Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

429results about How to "Reduce burning rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

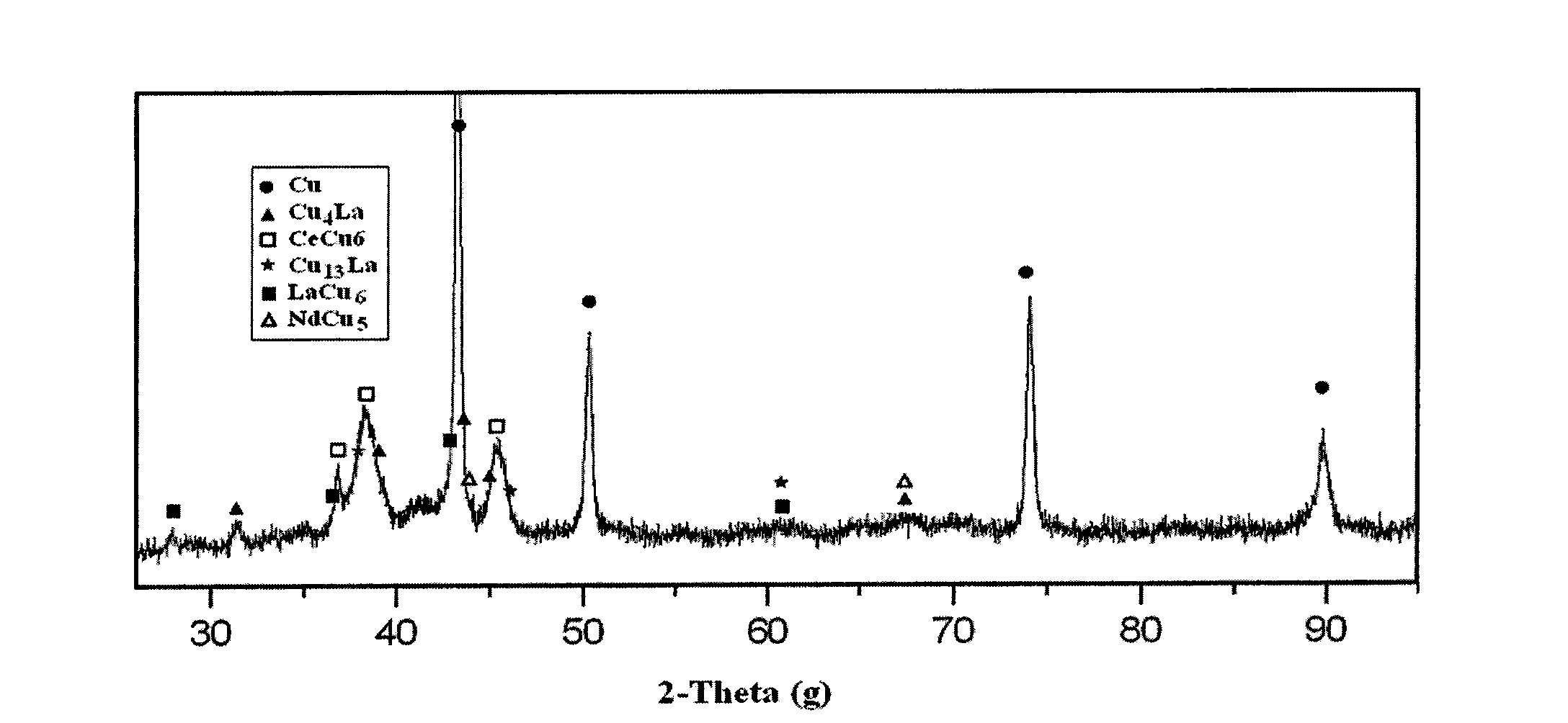

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Chinese herbal medicine health-care cigarette

InactiveCN101690613ASolve the disadvantages of containing a large amount of tar and other harmful substancesSolve the problem of irritating and easily causing drynessTobacco treatmentCigar manufactureChrysanthemum FlowerPeppermints

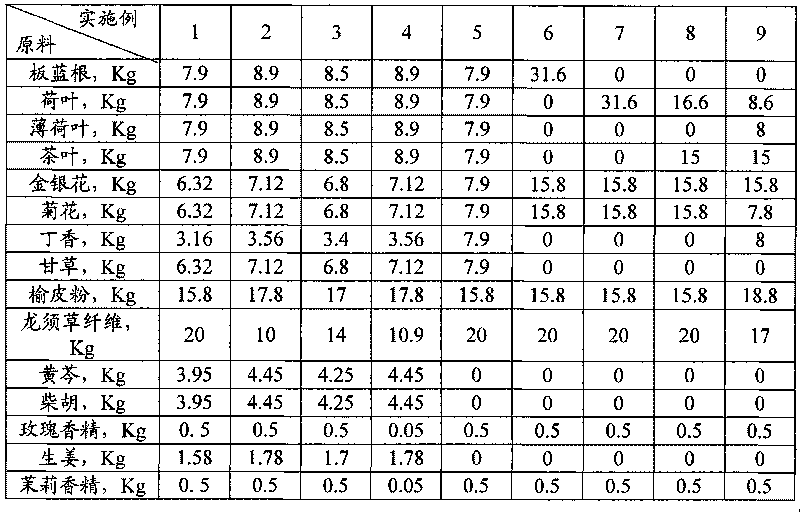

The invention discloses a Chinese herbal medicine health-care cigarette, comprising a cigarette stem and a filter tip connected with the cigarette stem, wherein shredded tobacco is contained in the cigarette stem; the shredded tobacco is prepared by mixing Chinese herbal medicines, Chinese alpine rush fibers and essence; the Chinese herbal medicines comprise elm bark powder matched with one or a plurality of radix isatidis, lotus leaf, peppermint leaf, tea leaf, honeysuckle flower, chrysanthemum flower, clove, liquorice, ginger, radix scutellariae and Chinese thorowax. The Chinese herbal medicine health-care cigarette adopts the elm bark powder instead of the traditional shredded tobacco adhesive containing large amounts of coke tar and other harmful substances, uses the Chinese alpine rush fibers and the essence as the auxiliary materials and combines the Chinese herbal medicines to prepare the Chinese herbal medicine health-care cigarette of which the mouth feel, the lasting taste, the burning speed and the ash color are close to those of the traditional cigarette. The health-care cigarette does not contain harmful substances contained in the traditional cigarette, so that smokers can enjoy the feel of traditional smoking and absorb the abstract of the Chinese herbal medicines at the same time; and therefore, the health-care cigarette performs the functions of keeping good health and strengthening the body.

Owner:何奇伟

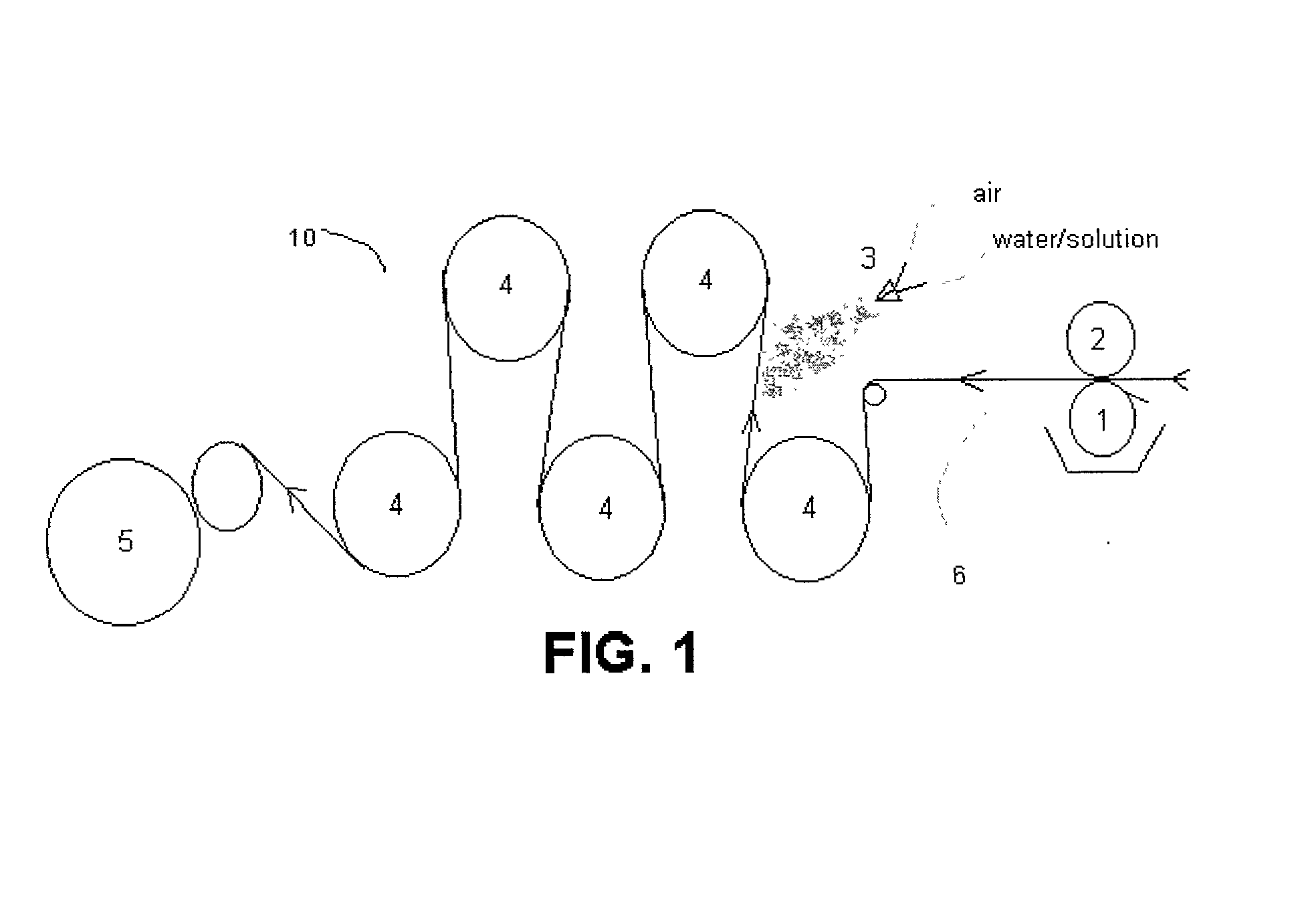

Novel materials and method of making same for low ignition propensity products

InactiveUS20020129824A1Reduce porositySufficient paper porosity closureNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceBurning chemicals

Novel materials for making low ignition propensity products are disclosed. Specifically, a treated cigarette paper for making low ignition propensity cigarettes are disclosed. The cigarette base paper containing a thermoplastic polymer aqueous suspension coated regions on a surface of the base paper so as to obtain coresta porosities of less than 15 is provided. This cigarette paper is further treated with a conditioning medium which is either water alone or water with a burning chemical such as an alkali metal containing organic salt either on the same surface bearing the thermoplastic polymer or on the opposite surface. The self-extinction characteristics of the cigarettes with the treated paper are improved. A method for making a cigarette paper for low ignition propensity cigarettes comprising a plurality of regions of a thermoplastic polymer aqueous suspension printed on to a surface of a base paper is also provided.

Owner:RF & SON

Open arc overlaying wire material with strong abrasive resistance for grinding roller and grinding disk

InactiveCN101658980AReduce splashFine particleWelding/cutting media/materialsSoldering mediaTitanium nitrideNanometre

The present invention provides an open arc overlaying wire material with strong abrasive resistance for a grinding roller and a grinding disk, which consists of a steel sheet and powder arranged in the steel sheet. A nano additive (A) is added into the powder, wherein the nano additive (A) can be one or any combination of three of nano TiN (titanium nitride), nano SiN (silicon nitride) and nano SiC (silicon carbide). The powder contains 3 to 5 weight percent of the nano additive (A). The nano additive (A) has the functions of strengthening dispersion of nano ceramic phases, improves cohesion strength, rupture strength and combination strength of a cladding layer material and has good high-temperature stability; and the nano additive (A) improves self lubricity of the material, improves theabrasive resistance of cladding layer metals and prolongs service life of the grinding roller and the grinding disk processed by overlaying. The service life of the grinding roller and the grinding disk processed by the overlaying is improved by 1.5 to 2 times than that processed by open arc overlaying; and the cladding efficiency is improved by 10 to 20 percent so as to save the overlaying wirematerial. The open arc overlaying wire material has light fume and less molten metal spatter in the process of overlaying, and a weld pass is smooth after the material is molded.

