Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5099 results about "Impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impact toughness is the ability of a weld to permanently deform while absorbing energy before fracturing, specifically when stress is applied rapidly—typically, in under one second. In simpler terms, it’s how much rapid-impact energy a weld can take before it cracks.

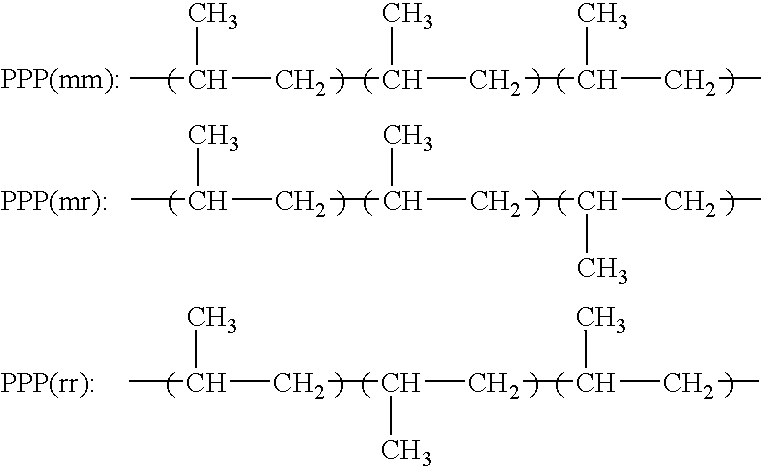

Plasticized hetero-phase polyolefin blends

InactiveUS20080045638A1Increase stiffnessImprove impact toughnessPigment pastesPolyolefinHigh stiffness

This invention relates to hetero-phase polyolefin compositions comprising: a) 30 to 99.7 wt % of a polypropylene-based TPO comprising at least 50 wt % propylene and at least 10 wt % ethylene, and b) 0.1 to 20 wt % of one or more non-functionalized plasticizer, and c) 0.2 to 50 wt % of one or more filler; based upon the weight of the composition, and having: i) an MFR of 5 dg / min or more, and ii) a flexural modulus of 500 MPa or more, and iii) a notched Charpy impact strength at −30° C. of 1 kJ / m2 or more or a notched Izod impact strength at −18° C. of 50 J / m or more.These compositions are especially useful in applications such as automotive parts that demand both high stiffness and high impact toughness, as well as good processibility during fabrication.

