An amorphous/nanocrystalline matrix high-hardness wear-resistant and corrosion-resistant alloy and its preparation method

A technology of corrosion-resistant alloys and nanocrystals, which is applied in the manufacture of mechanical wear-resistant parts, and the preparation of wear-resistant and corrosion-resistant cast iron alloys and their components. It can solve the problems of low alloy toughness, limited application range, and difficult application, and achieve casting Simple process requirements, good fluidity and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

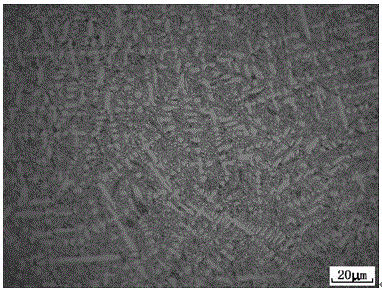

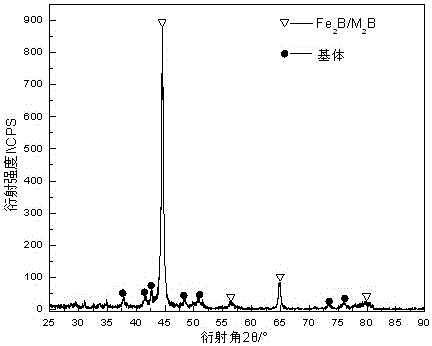

[0032] Embodiment 1. Select high-carbon ferrochrome, microcarbon ferrochrome, ferroboron, ferro-niobium, ferro-vanadium and industrial pure iron as raw material, and the composition range is as follows: Cr: 10.0wt.%; B: 2.9wt.%; C: 0.7wt.%; Nb: 0.4wt.%; V: 0.2wt.%; See Table 2 for the control of impurity elements. Induction melting and iron mold casting are adopted, the melting temperature is 1500°C, and the casting temperature is about 1400°C. When the temperature of the ingot is about 800°C, the iron mold is opened and air-cooled. The ingot weighs 40kg and the thickness is 30mm.

Embodiment 2

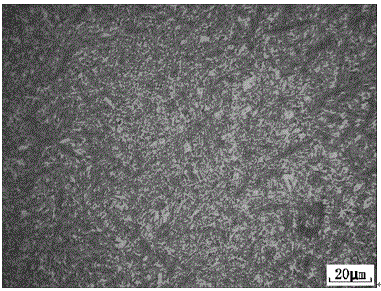

[0033] Embodiment 2. Select high-carbon ferrochromium, metal chromium, ferroboron, ferro-niobium and industrial pure iron as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.7wt.%; Nb: 0.5wt.%; see Table 2 for the control of impurity elements. Induction melting and sand casting are used to cast the master alloy into strips, the melting temperature is 1450°C, and the casting temperature is about 1400°C. Remelt the master alloy cast strips with a resistance furnace, the melting temperature is about 1300°C, and use a die-casting machine to die-cast them into precision parts. The weight of a single part is 300g, and the minimum thickness is 2mm.

Embodiment 3

[0034] Embodiment 3. select high-carbon ferrochrome, microcarbon ferrochrome, ferroboron, ferro-niobium and industrial pure iron as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.8wt.% %; Nb: 0.6wt.%; See Table 2 for the control of impurity elements. Induction melting and centrifugal iron mold casting are adopted, the melting temperature is 1500°C, and the casting temperature is about 1400°C. When the temperature of the ingot is about 800°C, the iron mold is opened and air-cooled. The ingot weighs 120kg and the thickness is 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com