Owner:JIANGXI HENGDA HI TECH CO LTD

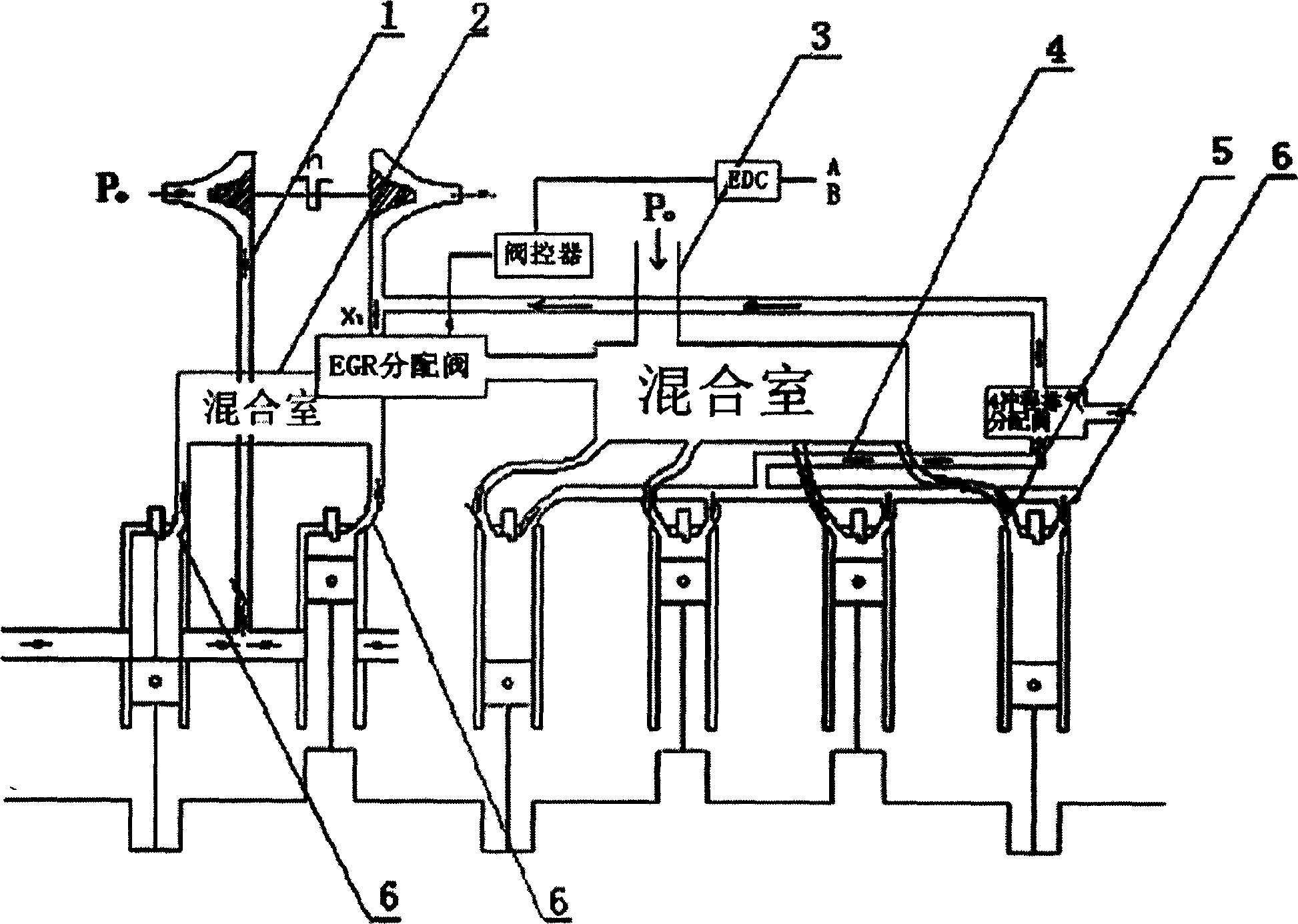

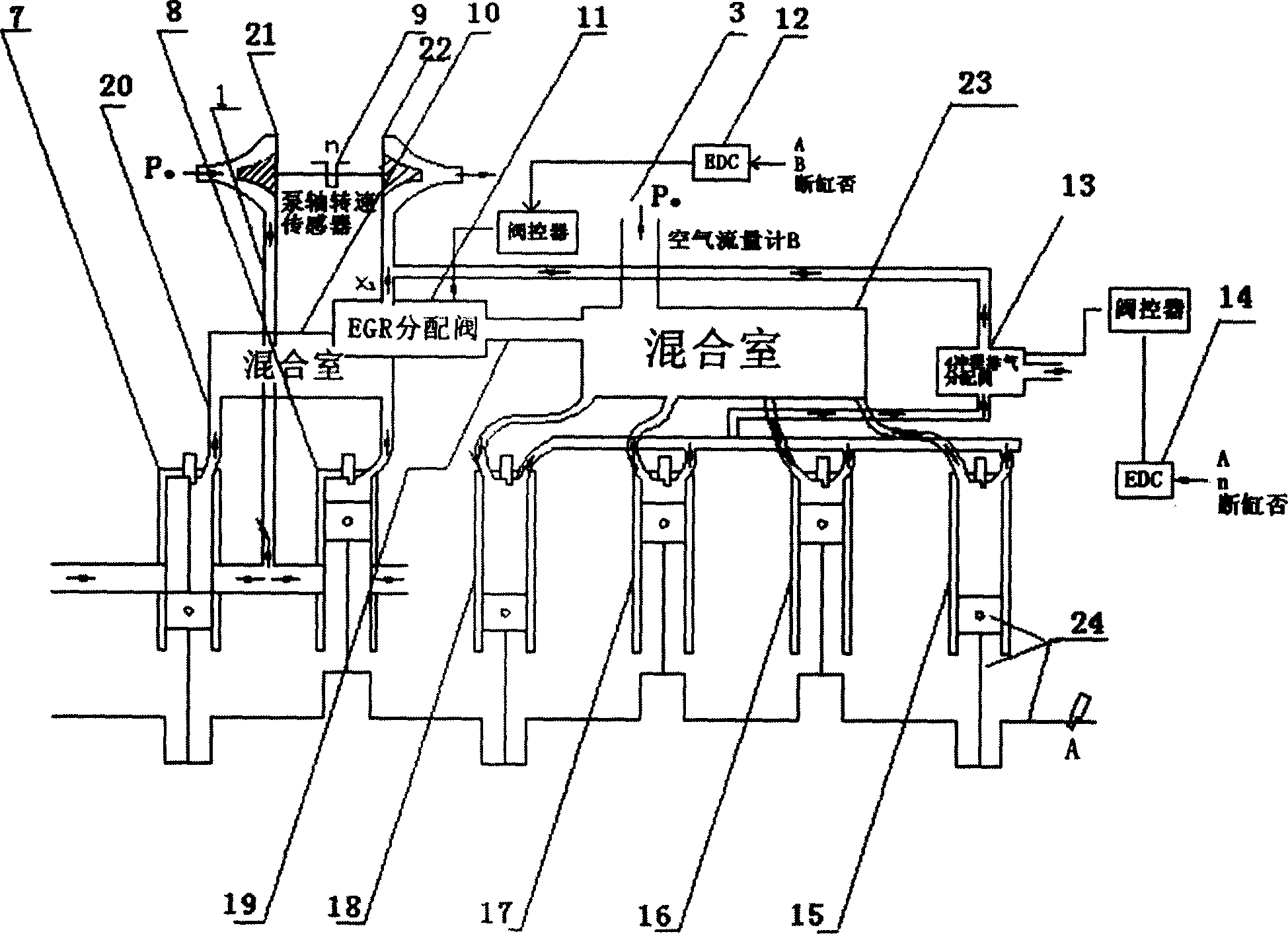

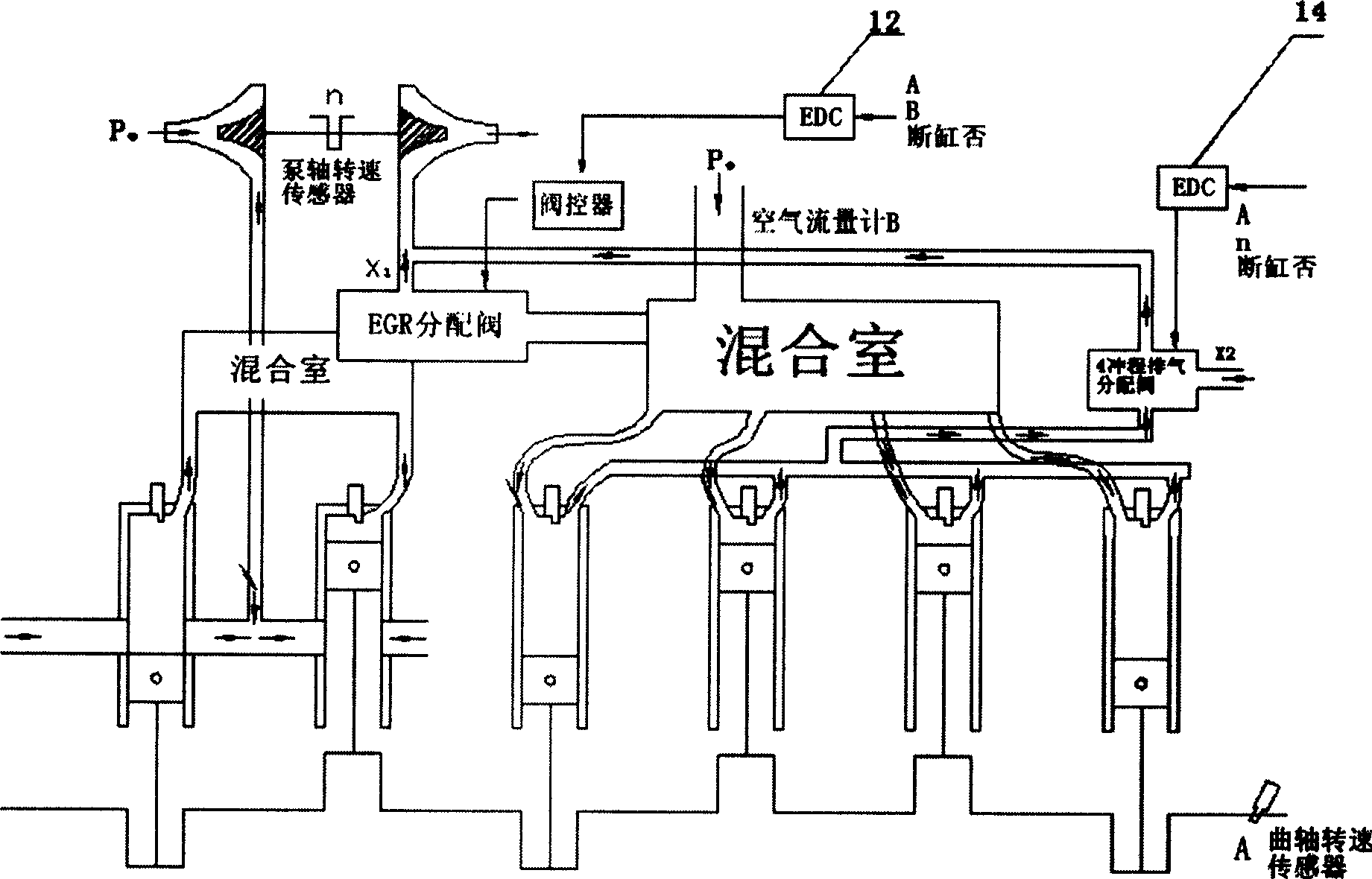

Variable stroke engine and working method thereof

InactiveCN1737350ADealing with Poor EmissionsHigh power outputEngine controllersMachines/enginesTurbochargerElectrical control

This invention relates to a variable stroke engine, in addition to its working method, which belongs to vehicle engine technique field. The engine comprises six cylinders, EGR, exhaust-gas turbocharger system, four strokes discharge distributing valve, exhaust duct, bent axle piston and electrical controlling unit. when working, it needs to decide whether the two stroke cylinders join to work with the jar cutting technique according to different power, making the engine switch in different working condition; the six cylinders will bedding-in work through each inlet distribution valve to increase pressure and power output. Said invention can be used in transporting vehicle such as tank armored vehicle, machineshop truck needs to provide large power output and so on.

Owner:清华大学苏州汽车研究院(吴江) +1

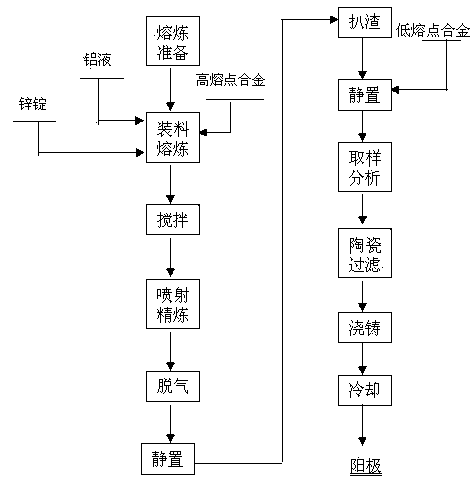

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

Smokeless flameless gunpowder agent

InactiveCN101215211AImprove stabilityImprove moisture resistanceNon-explosive/non-thermic compositionsFirecrackerFireworks

The invention discloses a firework agent with no smoke, which is characterized in that the invention is produced by nickel hydrazine nitrate blending with accessories , wherein, the nicker hydrazine nitrate is generated by mixing and reaction of nickelous nitrate hexahydrate and hydrazine hydrate, The weight ratio of raw materials of the nickel hydrazine nitrate is that nickelous nitrate hexahydrate takes 35-85 portions of weight per percentage, hydrazine hydrate takes 15-65 portions of weight per percentage, the weight ratio of raw materials of the fireworks agent with no smoke is that nickelous nitrate hexahydrate takes 20-62 portions of weight per percentage, excipients takes 40-80 portions of weight per percentage, wherein the excipients are mineral powders with 80-120 orders which are incombustible, such as pearlite powder or sepiolite powder or river sand, two or more of the excipients can be used in manufacture of different firework products. Protocol fireworks with color flowers and firecrackers which are made by the firework agent with no smoke are smokeless and flameless, and are in according with the environment-friendly requirement.

Owner:邹建文

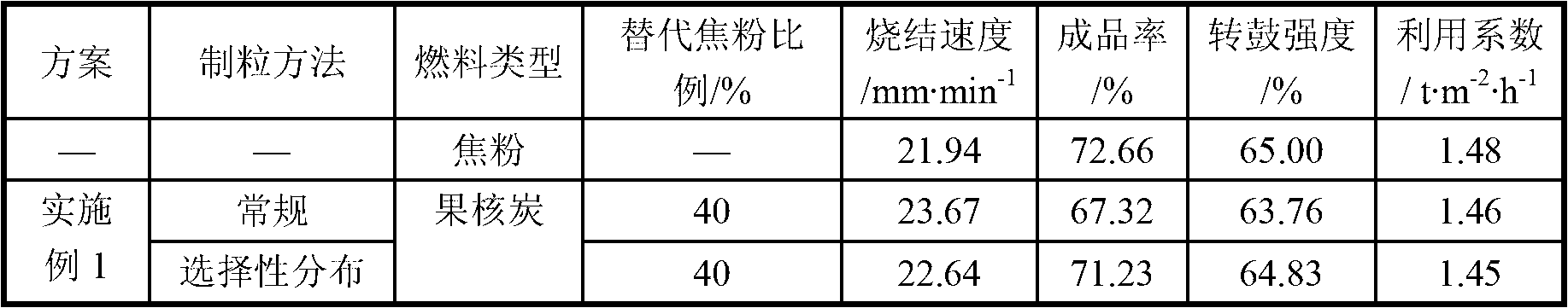

Selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy

A selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy distributes biomass fuel at the core part of a mixture before sintering by two-stage granulation to properly reduce the burning rate of the biomass fuel and improve the burning degree of the biomass fuel, so as to achieve the purpose of enhancing biomass energy sintering, wherein the two-stage granulation comprises the steps of: firstly preparing biomass fuel, iron ore and quicklime in a granulating disc into mother nuclide with the granularity of 3-5mm, then mixing with iron ore, limestone, dolomite, quicklime, sinter returns and coke powder (or coal), and carrying out second granulation for 3-6min in a granulating drum, so as to obtain the mixture before sintering with the biomass fuel wrapped at the core part. By selective distribution technology of the biomass fuel, the biomass fuel can be applied to iron ore sintering so as to successfully substitute for 10-60% of coke powder and not to influence the yield and quality indexes of the sintered ore.

Owner:CENT SOUTH UNIV

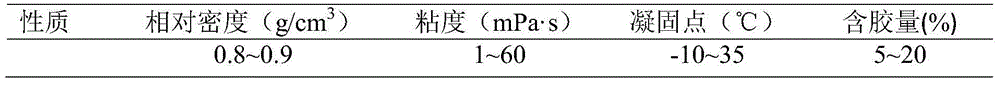

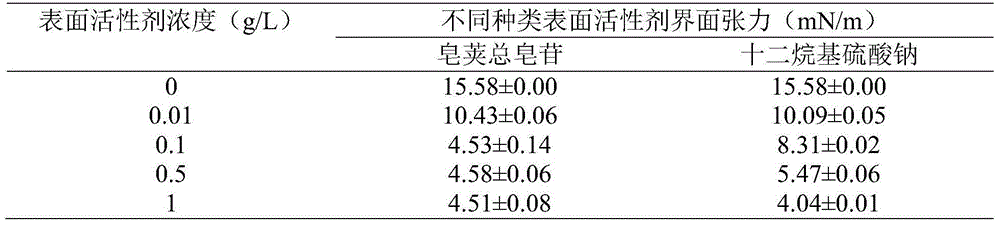

Application of plant source surface active agent

InactiveCN104874329AHas an activation effectIncrease gasification rateNon-ionic surface-active compoundsOther chemical processesEmulsionResource utilization

The invention relates to a total saponnis extraction technology of a honeylocust extract and an application field thereof. The total saponnis extraction technology is characterized in that the total saponnis is a plant source nonionic type surface active agent, and has the interfacial tension reduction property, emulsion activity, wetting property, temperature-resistant and salt-tolerant property, dispersant solubilizing and the like, so as to provide the applicability in the fields of recovery, storage and transportation of crude oil; the green surface active agent from the plant, namely the honeylocust, is applied to the bulk industrial purpose, so the resource utilization rate of the honeylocust is improved, the recovery rate of crude oil is improved, the storage and transportation cost of crude oil is reduced, and the pollution to the environment is reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

High-content environmental alcohol ether fuel used for compression ignition engine

InactiveCN105505484AEmission reductionLarge latent heat of evaporationLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol fuel

The invention discloses a high-content environmental alcohol ether fuel used for a compression ignition engine, which belongs to the technical field of alcohol ether fuel clean energy. The alcohol ether fuel comprises the following raw materials: methanol or ethanol or a mixture of methanol and ethanol, toluene, stearic acid, hexamethylphosphoric triamide, a nitryl solvent, acetone, fatty acid methyl ester, n-alkane, N-toluidine, plant oil, an alcohol fuel ether stabilizing agent, a catalysis combustion-supporting agent, an anti-knock reinforcing agent, a cetane number regulator, an eduction agent, an alcohol fuel recognition agent, an alcohol fuel rubber / plastic part corrosion and swelling inhibitor, an alcohol fuel metal corrosion inhibitor, an antioxidant anti-gum inhibitor, a metal deactivator, a corrosion inhibitor, an antistatic agent, a purification dispersant, an anti-wear repair agent, and an alcohol fuel sterilizing agent. The high-content environmental alcohol ether fuel has the advantages of stable performance, strong power, full combustion, good anti-knock property, good acceleration speed, easy starting, no air resistance, and low fuel consumption, and is especially suitable for the compression ignition engine.

