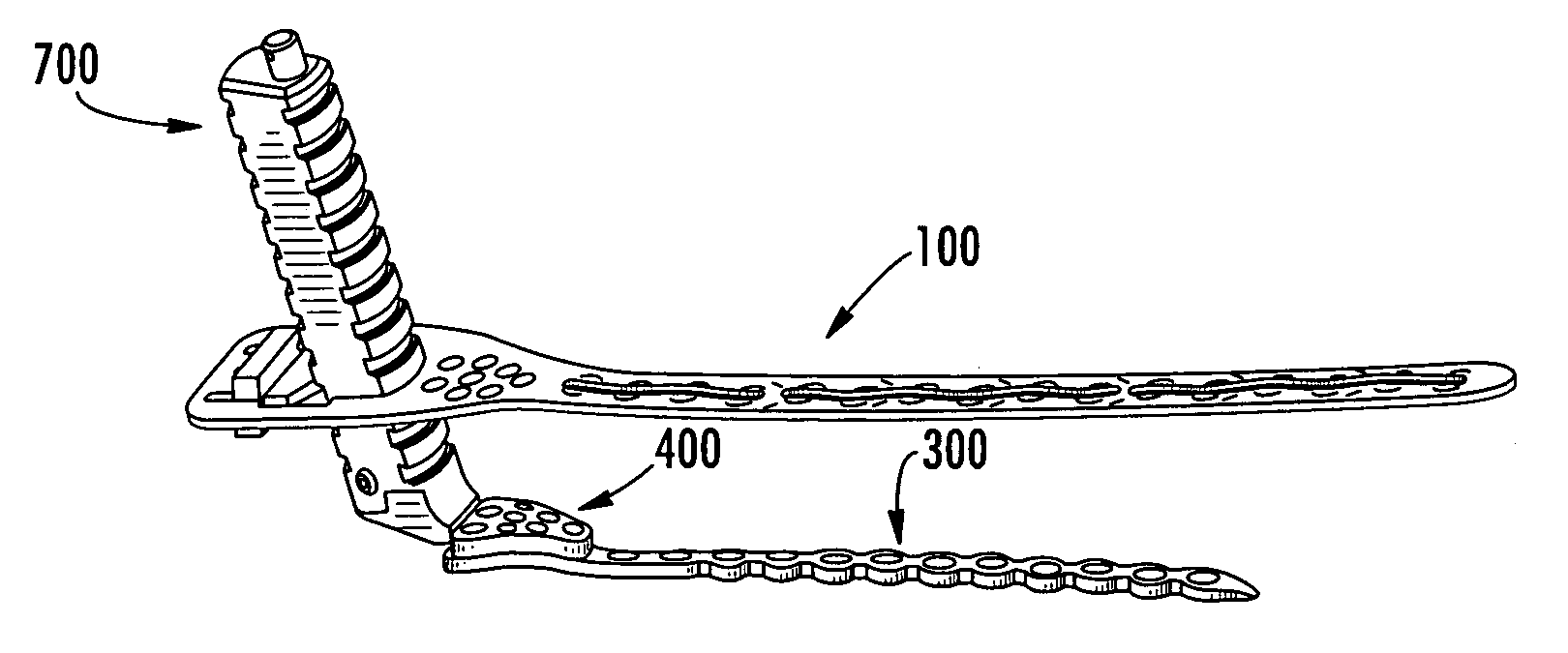

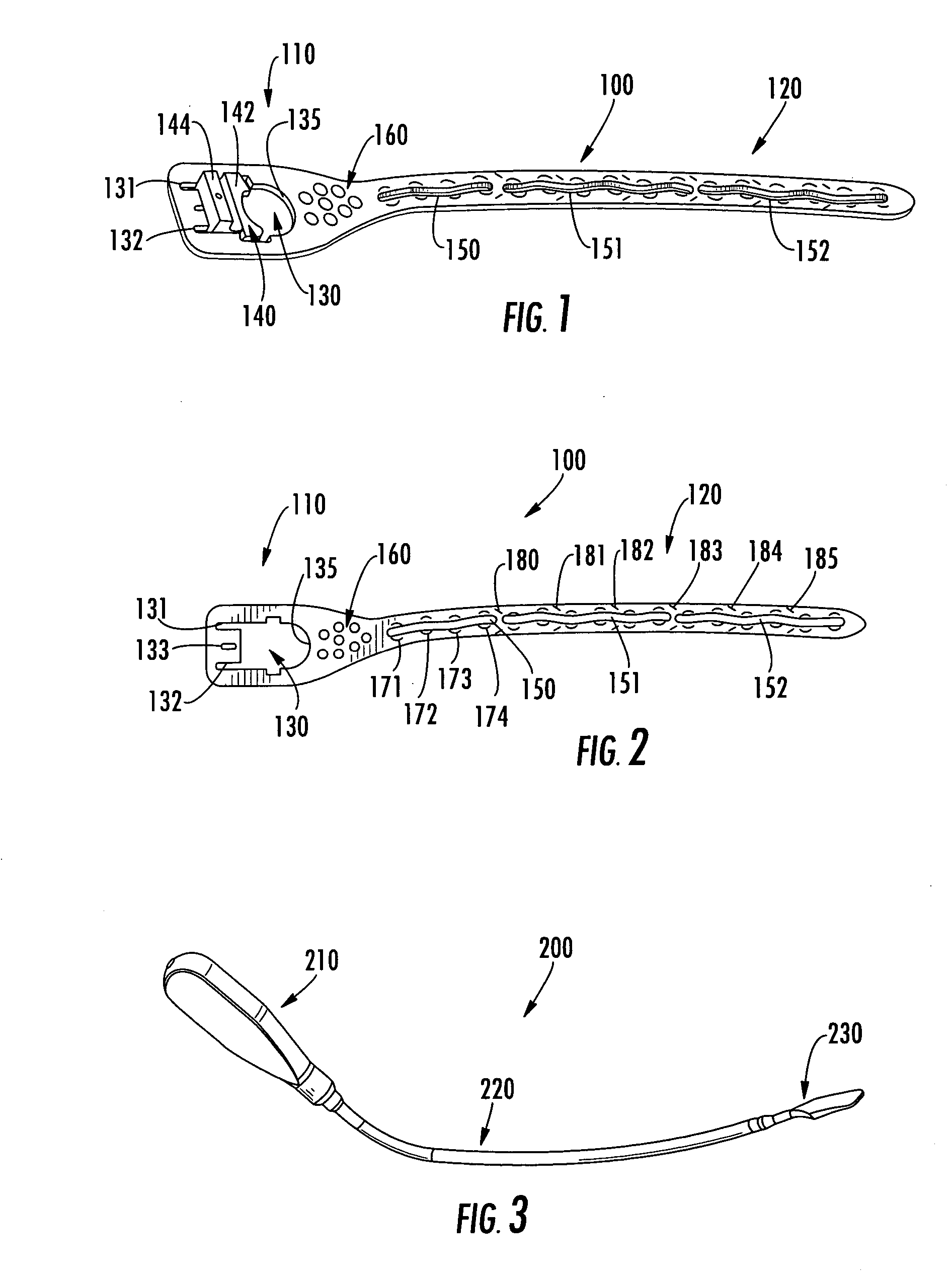

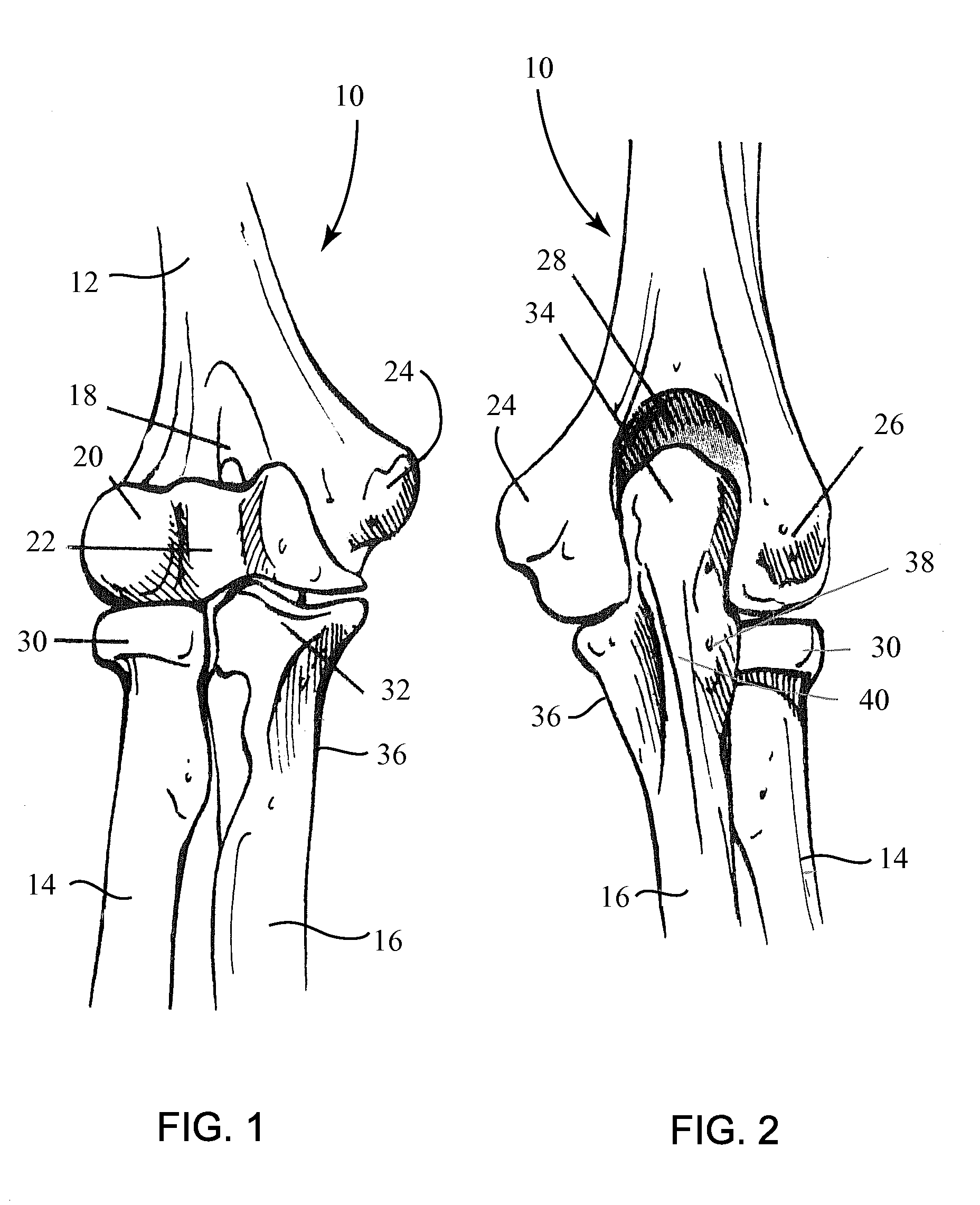

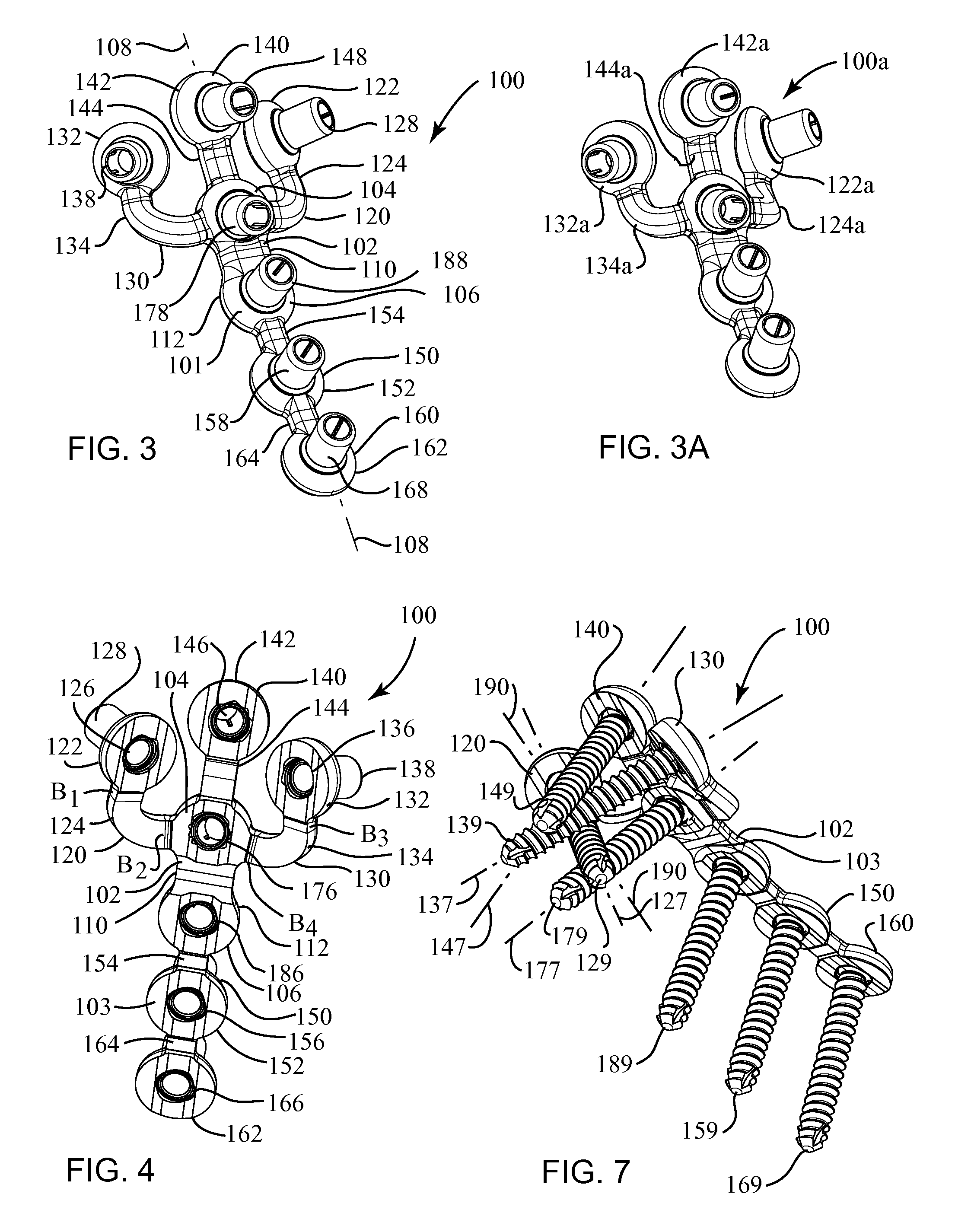

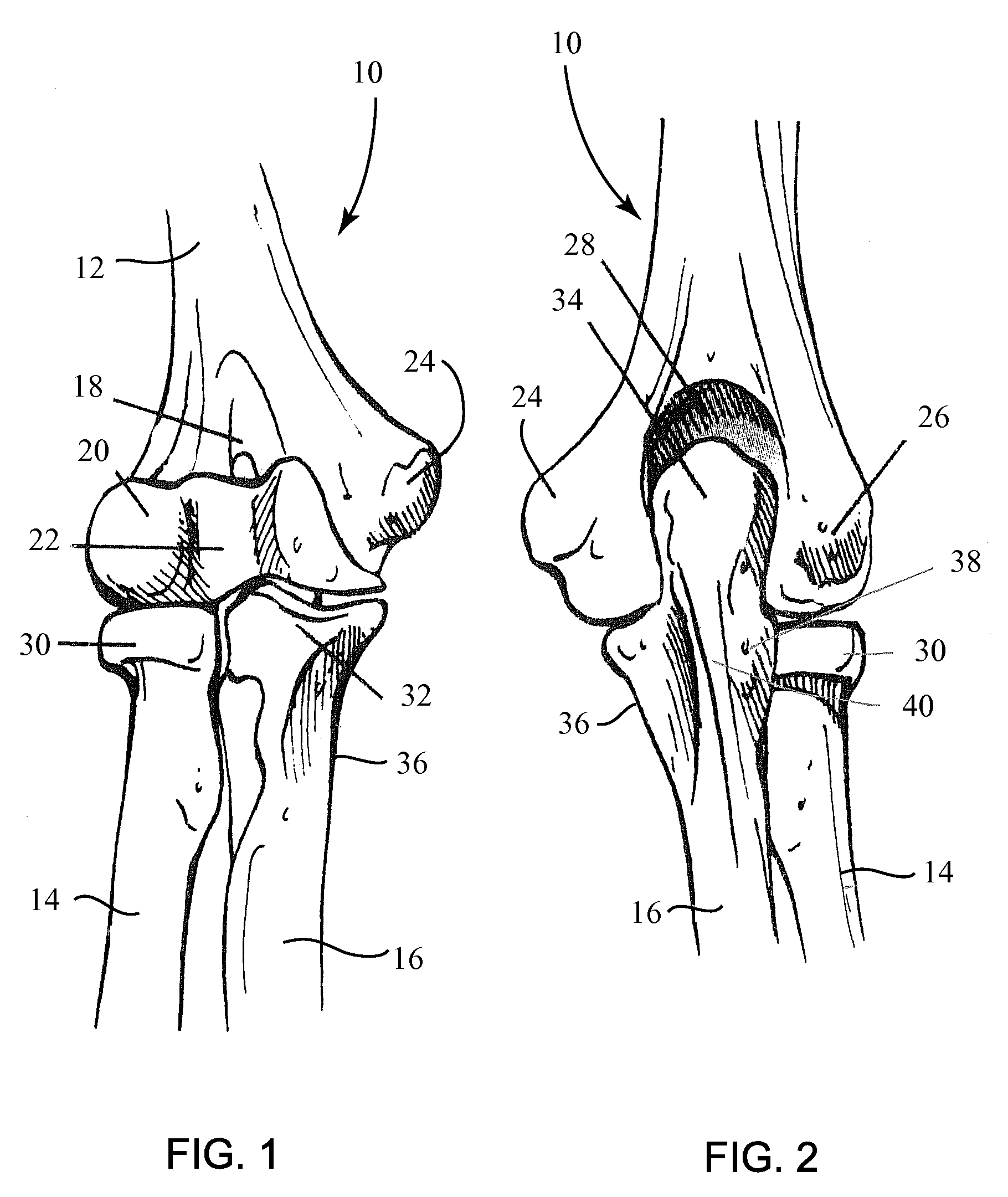

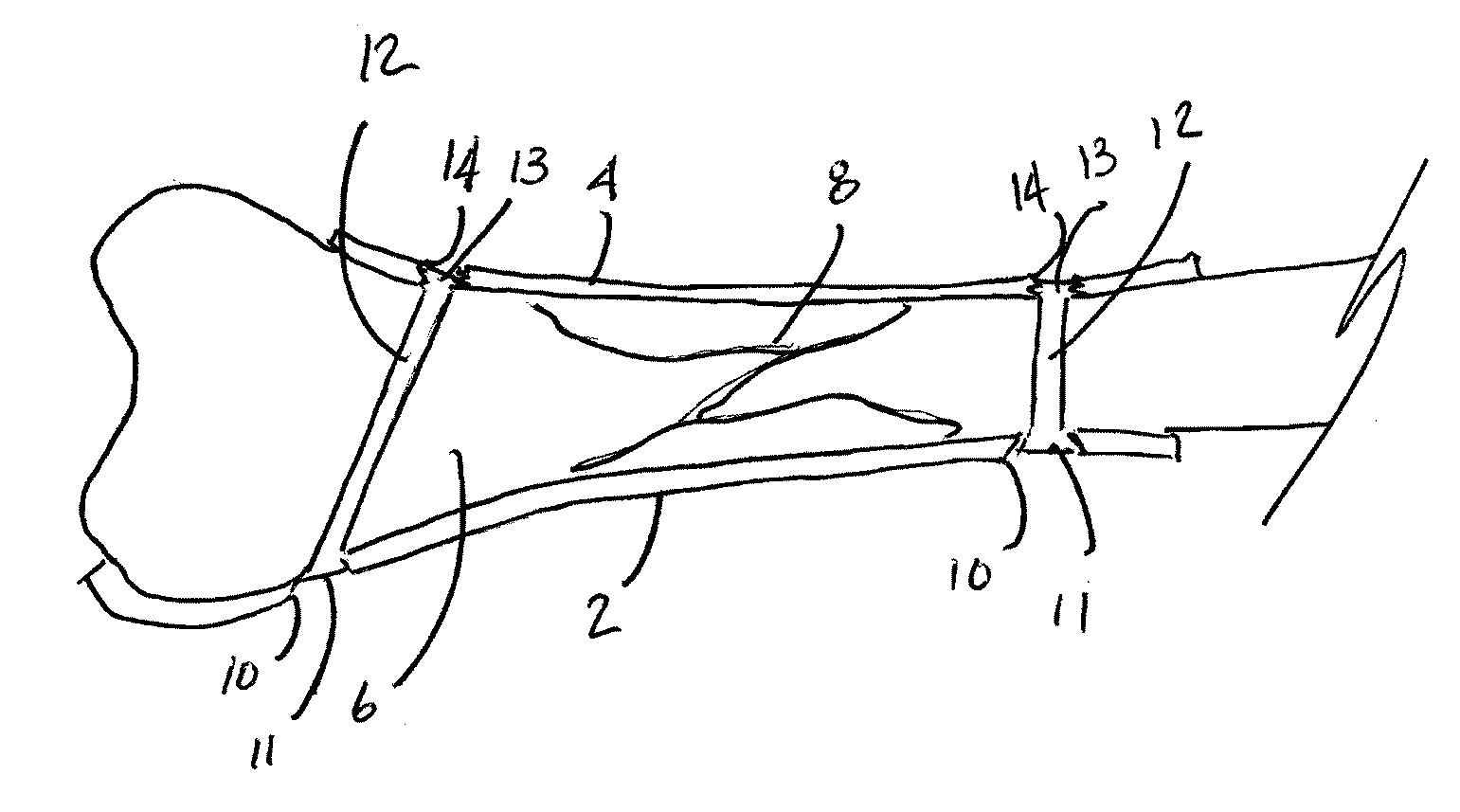

Fracture Fixation Plate for the Proximal Radius

ActiveUS20090118769A1Simple and safe processEasily and safely reconfiguredInternal osteosythesisMetal-working hand toolsProximal radiusInternal fixation

A system for the internal fixation of a fractured bone of an elbow joint of a patient includes at least one bone plate, each bone plate having a plurality of holes and generally configured to fit an anatomical surface of the fractured bone. The at least one plate is adapted to be customized to the shape of a patient's bone. The system also includes a plurality of fasteners including at least one locking fastener for attaching the bone plate to the bone. At least one of the holes is a threaded hole. Guides for plate benders, drills, and / or K-wires can be pre-assembled to the threaded holes, and the locking fastener can lock into any of the threaded holes after the guides are removed.

Owner:BIOMET CV

Electromagnetically tracked K-wire device

InactiveUS20060173291A1Improve accuracyReduce usageSurgical navigation systemsDiagnostic markersRadiologyComputer science

Devices and methods for registering, dynamically referencing, and navigating an anatomical region of interest of a patient are provided using a tracked Kirschner wire (K-wire), where the K-wire includes a position-indicating element.

Owner:PHILIPS ELECTRONICS LTD

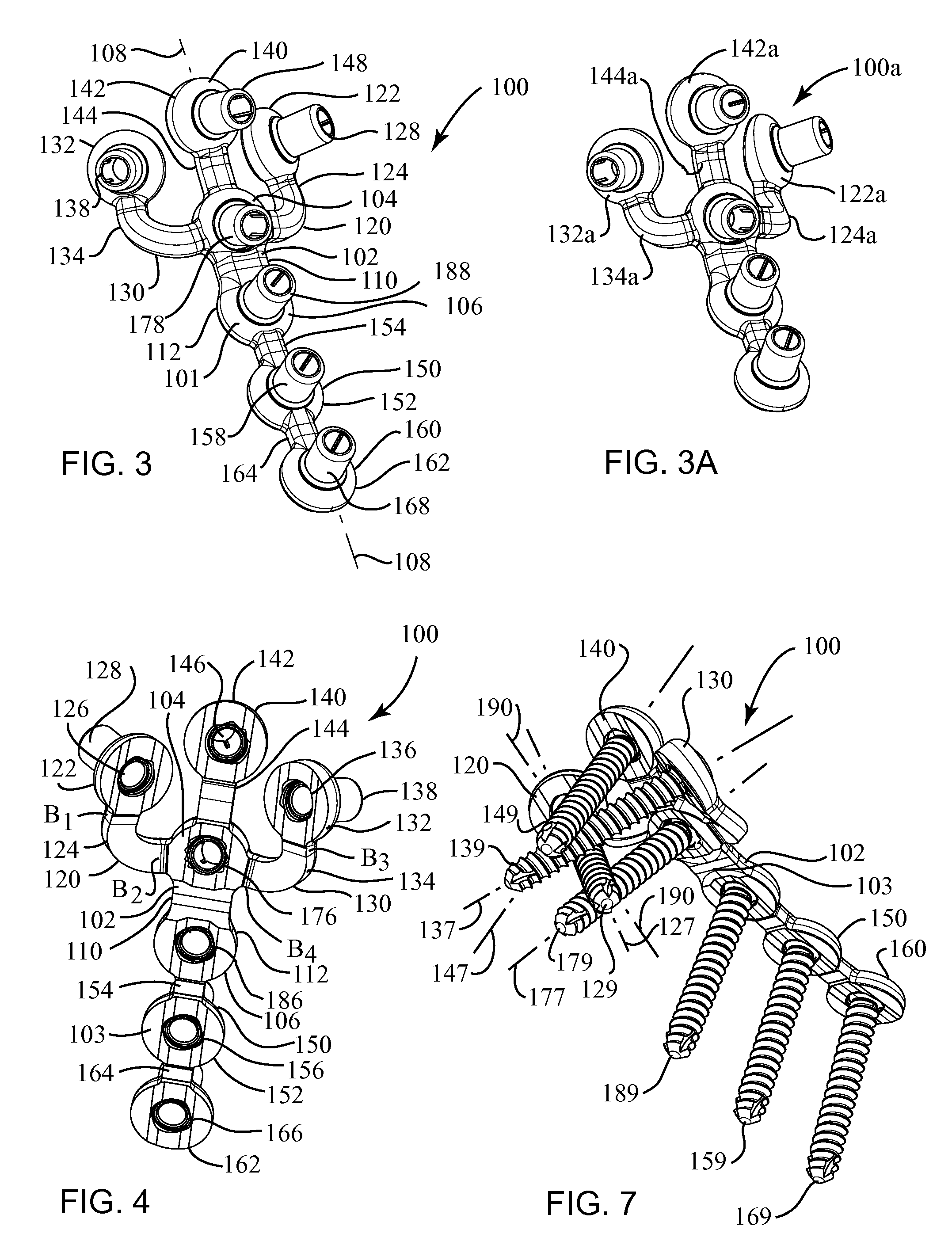

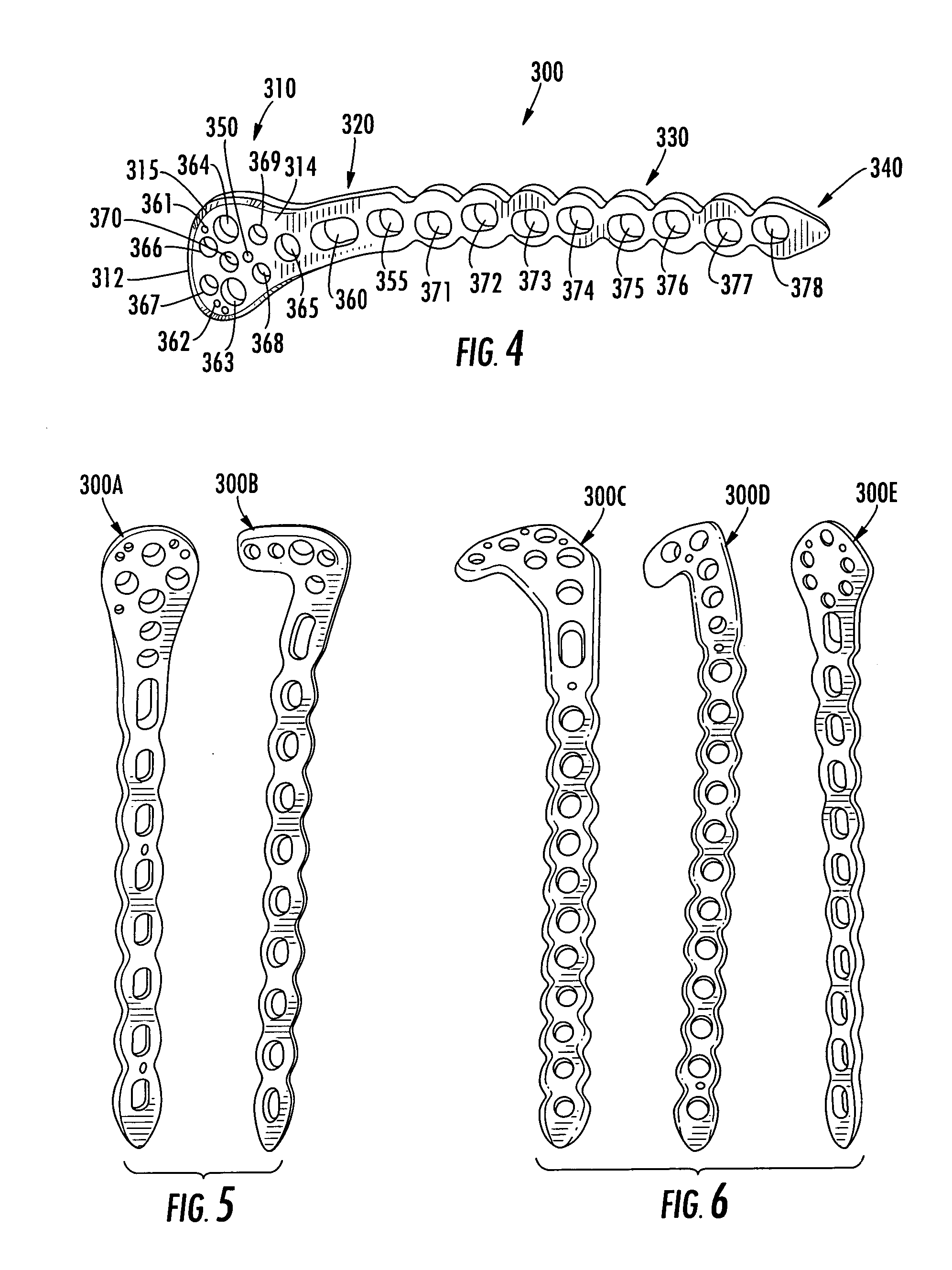

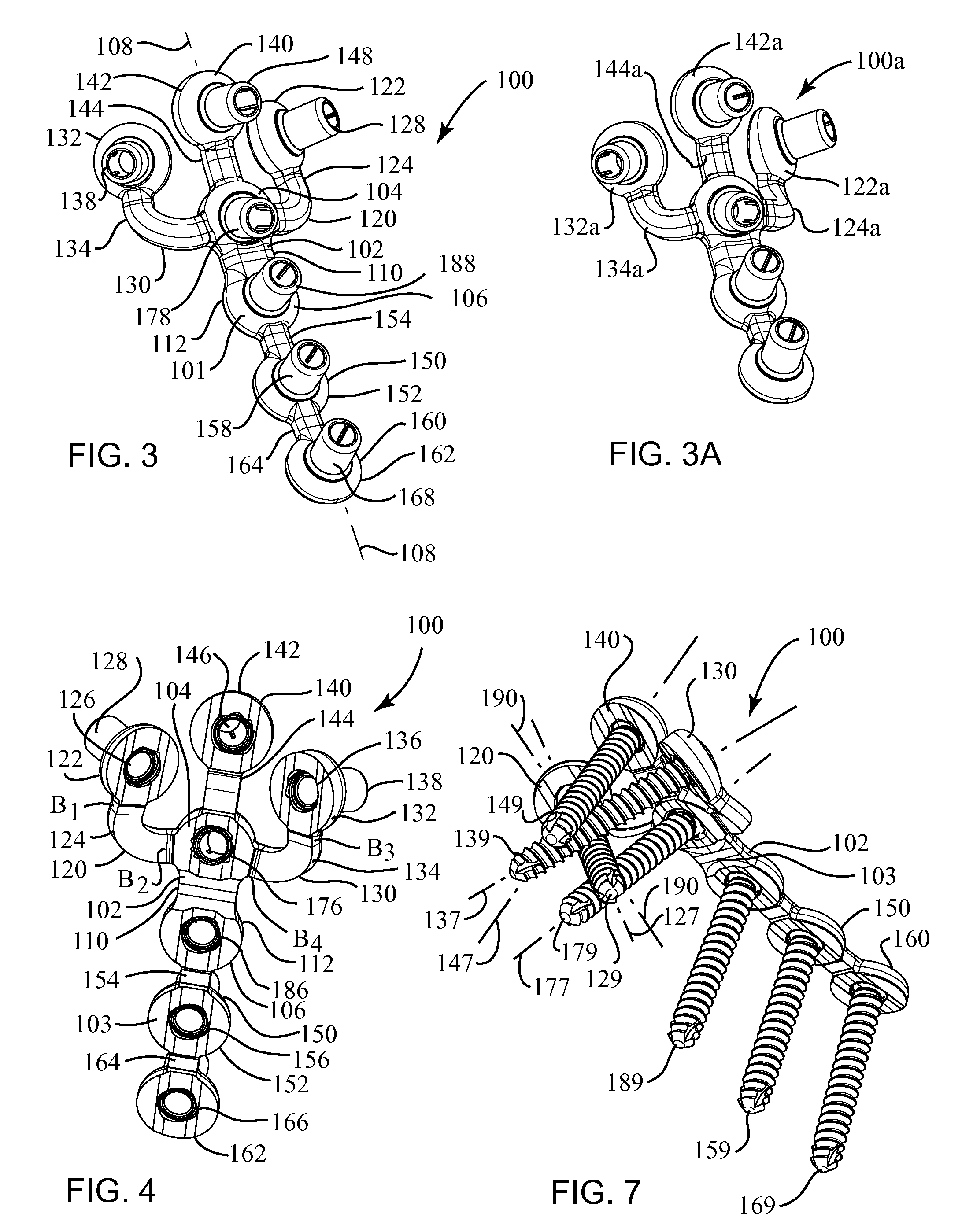

Bone plating implants, instruments and methods

Bone plating implants, instruments, systems and methods for fracture fixation are provided. The systems includes the instruments and implants comprising a trial component, handle, aiming block, bone plate, tissue spreader, drill guide, K-wire guide, monoaxial screw-locking inserts, polyaxial screw-locking inserts, cable plugs, K-wires, monoaxial screws and polyaxial screws. The methods include the use of the instruments and implants for either open or minimally invasive fracture fixation surgery.