Owner:EXXONMOBIL CHEM PAT INC

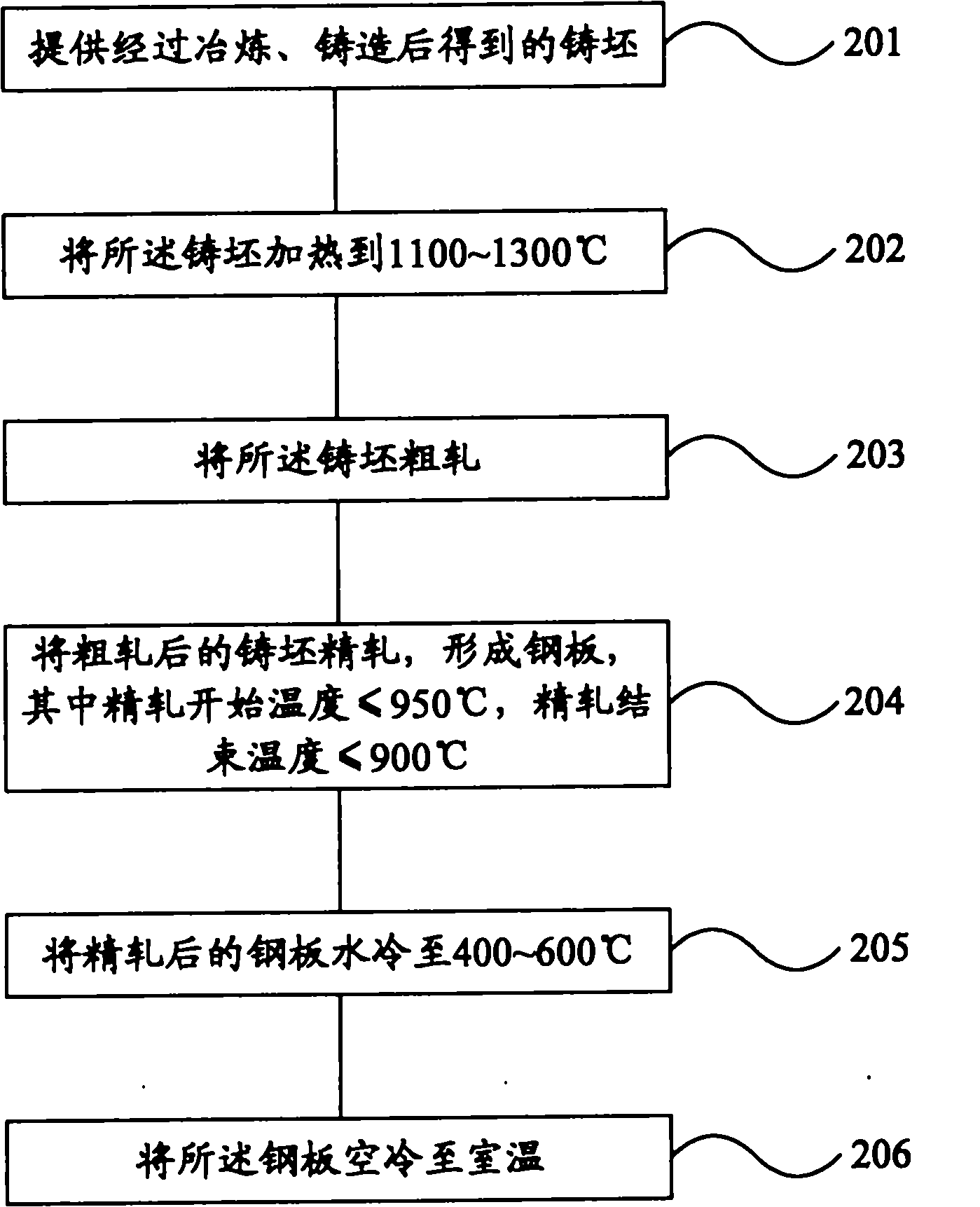

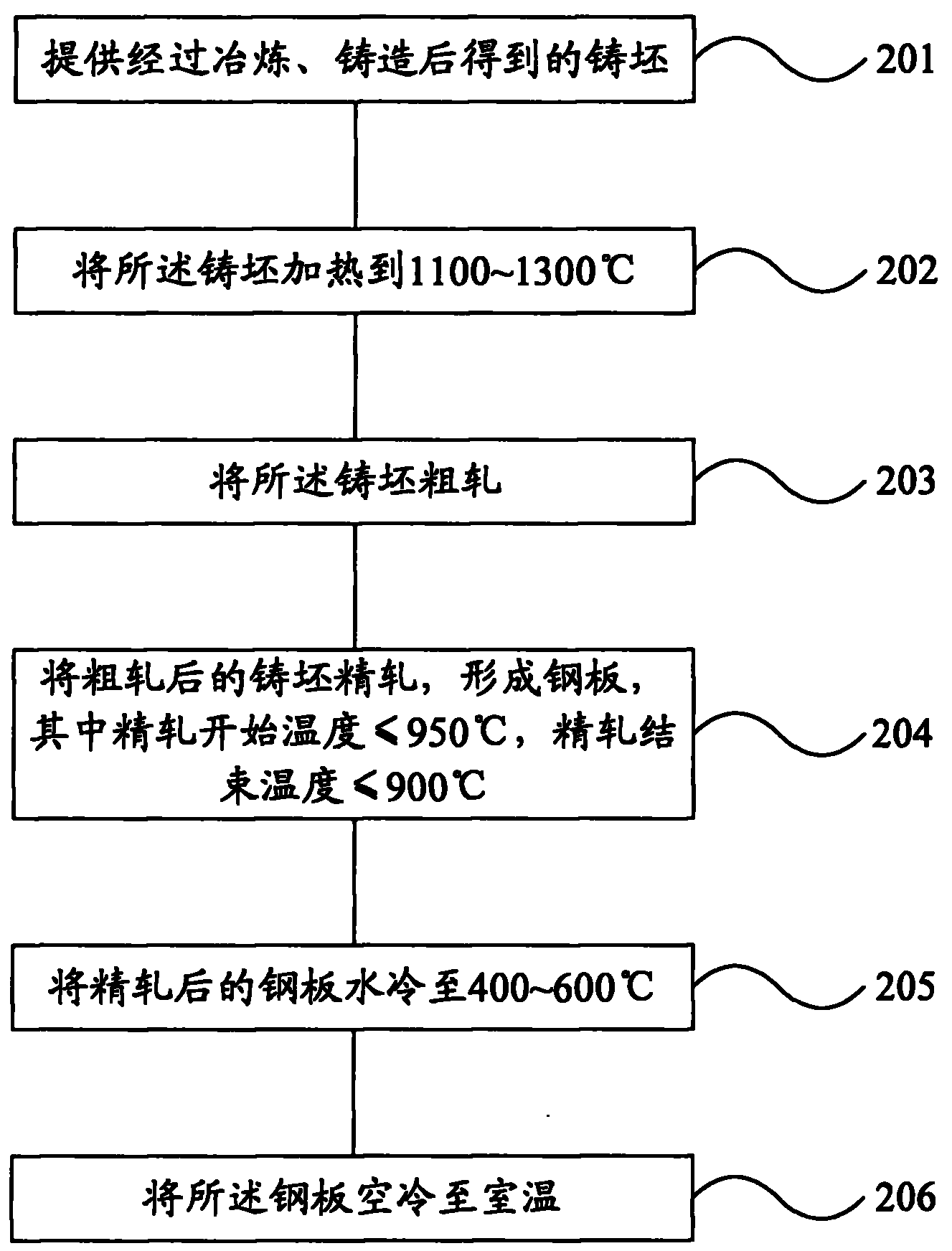

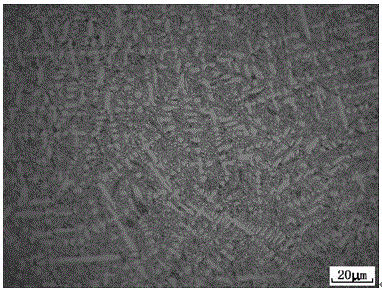

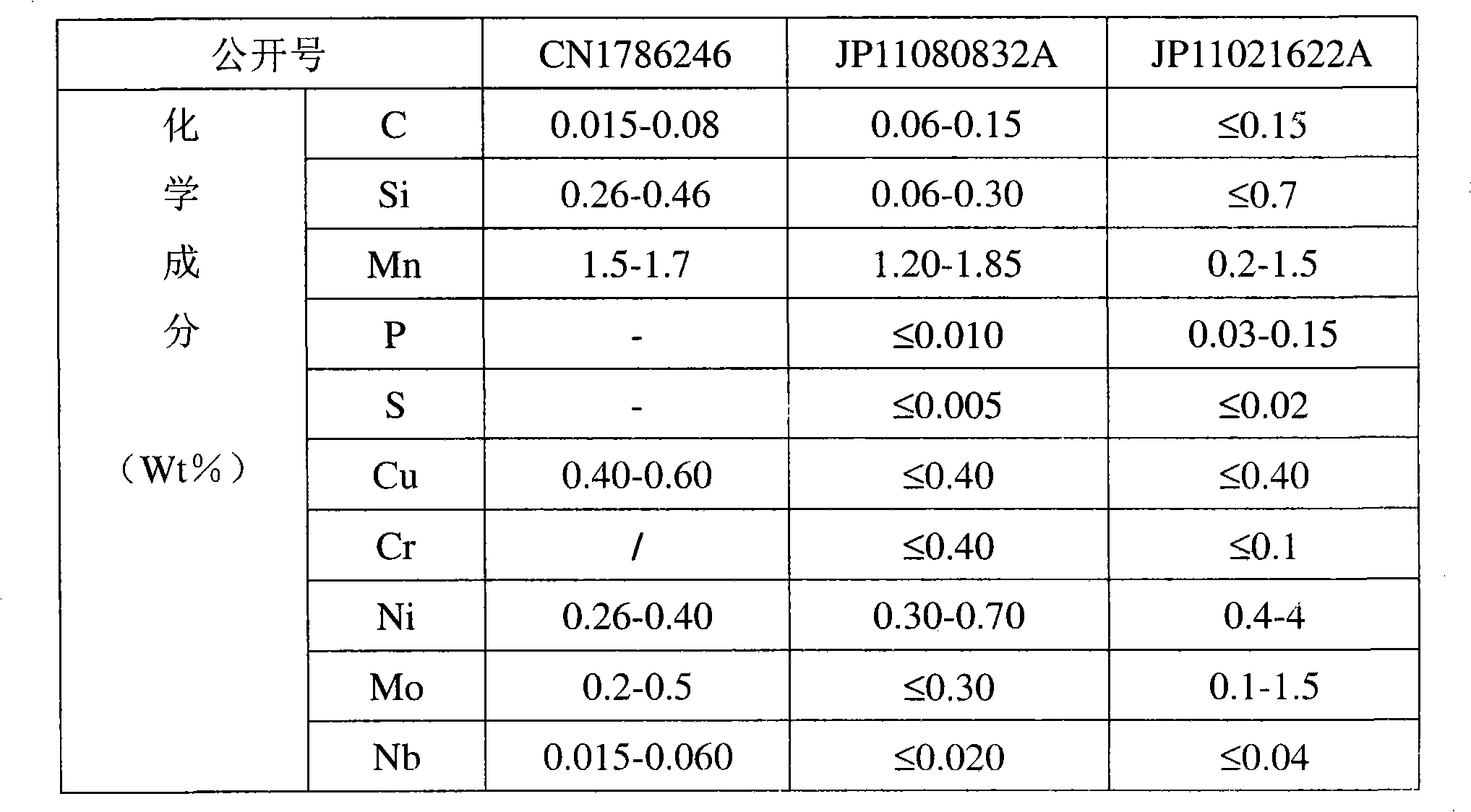

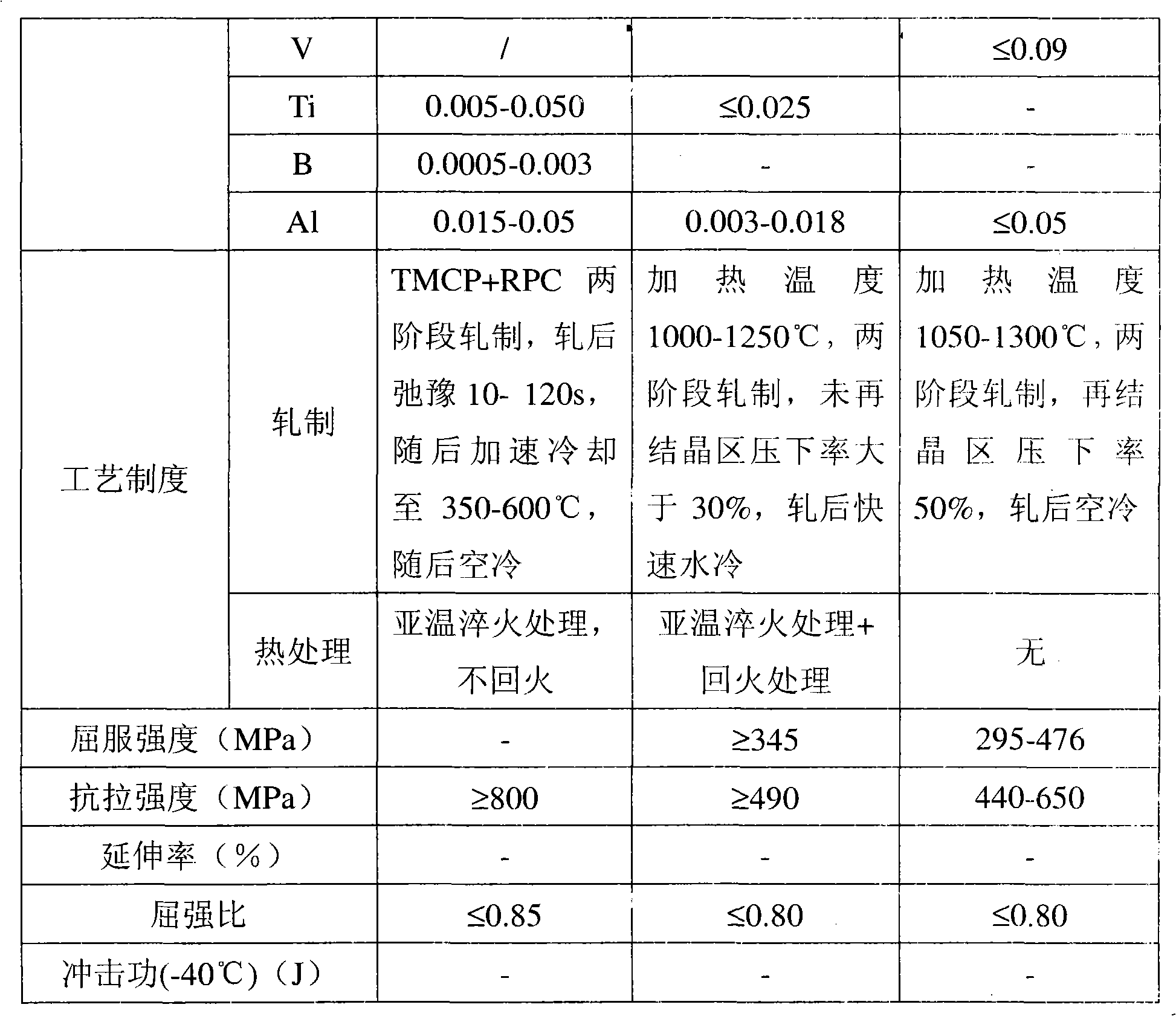

Weather resistant steel plate and manufacturing method thereof

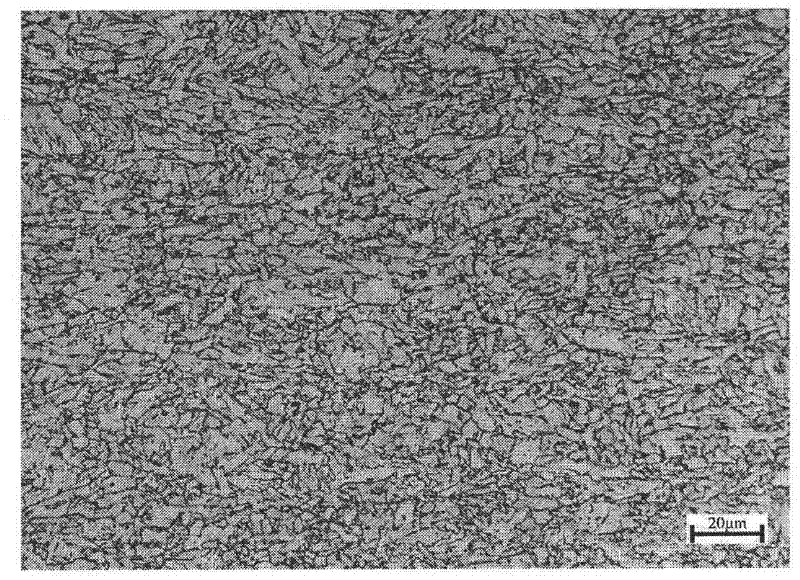

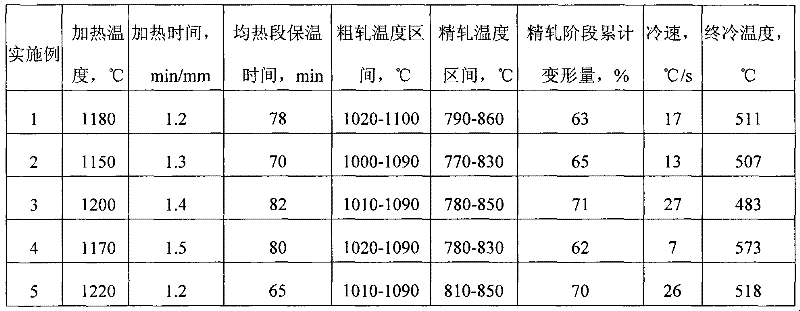

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

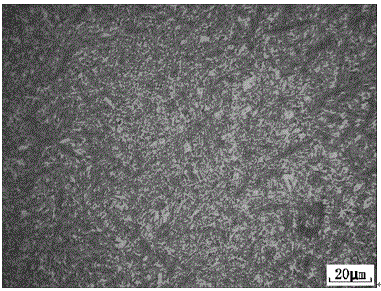

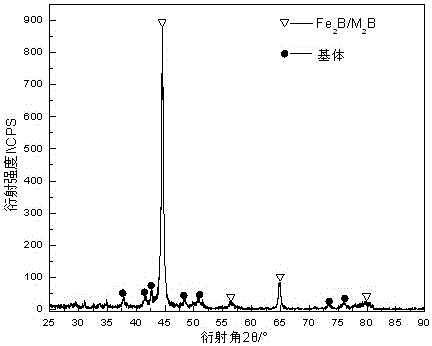

An amorphous/nanocrystalline matrix high-hardness wear-resistant and corrosion-resistant alloy and its preparation method

The invention provides a high-hardness, wear-resistant and corrosion-resistant alloy of an amorphous / nanocrystal matrix and a preparation method of the high-hardness, wear-resistant and corrosion-resistant alloy. The high-hardness, wear-resistant and corrosion-resistant alloy of the amorphous / nanocrystal matrix comprises the following elements in percentages by mass: 9.0-12.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, less than 0.3 of Mn, less than 0.07 of Si, less than or equal to 0.01 of S and P, and the balance of Fe, wherein the sum of C and B is 3.3-3.6; the content ratio of C / Cr is 0.06-0.08; and the sum of Nb and V is 0.5-1.0. Through multi-component alloying, an eutectic composition is formed, the melting point is low, fluidity is good, requirements of a casting technology are simple, large wear-resistant and corrosion-resistant castings can be cast, and small precision wear-resistant and corrosion-resistant castings can also be produced. The hardness of the alloy is HRC66-70, and impact toughness of the alloy is 4-9 J / cm (2).

