Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221results about How to "Good metamorphic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

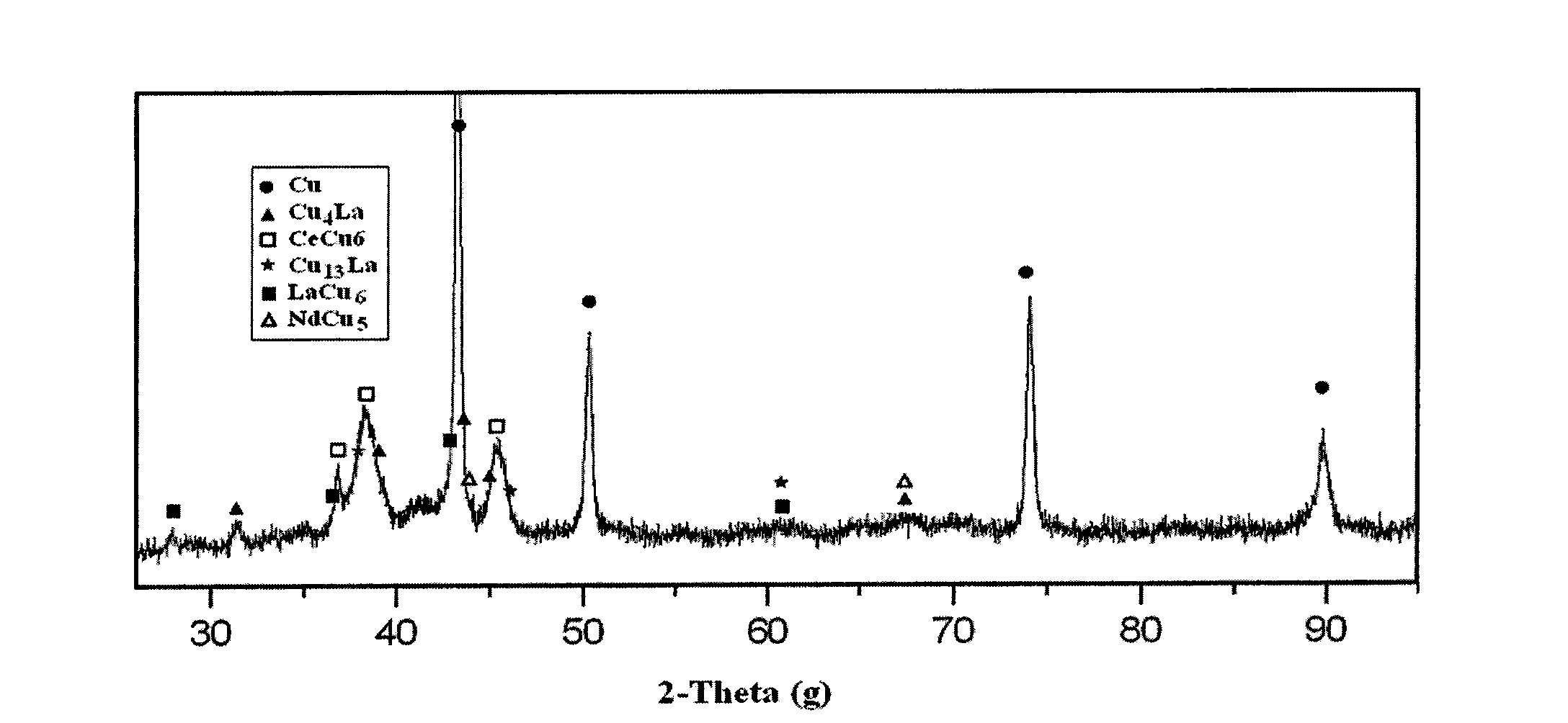

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

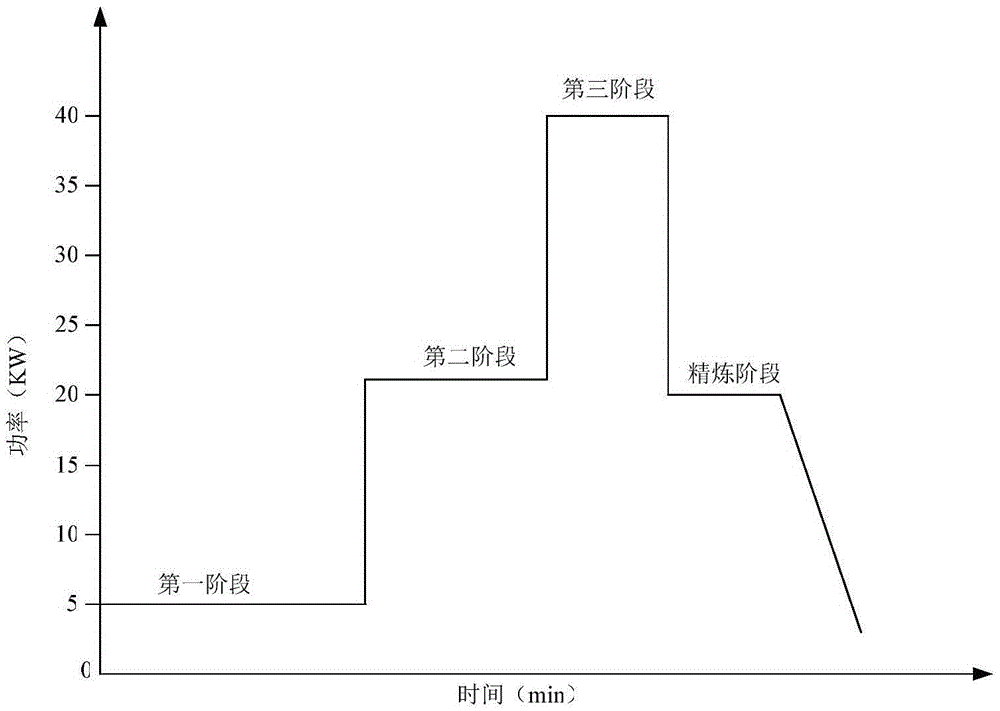

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

Method for modification and refinement of hypoeutectic and eutectic Al-Si alloy

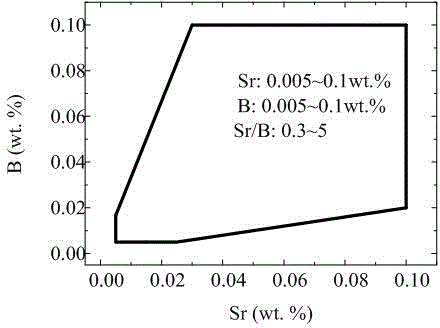

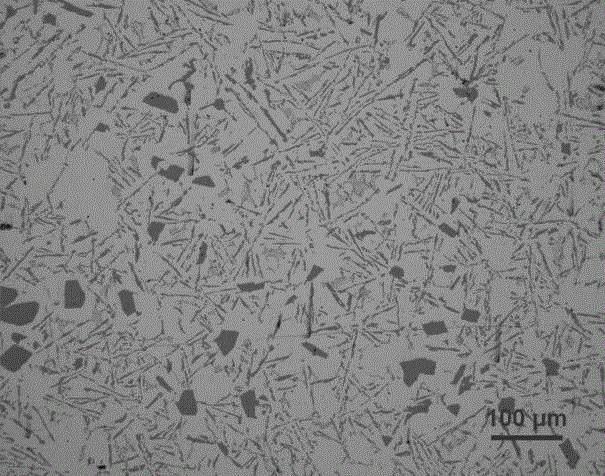

The invention relates to a method for modification and refinement of a hypoeutectic and eutectic Al-Si alloy. The hypoeutectic and eutectic Al-Si alloy with the Si content of 2-13.5 wt.% is subjected to modification and refinement treatment with Sr and B; after treatment, the Sr content in an alloy melt is 0.005-0.1%, the B content is 0.005-0.1%, and the mass ratio of Sr to B is 0.3-5. An Al-B intermediate alloy is used as a refiner, and has excellent grain refining effect on the Al-Si alloy; an Al-Sr intermediate alloy is used as a modifier, can effectively modify eutectic Si in the Al-Si alloy. By controlling melting, modification and refinement treatment processes, the grain refiner also has good refinement effect on alpha-Al while the added modifier has good modification effect on the eutectic Si, so that an ingot microstructure is simultaneously modified and refined, and a mutual poisoning effect between Sr and B can be effectively avoided.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Processing method of pitaya peel jam

InactiveCN105851994ASimple processing methodReduce manufacturing costSugar food ingredientsFood thermal treatmentFiberAcute hyperglycaemia

The invention discloses a processing method of pitaya peel jam. The method comprises the following steps: taking fresh pitaya peel, removing pedicels, terminal buds and other crude fiber parts, blanching the pitaya peel, beating the blanched pitaya peel, adding a sweetener and calcium chloride, boiling the obtained mixture, and bottling the boiled mixture in order to make jam foods. The jam obtained in the invention is a red or pale yellow gel product, has suitable sweet-sour taste, has acceptant mouthfeel, has oxidation preventing, free radical preventing, ageing preventing, eyesight improving, internal heat reducing and other health effects, has good youth keeping and beauty maintaining effects, and also can improve cerebrocellular degeneration prevention and inhibit dementia. The jam produced in the invention is suitable for routine populations to eat, and sugar-free or low-sugar nutritional jam can be produced for patients with three highs to meet diabetic patients and hyperglycemia patients' demands for low-sugar or sugar-free high dietary fiber foods, so the consumer group of the product is enlarged.