Owner:STRYKER EURO OPERATIONS HLDG LLC

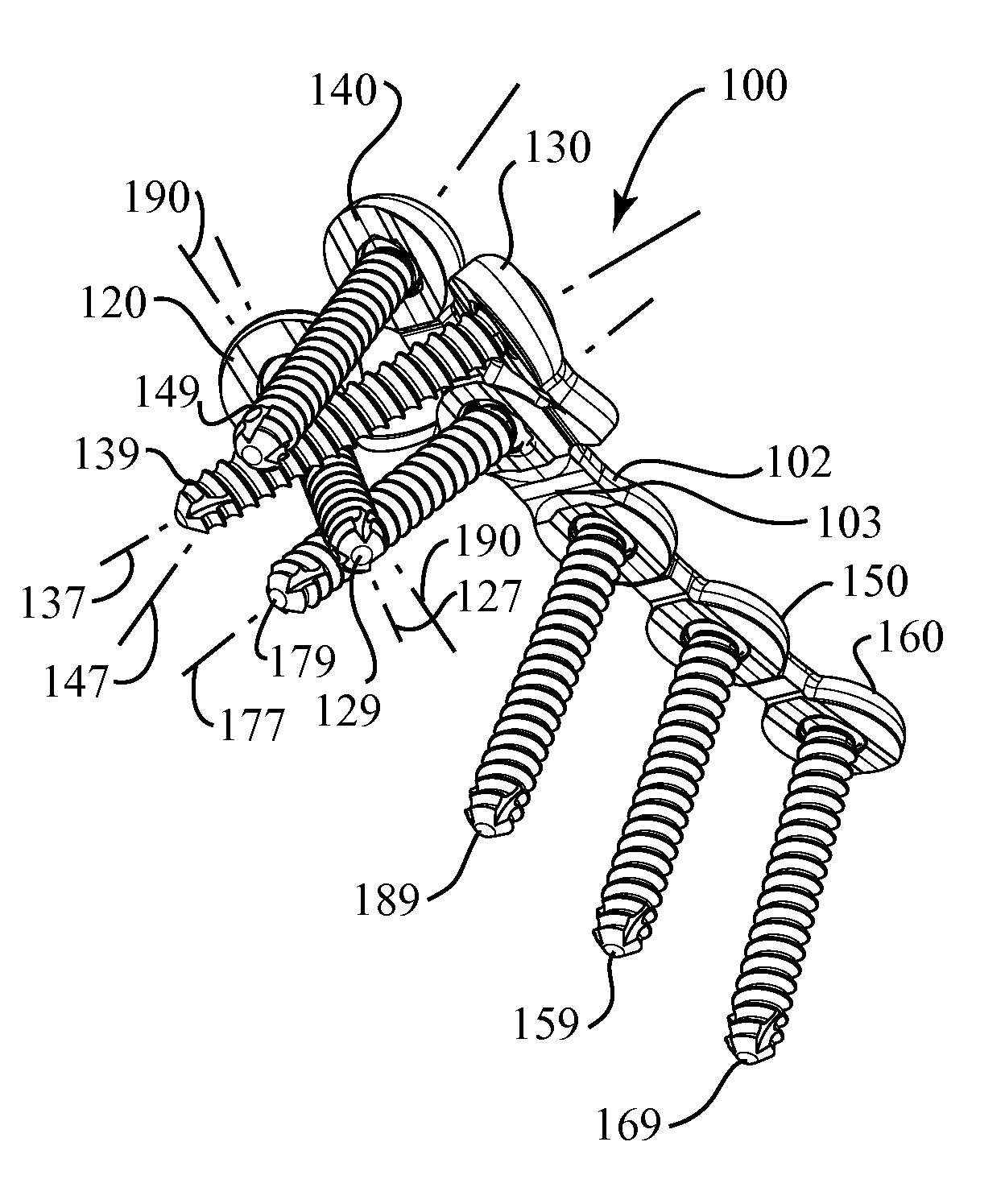

Elbow Fracture Fixation System

InactiveUS20090118768A1Simple and safe processEasily and safely reconfiguredSuture equipmentsInternal osteosythesisInternal fixationFractured bone

A system for the internal fixation of a fractured bone of an elbow joint of a patient includes at least one bone plate, each bone plate having a plurality of holes and generally configured to fit an anatomical surface of the fractured bone. The at least one plate is adapted to be customized to the shape of a patient's bone. The system also includes a plurality of fasteners including at least one locking fastener for attaching the bone plate to the bone. At least one of the holes is a threaded hole. Guides for plate benders, drills, and / or K-wires can be pre-assembled to the threaded holes, and the locking fastener can lock into any of the threaded holes after the guides are removed.

Owner:BIOMET CV

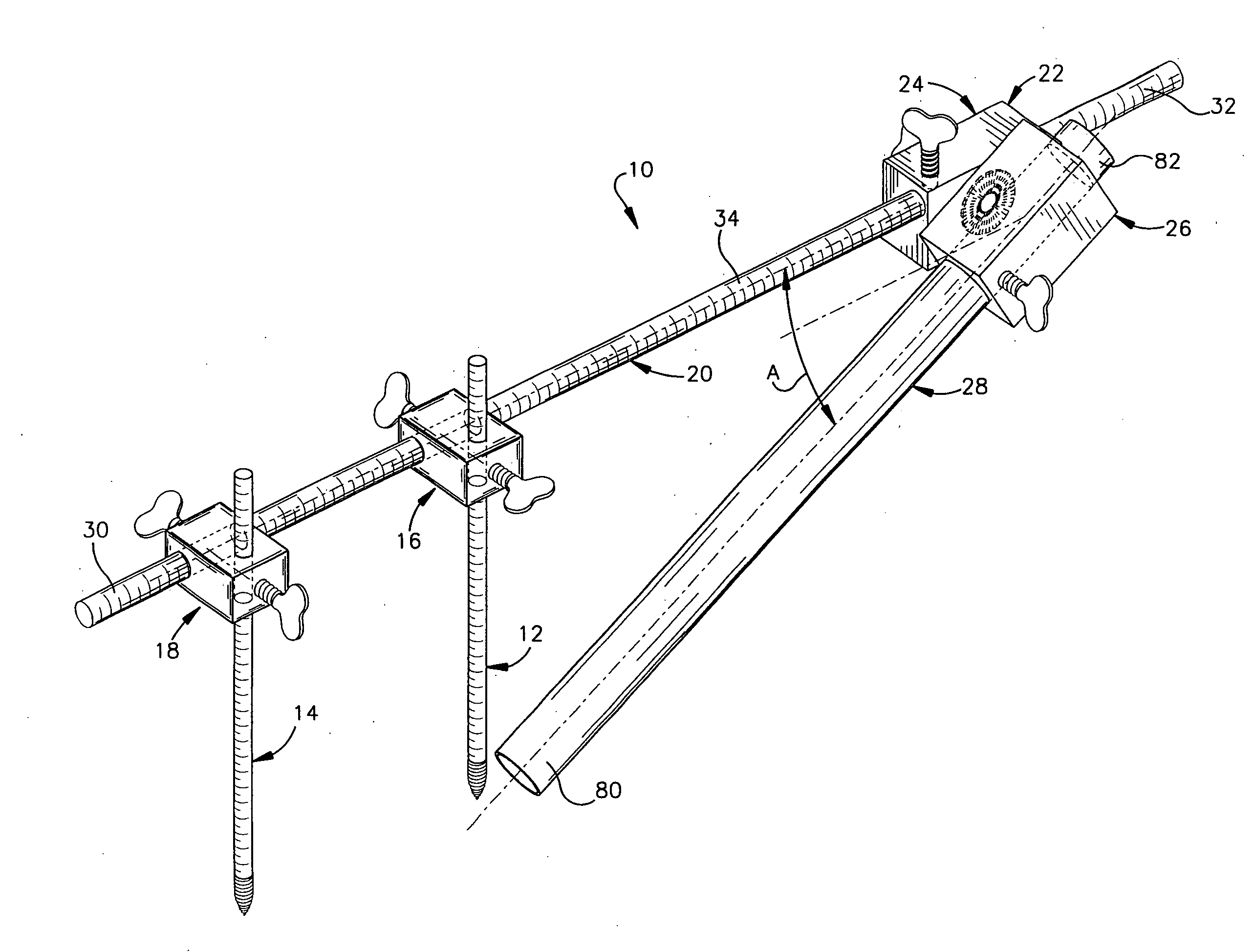

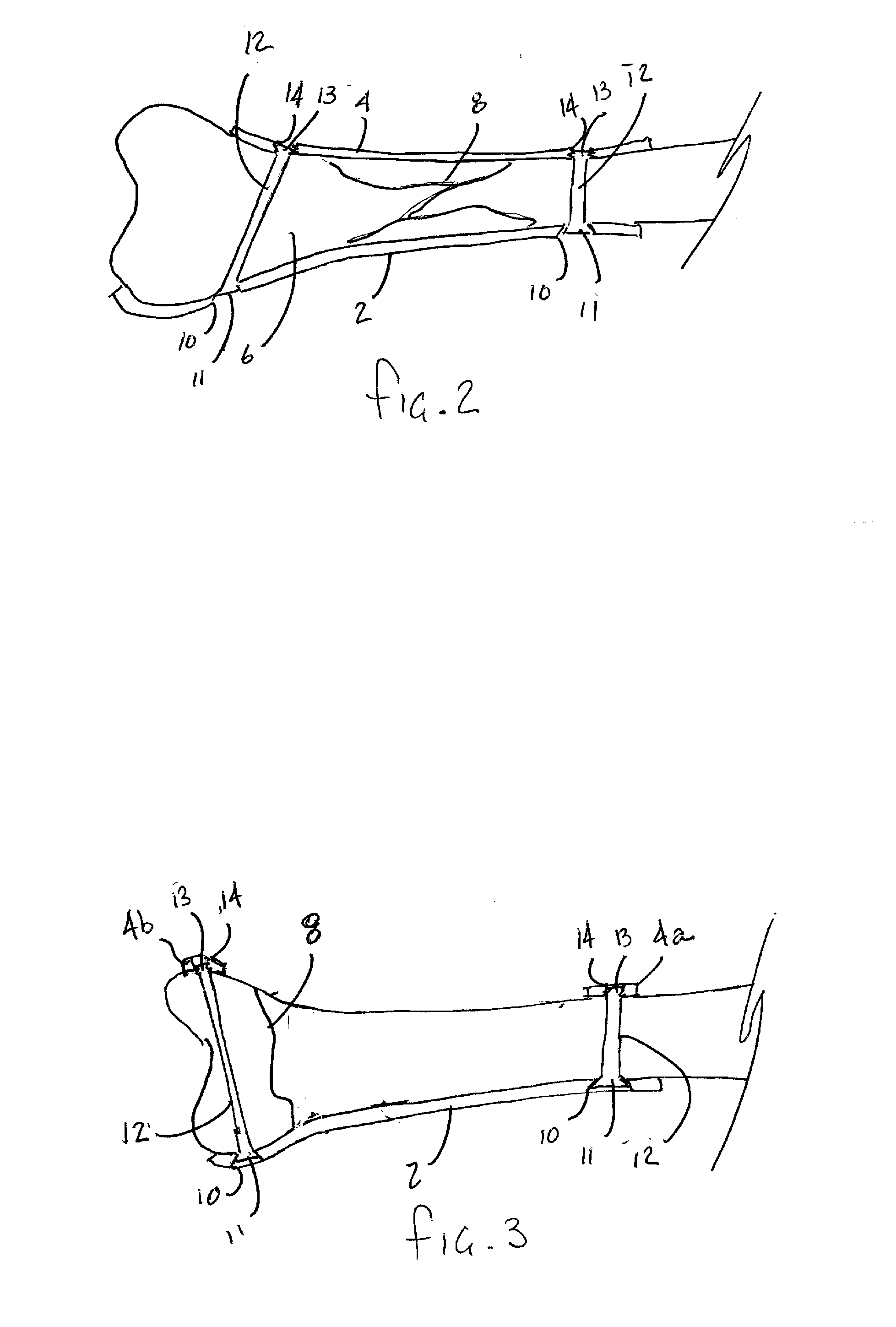

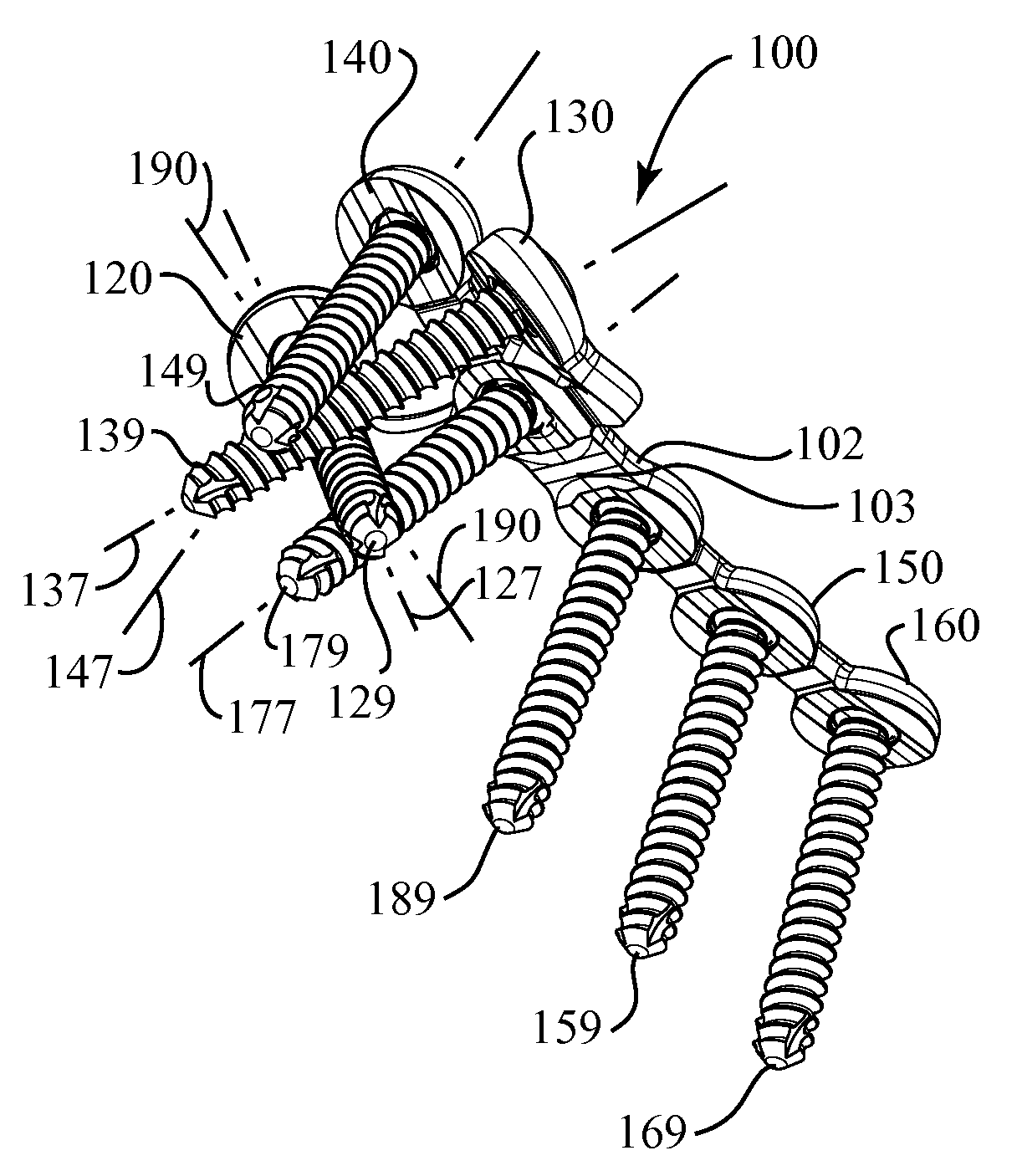

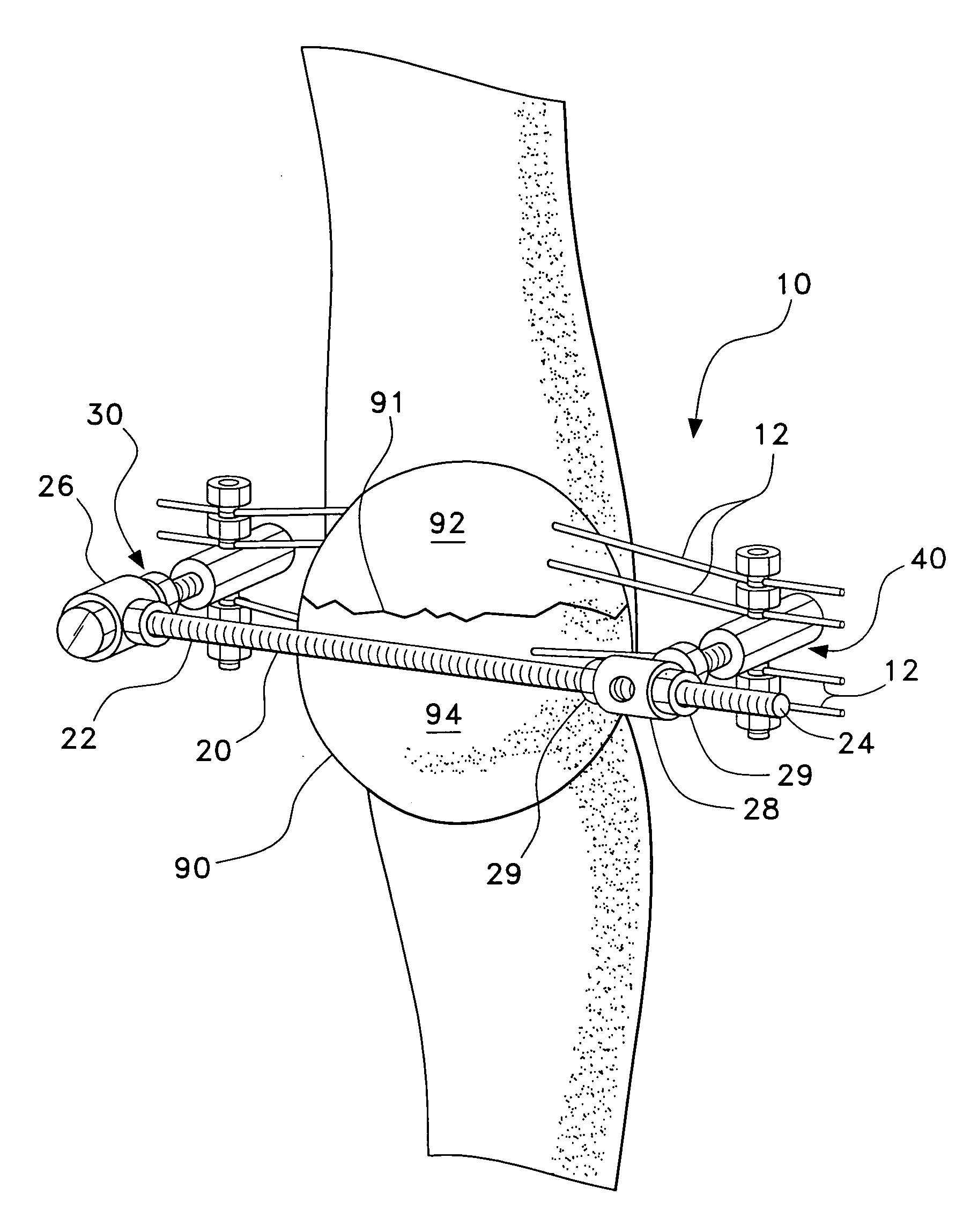

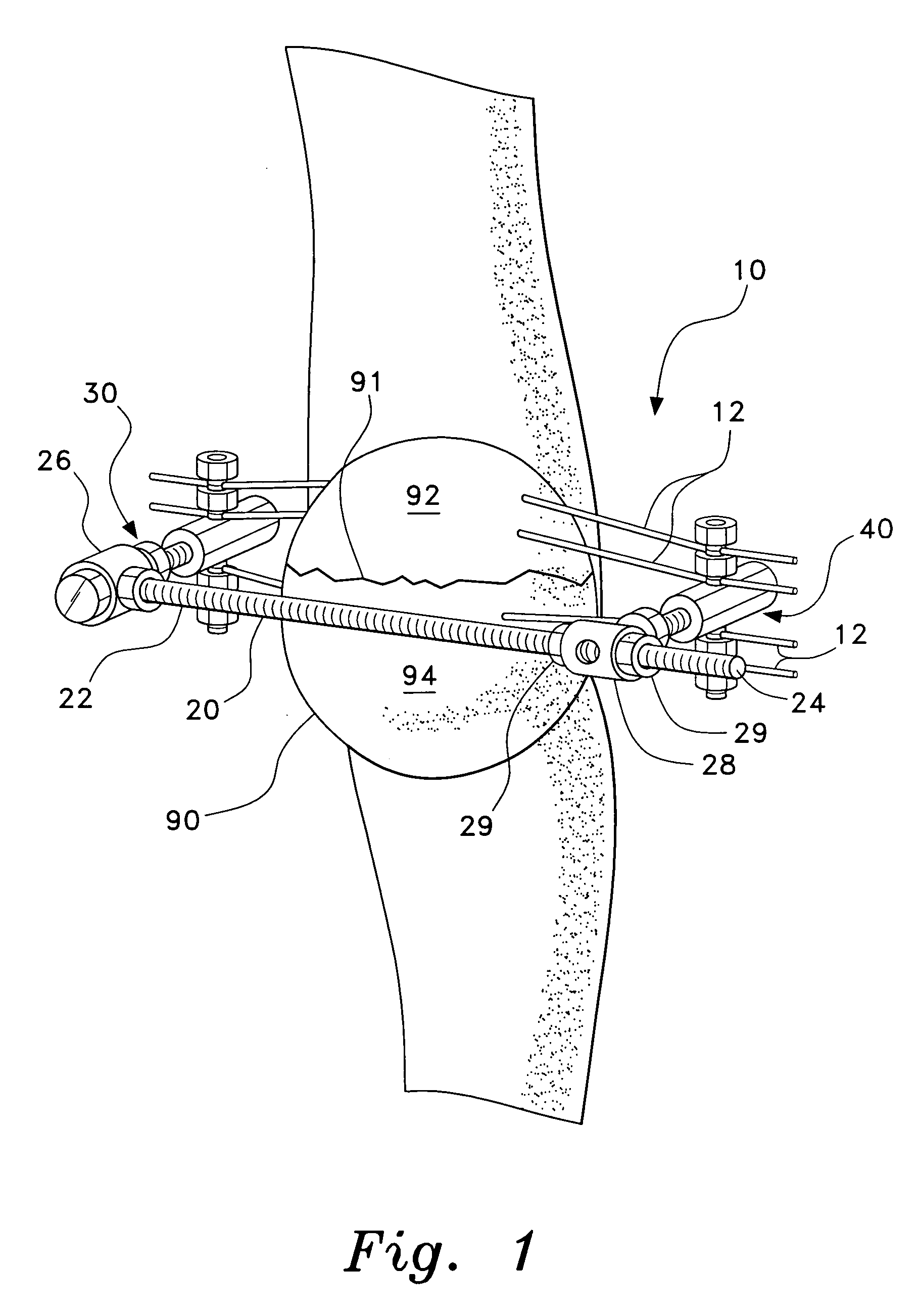

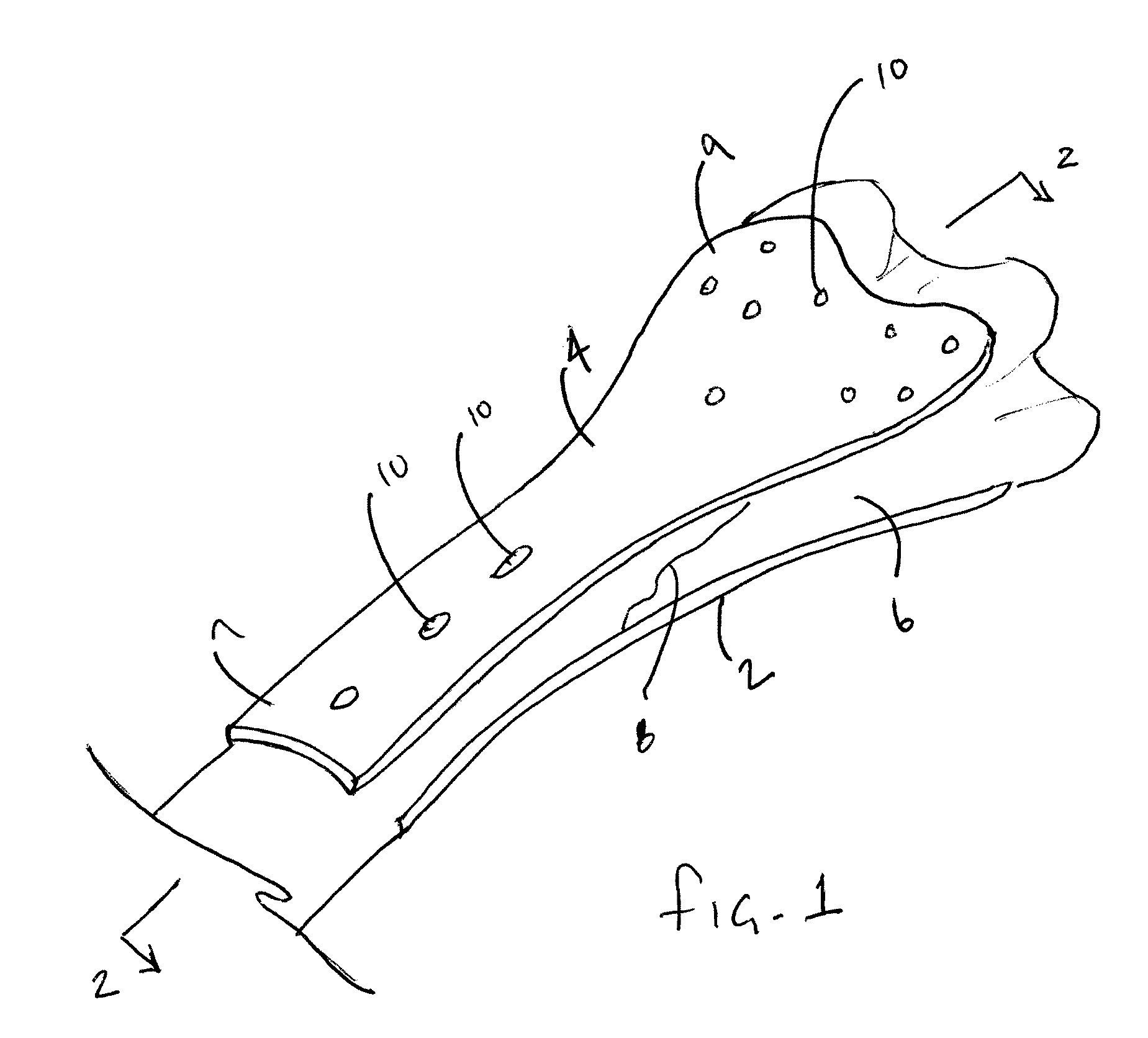

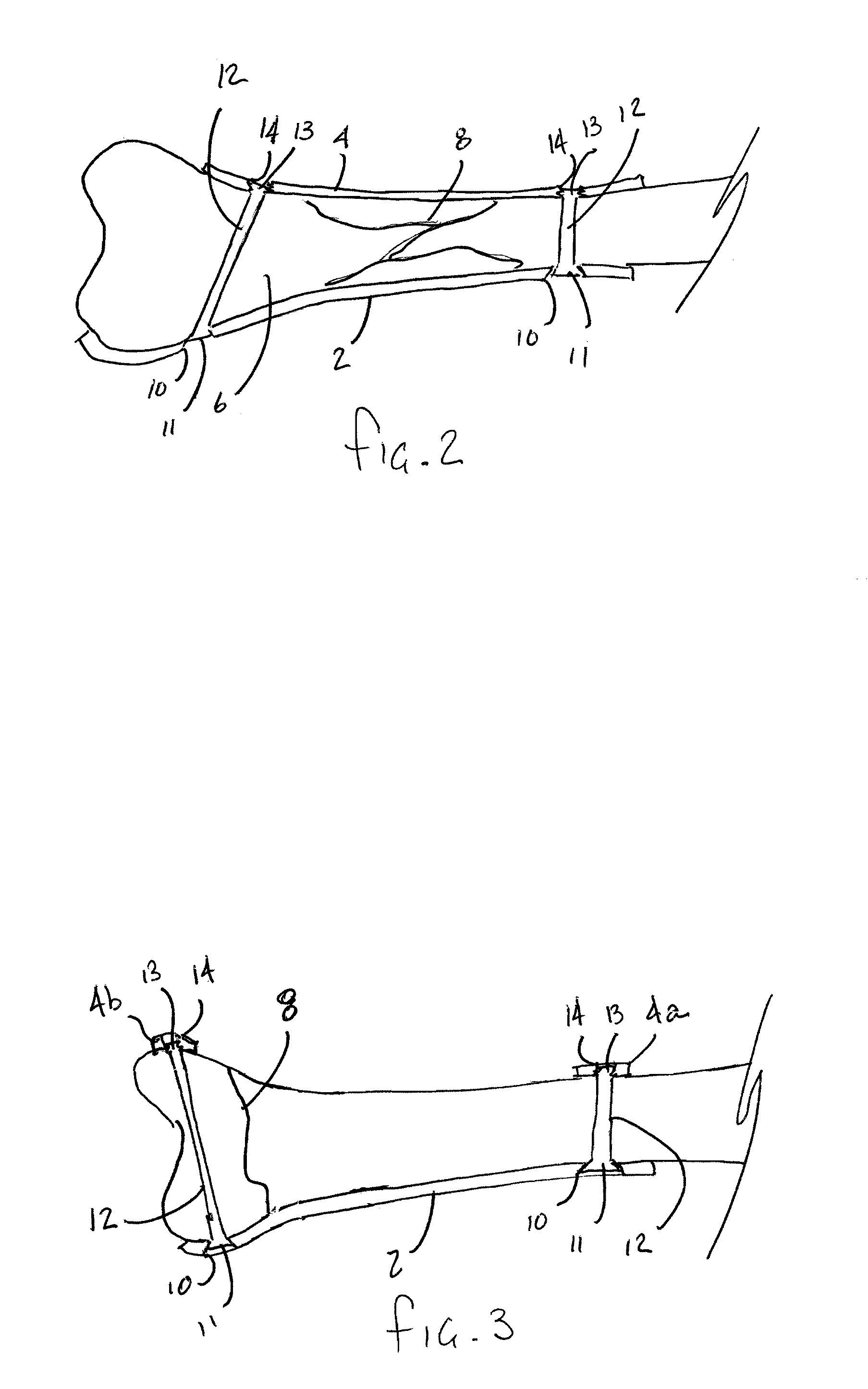

Minimally invasive method and apparatus for placing facet screws and fusing adjacent vertebrae

InactiveUS20060079908A1Minimally invasiveInternal osteosythesisDiagnosticsSacroiliac jointIliac screw

An example apparatus places translaminar screws across a facet joint between adjacent first and second vertebrae in a minimally invasive surgical procedure. The apparatus includes a first K-wire, a second K-wire, a first fixation block, a second fixation block, a support block, a first rod member, a second rod member, and a cannula. The first K-wire is inserted into the spinous process of the first vertebrae. The second K-wire is inserted into a transverse process of the second vertebrae. The first fixation block has perpendicularly extending first and second passages. The first K-wire extends into the first passage in the first fixation block. The second fixation block has perpendicularly extending first and second passages. The second K-wire extends into the first passage in the second fixation block. The support block has perpendicularly extending first and second passages. The first K-wire extends into the first passage in the support block. The first rod member extends through the second passage in the first fixation block and the second passage in the second fixation block. The second rod member further secures the first and second fixation blocks to the first and second vertebrae. The second rod member extends through the second passage in the support block. The cannula enables implantation of the translaminar screws across a facet joint between the first and second vertebrae.

Owner:THE CLEVELAND CLINIC FOUND

Electromagnetically tracked K-wire device

InactiveUS7840254B2Reduce usageEffective trackingSurgical navigation systemsDiagnostic markersBiomedical engineeringKirschner wire

Devices and methods for registering, dynamically referencing, and navigating an anatomical region of interest of a patient are provided using a tracked Kirschner wire (K-wire), where the K-wire includes a position-indicating element.