Owner:SICHUAN ZHENGJIA NEW ENERGY TECH CO LTD

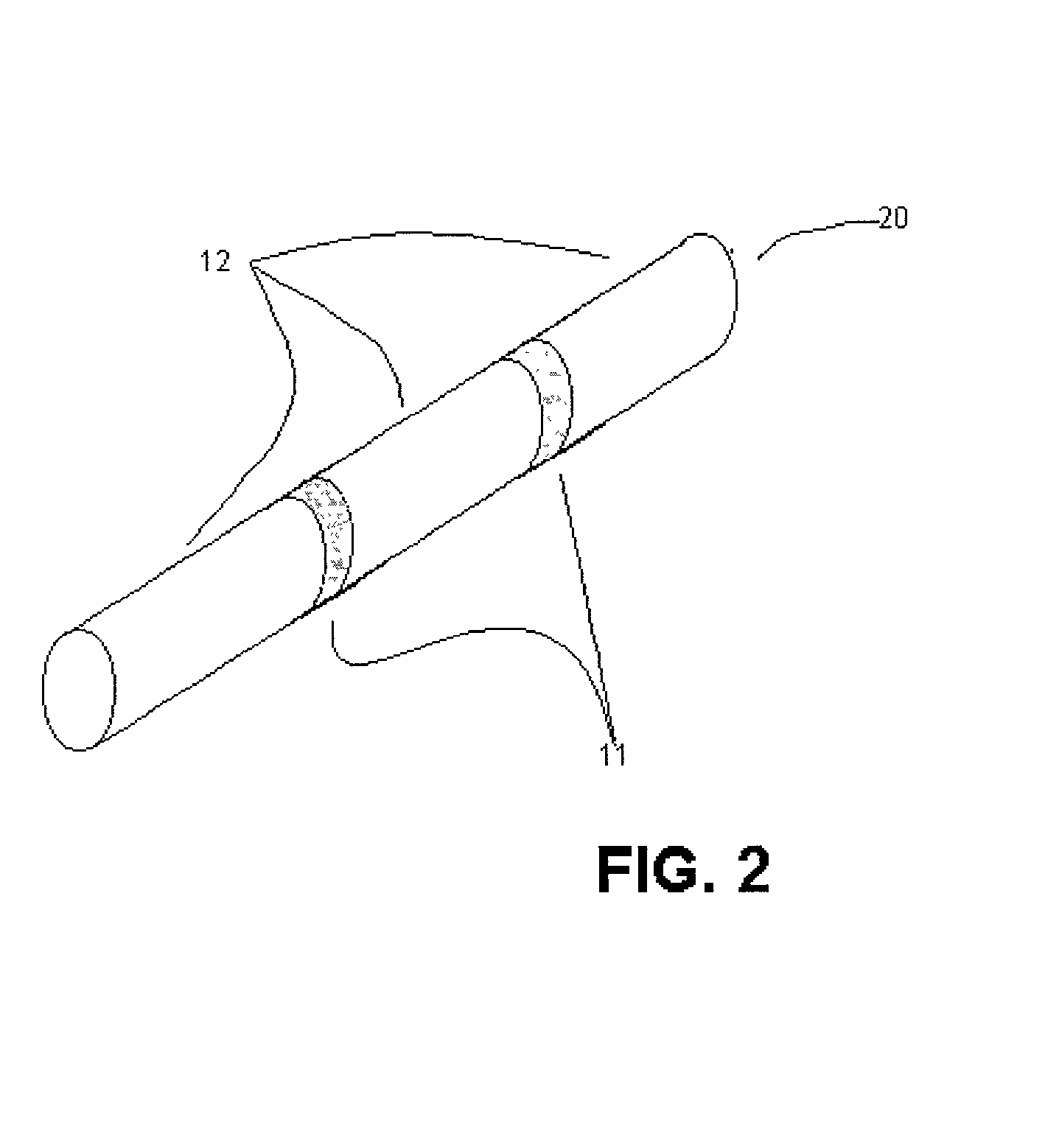

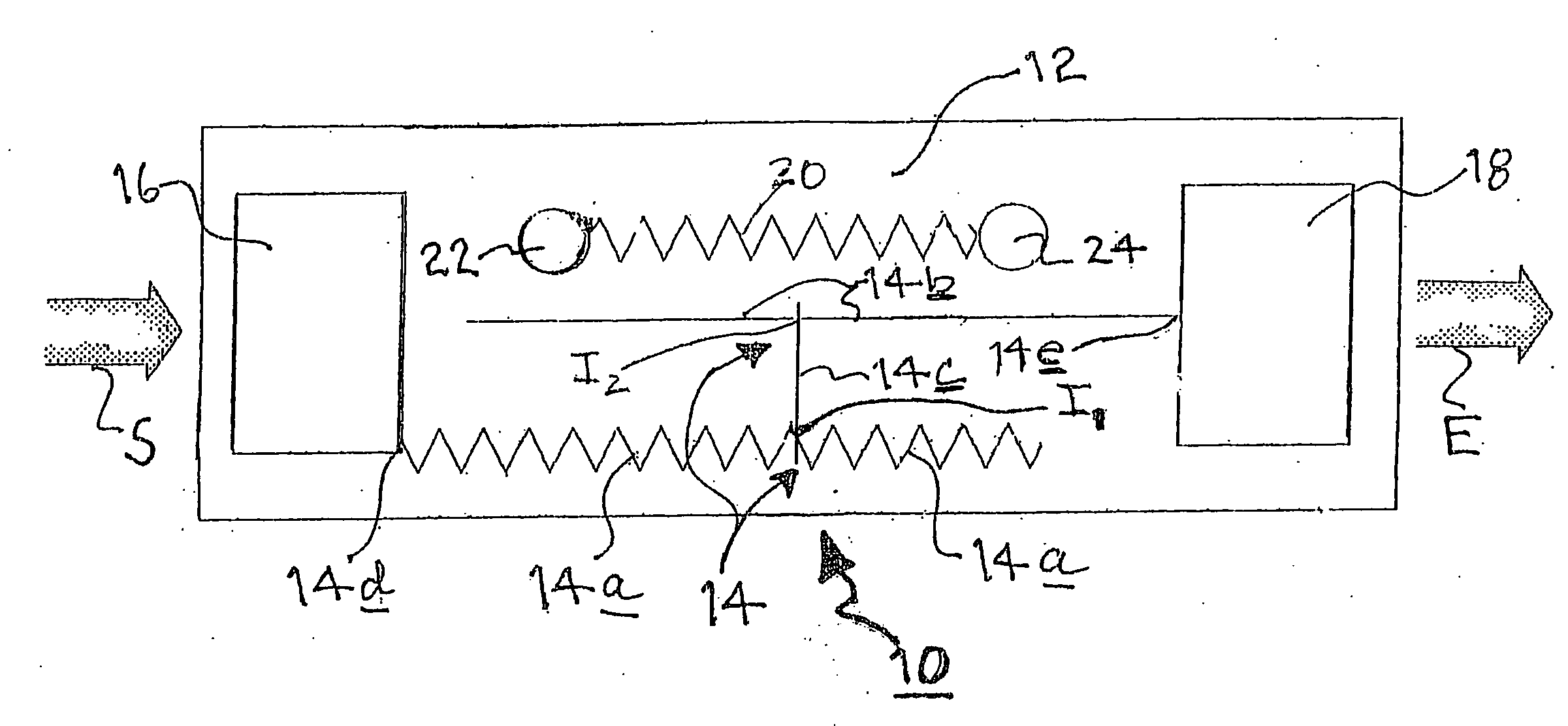

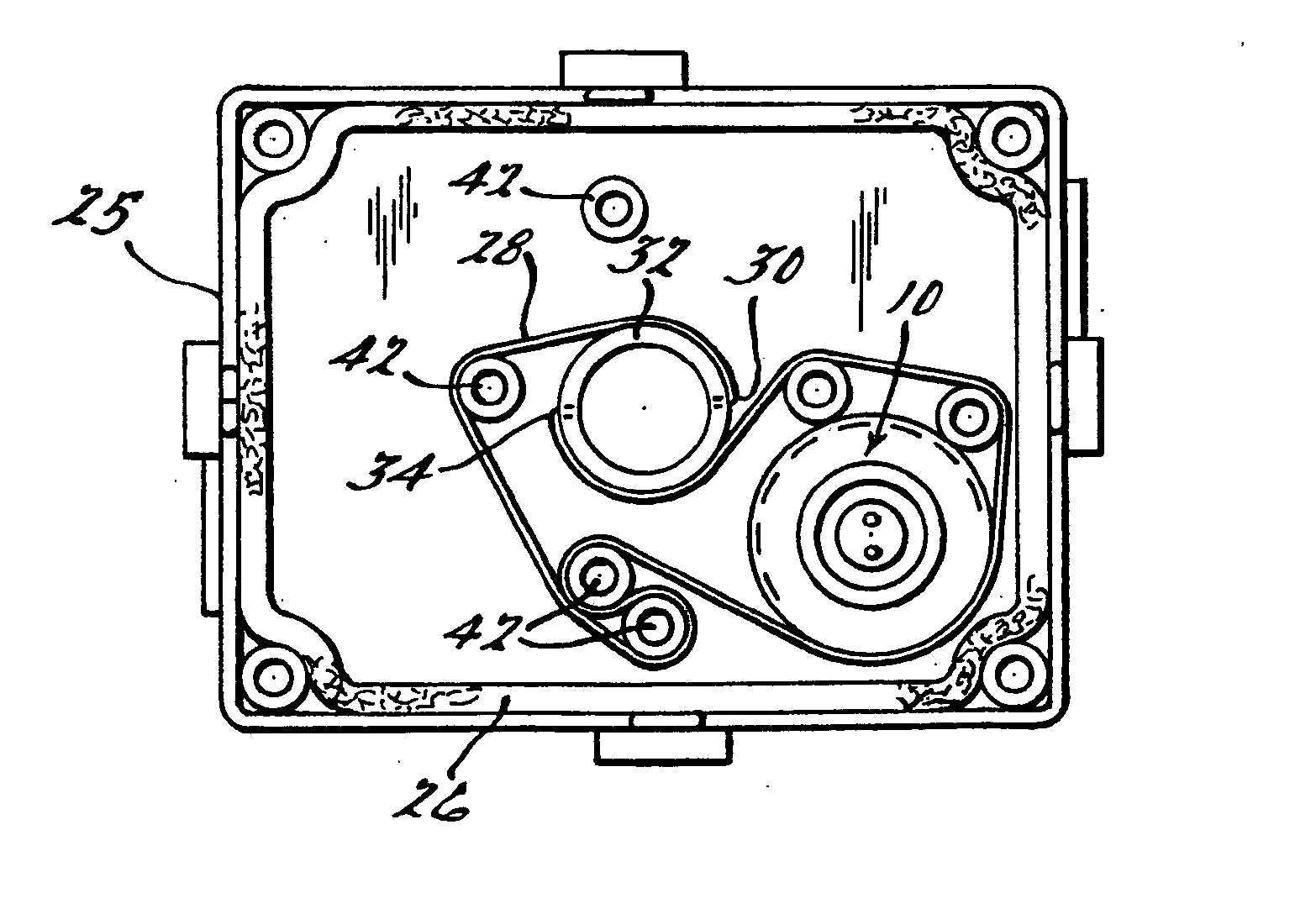

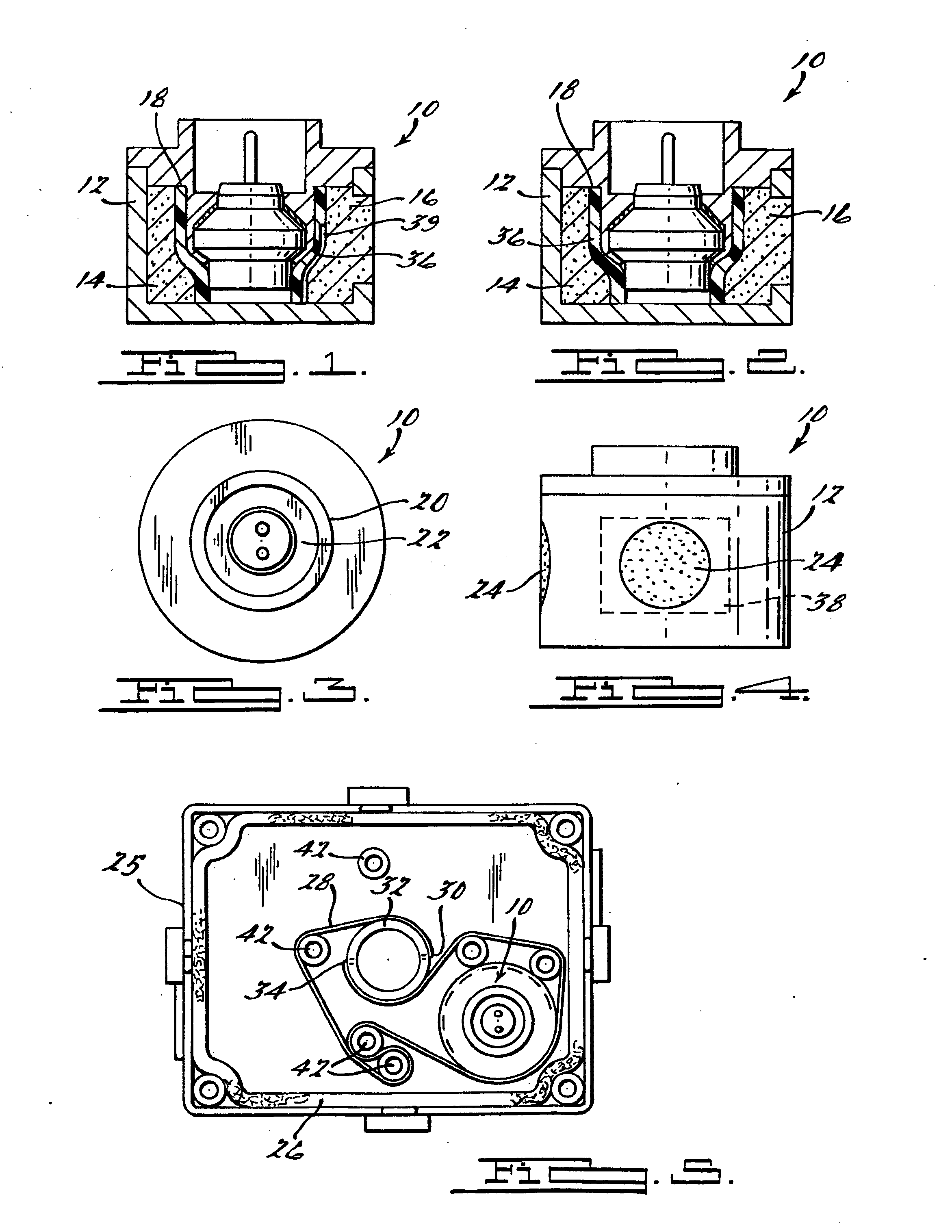

Delay units and methods of making the same

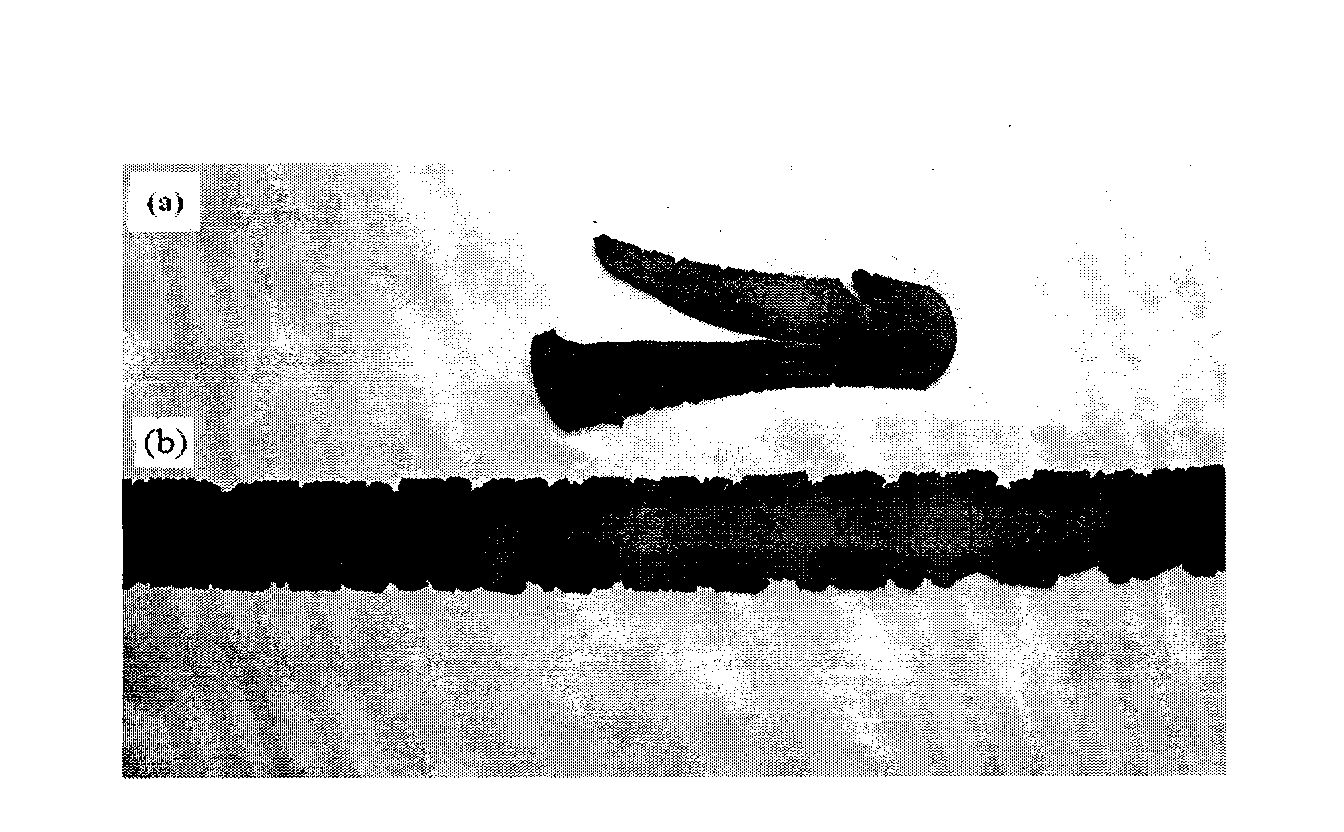

InactiveUS20060236887A1Increase and decrease burn rateReduce burning rateBlasting cartridgesImpact fuzesDelayed periodsEffective length

A delay unit (10) comprises a timing strip (14) and, optionally, a calibration strip (20) deposited on a substrate (12). The timing and calibration strips comprise energetic materials which optionally may comprise particles of nanosize materials, e.g., a fuel and an oxidizer, optionally applied as separate layers. A method of making the delay units comprises depositing onto a substrate (12) a timing strip (14) having a starting point (14d) and a discharge point (14e) and depositing onto the same or another substrate a calibration strip (20). Timing strip (14) and calibration strip (20) are of identical composition and are otherwise configured, e.g., thickness of the strips, to have identical burn rates. The calibration strip (20) is ignited and its burn rate is ascertained. The timing strip (14) is adjusted by an adjustment structure to attain a desired delay period, preferably on the basis that the burn rate of the timing strip (14) is substantially identical to that of the calibration strip (20) and ascertaining the burn rate of the calibration strip. The adjustment may be attained by one or more of providing the timing strip with jump gaps (164), an accelerant or retardant (166a, 166b), completing the timing strip with a bridging strip (14c), or establishing a selected effective length of the timing strip by positioning one or both of a pick-up charge (16) and relay charge (18) over a portion of the timing strip.

Owner:DYNO NOBEL INC

Aluminum alloy for subway station ceiling and preparing method of aluminum alloy

The invention relates to an aluminum alloy for a subway station ceiling and a preparing method of the aluminum alloy. The aluminum alloy is characterized by comprising chemical components, including by mass percent, 0.45% to 0.6% of Mg, 0.3% to 0.5% of Si, 0.1% to 0.3% of Mn, 0.1% to 0.2% of Cr, 0.1% to 0.3% of Zr, 0.1% to 0.3% of Hf, 0.05% to 0.2% of Ta, 0.05% to 0.15% of Cu, not larger than 0.05% of Zn, not larger than 0.20% of Fe, not larger than 0.05% of Ti, and the balance Al, wherein the single content of other impurity elements is not larger than 0.05%, and the total content of other