Owner:GUIZHOU UNIV

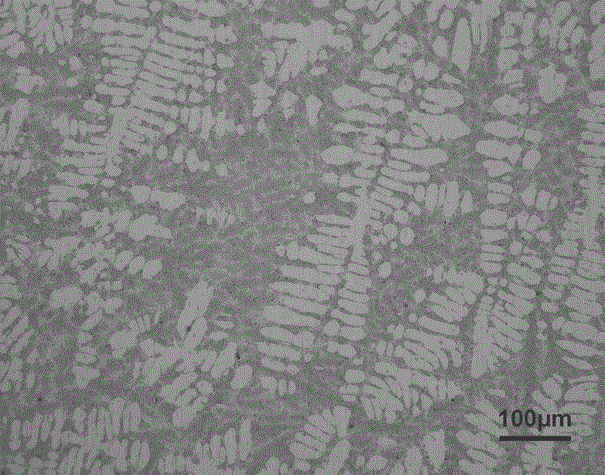

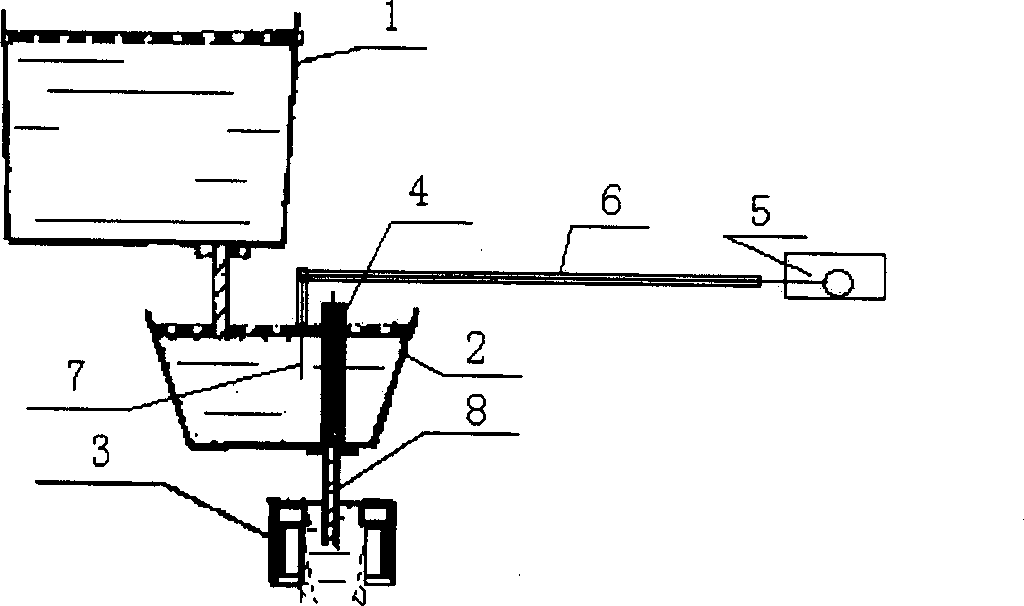

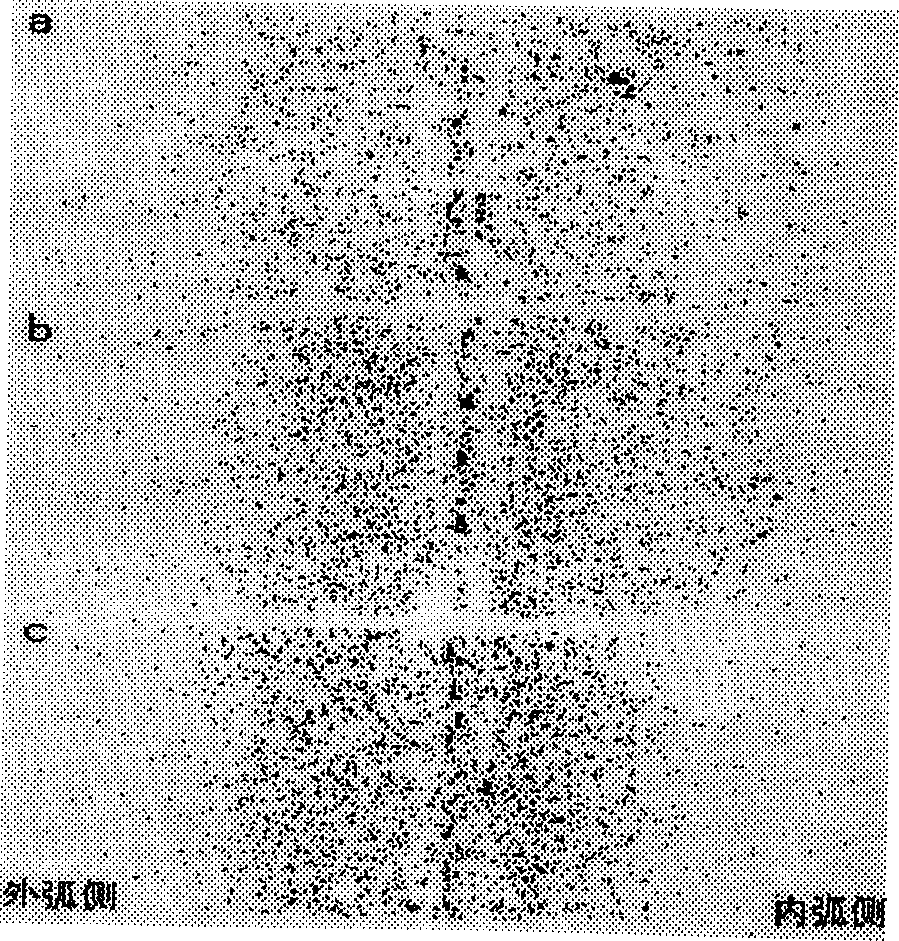

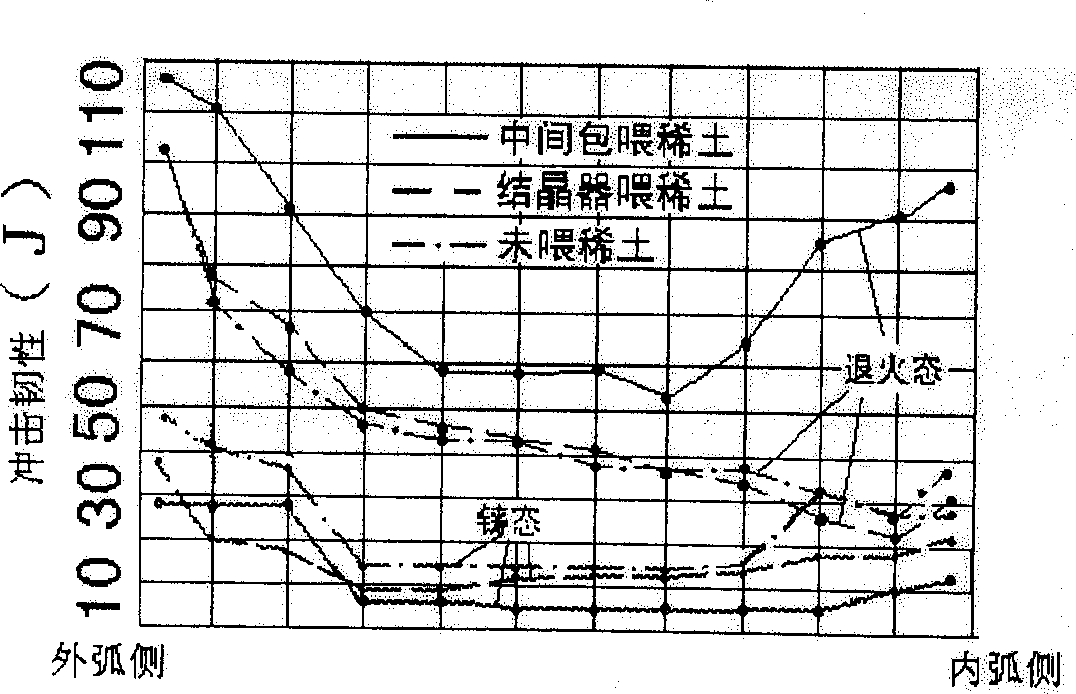

Conticasting technology for feeding rare-earth wires into tundish

A technology for feeding the rare-earth wire into conticasting tundish features that the molten steel flows from ladle into tundish and then into the crystallizer under the control of stopper, and the rare-earth wire comes into molen steel near the stopper in the tundish and is molten. Its advantages are uniform distribution of rare earth is molten steel, high effect on modifying sulfide, high rate of finished products and impact toughness, for conticast plate, and simple operation.