Owner:PHILIPS ELECTRONICS LTD

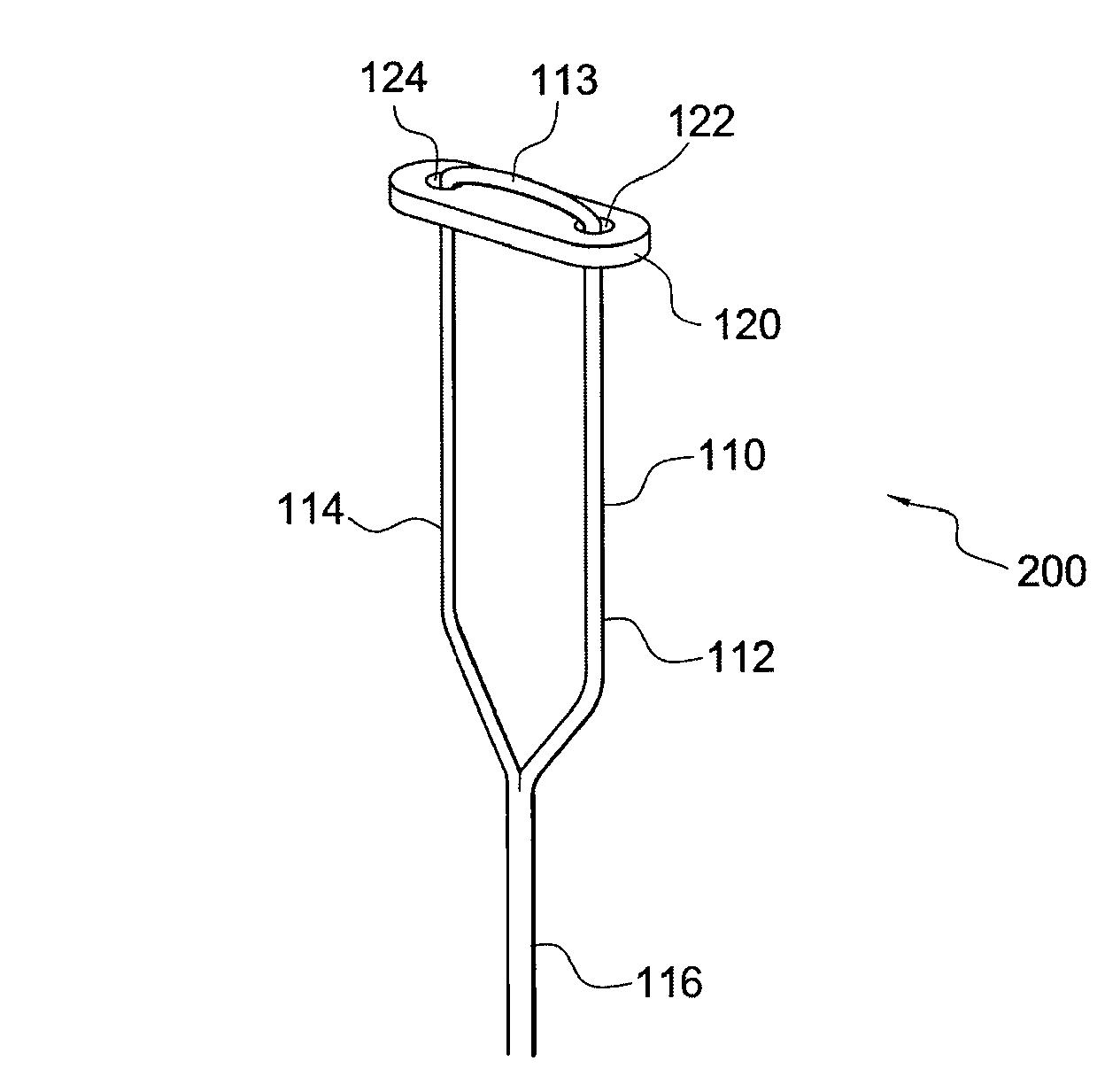

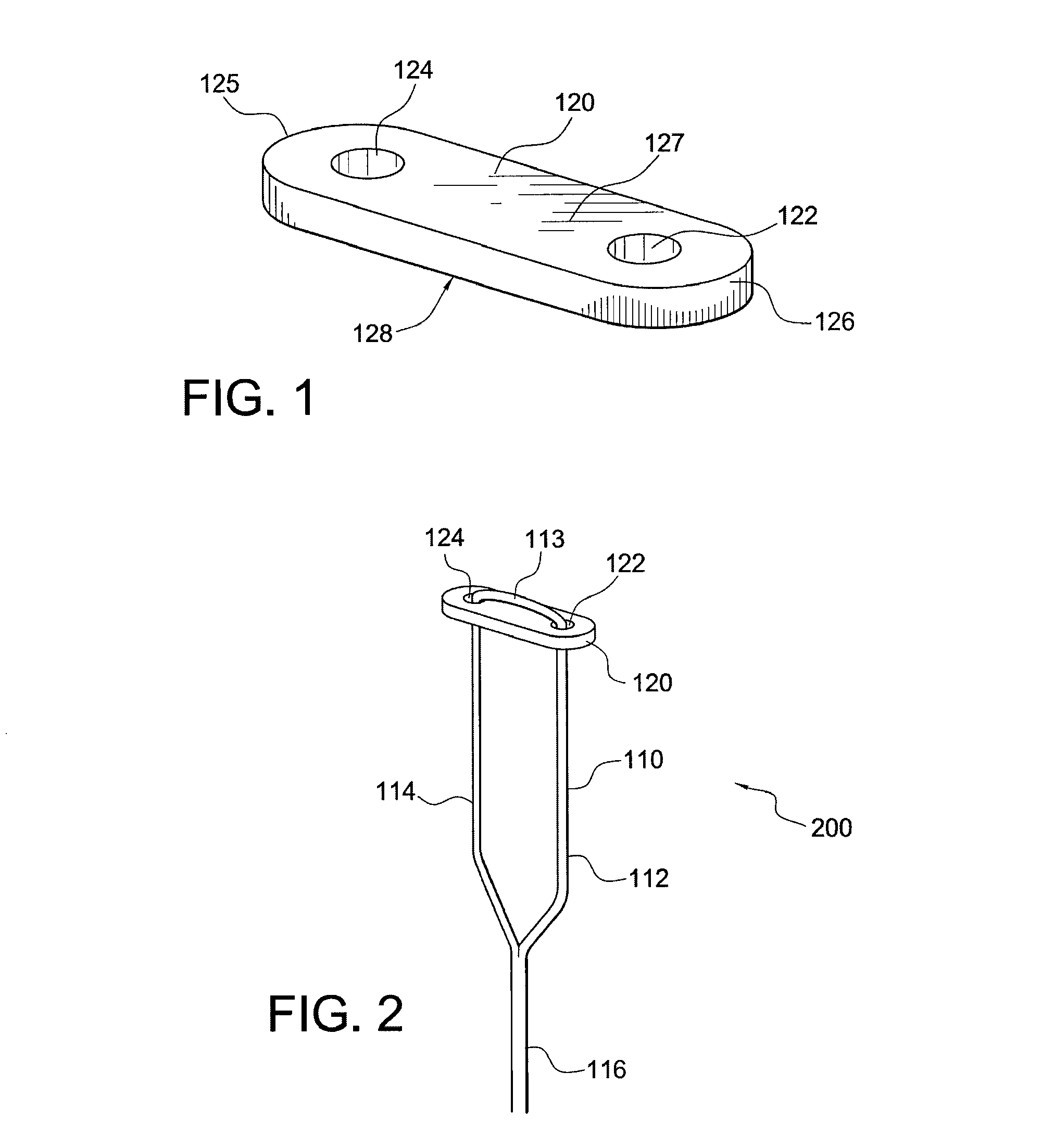

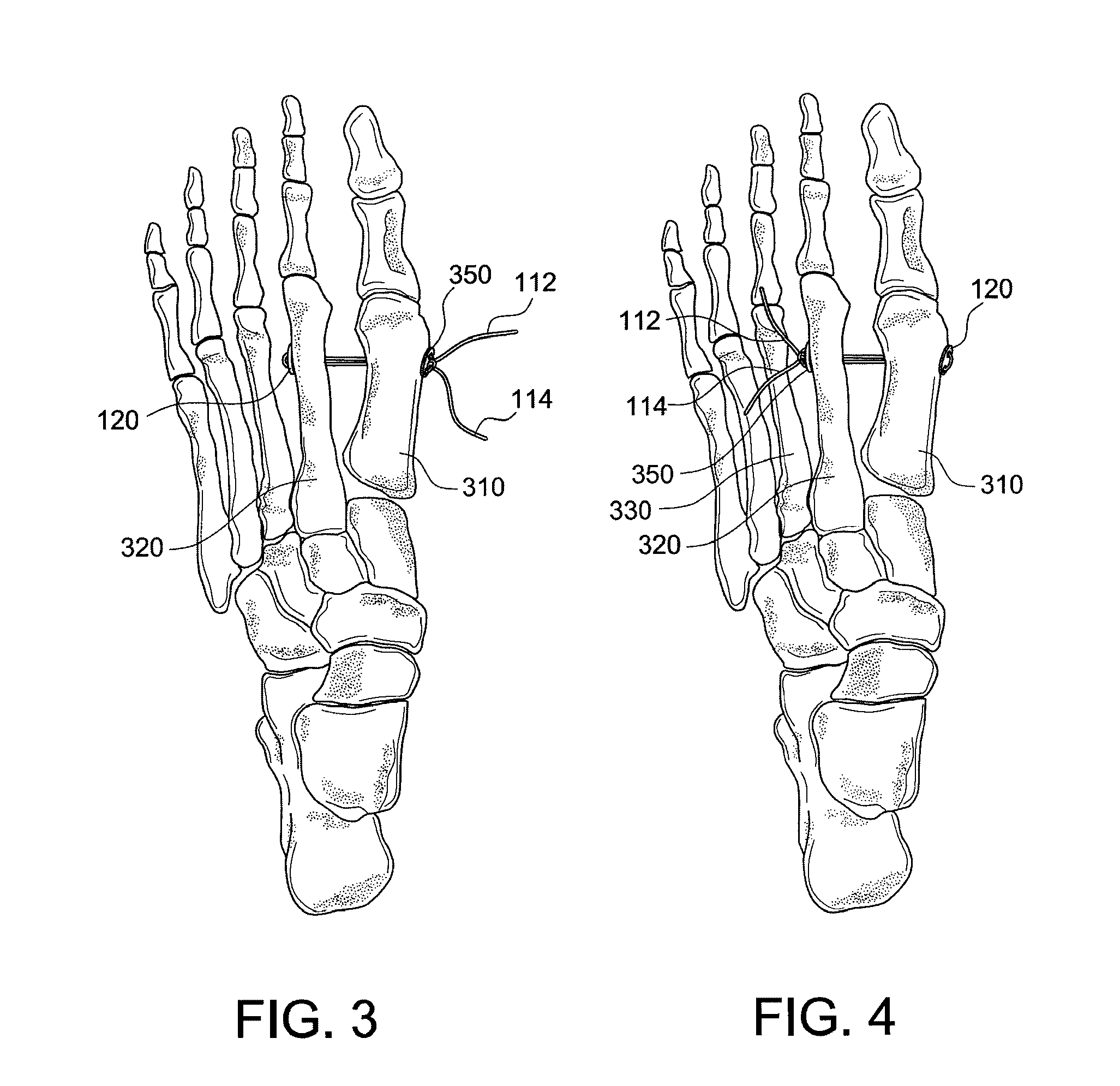

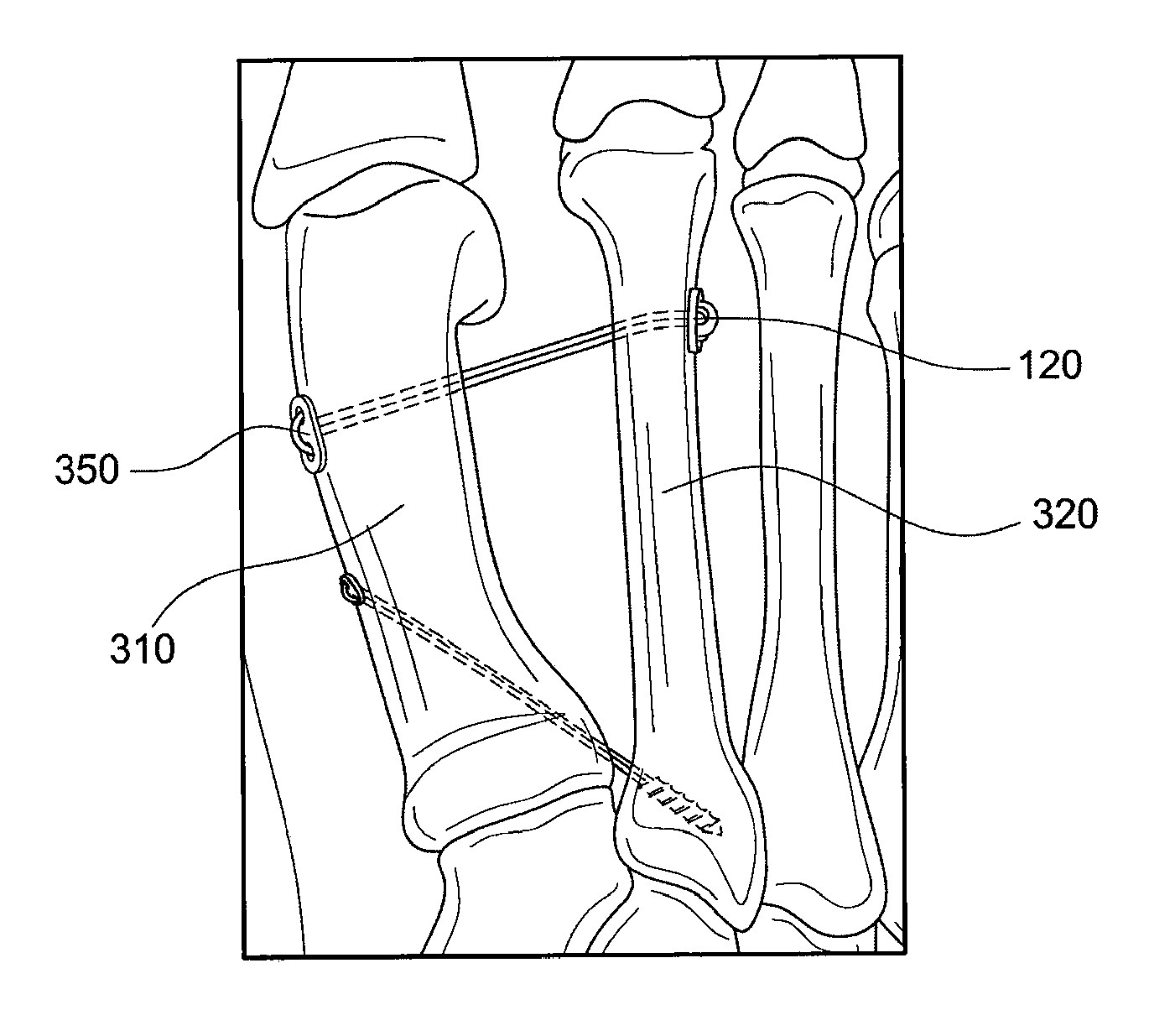

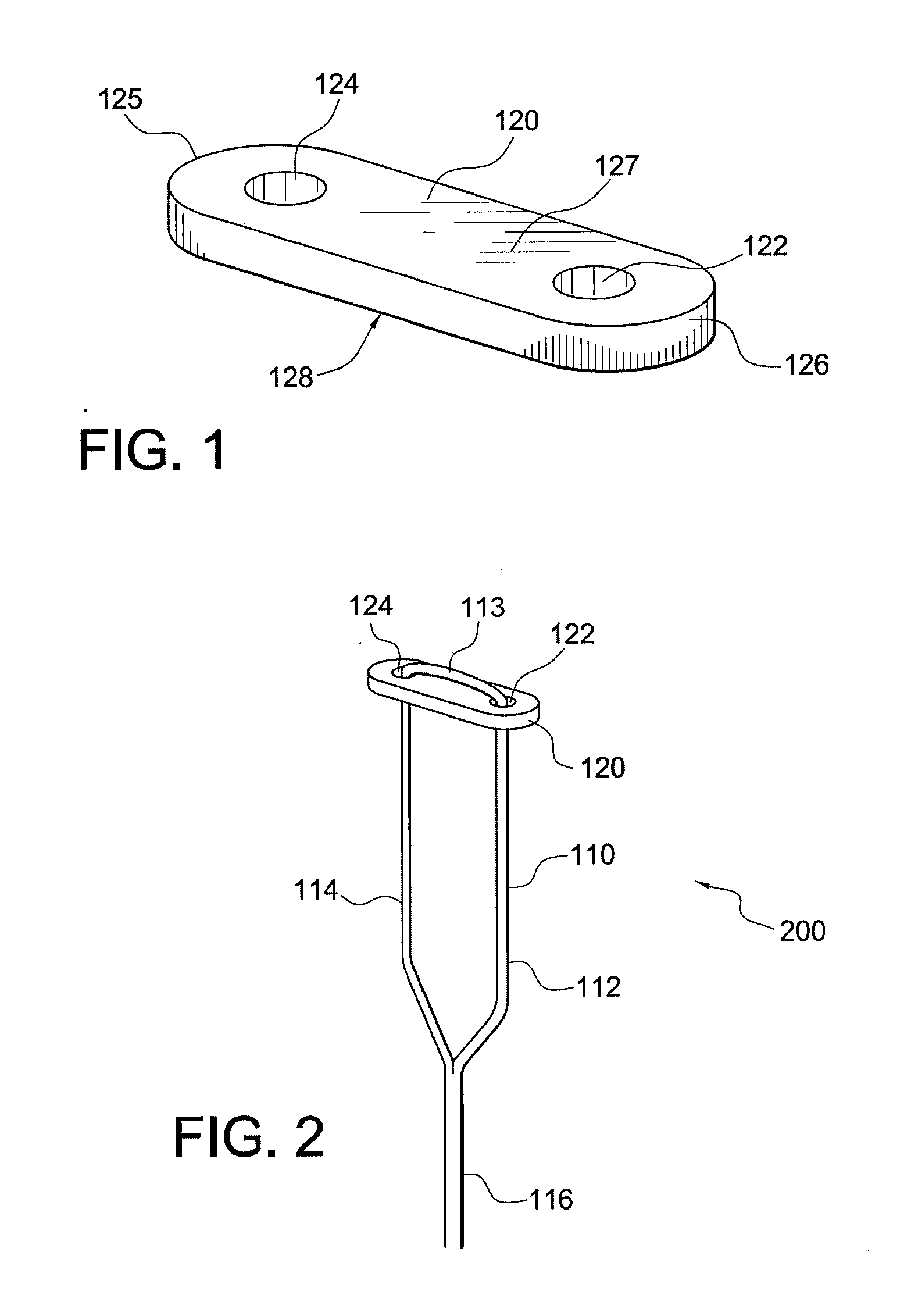

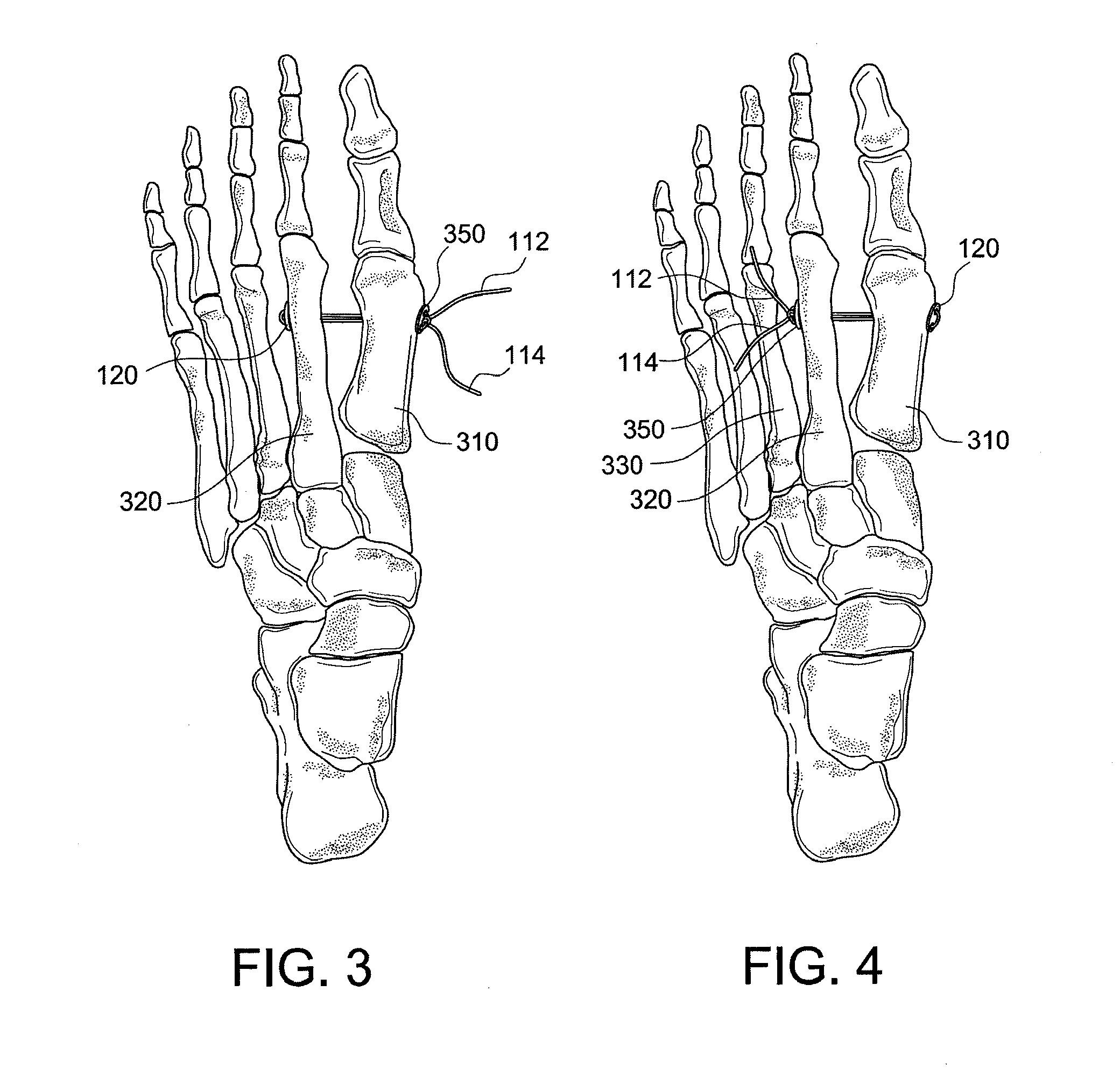

Hallux valgus repairs using suture-button construct

A technique and associated instrumentation for correcting large intermetatarsal angles that result from hallux valgus. The system includes a button and a suture loop attached to the button. A suture strand is threaded through holes in the button to attach the button to the suture. The suture ends are then brought together (by being swaged, spliced or cinched together, for example) to form the suture loop comprising a continuous, uninterrupted suture loop with a single strand of swaged-together ends. The swaged-together ends may be attached to a suture passing instrument such as a K-wire (Kirschner wire) that may be further used to drill a hole through the first and second metatarsals. The swaged-together ends of the suture are then passed through the drill holes in the first and second metatarsals; and the ends of the suture are pulled until the button abuts the second metatarsal. The swaged together portion of the suture loop is then cut, and the free suture ends are passed through holes in another (second) button. The suture ends are pulled to adjust the first metatarsal to a correct intermetatarsal angle, and the first metatarsal is secured in place by tying the ends of the suture together against the second button.

Owner:ARTHREX +1

Hallux valgus repairs using suture-button construct

A technique and associated instrumentation for correcting large intermetatarsal angles that result from hallux valgus. The system includes a button and a suture loop attached to the button. A suture strand is threaded through holes in the button to attach the button to the suture. The suture ends are then brought together (by being swaged, spliced or cinched together, for example) to form the suture loop comprising a continuous, uninterrupted suture loop with a single strand of swaged-together ends. The swaged-together ends may be attached to a suture passing instrument such as a K-wire (Kirschner wire) that may be further used to drill a hole through the first and second metatarsals. The swaged-together ends of the suture are then passed through the drill holes in the first and second metatarsals; and the ends of the suture are pulled until the button abuts the second metatarsal. The swaged together portion of the suture loop is then cut, and the free suture ends are passed through holes in another (second) button. The suture ends are pulled to adjust the first metatarsal to a correct intermetatarsal angle, and the first metatarsal is secured in place by tying the ends of the suture together against the second button.

Owner:ARTHREX INC

System for making a bone repair

ActiveUS20090312802A1Effective bone repairHighly stable repair structureSuture equipmentsInternal osteosythesisIliac screwBiomedical engineering

A method and system is provided for repairing bone fractures at locations where high levels of stability are required. The system employs two plates to buttress a fracture from both the dorsal and volar sides. The plates are affixed to one another using screws that are installed from a volar plate, through the bone and into a dorsal plate. The method provides for use of a directional guide that allows the precise placement of Kirschner wires for temporary fixation of the fracture, installation of a first bone fixation plate using the installed K-wires for alignment, installation of a second bone plate adjacent the bone to be repaired and opposite the first bone plate, and installation of cannulated fasteners between the two opposing bone plates such that the fasteners rigidly engage both of the bone plates.

Owner:SWISS ORTHO

CMC repair using suture-button construct

A button and attached suture loop for CMC repair. A suture strand is threaded through holes in the button to attach the button to the suture. The suture ends are then brought together (by being swaged, spliced or cinched together, for example) to form the suture loop comprising a continuous, uninterrupted suture loop with a single strand of swaged-together ends. The swaged-together ends are attached to a suture passing instrument such as a K-wire (Kirschner wire) that is also used to drill a hole through adjoining metacarpals (for example, the first and second metacarpals). The swaged-together ends of the suture are then passed through the drill holes in the first and second metacarpals, and the ends of the suture are pulled until the button abuts one of the first and second metacarpals. A second button is used to secure the cut suture ends to the other metacarpal.

Owner:ARTHREX

Fracture Fixation Plate for the Olecranon of the Proximal Ulna

ActiveUS20090118770A1Easily and safely reconfiguredIncreasing the thicknessSuture equipmentsInternal osteosythesisPelvic fixationInternal fixation

A system for the internal fixation of a fractured bone of an elbow joint of a patient includes at least one bone plate, each bone plate having a plurality of holes and generally configured to fit an anatomical surface of the fractured bone. The at least one plate is adapted to be customized to the shape of a patient's bone. The system also includes a plurality of fasteners including at least one locking fastener for attaching the bone plate to the bone. At least one of the holes is a threaded hole. Guides for plate benders, drills, and / or K-wires can be pre-assembled to the threaded holes, and the locking fastener can lock into any of the threaded holes after the guides are removed.