Owner:广州市信纳德生物科技有限公司

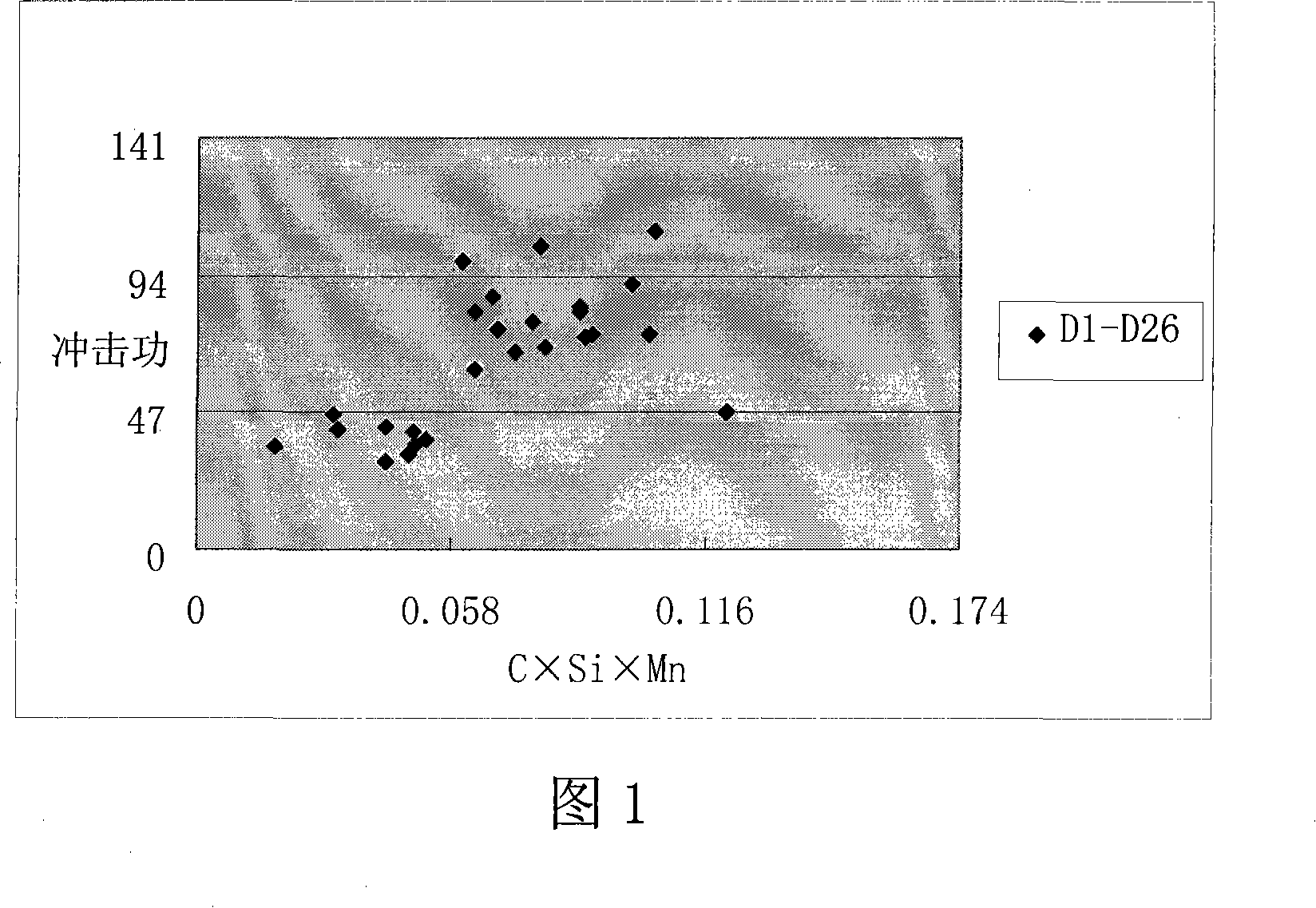

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

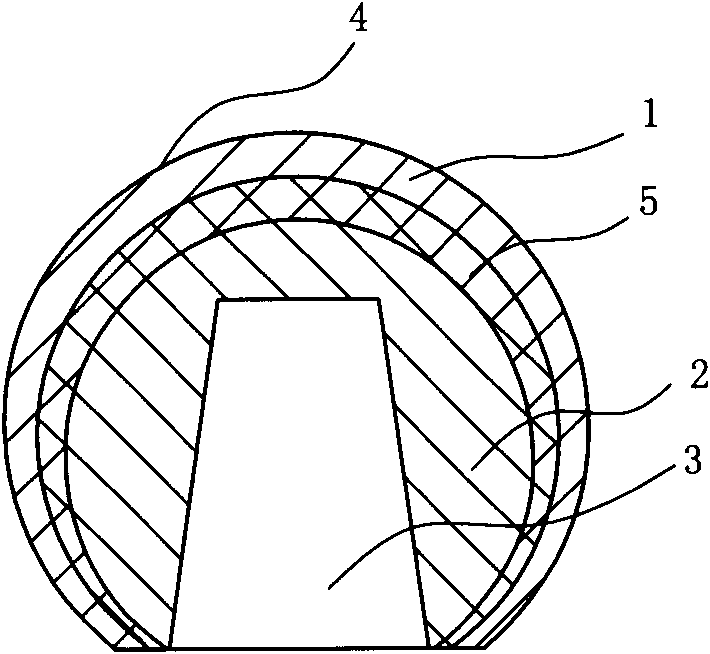

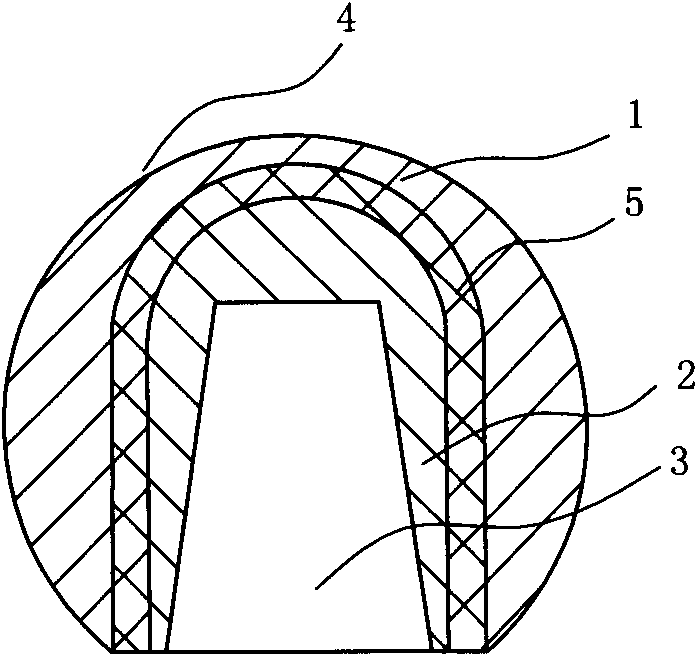

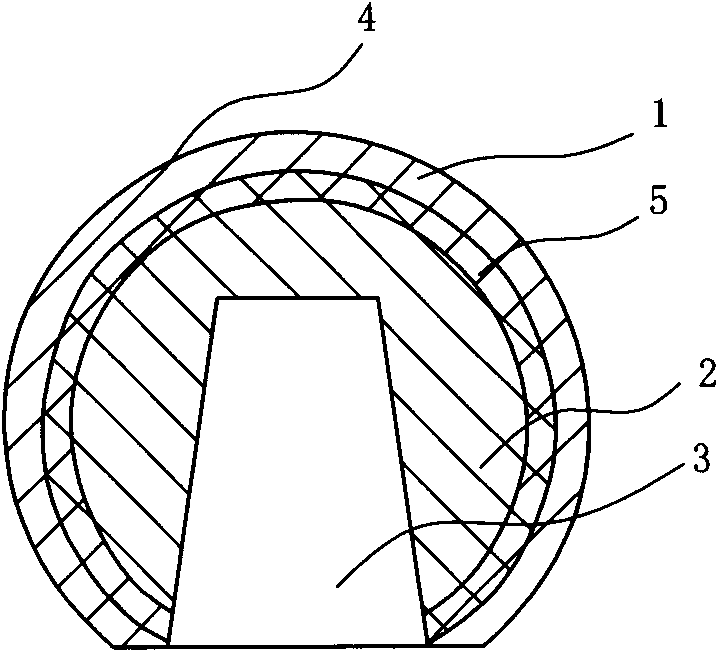

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

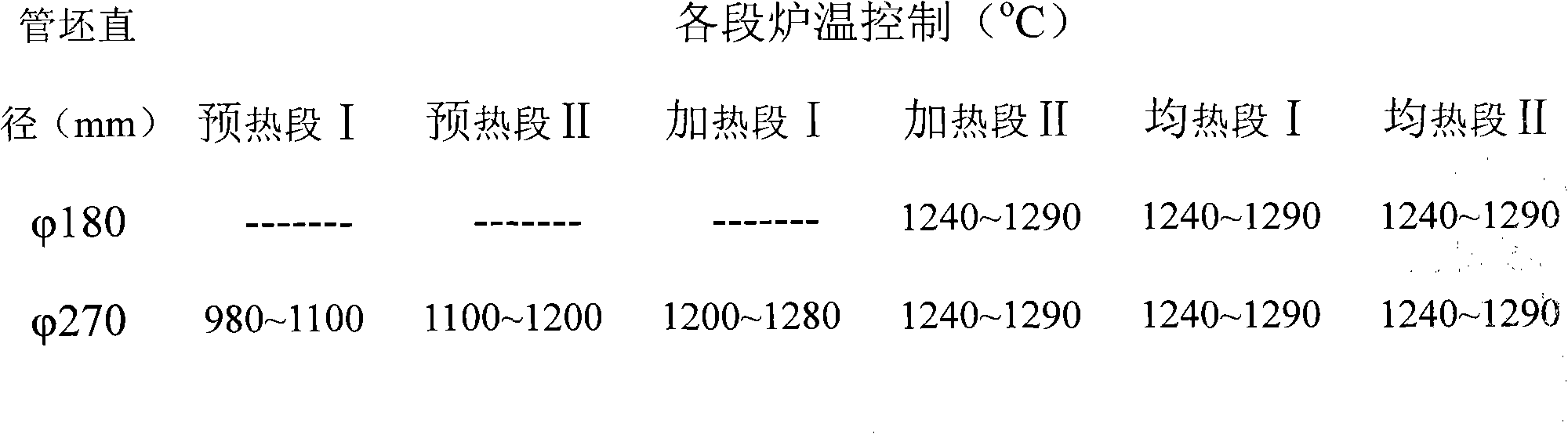

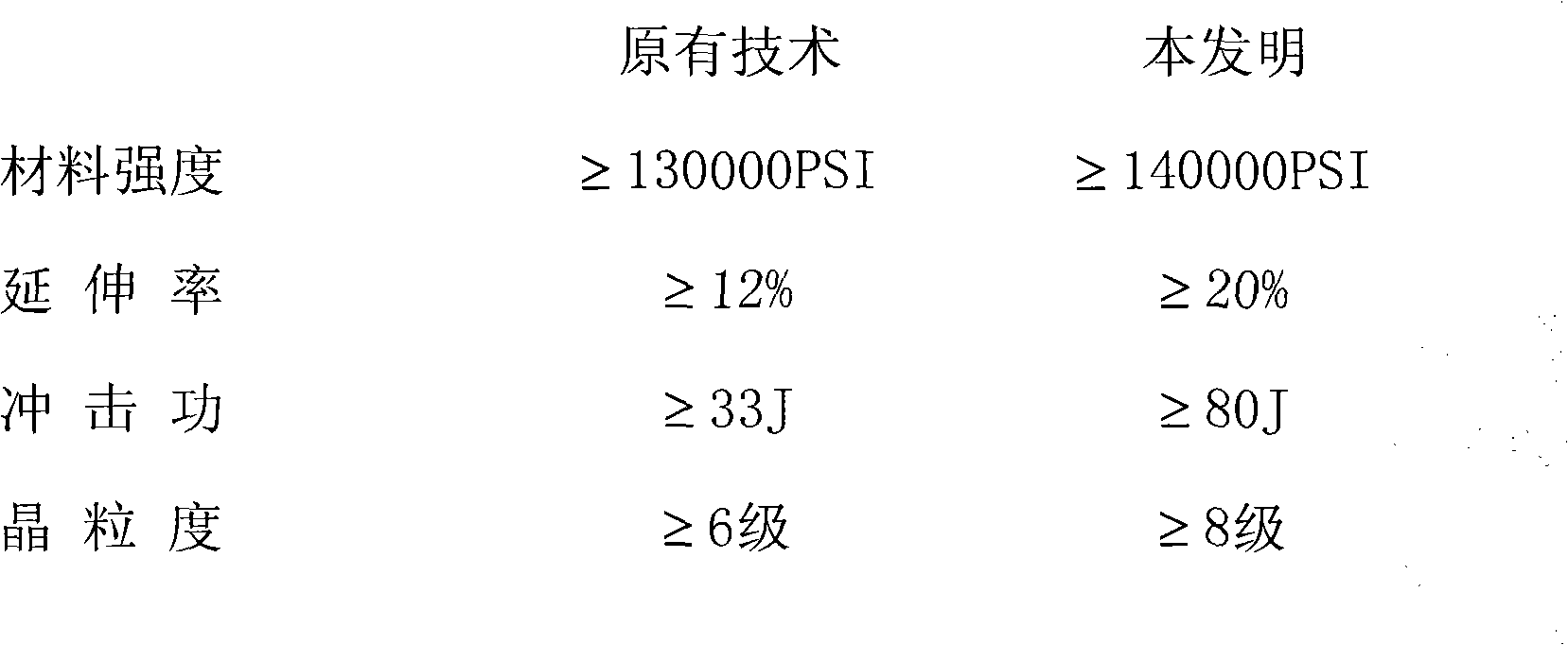

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

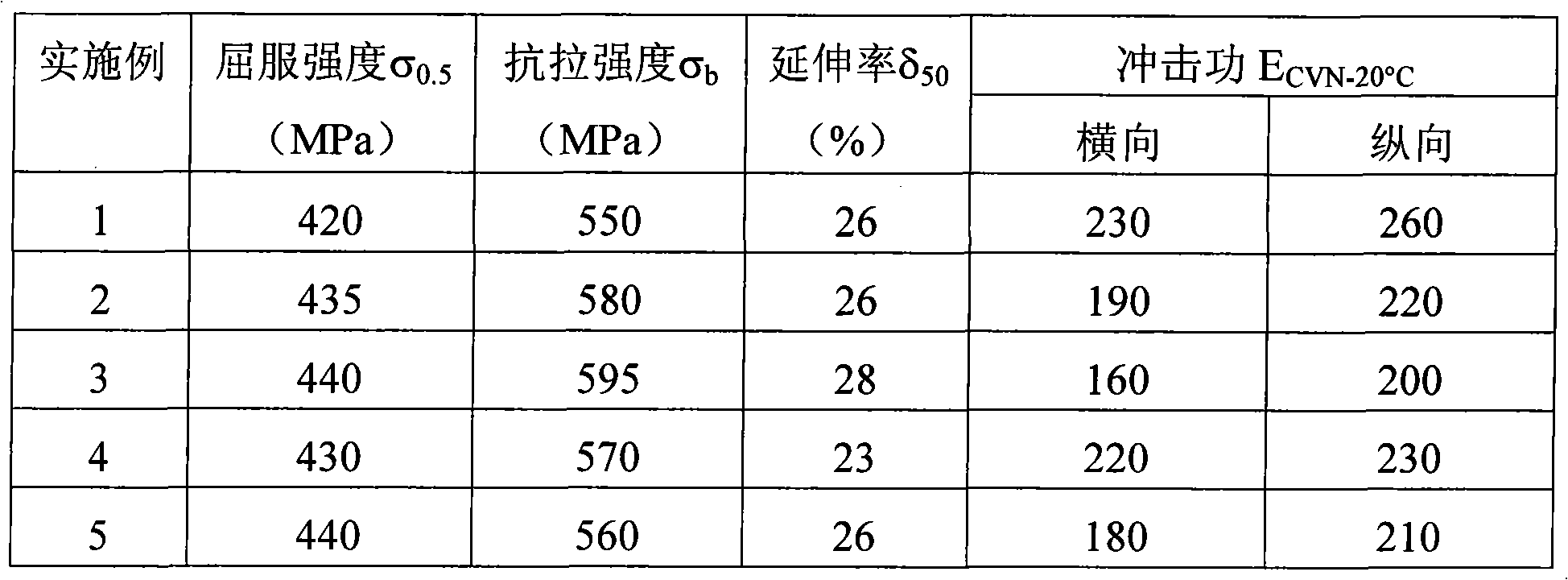

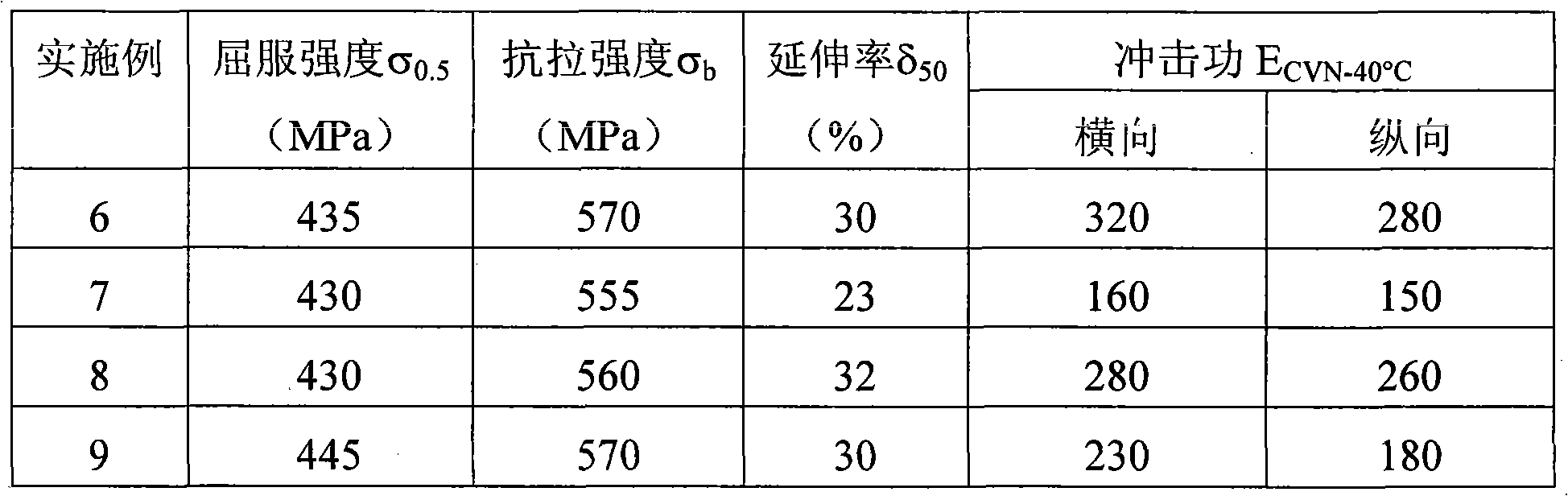

Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

ActiveCN102409224AGuaranteed toughnessSuitable for solderabilityRoll mill control devicesMetal rolling arrangementsHydrogenChemical composition

The invention provides a hot rolled steel plate with excellent low-temperature toughness for a thick submerged pipeline and a production method of the hot rolled steel plate. The hot rolled steel plate comprises the following chemical components by weight percentage: 0.02%-0.07% of C, 0.15%-0.40% of Si, 1.0%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.003% of S, less than or equal to 0.06% of Nb, less than or equal to 0.025% of Ti, less than or equal to 0.06% of V, less than or equal to 0.20% of Mo, less than or equal to 0.25% of Cu, 0.10%-0.30% of Ni, less than orequal to 0.25% of Cr, less than or equal to 0.008% of N, 0.010%-0.040% of Al, more than or equal to 2 of Al / N and the rest Fe and inevitable impurities. According to the steel for the submerged pipeline with the thickness being over 28mm, disclosed by the invention, the transversal and longitudinal bending strength can reach over 480MPa or 510MPa, the transversal and longitudinal tensile strengthcan reach over 560MPa or 600 MPa, the transversal impact toughness at the temperature of 60 DEG below zero is larger than or equal to 400 J, the transversal DWTT (Drop-Weight Tear Test) shearing areaat the temperature of 25 DEG C below zero is larger than or equal to 85%, simultaneously, the corrosion resistant of the steel plate is excellent, and the result of a 96-hour HIC (Hydrogen Induced Cracking) test conforms to the requirements of the standard 0284 of the NACE (National Association of Corrosion Engineers). The hot rolled steel plate is suitable to be as a raw material for manufacturing a pipeline for submerged oil and gas transmission.

Owner:ANGANG STEEL CO LTD

High-strength easy-formation atmospheric corrosion resisting steel

The invention relates to high strength easily forming atmospheric corrosion resistant steel. The invention provides the high strength easily forming atmospheric corrosion resistant steel aiming at the problems in existing steel that the weatherability is bad and the service life is lowered under the condition that the thickness is thinned. The high strength easily forming atmospheric corrosion resistant steel is composed of components of following weight percent: C: 0.04-0.09%, Si: 0.10-0.50%, Mn: 1.20-1.70%, P: <=0.020%, S: < =0.010%, Cu: 0.20-0.60%, Cr: 0.40-0.80%, Ni: 0.20-0.50% and Nb: 0.03-0.07%, and also comprises one or a plurality of Mo: <=0.20%, Ti: <=0.03% and Als: <=0.035%, and allowance is Fe and unavoidable impurity. The yield strength of the steel of the invention is more than or equal to 550MPa, the tensile strength is more than or equal to 650MPa, the percentage elongation is more than or equal to 18%, the corrosion resistance is equivalent to SPA-H steel which is used for previous containers, and the steel has excellent welding performance, cold roll forming performance and low temperature impact toughness, which is beneficial for extending and applying.