Owner:NANJING UNIV OF SCI & TECH +1

Rare-earth-modified Al-Si-Mg-Mn cast alloy and preparation method thereof

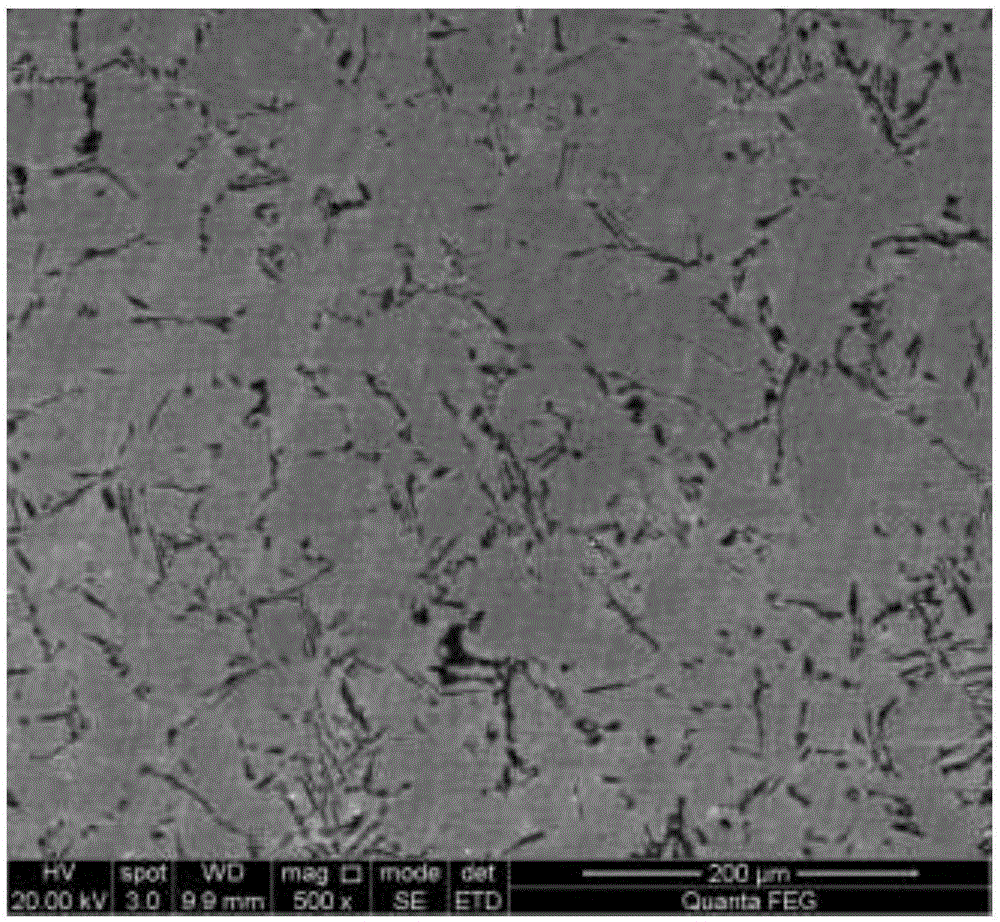

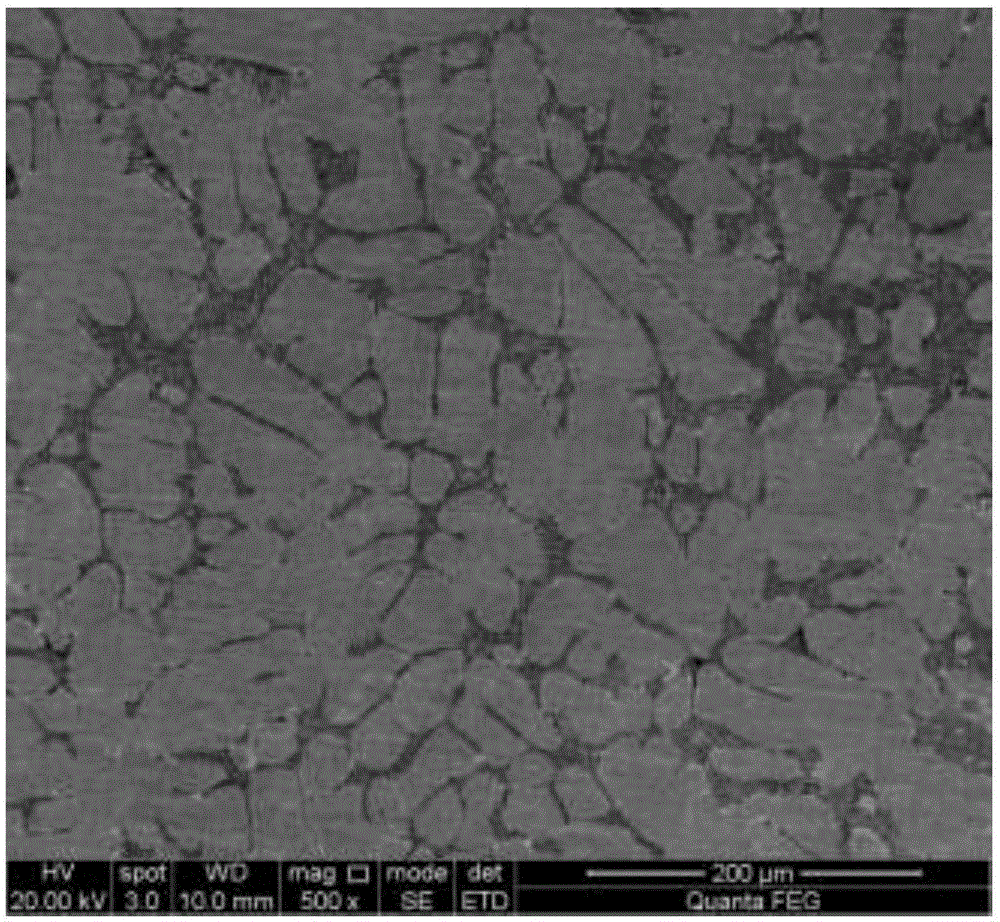

The invention relates to a rare-earth-modified Al-Si-Mg-Mn cast alloy and a preparation method thereof, and belongs to the technical field of metal materials and metallurgy. The rare-earth-modified Al-Si-Mg-Mn cast alloy comprises the following components, by weight percentage: 6.0-8.5% of Si, 0.65-1.5% of Mg, 0.25-0.75% of Mn, 0.08-0.25% of Ti, less than or equal to 0.2% of Be, less than or equalto 0.5% of Zn, less than or equal to 0.5% of Cr, less than or equal to 0.5% of Zr, and the balance Al. The preparation method comprises the following steps that (1) raw materials are prepared; (2) analuminum ingot is heated into an aluminum melt, the other raw materials are added into the aluminum melt, and uniform stirring is carried out after the other raw materials are molten; (3) a refiningagent is added for refining treatment, and then an Al-10RE modifier is added for modification treatment; (4) slagging-off is carried out after degassing is carried out, standing is carried out at thetemperature of 700-800 DEG C, and then casting is carried out to form a casting; and (5) solid solution treatment and aging treatment are carried out on the casting. According to the method, after modification is carried out by utilizing rare earth, the problem that the modifying effect degenerates and declines due to the fact that the Mn content is increased can be solved, the precipitation strengthening effect of the high-Mg alloy is brought into full play, and the mechanical property of the alloy can be improved.

Owner:DARE WHEEL MFG +1

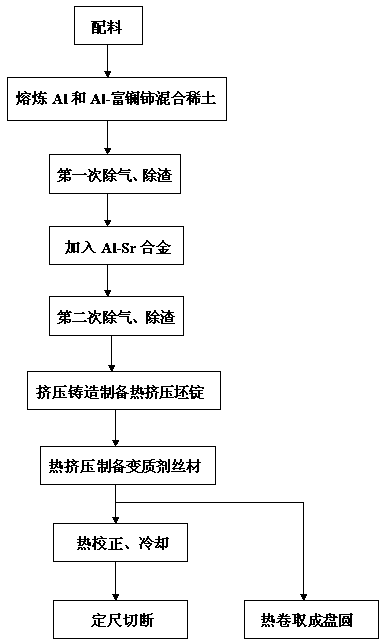

Permanent modifier capable of improving electrical conductivity of hypo eutectic Al-Si alloy as well as preparation method and using method of permanent modifier

The invention belongs to the metallurgical field and particularly relates to a permanent modifier capable of improving electrical conductivity of a hypo eutectic Al-Si alloy as well as a preparation method and a using method of the permanent modifier. The permanent modifier comprises the following components in percentage by weight: 1-4% of Sr, 5-20% of lanthanum-cerium-rich mixed rear earth and the balance of Al, wherein a weight ratio of the Sr to the lanthanum-cerium-rich mixed rear earth is 1 to (5-10). The preparation method for the permanent modifier comprises the following steps: firstly, preparing materials and smelting the prepared materials; and then, carrying out alloying and carrying out thermal extrusion by virtue of billets prepared by extruding and casting to prepare a modifier wire, thus obtaining the permanent modifier product capable of improving electrical conductivity of the hypo eutectic Al-Si alloy, wherein effective modifying time is at least 5 hours. The permanent modifier disclosed by the invention is convenient to use, stable in effect, long in effective modifying time, free of a modifying incubation period, and has effective modifying time of at least 5 hours according to detection. And moreover, the electrical conductivity of the alloy treated by virtue of the modifier wire is obviously improved.

Owner:SHENYANG POLYTECHNIC UNIV

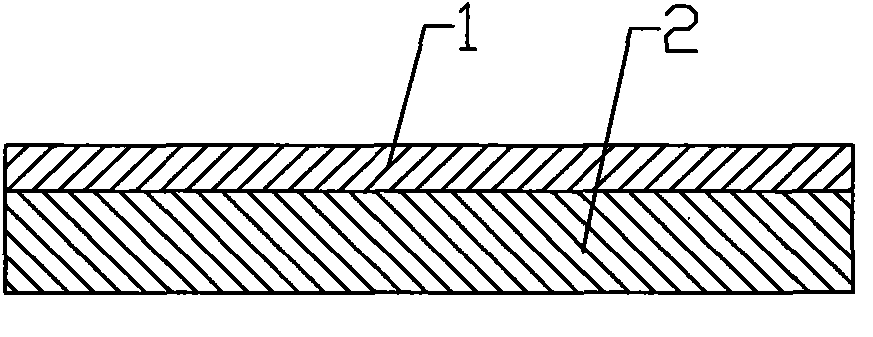

Collecting pipe material for micro-channel heat exchanger and preparation method thereof

The invention relates to a collecting pipe material for a micro-channel heat exchanger, which consists of a layer of brazing layer alloy and a layer of matrix alloy, wherein the brazing layer alloy comprises the following components in percentage by weight: 9-11% of Si, 0.2-0.4% of Fe, 0.005-0.05% of Cu, 0.005-0.05% of Mn, 0.005-0.05% of Mg, 0.005-0.05% of Cr, 0.3-0.7% of Zn, 0.005-0.05% of Zr, 0.005-0.10% of Ti and the balance of A1; the preparation method of the brazing layer alloy comprises the processes of casting, modifying and founding; the preparation method of the matrix alloy comprises the processes of casting, founding and homogenizing; processes of compositing, hot rolling, cold rolling and intermediate annealing are carried out on the brazing layer alloy and the matrix alloy to obtain the collecting pipe material; the brazing layer alloy has favorable grain refining effect so that favorable fluidity, wettability and gap filling capability are provided during the brazing of the material; cold machining is carried out on the material with a machining rate of 25-35% after the intermediate annealing treatment; and the machining rate can ensure that the forming property is favorable during the pipe making of the material and the fluidity of the brazing layer is favorable during the brazing of the collecting pipe.