Owner:BIOMET CV

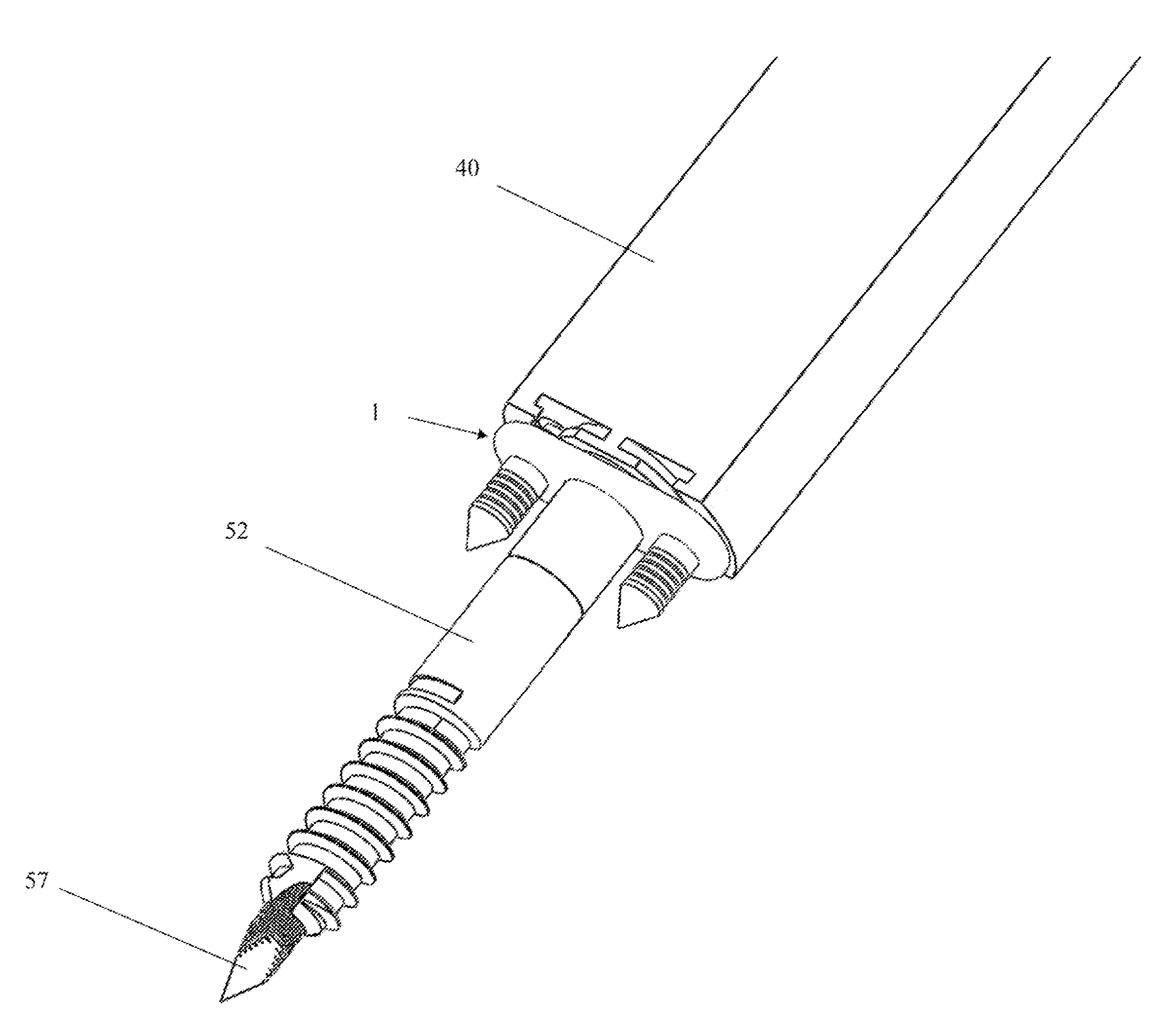

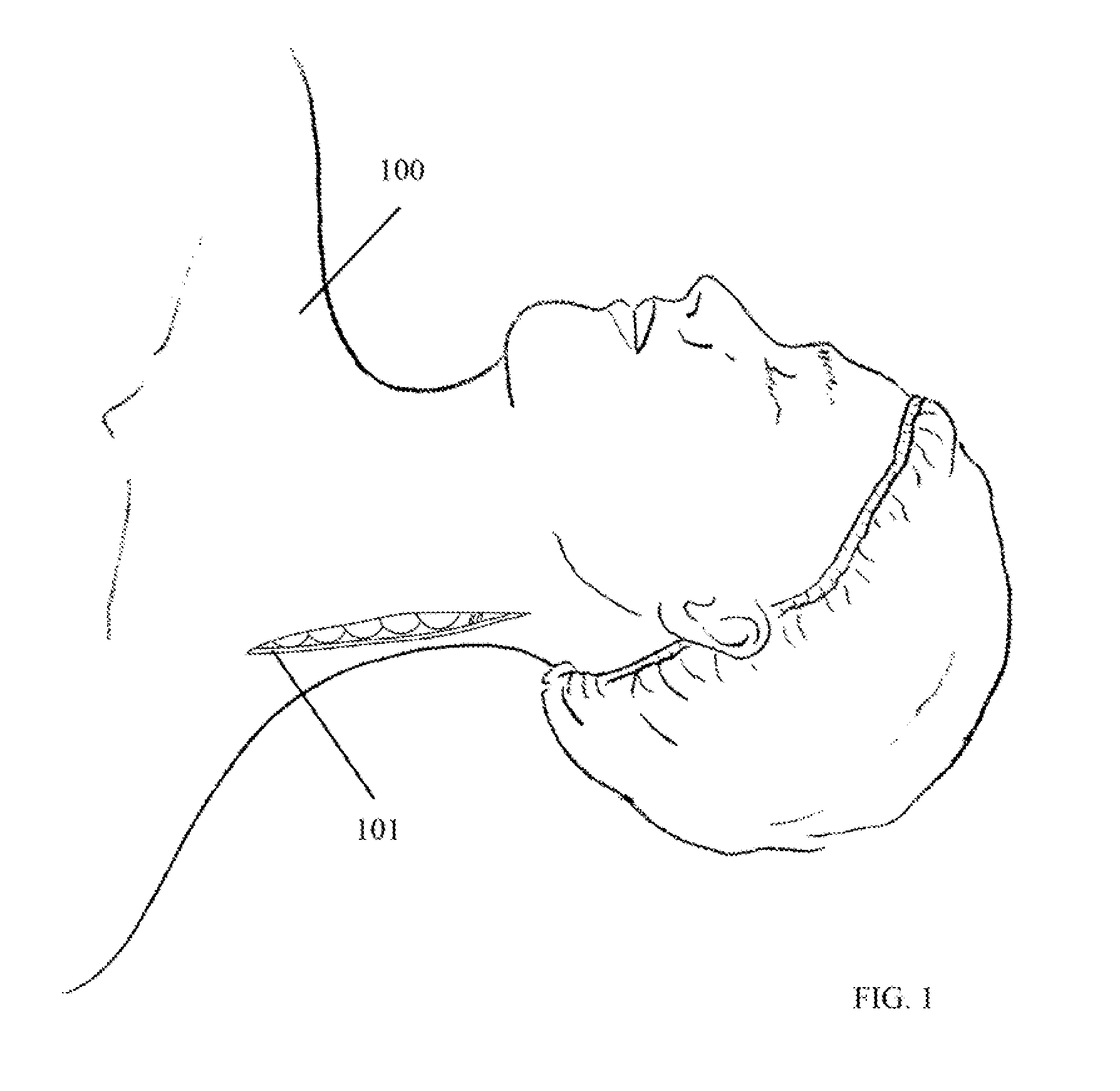

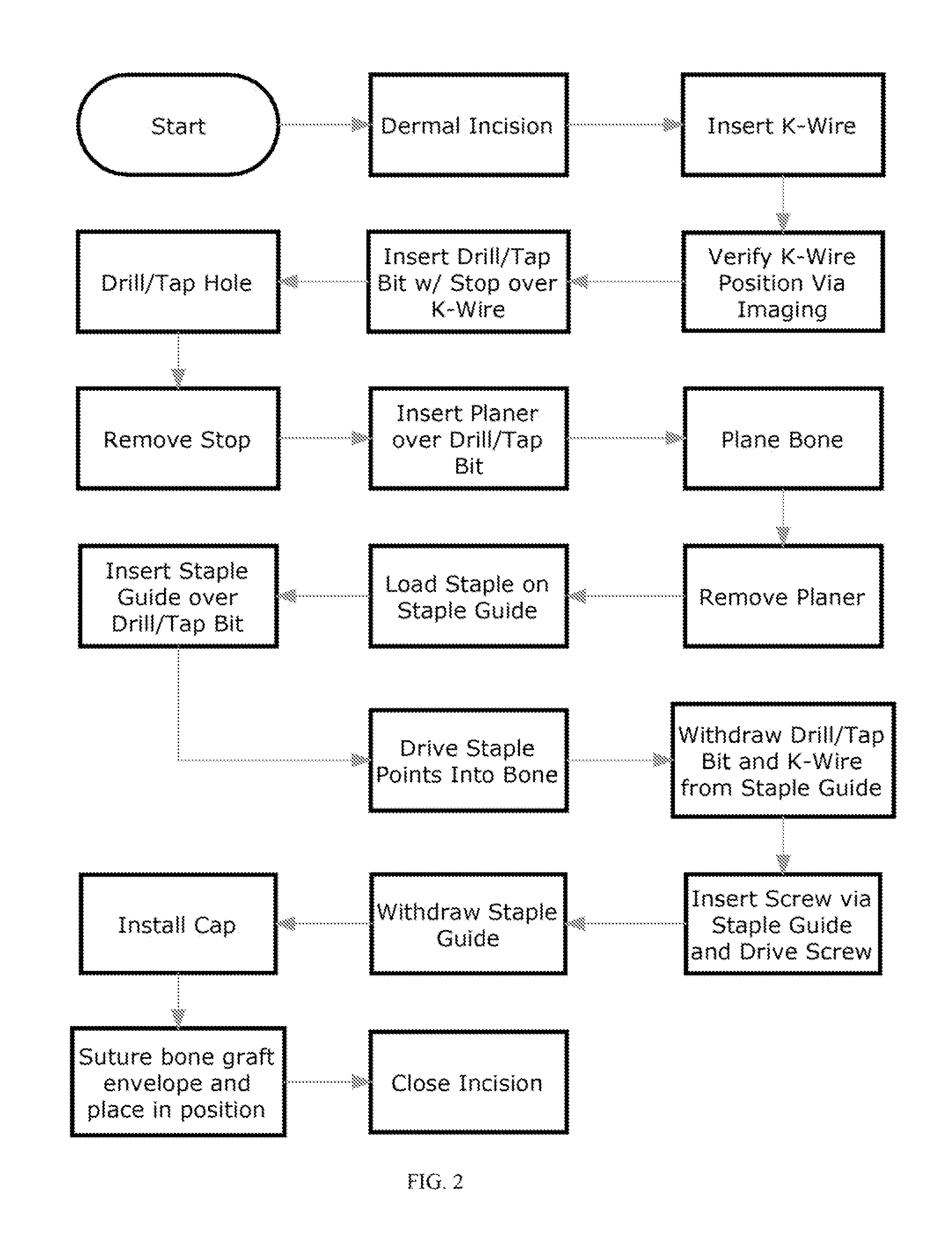

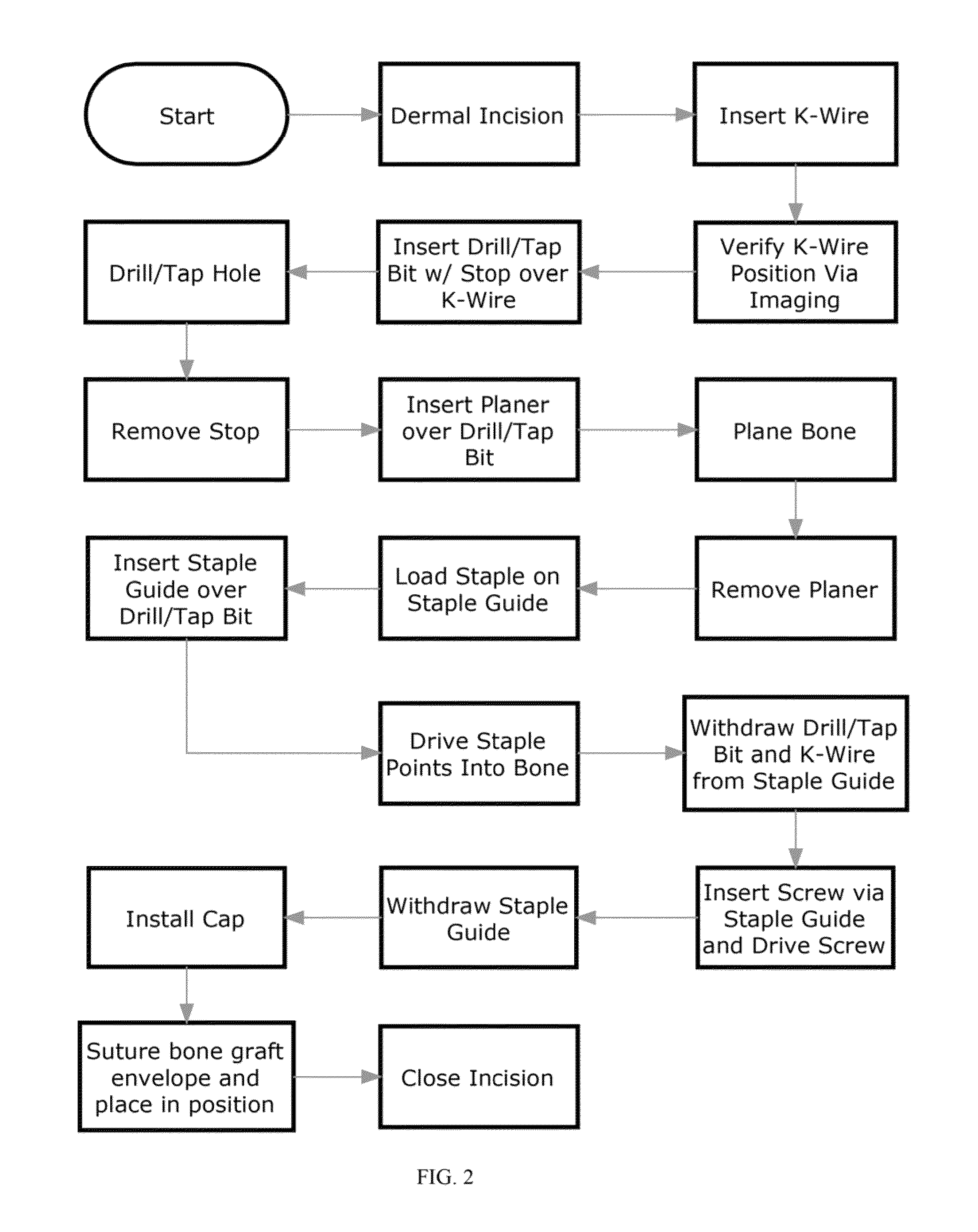

Method of lateral facet approach, decompression and fusion using screws and staples as well as arthroplasty

ActiveUS20100280555A1Good for long-term fixationImprove stabilitySuture equipmentsInternal osteosythesisPosterior approachFixation method

A method of performing vertebral facet fusion by lateral approach and related devices. The lateral approach to facet fusion involves identifying the lateral mass and introducing any of the fixation methods known or described herein laterally at one or more facets through the use of a Kirschner wire guide, a cannulated bone drill and cooperatively cannulated staple guide. A surgical bone staple have a perforated bridge is used across the lateral facet joint where fixation is required. Where fusion is desired, a bone screw have lateral perforations of the shank is inserted through the cannulated staple guide and bridge perforation at the joint to promote fusion. A staple cap and graft container for overlay grafting may be utilized for additional fusion. The method involves less surgical time, reduced blood loss and discomfort for the patient as compared to the posterior approach.

Owner:AFLATOON KAMRAN +1

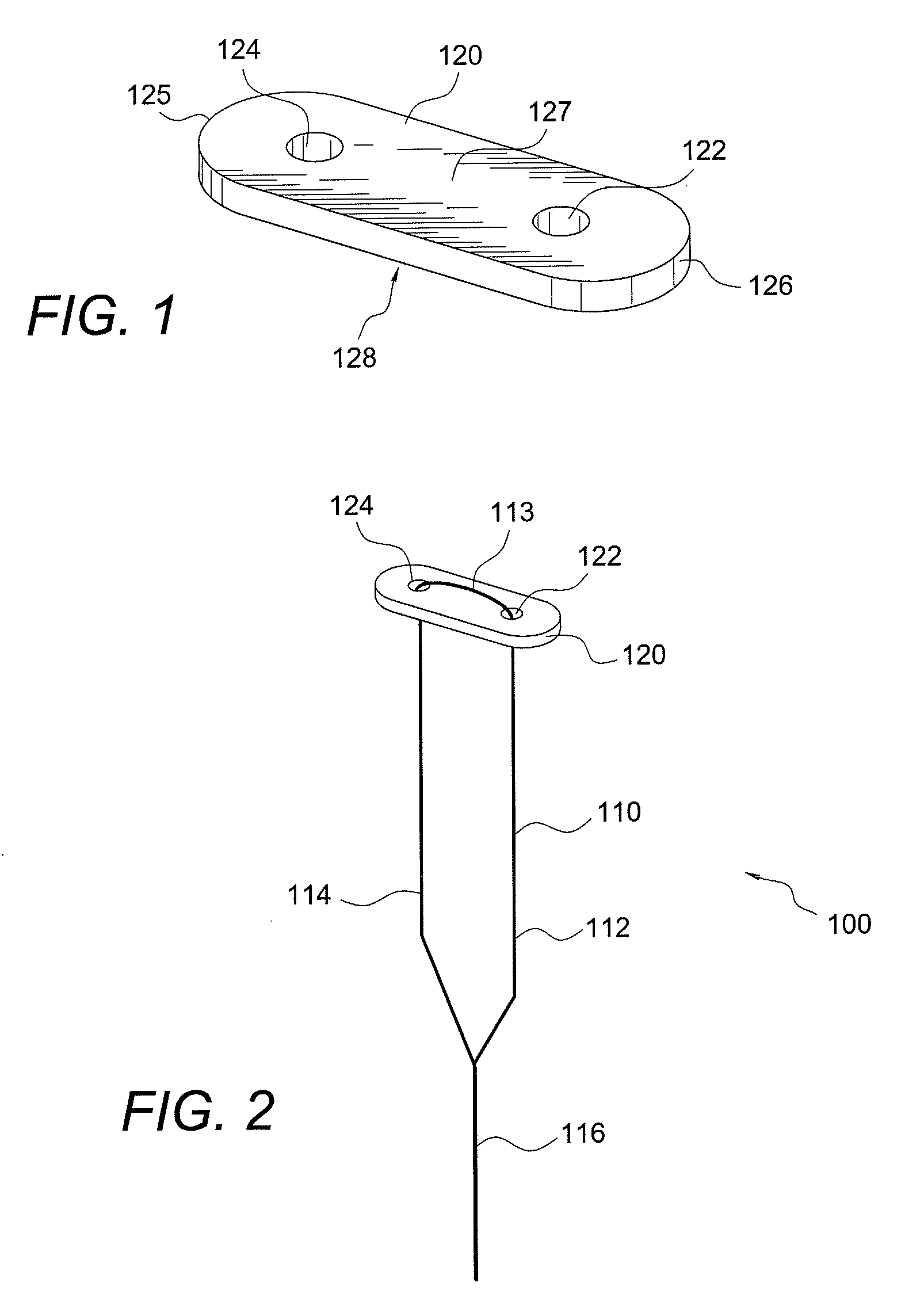

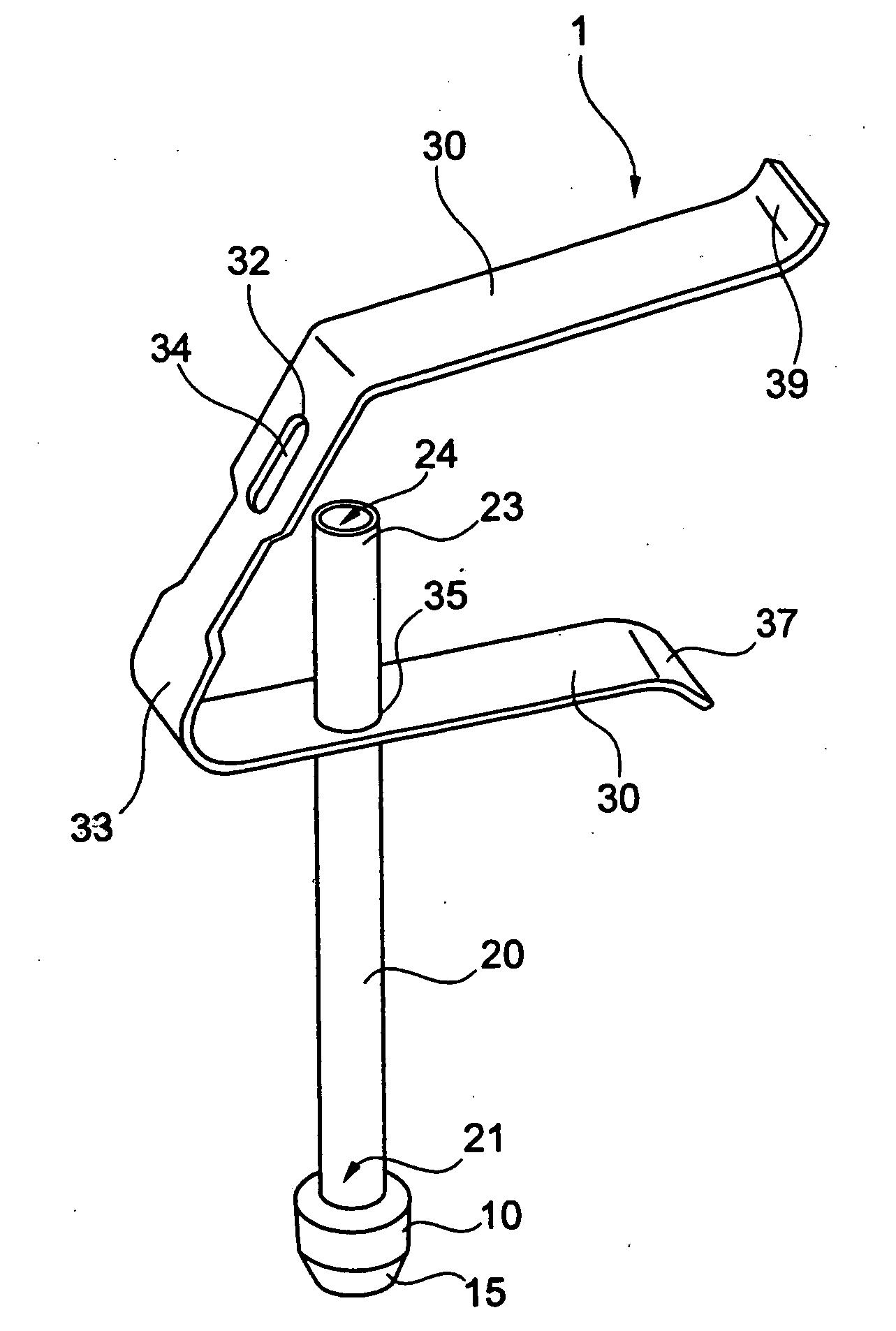

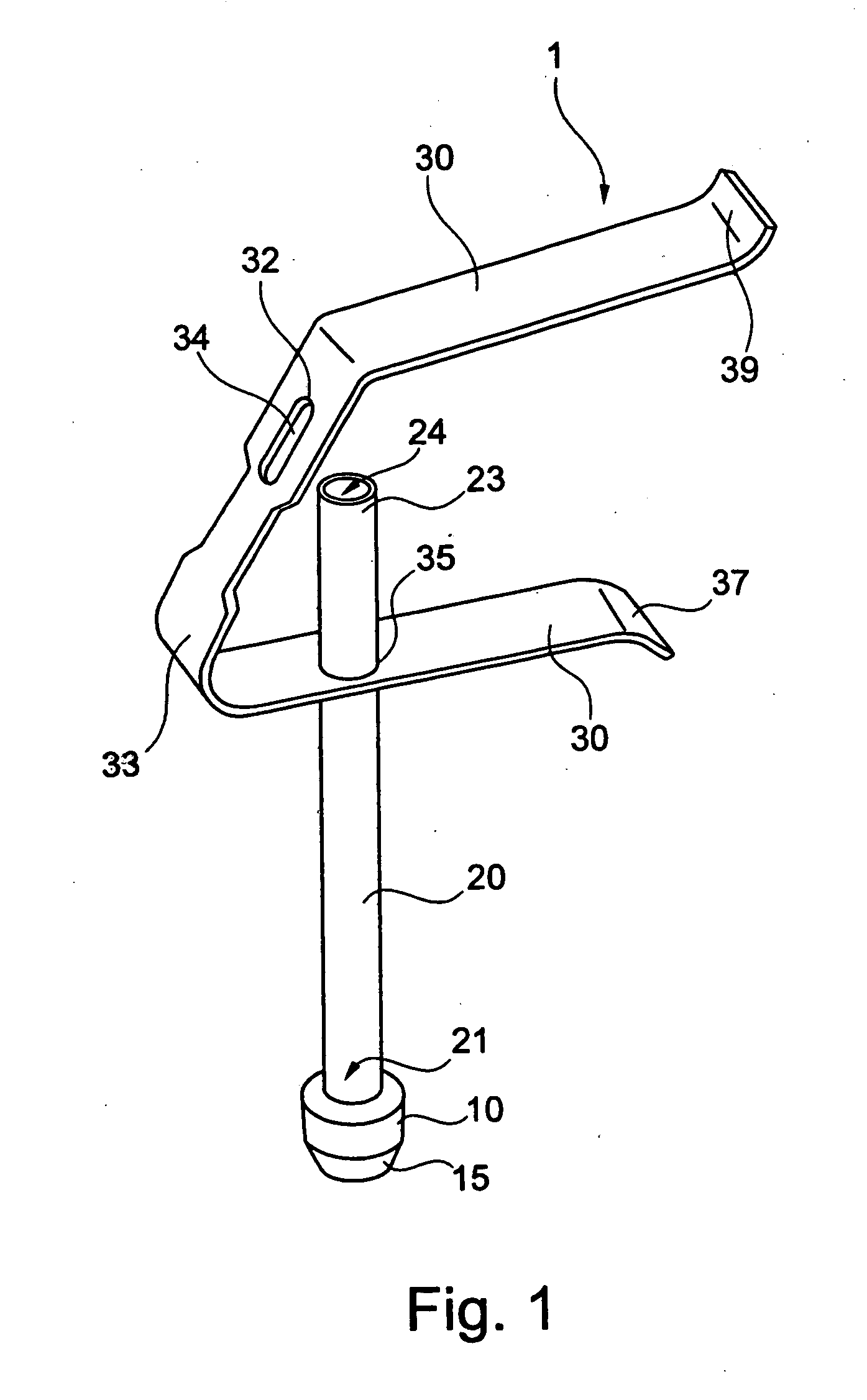

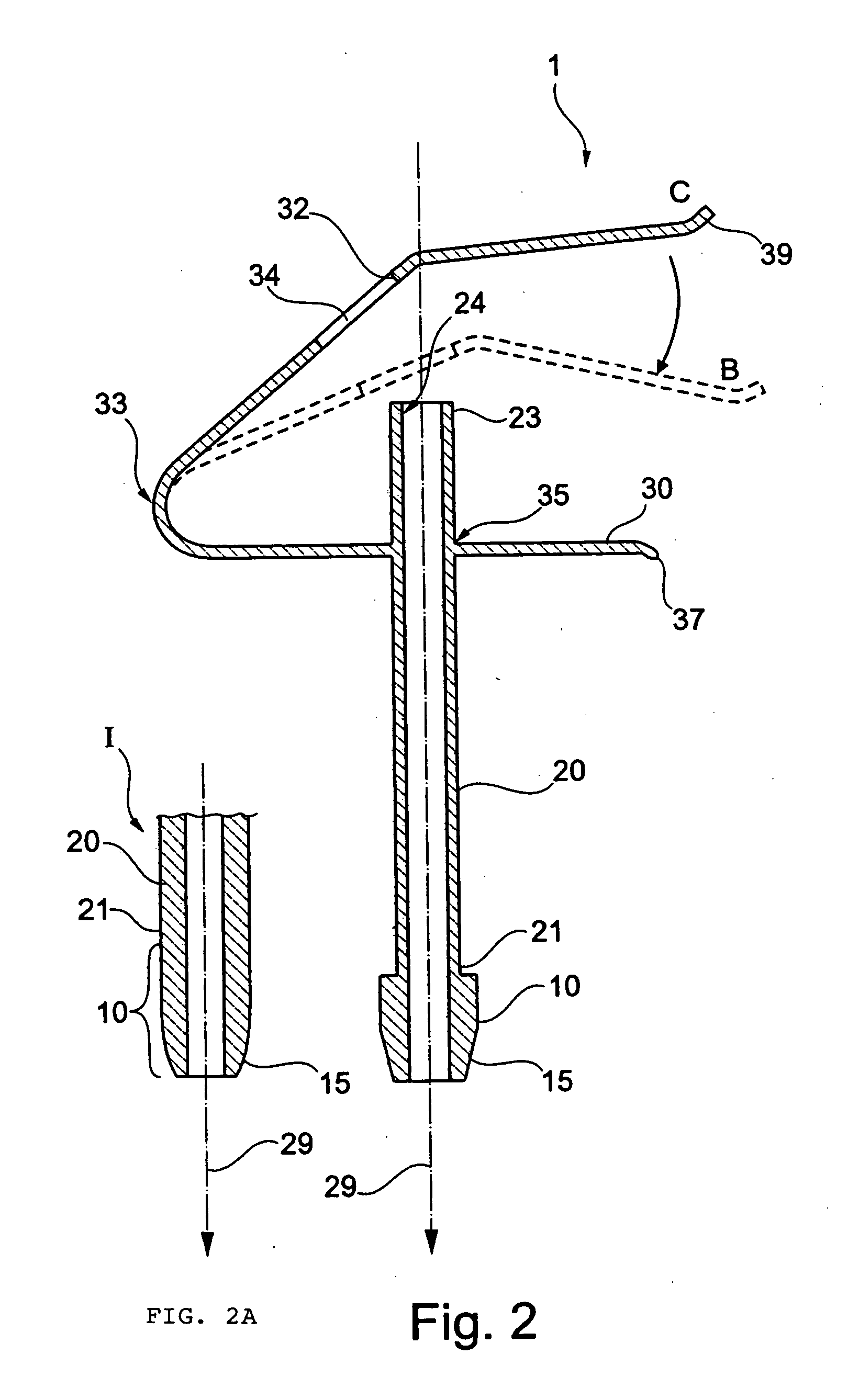

Kirschner wire clamp

A Kirschner wire clamp is used to reliably and simply fix bone plates to a bone surface. The wire clamp consists of a tubular guide member for receiving a Kirschner wire. The guide member has a bore surrounded by a wall and a base for engaging a hole in a bone plate such as a bone screw hole. A spring clamp is mounted adjacent an open end of the tubular guide bore opposite the base which clamps the Kirschner wire to the guide member after the wire has been fixed in bone. The Kirschner wire clamp can be aligned simply and reliably by the guide member, and by the clamping mechanism, can be reliably fixed to the Kirschner wire.