impurity elements is not larger than 0.15%. The aluminum alloy is obtained through the preparing method of smelting, refining, casting and homogenizing. Through optimizing of alloy components, adjustment is carried out, the trace of Zr, Hf and Ta is added, and the strength, the heat dissipation, corrosion resistance, humidity resistance, fatigue resistance, static electricity resistance, recrystallization resistance capacity and breaking resistance performance of the aluminum alloy can be obviously improved.

Owner:ALNAN ALUMINIUM CO LTD

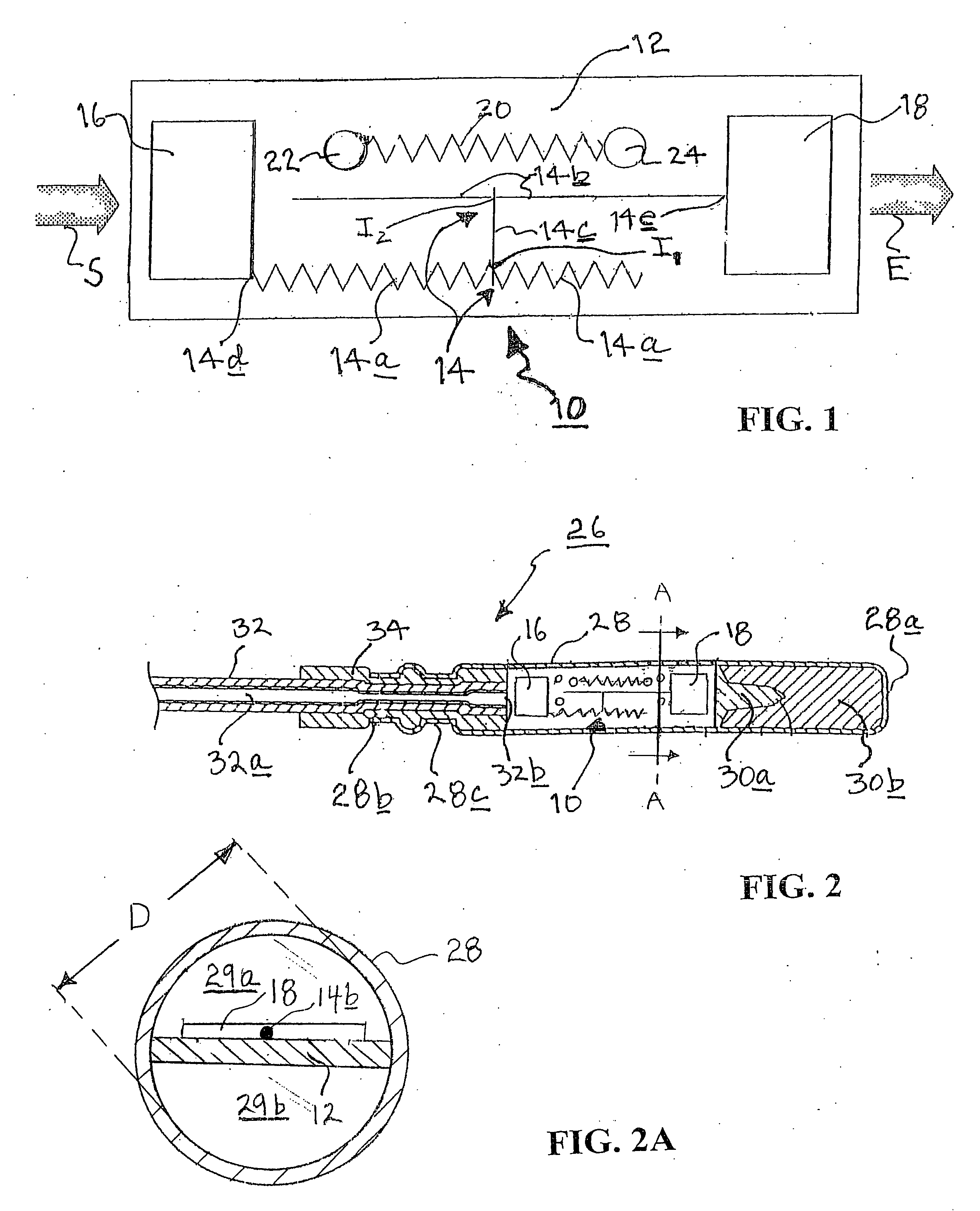

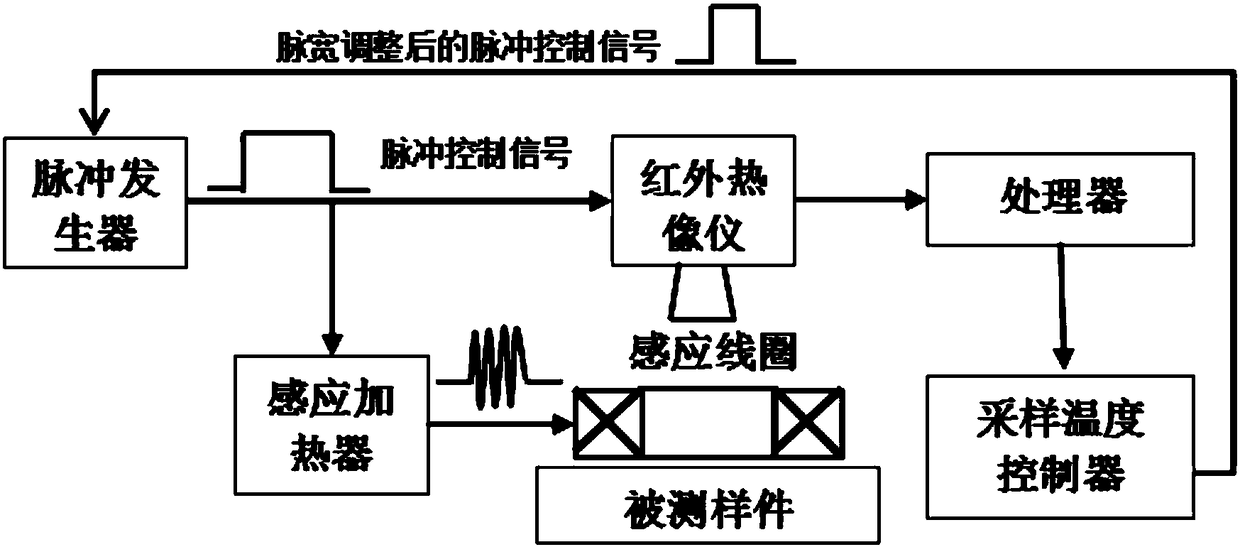

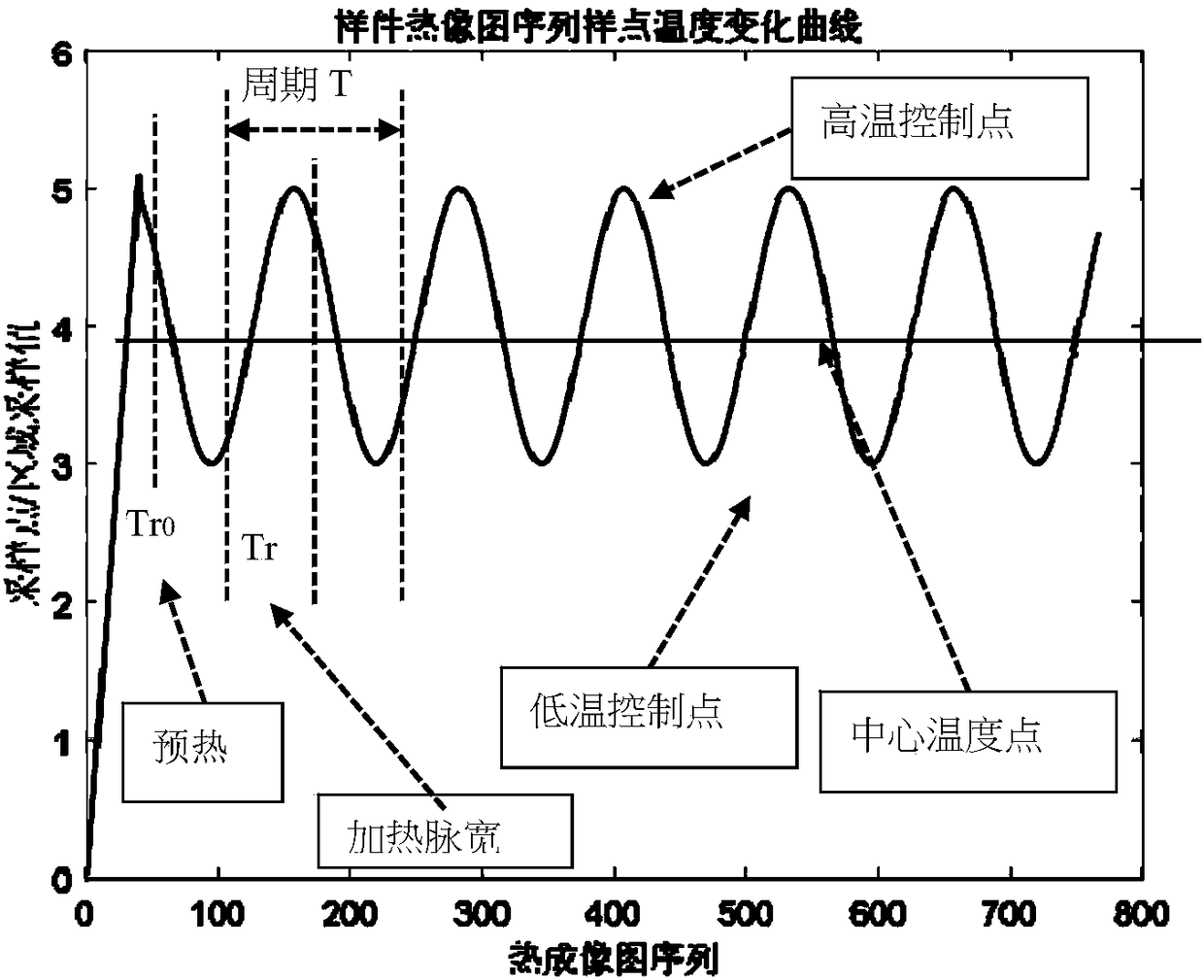

Eddy current pulsed thermography-based non-destructive detection method and system

InactiveCN108195884AThe maximum temperature is kept constantReduce burning rateMaterial flaws investigationAlternating currentElectricity

The embodiment of the invention discloses an eddy current pulsed thermography-based non-destructive detection method and an eddy current pulsed thermography-based non-destructive detection system. Themethod comprises the following steps: generating high-frequency alternating current by controlling an induction heater through an initial heating pulse signal, and combining an induction coil to provide eddy current excitation to heating a tested sample piece; measuring infrared thermal radiation of the tested sample piece to obtain surface heat distribution of the tested sample piece, acquiringan infrared thermography sequence according to the surface heat distribution and performing processing to acquire sampling temperature of a preset sampling point of the tested sample piece; if the sampling temperature is not less than a preset non-destructive detection high-temperature threshold value, outputting a heating stopping instruction to a pulse generator; if the sampling temperature is not more than a preset non-destructive detection low-temperature threshold value, outputting a heating starting instruction to the pulse generator; and controlling the induction heater to disconnect apower supply according to the heating stopping instruction, and controlling the induction heater according to the heating instruction to start the power supply to generate high-frequency alternating current. By application of the method and the system, the temperature control precision of heating can be improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Aluminum alloy welding wire for high speed train and preparation method of aluminum alloy welding wire for high speed train