Owner:潍坊三源铝业有限公司

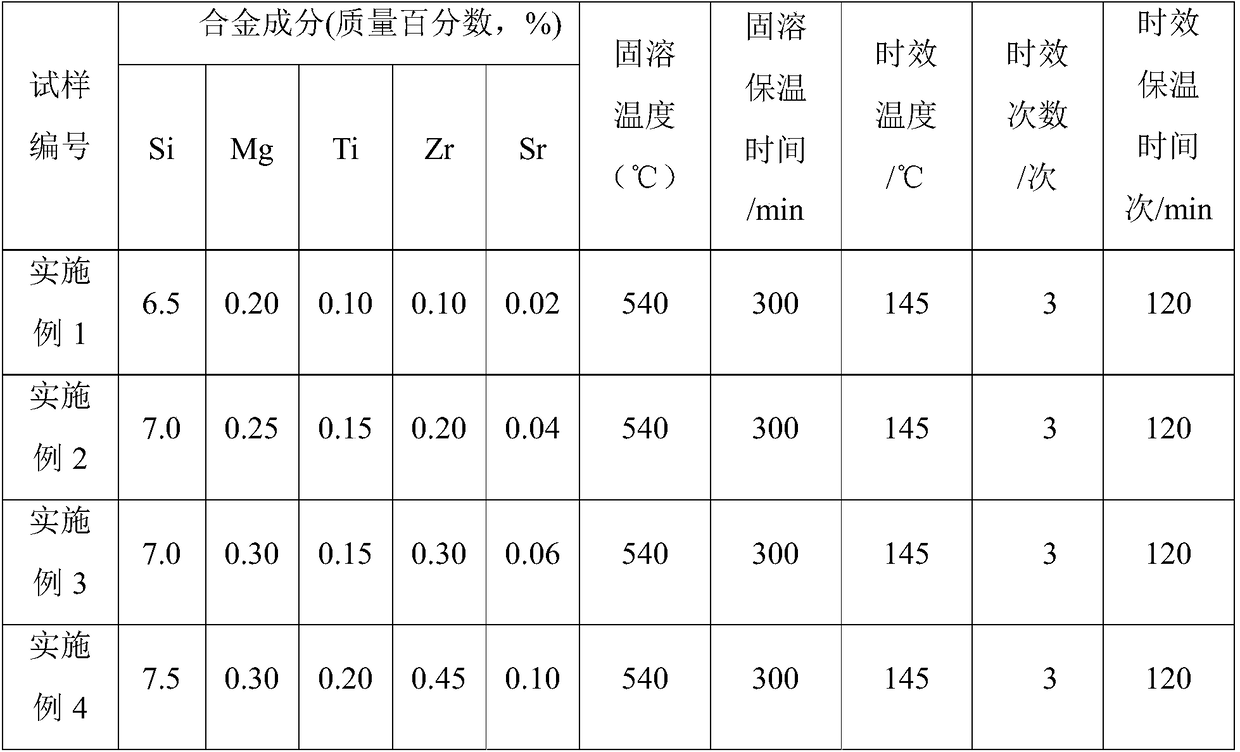

Li-W-RE high-strength heat resistant aluminum alloy material modified with C and preparation method thereof

The invention discloses a Li-W-RE high-strength heat resistant aluminum alloy material modified with C. The alloy comprises the following components by weight percent: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.0001 to 0.15 percent of C, 0.01 to 1.0 percent of Zr, 0.1 to 3.0 percent of Li, 0.01 to 1.0 percent of W, and 0.05 to 5 percent of rare earth element and the rest is Al. Through optimally choosing alloy host element Cu, Mn and RE prescription, the invention reduces alloy quasi-solid phase temperature range and solves the problems of large hot tear tend and low product high temperature strength in the casting process, guided by high quality melt, solid solution and phase diagram theory and taking a C element as modificator. The low cost multiple microalloyed element prescription is optimally choosen. Finally, a high-strength heat resistant aluminum alloy material is developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