Owner:STRYKER EURO OPERATIONS HLDG LLC

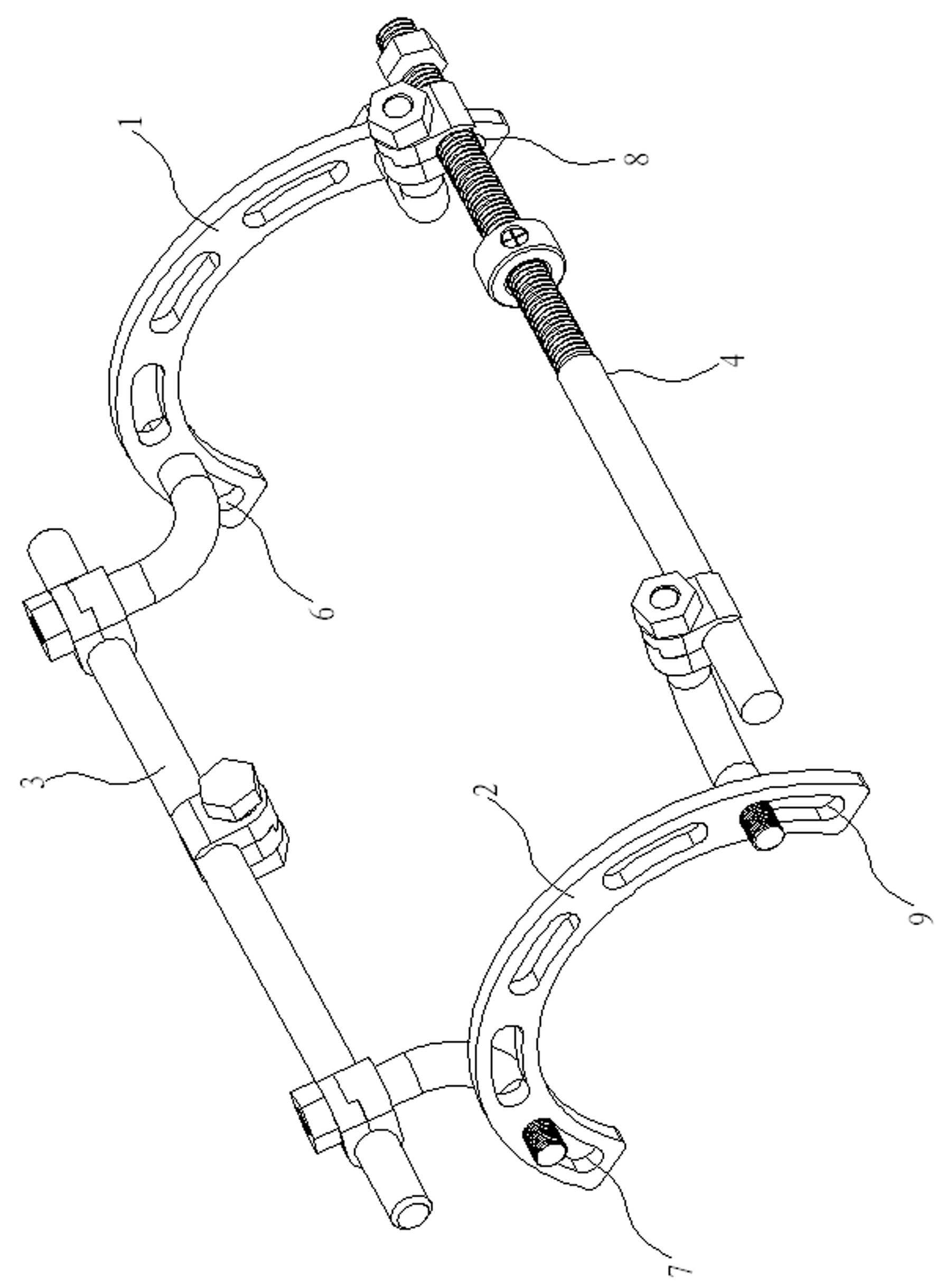

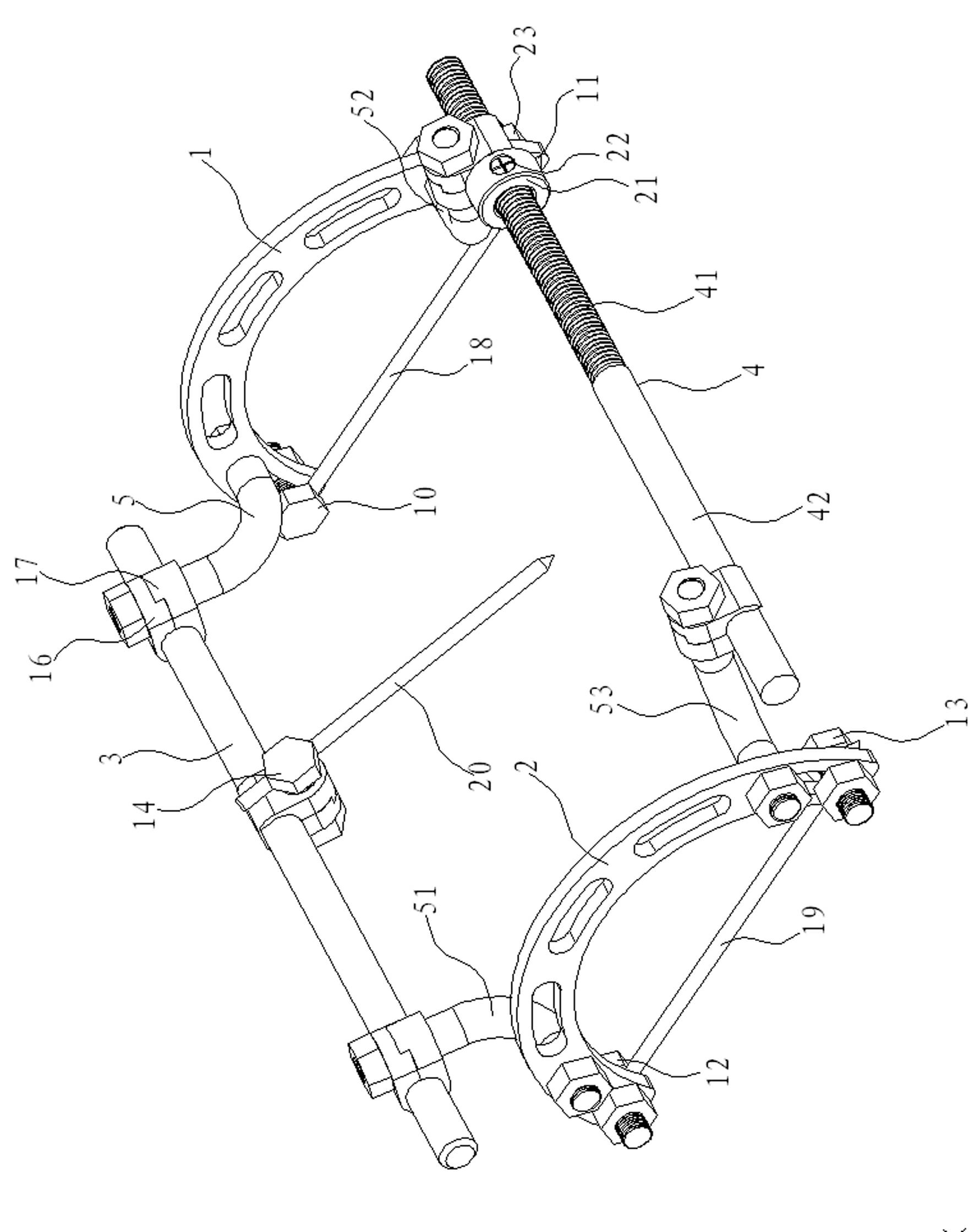

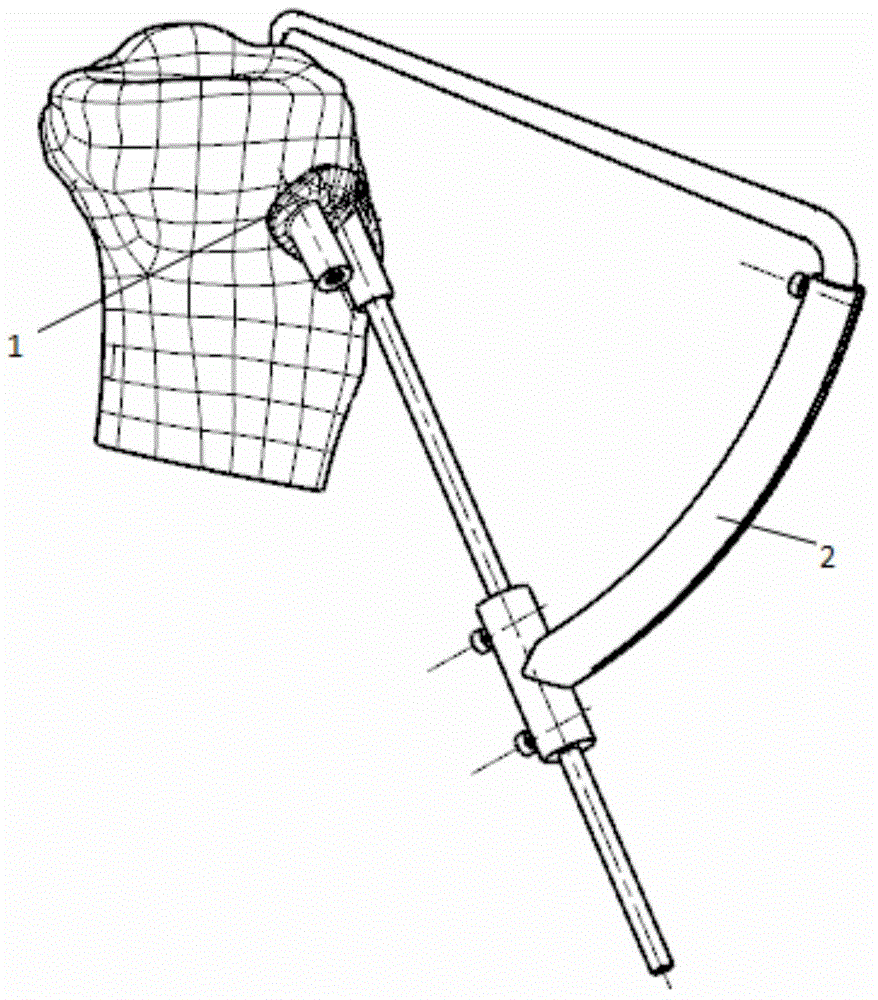

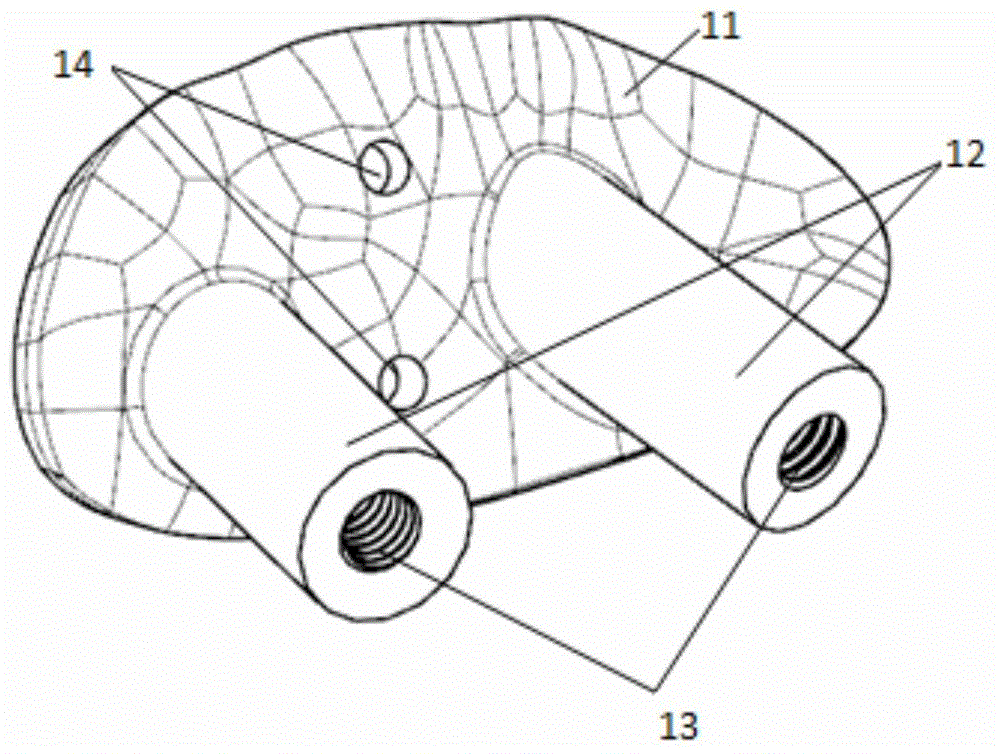

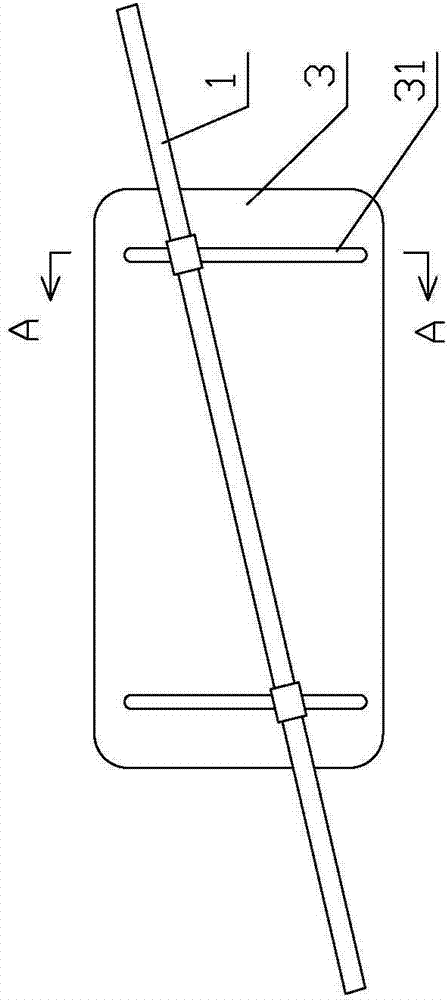

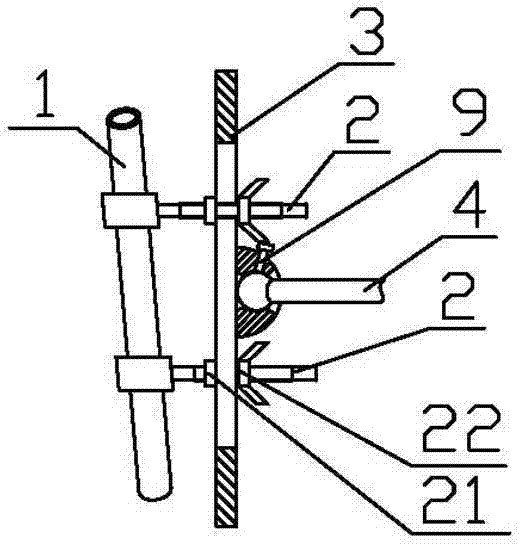

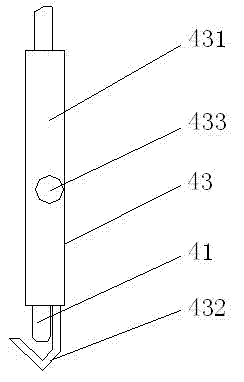

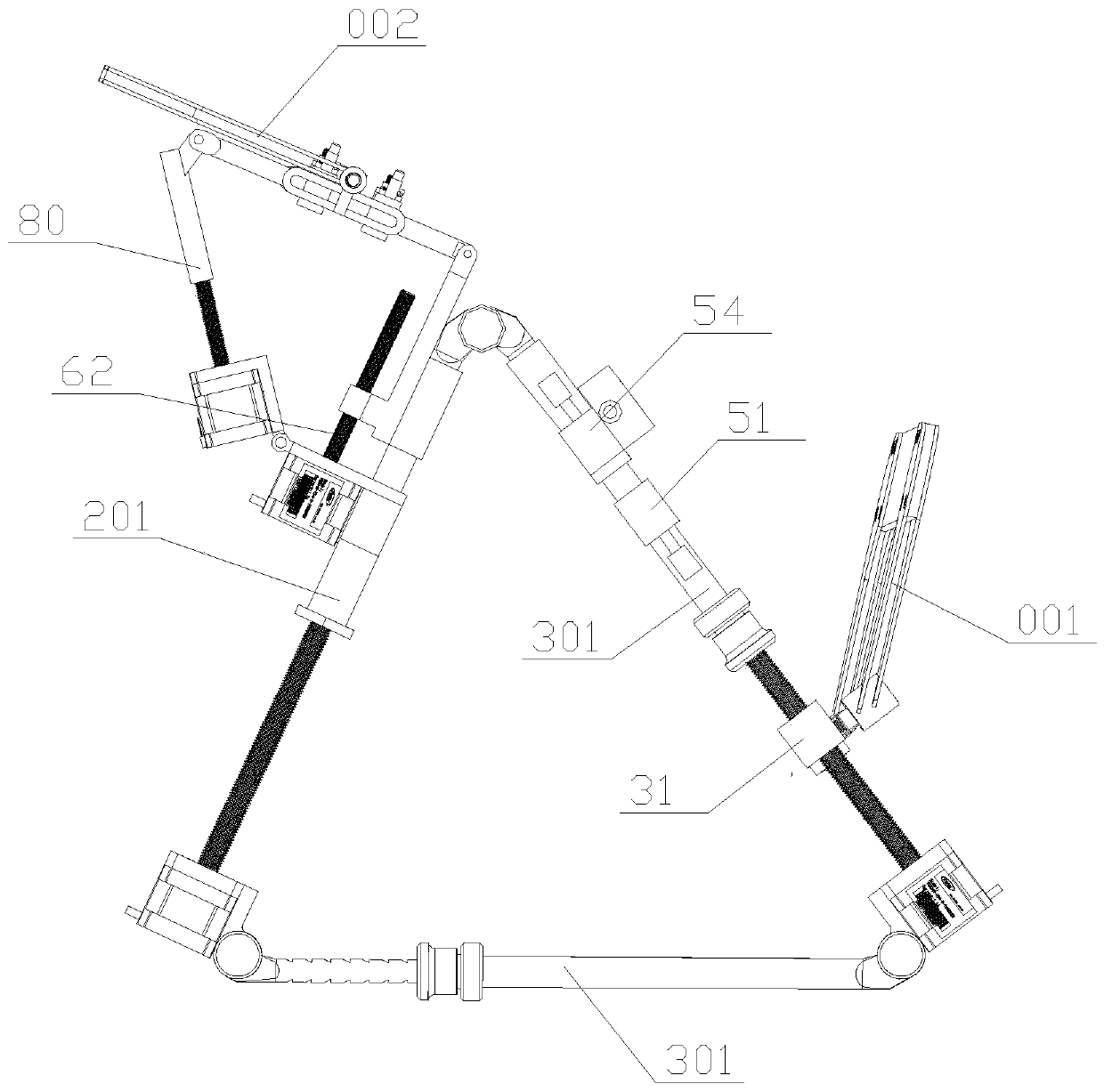

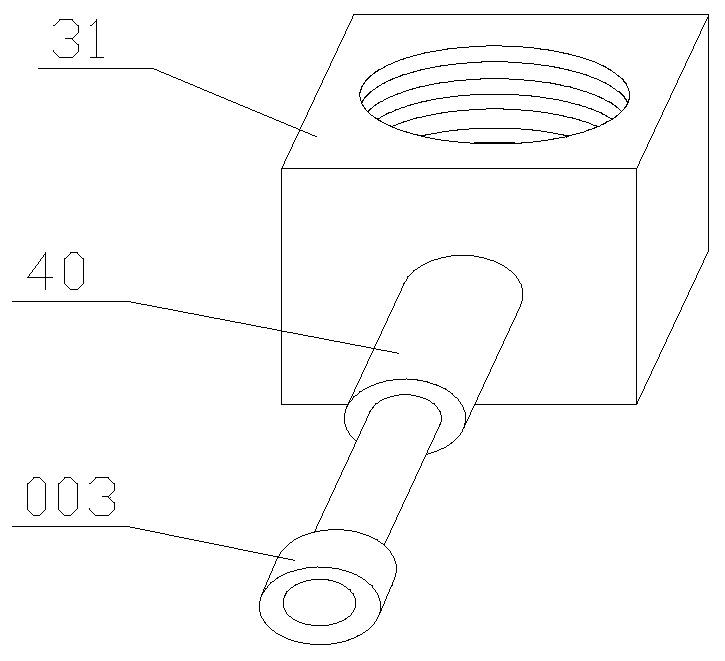

Combined three-dimensional traction mounting bracket for wrist joint

ActiveCN102247198AMeet strength requirementsAvoid camera occlusion problemsExternal osteosynthesisEngineeringMetacarpal bones

The invention relates to a combined three-dimensional traction mounting bracket for a wrist joint, and the mounting bracket provided by the invention mainly comprises two connecting rods and two arc-shaped rings, wherein the end surfaces, along the arc line direction, of the two arc-shaped rings are both provided with a plurality of through holes; two ends of each connecting rod are respectively locked and connected to the through holes corresponding to the two arc-shaped rings; each arc-shaped ring is provided with two purl screws; the end surfaces, adjacent to bolt parts, of the purl screwsare provided with needle penetrating grooves; the bolts of the purl screws are locked on the arc-shaped rings via nuts; two Kirschner wires are adopted for cooperating and fixing a metacarpal bone neck and a radius in a needle threading mode by virtue of the purl screws; and steel needles are cooperated to fix a wrist joint fracture block locked by the purl screws. The combined three-dimensional traction mounting bracket has the advantages of compact and stable integral structure, low cost and adjustable rigidity, is convenient to use and dismount, assists the fixation of wrist joints and fracture blocks, is free from stripping a periosteum and is favorable for healing wrist joint damages.

Owner:温建民 +1

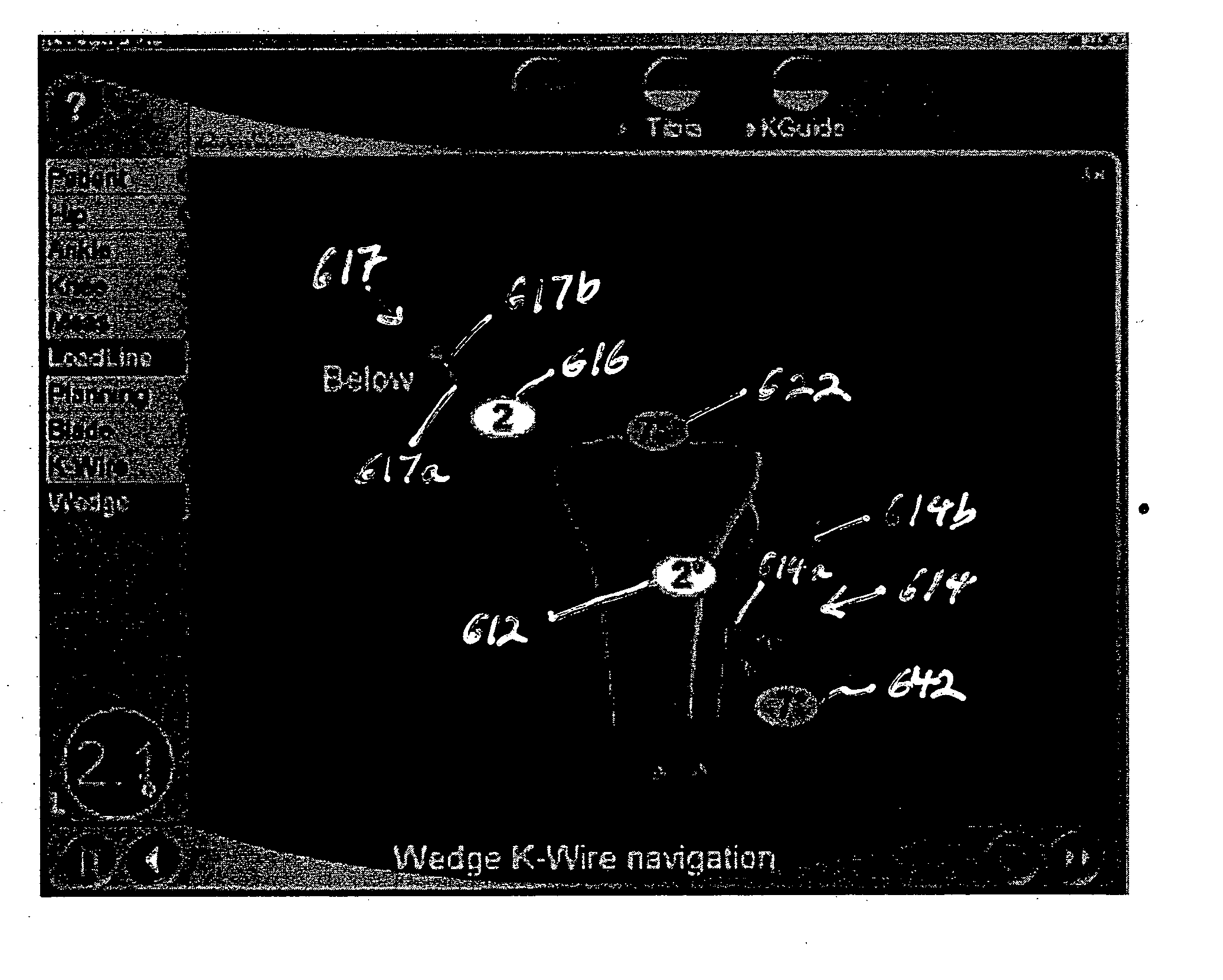

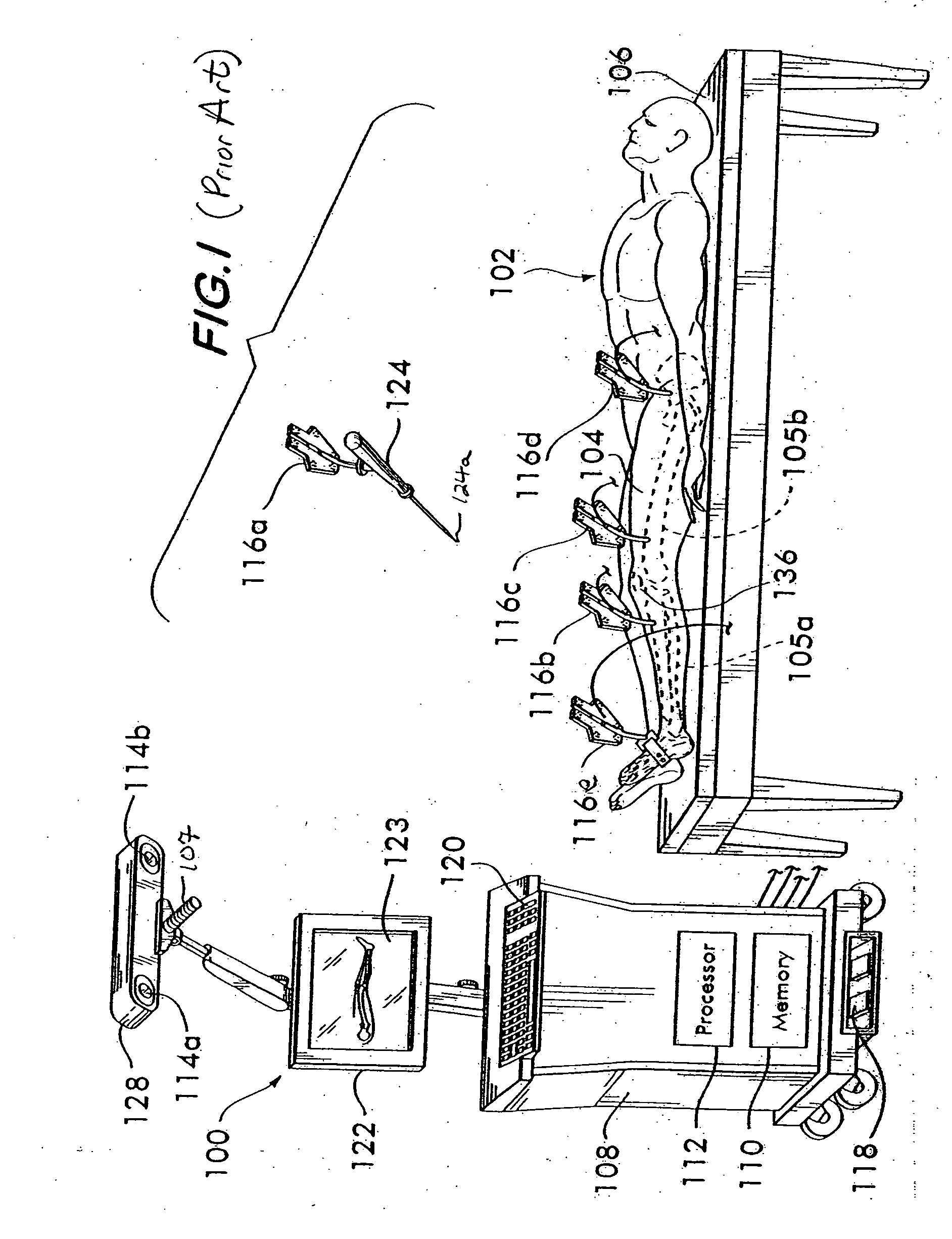

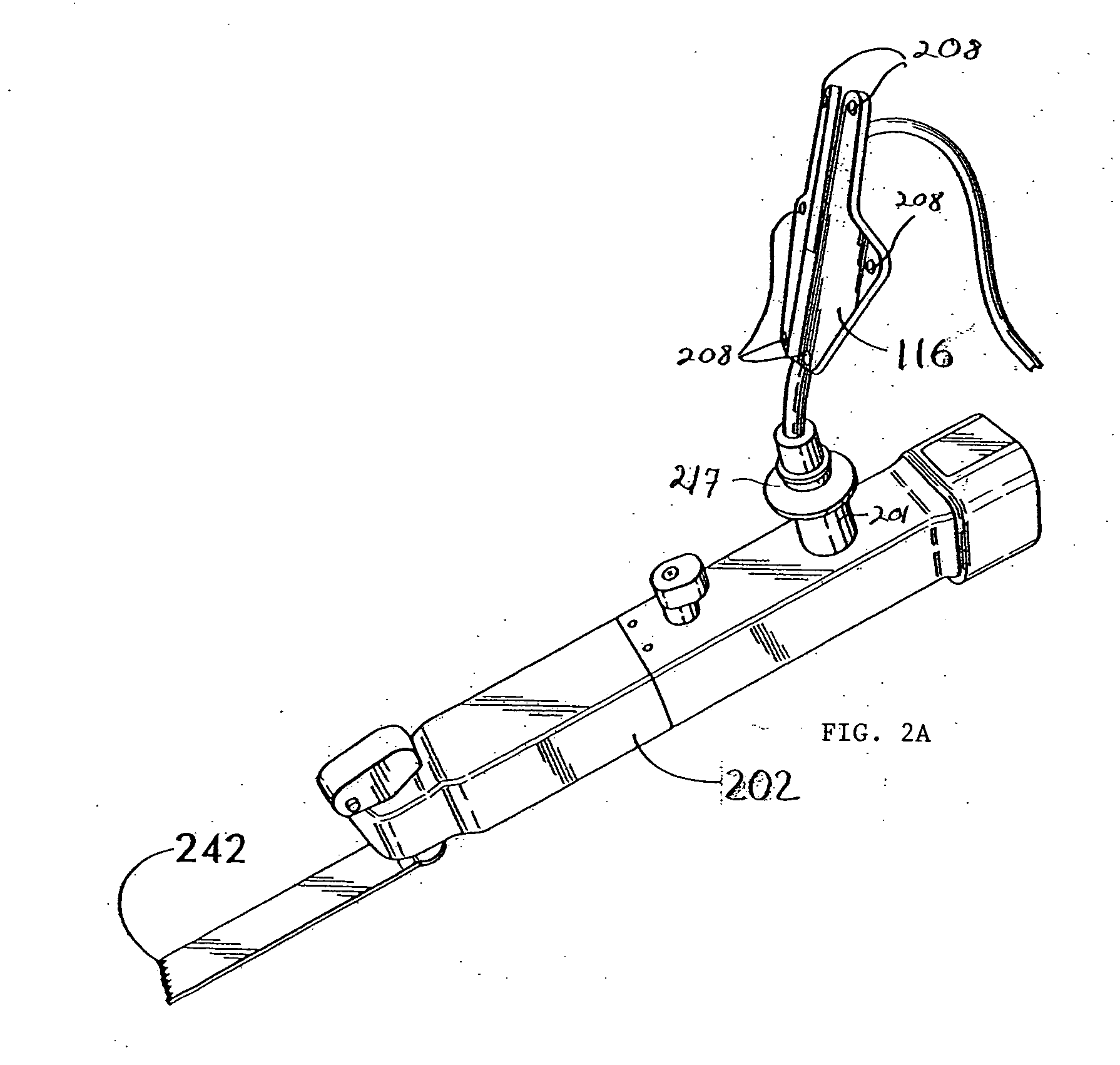

Method and apparatus for navigating a cutting tool during orthopedic surgery using a localization system

InactiveUS20070118140A1Precise cuttingImprove accuracyDiagnosticsSurgical navigation systemsTibiaLocalization system

The invention provides methods and apparatus for accurately cutting bones with a surgical cutting device, such as a sagittal saw, using a surgical navigation system without use of a complex cutting jig. A surgical navigation system is used to navigate a guide tube to be used to drill a k-wire into the bone. The k-wire will act as a guide to control at least one degree of freedom of a saw blade for making a cut in the bone. In an exemplary high tibial osteotomy procedure, in which two intersecting planar cuts must be made in the tibia in order to remove a wedge of bone, a surgical navigation marker is mounted on the guide tube. The surgeon uses the surgical navigation system to navigate the guide tube to the desired varus-valgus angle and height of the first cut and then drills a k-wire into the tibia at that varus-valgus angle using the guide tube. The process is repeated for the second cut. The surgeon then uses the two k-wires as guides for controlling the varus-valgus angle of a sagittal saw for the two planar cuts. The surgeon rests the saw blade flat on the respective k-wire to define the varus-valgus angle of the cut. The saw itself also is navigated, with the surgical navigation system providing a display showing the surgeon at least (1) the varus-valgus angle, (2) the cut depth, and (3) the anterior-posterior slope. The anterior-posterior slope and the depth of the cut is controlled freehand by the surgeon.