InactiveCN105772981AHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

The invention relates to an aluminum alloy welding wire for a high speed train and a preparation method of the aluminum alloy welding wire for the high speed train. The aluminum alloy welding wire for the high speed train is characterized by comprising the following chemical components in percentages by mass: 4.0-6.5% of Mg, 0.06-0.2% of Ti, 0.1-0.3% of Cr, 0.05-0.2% of Mn, 0.05-0.2% of La, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for the high speed train comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for the high speed train provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common ER5356 and ER5183 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

Low-porosity aluminum-magnesium-calcium rear earth based cellular Al alloy foam and preparation thereof

The invention discloses a low porosity rate Al-Mg-Ca-rare-earth-based closed-cell foamed aluminum alloy and a preparation method which are a foamed aluminum alloy with good corrosion-resistant performance, high strength, high finished product rate, simple method and low cost and a preparation method. The foamed aluminum alloy takes calcium carbonate as a foaming agent, the porosity rate is between 40 and 75 percent, wherein, the manganese accounts for 1 to 11 percent (mass percentage) of the alloy, the calcium accounts for 0.5 to 5 percent (mass percentage) of the alloy, the rare earth accounts for 0.10 to 1.2 percent (mass percentage) of the alloy. The preparation method is that: the pure aluminum is heated up for melting, the melting body is added with the manganese equivalent to 1 to 11 percent of the mass of the alloy, the calcium equivalent to 0.5 to 5 percent of the mass of the alloy and the rare earth equivalent to 0.10 to 1.2 percent of the mass of the alloy, and kept for 10 to 30 minutes; the temperature of the melting body is ensured between 650 and 690 DEG C, the melting body is stirred for 2 to 12minutes with the speed of between 300 and 600rpm; the calcium carbonate equivalent to 0.5 to 5 percent of the mass of the pure aluminum is added into the melting body to stir so as to make the aluminum alloy melting body to be foamed, the low porosity rate Al-Mg-Ca-rare-earth-based closed-cell foamed aluminum alloy is obtained after cooling.

Owner:SOUTHEAST UNIV

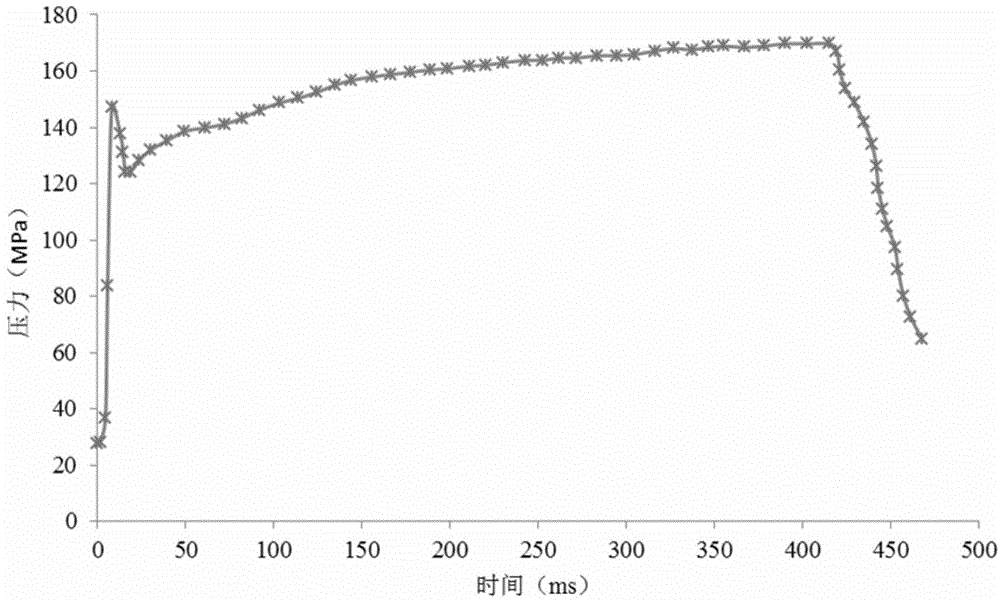

Gunpowder for realizing deep well deep bumming and fracturing

InactiveCN104402659AStable burning rateReduce burning rateExplosivesPtru catalystUltra high pressure

The invention discloses gunpowder for realizing deep well deep bumming and fracturing, the gunpowder includes solid powder and liquid powder; the solid powder comprises a binder, a plasticizer, an oxidizing agent, a metal combustion agent, a high-energy additive, a stabilizer and a catalyst; and the liquid powder comprises an oxidizing agent, a combustion agent, a performance modifier and water. The solid powder of the gunpowder can overcome the restriction of large stress difference coefficient and high fracturing pressure of deep-layer and ultra high pressure formation, a plurality of radial cracks and branched cracks are formed in a broken rock layer, main crack is preliminarily extended, the fracture pressure is reduced to help the liquid powder to continue to fracture the formation, at the same time, the role of ignition of the liquid powder is played, after the solid powder is burn out, the liquid powder continues to maintain a high pressure environment in a wellhole, and effects on the formation for longer time, the main crack length is further extended, the branched cracks are developed, natural cracks are communicated, and a complex fracture network structure is formed in a larger-range purpose layer near the wellbore.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

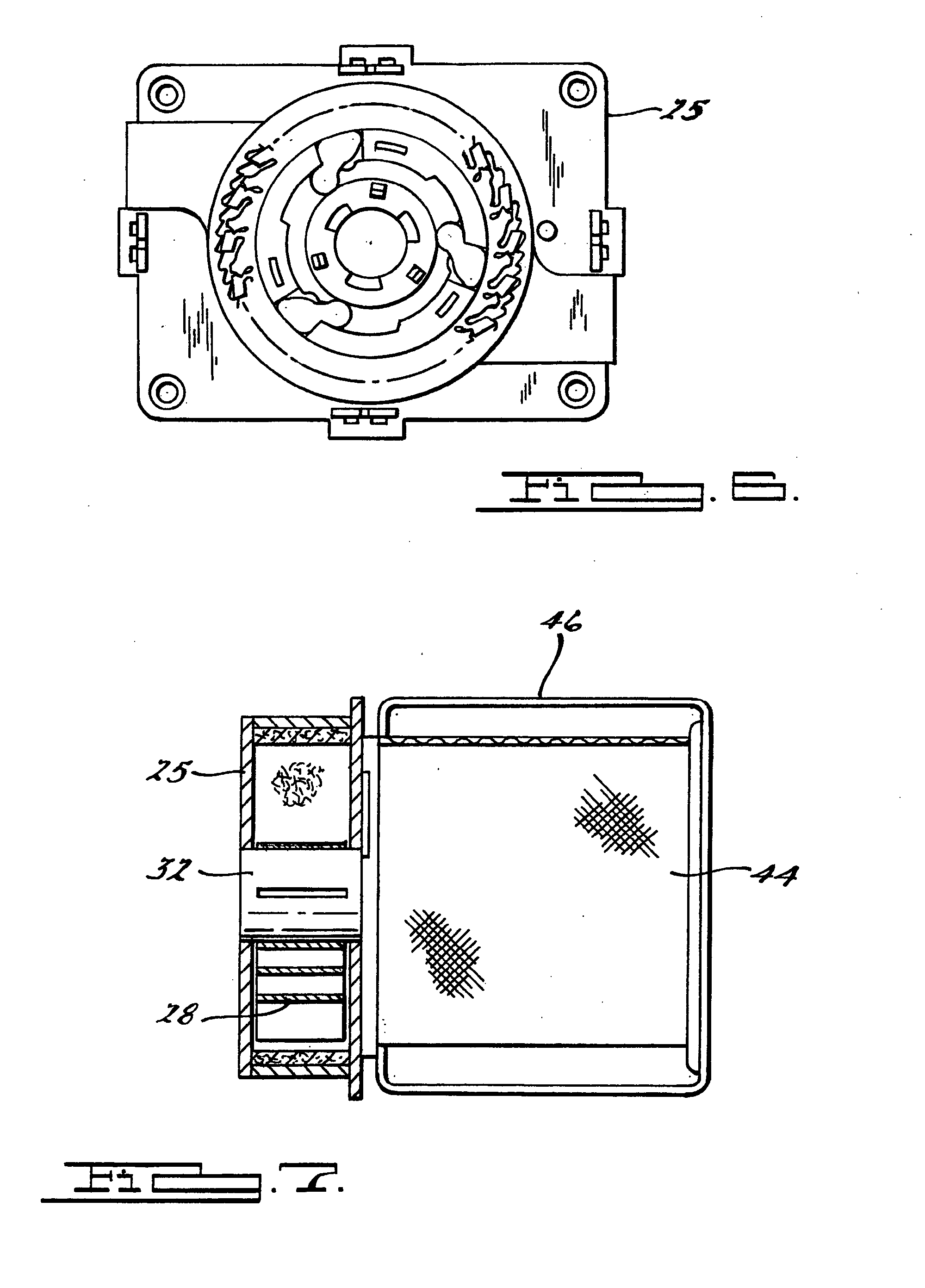

Micro gas generator including an initiator blast shield

InactiveUS20050017496A1Gradual and controlled combustionReduce burning rateBelt retractorsPedestrian/occupant safety arrangementCombustionNuclear engineering

A micro gas generator 10 is provided primarily for supplying and directing gas from the combustion of pyrotechnic materials into a seatbelt pretensioner 26, for example. A perforated housing 12 of gas generator 10 provides a body for containment of the other gas generant constituents, and forms a propellant chamber 14. A propellant or gas generant 16 is contained within chamber 14 and provides combustion thereof. An annular bore 20 is centrally oriented within the bore seal 18 thereby providing a seat for an associated initiator 22. An initiator blast shield 36 is encased about the initiator 22 thereby attenuating or mitigating the force and progression of the combustion of an ignition compound (not shown) within the initiator 22.

Owner:AUTOMOTIVE SYST LAB

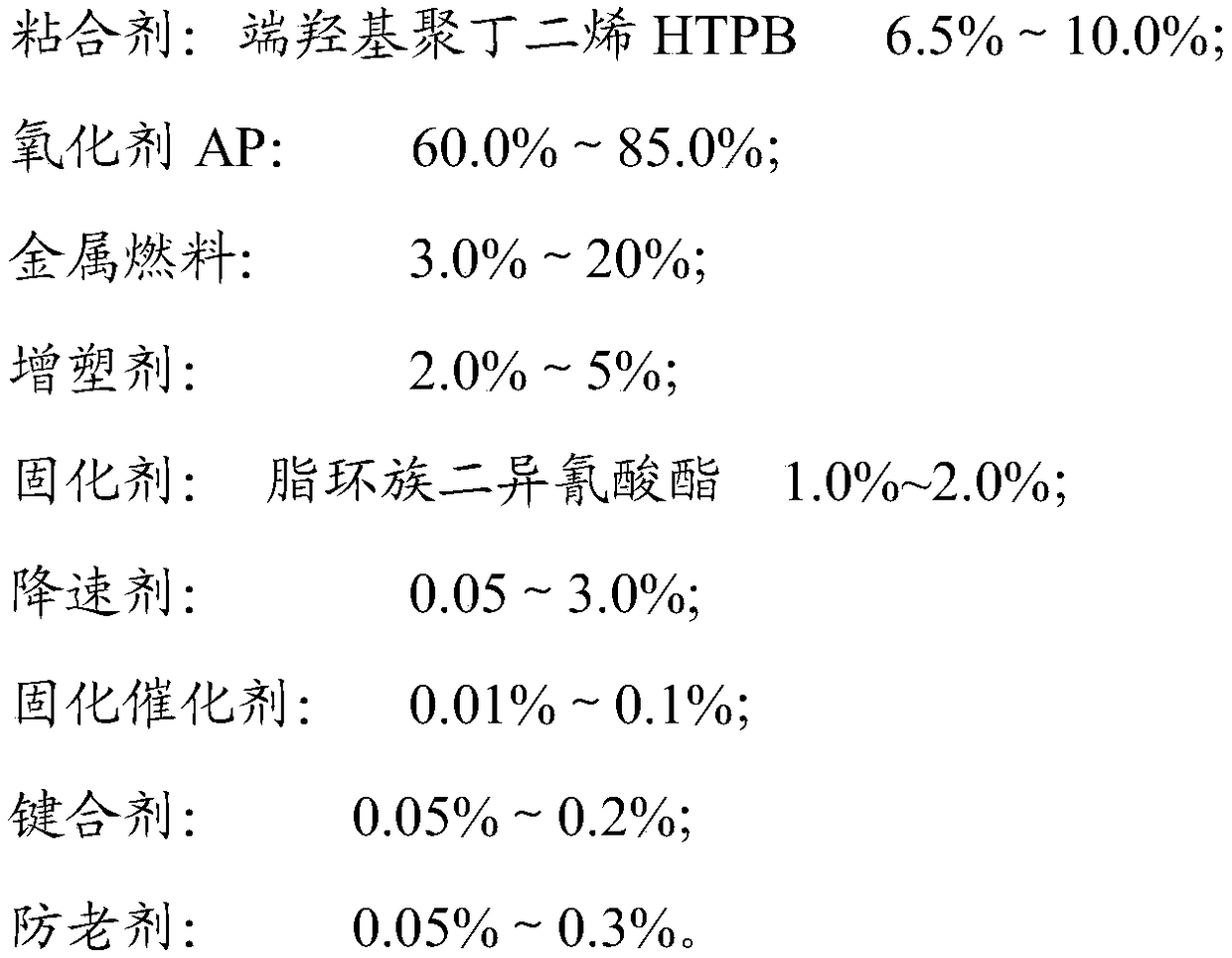

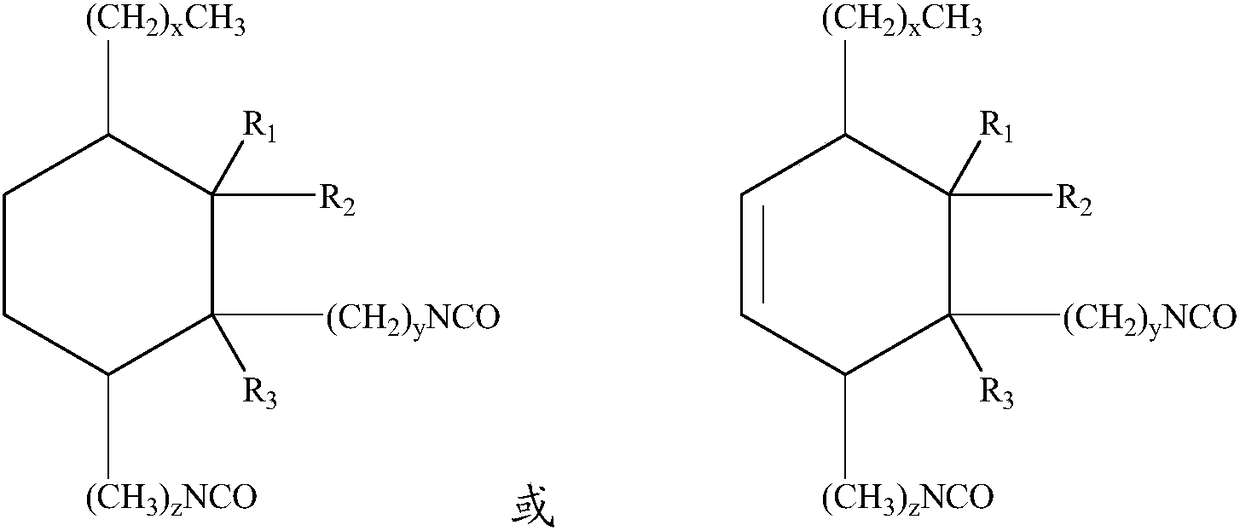

Low-burning rate and high-energy HTPB propellant and application of alicyclic diisocyanate