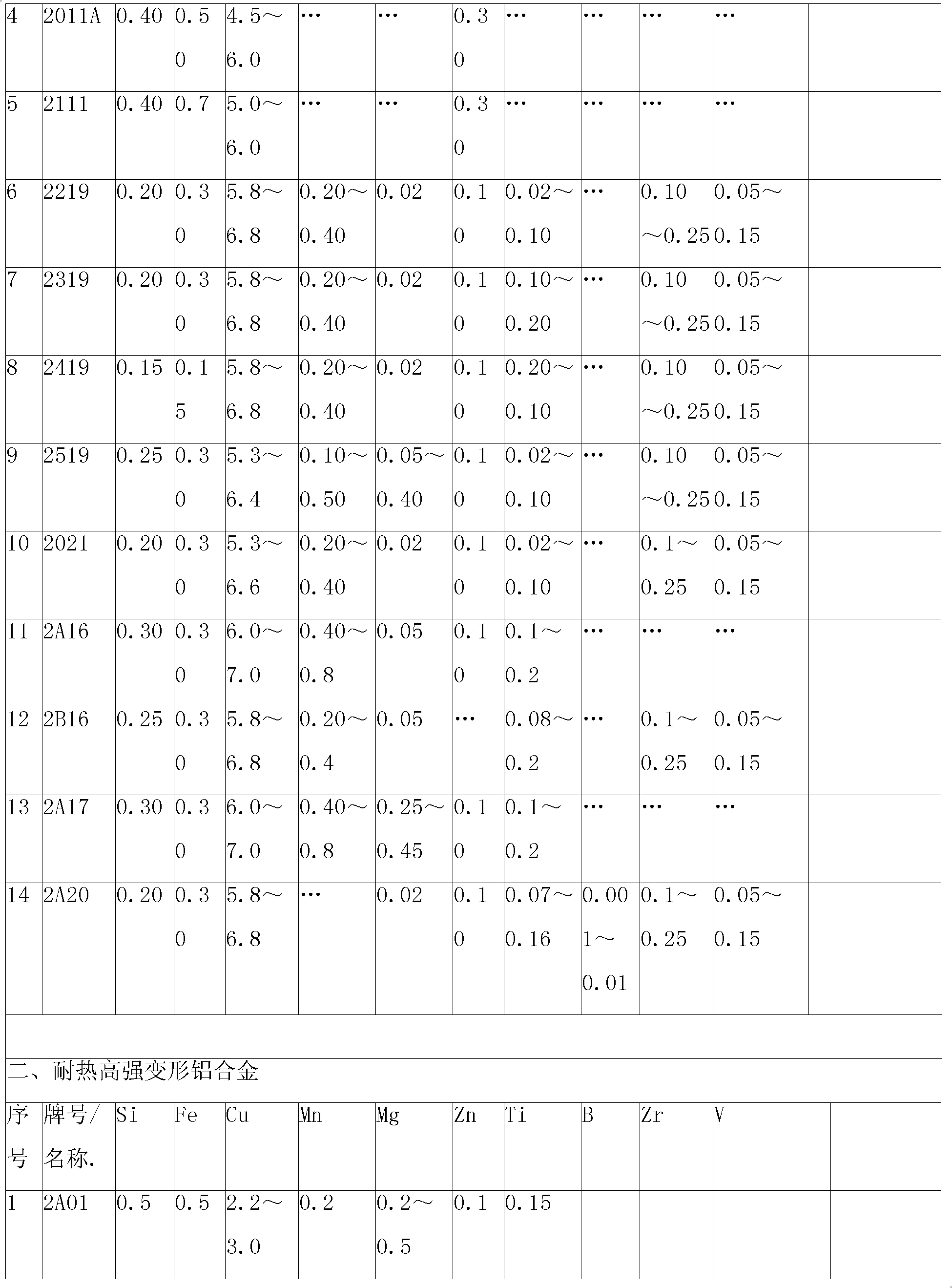

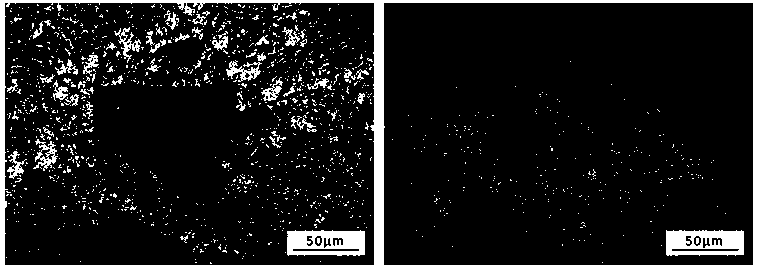

Modified A356 aluminum alloy and multi-time aging heat treatment method thereof

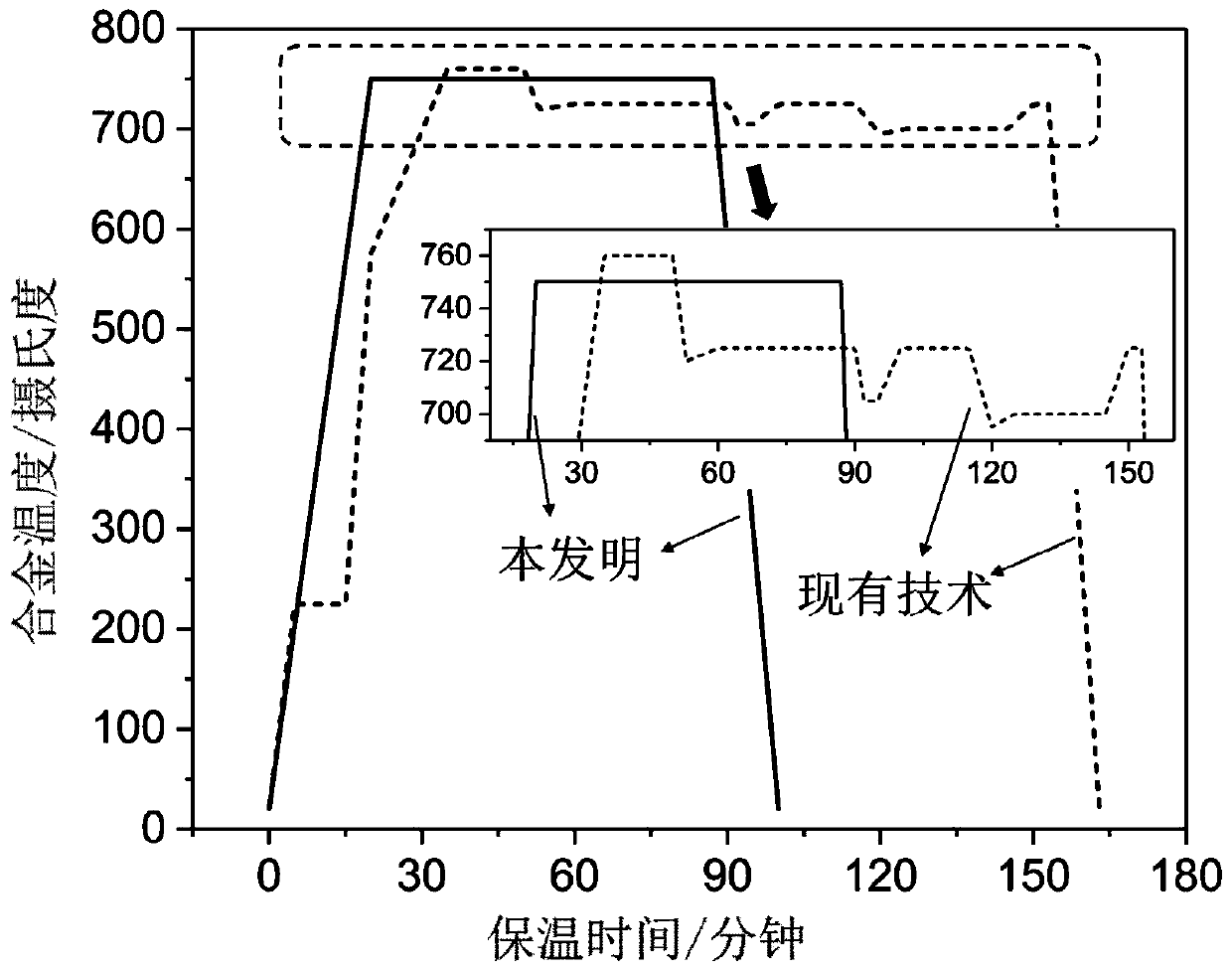

The invention discloses modified A356 aluminum alloy and a multi-time aging heat treatment method thereof. On the basis of components of traditional A356 aluminum alloy, microscale Zr and Sr elementsare added during smelting for conducting grain refinement and modification on a melt, an ingot is obtained through smelting and casting, and then the ingot is subjected to solid solution treatment andmulti-time aging T6 heat treatment to prepare the high-performance A356 aluminum alloy. Compared with A356 aluminum alloy produced by an existing traditional technology, the high-performance A356 aluminum alloy prepared by the technology has the advantages that the mechanical property is remarkably improved, the preparation method is simple, and the production cost is low.

Owner:HEFEI UNIV OF TECH

Pre-hardened plastic die steel having high acid corrosion resistance and preparation method thereof

InactiveCN105200343AImprove organizational structureMetamorphic effect is stableRare earthAcid corrosion

The invention discloses pre-hardened plastic die steel having high acid corrosion resistance. According to the die steel, proportions of elements such as Cr, Mo, V, Mg and the like are properly increased on the basis of proportions of elements of traditional pre-hardened plastic die steel, meanwhile, usage amounts of other alloy elements are controlled, mechanical properties and processability of an alloy material are further improved on the basis that mechanical properties of the traditional plastic die steel are guaranteed, the die steel has the excellent acid corrosion resistance and is low in corrosion ratio at the high temperature, the surface is not abraded easily, by means of an added compound modifier formed by coating a nano tungsten carbide with rare-earth oxide-graphene oxides, the organizational structure of the die steel is refined, the interfacial compatibility among crystals is improved, strengthening and toughening effects are significant, and the modification effect is uniform and stable. A preparation method of the die steel is simple and efficient, the manufacturing period is short, and the die steel is durable, can effectively improve surface quality of plastic pieces and has great production and application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Pre-hardened plastic die steel with oxidation corrosion resistance and high thermal stability and preparation method of pre-hardened plastic die steel

InactiveCN105349893AGuaranteed mechanical propertiesImprove organizational structureAlloy elementOxidation resistant

The invention discloses pre-hardened plastic die steel with oxidation corrosion resistance and high thermal stability. According to the die steel, based on the element ratio of traditional pre-hardened plastic die steel, the ratio of Ni, Mn, W, Co and other elements is properly increased, and meanwhile the use level of other alloy elements is controlled; on the basis of guaranteeing the mechanical performance of the traditional plastic die steel, the mechanical performance and processing performance of alloy materials are further improved; the pre-hardened plastic die steel has excellent oxidation corrosion resistance and high thermal stability, the surface quality of plastic die pieces is guaranteed, and pouring of plastic pieces of various types can be achieved; and by means of an added rare earth oxide-graphene oxide coated nano tungsten carbide composite modificator, the structure of the die steel is refined, interfacial compatibility of crystals is improved, the reinforcing and toughening effects are remarkable, and the metamorphism effect is even and stable. The die steel is smooth in surface and durable, a preparation method is simple and efficient, the manufacturing cycle is short, and extremely high production and application value is achieved.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Special welding electrode for surfacing and repairing broken teeth of cast steel gear

InactiveCN101920414AReduce hardnessLow costWelding/cutting media/materialsSoldering mediaCrack resistanceHigh carbon

The invention relates to a welding electrode for surfacing and repairing broken teeth of a cast steel gear, belonging to the materials science and engineering field. The welding electrode comprises the following chemical components: 45-55wt% of marbles, 4-7wt% of chalk, 20-30wt% of fluorite, 1-3wt% of quartz, 2-4wt% of rutile, 6-10wt% of ferrotitanium, 3-5wt% of high carbon ferromanganese, 1-2wt% of ferrosilicon, 2-4wt% of yttrium oxide and 1-3wt% of metallic nickel. The core wire is H08A steel welding wire. An adopted water glass binder has modulus of 2.7-3.0 and concentration (Baume degree) of 48-50. The surfacing welding electrode can be used for surfacing and repairing the broken teeth of the cast steel gear without preheating before welding and heat treatment after welding. The surfacing metal has higher crack resistance, certain hardness (HB160-260) and abrasive resistance and simultaneously certain processability.

Owner:YANSHAN UNIV

High strength and ductility high-silicon aluminum alloy suitable for squeeze casting and preparation process of high strength and ductility high-silicon aluminum alloy

The invention discloses a high strength and ductility high-silicon aluminum alloy suitable for squeeze casting and a preparation process of the high strength and ductility high-silicon aluminum alloy.Components of the high strength and ductility high-silicon aluminum alloy comprise, by weight percent, 17%-23% of Si, 0.5%-1% of Cu, 0.3%-0.8% of Mg, 0.2%-0.5% of Fe, 0.5%-0.8% of Mn, 0.2%-0.6% of RE, 0.05%-0.1% of P, 0.3% of other microelements such as Cr and Ti and the balance Al. The high-silicon aluminum alloy has an excellent metallographic structure and can be suitable for manufacturing high-strength aluminum alloy structure parts needing to bear heavy loads; a high-silicon aluminum alloy product has excellent mechanical performance; the heat treatment procedure is omitted; energy consumption is reduced; the production efficiency is high; and the production cost is saved.

Owner:FUZHOU UNIV

Process for smelting and gravity casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and gravity casting of an aluminum alloy wheel hub, which comprises the following steps: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining; 2, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into a modification chamber to perform the combined modification and refinement treatment of the molten aluminum alloy in the modification chamber, and blowing nitrogen to the modification chamber to perform secondary degassing; 3, transferring the molten aluminum alloy into a using chamber to keep the temperature of the molten aluminum alloy between 690 and 720 DEG C for later use; and 4, pouring the melt in the using chamber into a mold by using an iron spoon at a speed, which increases first and then decreases, for 23 to 25 minutes at each time. The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