Owner:AESCULAP AG

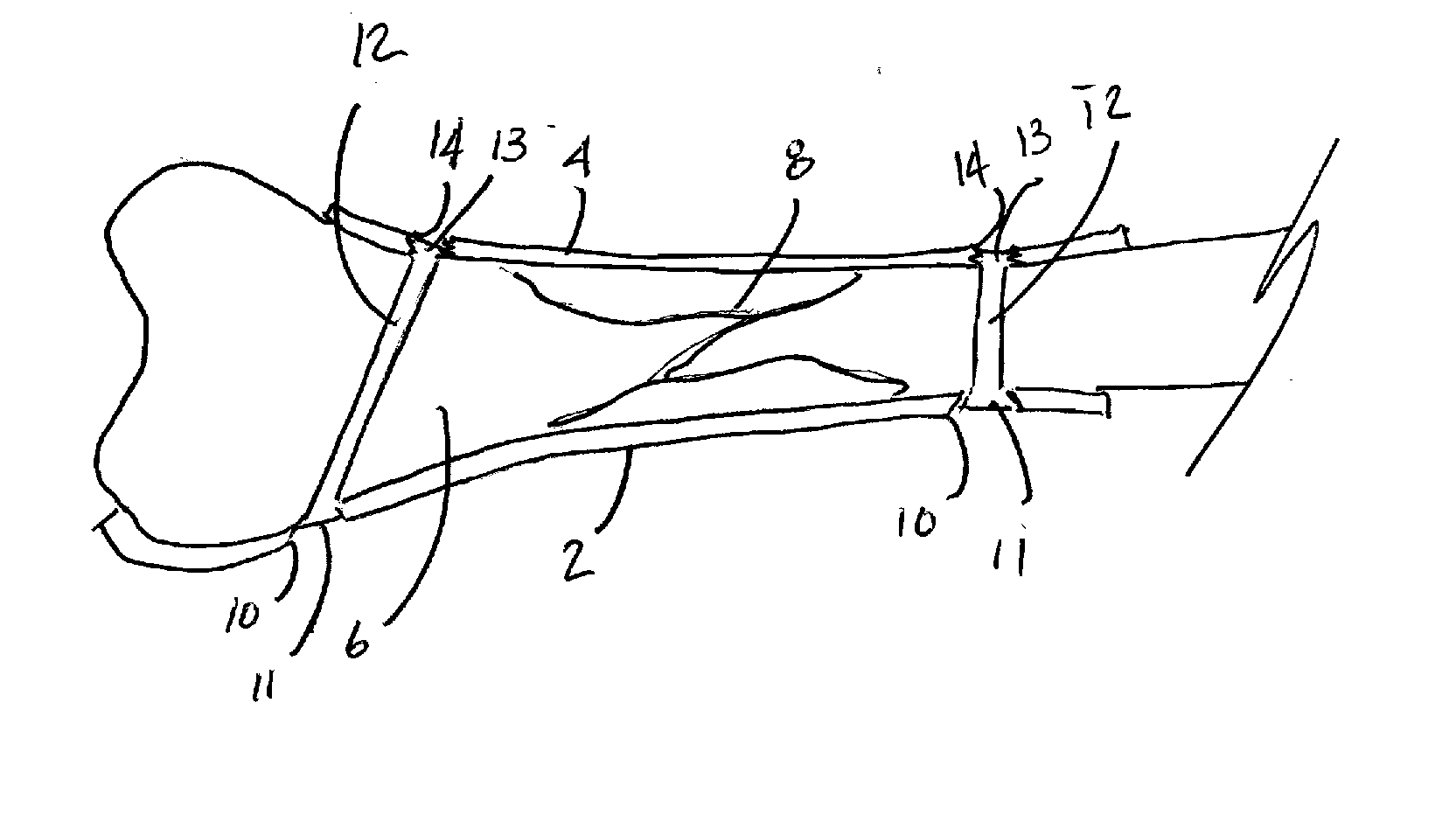

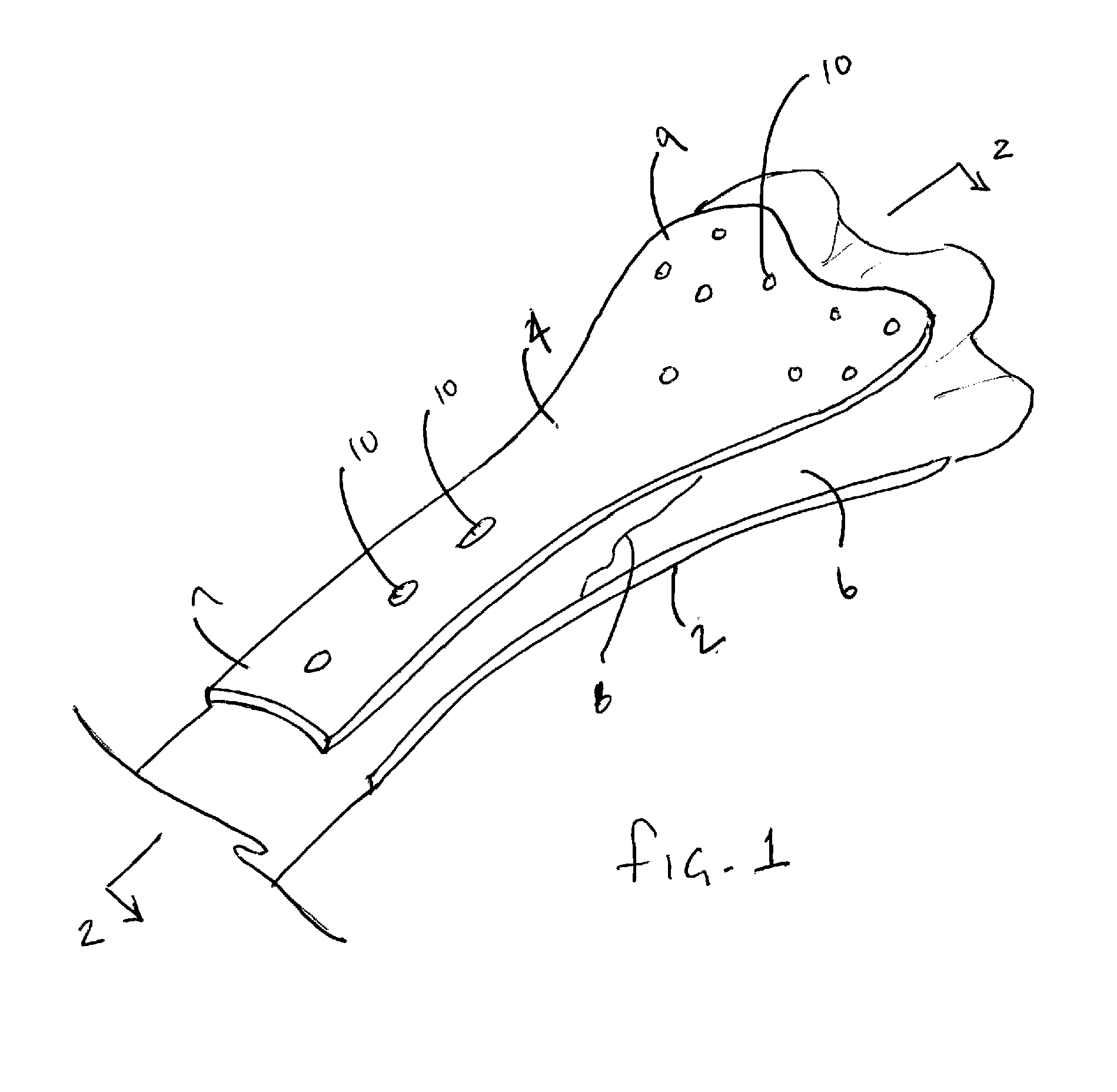

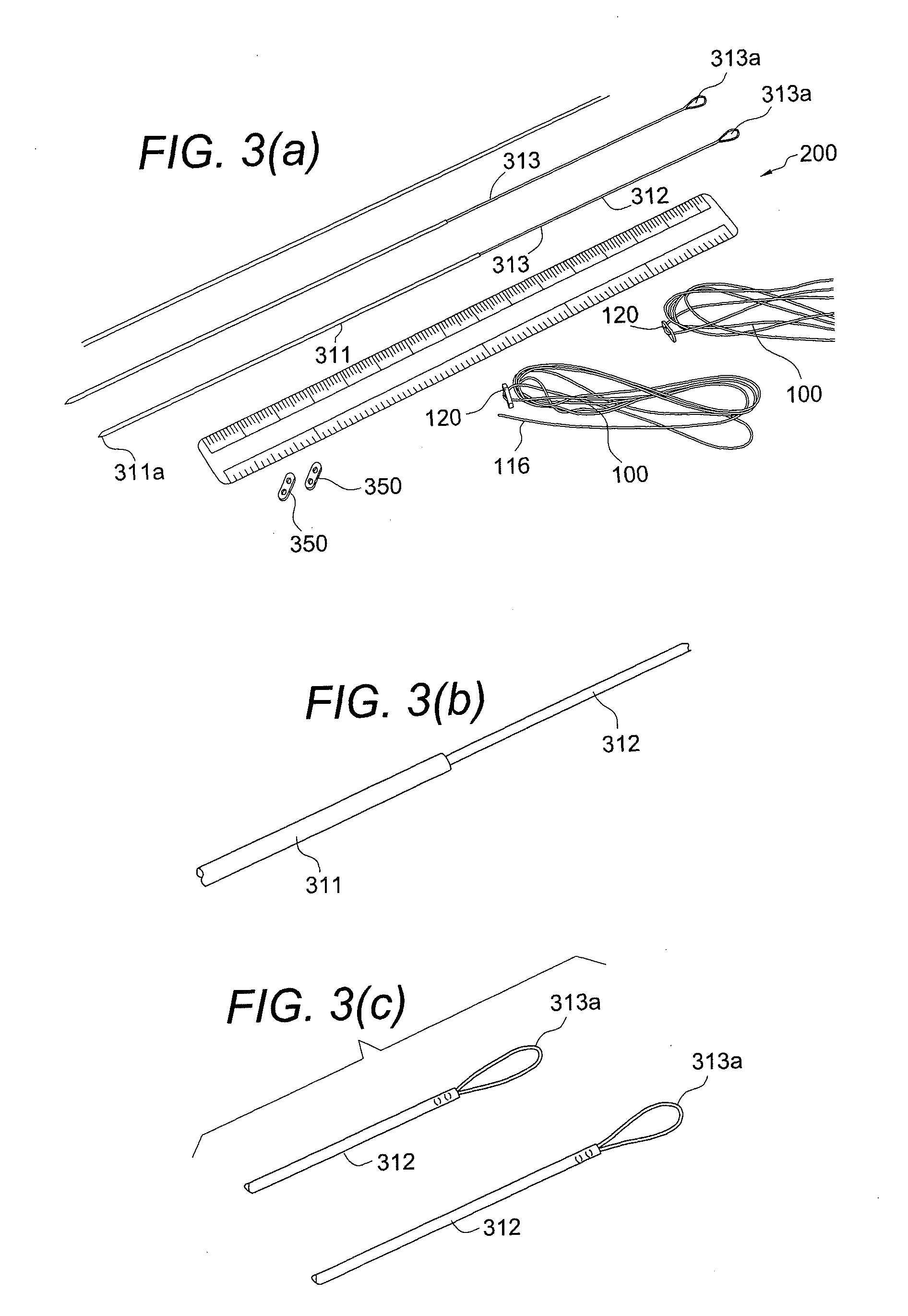

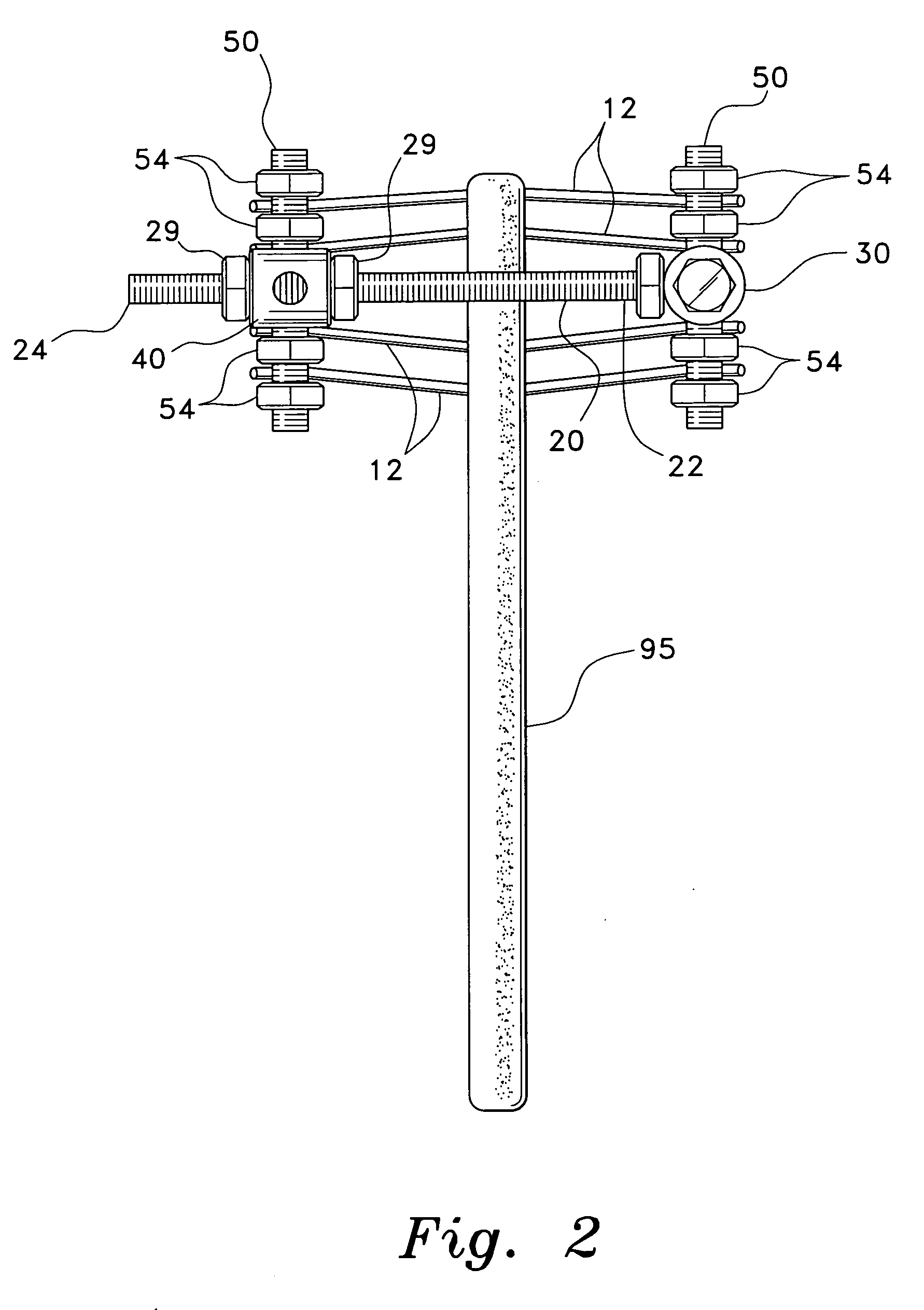

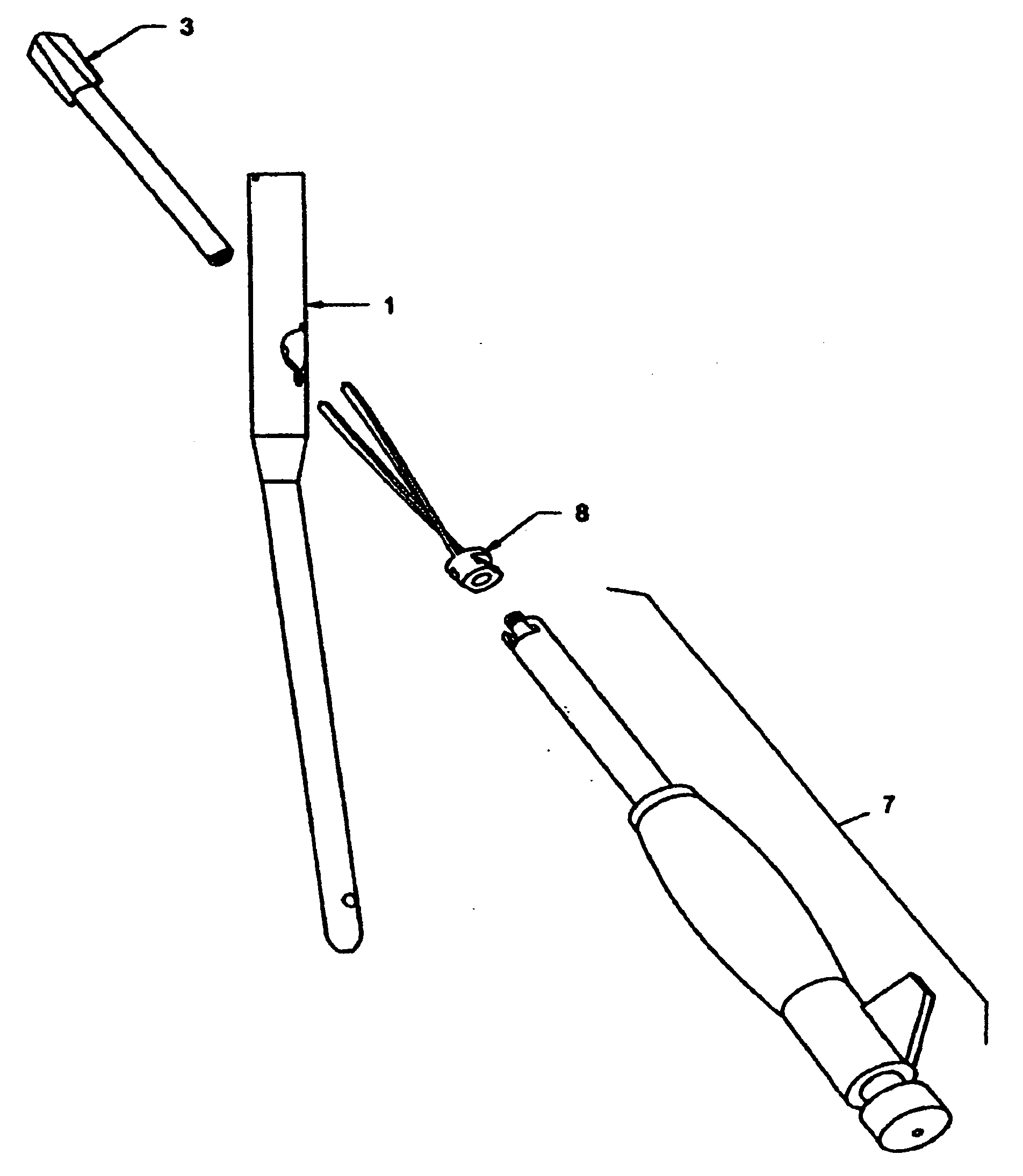

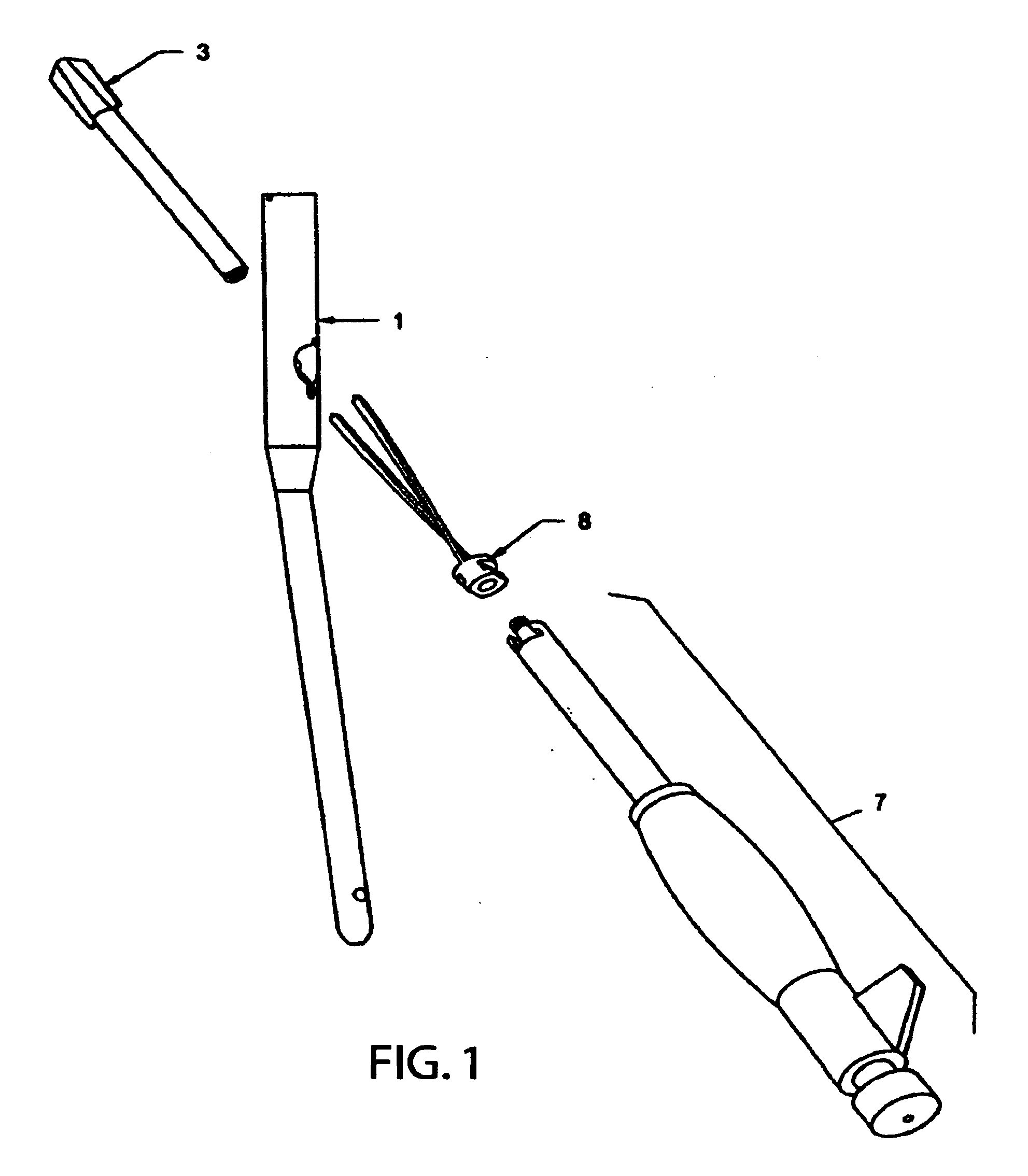

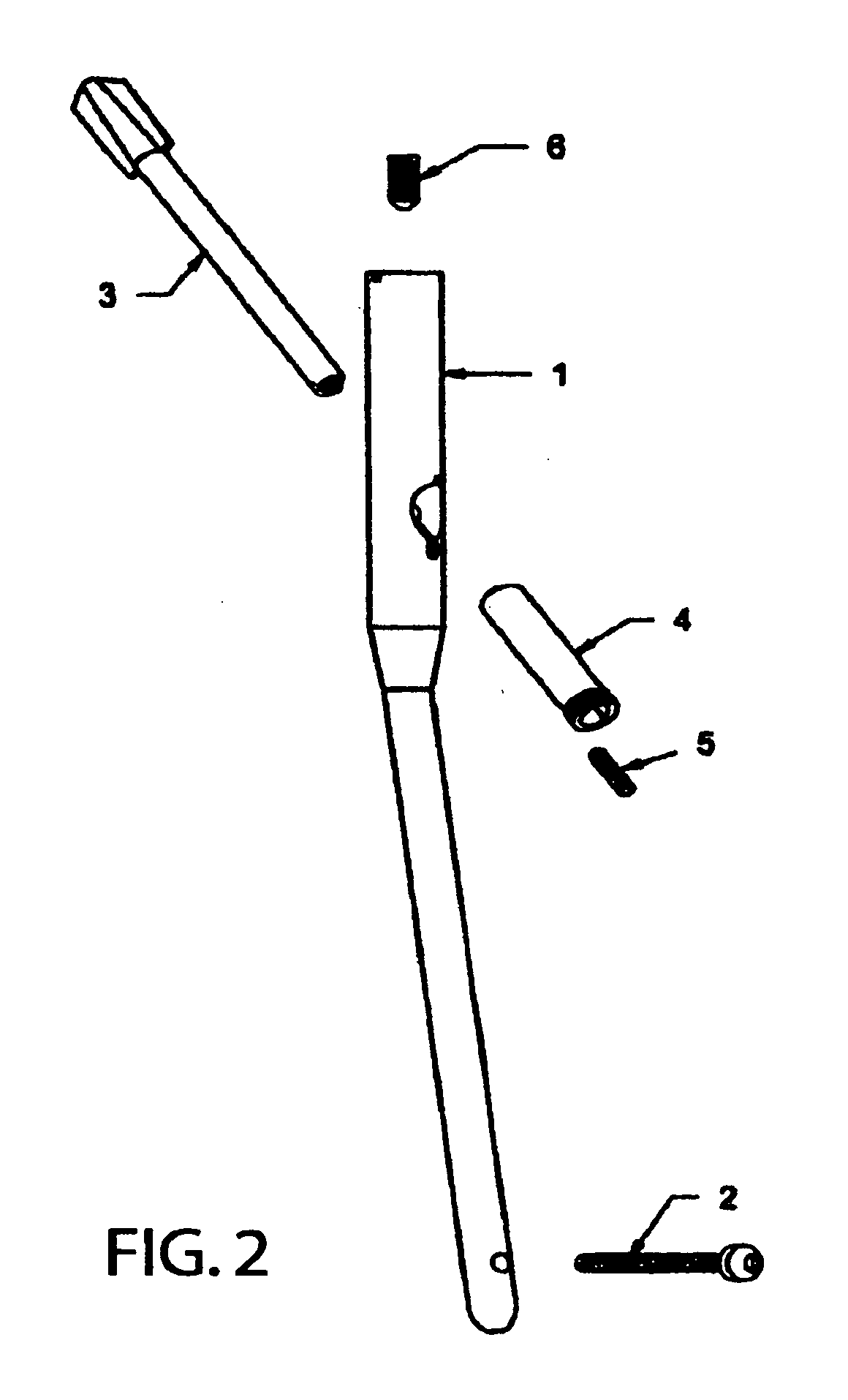

Method and apparatus for external fixation of bone fractures

The method and apparatus for external fixation of bone fractures provides for external fixation of bone fractures, especially fractures of the patella and the olecranon. An apparatus for external fixation of bone fractures comprises a support member, and a pair of tensioning assemblies disposed along the support member. A first tensioning assembly is connected to the first end of the support member, and a second tensioning assembly is slidably disposed along the support member. Filaments, attached to and extending between the first and second tensioning assemblies, may be tensioned by moving the second tensioning assembly along the support member away from the first tensioning assembly. Filaments, such as Kirschner wires, are inserted through bone fragments on opposite sides of a fracture. The filaments are tensioned by moving the tensioning assemblies apart. Tension applied to the filaments draws the filaments together, compressing the bone fragments together at the fracture.

Owner:ISMAIL WARDAK MOHD

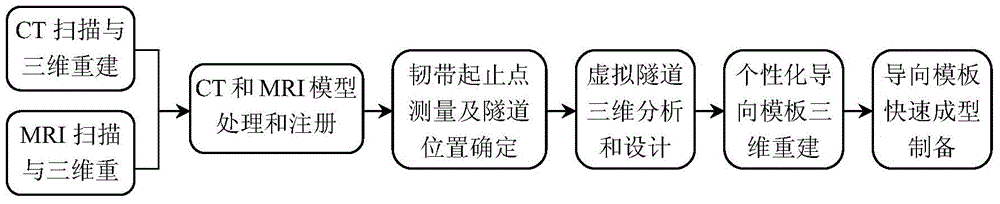

Tibia tunnel locating device and method based on personalized navigation template

ActiveCN104083204AIncrease success ratePrevent the error from being magnified when drilling into the tunnelDiagnosticsOsteosynthesis devicesCruciate ligamentPersonalization

The invention relates to a tibia tunnel locating device and method based on a personalized navigation template and belongs to cruciate ligament reconstruction surgery. The method comprises the steps that firstly, CT data and MRI data of a patient are collected, a data model is processed, and three-dimensional reestablishment is conducted on the data model; secondly, according to the three-dimensional model, the position of a tunnel is measured and determined, a bone surface needed by locating is obtained through partition, and a navigation template model is established; thirdly, the navigation template is manufactured through the rapid forming technology; finally, locating and verification are conducted through the navigation template and a locating device of a guider, and then a Kirschner wire is inserted through drilling. According to the tibia tunnel locating device and method based on the personalized navigation template, the navigation template is easy to locate and easy to operate, due to the auxiliary locating calibration of the guider, it is avoided that the error of the Kirschner wire inserted into the inner opening of the tunnel through drilling is amplified due to navigation template catheter small-angle swing deviation caused by soft tissues residues and other factors, the locating precision can be effectively guaranteed, and the surgical effect is more reliable.

Owner:GUANGXI UNIV

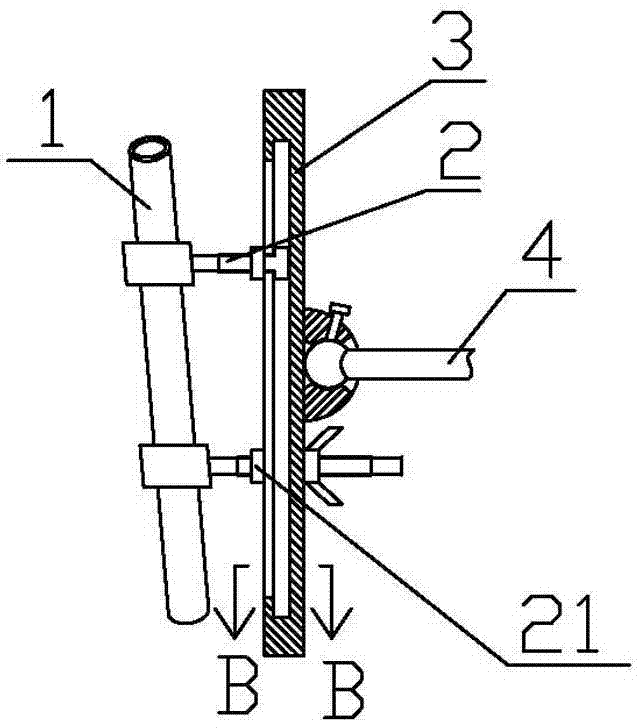

Axis odontoid screw sighting device

The invention relates to a medical instrument, in particular to an axis odontoid screw sighting device for guiding positioning of hollow screws during axis odontoid fracture treatment. The axis odontoid screw sighting device comprises a hollow guide tube and is characterized in that at least two telescopic connection rods are installed on the hollow guide tube, one ends of the telescopic connection rods are provided with sleeves, the hollow tube is inserted in the sleeves, and the other ends of the telescopic connection rods are connected onto a fine control panel which is connected with a supporting rod through a spherical joint. The axis odontoid screw sighting device is simple in structure and convenient to use, and can be used for guiding accurate positioning of kirschner wires during the axis odontoid fracture treatment. Therefore, operation quality is improved, operation errors are reduced, and pain of patients is alleviated.

Owner:周健

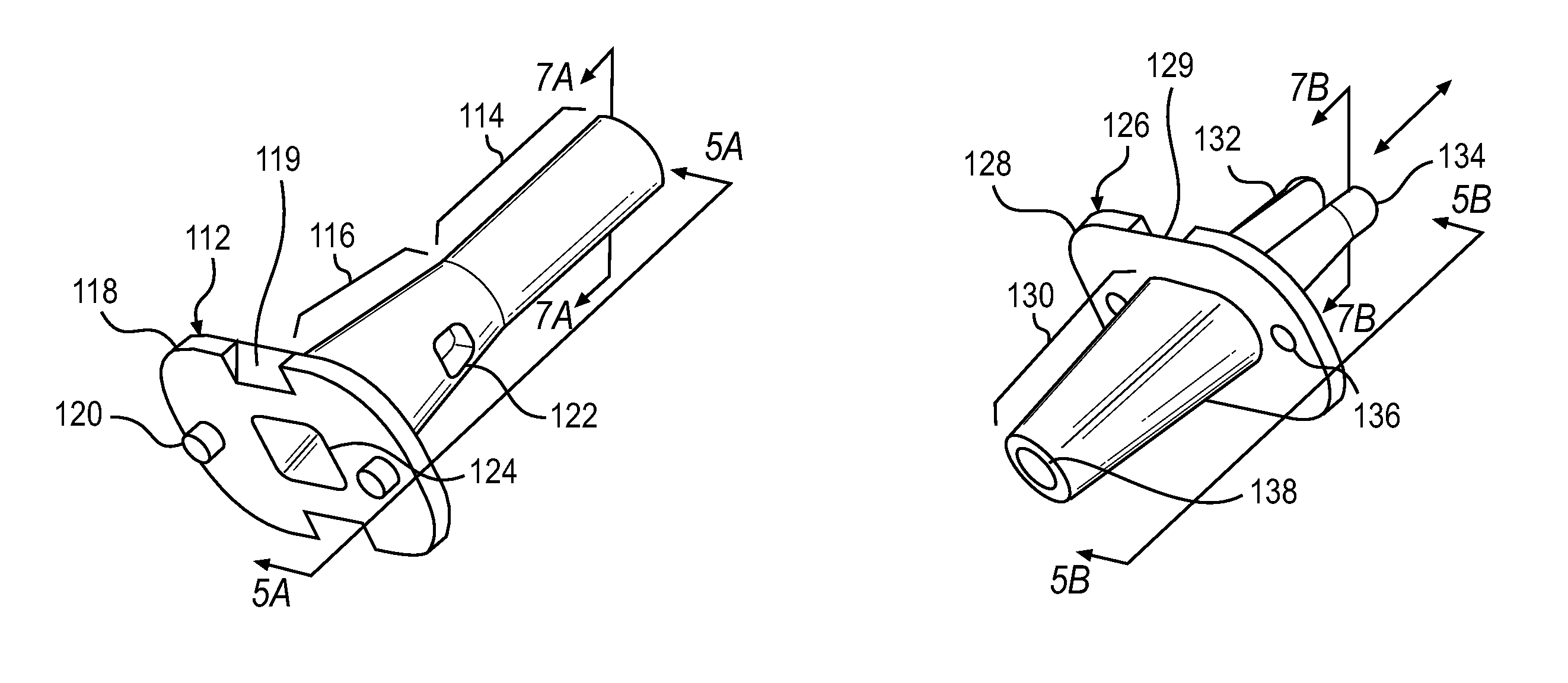

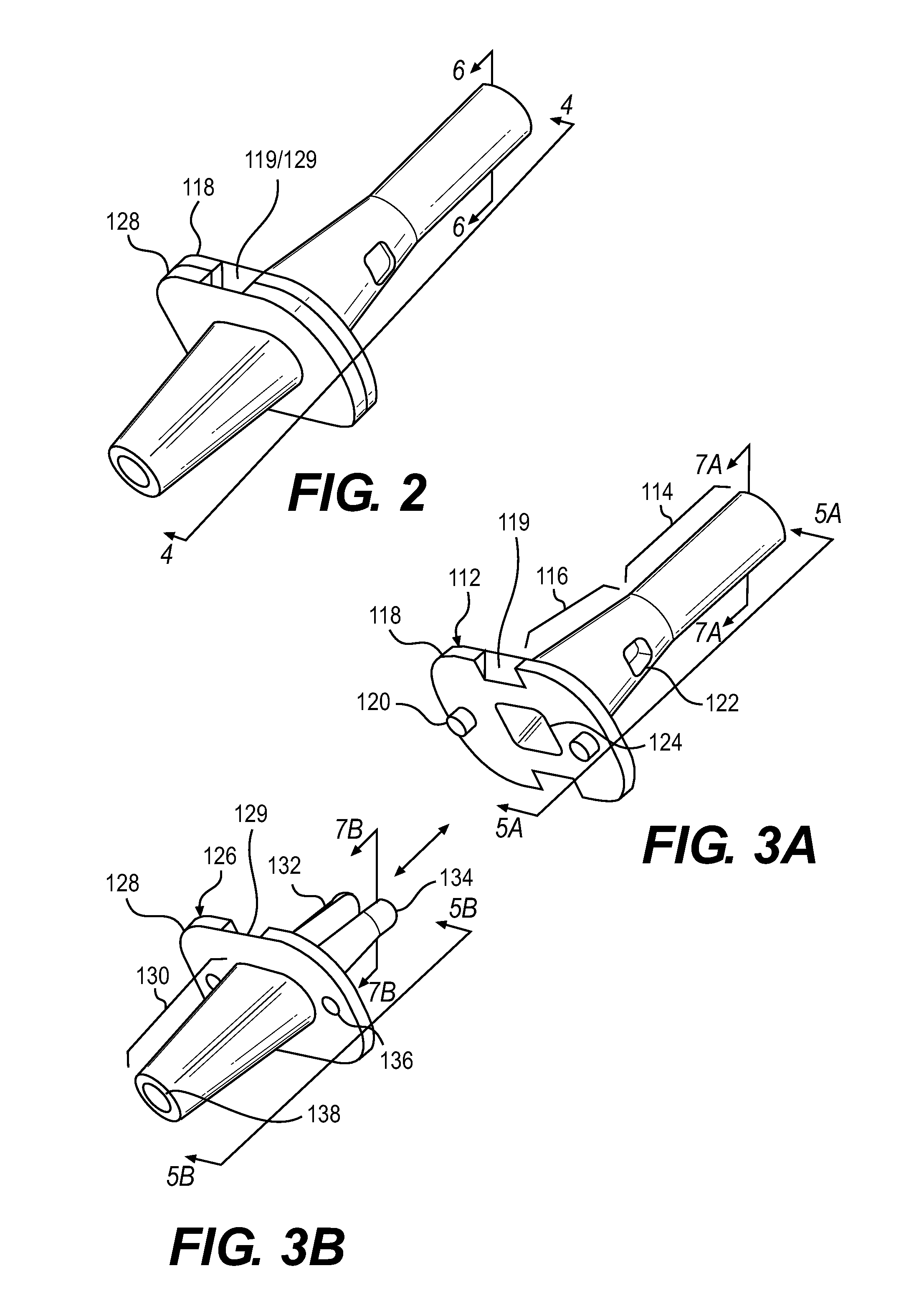

Interphalangeal joint implant methods and apparatus

ActiveUS8764842B2Decreasing eliminating incidenceSimple procedureFinger jointsInternal osteosythesisProximal phalanxDetent

A method and apparatus for correcting malformed joints, in particular the “hammer toe” contraction of the proximal interphalangeal joint. The disclosure comprises a two-component implant: a proximal phalanx component and a middle phalanx component. An endosseous stem on each component is inserted axially into the end of a respective host bone and, after insertion, the components are attached. The attached components are held together in various ways, for example a detent arm / aperture mechanism. Each component can be cannulated to allow for the passage of a kirschner wire, if necessary, to stabilize adjacent joints such as the proximal interphalangeal joint. The bones of the treated joint can be set to form a desired angle by adjusting the angle formed by the corresponding endosseous stems.

Owner:GRAHAM MICHAEL

System for making a bone repair

ActiveUS8821580B2Improve the level ofEfficient repairSuture equipmentsInternal osteosythesisIliac screwBiomedical engineering

A method and system is provided for repairing bone fractures at locations where high levels of stability are required. The system employs two plates to buttress a fracture from both the dorsal and volar sides. The plates are affixed to one another using screws that are installed from a volar plate, through the bone and into a dorsal plate. The method provides for use of a directional guide that allows the precise placement of Kirschner wires for temporary fixation of the fracture, installation of a first bone fixation plate using the installed K-wires for alignment, installation of a second bone plate adjacent the bone to be repaired and opposite the first bone plate, and installation of cannulated fasteners between the two opposing bone plates such that the fasteners rigidly engage both of the bone plates.

Owner:SWISS ORTHO

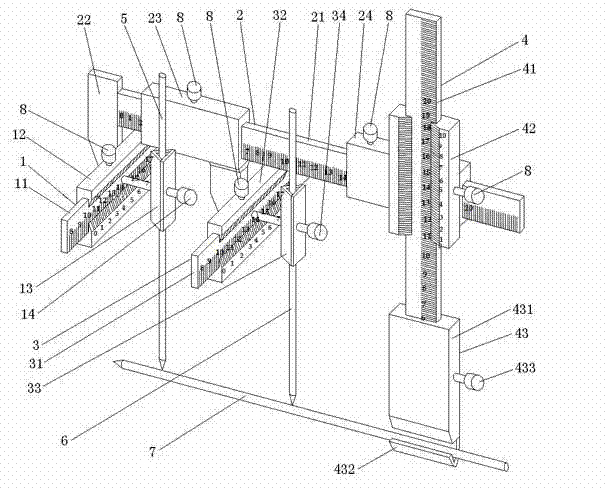

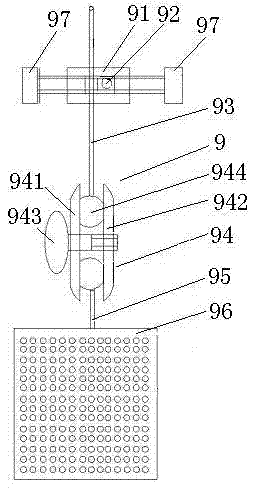

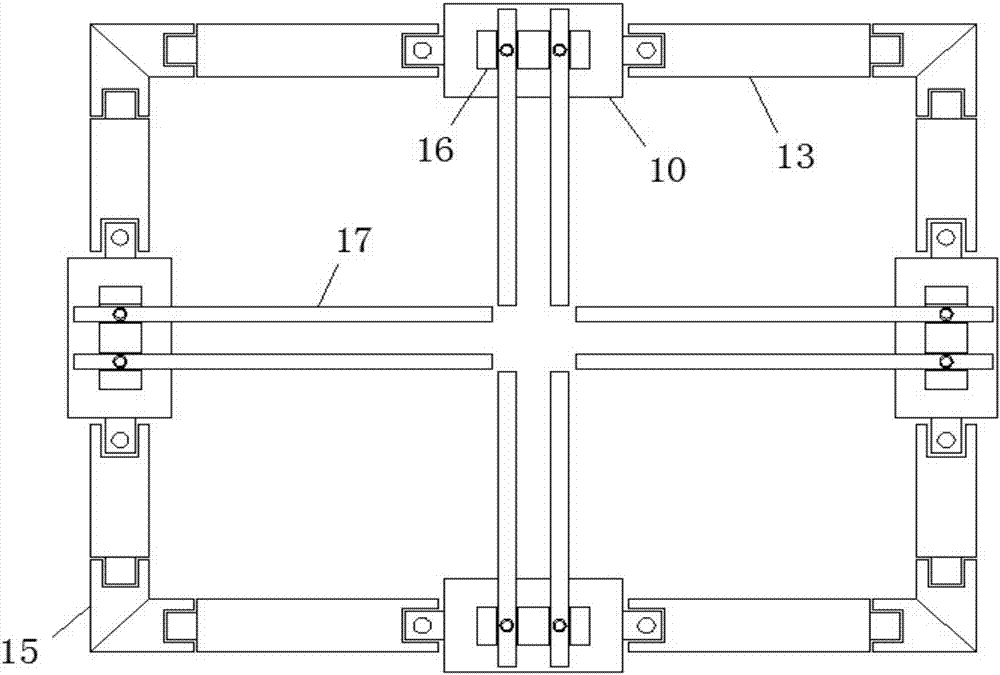

Three-dimensional coordinate-positioning drilling guiding system

InactiveCN102488543APrecise positioningReduce X-ray exposureDiagnosticsBone drill guidesRetainerEngineering

The invention discloses a three-dimensional coordinate-positioning drilling guiding system. The guiding system comprises an x1 axis vernier caliper and an x2 axis vernier caliper arranged along an axis x, an axis z vernier caliper arranged along an axis z, an axis y vernier caliper arranged along an axis y, positioning needle fixers arranged on the x1 axis and the x2 axis, and a guide needle fixer on the axis Y, wherein the x2 axis vernier caliper and the x1 axis vernier caliper are parallel to each other. After fracture reposition, a body surface positioner is mounted on bones, projections of a target point and a reference point on the body surface are positioned by X-ray; the positioning needles are inserted in vertically to respectively confirm the coordinates of the target point and the reference point on the three-dimensional positioning rack x1 axis, x2 axis, and axis y relative to positioning needle points; the verniers on each axis can be regulated and fixed based on the coordinates; and drill bits and Kirschner wires are drilled in from the guide needle fixer. The guiding system has the advantages that application range is wide, drilling is accurate, and the drill bit or the Kirschner wire can be in optional size below 6mm.