Owner:武钢集团有限公司

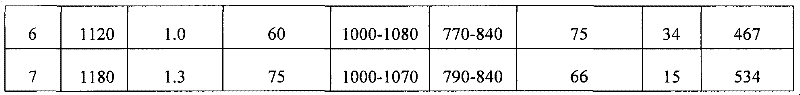

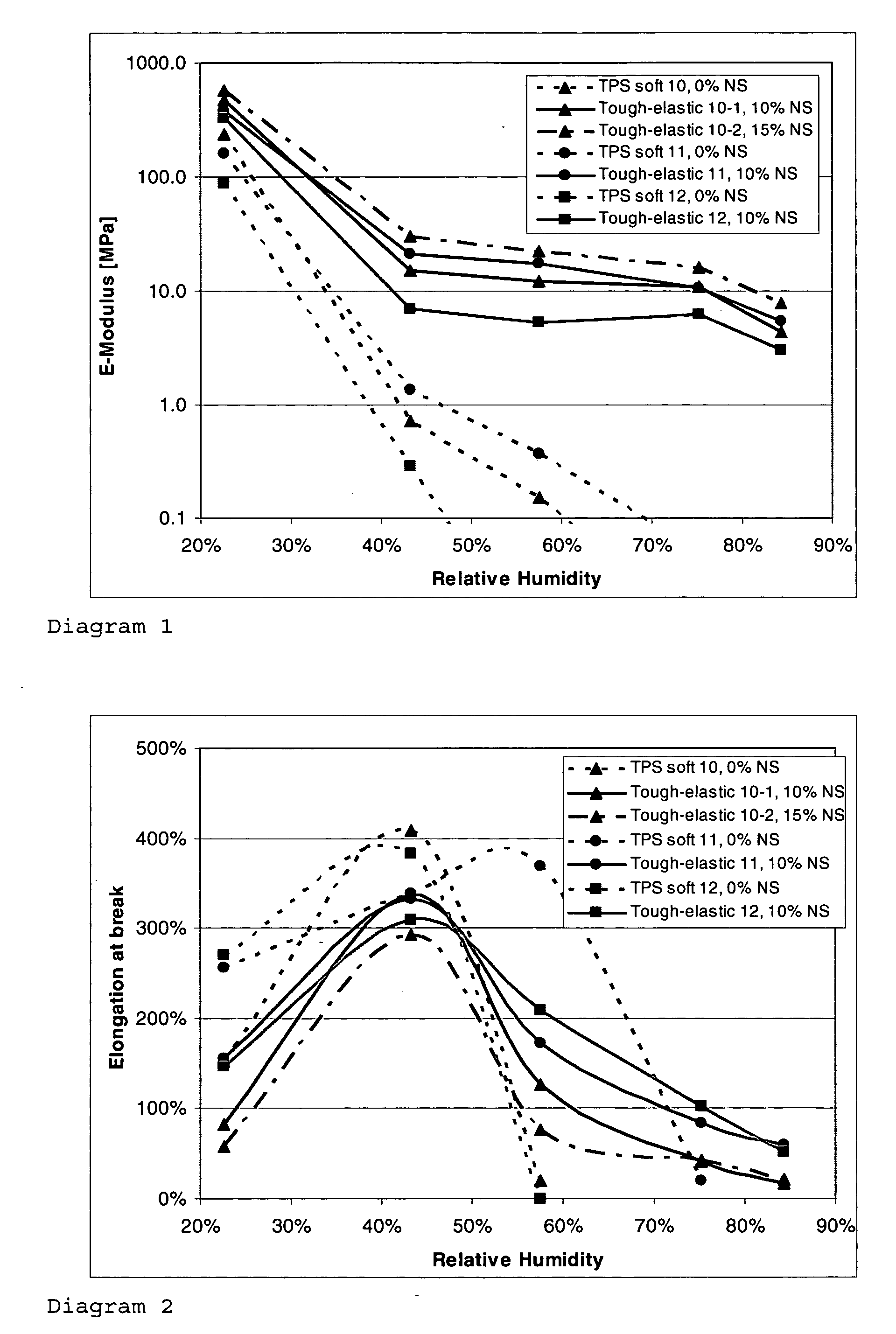

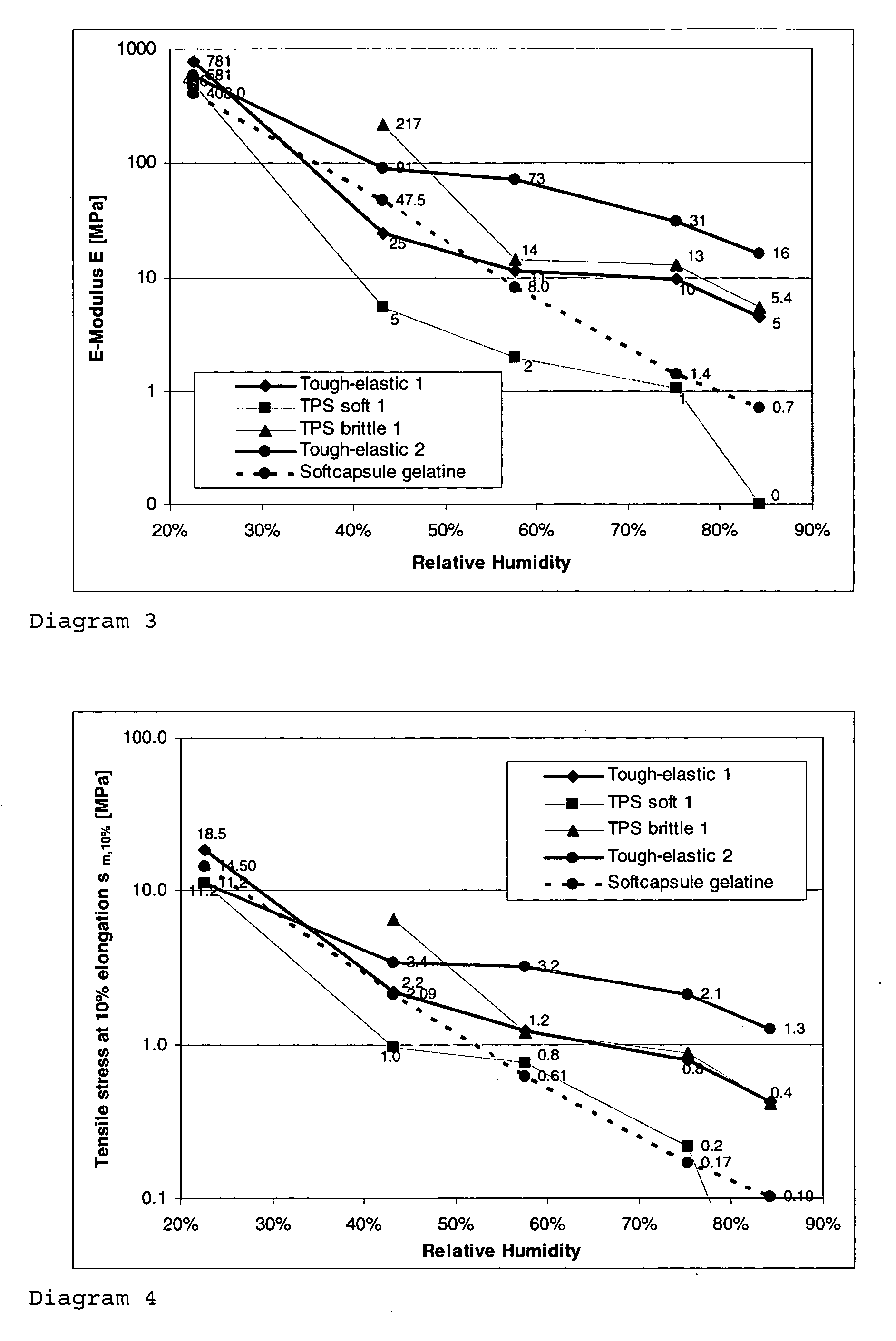

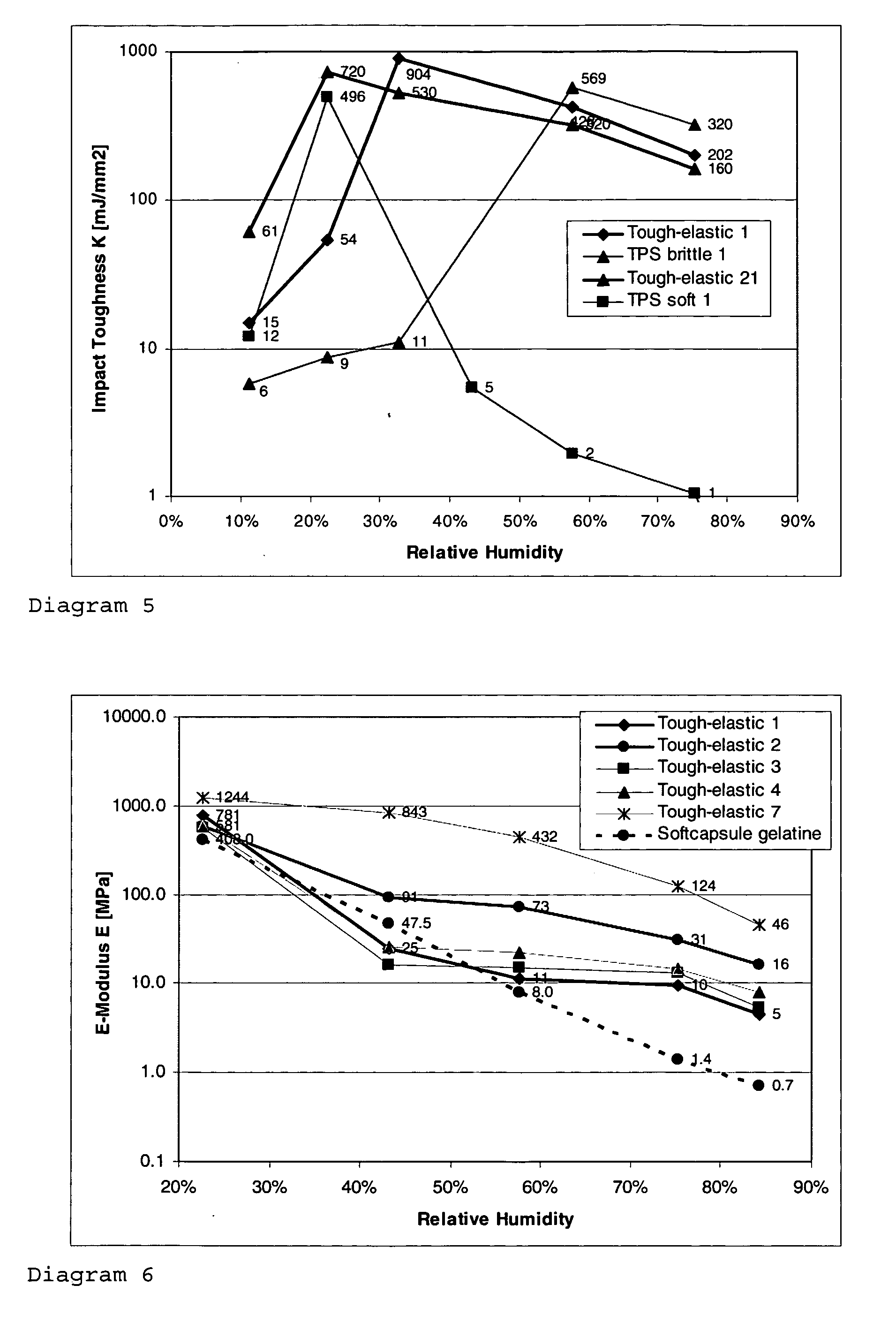

Viscoelastic material

InactiveUS20060004193A1Increase chain lengthSimplify discussionCapsule deliveryHigh humidityHard Capsule

The invention relates to a tough-elastic material based on starch, which on the one hand has high impact toughness at low humidities, and on the other hand still has a high modulus of elasticity at high humidities and has a high elongation capacity in a broad range of humidities and on account of its property profile is suited to use as moulded elements such as for example for foils, films, fibres, injection-moulded articles, in particular as edible film and for the packaging of active ingredients, chemicals, aromas and perfumes as well as high-quality substitution of gelatine in the area of soft and hard capsules. The tough-elastic material can be obtained transparent and adjusted such that it dissolves on swelling in water or respectively disintegrates or remains intact.