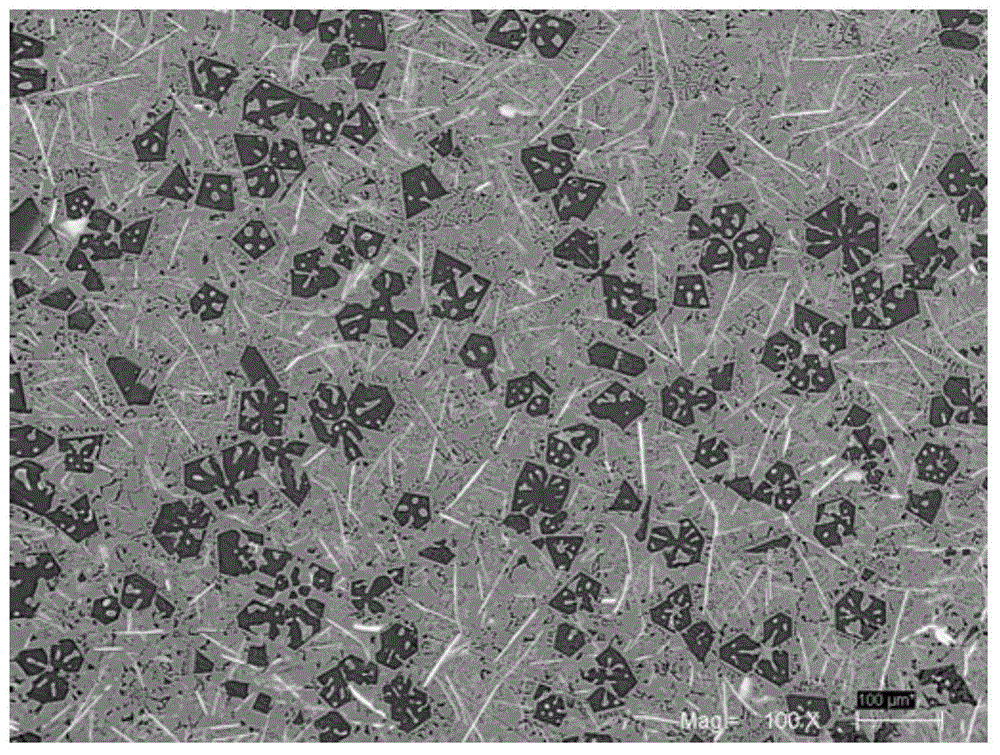

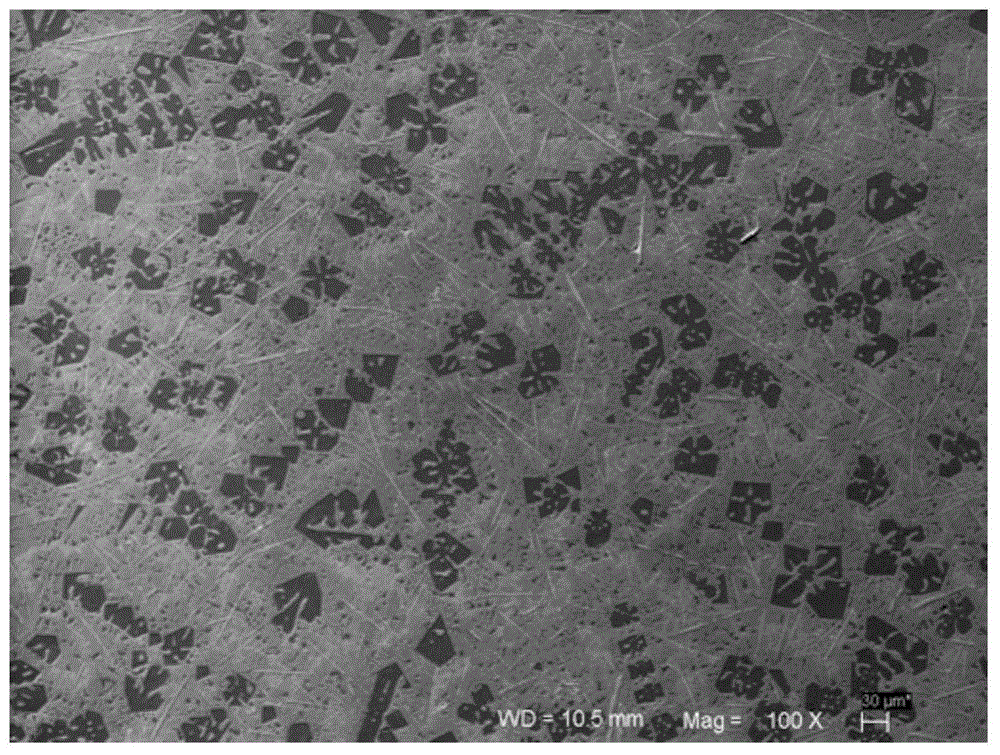

Combined treating method for modified Mg2Si/Fe-rich aluminum matrix composite texture

The invention discloses a combined treating method for modified Mg2Si / Fe-rich aluminum matrix composite texture. The combined treating method comprises the following steps that firstly, melt of a Mg2Si / Fe-rich aluminum matrix composite is prepared, and heat preservation is carried out at 700-750 DEG C; secondly, a refining modificator is put into the melt, heat preservation is continued for 10-20 min at 700-750 DEG C, and stirring is carried out, wherein the refining modificator comprises Cr and B, the adding amount of Cr accounts for, by mass, 0.8-1.5% of the Mg2Si / Fe-rich aluminum matrix composite, and the adding amount of B accounts fro, by mass, 0.2-0.4% of the Mg2Si / Fe-rich aluminum matrix composite; and thirdly, degassing, purifying and refining molding are carried out on the melt obtained in the second step. According to the combined treating method, the synchronous refining modification of the Fe-phase and the Mg2Si-phase in the Mg2Si / Fe-rich aluminum matrix composite is achieved, and the combined treating method is simple in technology, easy to operate, obvious in modification effect and free of pollution.

Owner:SOUTH CHINA UNIV OF TECH +1

Strontium-silicon alterative for hypereutectic AlSi alloy

The invention provides a strontium-silicon alterative for hypereutectic AlSi alloy, and belongs to a flux for altering melt in the AlSi alloy casting process. The strontium-silicon alterative for hypereutectic AlSi alloy consists of the following components in percentage by mass: 20 to 88.5 percent of strontium, and 11.5 to 80 percent of silicon. The preparation method comprises the following steps: (1) weighing silicon powder and strontium powder according to the mass percentage that strontium accounts for 20 to 88.5 percent and silicon accounts for 11.5 to 80 percent, and uniformly mixing the silicon powder and the strontium powder in vacuum; (2) compacting the mixed powder into a briquette at a pressure of 1kN; (3) melting the compacted Si and Sr briquette into Si-Sr alloy in a rapid heating furnace, heating the rapid heating furnace from room temperature to 1500 DEG C in 30 minutes, preserving the temperature for 60 minutes, and cooling along with the furnace; (4) crushing the silicon-strontium alloy which is prepared in the step 3, and performing ball milling; and (5) thermally treating the ball-milled Si-Sr alterative at the temperature of between 700 and 1045 DEG C to acquire a corresponding eutectic structure. The strontium-silicon alterative has the advantages that: primary silicon phase and eutectic silicon phase in the hypereutectic AlSi alloy are refined, so that the using performance of the alloy is improved; the alternation effect is stable and long-acting; and the preparation process is simple, and has low environmental pollution.

Owner:CHINA UNIV OF MINING & TECH

Hypereutectic cast aluminum-silicon alloy modification method

The invention discloses a hypereutectic cast aluminum-silicon alloy modification method. The method comprises the following steps that material preparation is prepared with the following elements of,by mass, 6.000%-12.600% of Si, 0.001%-0.150% of Sr, 0.020%-0.122% of La or RE, 0.001%-0.150% of B, and the balance Al, wherein the mass ratio of the Sr to the B is not larger than 1.351, the mass ratio of the La to the B or the RE to the B is within 1-5, then smelting and casting are conducted through the processes of melting, refining and degassing, feeding and heat preservation casting to obtainan aluminum-silicon alloy, wherein the modification grade is 4-6 grades, and the modification period is 2-3 hours. According to the method disclosed, the total feeding amount of the Sr, the La and the B is reduced by 62.3%-72.5%, the sum of the mass fractions of the modified elements is only 0.022%-0.237%, that the production time is shortened by 37.5%-52.0%, and only reaches 60-100 minutes, andthe method has extremely high economic value.

Owner:SHANGHAI UNIV

Low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and preparation method of low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy

The invention discloses a low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and a preparation method of the low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy. The low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier is prepared from Al-xNb-yTi-zB-kRE, wherein 0.01<x<=6wt%, 0.01<y<=6wt%, 0.01<z<=1wt%, 0.01<k<=1wt%, and the balance is Al; and RE is one of La, Ce, Nd, Er, Gd, Y, Yb and Sc or a mixture of two or more of La, Ce, Nd, Er, Gd, Y, Yb and Sc. A preparation technology is simple, and the compositions can be precisely controlled. The composite refining modifier is used for processing aluminum alloy, and the refining effect and the modifying effect are excellent; for all parts of castings complex in shape and different in thickness, namely, all parts with different cooling rates, the cooling rate sensitivity of the refining effect is low; and the mechanical performance of the obtained alloy is remarkably improved, and the performance difference between the parts with different cooling rates is remarkably reduced.

Owner:北京航大新材科技有限公司

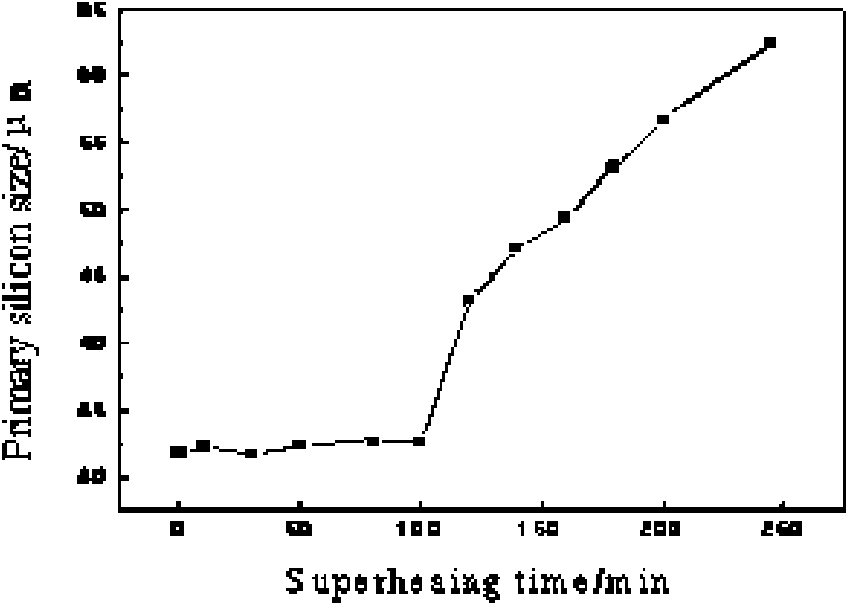

Physical-method modification process for high-silicon aluminum alloy or other alloy containing second hard brittle phase

The invention provides a physical-method modification process for high-silicon aluminum alloy or other alloy containing second hard brittle phase, which belongs to the field of metal materials, and solves the disadvantage that modification processes in the prior art are complex, difficult to control, pollution-causing, high in cost, unsuitable for large-scale industrial production and the like. The process comprises the steps of mixing two alloy melts different in components and temperature pro rata, forming another type of melt with required components and performing overheating treatment on the mixed melt to refine or modify a second coarse hard brittle phase contained by the melt. After the component-complementation melt temperature treatment process, the size of primary Si-phase grains in aluminum-silicon alloy containing Si of 20 percent can be stabilized at about 40 mu m while heat is preserved within 100 minutes. The process has the advantages of obviously improving the form, size and distribution of silicon particles and improving mechanical properties thereof, along with simple procedure, strong flexibility, environmental protection and no pollution, and can finally manufacture high-silicon aluminum alloy materials which can satisfy various uses and are excellent in comprehensive performance.

Owner:FUZHOU UNIV

Aluminium-phosphorus intermediate alloy and its preparation method

An Al-P intermediate alloy used for fining the crystallized silicon in Al-Si alloy is prepared from the industrial pure aluminium, Cu-P alloy, crystallized silicon, red phosphorus and aluminium phosphite through proportioning, smelting pure aluminium, sequentially adding others, stirring, until full reaction, and casting into ingot or extruding into wire material. Its advantages are no pollution,high smelting speed, and long and stable modifying effect.

