Permanent modifier capable of improving electrical conductivity of hypo eutectic Al-Si alloy as well as preparation method and using method of permanent modifier

A modification agent and hypoeutectic technology, applied in the field of metallurgy, can solve problems such as unsatisfactory improvement of electrical conductivity, reduction of mechanical properties of alloys, inclusion of strontium-containing compounds, etc., to achieve obvious electrical conductivity, improve electrical conductivity, and reduce shrinkage cavities and pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

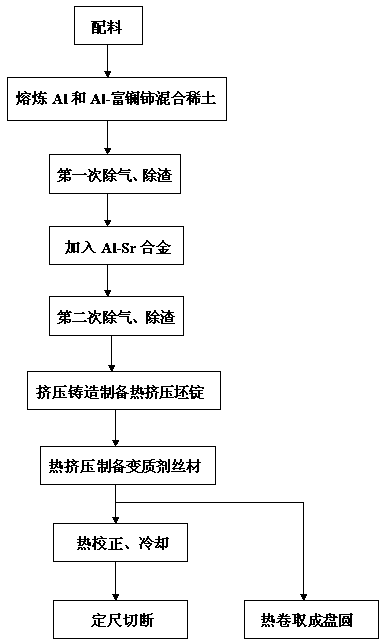

Method used

Image

Examples

Embodiment 1

[0042] 20Kg composite modificator master alloy, its composition according to mass percentage is: Sr: 3%, lanthanum-cerium-rich mixed rare earth: 18%, and the balance is Al.

[0043] Its preparation method is as follows:

[0044] (1) Ingredients: according to the mass percentage: Sr: 3%, lanthanum-cerium-rich mixed rare earth: 18%, and the balance is Al. Weigh Al-Sr alloy, Al-lanthanum-cerium-rich mixed rare earth ingot and pure Al ingot Ingredients, including Al-10Sr 6Kg, Al-30 lanthanum-cerium-rich mixed rare earth 12Kg, pure Al 2Kg;

[0045] (2) Smelting: Heat the pure Al ingot and the mixed rare earth ingot rich in lanthanum and cerium to 740°C to melt, inject Ar gas and add a slag removal agent, perform the first degassing and slag removal treatment, and remove the slag after holding for 10 minutes;

[0046](3) Alloying: Lower the temperature to 720°C, add Al-Sr alloy ingots until they are completely melted and stir the melt evenly, inject Ar gas and add slag remover, and...

Embodiment 2

[0055] 10Kg composite modifier master alloy, its composition and weight ratio are: Sr: 2.0%, lanthanum-cerium-rich mixed rare earth: 15.0%, and the balance is Al.

[0056] Its preparation method is as follows:

[0057] (1) Ingredients: According to the mass percentage: Sr: 2%, lanthanum-cerium-rich mixed rare earth: 15%, and the balance is Al. Weigh Al-Sr alloy, Al-lanthanum-cerium-rich mixed rare earth ingot and pure Al ingot Ingredients, including Al-10Sr 2Kg, Al-30 lanthanum-cerium-rich mixed rare earth 5Kg, pure Al 3Kg;

[0058] (2) Smelting: Heat the pure Al ingot and Al-lanthanum-cerium-rich mixed rare earth ingot to 730°C to melt, inject Ar gas and add a slag remover, perform the first degassing and slag removal treatment, and remove the slag after holding for 8 minutes;

[0059] (3) Alloying: Lower the temperature to 700°C, add Al-Sr alloy ingots until they are completely melted and stir the melt evenly, inject Ar gas and add slag remover, and perform the second degas...

Embodiment 3

[0066] 10Kg composite modificator master alloy, its composition and weight ratio are: Sr: 1.0wt.%, Lanthanum-Cerium-rich mixed rare earth: 10wt.%, and the balance is Al.

[0067] Its preparation method is as follows:

[0068] (1) Ingredients: according to the mass percentage: Sr: 1wt.%, lanthanum-cerium-rich mixed rare earth: 10 wt.%, and the balance is Al. Weigh Al-Sr alloy, Al-lanthanum-cerium-rich mixed rare earth ingot and pure Al ingots are batched, including 1Kg of Al-10Sr, 3.3Kg of Al-30 rich lanthanum and cerium mixed rare earth, and 5.7Kg of pure Al;

[0069] (2) Smelting: Heat the pure Al ingot and Al-lanthanum-cerium-rich mixed rare earth ingot to 750°C to melt, inject Ar gas and add a slag remover, perform the first degassing and slag removal treatment, and remove the slag after holding for 15 minutes;

[0070] (3) Alloying: Lower the temperature to 710°C, add Al-Sr alloy ingots until they are completely melted and stir the melt evenly, inject Ar gas and add slag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com