Owner:INNOGEL AG

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

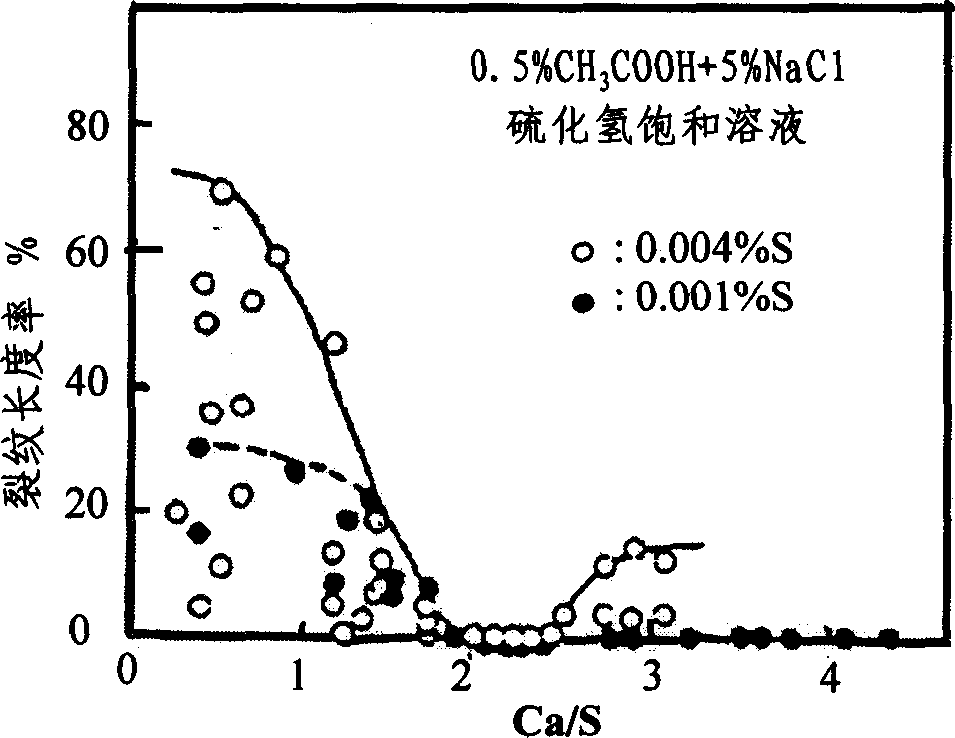

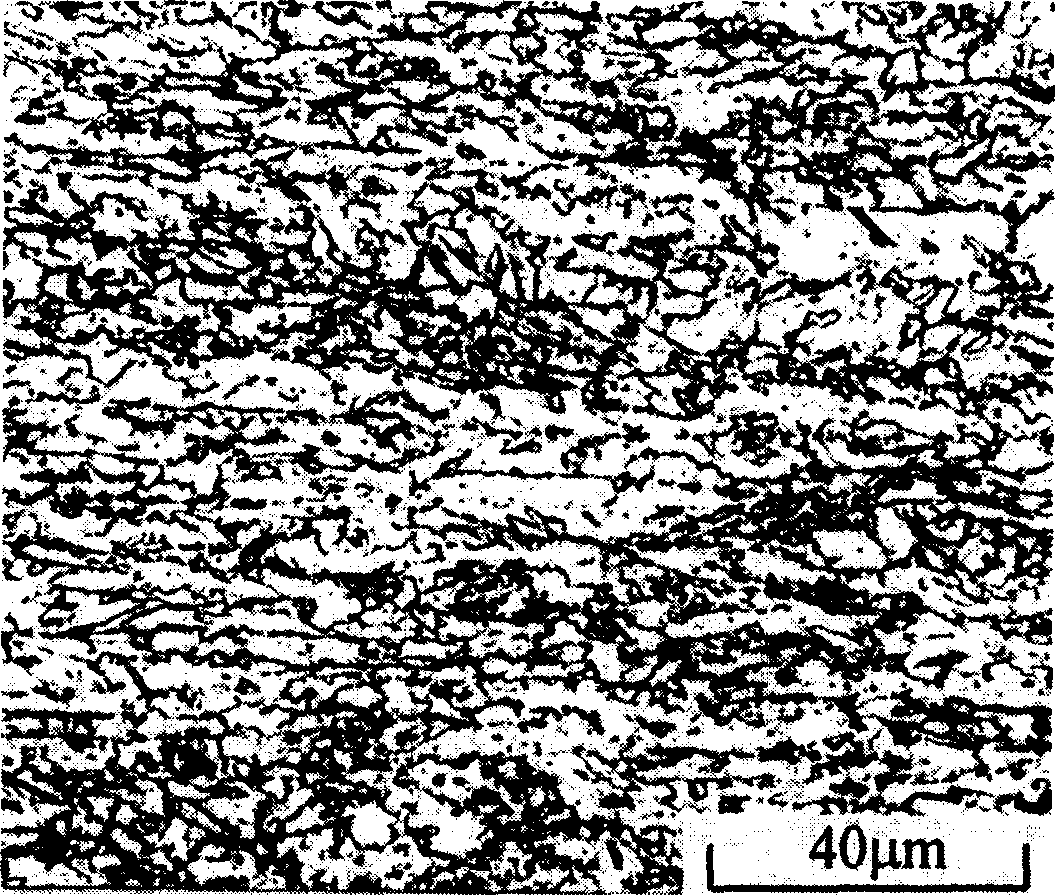

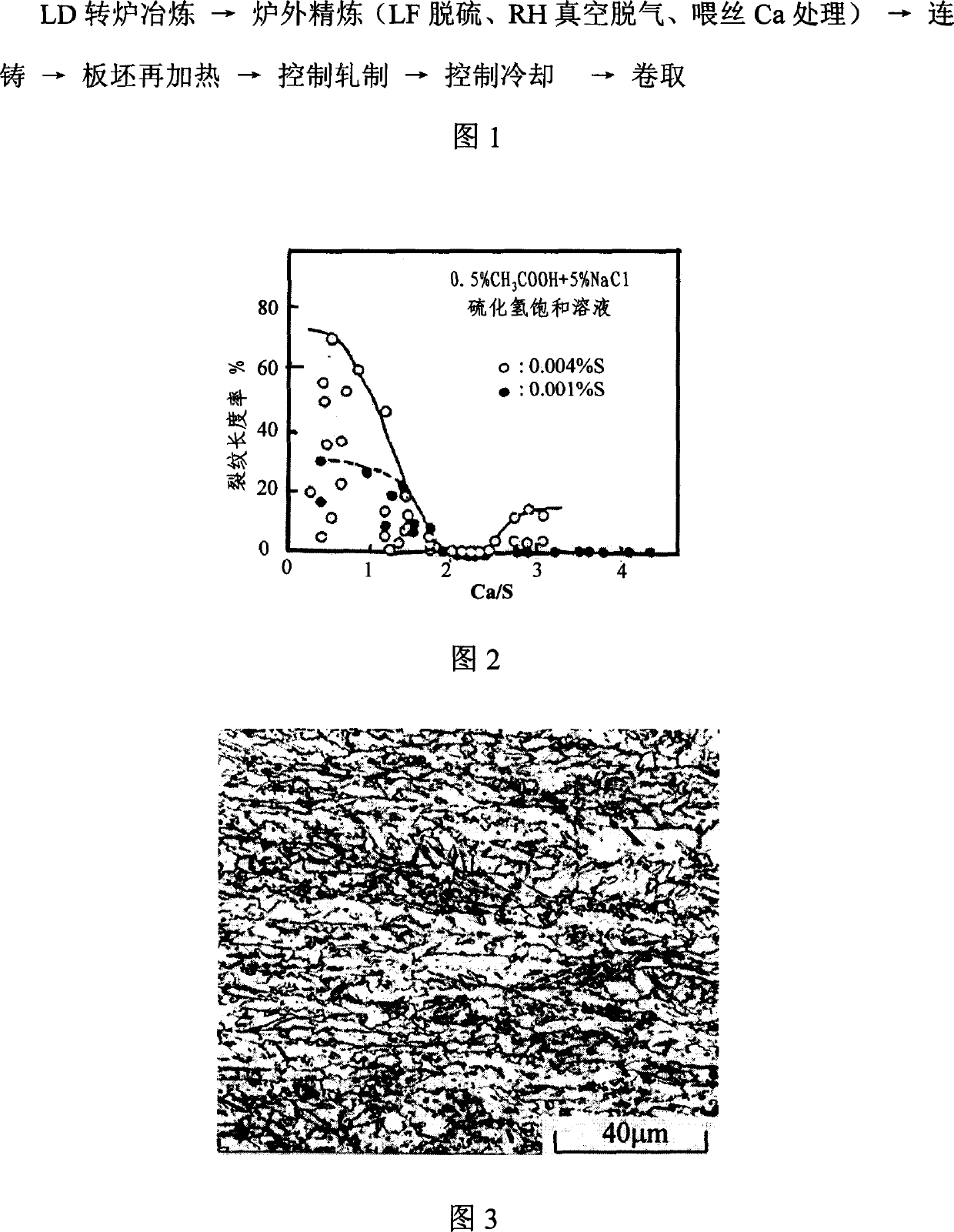

X65 pipeline steel for use in acid condition and its making process

ActiveCN1811002AImprove the effect of controlled rollingImproved dynamic tear resistanceManufacturing convertersProcess efficiency improvementMetallurgyTear resistance

The X65 pipeline steel for use in acid condition consists of C 0.02-0.05 wt%, Mn 1.20-1.50 wt%, Si 0.10-0.50 wt%, S not more than 0.0020 wt%, P 0.004-0.012 wt%, Nb 0.05-0.07 wt%, Ti 0.005-0.025 wt%, Mo 0.050-0.195 wt%, Cu not more than 0.35 wt%, Ni not more than 0.35 wt%, N not more than 0.0080 wt%, Ca 0.0015-0.0045 wt% and Ca / S not less than 2.0 except Fe. Its making process includes the following steps: smelting in a converter or an electric furnace; secondary steel making including LF desulfurizing + RH vacuum deairing and Ca treatment; continuous casting; rolling with initial rolling termination temperature of 940-1020 deg.c and finish rolling termination temperature of 780-840 deg.c; and winding at 500-580 deg.c. The X65 pipeline steel has low manufacture cost, high HIC resistance, high dynamic tear resistance and high impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

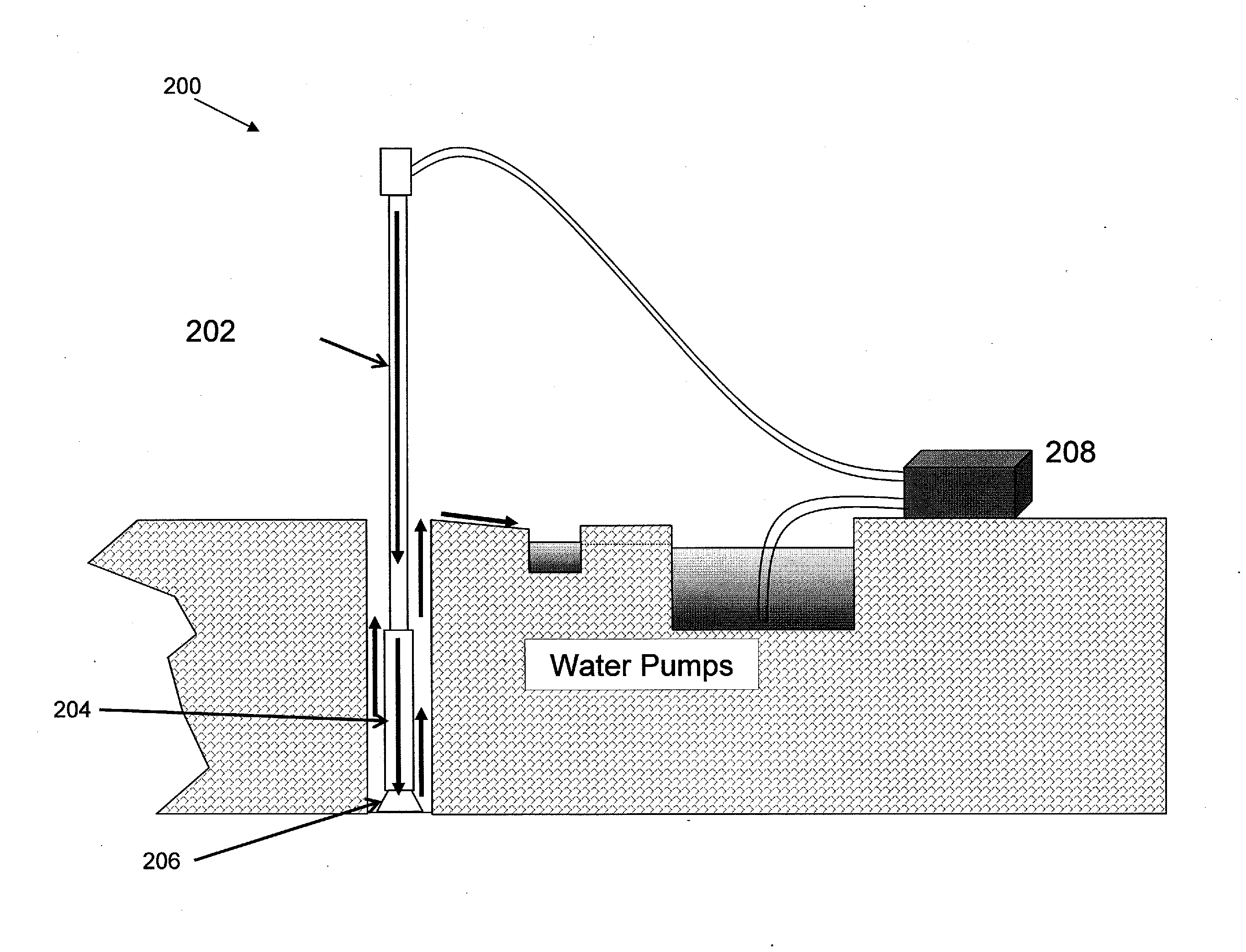

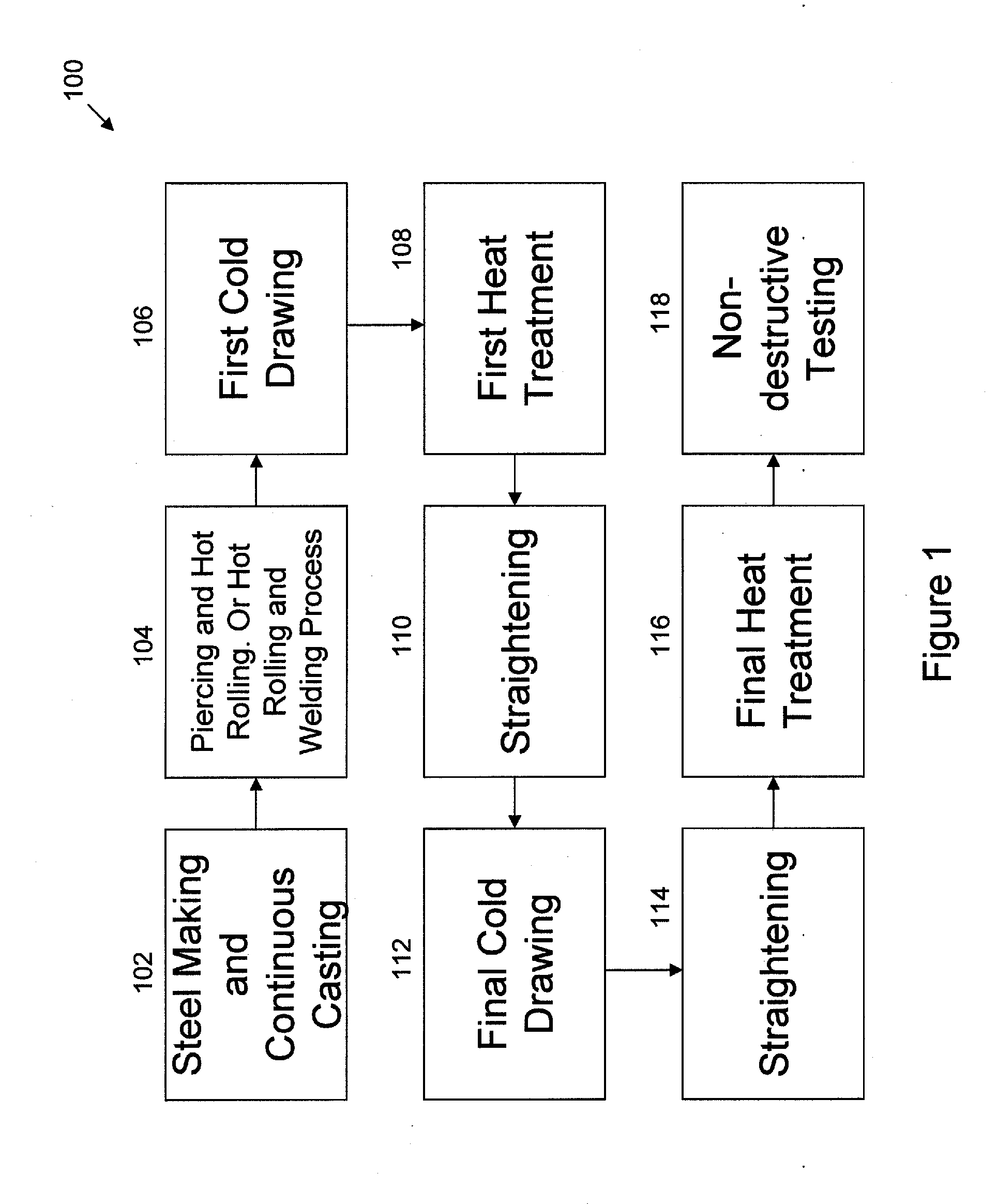

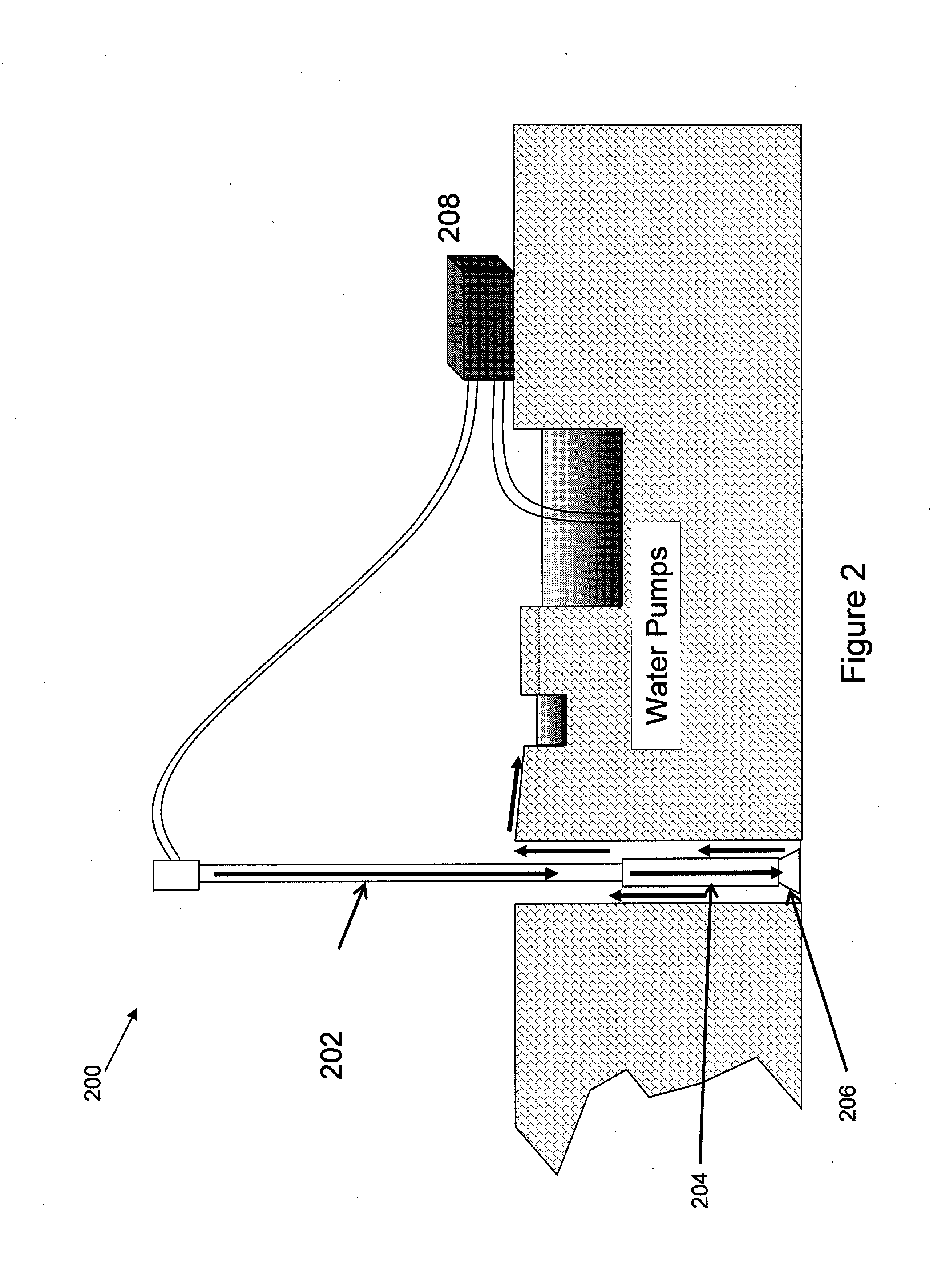

Methods of manufacturing steel tubes for drilling rods with improved mechanical properties, and rods made by the same

ActiveUS20130264123A1Reduce areaReduce the cross-sectional areaDrilling rodsFurnace typesHardnessWear resistance

Embodiments of the present disclosure are directed to methods of manufacturing steel tubes that can be used for mining exploration, and rods made by the same. Embodiments of the methods include a quenching of steel tubes from an austenitic temperature prior to a cold drawing, thereby increasing mechanical properties within the steel tube, such as yield strength, impact toughness, hardness, and abrasion resistance. Embodiments of the methods reduce the manufacturing step of quenching and tempering ends of a steel tube to compensate for wall thinning during threading operations. Embodiments of the methods also tighten dimensional tolerances and reduce residual stresses within steel tubes.