Owner:SHANDONG UNIV

Al-P intermediate alloy and preparation method thereof

InactiveCN102352455AMeet the requirements of on-line deterioration treatment in productionImprove yieldMetallic materialsBlack phosphorus

The invention belongs to the field of metal materials and particularly relates to an Al-P intermediate alloy which is used to refine primary crystal silicon in the Al-Si alloy and Mg2Si in the Mg-Si alloy, and a preparation method thereof. The Al-P intermediate alloy contains two elements, namely Al and P. The Al-P intermediate alloy is characterized in that the alloy comprises the following components by weight percent: 92.5-98.5% of Al, 1.5-7.5% of P and less than 0.8% of impurities. The preparation method of the Al-P intermediate alloy comprises the following steps of: mixing aluminum powder and black phosphorus powder evenly, drying, briquetting with a press machine, placing the obtained blocks in an electric furnace with the inert atmosphere or other heating devices, heating to 600-750 DEG C, keeping the temperature for 45-120 minutes, stopping heating, and cooling along with the furnace to obtain the blocky Al-P intermediate alloy or extruding the sintered blocks into wires. The Al-P intermediate alloy has a good refinement effect on the Al-Si alloy and the Mg-Si alloy.

Owner:SHANDONG UNIV +1

Modifying process of cast Al-si alloy

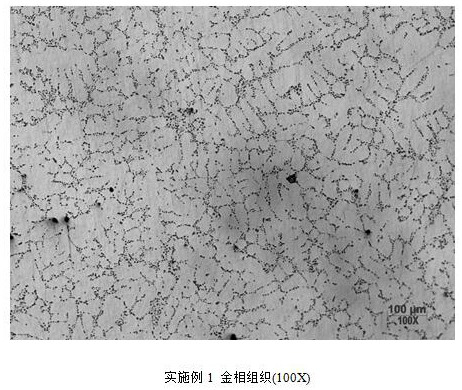

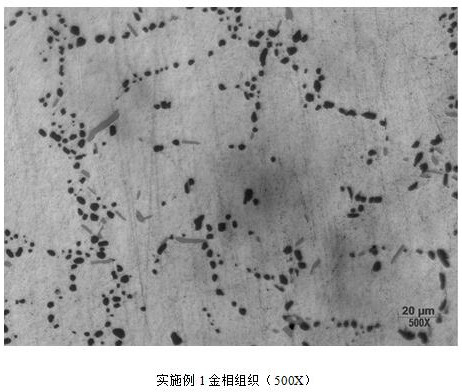

The present invention is modifying process of cast Al-Si alloy, and belongs to the field of metallurgical structure controlling technology in metal heat treatment. The modifying process of cast Al-Si alloy includes the following steps: smelting cast Al-Si alloy, adding 0.25-2.0 wt% Ce into the mother liquid at 800-850 deg.c, stirring intensely for full reaction, deairing and eliminate slag, maintaining the temperature for 30-60 min, casting, and cooling in the mold to room temperature to obtain the modified cast Al-Si alloy ingot. The modified cast Al-Si alloy ingot has obviously changed microscopic metallurgical structure, homogeneously distributed short rod or granular metallurgical structure, and greatly raised mechanical performance and other advantages.

Owner:SHANGHAI UNIV

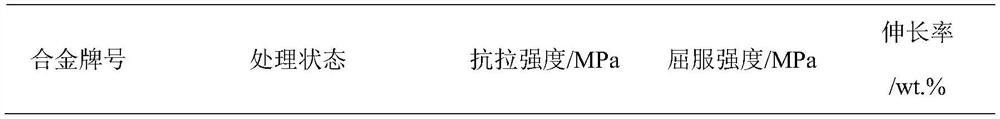

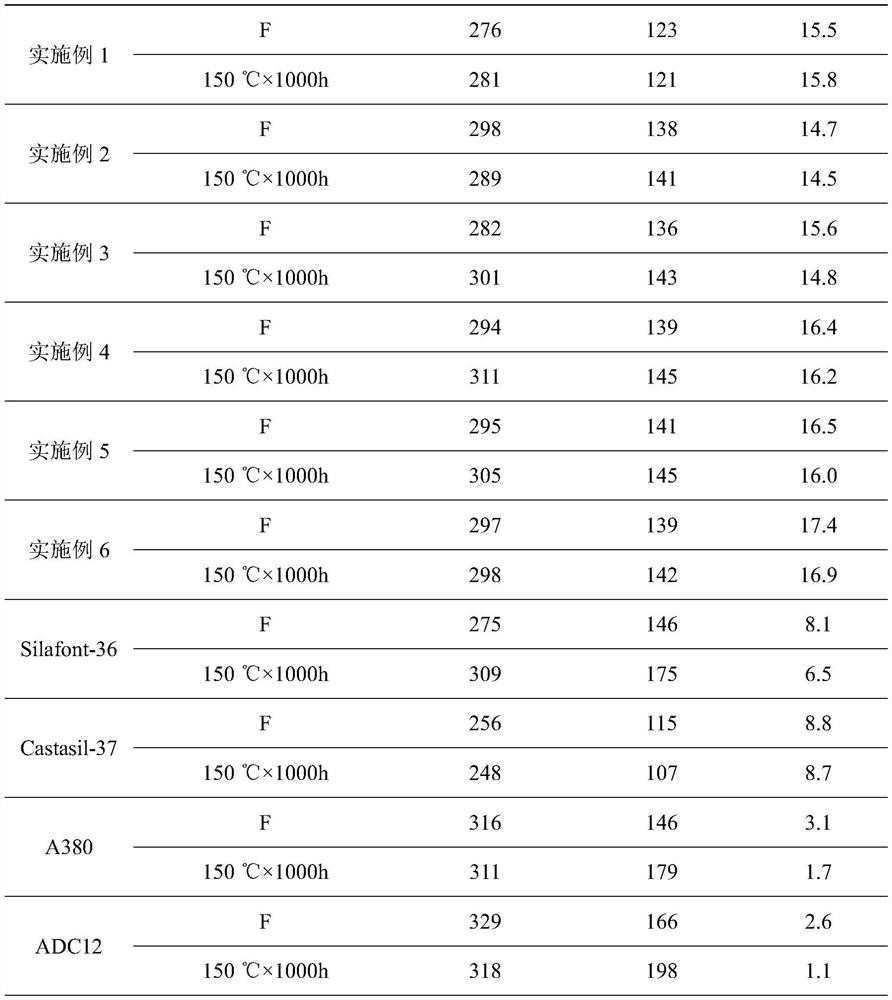

Heat-treatment-free high-toughness die-casting aluminum alloy and preparation method thereof

ActiveCN114717455AImprove thermal stabilityFine and uniform grain sizeMotor vehicle partHeat stability

The invention discloses a heat-treatment-free high-toughness die-casting aluminum alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 7.5 to 9.5 percent of Si, 0 to 1.5 percent of Ni, 0.4 to 0.8 percent of Mn, 0 to 0.4 percent of Mg, 0.08 to 0.3 percent of Cr, 0.01 to 0.15 percent of Zr, 0.03 to 0.1 percent of Ti, 0.005 to 0.025 percent of Sr and the balance of aluminum and inevitable impurity elements. The die-casting aluminum alloy is good in thermal stability, the mechanical property change does not exceed 10% after the die-casting aluminum alloy is kept at the temperature not higher than 150 DEG C for 1000 h, the die-casting state yield strength is larger than 120 MPa, the elongation is larger than 14%, the performance requirement of a car body die-casting structural part can be met without subsequent heat treatment, and the die-casting aluminum alloy is suitable for large-scale production. And the percent of pass of thin-wall die-casting structural part products can be greatly increased, and the use cost of automobile parts is reduced.

Owner:BEIJING CHEHEJIA AUTOMOBILE TECH CO LTD +1

Complex flame-retarding and modifying process for Mg alloy

A fire-retarding and modifying technology for Mg alloy includes smelting the cast Mg alloy under the covering protection of flux, adding fire-retarding modifier, stirring, removing float slags and covering agent, blowing argon gas while stirring, inocualting at 710-770 deg.c and casting. Its advantages are not oxidizing combustion in atmosphere under 800 deg.C, and fine alloy structure.

Owner:UNIV OF JINAN +1

Composite toughening technology of cast aluminum alloy wheel hub

InactiveCN101760657AReduces mushy solidification tendencyReduce surface tensionHubsRare earthNitrogen gas

The invention relates to a composite toughening technology of a cast aluminum alloy wheel hub, comprising the following steps of: melting aluminium alloy melt into an aluminum alloy solution; adding Al-Sr intermediate alloy, mischmetal (Re) and Al-Zr intermediate alloy to the solution when the solution temperature reaches 710-730 DEG C under the condition of stirring to carry out composite modifying and refining treatment; and meanwhile, blowing nitrogen into the solution to remove harmful gas out of the solution. The technology not only can reduce alloy getter and improve the flowability of an aluminum solution, but also can ensure that the tissues and the performance of castings doe not fluctuate, thereby improving the quality of products.

Owner:郑东海

High-toughness cast aluminum alloy and heat treatment process and preparation method thereof

ActiveCN114250389AHigh strengthHigh elongationMolten metal pouring equipmentsProcess efficiency improvementUltimate tensile strengthToughness

The invention discloses a high-toughness cast aluminum alloy as well as a heat treatment process and a preparation method thereof. The aluminum alloy comprises the following components in percentage by weight: 5 to 8.5 percent of Si, 1 to 3 percent of Cu, 0.3 to 0.5 percent of Mg, 0.5 to 1.0 percent of Zn, 0.1 to 0.2 percent of Fe, 0.1 to 0.3 percent of Ti, 0.1 to 0.3 percent of Cr, 0.1 to 0.3 percent of Zr, 0.02 to 0.06 percent of Sr, 0.2 to 0.4 percent of mischmetal Re, no more than 0.15 percent of other inevitable impurity elements in total and the balance of aluminum. The aluminum alloy is subjected to special treatment through the solid solution and aging heat treatment process, the obtained aluminum alloy has ultrahigh strength and toughness, the yield strength of the aluminum alloy exceeds 350 MPa, the tensile strength of the aluminum alloy exceeds 400 MPa, the ductility of the aluminum alloy is larger than 3%, and the problems that an existing aluminum alloy is low in strength and poor in toughness can be effectively solved.