ActiveCN108117466AReduce base burn rateReduce energy lossNon-explosive/non-thermic compositionsPressure gas generationCombustionAdhesive

The invention relates to a low-burning rate and high-energy HTPB propellant and application of alicyclic diisocyanate. The HTPB propellant comprises 6.5-10.0% of hydroxyl-terminated polybutadiene HTPBas an adhesive, 60.0-85.0% of an oxidant AP, 3.0-20% of metal fuel, 2.0-5% of a plasticizer, 1.0-2.0% of alicyclic diisocyanate as a curing agent, 0.05-3.0% of a burning rate inhibitor, 0.01-0.1% ofa curing catalyst and the like. In the HTPB propellant, the alicyclic diisocyanate is used as the curing agent, the oxidant AP, the metal fuel, the plasticizer, the burning rate inhibitor, the curingcatalyst and other components are added, and the using amount of each component is reasonably selected and optimally designed, so that the basic burning rate of the HTPB propellant is significantly reduced; the addition amount of the inert burning rate inhibitor is reduced, so that the energy loss of the propellant is reduced and the combustion efficiency of the propellant is significantly improved; and a formula of the HTPB propellant with low burning rate and high energy is obtained.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

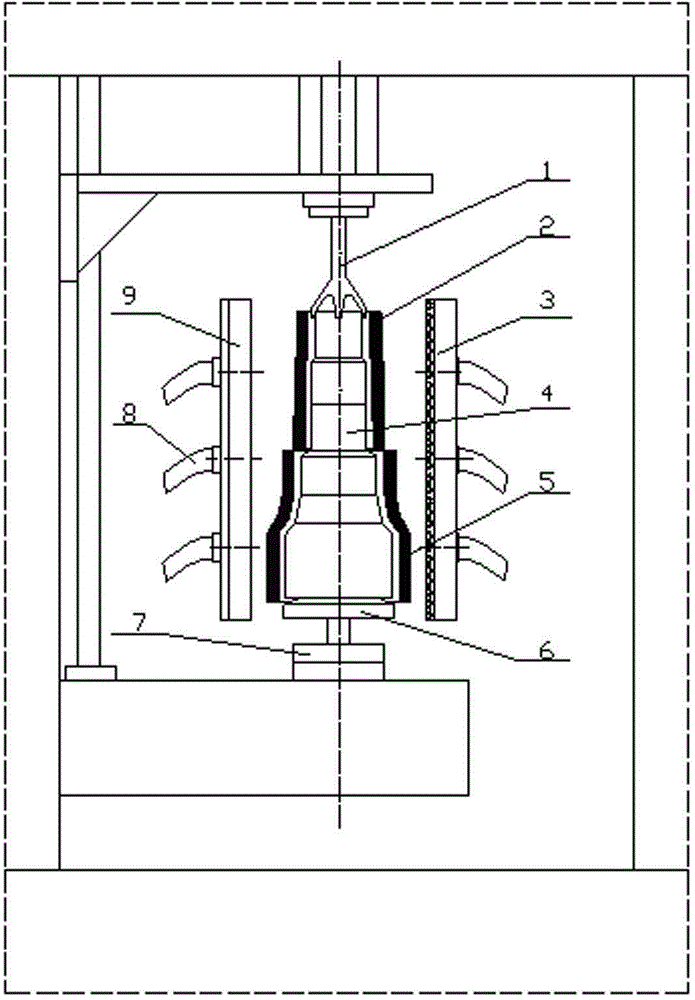

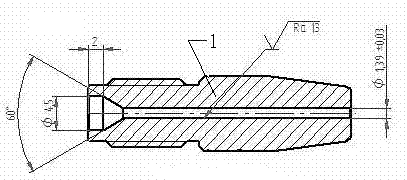

Novel quenching technology applied to vehicular hollow variable cross-section spindle nose and use equipment of novel quenching technology

InactiveCN104611538AAccelerateReduce energy consumptionFurnace typesHeat treatment furnacesHardnessMachine tool

The invention provides a novel quenching technology applied to a vehicular hollow variable cross-section spindle nose, which adopts a technical process of charging, induction heating, spray cooling, blanking, quenching hardness detection, tempering, cooling, hardness detection and mechanical property analysis. Equipment used by the quenching technology is characterized in that a turntable is arranged on a machine tool station, a locating disc is arranged on the turntable, a workpiece is placed on the locating disc, an induction coil is arranged at the periphery of the workpiece, water spray plates with a plurality of water inlet pipes are arranged at the periphery of the induction coil, and an upper centre having a clamp action is arranged at the upper part of the workpiece. The technology is energy-saving, efficient, environment-friendly and easy to control, easily achieves automatic heat treatment, can allow the vehicular spindle nose to obtain good comprehensive mechanical properties after heat treatment and ensures that products of all batches and all workpieces can keep relatively high consistency.

Owner:南阳市红阳锻造有限公司

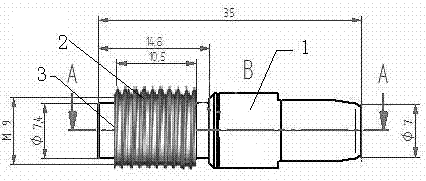

Welding gun contact tube

InactiveCN102825370AReduce burning rateDissipate quicklyElectrode accessoriesSoldering gunHigh current

The invention discloses a welding gun contact tube which comprises a contact tube body. The welding gun contact tube is characterized in that the tail part of the contact tube body is provided with an external thread which is matched with the thread hole of a contact tube seat at the head part of a welding gun; the external thread is an M9 lengthened thread; the length of the contact tube body is arranged to be 35mm by lengthening; the tail part of the contact tube body is a thread connecting part; the thread connecting part is arranged to be 14.8 by lengthening. According to the welding gun contact tube provided by the invention, the body is longer than the general contact tube, and the length of the thread part is increased, so that the contact tube is lengthened at the welding gun connecting part; and the welding gun contact tube is excellent in contact performance and heat radiating effect aspect, is adaptive to the welding requirement well, can show the excellent performance in each aspect, especially is suitable for high-current welding of 300A above, and shows obviously in welding with aluminum; and the production efficiency of welding is improved, and the burning and damage ratio of the contact tube is reduced.

Owner:EWM HIGHTEC WELDING KUNSHAN

Paint

InactiveCN102352146AEasy to getLow costFireproof paintsNatural resin coatingsChlorinated paraffinsMaterials science

The invention belongs to the technical field of chemical engineering, and specifically relates to paint comprising components of, by mass: 40 to 50 parts of a paint component, 20 to 30 parts of a mixture of chlorinated paraffin and antimony oxide, and 10 to 15 parts of zeolite powder. The paint is advantaged in that: the raw materials mainly comprise the paint component which is a paint commonly used in markets; the raw materials are easy to obtain, and the cost is not high; a mixture of chlorinated paraffin and antimony oxide is added to the paint provided by the invention, such that a main function of fire retarding is provided. When an accident is happened, burning velocity of fire can be retarded as far as possible, such that safety coefficient of the paint is improved.