Owner:TENARIS CONNECTIONS

High-strength abrasion-proof steel plate and method for producing the same

InactiveCN101451220AGuaranteed hardenabilityImprove wear resistanceFurnace typesHeat treatment furnacesSheet steelChemical composition

The invention relates to a high strength wear resistant steel plate, which comprises the following chemical components by weight percentage: 0.12 to 0.16 percent of C, 0.10 to 0.70 percent of Si, 0.90 to 1.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.05 to 0.30 percent of Ni, 0.03 to 0.08 percent of V, 0.01 to 0.06 percent of Nb, 0.020 to 0.08 percent of Al, 0.20 to 0.70 percent of Cr, 0. 1 to 0.50 percent of Mo, 0.010 to 0.060 percent of Ti, 0.0005 to 0.0030 percent of B, and the balance being Fe and inevitable impurities. The steel plate manufactured through reasonable design of alloy components and main control of quenching and temper processes has the thickness of 60mm, ball hardness number between 360 and 440, even hardness distribution, tensile strength not less than 1,220MPa, good welding performance, good cold bending performance, good impact toughness, excellent steel plate shape, and wide application prospect, and can be widely applied to engineering machinery manufacturing.

Owner:WUYANG IRON & STEEL

Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

The invention relates to ultrahigh-malleability tunnel supporting anchor pile steel of converter continuous cast billet and a production method, which belongs to the technical field of a mine anchor rod. The anchor rod steel comprises the following components by weight percent: 0.5 to 0.70 percent of carbon, 0.15 to 1.20 percent of silicon, 0.5 to 2.5 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.045 percent of sulfur, 0 to 1.00 percent of chrome, 0 to 1.00 percent of nickel, 0 to 1.00 percent of molybdenum, 0 to 0.30 percent of copper, 0.03 to 0.40 percent of vanadium, 0.01 to 0.2 percent of aluminum, 0 to 0.10 percent of titanium, 0 to 0.10 percent of boron, 0.001 to 0.0 percent of niobium, 0.004 to 0.020 percent of nitrogen, and iron for the surplus; the yield strength Rel is larger than or equal to 600 MPa, the percentage elongation delta 5 is larger than or equal to 20 percent, the impact strength is 20 DEG C, Akv is larger than or equal to 27 J, and the breaking load is larger than or equal to 300 KN. By adopting the production process flow of converter crude metallurgy, LF furnace fine metallurgy and full protection continuous casting, the steel grade has the advantages that the purity is high, the structure is dense, the grain is fine, the physical chemistry properties of the steel are stable, the over-all mechanical property is good, the production operation and process flow are simple, and the rolled metal finished product can be directly used without heat treatment to the rear part.

Owner:SHOUGANG CORPORATION

Wind power flange alloy steel and preparation technology of parts thereof

The invention discloses wind power flange alloy steel and a preparation technology of parts thereof. The alloy steel comprises the following chemical compositions: carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, nickel, copper, nitrogen, oxygen, hydrogen, rare earth and the balance of iron and the inevitable impurities. The preparation technology of the alloy steel parts comprises the following steps: pretreating molten iron, smelting in a converter, performing external refining, casting steel ingots, performing flame cleaning, heating, forging, slowly cooling, performing heat treatment, machining, performing flaw detection, inspecting, packaging and warehousing. Compared with the existing alloy steel used in the wind power generation at home and aboard, the alloy steel disclosed by the invention has higher tensile strength, yield strength, elongation after fracture and reduction of area, particularly higher low-temperature impact toughness. The atmosphere corrosion resistance and the sea atmosphere corrosion resistance are increased by two levels.

Owner:江阴同庆机械制造有限公司

Roll sleeve of ultra-strong wear-resistant high alloy steel roll squeezer and manufacturing method roll sleeve

The invention relates to a roll sleeve of an ultra-strong wear-resistant high alloy steel roll squeezer and a manufacturing method of the roll sleeve, belonging to the technical field of casting in building material industry. The technical scheme is as follows: an outer layer adopts ultra-strong wear-resistant high alloy steel, an inner layer is formed by compounding low-carbon medium alloy steel, and the roll sleeve is manufactured through the process steps of melting the outer-layer ultra-strong wear-resistant high alloy steel, melting the inner-layer low-carbon medium alloy steel, centrifugally casting the compound roll sleeve and performing heat treatment on the compound roll sleeve. The roll sleeve and the manufacturing method thereof, disclosed by the invention, have the positive effects that: the preferential mixture ratio of the inner-layer material to the outer-layer material of the roll sleeve is adopted and a reasonable centrifugal compound casting process is adopted, thereby the inner layer and the outer layer are subjected to metallurgical bonding and a good bonding state is achieved. According to the characteristics of high alloy of the roll sleeve, the fracture toughness of the roll sleeve is enhanced by raising tempering temperature and performing multiple tempering processes. The outer layer of the roll sleeve disclosed by the invention has the hardness of 60-64HRC and the impact toughness of 12J / cm<2>, the inner layer has the hardness of 26-30HRC, the tensile strength of 800-900MPa and the yield strength of 730MPa, and the service life of the roll sleeve is prolonged by above 2 times in comparison with the traditional roll sleeve formed by forging and overlaying welding.

Owner:河北津西钢铁集团重工科技有限公司

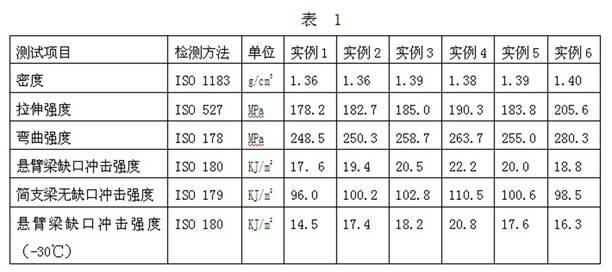

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

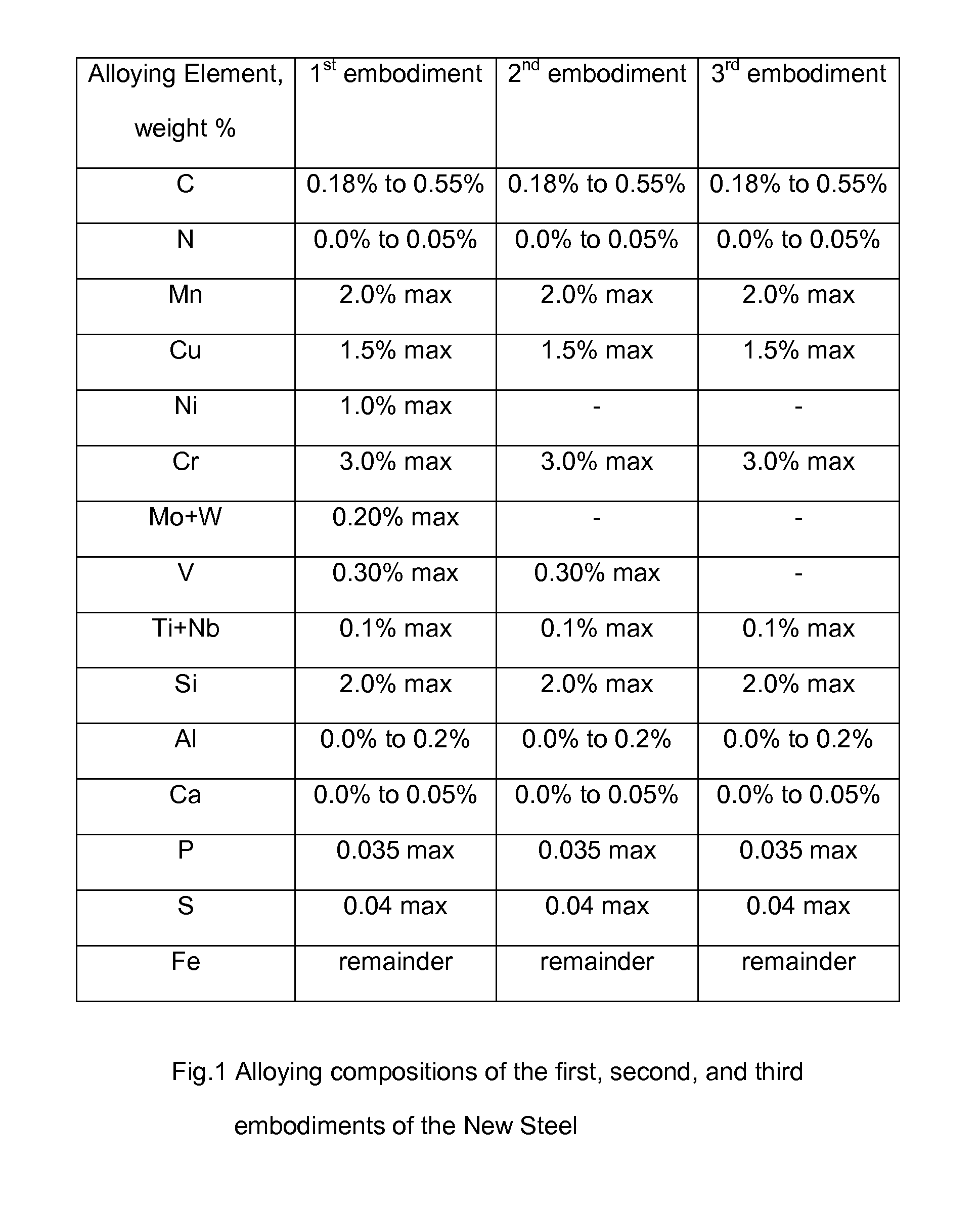

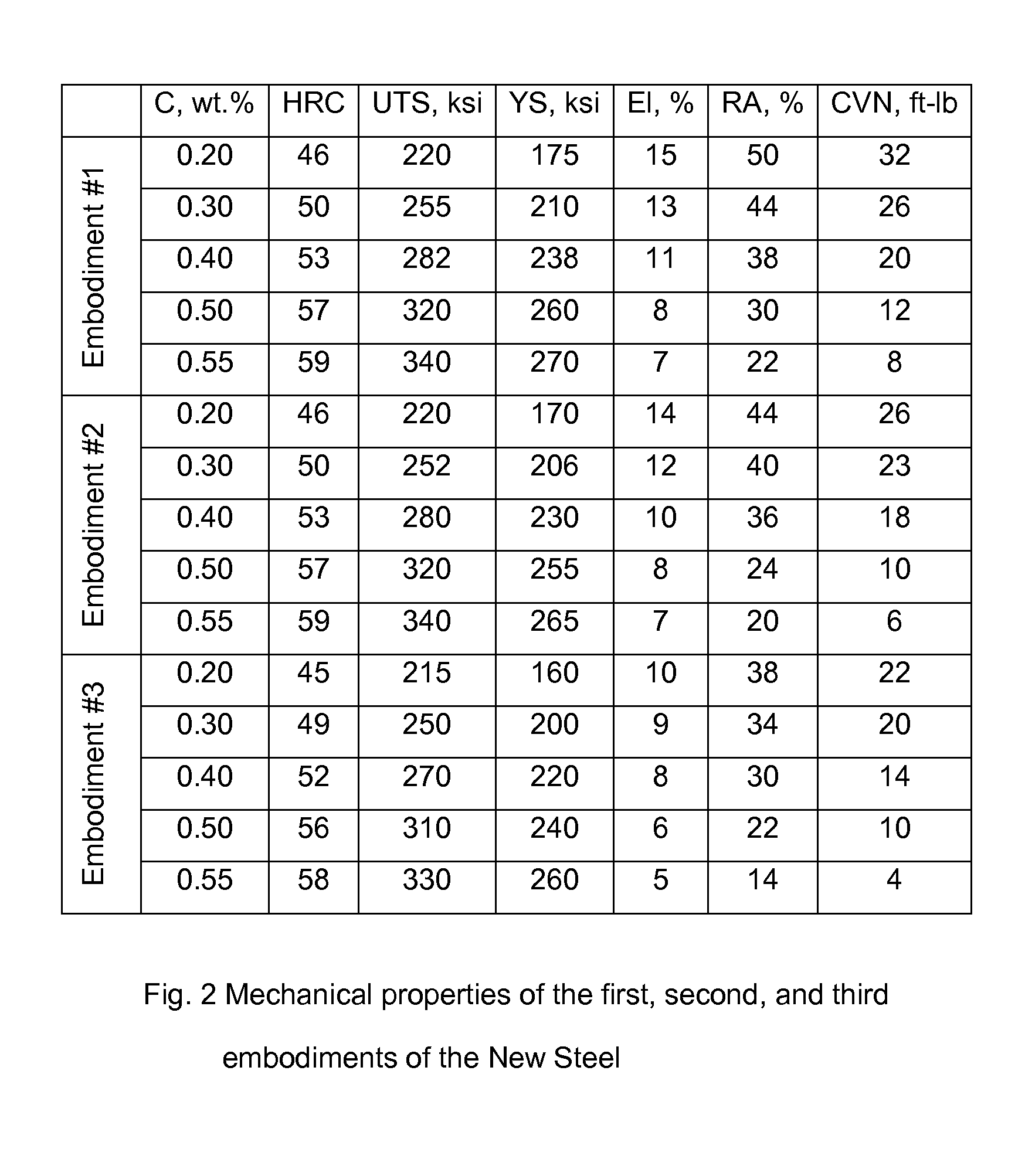

High Strength Low Alloy Steel and Method of Manufacturing

The present invention relates to a wrought, quenched and tempered, fine-grained, with deep hardenability, high strength and low alloy steel having a sum of the alloying elements: nickel, molybdenum, tungsten, vanadium, titanium, and niobium in weight percentage of 1.60% maximum in the first embodiment; vanadium, titanium, and niobium in weight percentage of 0.40% maximum in the second embodiment; titanium and niobium in weight percentage of 0.10% in the third embodiment. The air melted and hot forged steel of the first embodiment has hardness of HRC 55, an ultimate tensile strength of 300 ksi, a yield strength of 257 ksi, a total elongation of 9%, a reduction of area of 32%, and Charpy v-notch impact toughness energy of 15 ft-lb after normalizing, gas quenching, and tempering at 450° F.

Owner:VARTANOV GREGORY

Recomposed bamboo board producing process

ActiveCN103496024AHigh hardnessHigh strengthFlat articlesDomestic articlesHardnessVolumetric Mass Density

The invention relates to the field of bamboo production, in particular to recomposed bamboo board producing process. The recomposed bamboo board producing process uses renewable bamboo as raw materials, the utilization rate of bamboo is high and can reach more than 90%, and resource waste is reduced. The density of recomposed bamboo boards manufactured in the recomposed bamboo board process is high as 1200kg / m<3> and is more than 1.6 times of the density of ordinary bamboo floors. The recomposed bamboo boards have the advantages of being high in hardness, high in strength, high impact toughness and wearproof. The recomposed bamboo boards manufactured in the recomposed bamboo board producing process further have the advantages of being capable of resisting to water absorption, free of deformation and the like. Tests show that the thickness expansion rate is only 0.4% after the recomposed bamboo boards absorb water for 24 hours and is far better than and smaller than the European standard of 2.0%. The free formaldehyde emission of the recomposed bamboo boards manufactured in the recomposed bamboo board producing process is below 0.4mg / L, so that harm of formaldehyde to people is reduced.