Owner:王光明

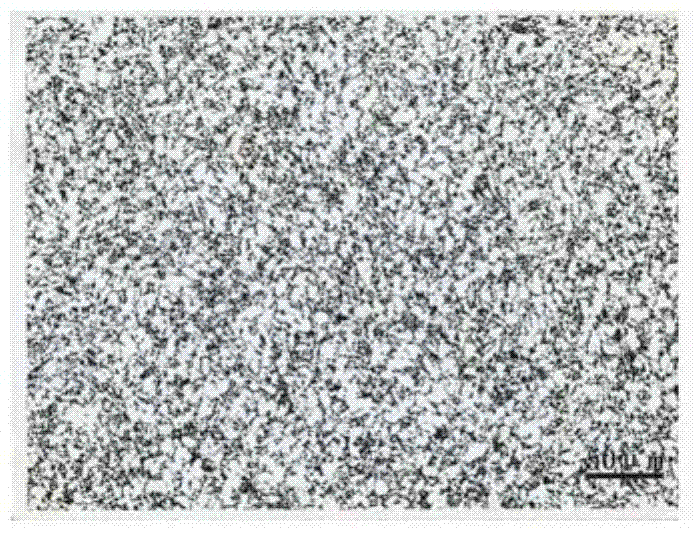

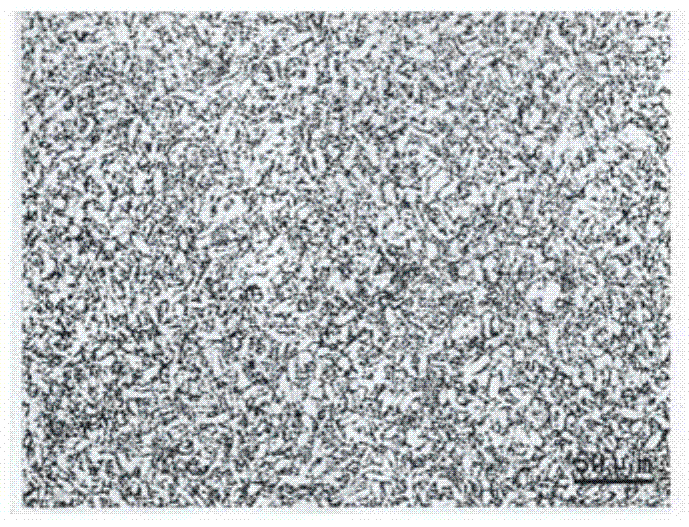

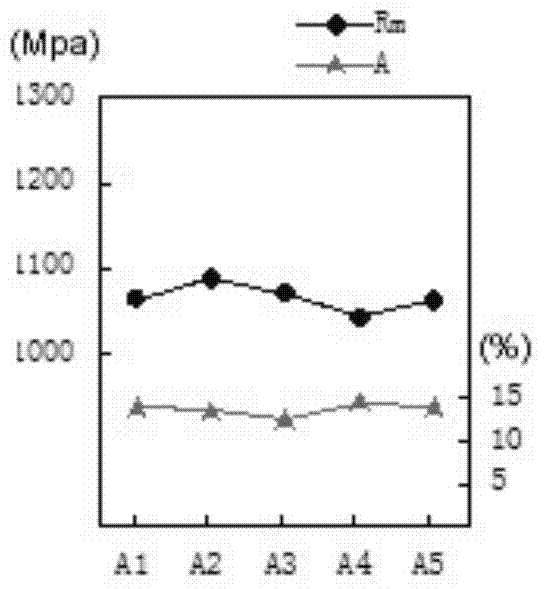

Preparation process of medical Ti-6Al-7Nb alloy wires for manufacturing Kirschner wires

The invention provides a preparation process of medical Ti-6Al-7Nb alloy wires for manufacturing Kirschner wires. Special class-0 titanium sponge is adopted, honorary alloy composition burdening is performed according to marks, electrodes are pressed for assembly and welding, three-time smelting is performed through a vacuum consumable electro-arc furnace to form fai 370 mm alloy ingots; a metallographic phase method is adopted to measure (alpha+beta) / beta phase transformation points (TB) of the alloy ingots; the alloy ingots are subjected to surface scalping, riser ingot bottoms are cut off, a beta phase zone is heated through an electric furnace, cogging and forging are performed through a 2500-tons oil press, surface defect coping is performed, and further a two-phase zone is heated; two-time rolling is performed to form fai 9.5 mm rod and wire blanks, the rod and wire blanks are heated to be lower than the phase transformation points and are repeatedly subjected to heating and multiple-die drawing to form wires commonly used for Kirschner wires of fai 4.0 mm and under through a 30KW drawing machine and a 11 KW drawing machine, and annealing, straightening, polishing and heat treatment are performed. For the high-strength Ti-6Al-7Nb Kirschner wires serving as a medical material for human, the safety and reliability of the wires are especially important. The work-hardening capacity of the Ti-6Al-7Nb wires is the key of high strength achievement through heat treatment strengthening.

Owner:宝鸡鑫诺新金属材料有限公司

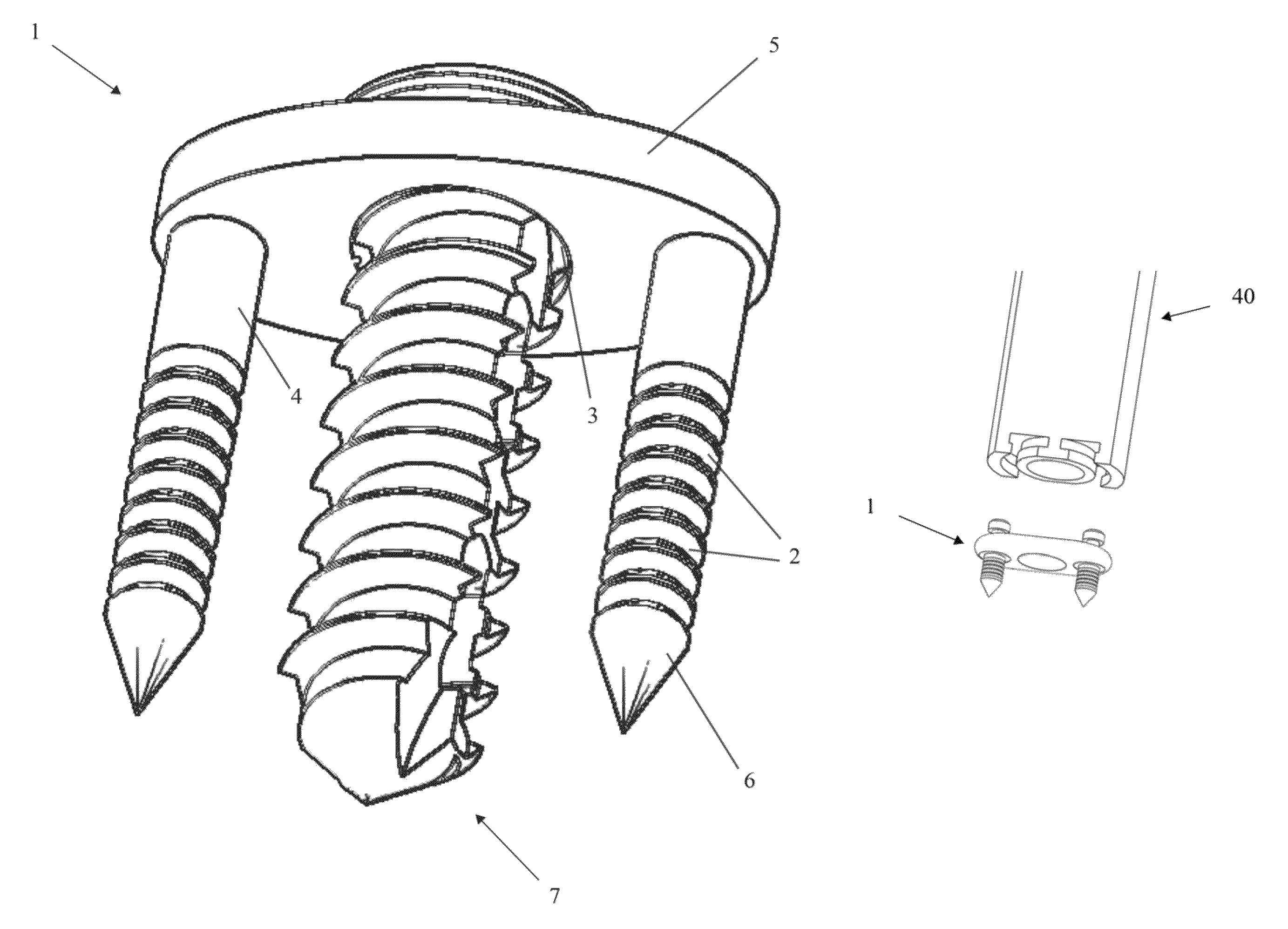

Hip Helical Implant

ActiveUS20100063503A1Diminishes bone lossSimple technologyInternal osteosythesisJoint implantsSet screwRight femoral head

An intramedullary osteosynthetic device includes an intramedullary nail, a hip helical implant, a sliding sleeve, a lateral set screw, and at least one distal locking screw. The intramedullary nail is cannulated. The cannulation is at least partially threaded to receive a coaxial set screw. The intramedullary nail includes at least one oblique slotted bore in communication with the cannulation, where the at least oblique slotted bore receives a sliding sleeve, and further includes a threaded notch compatible with the lateral set screw. The hip helical implant includes a frontal helical portion having a truncated conical shape, at least two helical twisted blades attached to the frontal helical portion, and a rear smooth shaft, the shaft having an external flat surface. Each blade of the hip helical implant has a hole for receiving a peg from a step helix fixating the hip helical implant to the step helix. The hip helical implant is cannulated to receive a Kirschner wire during insertion of the implant into a femoral head. The sliding sleeve includes a tube having an internal flat corresponding to the external flat of the hip helical implant and has external threads at the rear of the sleeve engaging the lateral set screw. The coaxial set screw fixes the sliding sleeve to the intramedullary nail by tightening the sliding sleeve inside the oblique bore.

Owner:DEPUY SYNTHES PROD INC

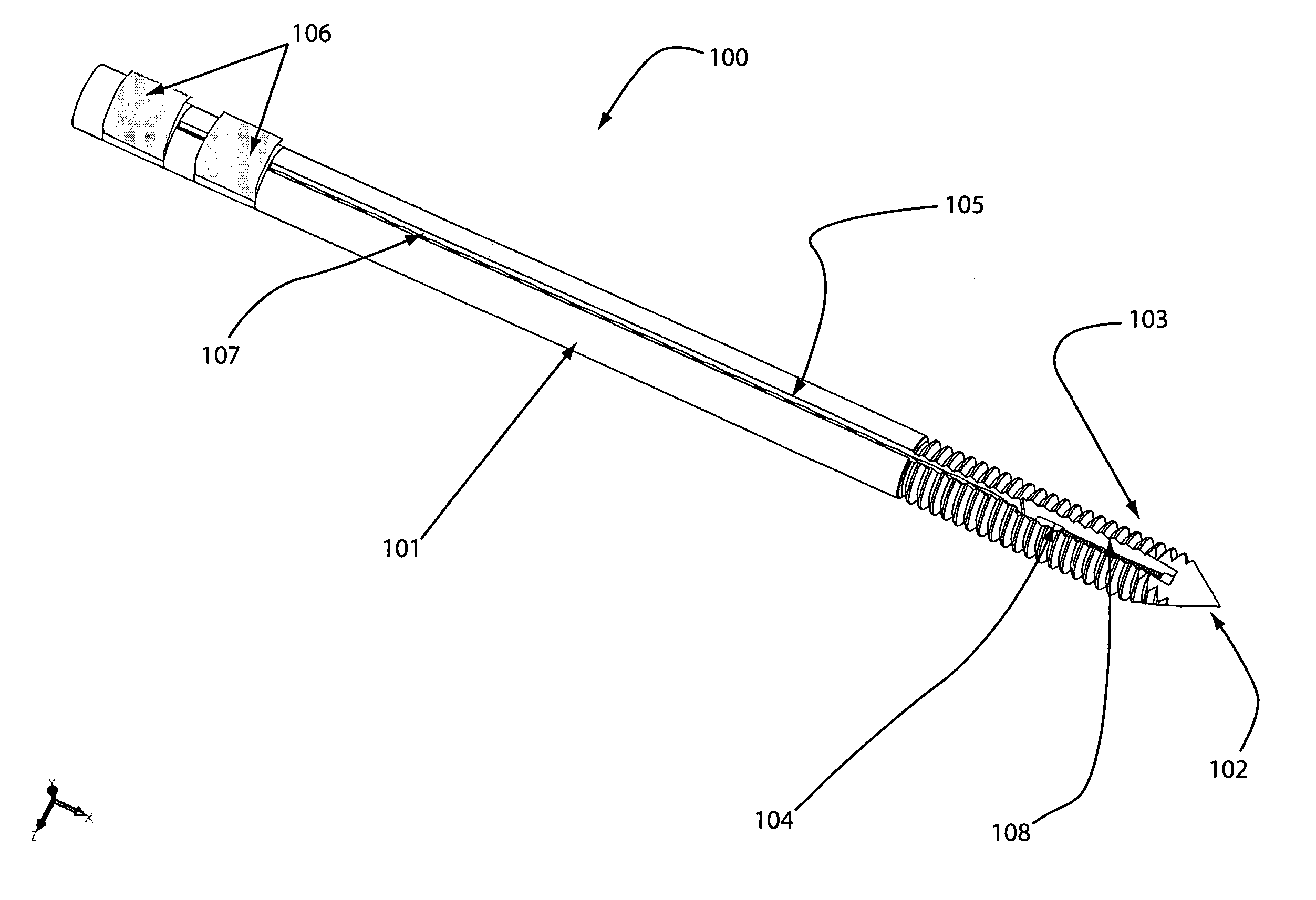

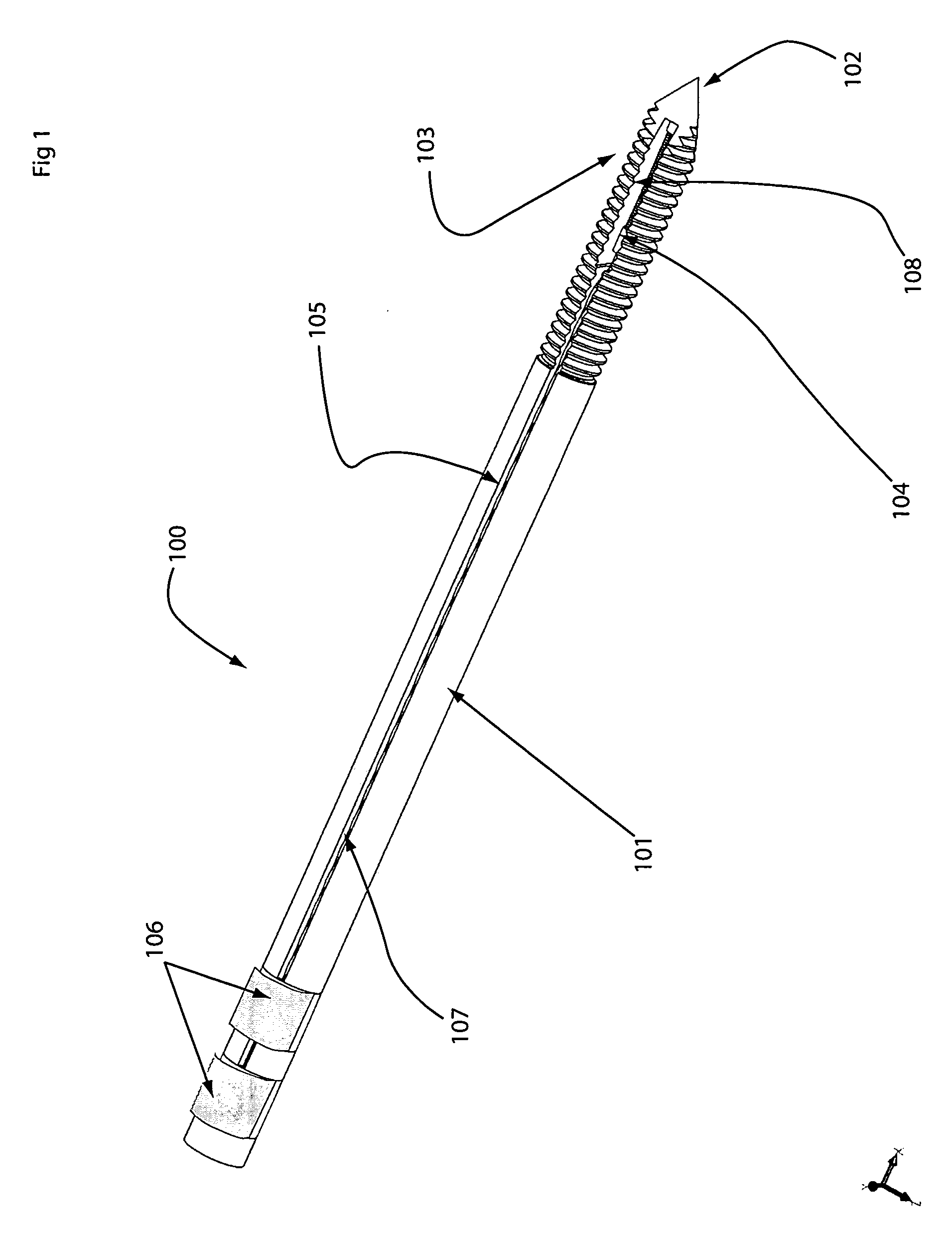

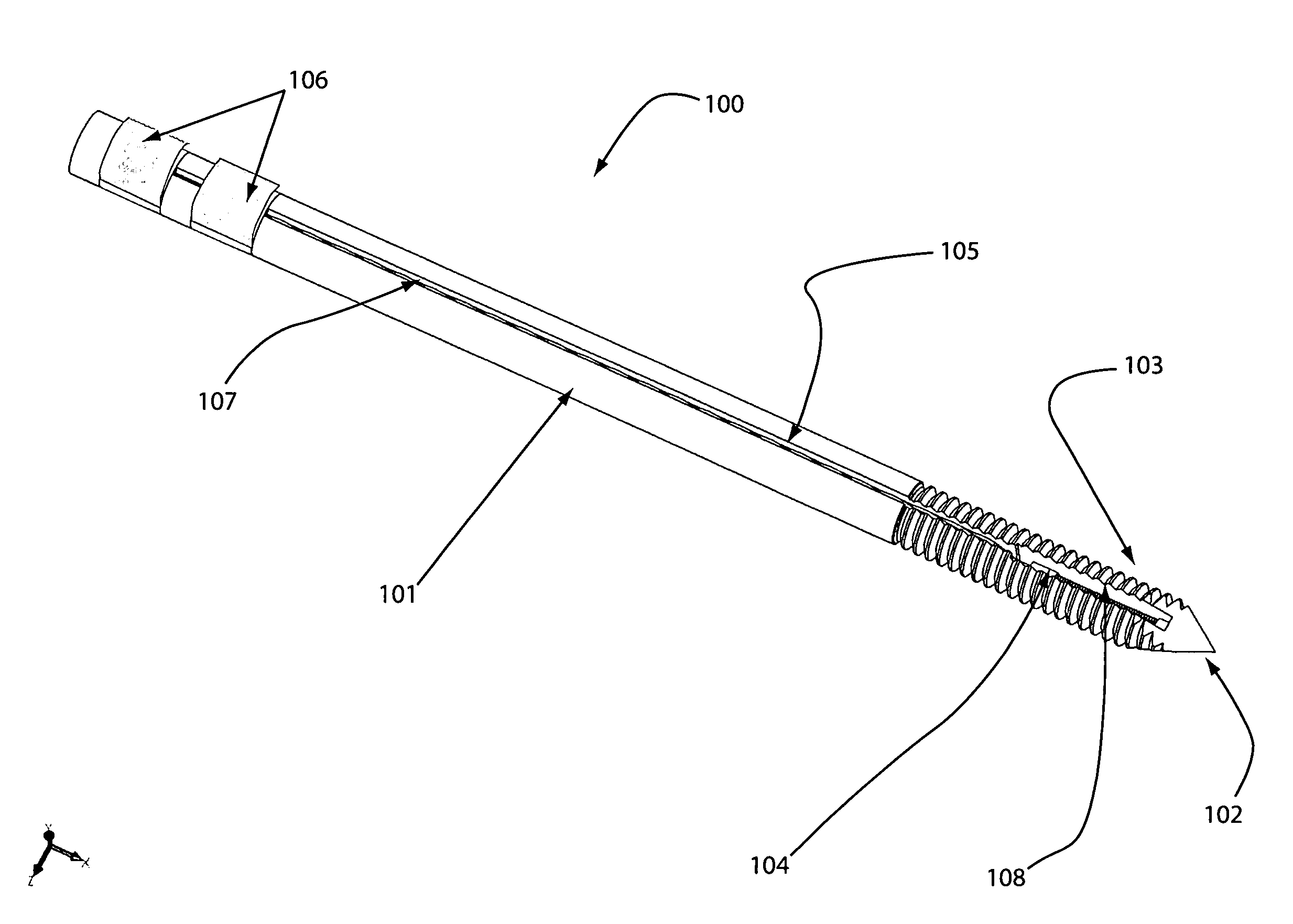

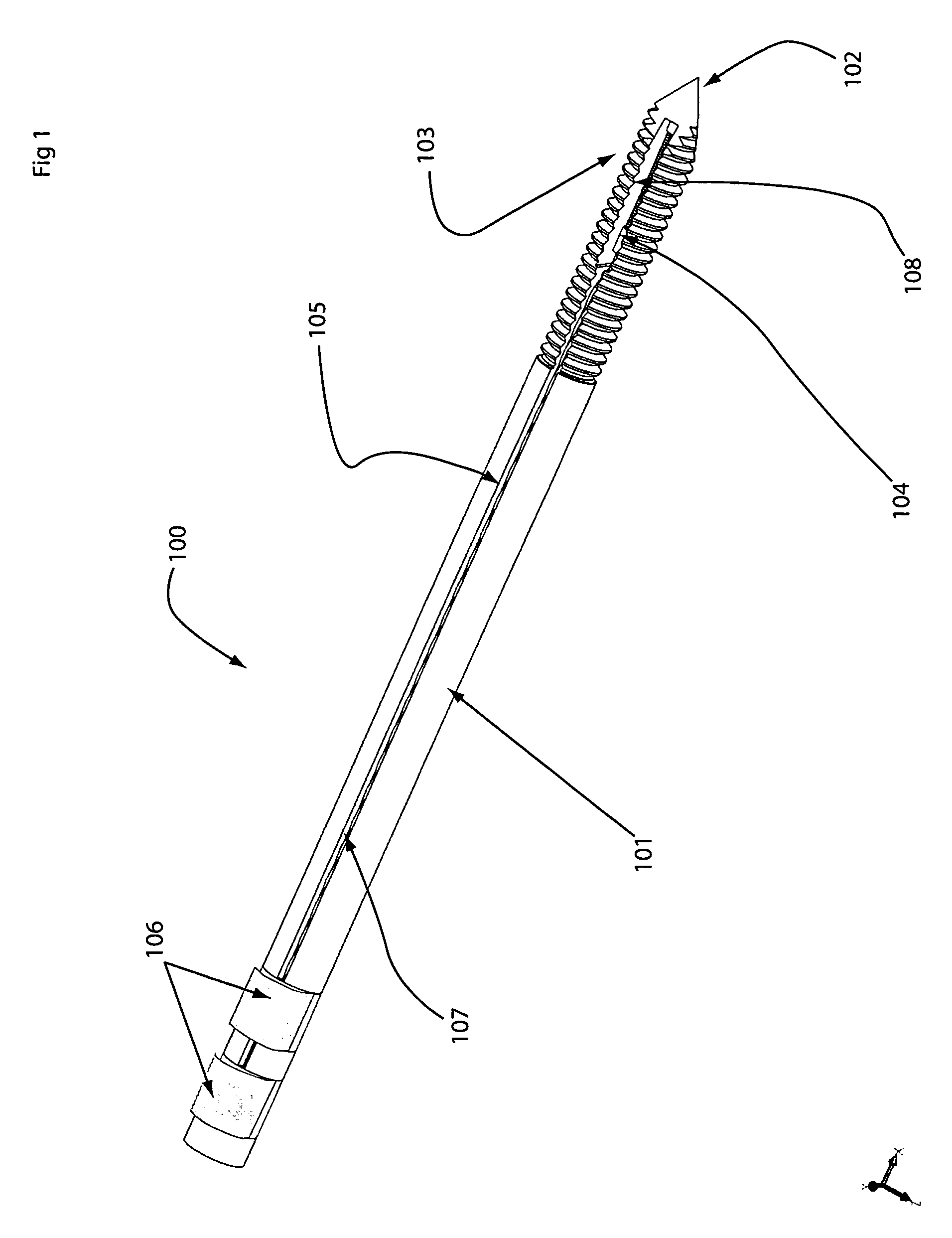

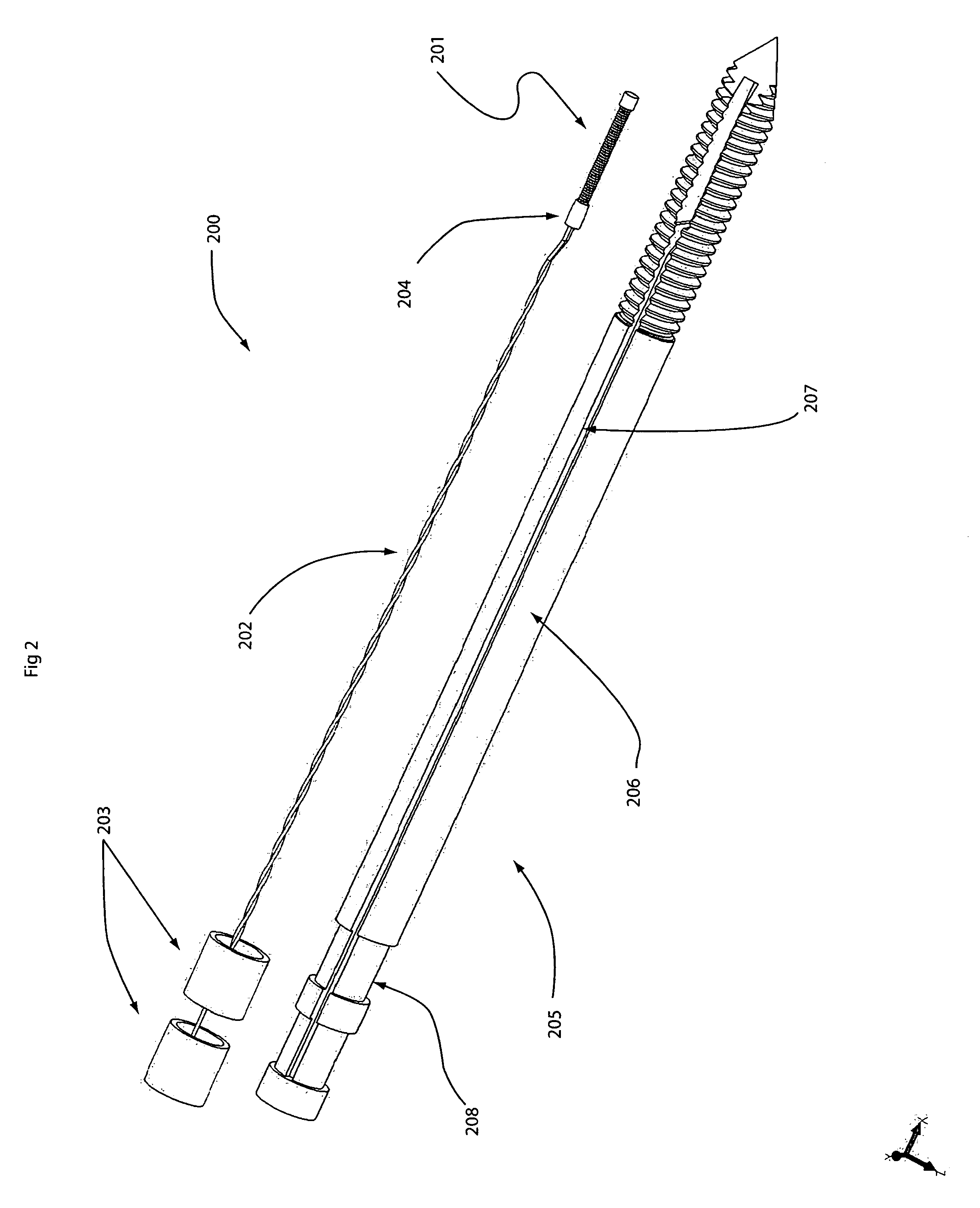

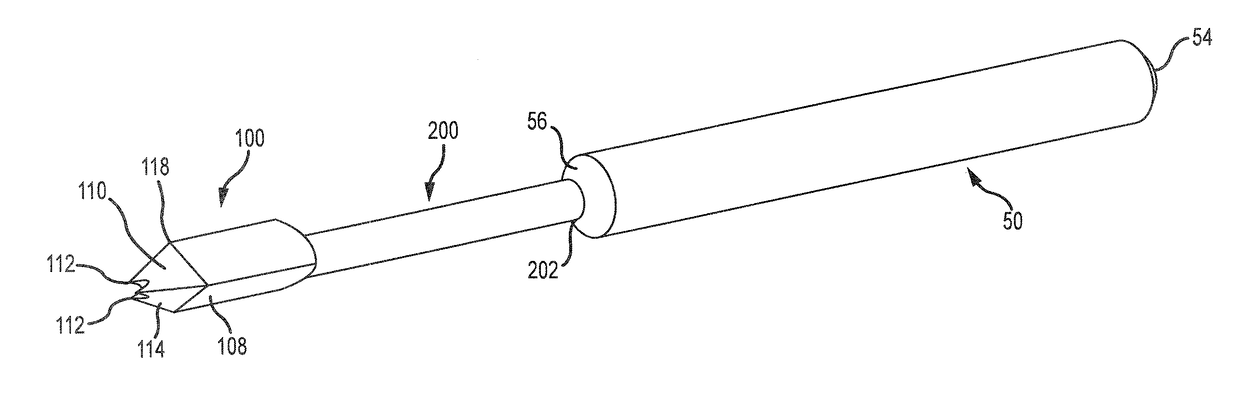

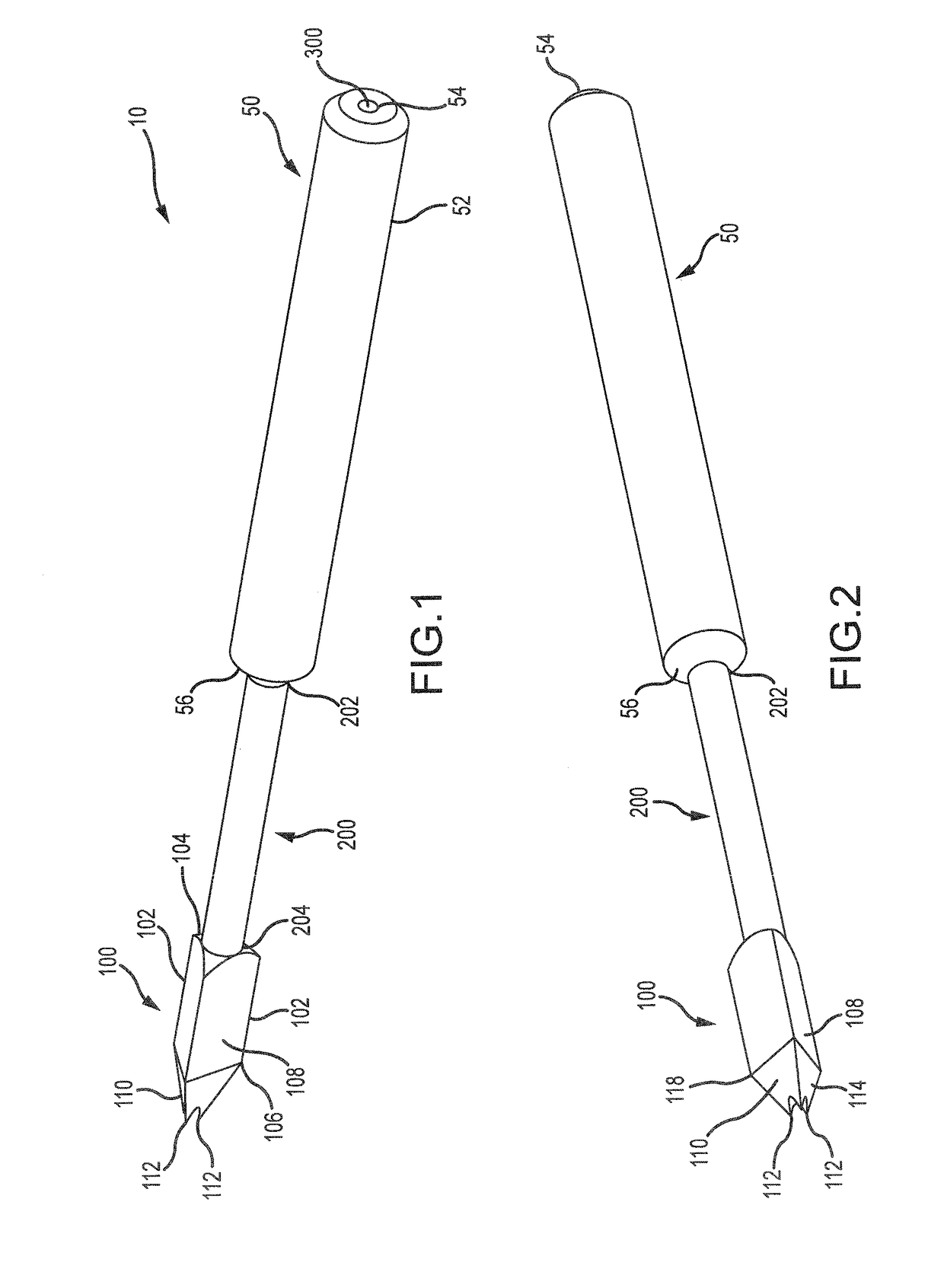

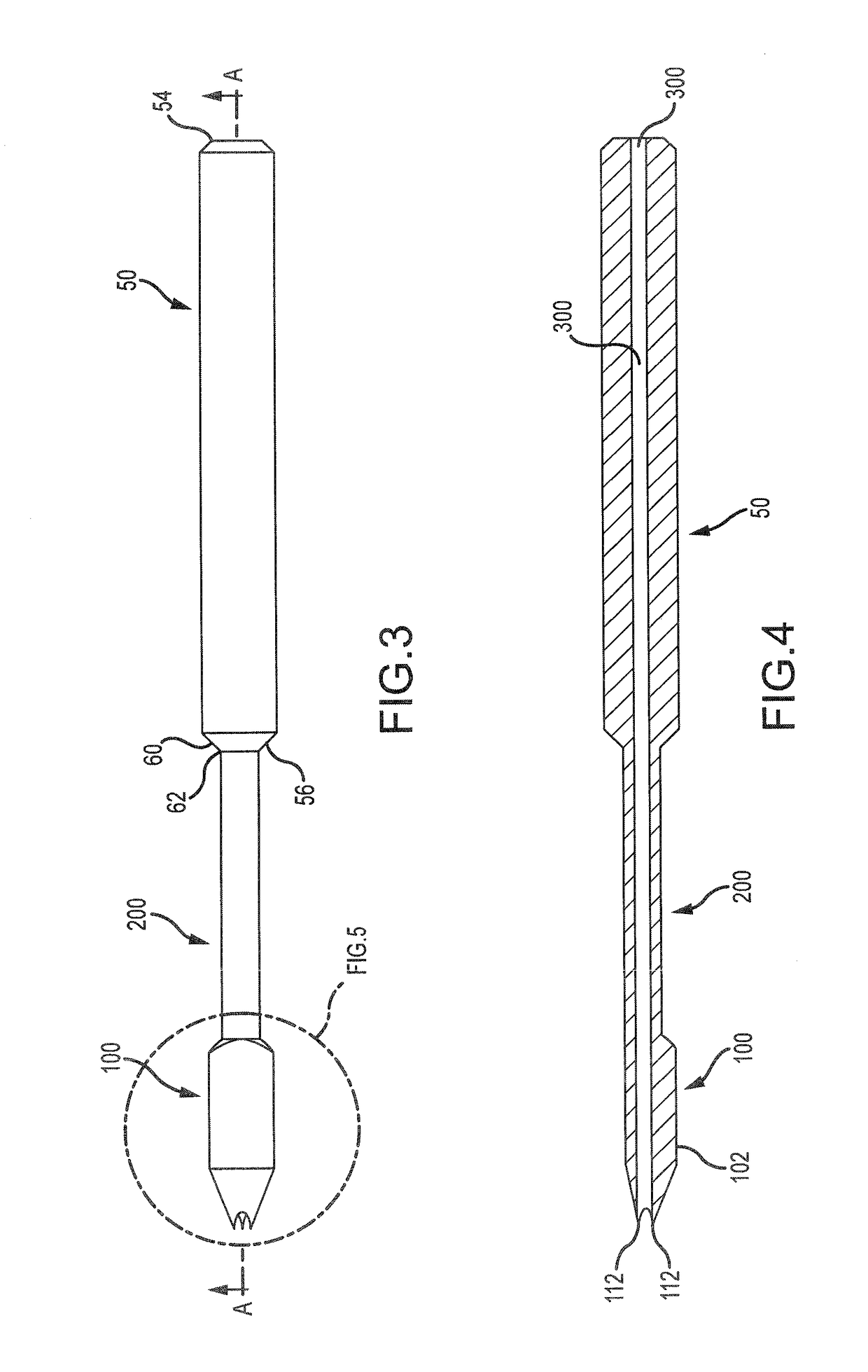

Tool for percutaneous joint cartilage destruction and preparation for joint fusion

A tool for scrubbing, removing tissue from the medullary cavity or joint cavity of a bone or removing cartilage and / or cortical bone from a joint cavity has a proximal end, a distal end, and a cannula extending therethrough. The distal end includes at least one scraping surface and / or cutting surface to soften marrow in the medullary cavity or joint cavity as the scraping and / or cutting surface(s) are rotated or otherwise moved relative to the medullary cavity or joint cavity. When used, the tool may be attached to a drill and the cannula receives a K-wire previously inserted into the medullary or joint cavity. The drill rotates the tool around the K-wire and pushes the tool over the K-wire into the medullary cavity or joint cavity.