Owner:王琴

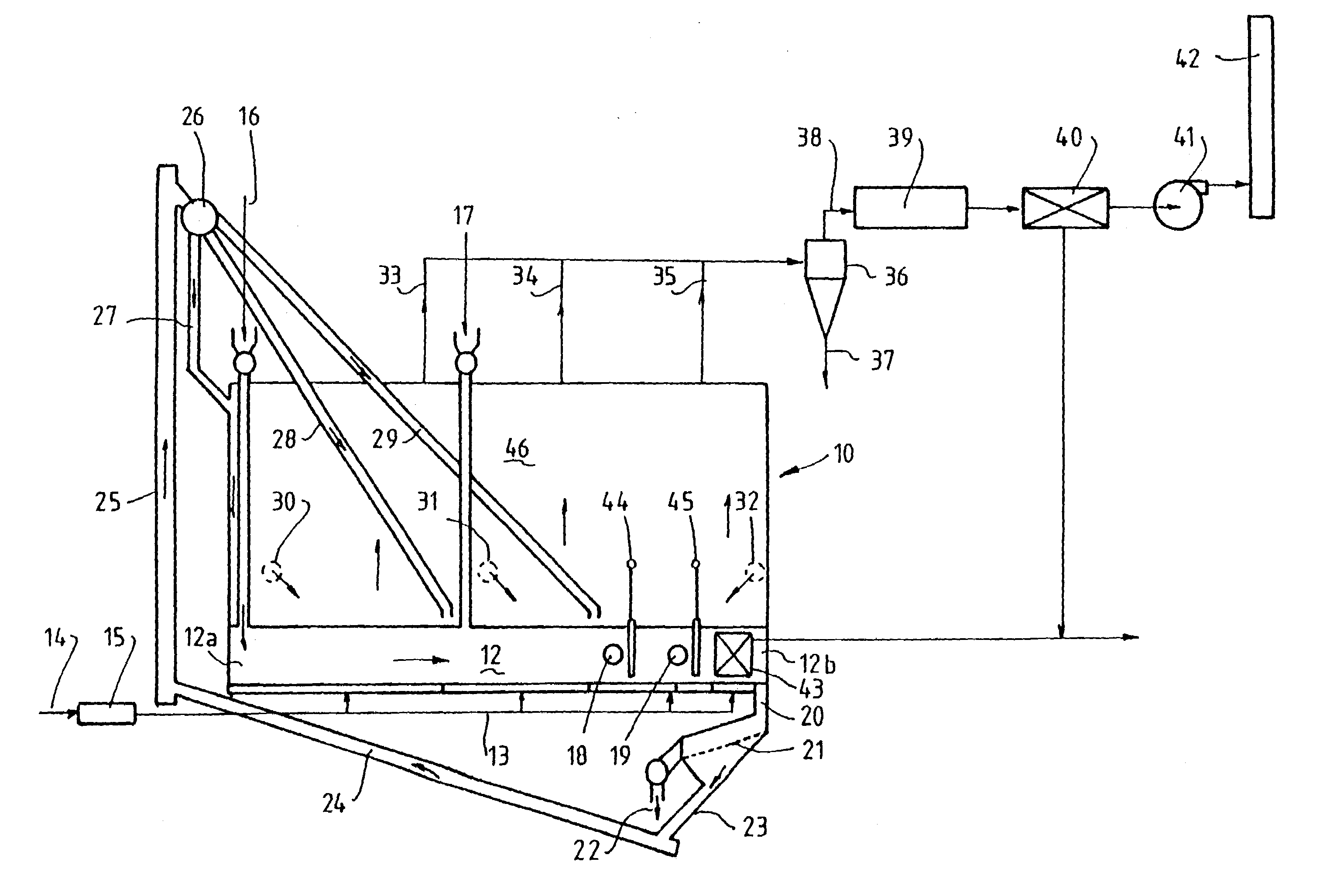

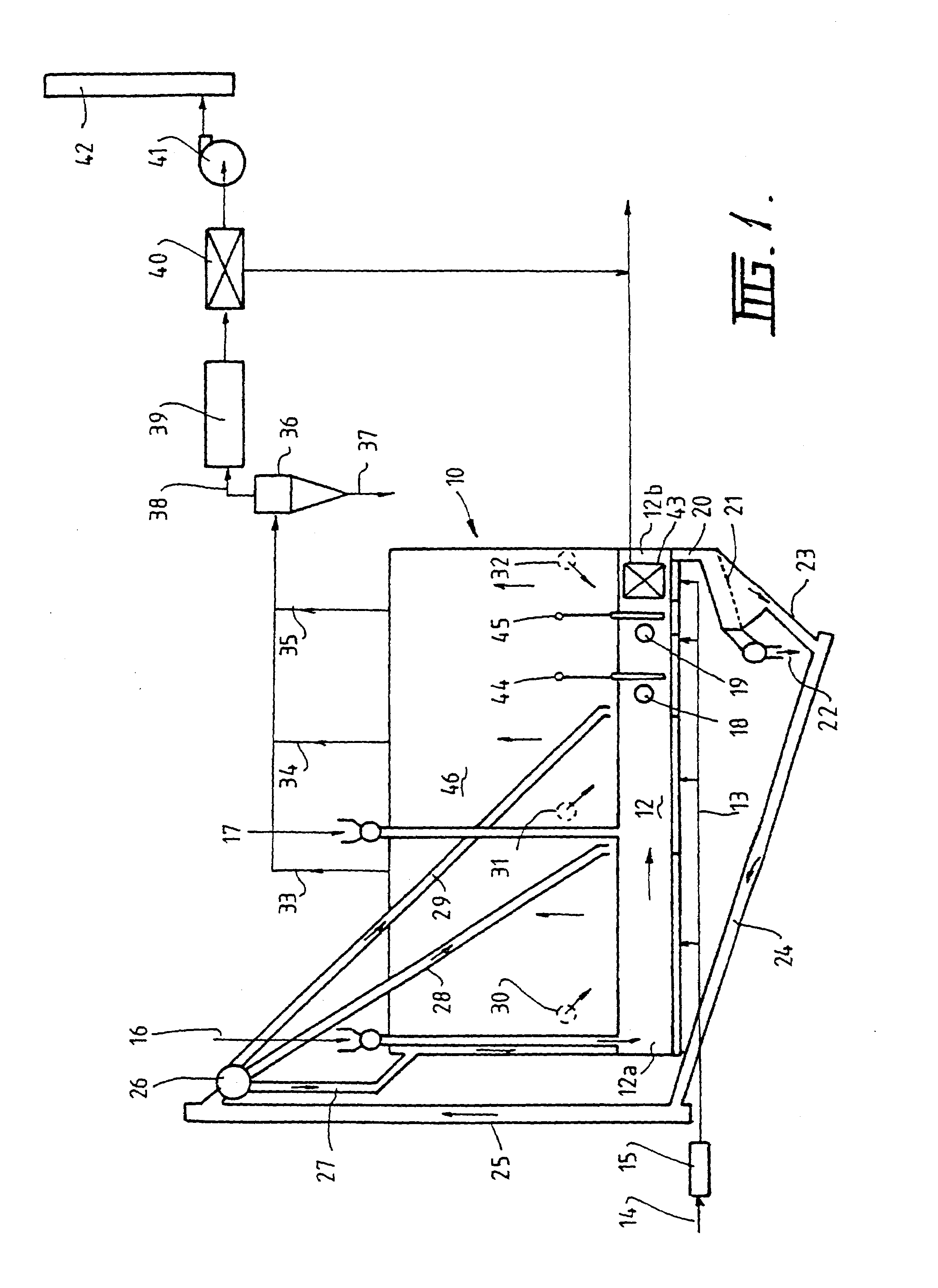

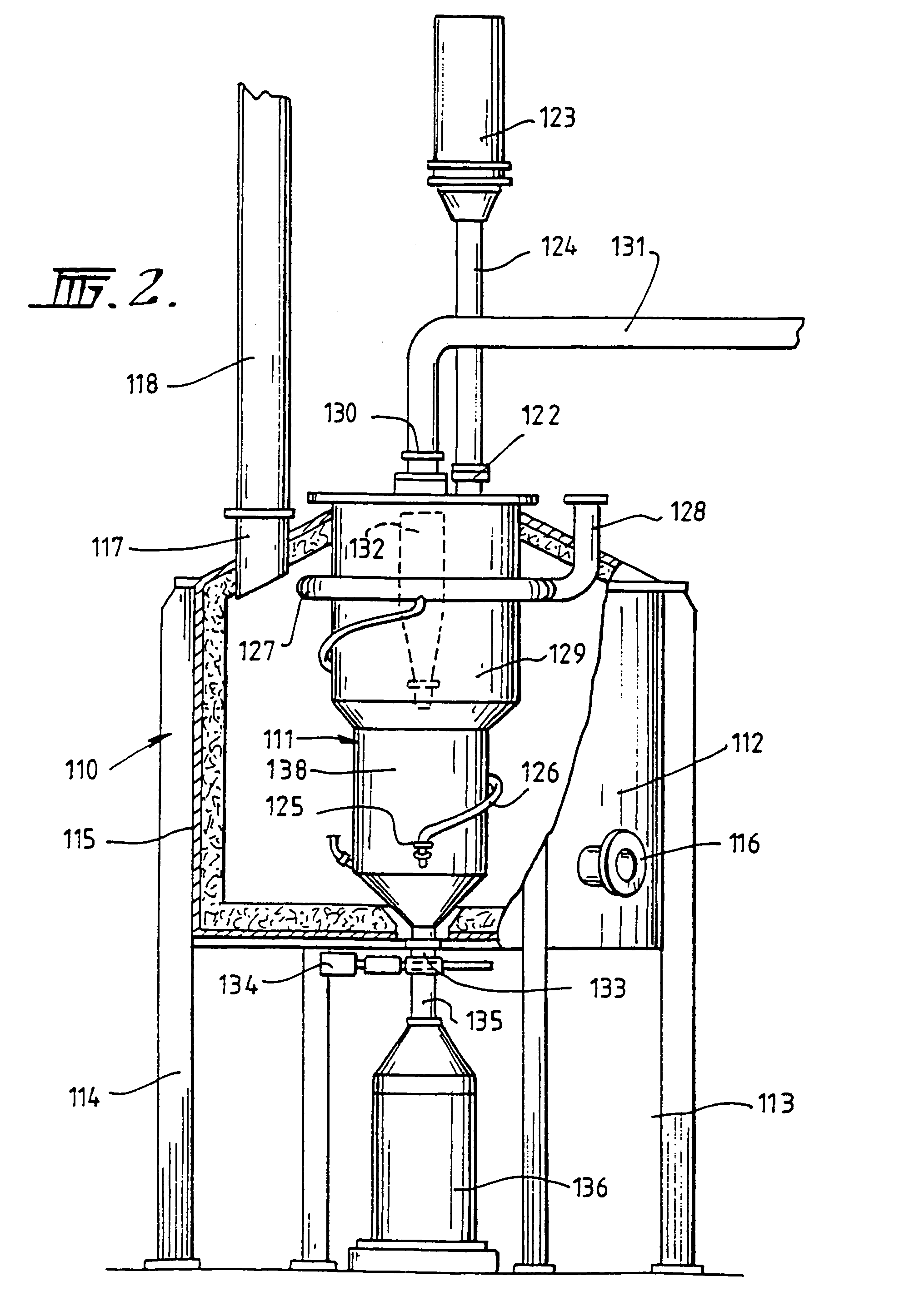

Process for carbonizing wood residues and producing activated carbon

InactiveUS7029273B2Improve heat transfer performancePromote combustionProductsCarbon compoundsActivated carbonFluidized bed

An apparatus and process for preparing activated carbon from a wood or wood residue feedstock using fluidized bed technology. The fluidized bed apparatus has a number of wood residue inlets that allow differing residence times in the fluidized bed apparatus appropriate for the wood or wood residue feedstock to be carbonized. The carbonized material may then be activated to form activated carbon.

Owner:COMMONWEALTH SCI & IND RES ORG

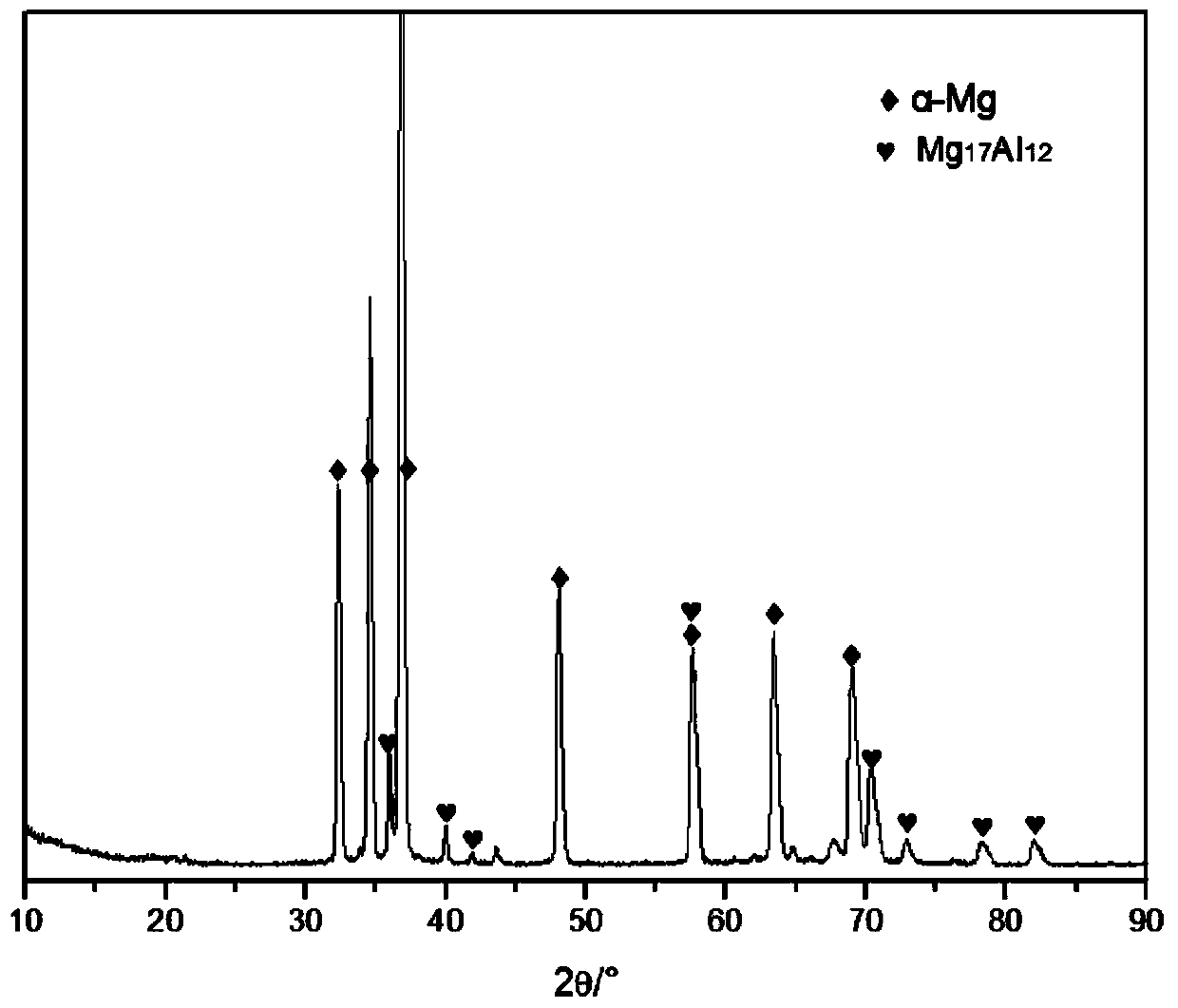

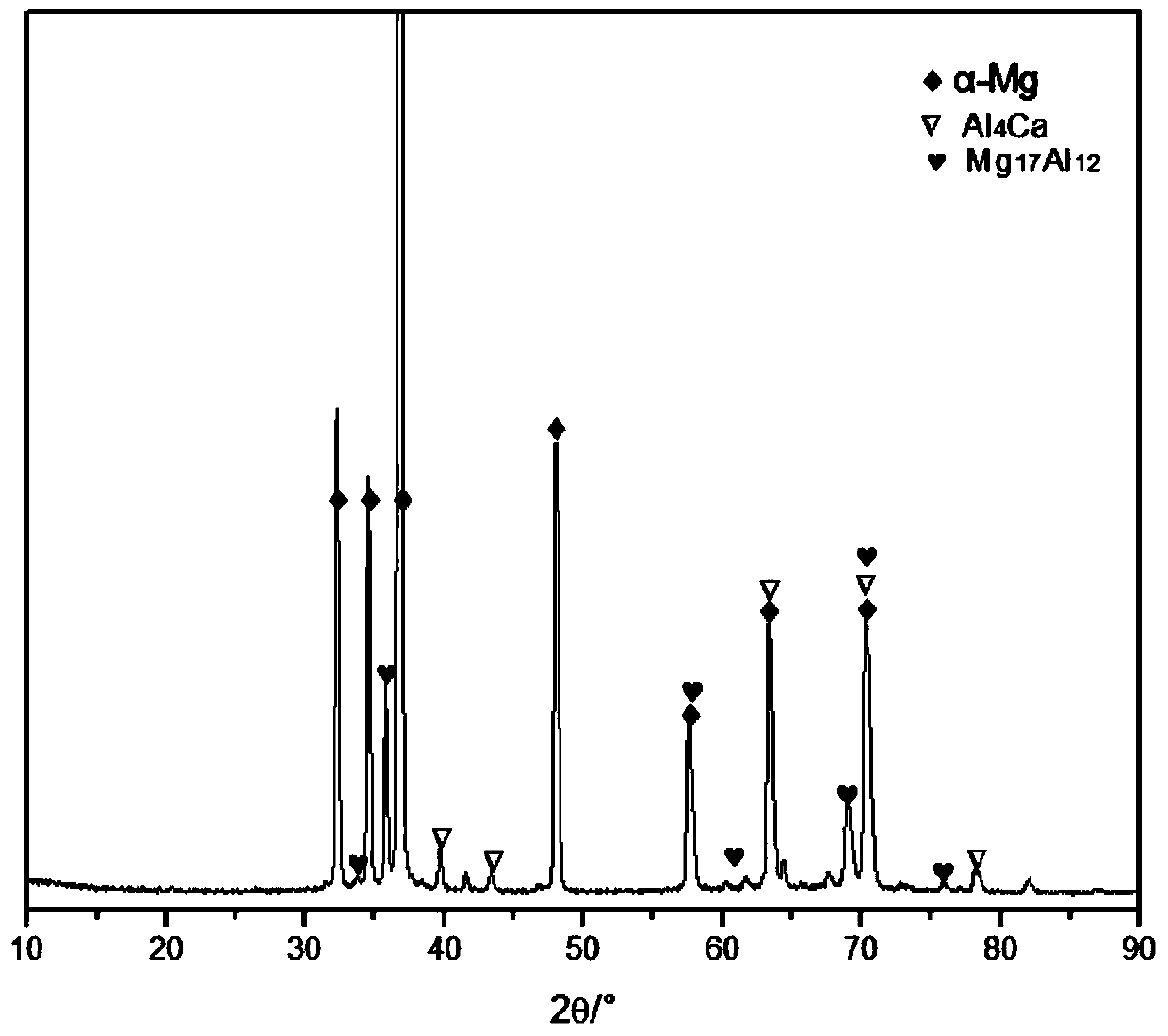

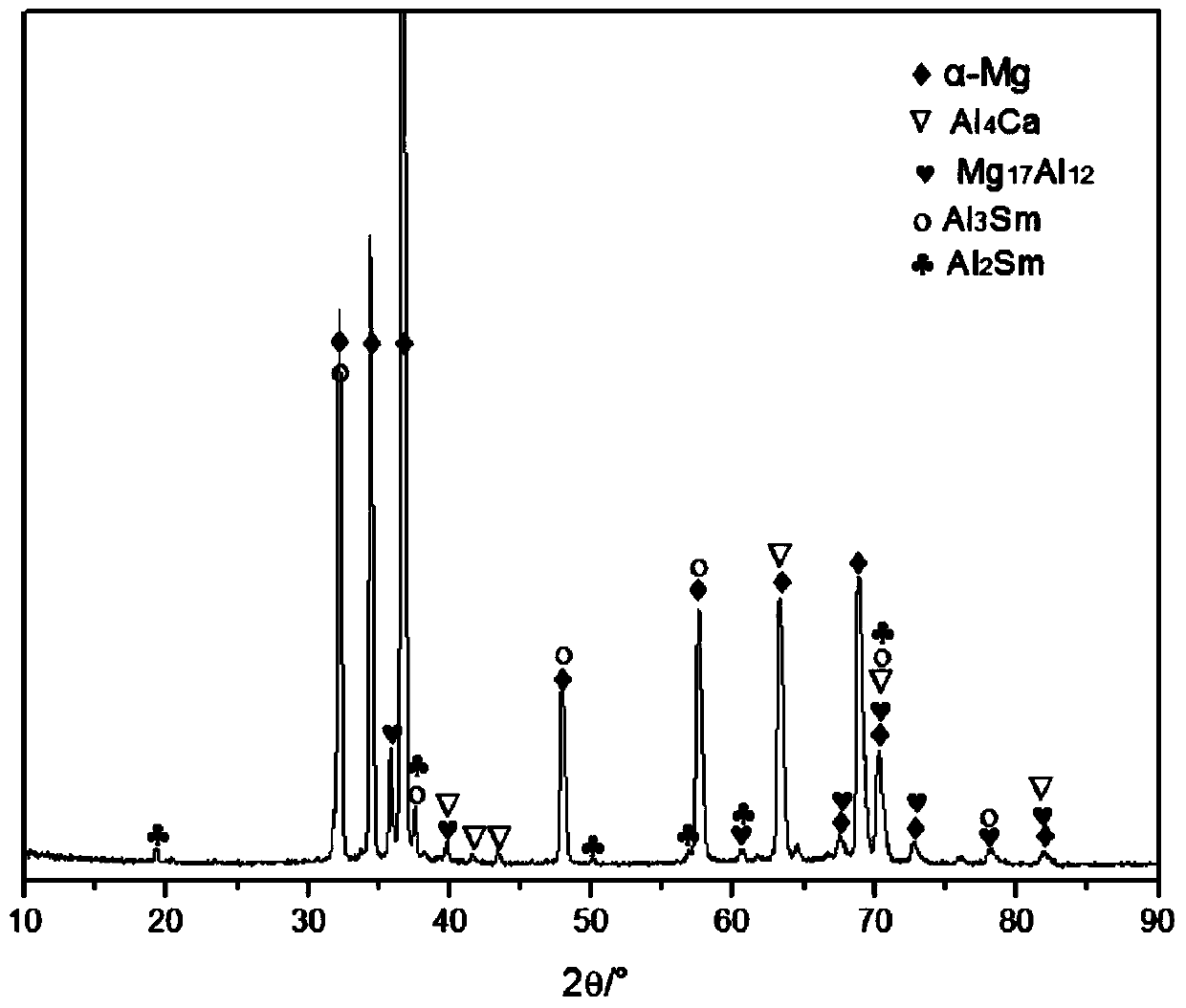

Magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium

InactiveCN103469039AGood casting performanceImprove antioxidant capacityRare earthThermal deformation

The invention relates to a magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium. The wrought magnesium alloy comprises the following components by mass percent: 5.3% to 6.0% of Al (aluminum), 0.7% to 1.0% of Zn (zinc), 0.4% to 0.5% of Ca (calcium), 0.2% to 1.5% of Sm (samarium), less than or equal to 0.15% of inevitable impurities and the balance of Mg (magnesium), wherein all the components taken as raw materials in proportion are fused and rapidly cooled in a salt bath; an obtained alloy spindle is annealed in a homogenization manner at 400 DEG C and air-cooled to reach a room temperature; then the hot extrusion is carried out on the alloy spindle at 360 DEG C according to the extrusion ratio being 25:1, so that the magnesium-aluminum-zinc wrought magnesium alloy containing the calcium and the rare-earth samarium is obtained. After the thermal deformation is carried out on the magnesium alloy, the tensile strength and the yield strength of the magnesium alloy are improved. Thus, the foundation for actual production applications of the wrought magnesium alloy is laid.