Owner:上海交通大学四川研究院

Method of metamorphosing hypo eutectic aluminum-silicon alloy by using rear earth Er

A method of metamorphosing hypo eutectic aluminum-silicon alloy by using rear earth Erbelongs to the technical field of aluminum alloy casting. The method comprises the steps of after melting aluminum-silicon alloy, adding a refining agent to refine to degas, then adding Er element, standing and performing heat preservation at the temperature of 720 DEG C, and forming by casting at a certain temperature. The earth Er element has good metamorphism, the metamorphism incubation period thereof is short, and the incubation period effective time is long. In addition, Er has the effects of dehydrogenizing and degassing, and reducing oxide inclusion on aluminum alloy, improves the structure of the alloy, and improves the mechanical property of the alloy.

Owner:BEIJING UNIV OF TECH

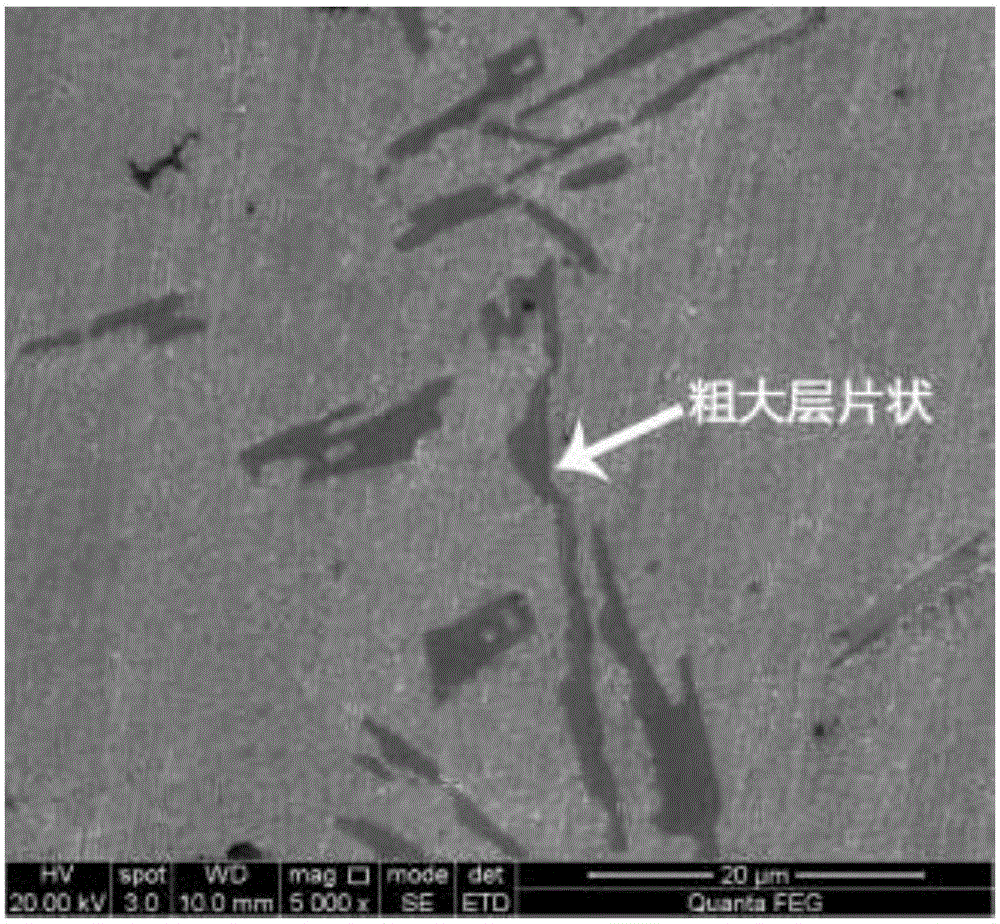

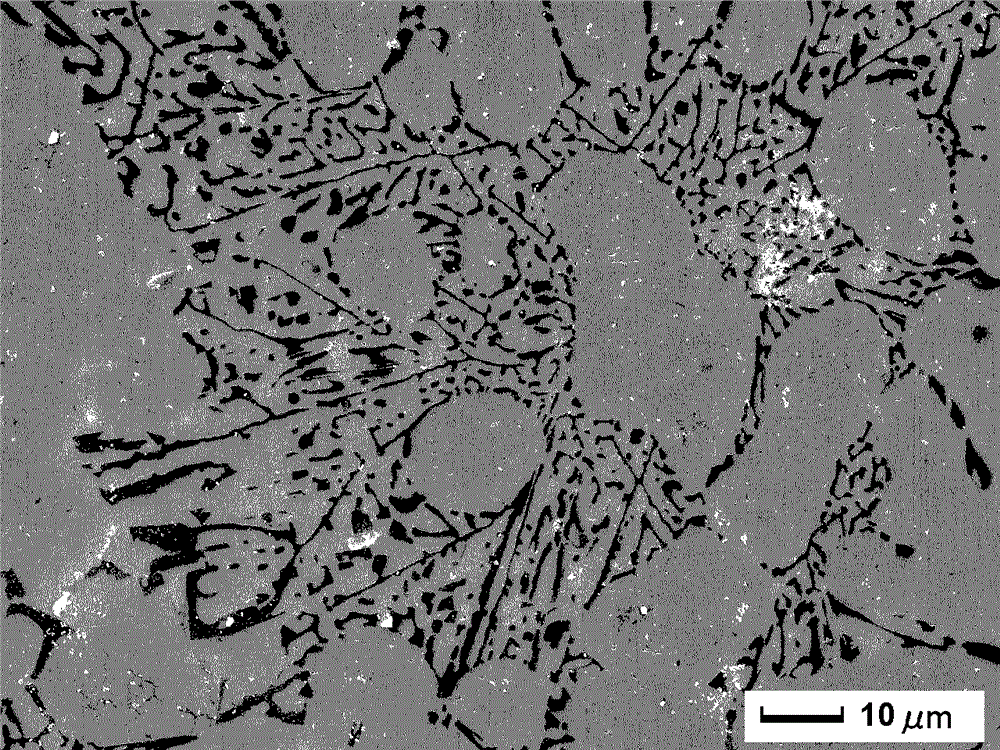

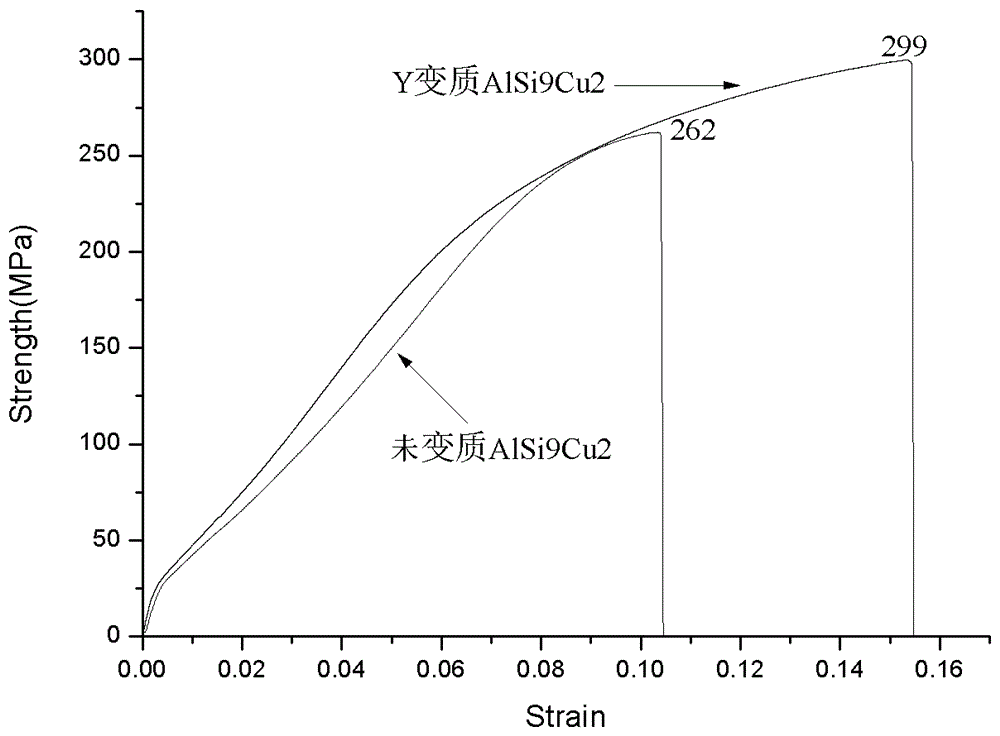

Method for modifying AlSi9Cu2 cast aluminum alloy by rare-earth Y

The invention discloses a method for modifying an AlSi9Cu2 alloy by rare-earth Y, and relates to a method for modifying a cast aluminum-silicon alloy. By using the method for modifying the AlSi9Cu2 alloy by the rare-earth Y, the problem that a gas-hole defect exists in an AlSi9Cu2 cast alloy obtained by adopting a modifier Sr is solved. The method provided by the invention comprises the following steps of weighing to take high-purity aluminum, an Al-2OSi intermediate alloy, high-purity copper and an Al-10Y intermediate alloy raw material, fusing the high-purity aluminum and the Al-2OSi intermediate alloy, then pressing the high-purity copper into an obtained first mixture, smelting an obtained second mixture to obtain a fused mass, then adding the Al-10Y intermediate alloy into the fused mass, smelting an obtained third mixture, and pouring the smelted third mixture, so that the AlSi9Cu2 alloy is obtained subsequently. The method provided by the invention is simple, and is suitable for mass production. No gas holes exist in the obtained Y-modified AlSi9Cu2 alloy; the cast structure of the alloy is obviously thinned; the obdurability of the AlSi9Cu2 alloy is improved; and the compactability of a casting is increased.

Owner:镇江创智特种合金科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com