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

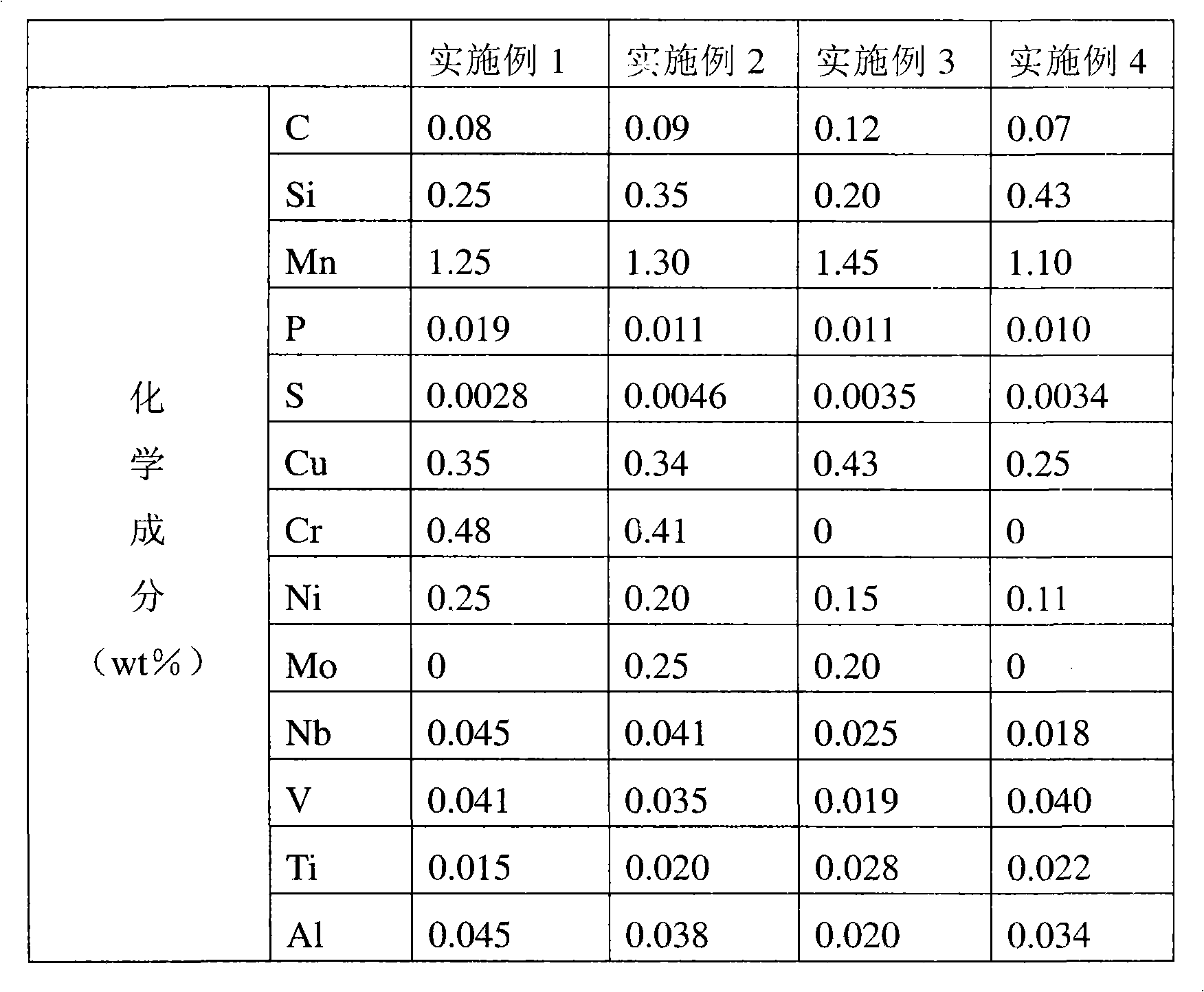

Ultra-strength, high toughness and low yield ratio steel and steel plate and manufacturing method thereof

The invention provides ultra-strength, high toughness and low yield ratio steel, which comprises the following chemical components: 0.05 to 0.12 weight percent of C, 0.15 to 0.50 weight percent of Si,1.0 to 1.5 weight percent of Mn, less than or equal to 0.025 weight percent of P, less than or equal to 0.015 weight percent of S, 0.20 to 0.50 weight percent of Cu, less than or equal to 0.25 weightpercent of Ni, 0.015 to 0.05 weight percent of Nb, 0.015 to 0.045 weight percent of V, 0.010 to 0.050 weight percent of Ti, less than or equal to 0.55 weight percent of Cr, less than or equal to 0.30weight percent of Mo, 0.015 to 0.05 weight percent of Al and the balance of Fe and inevitable impurities. The invention also provides a steel plate manufactured by using the ultra-strength, high toughness and low yield ratio steel and a manufacturing method thereof. The steel plate has excellent mechanical property, has a yield strength of more than or equal to 460 Pa and a yield ratio of less than or equal to 0.80. Moreover, the steel plate has good low-temperature impact toughness and weldability, and is suitable for high steel-structure buildings and other large-scale steel structure fields with low yield ratio requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

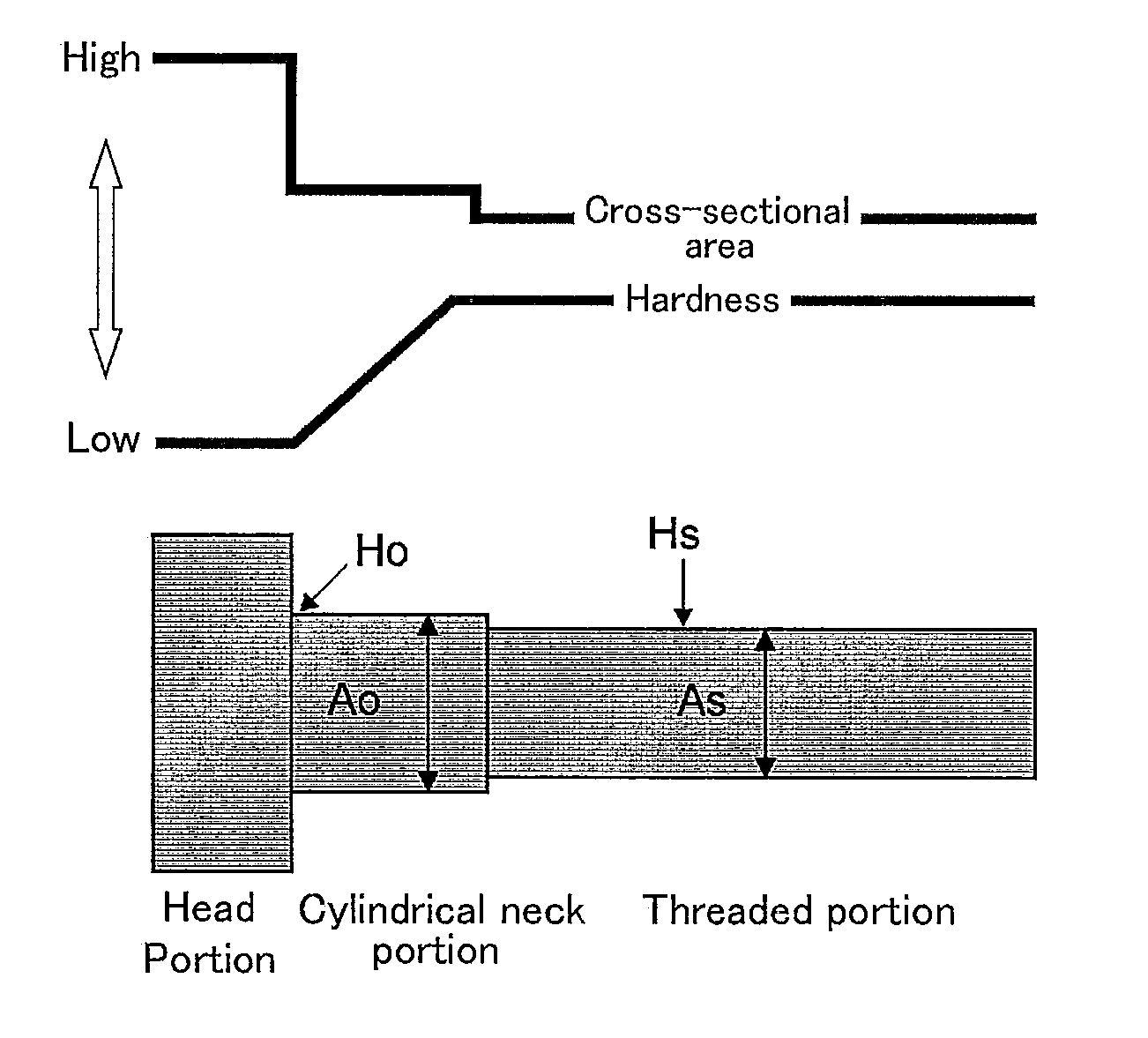

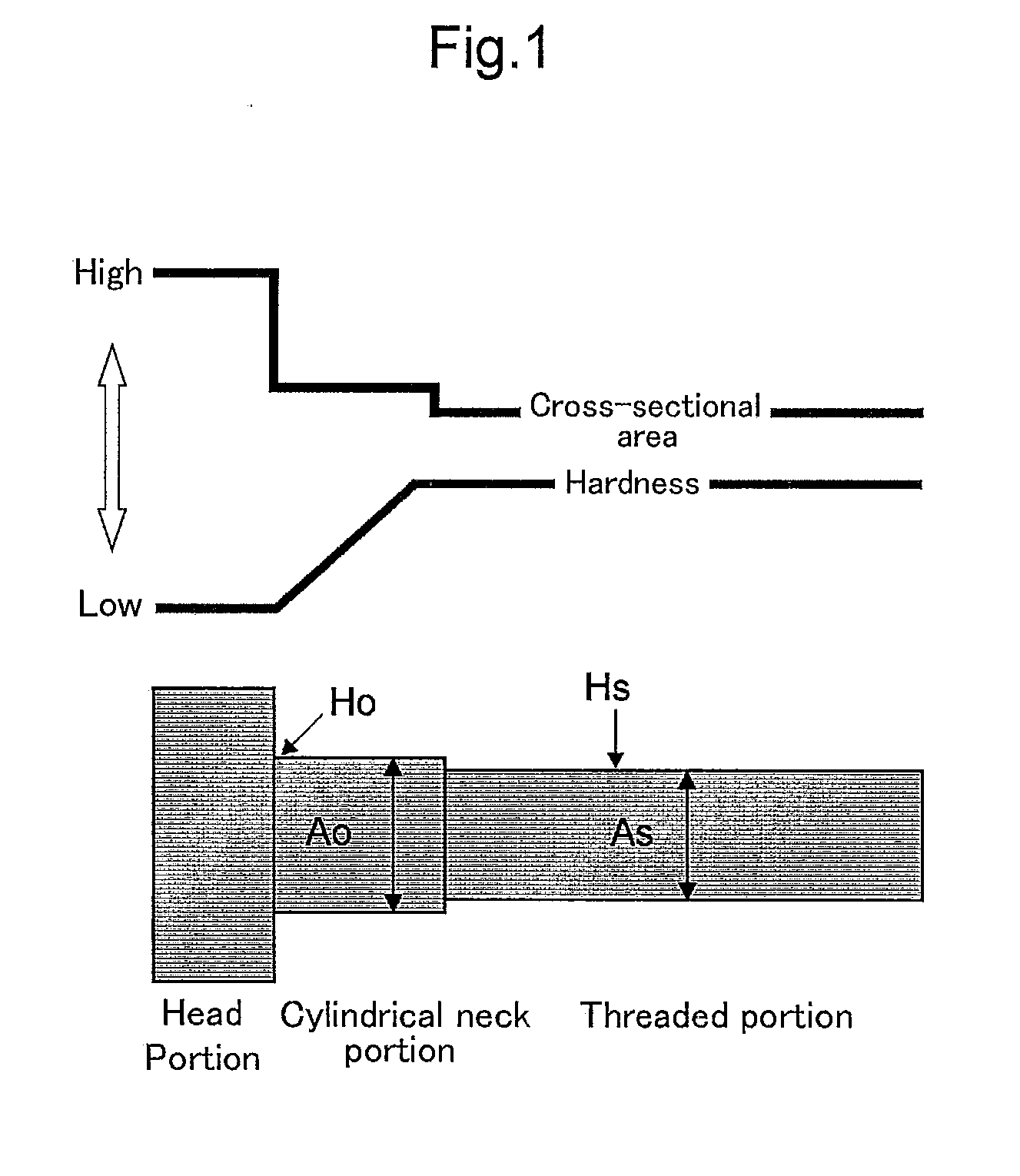

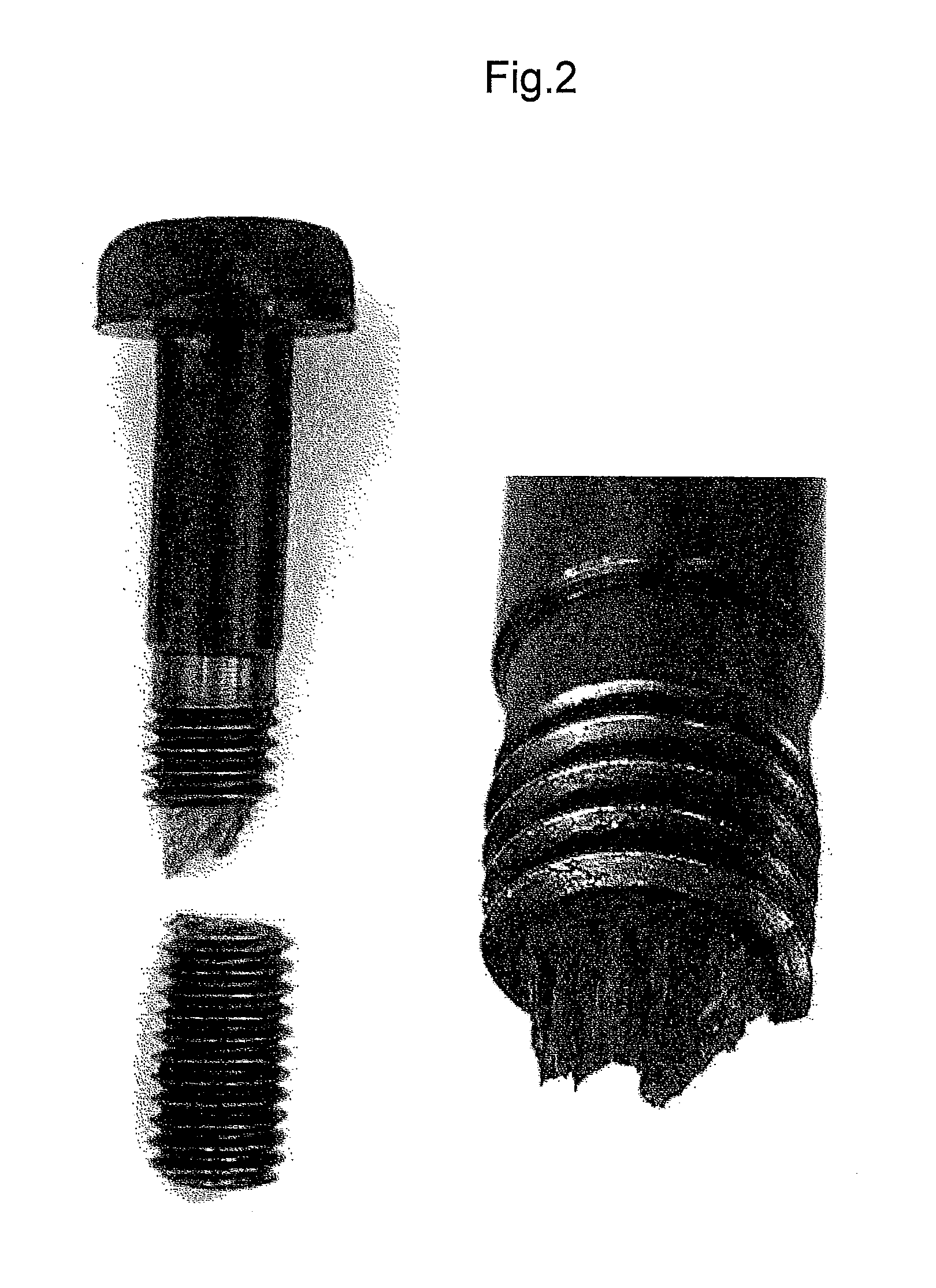

High-Strength Bolt

Provided is a high-strength bolt which has a tensile strength of 1,200 MPa or more while exhibiting excellent ductility and delayed facture resistance, and further has an excellent impact toughness which had not been obtained in the conventional high-strength bolt. The high-strength bolt has a tensile strength of 1.2 GPa or more and includes a threaded portion and cylindrical neck portion. The bolt has K of 0.8 or more and satisfies Ho<Hs, where K is defined by the equation: (Ao×Ho) / (As×Hs)=K, in which Ao is an effective cross-sectional area of the cylindrical neck portion with a diameter larger than that of the threaded portion, Ho is a Vickers hardness of a portion at which Ao is measured, As is an effective cross-sectional area of the threaded portion, and Hs is a Vickers hardness of the threaded portion.