Owner:CHONGQING UNIV

Healthcare cigarette containing Chinese herbal medicine

ActiveCN103720040AReduce burning rateSolve the problem of dryness caused by strong irritationTobacco treatmentCigar manufactureSmoke EmissionTraditional medicine

The invention discloses a healthcare cigarette containing Chinese herbal medicine. The healthcare cigarette comprises a cigarette stem and a filter tip connected with the cigarette stem. The cigarette stem contains tobacco shreds. The healthcare cigarette is characterized in that the tobacco shreds contain, by weight, 60-70 parts of the Chinese herbal medicine, 20-30 parts of Chinese alpine rush fibers and 3-5 parts of essence. The healthcare cigarette containing the Chinese herbal medicine has the advantages that the healthcare cigarette is aromatic and is good in taste, colors of ash and smoke of the healthcare cigarette are close to colors of ash and smoke of the traditional cigarette, and smoking control and healthcare effects can be realized after a smoker smokes healthcare cigarettes containing Chinese herbal medicine for a period of time.

Owner:刘睛睛

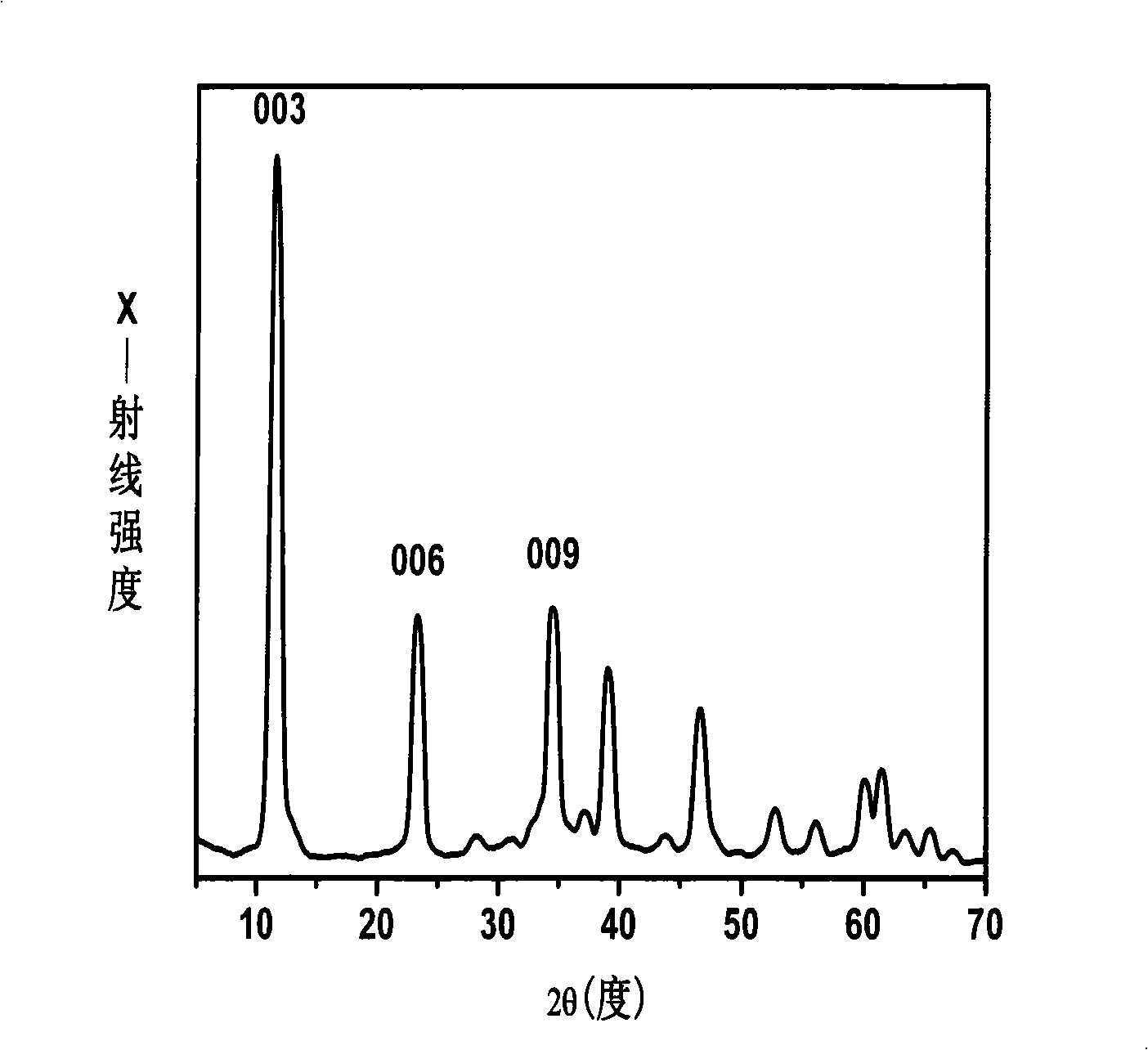

Catalysis carbon-forming type flame-retardant composite material and preparation method thereof

The invention discloses a catalysis carbon-forming type flame-retardant composite material and a preparation method thereof, belonging to the technical field of preparation of flame-retardant composite materials. The technical proposal is as follows: firstly hydrotalcite with the particle size of nano level or submicron level is prepared, and the hydrotalcite and the polymer are processed by melt blending reaction so as to prepare the catalysis carbon-forming type halogen free flame-retardant composite material. The composite material employs the property that the hydrotalcite can promote the polymer to be transformed to graphite-structure carbon, thus reducing the content of combustible gas released by polymer pyrolysis in the combustion process, reducing the combustion speed of the materials and leads the materials to have self-protecting function. The hydrotalcite absorbs large amount of heat when being heated for decomposition, and water and carbon dioxide gas released by decomposition can dilute and block the combustible gas; the products after decomposition is alkali porous material, has large specific surface, and can absorb harmful gases, especially acid gases, thus having double functions of retarding flame and suppressing smoke. The method has simple technique and good product performance and is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

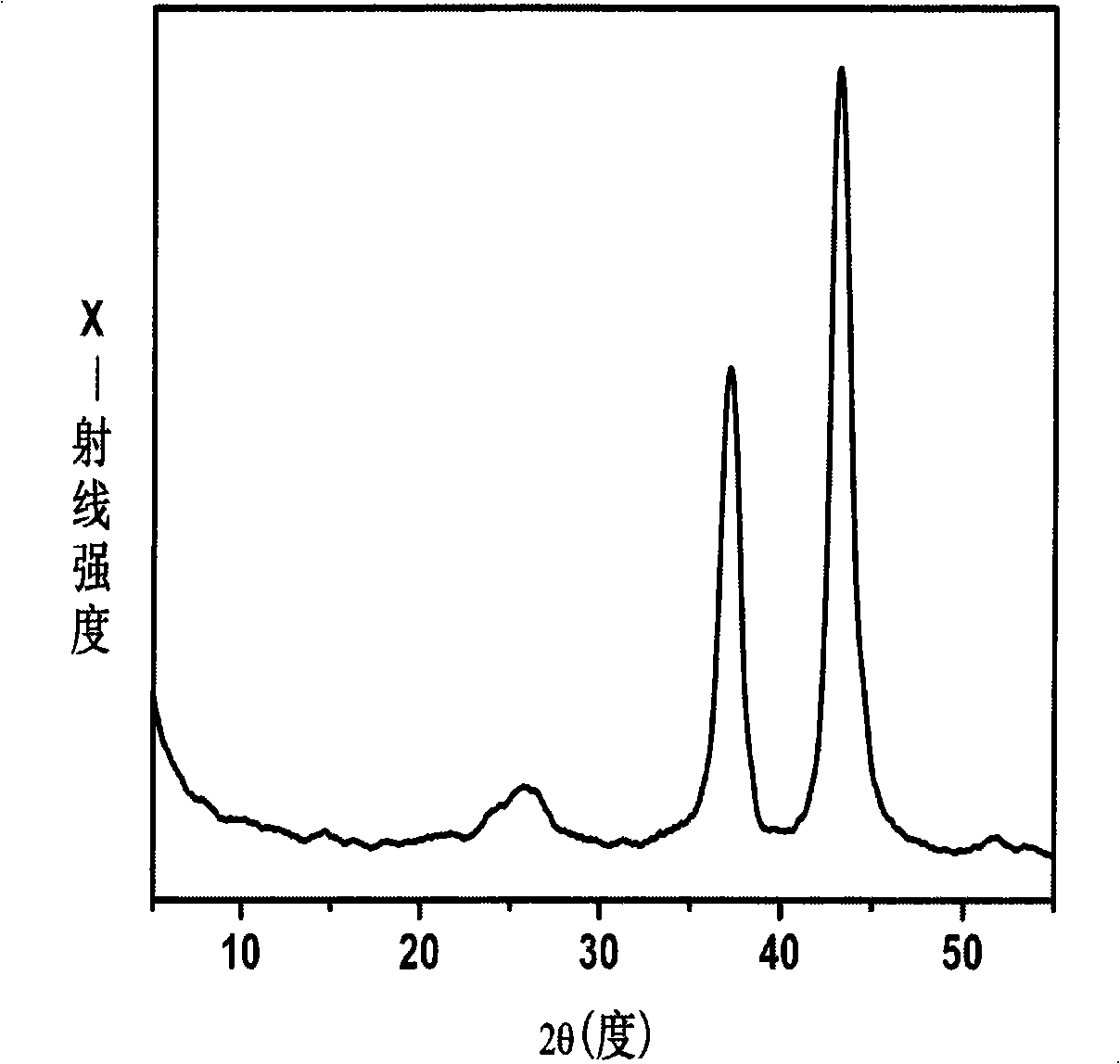

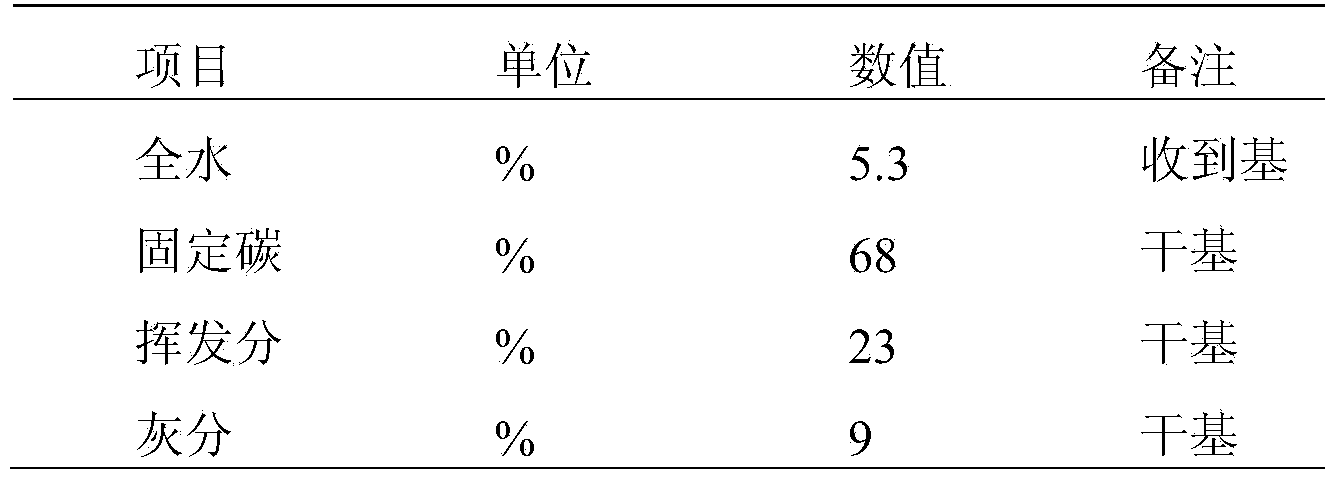

Method for preparation of raw materials for smelting calcium carbide

ActiveCN103708743AReduce manufacturing costCalcination temperature is lowCalcium carbideLime productionTarCoal particle

The invention discloses a method for preparation of raw materials for smelting calcium carbide. The method comprises the following steps: drying low-mid-rank coal to obtain dried low-mid-rank coal; crashing limestone and the dried low-mid-rank coal to respectively obtain limestone particles and low-mid-rank coal particles; mixing and molding the limestone particles and the low-mid-rank coal particles to obtain a molded material; putting the molded material into an annular furnace and calcining the molded material under an inert atmosphere to obtain high-calorific value synthetic gas, tar and calcium carbide smelting raw materials, wherein the calcium carbide smelting raw materials include semicoke and unslaked lime. Thus, the calcining temperature and calcining time of the limestone can be remarkably reduced, so that the production cost for preparing the calcium carbide smelting raw materials is lowered.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Device and method for reducing nitrogen oxide generated by coke oven

ActiveCN105670650AReduce generationReduce burning rateCombustible gas coke oven heatingCoke oven detailsNitrogen oxidesControl system

The invention discloses a device for reducing nitrogen oxide generated by a coke oven.The device comprises a bidirectional axial-flow fan, an electric control system and a measuring device.The bidirectional axial-flow fan is arranged at a smoke distribution flue corridor of the coke oven, a wind opening is communicated with a waste gas channel of the coke oven via a pipeline, and another wind opening is communicated with an air channel of the coke oven via a pipeline.The rotational speeds and the rotational directions of the bidirectional axial-flow fan are controlled by the electric control system; the concentration of the nitrogen oxide in waste gas in the pipelines is detected by the measuring device.A method for reducing the nitrogen oxide generated by the coke oven includes exhausting the waste gas in the waste gas channel of the coke oven, forcedly feeding the waste gas into the air channel of the coke oven and mixing the waste gas with air; reducing the content of oxygen in the air by the aid of the waste gas.The device and the method have the advantages that the internal structure of the coke oven does not need to be changed, the concentration of the nitrogen oxide in the waste gas and the absolute emission load of the nitrogen oxide can be obviously lowered, and surrounding atmospheric environments of enterprises can be improved.

Owner:JINNENG SCI & TECH

Fire retardant coating

The invention relates to the field of building materials, in particular to a fire retardant coating. The fire retardant coating comprises the following components in percentage by mass: 7 to 20 percent of cyanoethyl cellulose, 10 to 20 percent of fluoro ethylene-vinyl ether (FEVE) fluorocarbon resin, 10 to 15 percent of glass bead, 10 to 30 percent of pigment, 5 to 20 percent of ammonium polyphosphate, 3 to 8 percent of curing agent, 20 to 30 percent of phenol propane epoxy resin, and the balance of solvent. A product has good fireproof performance, and a wide application range, and is good in film property, and is suitable to be popularized and applied.

Owner:蓝烟(北京)科技有限公司

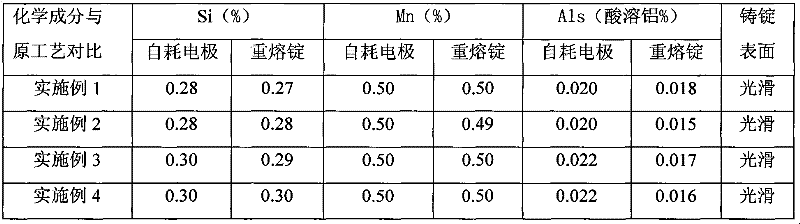

Remelting slag for electroslag remelting plate blank and manufacturing method thereof

The invention relates to remelting slag for an electroslag remelting plate blank and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: mixing 28 to 30 weight percent of lime, 30 to 32 weight percent of aluminum oxide, 39 to 41 weight percent of fluorite and 1 to 3 weight percent of magnesium oxide uniformly, premelting at the high temperature of 1,200 and 1,550 DEG C, and cooling and crushing to form granules of between 3 and 20 millimeters. The premolten remelting slag comprises the following chemical ingredients in percentage by weight: 39 to 41 percent of CaF2, 8 to 30 percent of CaO2, 32 to 34 percent of Al2O3, less than or equal to 0.01 percent of SiO2, less than or equal to 0.01 percent of P2O5, less than or equal to 0.01 percent of S and less than or equal to 0.01 percent of total carbon, wherein CaO / Al2O3 is 0.9 to 1.0. The invention has the advantages that: 1) the chemical ingredients of a remelting slag system in the process of remelting the plate blank are not deteriorated, and the slag system is stable relatively; and 2) the content of the fluorite in the components is low, so the pollution of fluorine on environment is reduced.

Owner:LIAONING TIANHE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com