Owner:EXSOMED CORP

Method of lateral facet approach, decompression and fusion using screws and staples as well as arthroplasty

ActiveUS8986305B2Improve stabilityFixationSuture equipmentsInternal osteosythesisPosterior approachFixation method

A method of performing vertebral facet fusion by lateral approach and related devices. The lateral approach to facet fusion involves identifying the lateral mass and introducing any of the fixation methods known or described herein laterally at one or more facets through the use of a Kirschner wire guide, a cannulated bone drill and cooperatively cannulated staple guide. A surgical bone staple have a perforated bridge is used across the lateral facet joint where fixation is required. Where fusion is desired, a bone screw have lateral perforations of the shank is inserted through the cannulated staple guide and bridge perforation at the joint to promote fusion. A staple cap and graft container for overlay grafting may be utilized for additional fusion. The method involves less surgical time, reduced blood loss and discomfort for the patient as compared to the posterior approach.

Owner:AFLATOON KAMRAN +1

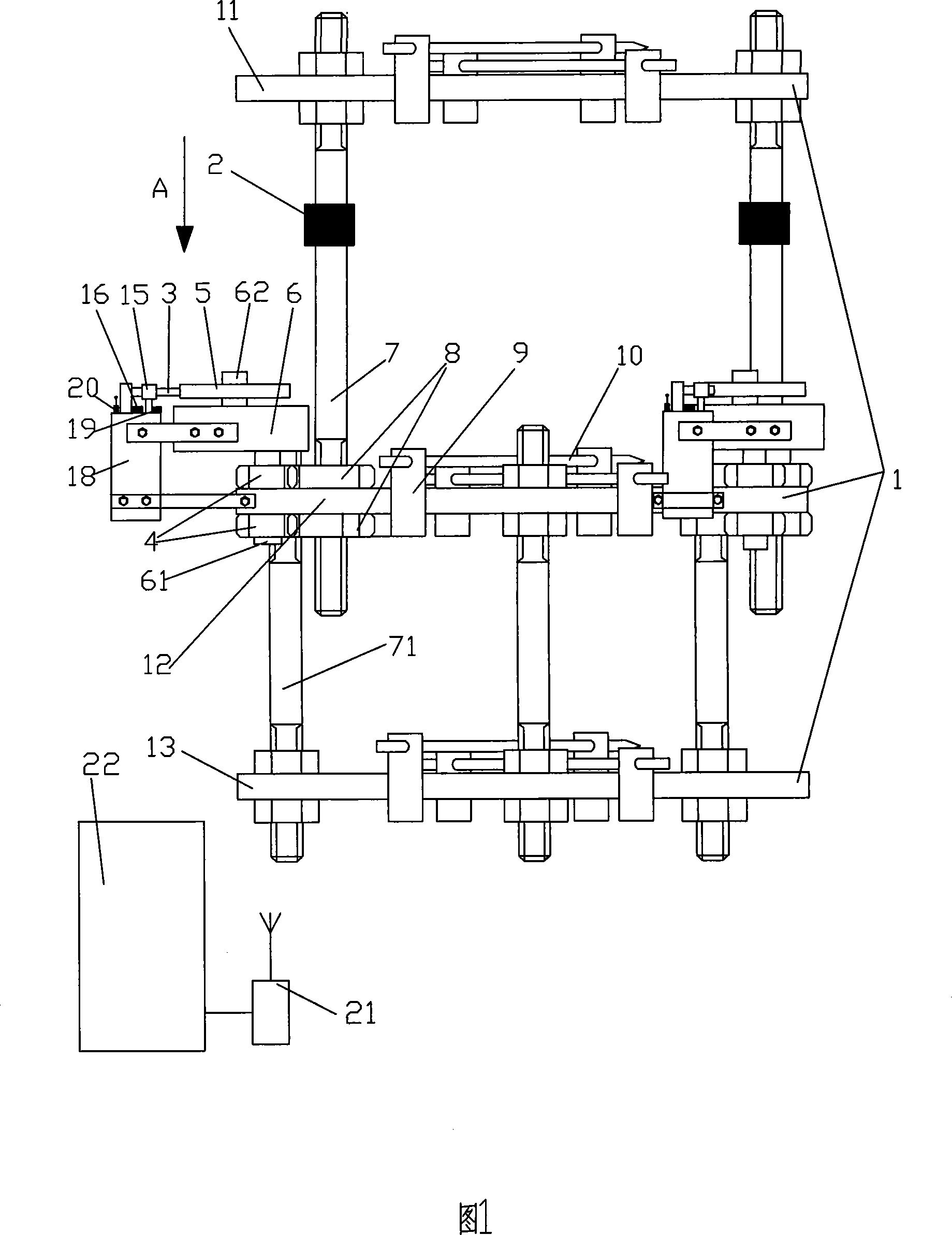

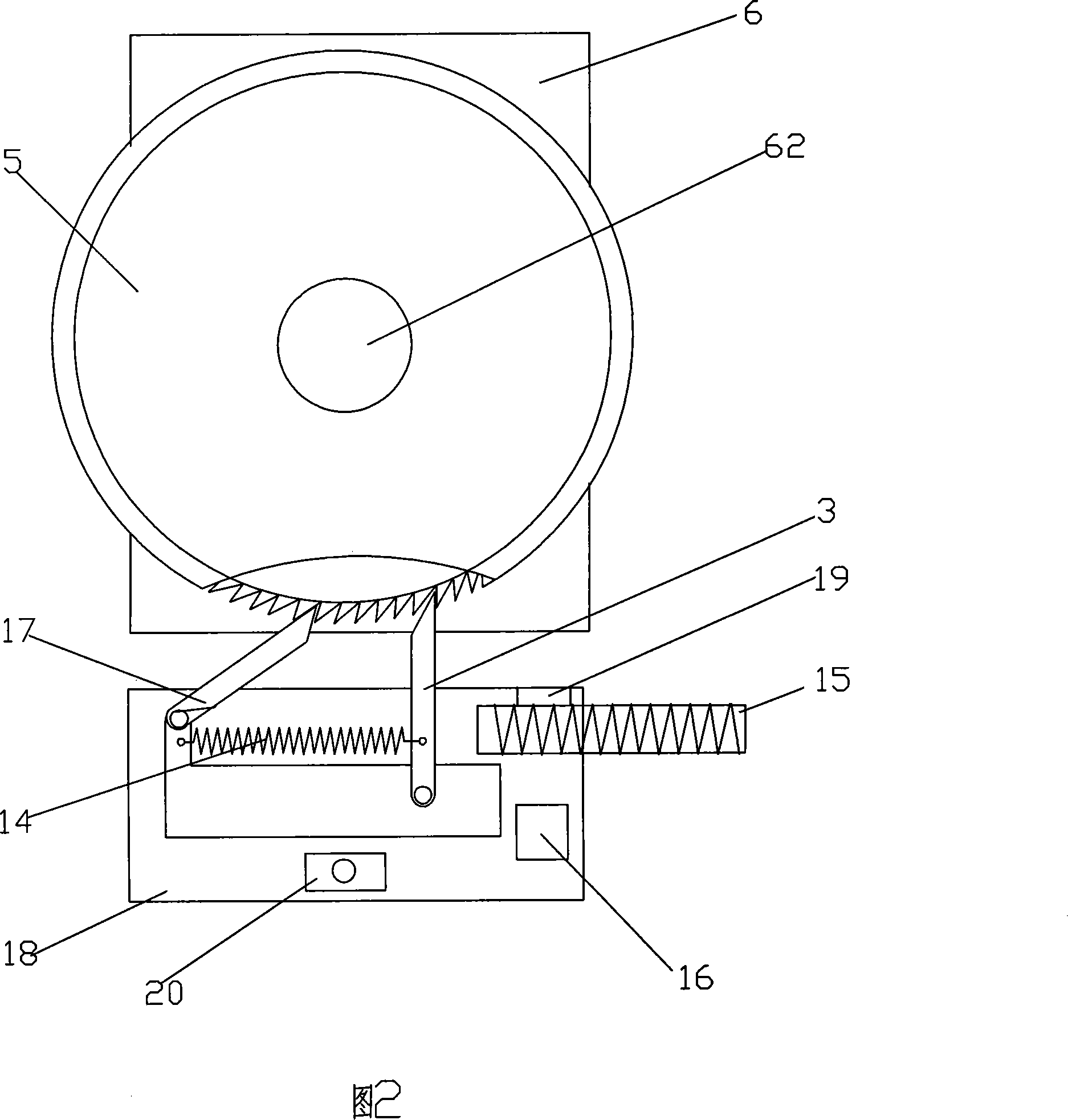

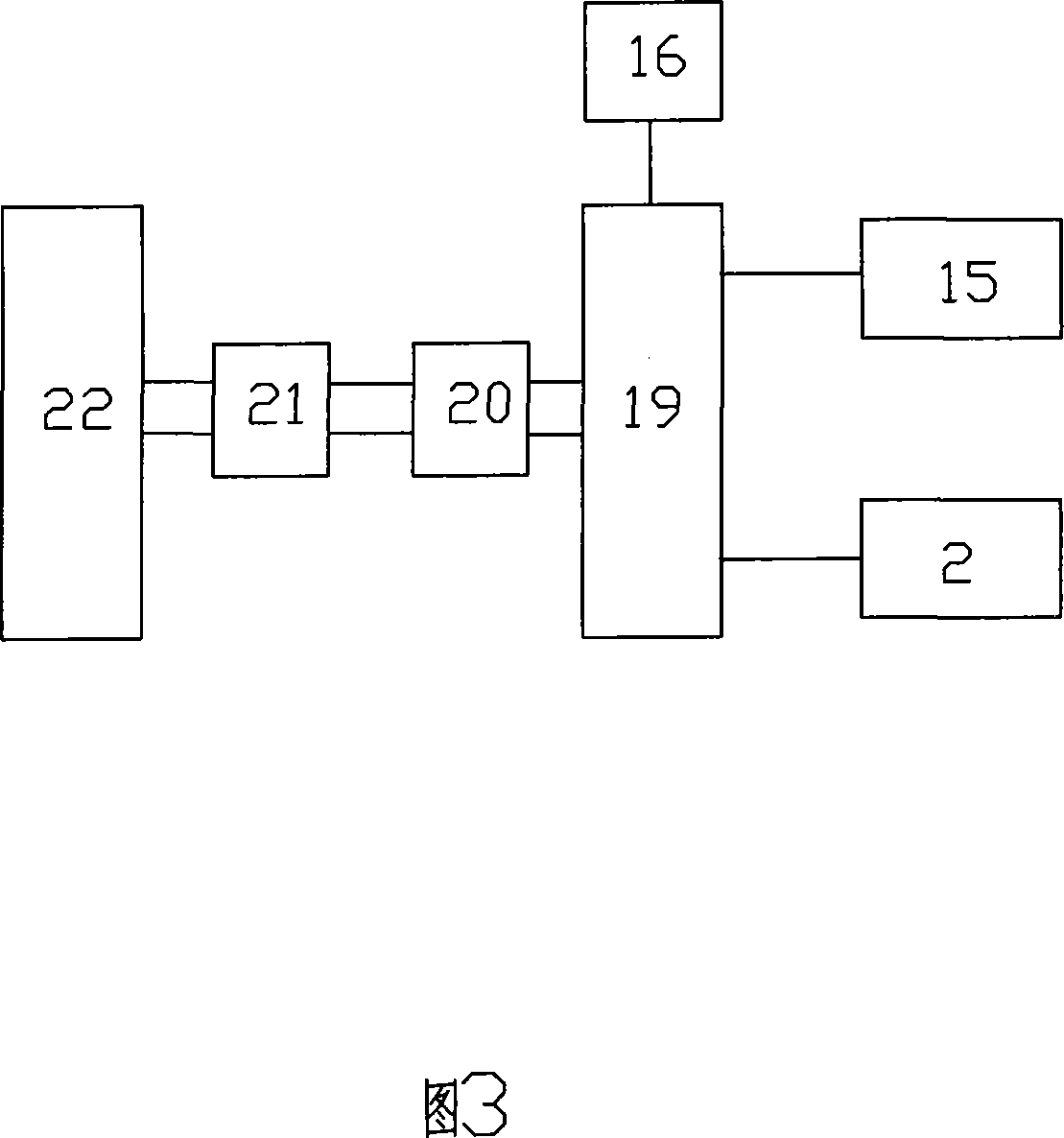

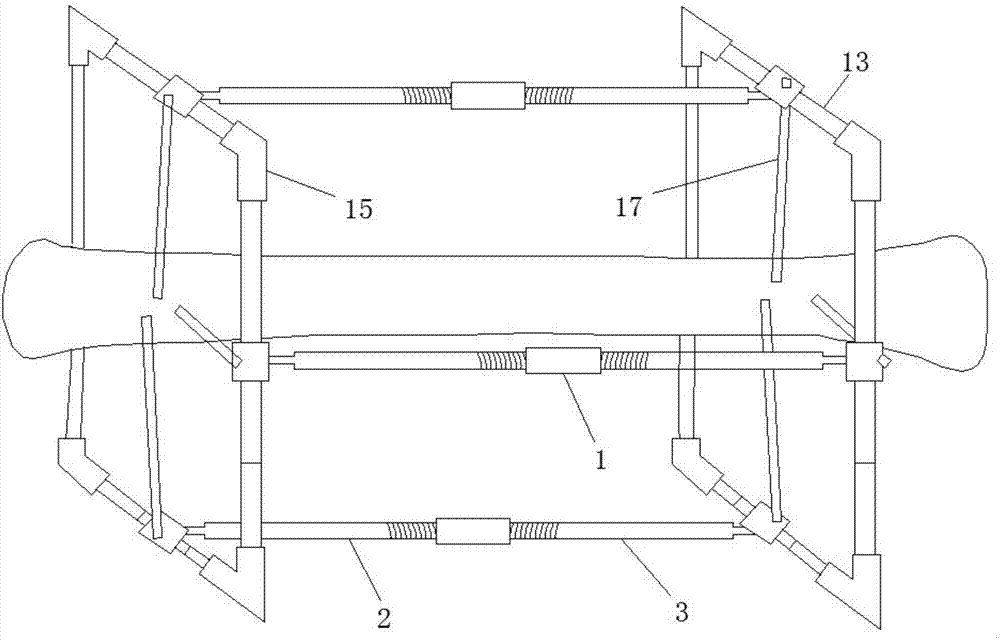

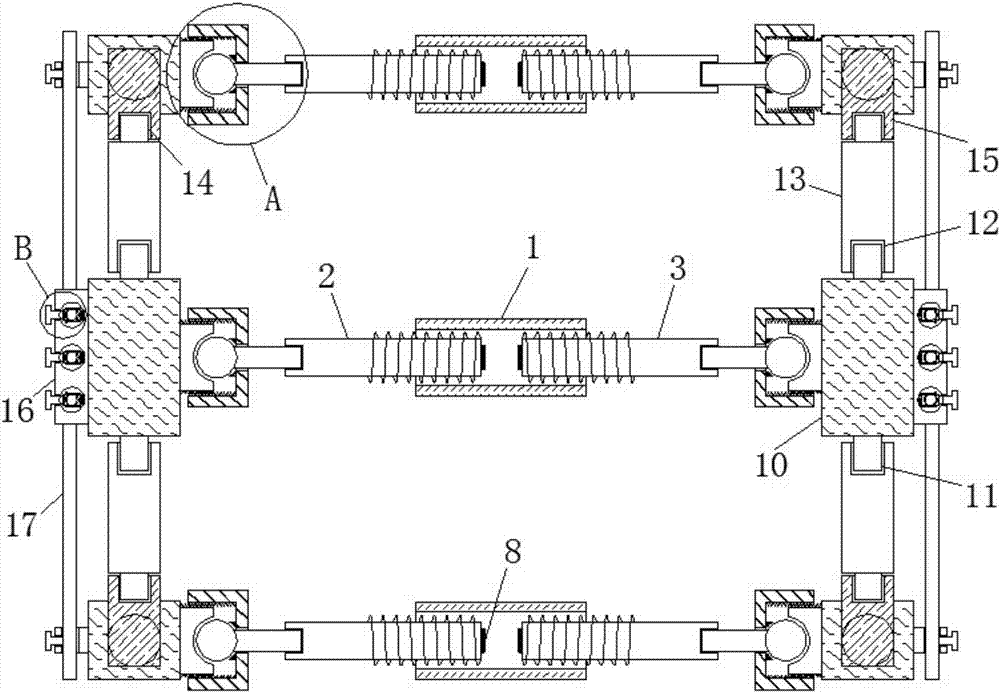

Self-adjusting orthopaedics external fixing device

InactiveCN101234036AEven by forceAvoid oppressionExternal osteosynthesisExternal fixatorAutomatic control

The invention discloses a self-adjusting orthopedic external fixator which comprises at least two fixing rings, a knighthead, an adjusting nuts positioned on the knighthead and used for fixing and adjusting the distance between the two retainers, a Kirschner wire, a thread needle fixture and a pressure sensor positioned on the knighthead as well as a driving system and a PLC automatic control system which are corresponding to the adjusting nuts; wherein, the driving system adopts a ratchet, a ratchet rod and a gear structure. The self-adjusting orthopedic external fixator of the invention controls and adjusts the relative position between the two retainers automatically, avoids errors caused by manual manipulation, ensures that all knightheads are uniformly forced and avoids deviation caused by disequilibrium of the knightheads; besides, the self-adjusting orthopedic external fixator has convenient operation, thus ensuring that the processes of fracture healing and bone lengthening are operated smoothly to improve efficiency and success rate of operation and alleviate the suffering of the sufferer.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

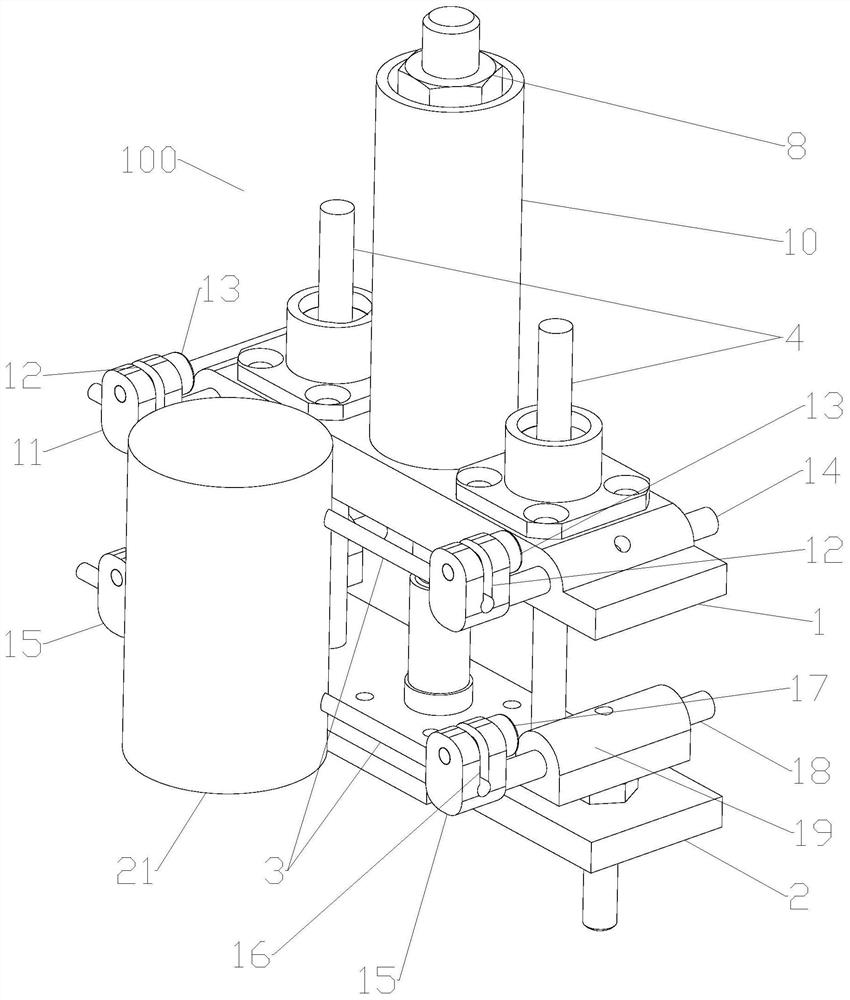

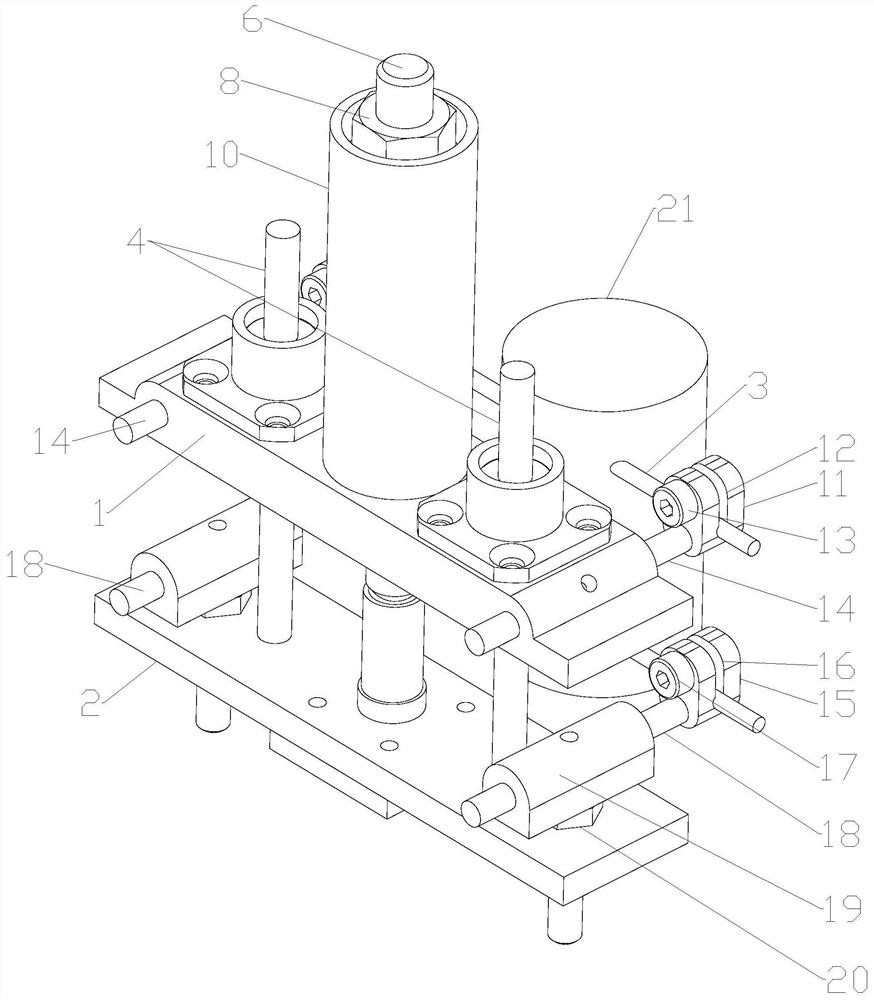

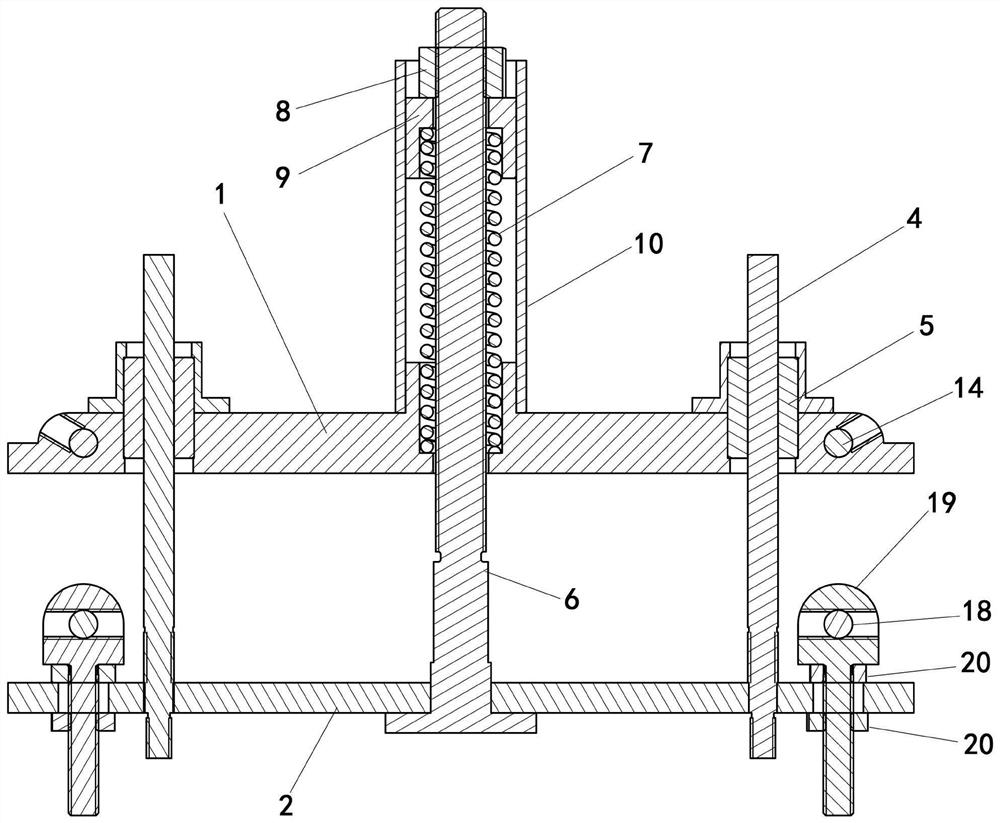

Spine motion segment in-vivo loading device

The invention discloses a spinal motion segment in-vivo loading device, which relates to the technical field of medical equipment, and comprises a first loading plate, a second loading plate, a sliding mechanism and a driving device, the first loading plate is provided with a first mounting seat for mounting a kirschner wire, the second loading plate is provided with a second mounting seat for mounting the kirschner wire, the first loading plate and the second loading plate are slidably connected through a sliding mechanism, and the driving device is used for driving the first loading plate and the second loading plate to be close to each other. During use, the kirschner wire on the first mounting seat penetrates through the upper section of the spine, the kirschner wire on the second mounting seat penetrates through the lower section of the spine, the first mounting seat and the second mounting seat are driven by the driving device to get close to each other, and axial loading can be performed on the spine; and therefore, a researcher can complete the research on the specific relation between the mechanical load and the iliac bone mass, the structure and the mechanical property.

Owner:WANGJING HOSPITAL OF CHINA ACAD OF CHINESE MEDICAL SCI

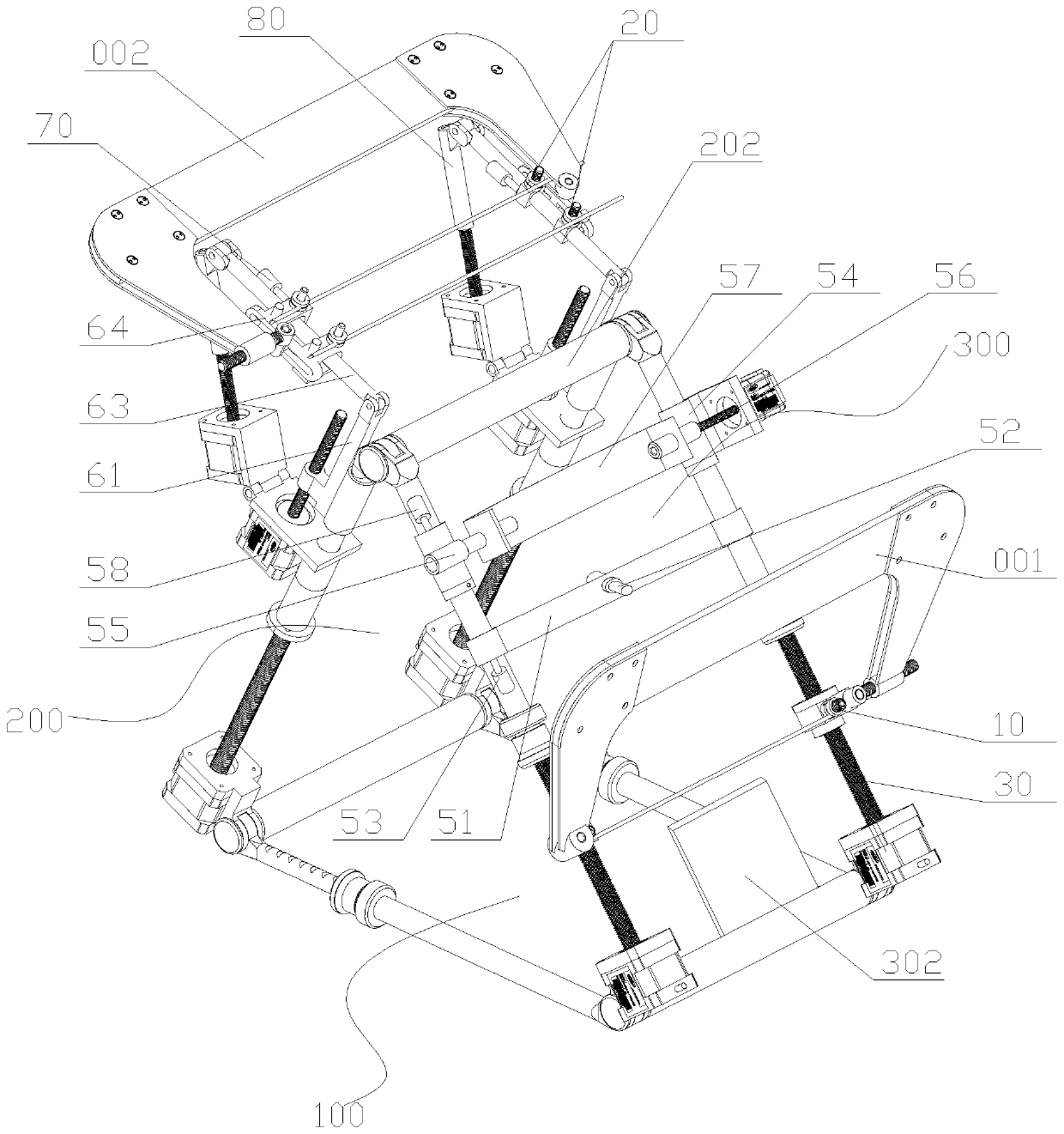

Automatic traction device for lower-limb fracture setting operation

PendingCN110916794AStable hold reset stateAngle adjustableOsteosynthesis devicesLower extremity fractureBearing surface

The invention discloses an automatic traction device for a lower-limb fracture setting operation. According to the invention, a supporting frame is of a triangular structure, is used for supporting alower limb of a patient to form and keep a leg bending state, and comprises a horizontally-arranged supporting bottom surface, and a thigh bearing surface and a shank bearing face which are oppositelyarranged two ends of the supporting bottom surface, wherein the end parts of every two adjacent surfaces are hinged; and the lengths of all the surfaces can be adjusted and locked through edge adjusting mechanisms. A tibia kirschner wire mounting position is provided with two tibia kirschner wire mounting structures which are respectively arranged at two sides of the shank supporting surface. Twothighbone kirschner wire mounting positions are arranged in parallel at an interval, and each thighbone kirschner wire mounting position is provided with two thighbone kirschner wire mounting structures which are respectively arranged at two sides of the thigh supporting surface.

Owner:THE THIRD HOSPITAL OF HEBEI MEDICAL UNIV +2

Combined type fracture restorer

The invention relates to the fracture restorer technical field, and specifically relates to a combined type fracture restorer; the left cavity of a nut is screwed with a forward spinning screw rod; the right cavity of the nut is screwed with a backward spinning screw rod; a compaction rod is plugged in a second through hole; the top and bottom of a first press block are respectively connected with a boss; one side, far away from the second through hole, of the boss is connected with a third straight rod; the first press block and a second press block are arranged on two sides of a Kirschner wire. The combined type fracture restorer can be freely mounted / dismounted according to needs, can restore long bone fractures and arms and legs surrounding fractures, and different parts can be combined so as to realize long bone linear mode restoration and joint surrounding fracture right angle mode restoration; the combined type fracture restorer is simple and easy to operate, and needs no special training; the parts are simple in design and easy to use, and no special training is needed; the combined type fracture restorer is low in cost, and suitable for primary hospitals.

Owner:唐佩福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com