Owner:NAT INST FOR MATERIALS SCI +2

Postweld heat treatment method of welded joint of bainite steel rail

ActiveCN103898310AImprove impact toughnessEvenly distributedFurnace typesHeat treatment furnacesSafe operationHeat treated

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

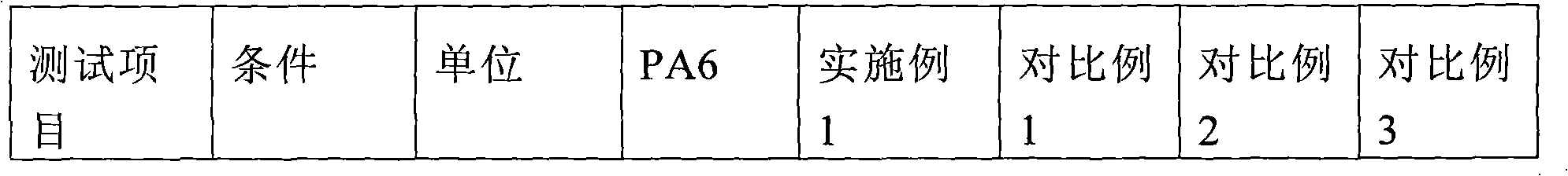

Low water absorption polyamide composite and preparation method thereof

The invention relates to a low water absorption polyamide composite and preparation method thereof. 10-90 parts by weight of polyamide and 3-10 parts by weight of phyllo-silicate clay and less than 2 parts by weight of additive are placed into a high speed mixer to be premixed for 20min and then are added into a double screw extrusion machine, and conveying, melting, cutting, extrusion, cooling and granulation are carried out, thus obtaining polyamide / phyllo-silicate master batch, then the polyamide / phyllo-silicate master batch, 10-60 parts by weight of styrene resin, 2-10 parts by weight of compatilizer and 5-20 parts by weight of short glass fiber are placed into the high speed mixer to be premixed for 20min, temperature is controlled to be 40-60 DEG C, and finally extrusion granulationis carried out in the double screw extrusion machine, thus obtaining the low water absorption polyamide composite. Compared with prior art, the invention has the advantages of solvent resistance, high tenacity and easy processability of polyamide and the advantage of low water absorption of ABS resin; besides, phyllo-silicate clay speeds up crystallization of nylon, degree of crystallization and mechanical strength are improved, extremely low water absorption is obtained, and size stability is greatly improved while impact toughness is maintained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

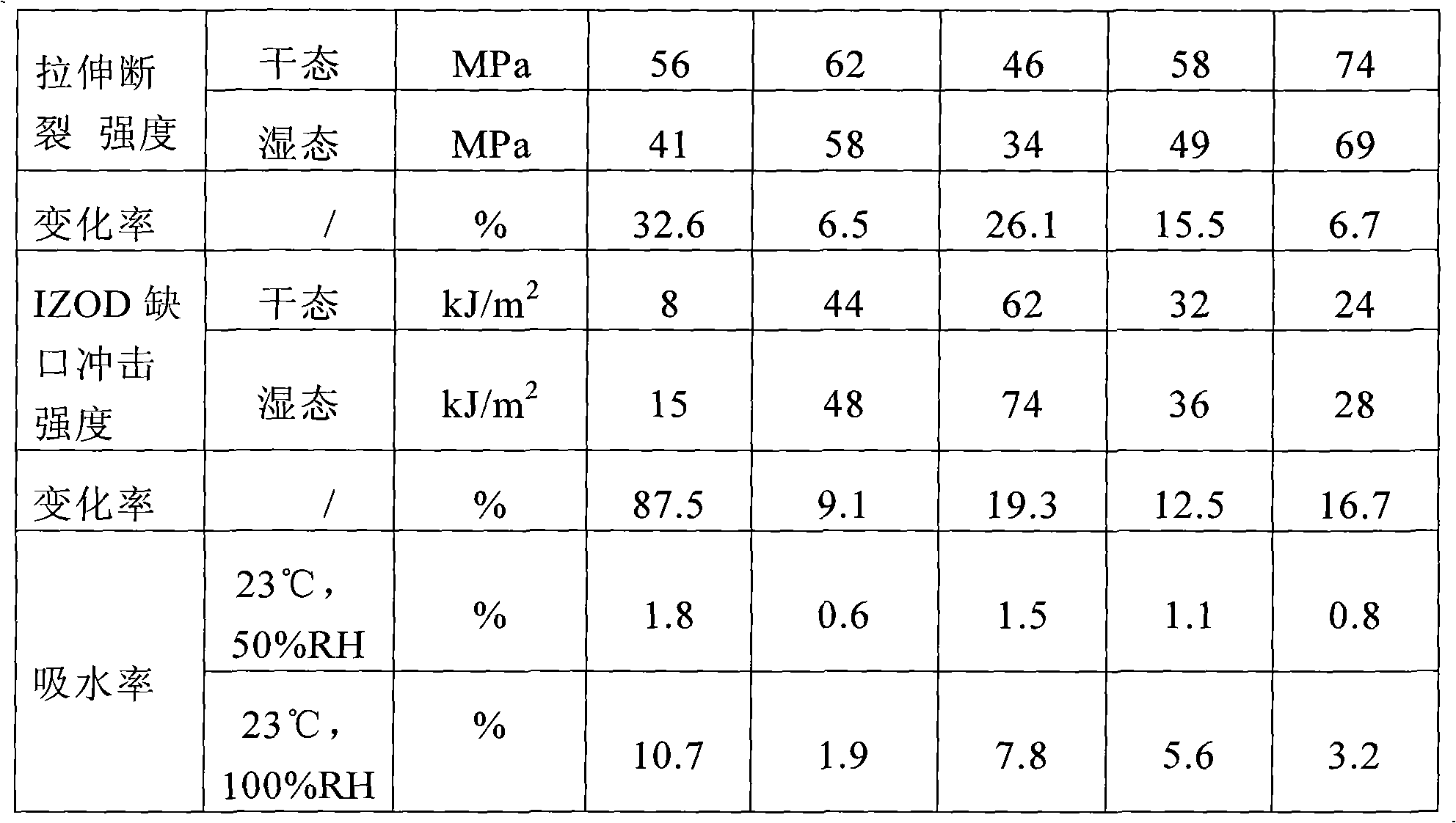

Alloy for cutter ring of disk type hobbing cutter and preparation method thereof

The invention relates to an alloy for a cutter ring of a disk type hobbing cutter, which comprises the following components in percentage by mass: 0.4-0.46% of C, 0.45-1.0% of Si, 0.48-0.74% of Mn, 1.3-5.4% of Cr, 0.4-1.4% of Mo, 0.86-1.33% of V, 0.06-0.54% of Nb, 0-0.05% of Al, 0-3% of Ni, no more than 0.009% of S, no more than 0.03% of P and the balance of Fe. The preparation method comprises the following steps: performing vacuum induction smelting on the raw materials, casting, forging, performing spheroidal annealing, performing gas carburization, performing vacuum quenching, and performing double tempering. The carburized layer of the prepared cutter ring of a disk type hobbing cutter is 1mm thick, the surface hardness of the carburized layer can be up to 60-63HRC, the internal average hardness is higher than 55HRC, and the impact toughness aku is up to 15-22J / cm<2>; and the shield cutter ring is high in hardness and favorable in toughness.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD +1

Thermal treatment method for wear-resistant low alloy steel

InactiveCN102758067AImprove wear resistanceImprove mechanical propertiesHeat treatment process controlTemperingMetallic materials

The invention discloses a thermal treatment method for wear-resistant low alloy steel, and relates to the field of the machining of metal materials. The thermal treatment method provided by the invention comprises the following steps of: heating a low alloy steel workpiece in thermal equipment, discharging out of a furnace after heat preservation at constant temperature, immediately putting the part which needs wear resistance in the workpiece discharged out of the furnace into a quenching pond which is filled with water and quenching oil at the same time to be quenched, naturally cooling after quenching, transforming the workpiece into a tempering furnace, preserving the heat in a heating way, and carrying out furnace cooling or air cooling in a discharging way after the heat is preserved. The thermal treatment method disclosed by the invention has the characteristics that the local water quenching, the local oil quenching and the local air cooling of the workpiece can be combined with one another, the hardness, the strength and the abrasive resistance of the part which is easy to wear in the workpiece can be improved as required, the workpiece is guaranteed to be hard to wear, the impact toughness of the part which needs high tenancy can be guaranteed, the whole comprehensive mechanical property of the workpiece can be improved, and the use requirement of wear-resistant pieces such as the wear-resistant plate hammer, the lining plate, the hammer head, the impact plate, the bucket teeth and the like can be met. The thermal treatment method disclosed by the invention has the advantages of being simple and easy, and low in production cost.

Owner:JINAN UNIVERSITY

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

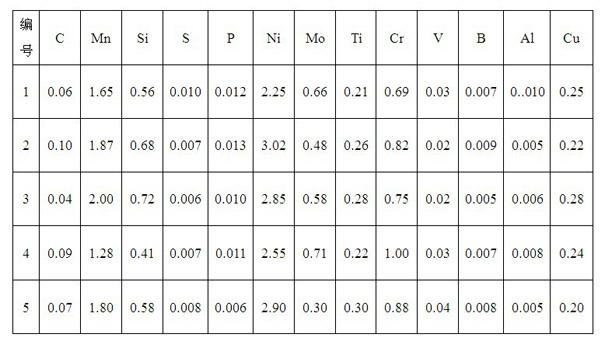

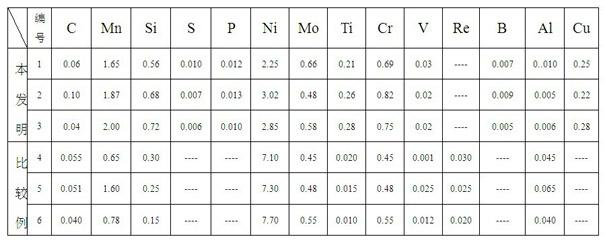

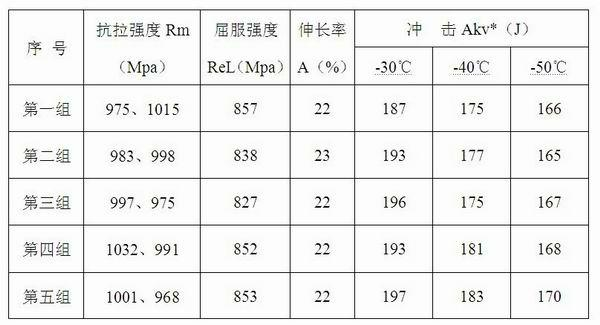

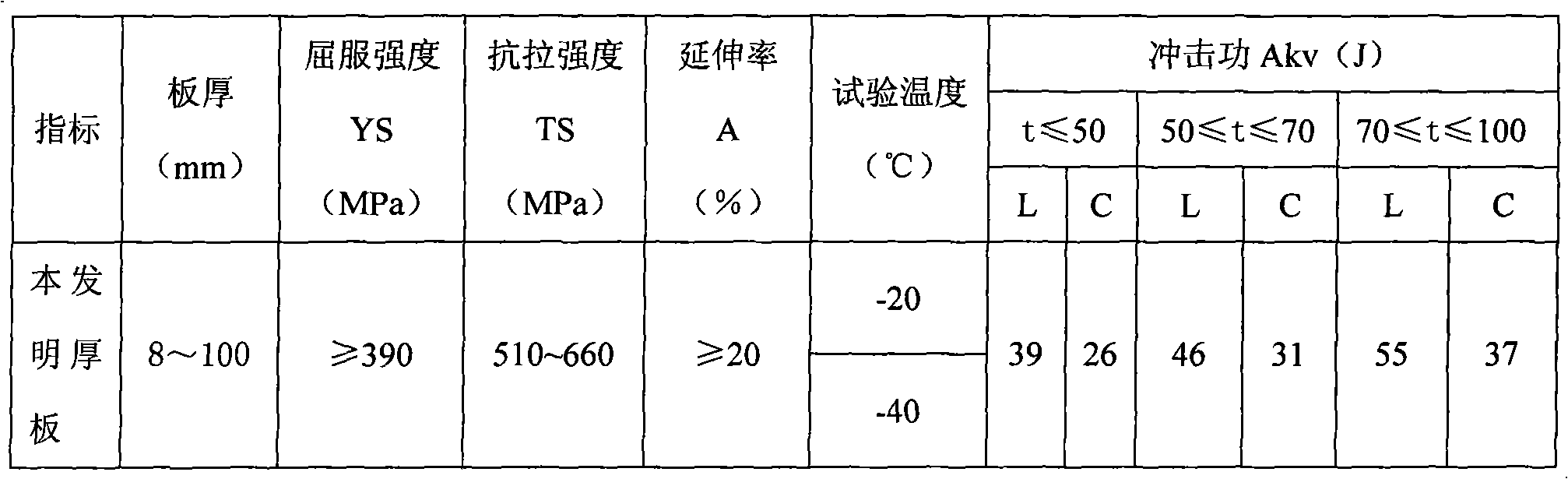

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

TMCP ocean structure thick plate and method for manufacturing same

InactiveCN101514424ASimple ingredientsReduce manufacturing costMetal rolling arrangementsHull structureChemical composition

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength abrasion-proof cast steel lining board and manufacturing method thereof

InactiveCN101173343ASimple production processImprove wear resistanceMolten metal pouring equipmentsFurnace typesChemical compositionEconomic benefits

The invention relates to a lining plate of cast steel with high strength and abrasion resistance and the fabrication method, belonging to the technical field of metal abrasion-resistant material. The chemical composition of the lining plate (in weight ratio) is that: 0.25 to 0.45 C, 1.0 to 2.0 Mn, 0.8 to 1.5 Cr, 0.003 to 0.008 B, 0.02 to 0.08 Al, 0.04 to 0.15 Ti, 0.02 to 0.10 La, 0.02 to 0.10 Ce, 0.02 to 0.08 Ba, 0.02 to 0.10 Ca and Fe and other inevitable micro impurity retaining; wherein, the sum of Si, Mn and Cr is more than 3.5 and lower than 4.5, while the sum of the La and Ce is more than 0.05 and lower than 0.18. The lining plate of cast steel can be fabricated with an electric stove and a method of sand sell molding. Therefore, the tensile strength of the lining plate is as high as to 1450 to 1600 MPa, the hardness reaches to 50 to 55 HRC; the abrasion resistance is good; and the impact toughness reaches 65 to 80 J / cm2. The lining plate can neither fracture nor peel in use, with much better service performance than the Mn13 high manganese steel lining plate. With the steel cuttings adopted as the main materials, the lining plate has the advantages of simple fabricating technique, low manufacturing cost, and can improve the operating efficiency of ball mill and lower the material-grinding cost, therefore is possessed with good economic benefit.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com